Concrete explosion-proof wall with embedded steel framework

A concrete and steel frame technology, applied in the direction of walls, anti-seismic, building components, etc., can solve the problems of weak anti-blast ability, low overall rigidity, high investment cost of blast-proof walls, etc., achieve strong blast effect ability, simple processing technology, and construction procedures Variety of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with specific examples. However, the scope of application of the present invention is not limited to the following examples.

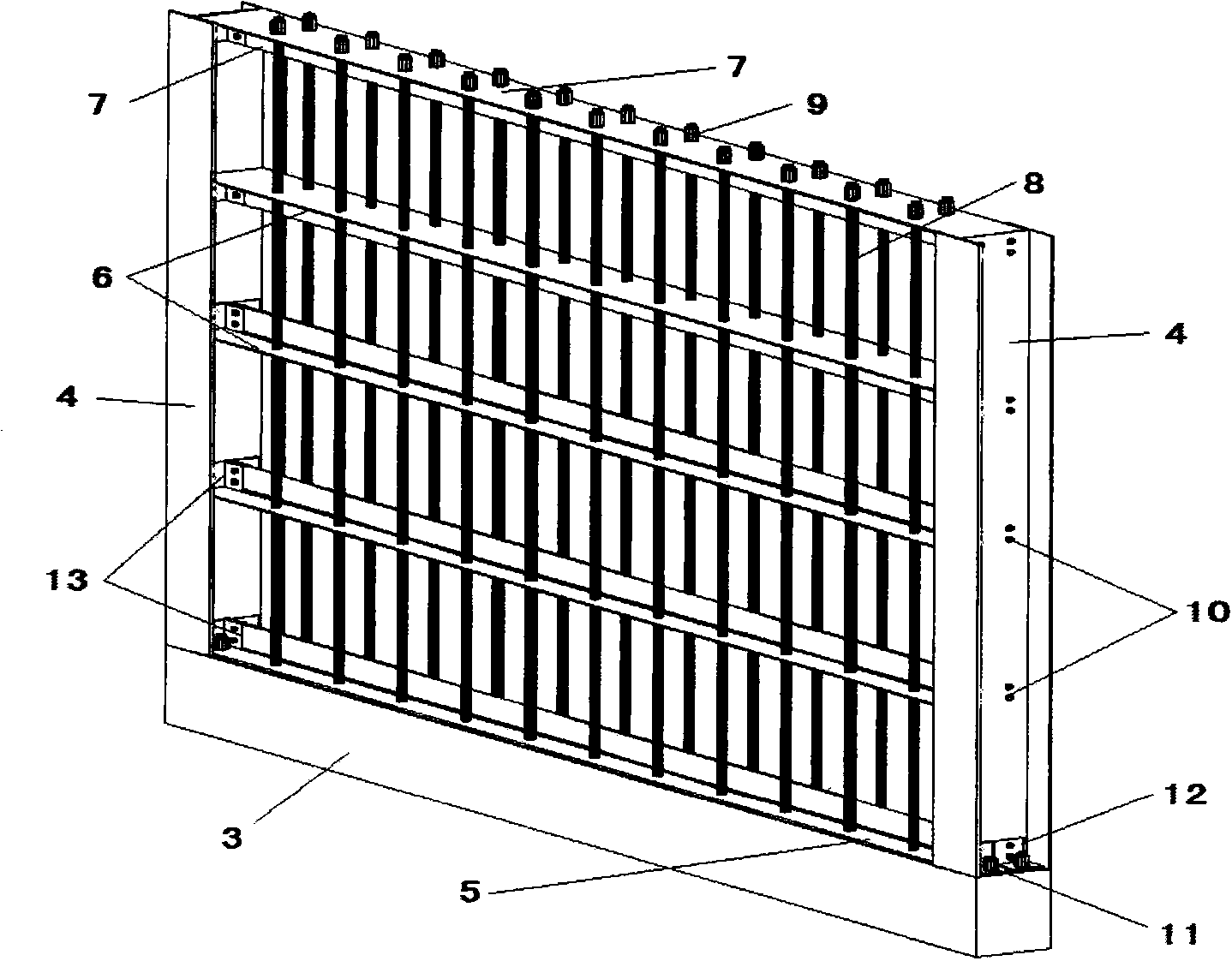

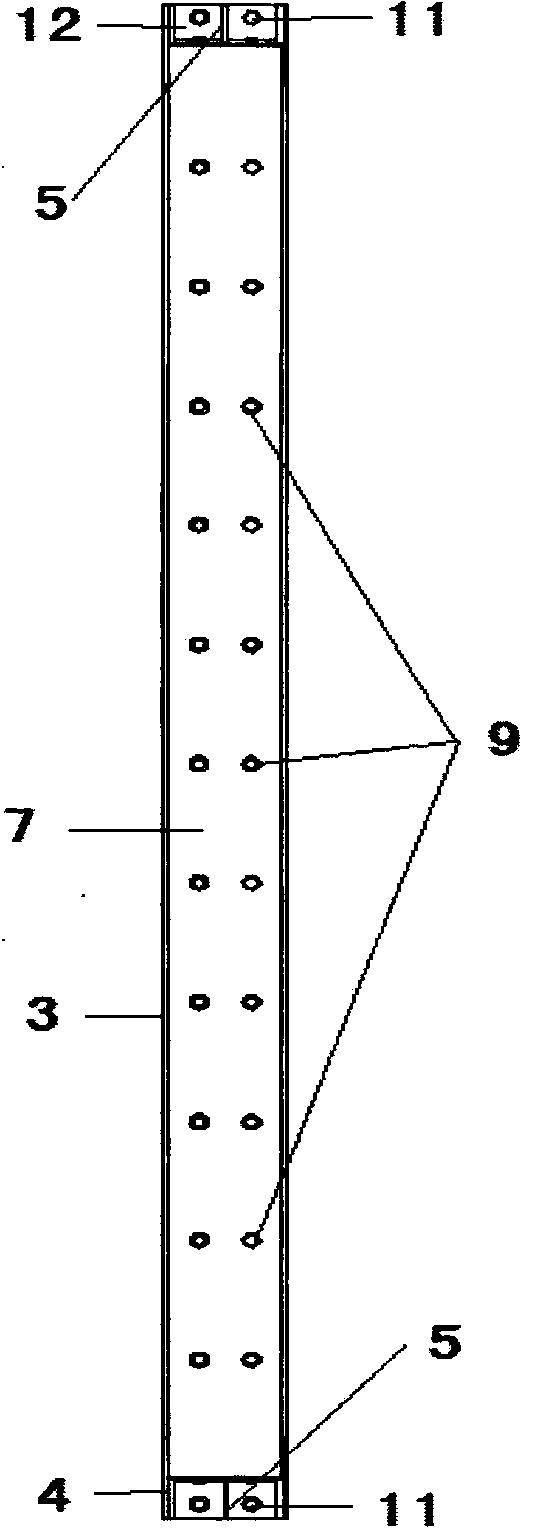

[0038] Such as Figure 1 to Figure 10 , a concrete explosion-proof wall with a built-in steel frame, comprising a wall 1 and a foundation 2 integrally poured with concrete with the wall 1, a steel frame forming an integral body is embedded in the wall 1 and the foundation 2, and the feature is that the steel frame consists of two sides It consists of upright columns 4, five beams, and pre-embedded iron parts 3 of the foundation 2. The two ends of each beam are respectively fixed and connected horizontally according to different elevations (the connection is realized through the cooperation of screws 10, inner angle irons 13, and screw holes 21). On the column 4; where:

[0039] a. The column 4 adopts H-shaped steel, and the H-shaped steel is composed of H-shaped steel flanges...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com