Metallic paint composition and preparation method thereof

A composition and metal paint technology, applied in the field of metal paint materials, can solve problems such as peeling, paint film cracking, and paint film brittleness, and achieve the effects of not being brittle and falling off, good adhesion, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

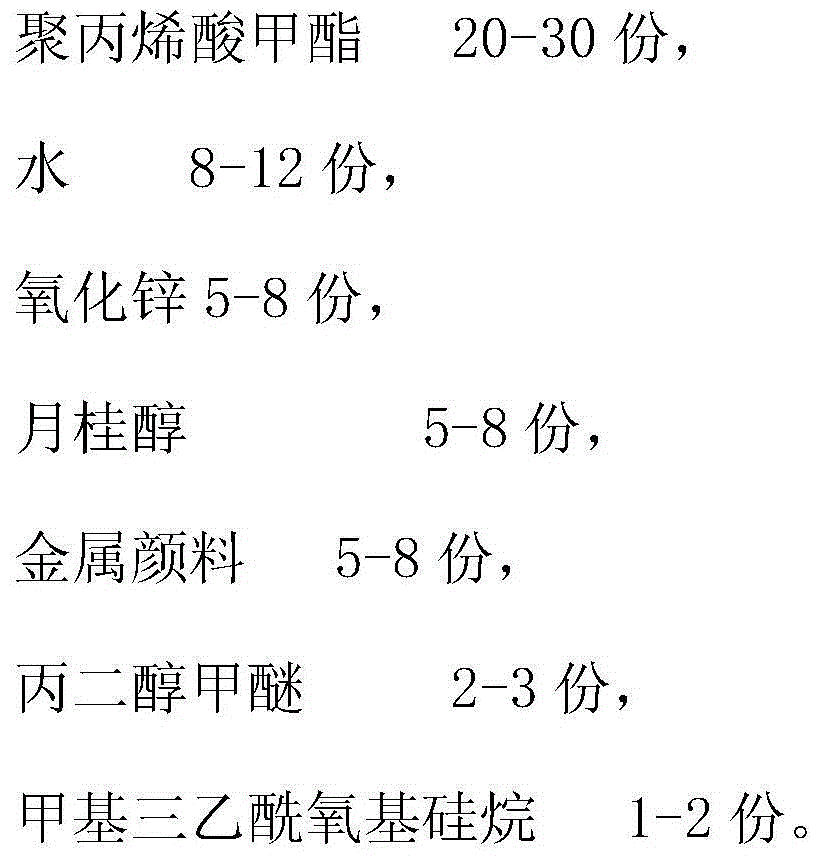

Method used

Image

Examples

Embodiment 1

[0022] (1) Take by weighing polymethyl acrylate 20kg, lauryl alcohol 8kg, nano zinc oxide powder 6kg, aluminum powder 5kg and methyltriacetoxysilane 1kg;

[0023] (2) Add the above components into a homogenizer and mix them uniformly at 60°C, then add 8kg of water, 2kg of hydrogenated soybean oil, and 2kg of propylene glycol methyl ether in sequence, and stir for 15 minutes at a stirring rate of 1100 rpm. Degassing at low temperature for 1 hour to obtain a metallic paint composition.

[0024] The performance test results of the prepared metallic paint composition are shown in Table 1.

Embodiment 2

[0026] (1) Take by weighing polymethyl acrylate 25kg, lauryl alcohol 5kg, nano zinc oxide powder 8kg, copper powder 7kg and methyltriacetoxysilane 1kg;

[0027] (2) Put the above components into a homogenizer and mix them uniformly at 75°C, then add 12kg of water, 1kg of hydrogenated soybean oil, and 3kg of propylene glycol methyl ether in sequence, and stir for 10 minutes at a stirring rate of 1250 rpm. Degassing at low temperature for 2 hours to obtain a metallic paint composition.

[0028] The performance test results of the prepared metallic paint composition are shown in Table 1.

Embodiment 3

[0030] (1) Take by weighing polymethyl acrylate 30kg, lauryl alcohol 7kg, nano zinc oxide powder 5kg, stainless steel powder 8kg and methyltriacetoxysilane 2kg;

[0031] (2) Put the above components into a homogenizer and mix them uniformly at 70°C, then add 10kg of water and 2kg of propylene glycol methyl ether in turn, stir for 10 minutes at a stirring rate of 1100 rpm, and defoam for 1 hour under vacuum , to obtain a metallic paint composition.

[0032] The performance test results of the prepared metallic paint composition are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com