Gravel pile and plain concrete pile combined composite foundation

A composite foundation and plain concrete pile technology, which is applied in the direction of foundation structure engineering, soil protection, construction, etc., can solve the problems of enhanced pile negative friction resistance, deformation, incomplete consolidation, etc., so as to improve the bearing capacity and benefit soil The effect of consolidation and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

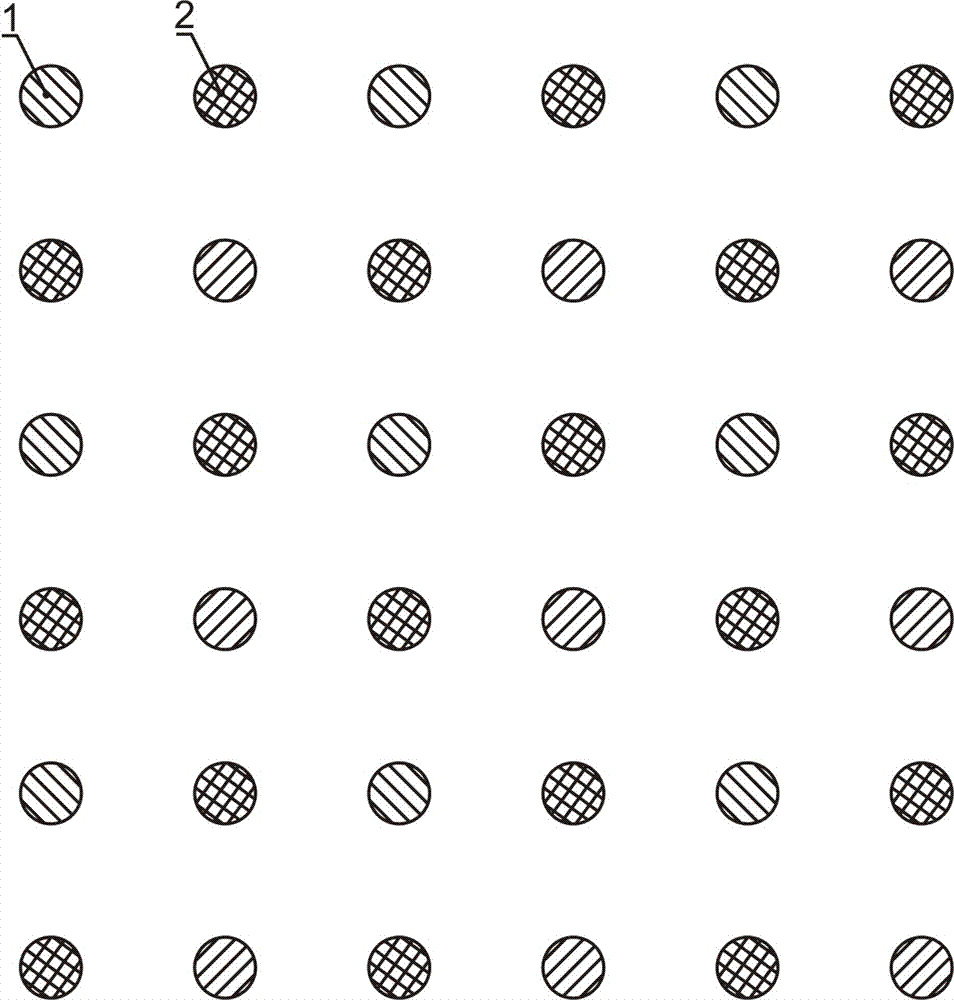

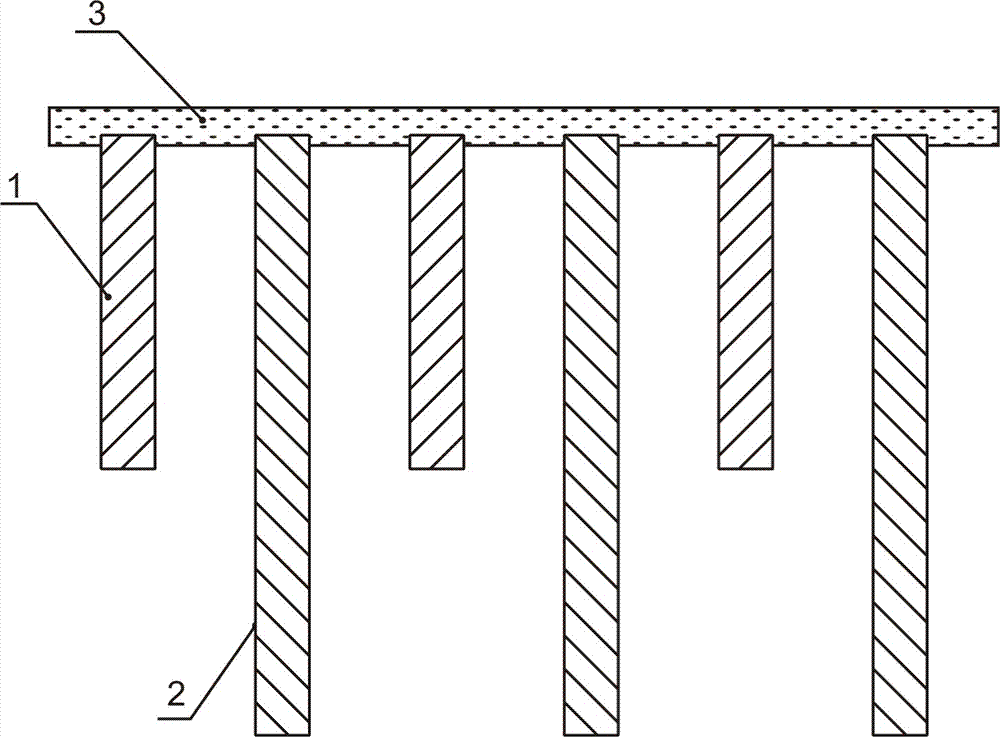

[0010] Such as figure 1 , figure 2 As shown, gravel piles (1) and plain concrete piles (2) are intersected on the construction site, and a 20-30cm thick gravel cushion (3) is set on the top of the piles, where the gravel piles and plain concrete The pile length ratio is 1:2. The invention can solve the problems of uncompleted consolidation of newly filled soil and negative frictional resistance of reinforced piles caused by self-weight consolidation in the later stage of newly filled soil, and effectively improves the bearing capacity and deformation modulus of the natural foundation by forming a secondary composite foundation. Its economy is more prominent, and its efficiency is greatly improved compared with the existing single foundation treatment method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com