Laser forming electro-galvanizing wire conducting roller and manufacturing method thereof

A laser forming, conductive roller technology, applied in manufacturing tools, laser welding equipment, electrolysis process, etc., can solve problems such as affecting the overall performance of surface functional materials, affecting the service life of conductive rollers, and failing to reach an ideal level, achieving great practical value. , The production cost is low, and it is not easy to be electrically ablated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

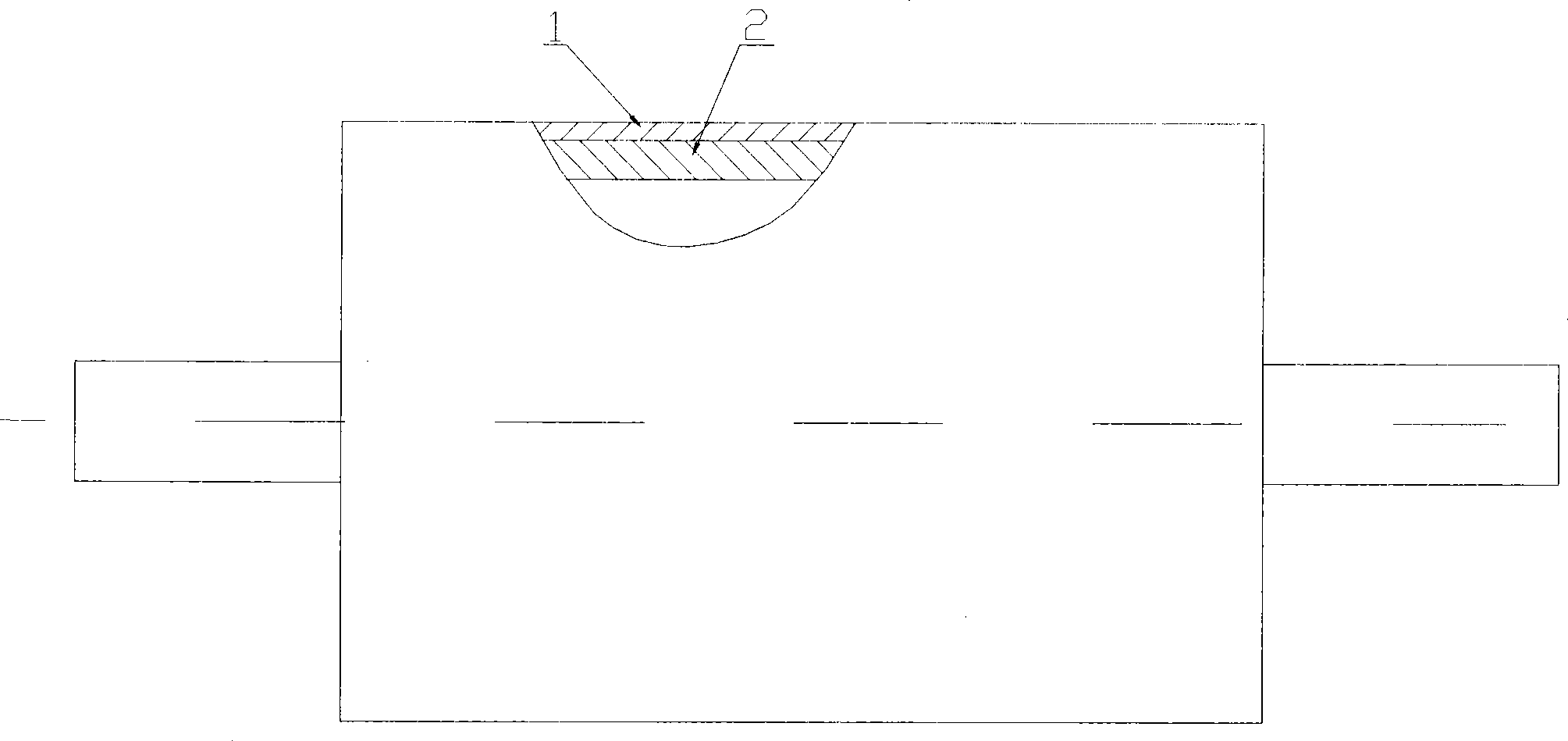

[0019] Conductive roll structure such as figure 1 As shown: the conductive roller is composed of a base 1 and a laser cladding layer 2, and the laser cladding layer 2 covers the base 1.

[0020] The process steps are as follows:

[0021] 1. Make the conductive roller base 1, and leave a 3.5mm laser cladding margin on the outer circle of the inner cylinder;

[0022] 2. Laser cladding the intermediate transition layer, using cross-flow continuous CO 2 The laser cladding a layer of nickel-based alloy powder on the outer circle of the substrate 1 as a base layer, as the intermediate transition layer, the thickness of the cladding is 0.8-0.9mm, and the main chemical composition and content (weight percentage) of the intermediate transition layer are: Mo: 15.8%, Cr: 14%, W: 3.7%, Fe: 18.5%, and the balance is Ni and a small amount of other added elements. The laser cladding process parameters are: laser power 2000W, spot diameter 2.5mm, scanning speed 5mm / s.

[0023] 3. Machinin...

Embodiment 2

[0027] Conductive roll structure such as figure 1 As shown: the conductive roller is composed of a base 1 and a laser cladding layer 2, and the laser cladding layer 2 covers the base 1.

[0028] The process steps are as follows:

[0029] 1. Make conductive roller base 1, leaving 3.0mm laser cladding margin on the outer circle of the inner cylinder;

[0030] 2. Laser cladding the intermediate transition layer, using cross-flow continuous CO 2 The laser clads a layer of nickel-based alloy powder on the outer circle of the substrate 1 as an intermediate filter layer. The cladding thickness is 0.8-0.9mm. The main chemical composition and content (weight percentage) of the intermediate transition layer are: Cr: 26%, Ni: 11%, W: 7.5%, Fe: 2.0%, the balance is Co and a small amount of other added elements. The laser cladding process parameters are: laser power 2000W, spot diameter 2.5mm, scanning speed 3.3mm / s.

[0031] 3. Machining. Remove the laser cladding scale on the surfac...

Embodiment 3

[0035] Conductive roll structure such as figure 1 As shown: the conductive roller is composed of a base 1 and a laser cladding layer 2, and the laser cladding layer 2 covers the base 1.

[0036] The process steps are as follows:

[0037] 1. Make conductive roller base 1, and leave 10mm laser cladding margin on the outer circle of the inner cylinder;

[0038] 2. Laser cladding the intermediate transition layer, using CO 2 The laser cladding three layers of nickel-based alloy powder on the outer circle of the substrate 1 as the middle filter layer, the cladding thickness is 1.9 ~ 2.0mm, the main chemical composition and content (weight percentage) of the middle transition layer are: Cr: 26%, Ni: 11%, W: 7.5%, Fe: 2.0%, the balance is Co and a small amount of other added elements. The laser cladding process parameters are: laser power 2000W, spot diameter 4mm, scanning speed 12mm / s.

[0039] 3. Machining. Remove the laser cladding scale on the surface, and ensure that the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com