Manufacturing method for steel wire inhaul cable with polyurea protective materials on outer layer

A technology of protective materials and production methods, applied in bridge materials, bridge parts, bridges, etc., can solve problems such as reducing the strength level of steel wires, and achieve good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0153] A method for making a steel wire cable with a polyurea protective material on the outermost layer of the steel wire assembly coated with a polyurea protective coating I:

[0154] The steel wire includes a pretreated smooth steel wire or a surface with epoxy coating, galvanized coating, plastic coating, anti-corrosion grease coating, oily wax or metal coating on the outer periphery of the smooth steel wire 1 Corrosion-resistant steel wire with coating or plating 2:

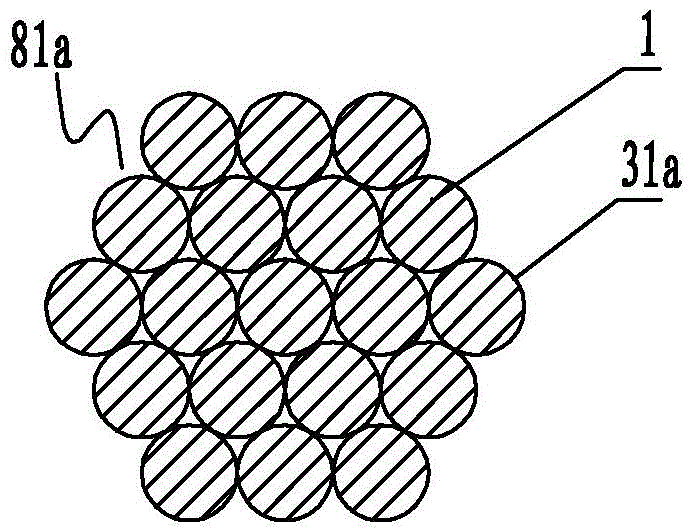

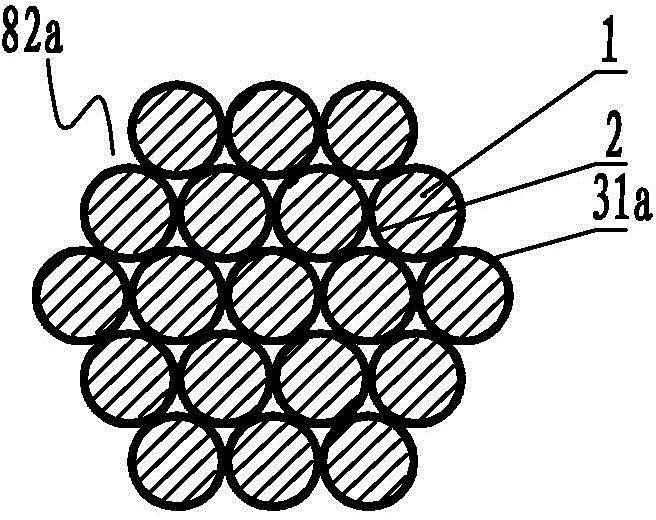

[0155] In this embodiment, the outermost layer of the steel wire assembly is coated with a polyurea protective coating I. The production method of the steel wire cable with the polyurea protective material in the outer layer is to use 19 smooth steel wires after pretreatment or It is an anti-corrosion steel wire with epoxy coating, galvanized coating, plastic coating, anti-corrosion grease coating, oily wax or metal coating attached to the surface of the smooth steel wire 1, and the coating or coating 2 is d...

Embodiment 2

[0177] The production method of the steel wire cable with the outer layer of the wrapping tape and the outer layer of the polyurea protective material in the steel wire assembly:

[0178] The method is to wrap the steel wire cables Ia and IIa with polyurea protective material on the outer layer produced in Example 1 through the G: wrapping process, and wrap a layer of wrapping tape 5 on the outer periphery of the steel wire assembly to form an outer layer with a protective material. Steel wire cables Ⅰa0, Ⅱa0 of polyurea protective material (see diagram 2-1 , Figure 2-2 );

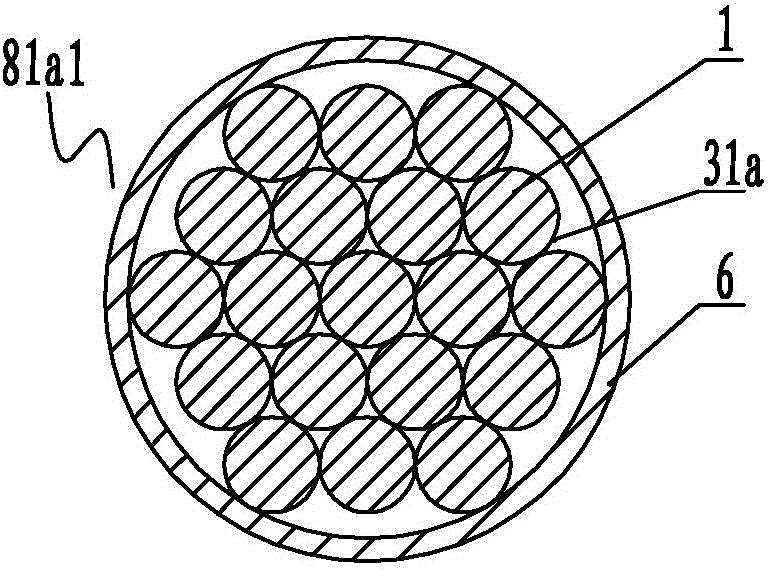

[0179] As a transformation of the embodiment of the present invention, the steel wire cables Ia0 and IIa0 with polyurea protective material on the outer layer produced through the A-F and G processes are then passed through the I1:PE sleeve extrusion process I or sequentially passed through the I1:PE Sleeve extrusion process Ⅰ and I2: PE sleeve extrusion process Ⅱ; the outer layer of the wrapping tape ...

Embodiment 3

[0186] Embodiment three: the outer layer of the wrapping tape of the steel wire cable is coated with the polyurea protective coating II, and the outer layer has the steel wire cable of the polyurea protective material:

[0187] Such as Figure 3-1~Figure 3-2 As shown, the steel wire cables Ia0 and IIa0 with polyurea protective material on the outer layer made of the steel wire assembly wrapped with a layer of wrapping tape 5 on the outer periphery of the steel wire assembly produced in Example 2 are then subjected to the H: polyurea material coating process Ⅱ, namely: through one of the following methods:

[0188] ①Extrusion coating: Polyurea material hot-extruded by steel wire cables Ⅰa0 and Ⅱa0 through extrusion equipment;

[0189] ② Spraying: heat and pressurize the equipment, the raw materials are mixed at the nozzle, and then the polyurea material is sprayed from the spray gun to the wire cables Ⅰa0 and Ⅱa0;

[0190] ③ Soaking and pumping coating: steel wire cables Ⅰa0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com