Patents

Literature

418results about How to "Reduce the amount of smoke" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Moistureproof type low-smoke halogen-free flame-retarding wire and cable insulation material used for building

ActiveCN103467838AImprove hydrophobicityAvoid short circuit accidentsRubber insulatorsPlastic/resin/waxes insulatorsInsulation layerMoisture absorption

The invention discloses a moistureproof type low-smoke halogen-free flame-retarding wire and cable insulation material used for building. The insulation material comprises components, by weight, 100 parts of vinyl copolymer and / or ethylene propylene rubber, 100-250 parts of halogen-free flame retardants, 1-20 parts of compatilizer, 0.3-5 parts of antioxygen, 0.5-5 parts of lubricants, 0-3 parts of coupling reagents, 0-2 parts of dispersing agents, and 2-20 parts of one or more of vinyl silicone oil, silicone, silicone grease, silicone rubber, and mineral oil. Wires made of the material is low in smoke, free of halogen, incapable of releasing poisonous gas. Flames can be retarded due to the fact that a single stick of wire can vertically combust at combusting time. Moreover, some special addition agents are added in materials of insulation layers or protective sleeve layers, so that the surface hydrophobic property of products is increased and can be used in a high-temperature humid environment for a long time, and short circuit accidents caused by moisture absorption of the wire insulation layers are avoided.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +1

Production process for firing alumina foamed ceramic filter board in roller kiln

The invention relates to the field of the production of foamed ceramic filter boards, and aims to provide a production process for firing an alumina foamed ceramic filter board in a roller kiln. The process comprises the following steps of: weighing according to a formula, performing ball-milling and mixing uniformly to form slurry; cutting sponge, impregnating the sponge and sizing; drying, and guniting; and sintering in the lengthened roller kiln. According to the production process, the alumina foamed ceramic filter board is fired by utilizing the lengthened roller kiln, so the process is small in unit consumption, gas amount required by the roller kiln is little under the condition of producing the same quantity of the filter boards, the amount of discharged flue gas is also reduced greatly, and compared with the conventional technology, the production process has the advantages of energy conservation and environment friendliness; and the quality of the fired foamed ceramic filterboard is more stable.

Owner:HANGZHOU ZHONGYA NEW MATERIALS TECH

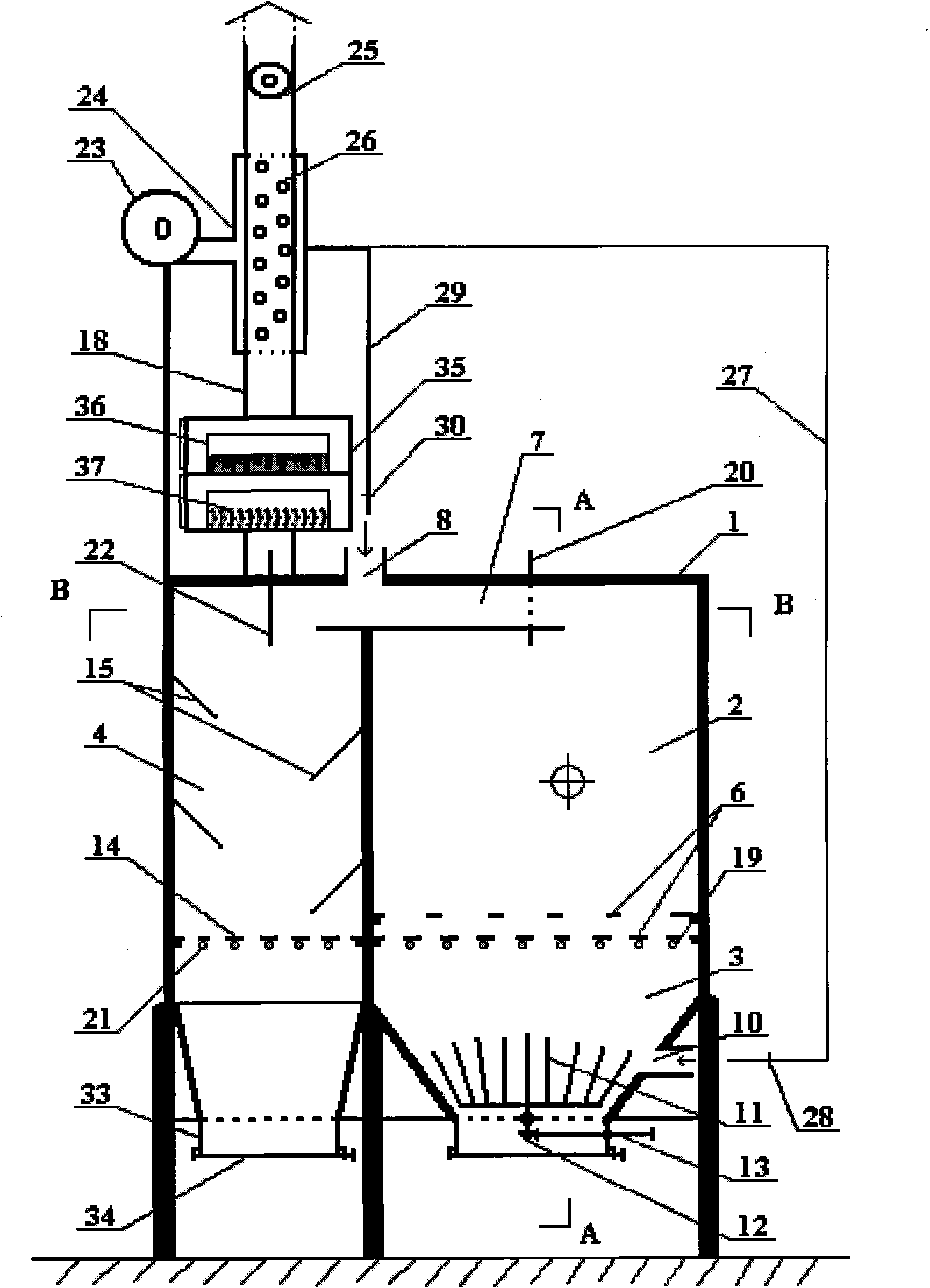

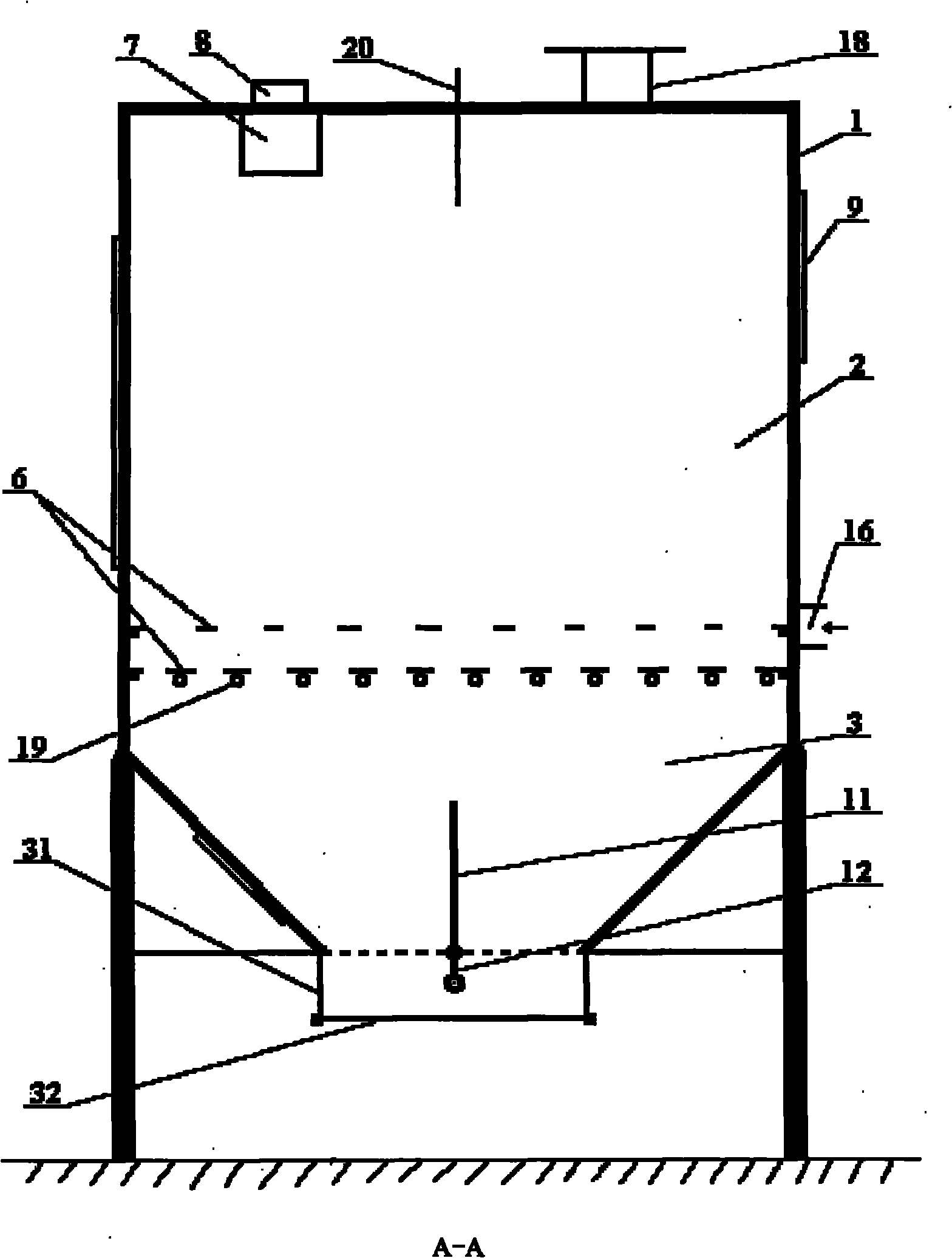

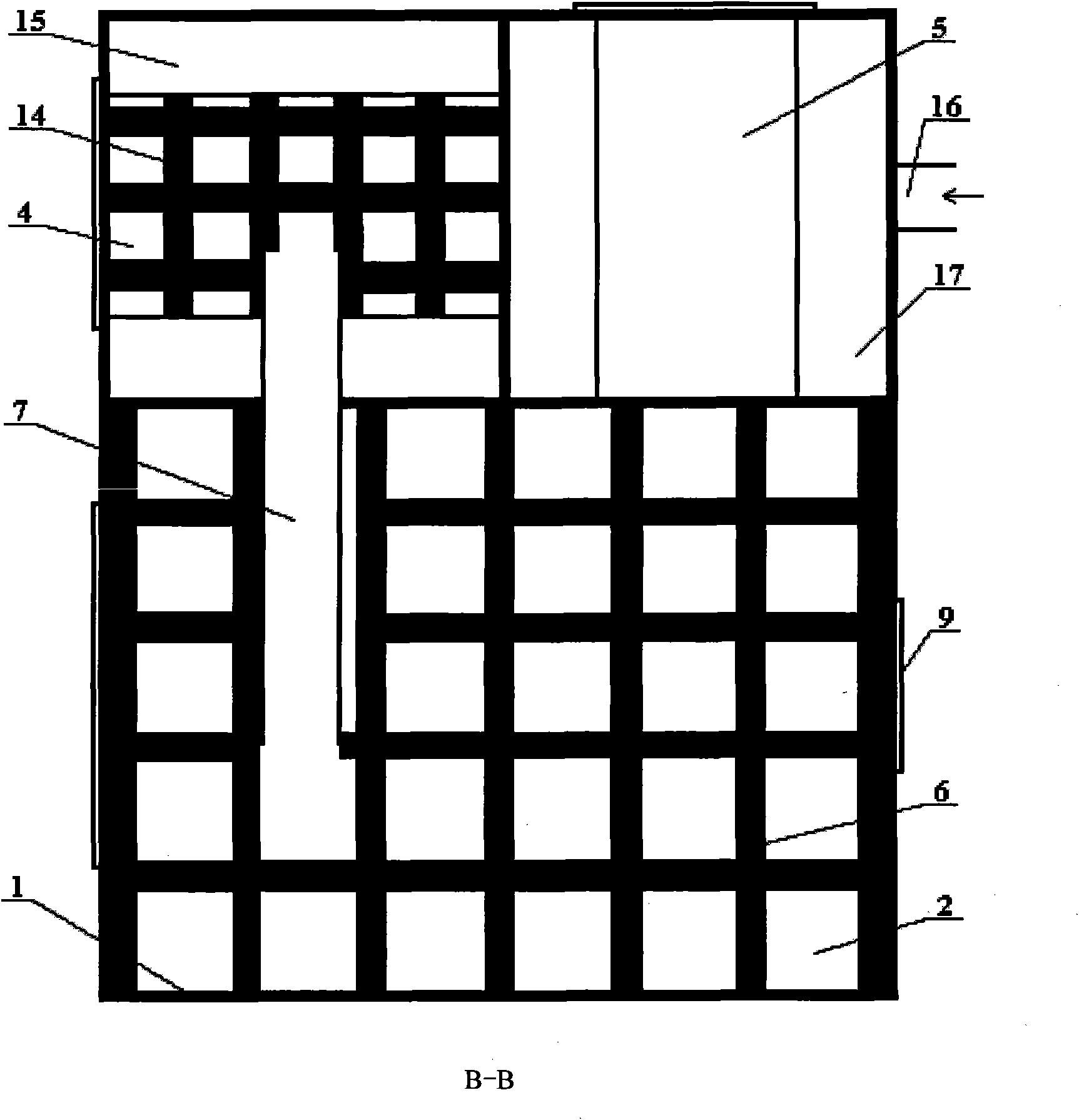

Small efficient medicinal rubbish pyrolysis incinerator

InactiveCN102042601AProblem Solving Using Unitary Furnace StructureLarge capacity reduction ratioIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberGas phase

The invention discloses a small efficient medicinal rubbish pyrolysis incinerator, which belongs to rubbish burning treatment equipment and solves the problems that a gas combustion chamber has simple structure, an auxiliary fuel is needed, the temperature cannot be accurately measured or controlled, and defects are produced in cloth bag dust removal and the like. The hearth of the incinerator consists of a pyrolysis and gasification chamber, a solid-phase burn-out chamber, a gas-phase combustion chamber and a flue gas treatment chamber; the solid-phase burn-out chamber is positioned below the pyrolysis and gasification chamber and communicated through a netlike fire grate; the gas-phase combustion chamber is arranged in parallel to the pyrolysis and gasification chamber, and the top of the gas-phase combustion chamber is communicated with a flue; the flue gas treatment chamber is arranged in parallel to the gas-phase combustion chamber and the pyrolysis and gasification chamber; and the gas-phase combustion chamber is communicated with the lower part of the flue gas treatment chamber, the gas-phase combustion chamber and the flue gas treatment chamber are provided with a fireproof baffle plate respectively, and the lower part of the gas-phase combustion chamber is provided with the netlike fire grate. The temperature in the incinerator is measured and controlled in real time through an electric heating and automatic temperature measurement and control system. A high-temperature granule dust removal and filter device avoids regeneration of dioxin, and the cost is reduced. The incinerator effectively and cleanly burns the medicinal rubbish on the aspects of incinerator shape design, ignition and combustion modes, temperature measurement and control, high-temperature flue gas treatment and the like.

Owner:杨显志

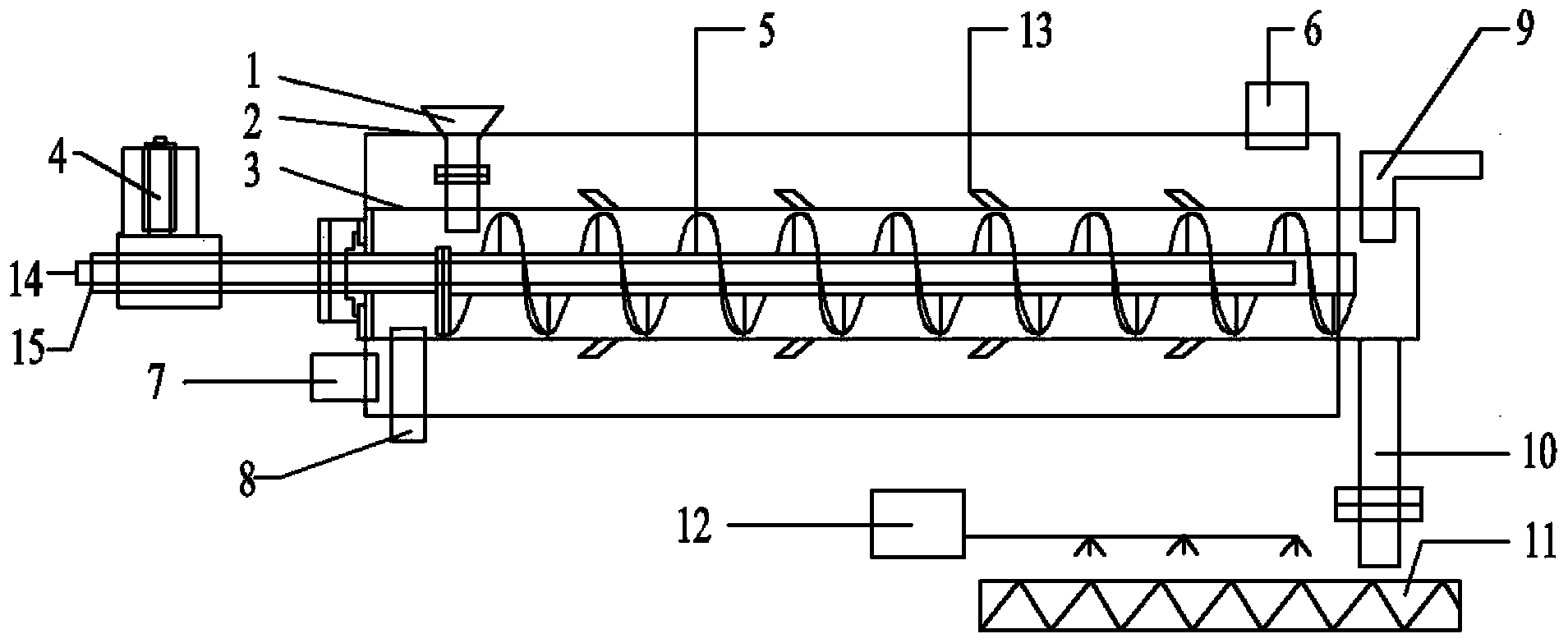

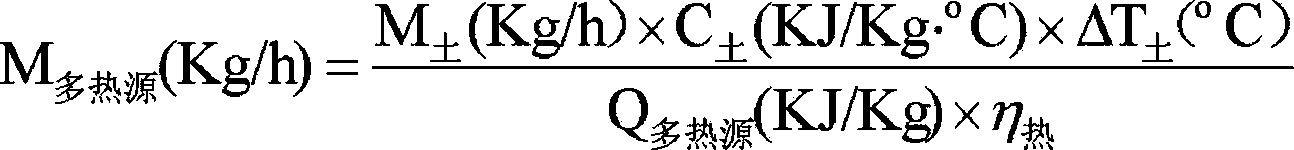

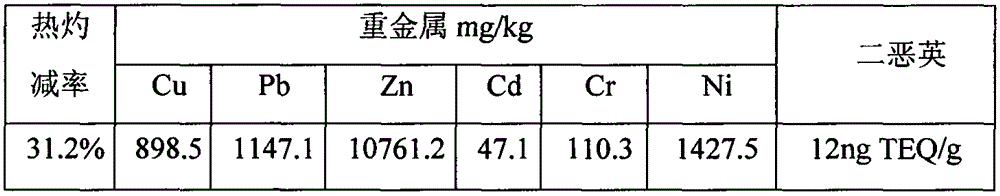

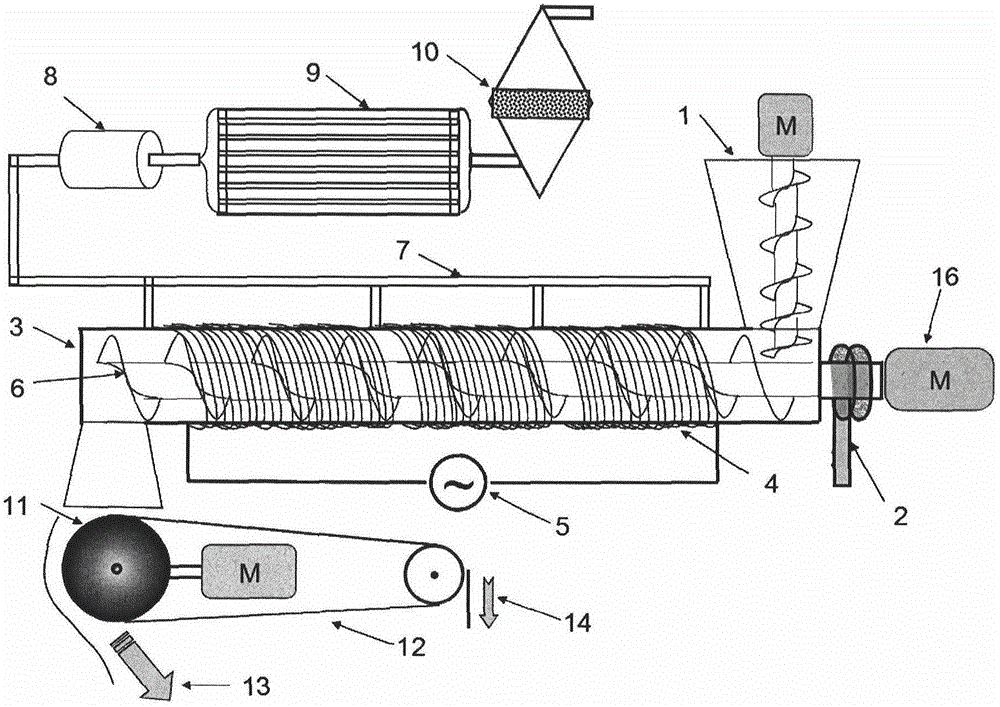

Multi-heat source and shaft intervallic heating type thermal desorption device for organic pollutant contaminated soil repair

ActiveCN103506378AEconomical and efficient processingRemove completelyContaminated soil reclamationHigh concentrationEngineering

The invention relates to the field of environmental protection, and aims to provide a multi-heat source and shaft intervallic heating type thermal desorption device for repairing organic pollutant contaminated soil. An intervallic heating type thermal desorption machine of the device is a jacket type heating furnace; a soil feeding port, an unearthing machine, a first multi-heat source inlet and a first multi-heat source outlet are formed in the outer cylinder; a carrier gas inlet and a carrier gas outlet are formed in the inner cylinder; and a hollow shaft type revolving shaft adopting a jacket structure is formed by an outer shaft sleeve and a hollow inner shaft sleeve; a second multi-heat source inlet and a second multi-heat source outlet respectively connected with the outer shaft sleeve or the inner shaft sleeve are formed in the hollow shaft type revolving shaft. The device can effectively treat the organic pollutant contaminated soil, is particularly suitable for repairing high-concentration and multi-component organic pollutant contaminated soil fields, has excellent adaptability to various heat sources, improves the synthetic utilization efficiency of the heat sources, has great soil processing capacity in unit time, and is particularly suitable for sandy contaminated soil. For the organic pollutant contaminated soil, the device can achieve the organic pollutant removing efficiency above 99.9%.

Owner:ZHEJIANG UNIV

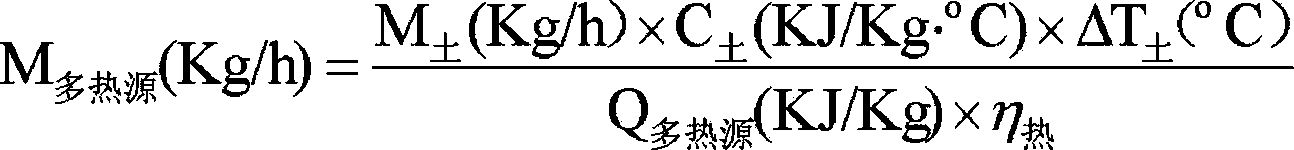

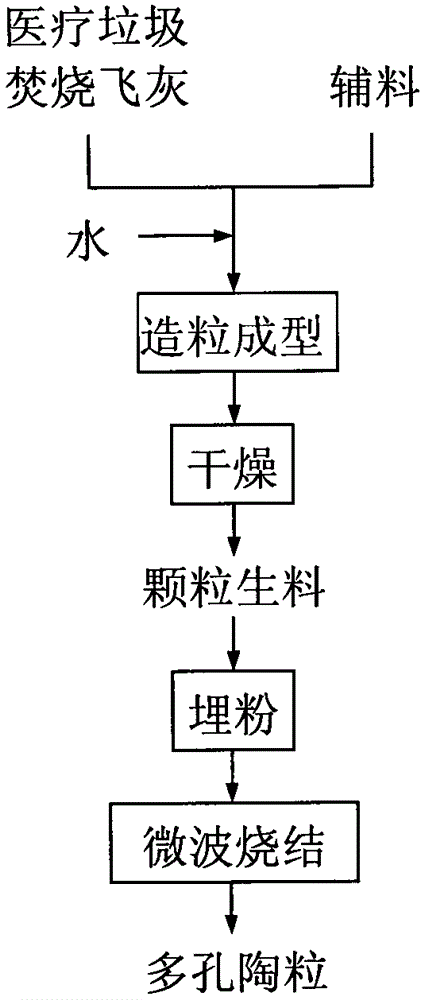

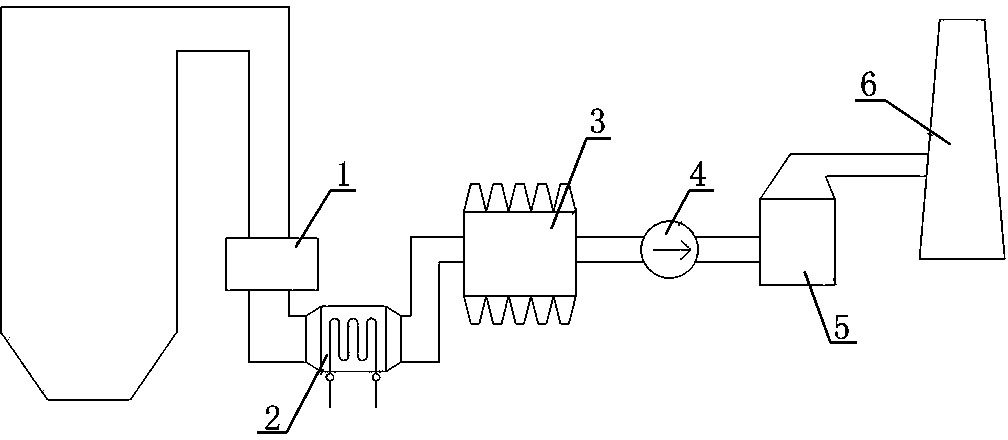

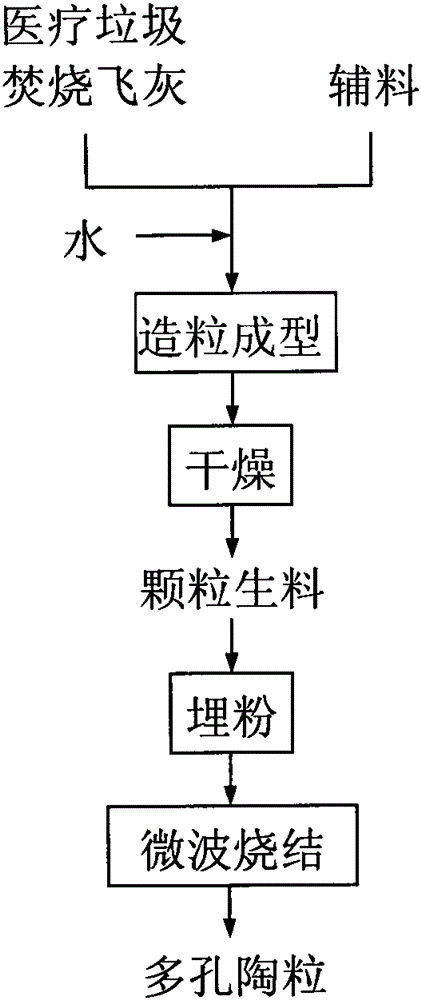

Method for microwave firing of porous ceramsites by adopting medical waste incineration fly ash

The invention discloses a method for microwave sintering of porous ceramsites by adopting medical waste incineration fly ash. The method comprises the following steps: (1) fully mixing the medical waste incineration fly ash with an auxiliary material, adding a small amount of water into the mixture, and carrying out granulation molding by a molding machine; (2) carrying out granulation molding, drying to obtain a particle raw material, filling the periphery of the particle raw material with a microwave coupling agent powder; and (3) carrying out microwave sintering of the particle raw material filled with the powder, and after sintering, cooling to the room temperature to obtain the porous ceramsites. The method can utilize a 'hot spot' effect of fly ash high-content active carbon in a microwave field to instantly completely decompose dioxins in the fly ash, at the same time, allows most heavy metals to be wrapped and cured in grids of the sintered product, and rapidly sinters the fly ash into the porous ceramsites; and the ceramsites can be used for building aggregates or wastewater filter materials, achieves further resource utilization while achieving harmlessness treatment of the medical waste incineration fly ash, and achieves many things at one stroke.

Owner:TIANJIN CHENGJIAN UNIV

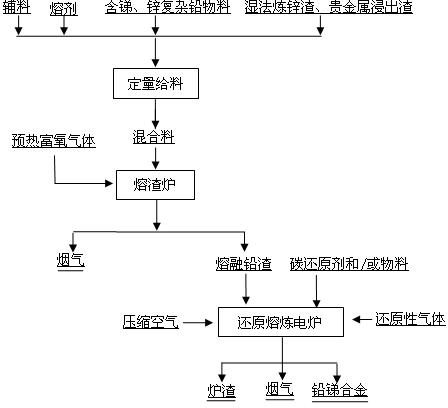

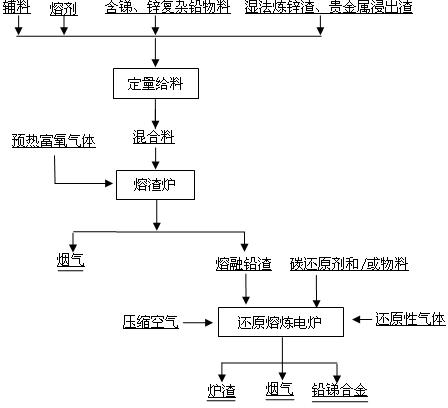

Smelting method of lead concentrate containing antimony and zinc

InactiveCN102433448AEfficient use ofNo explosion hazardProcess efficiency improvementFlue gasSmelting process

The invention relates to a nonferrous metal, and in particular relates to a smelting method of lead concentrate containing antimony and zinc. The smelting method is characterized in that in the smelting process, oxidizing smelting is performed to the lead concentrate containing antimony and zinc in a slagging furnace to generate a flue gas containing SO2, smelting dust and slagging furnace slag; then reduction smelting is performed to the slagging furnace slag in an electric furnace to generate a lead-antimony alloy, a flue gas and slag, and after the slag and the lead-antimony alloy are clarified and layered, the lead-antimony alloy is discharged from a lead discharge hole; and zinc oxide is recycled from the flue gas obtained in the reduction process and then the obtained flue gas is discharged to the outside. The method has the following advantages: the flow is short, continuous production is realized, energy is saved, the production capacity is large, resources can be efficiently utilized, the environment can be protected, the safety and labor hygiene are good, foamed slag has no explosion danger and the production is safe. The smelting method is suitable for not only the treatment of the complex lead materials containing antimony and zinc, but also the treatment of wet method zinc metallurgical slag and lead-precious metal system slag, lead, zinc and antimony are matched mutually, the lead-zinc-antimony combination enterprises are more superior and the recovery rates of lead and the associated valuable metals such as copper and antimony, and precious metals are higher.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

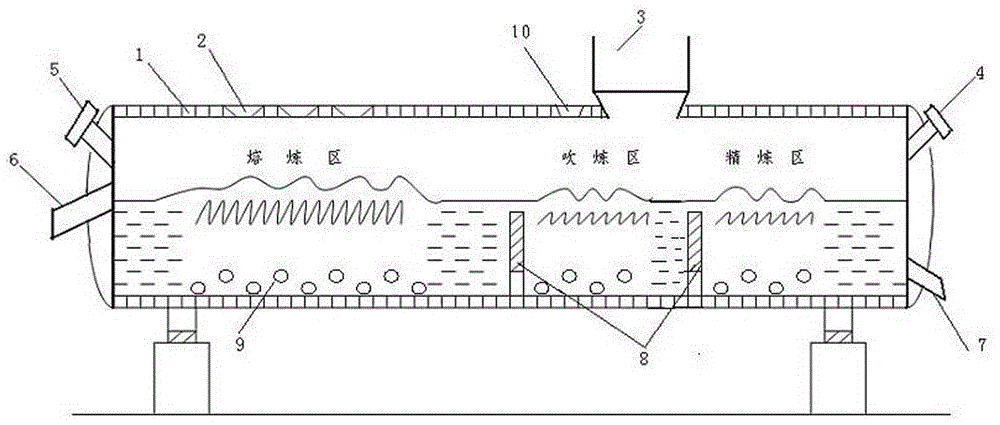

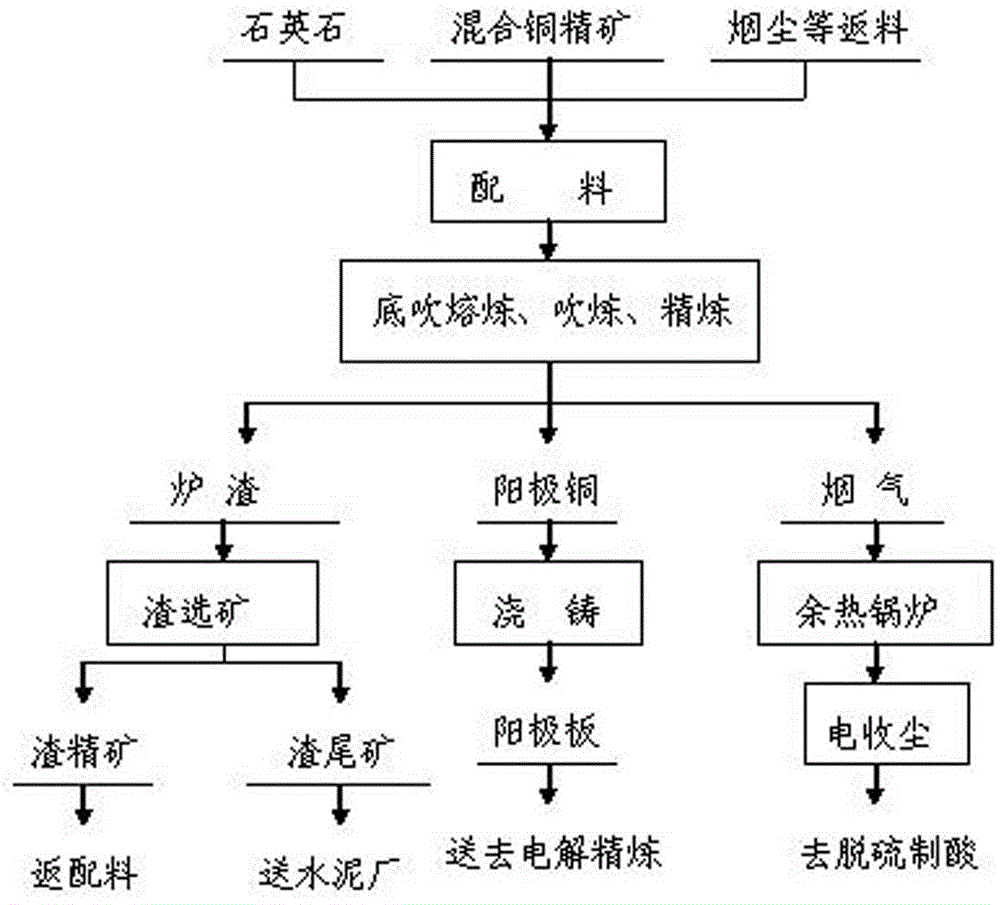

One-step copper smelting technology and device thereof

The invention relates to a one-step copper smelting technology and a device thereof. The interior of a furnace body is divided into three zones, namely a smelting zone, a blowing zone and a refining zone, by a retaining wall; and two rows of spray guns which are arranged in a staggered manner and have an included angle with a vertical line are arranged at the bottoms of the zones; return dust is mixed and then added into mixed copper concentrate and a solvent through a charging opening of the smelting zone, oxygen-enriched air is sprayed through the spray guns to carry out self-heating smelting, to generate copper matte; the spray guns in the blowing zone spray oxygen-enriched air so as to blow copper matte into crude copper and slag; the spray guns in the refining zone supply oxygen-enriched air for oxidization, and supply natural gas as a reductant for reduction, and the generated anode copper with high purity is interruptedly discharged form a copper discharging opening, so that the low-altitude pollution problem caused by SO2 can be solved, the operation environment can be greatly improved, the utilization rate of sulfur and heat can be obviously increased, and further the economic benefits can be increased further; in addition, the invention provides a one-step copper smelting technology which is more advanced, shorter in flow, lower in investment, lower in comprehensive energy consumption, higher in recovery rate, and better in comprehensive utilization in comparison with the existing continuous copper smelting technology.

Owner:DONGYING LUFANG METAL MATERIAL

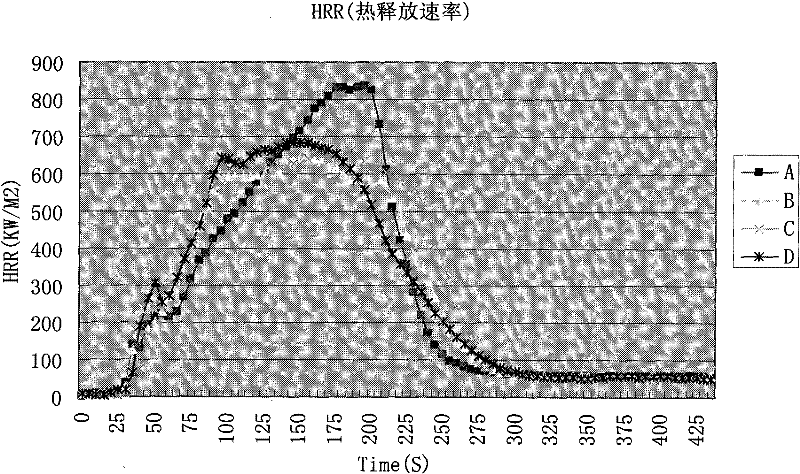

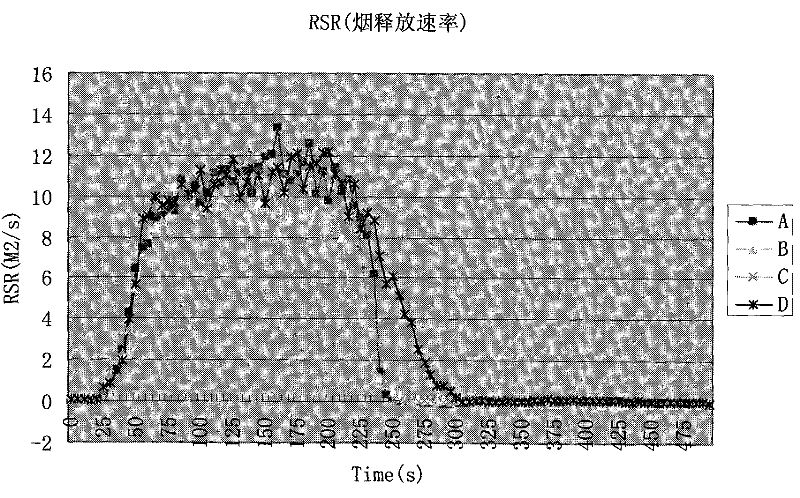

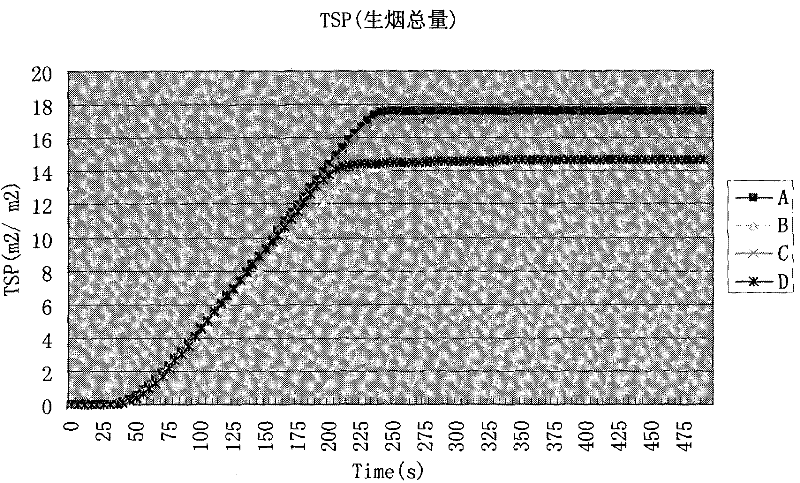

Low-heat low-smoke flame retardant and application thereof in preparing flame-retardant master batch

The invention relates to a low-heat low-smoke flame retardant and application thereof in preparing a flame-retardant master batch. The low-heat low-smoke flame retardant comprises the following components in percentage by weight: 40-70% of hypophosphite, 20-50% of melamine compound, 0.1-10% of nano inorganic substance and 5-15% of assistant. The low-heat low-smoke flame retardant can be used for preparing a flame-retardant master batch. Compared with the prior art, the invention can effectively reduce the heat release rate, smoke release rate and total smoke generation quantity, thereby performing active functions of postponing the propagation of flame, reducing the rate of burning released substances and increasing the escape probability.

Owner:上海安凸塑料添加剂有限公司

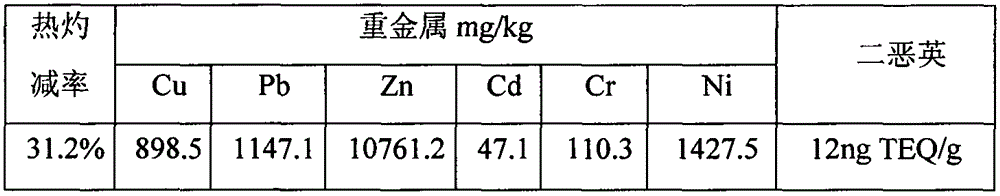

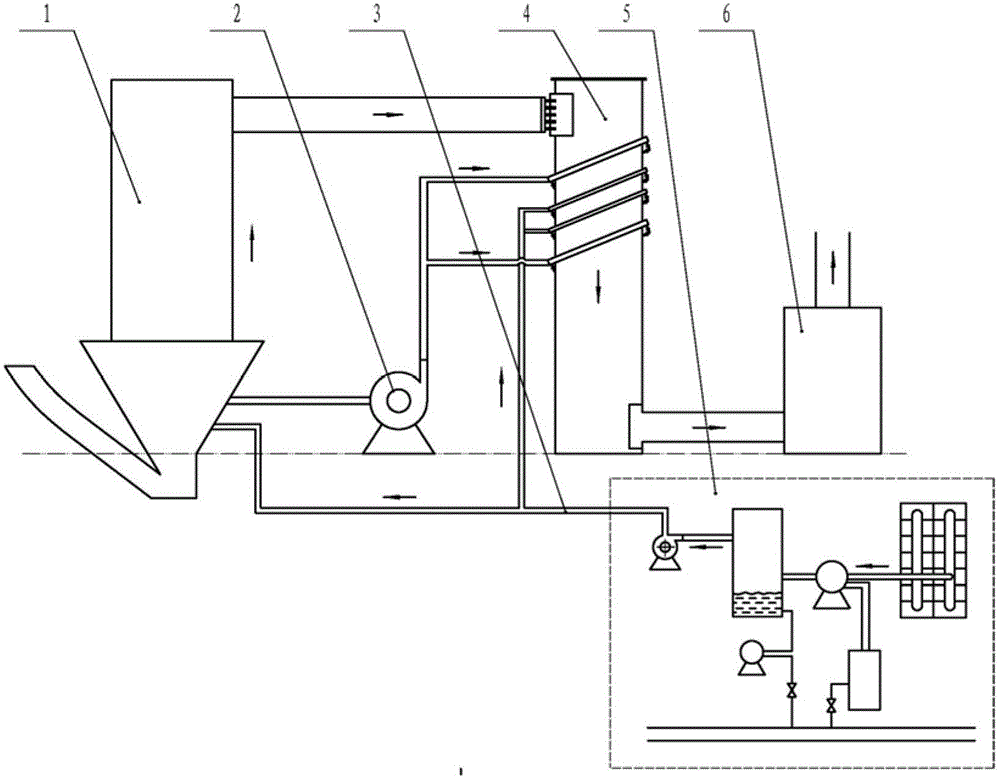

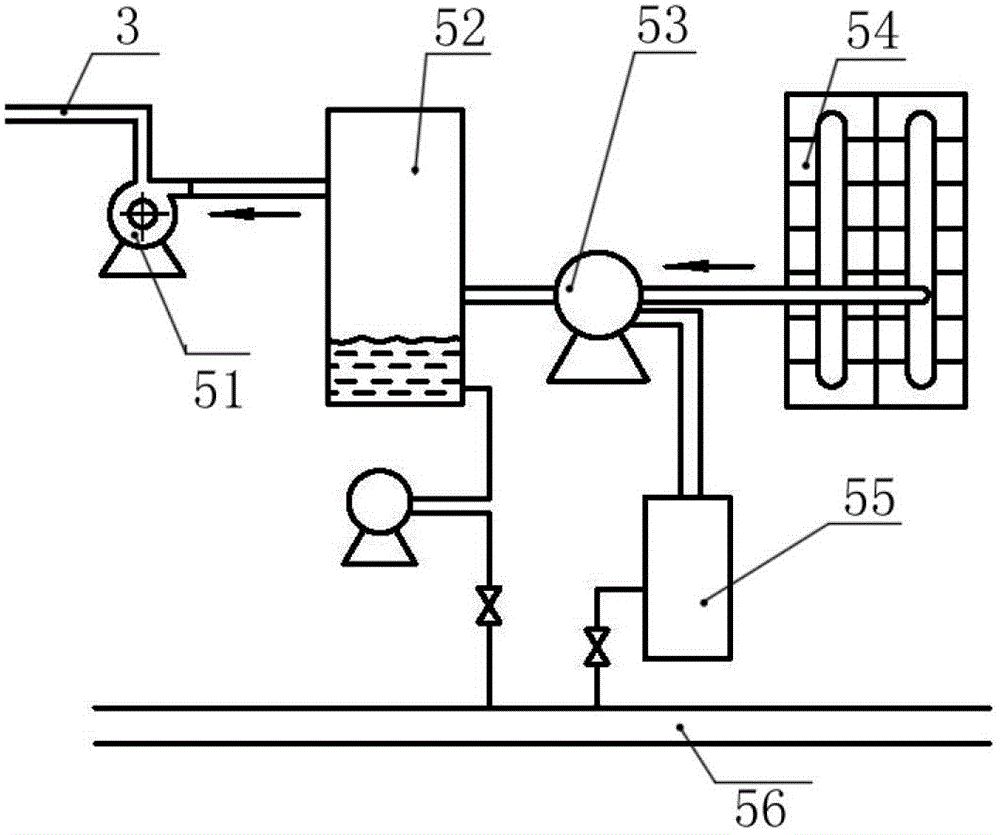

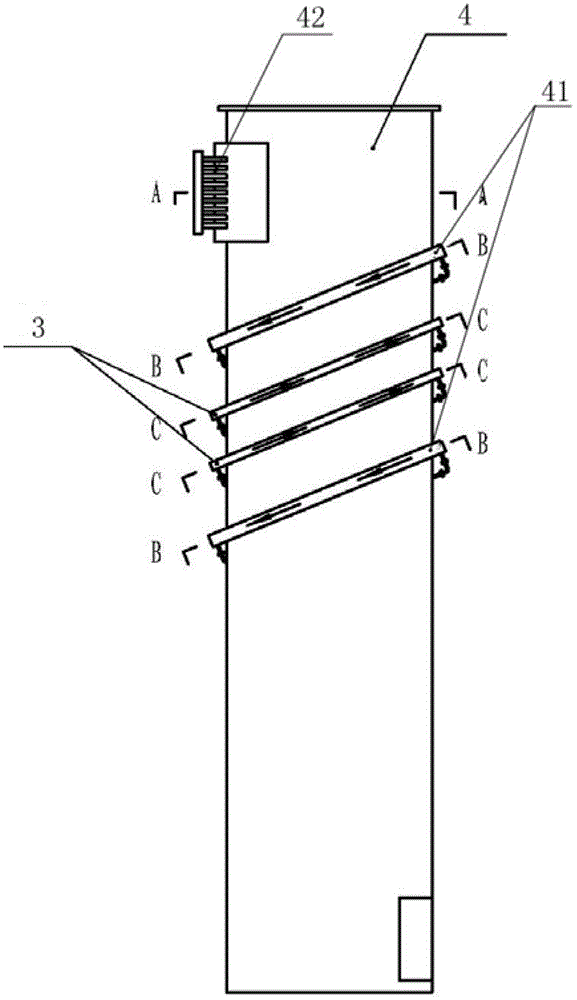

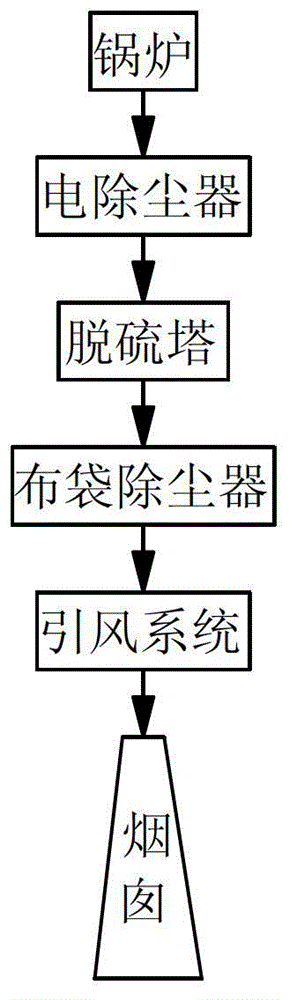

Low temperature electric precipitation system in fuel electric plant

InactiveCN103363536AImprove the dust collection rateMeet the requirements of emission standardsLighting and heating apparatusAir preheaterEnvironmental resistance

A low temperature electric precipitation system in a fuel electric plant comprises at least one air preheater, at least one electric precipitator and connecting pipes for connecting the air preheater and the electric precipitator together, a flue-gas heat exchanger for lowering the flue-gas temperature entering the electric precipitator to enable the flue-gas temperature to reach or be lower than flue-gas dew point at the temperature of 90 DEG C is arranged between the air preheater outlet and the electric precipitator inlet; the electric precipitator is communicated with a desulfuration absorption tower through an induced-draft fan; a chimney is connected with the rear part of the desulfuration absorption tower. The flue-gas heat exchanger adopts a backward flow heat exchange type; a vertical pipe heat exchange flow passage or a horizontal pipe heat exchange flow passage is arranged at the inner part of the flue-gas heat exchanger; the system has the characteristics that the project equipment investment is reduced; the auxiliary power ratio is lowered; the energy is saved; the consumption is reduced; the heat economy of the unit can be improved; the latest environment-friendly emission standard can be satisfied.

Owner:ZHEJIANG ELECTRIC POWER DESIGN INST +1

Technique for smelting vanadium iron from calcium vanadate

A production of ferrovanadium concerned with calcium vanadate is carried out by smelting calcium vanadate, Al and ferrous powder at weight ratio of 100: (23-28): (23-27). The said calcium vanadate is selected from m-calcium vanadate, p-calcium vanadate or o-calcium vanadate, one of them at least, with V content of 24-43%. It has high recovery rate and no wastewater pollution.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

A method of microwave firing porous ceramsite from medical waste incineration fly ash

ActiveCN103601526BPromote formationGood consolidationSolid waste disposalCeramicwarePrillResource utilization

The invention discloses a method for microwave sintering of porous ceramsites by adopting medical waste incineration fly ash. The method comprises the following steps: (1) fully mixing the medical waste incineration fly ash with an auxiliary material, adding a small amount of water into the mixture, and carrying out granulation molding by a molding machine; (2) carrying out granulation molding, drying to obtain a particle raw material, filling the periphery of the particle raw material with a microwave coupling agent powder; and (3) carrying out microwave sintering of the particle raw material filled with the powder, and after sintering, cooling to the room temperature to obtain the porous ceramsites. The method can utilize a 'hot spot' effect of fly ash high-content active carbon in a microwave field to instantly completely decompose dioxins in the fly ash, at the same time, allows most heavy metals to be wrapped and cured in grids of the sintered product, and rapidly sinters the fly ash into the porous ceramsites; and the ceramsites can be used for building aggregates or wastewater filter materials, achieves further resource utilization while achieving harmlessness treatment of the medical waste incineration fly ash, and achieves many things at one stroke.

Owner:TIANJIN CHENGJIAN UNIV

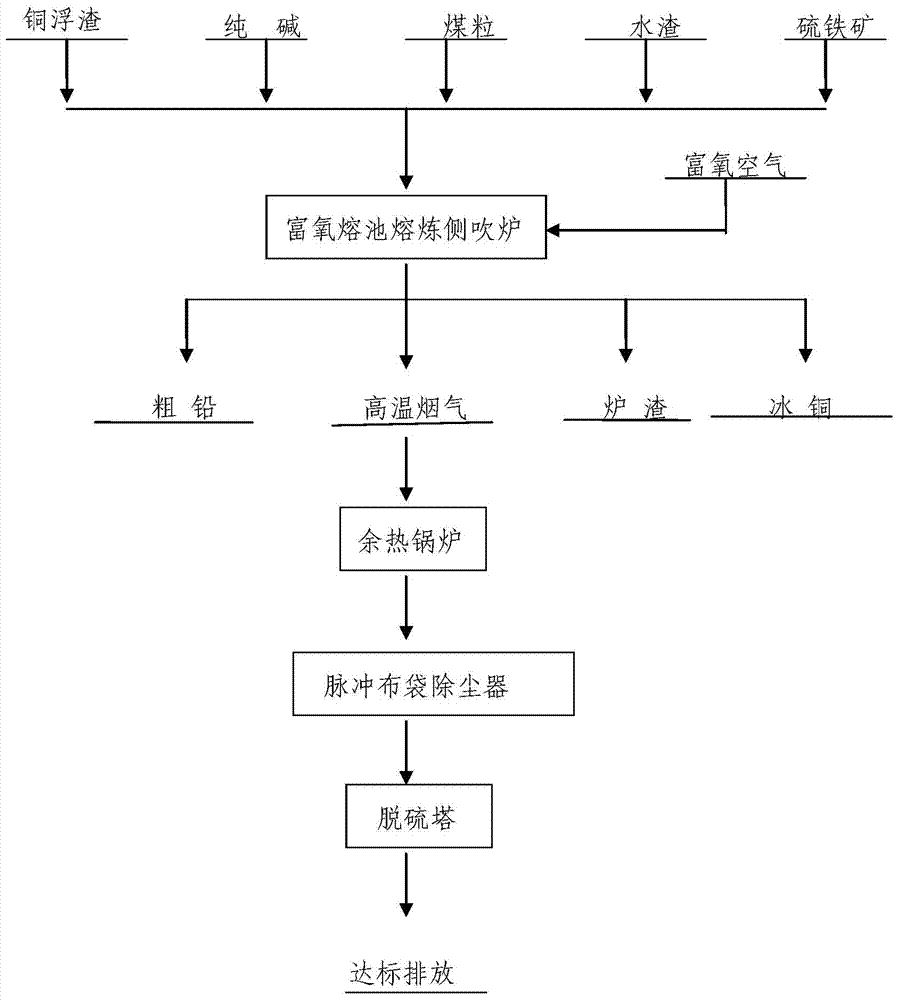

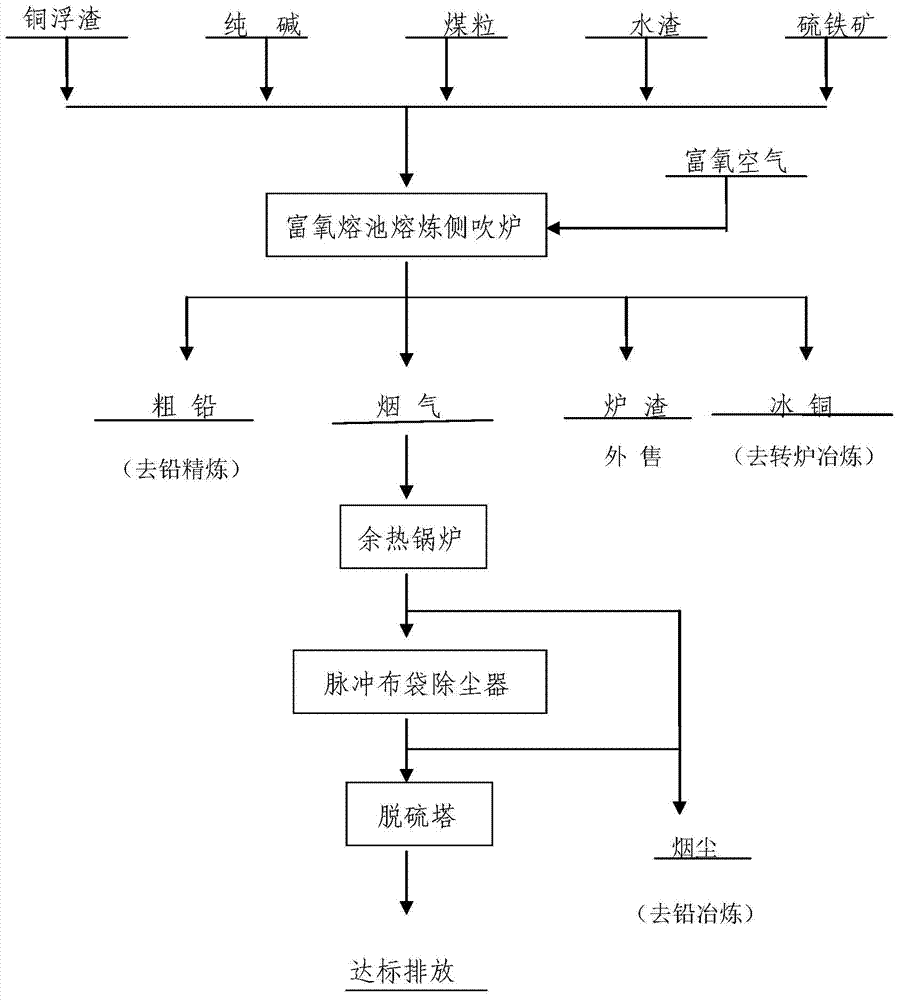

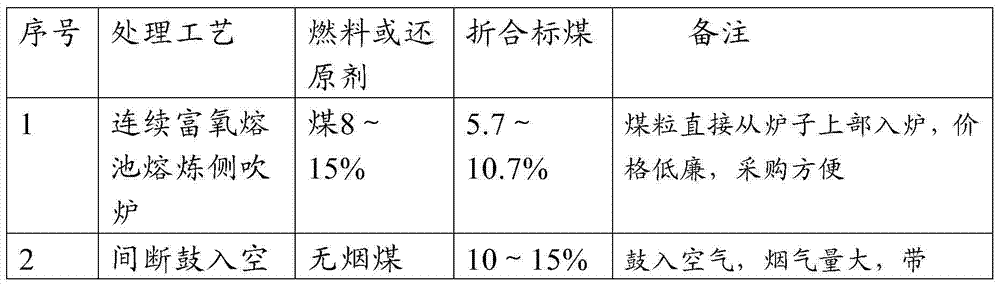

Method for treating copper dross

ActiveCN103924094AImprove melting efficiencyHigh direct metal recovery rate and recovery rateProcess efficiency improvementAutomatic controlPyrite

The invention provides a method for treating copper dross. According to the method, copper dross is treated by using an oxygen enrichment molten pool smelting side blowing furnace, coal granules are adopted as a reducing agent and fuel, copper dross, pure alkali, pyrite and water granulated slag are adopted for blending, together with the coal granules, are fed into the furnace from the feeding hole of the oxygen enrichment molten pool smelting side blowing furnace through a belt, and are blown into an oxygen enrichment air smelting pool for smelting so as to obtain crude lead, copper matte, furnace slag and high-temperature flue gas. By adopting the method provided by the invention, continuous feeding is achieved; due to adoption of a DCS automatic control technique, the working intensity of operators is low, the flushing and casting environment is good, the side blowing treatment bed is high in capacity, the efficiency of the smelting pool is high, the metal recycling rate is high, and the smelting energy consumption is low.

Owner:JIYUAN WANYANG SMELTING GROUP

Corn husk tobacco thin sheet and method for producing the same

ActiveCN101411544AReduce net contentReduce the amount of smokeTobacco preparationCigar manufactureAlcoholActive enzyme

The invention relates to a corn husk tobacco sheet and a production method thereof. The production method adopts the following steps: (1) the biodegradation and the extraction treatment are performed, wherein a. when a corn husk is heated to 55 DEG C in water, active enzyme is added; b. the mixture reacts for 2 hours at a temperature of 60 DEG C, and alcohol with the same amount of the water is added; c. biological enzyme is inactivated at a temperature of 90 DEG C to reclaim the alcohol; and d. the corn husk is dehydrated, and reaction extraction liquid is condensed to be pasty; (2) the corn husk after the treatment is produced into paper pulp; (3) the paper pulp is produced into a corn husk sheet; and (4) the pasty extraction liquid is coated on two surfaces of the corn husk sheet and is subject to drying treatment. The corn husk tobacco sheet has the advantages that the corn husk tobacco sheet is blended into tobacco to produce cigarettes, which can provide harmonious aroma for the cigarettes and excite sweet gas of smoke gas; and the corn husk tobacco sheet at least can substitute more than 5 to 15 percent of the using amount of the tobacco, and effectively reduce the smoke gas volume and harmful ingredients of one cigarette.

Owner:彭荣臻

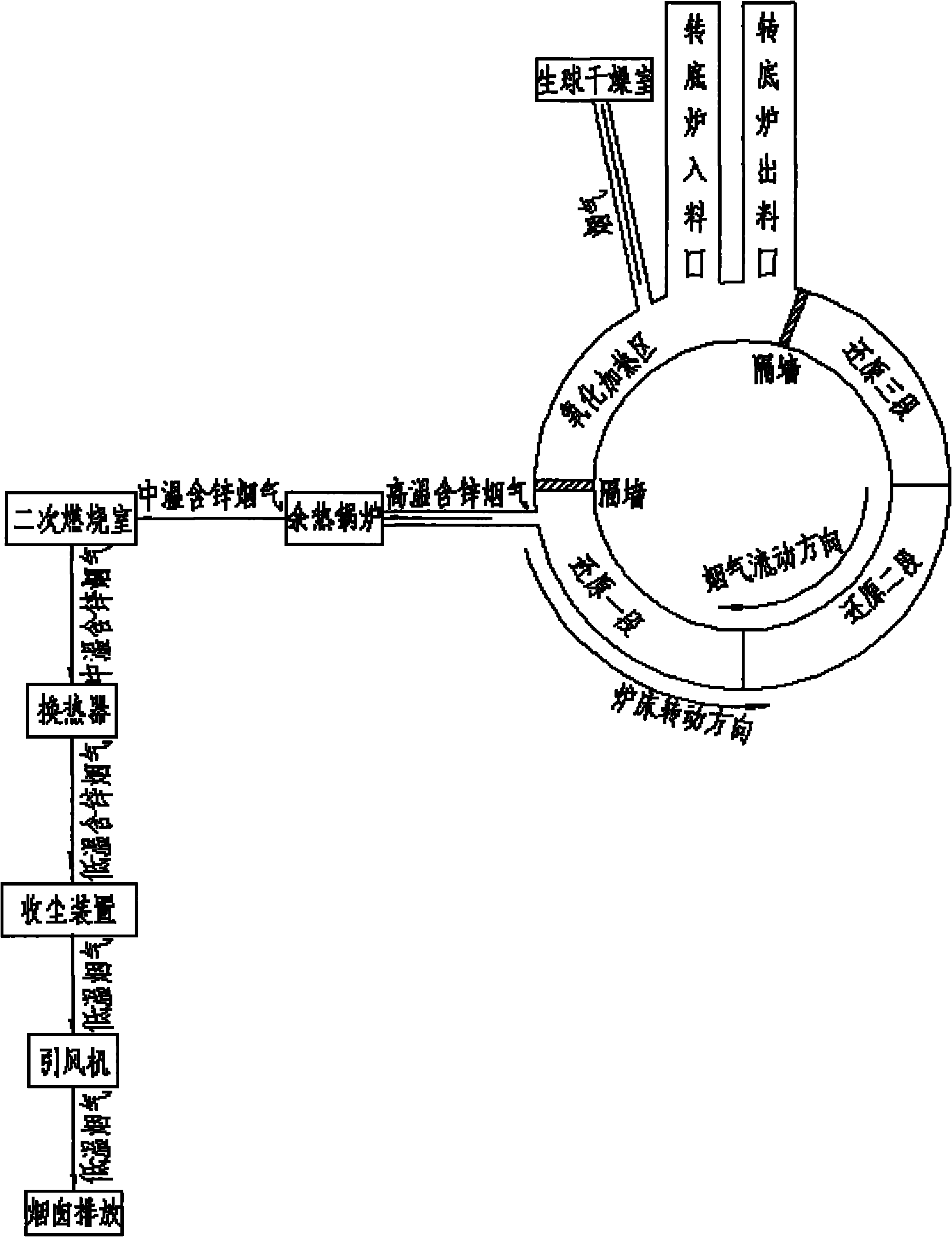

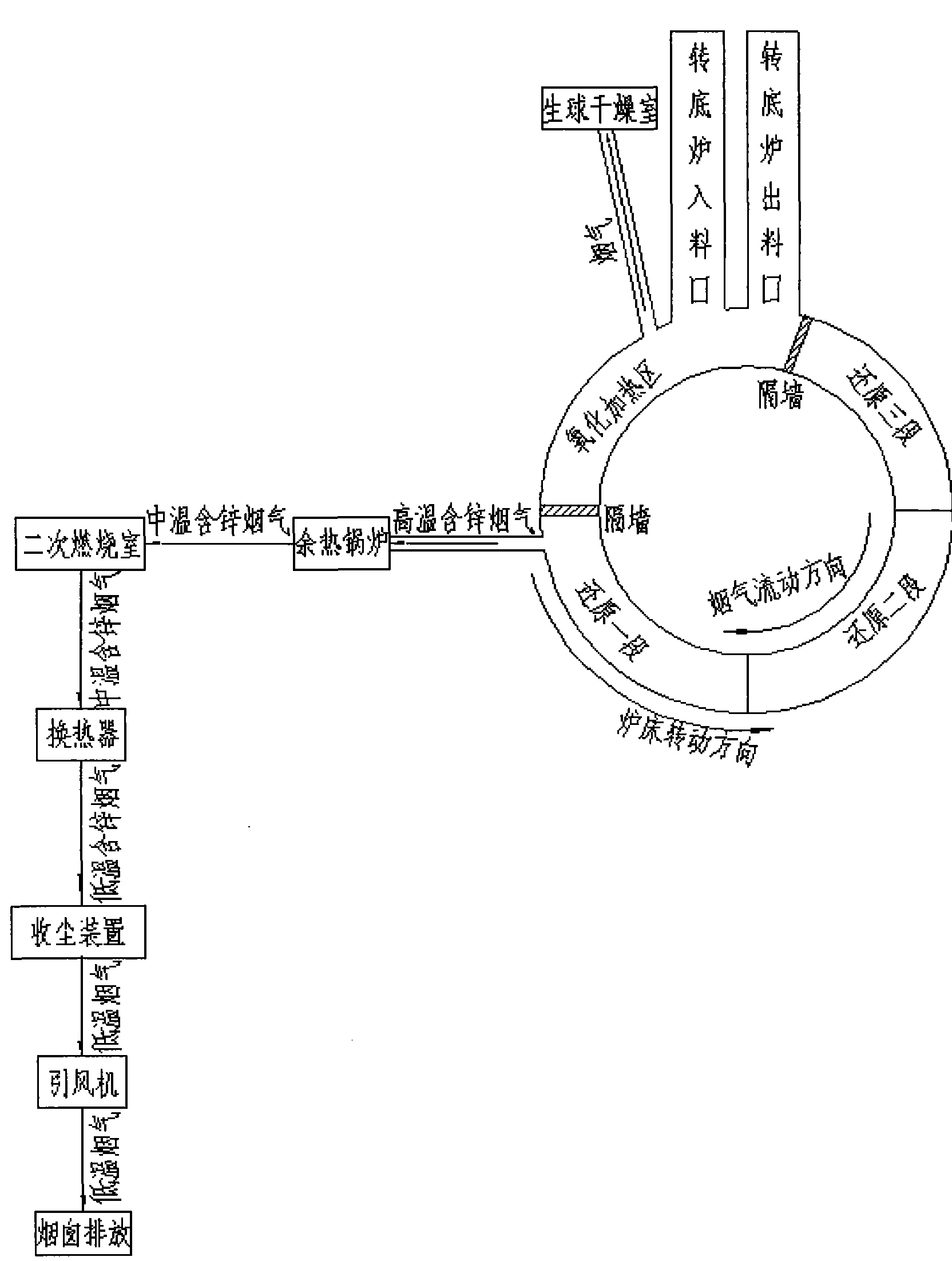

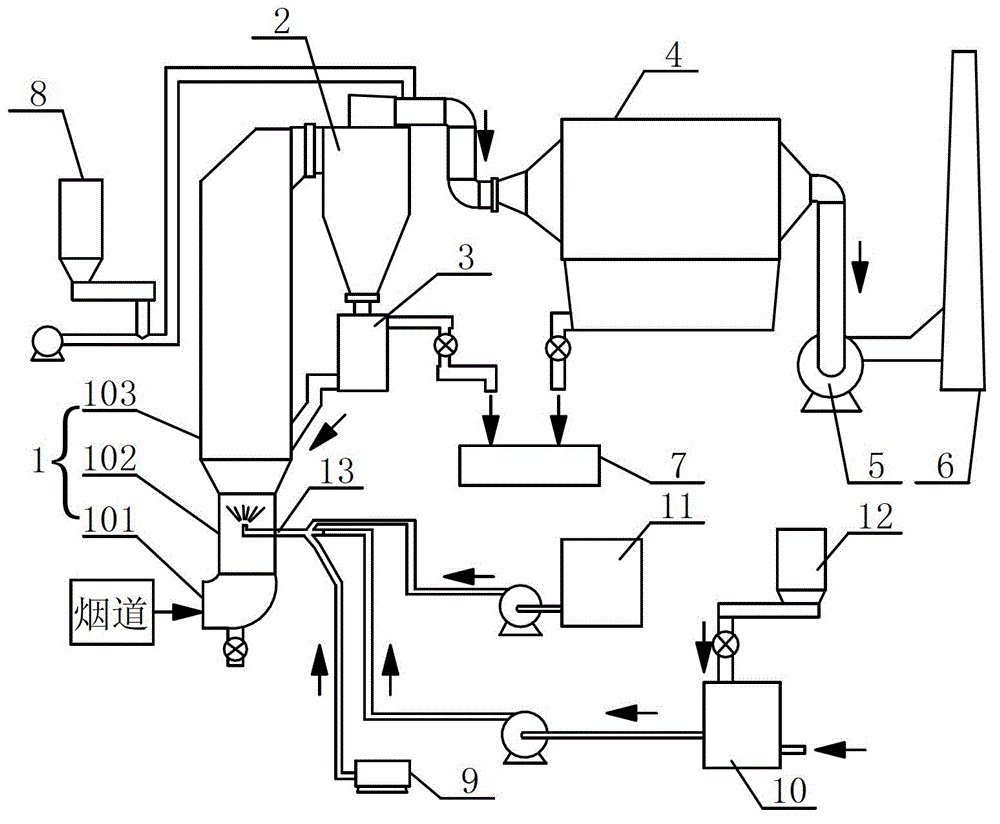

Process for processing smoke

InactiveCN101893387AHigh recovery rateReduce processingEnergy industryIncreasing energy efficiencyCombustionProcess engineering

The invention relates to a process for processing smoke, which is characterized in that: in the process, the smoke generated by a rotary hearth furnace is subjected to segmental processing. In the process for processing the smoke, the segmental processing is performed on the smoke generated by the rotary hearth furnace, and the low zinc content smoke in an oxidation heating region is used for drying a preheated green ball, so the waste heat of the smoke can be completely recycled, unburned gas can also be combusted completely to recycle usable waste heat further; the smoke in a high-temperature reducing region where the zinc is gasified and volatilized intensively is subjected to dust removal and zinc recycling after waste heat recycling and secondary combustion, and the amount of the smoke which needs to perform zinc recycling is reduced, so the equipment investment and operation cost of a smoke processing system are reduced; and due to the secondary waste heat recycling and the secondary combustion of the smoke in the high-temperature reducing region, the waste heat of the smoke in the region can be completely recycled, the recovery rate of the zinc is improved, and the environmental pollution is reduced.

Owner:CISDI ENG CO LTD

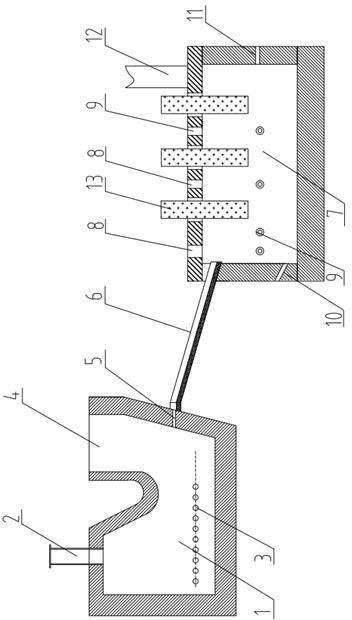

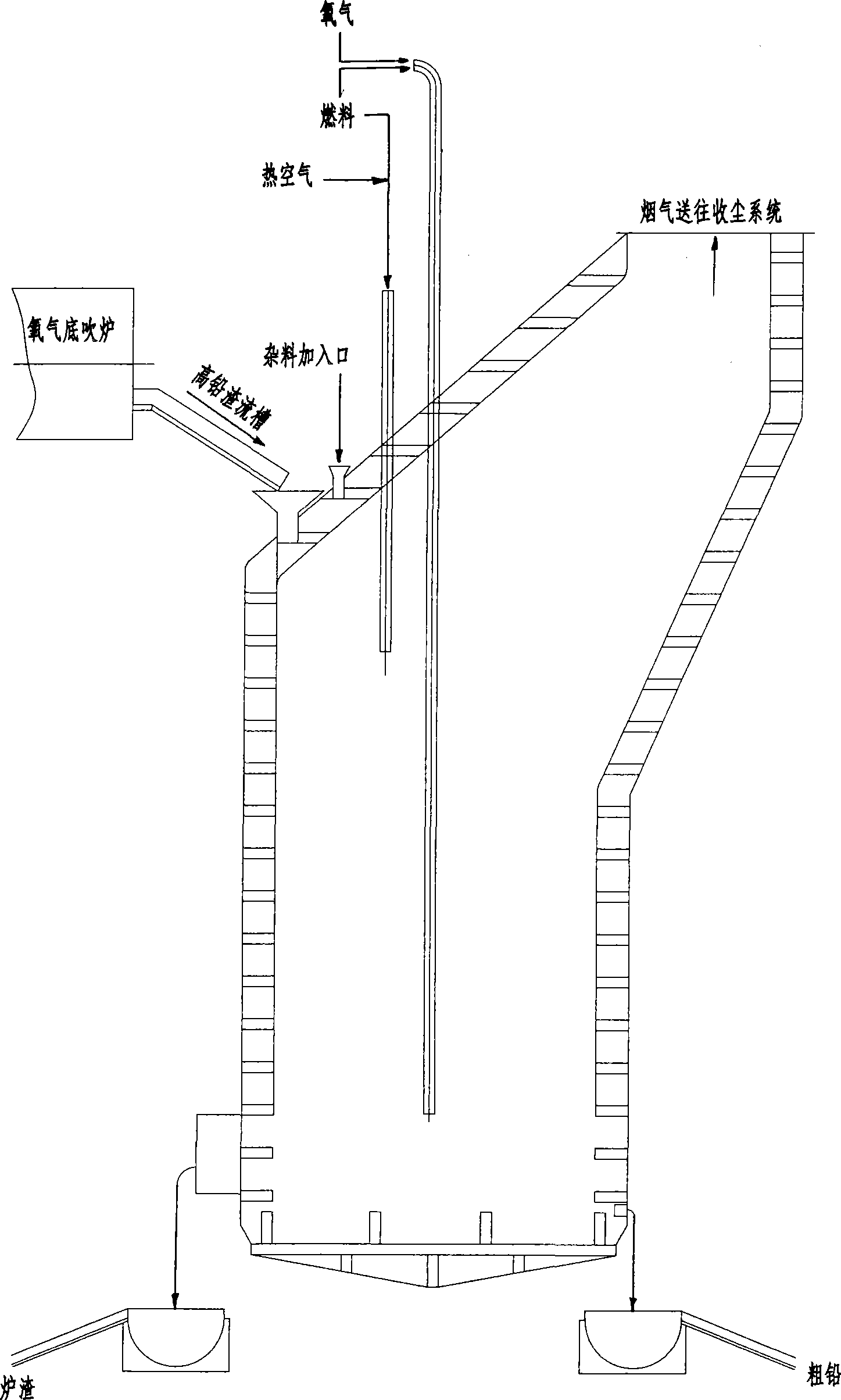

Process for direct reduction of liquid high-lead skim with reduction furnace

The invention discloses a process of directly reducing liquid high lead slag in reducing furnace, secondary lead-containing materials such as the liquid high lead slag, lead concentrate, scrap leads, waste accumulators and the like generated from the oxygen bottom blowing smelting furnace or zinc leaching residues are used as raw materials and are added from the top end of the reducing furnace; coal powder and natural gas used as fuel and oxygen-enriched air used as combustion improver are continuously led in from the top of the reducing furnace to carry out combustion reaction; the temperature in the reducing furnace is kept at 1000-1500 DEG C; the coal powder and natural gas can be simultaneously used as reducing agents and fall into the reaction tank at the bottom of the reducing furnace after being fully mixed with the raw materials; the lead oxides in the raw materials are reduced to crude lead and the addition of the reducing agents is subject to full reduction of the lead oxides in the raw materials. The process of the invention directly reduces the liquid high lead slag, fully utilizes the thermal energy of the high lead slag and further reduces the coke consumption and flue gas volume, thereby dramatically reducing the smoke dust rate and the smelting cost.

Owner:安徽铜冠有色金属(池州)有限责任公司

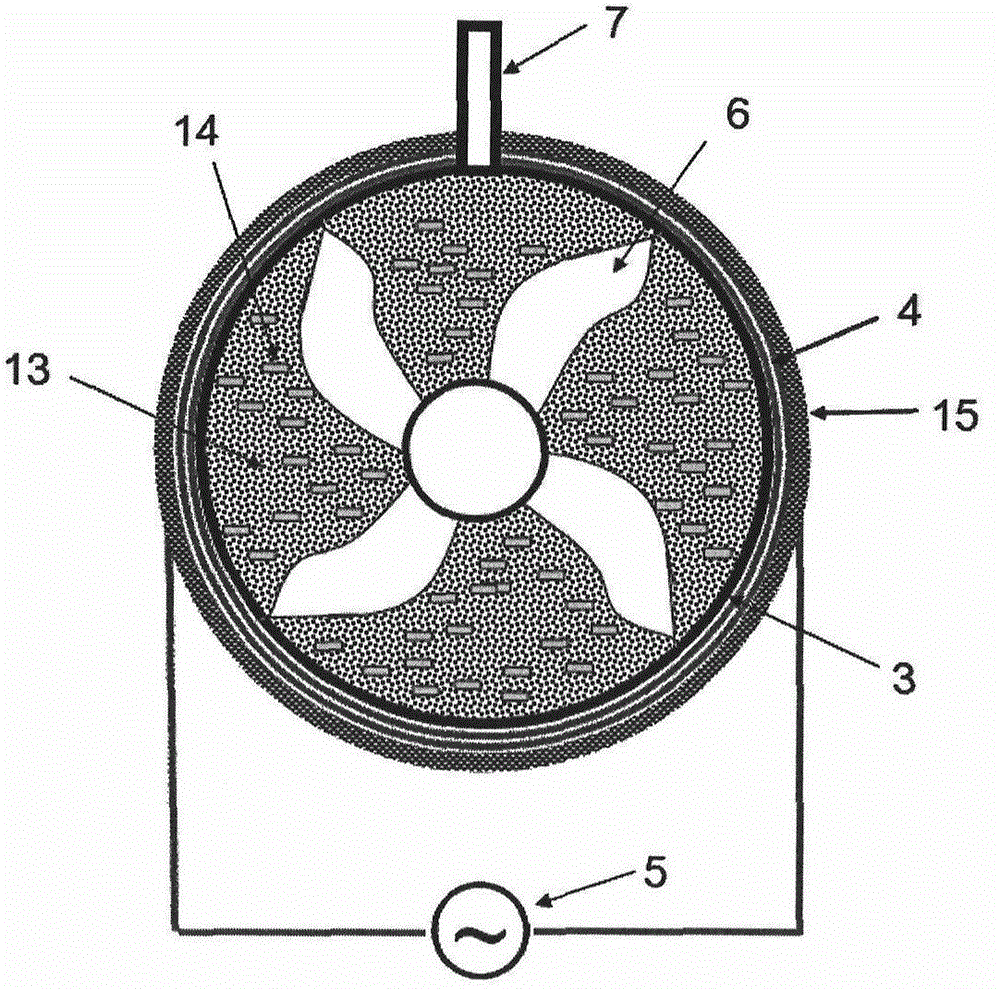

Magnetic separation enhanced type electromagnetic thermal desorption method and device for remediating soil

InactiveCN105983569AFast temperature controlFast control timeContaminated soil reclamationElectromagnetic heatingThermal desorption

The invention provides a magnetic separation enhanced type electromagnetic thermal desorption method and device for remediating contaminated sites. The method is characterized in that ferromagnetic materials, such as reducing iron powder, are doped into contaminated soil in an ex-situ mixing and stirring manner, the contaminated soil spirally stirred is heated by using electromagnetism, and a thermal desorption heat transfer gasifying effect is improved through the in-situ electromagnetic eddy heating of the ferromagnetic materials; the reaction activity and oxidation reduction capability of the ferromagnetic materials are improved when the ferromagnetic materials produce heat; after thermal desorption is finished, the ferromagnetic materials of which the surfaces react and adsorb pollutants can be separated from the contaminated soil through magnetic separation, recycled and reutilized; and the continuous remediation of contaminated soil is realized. The device also can be used for the in-situ remediation of contaminated soil. After the ferromagnetic materials are added to the soil in situ through a ploughing stirring device, the soil is heated in situ by utilizing an electromagnetic induction coil to carry out excitation eddy heating in the contaminated soil, pollutants are desorbed, and at the same time, the reaction activity of the magnetic materials(for example, reducing iron powder) can be improved; and after reaction is finished, the iron powder can be separated from the contaminated soil through a magnetic separation technology. The device also can be placed in soil to realize in-situ oxidation reduction degradation. The method and device are suitable for the in-situ thermal desorption remediation of circumjacent large area of low-concentration contaminated soil.

Owner:李泽唐

Technique for preparing sulfuric acid from SO2 by non-equilibrium state high-concentration twice conversion

ActiveCN103011092AConducive to expansion and transformationReduce the amount of smokeSulfur compoundsEnergy inputPtru catalystFlue gas

Owner:CHINA NERIN ENG +1

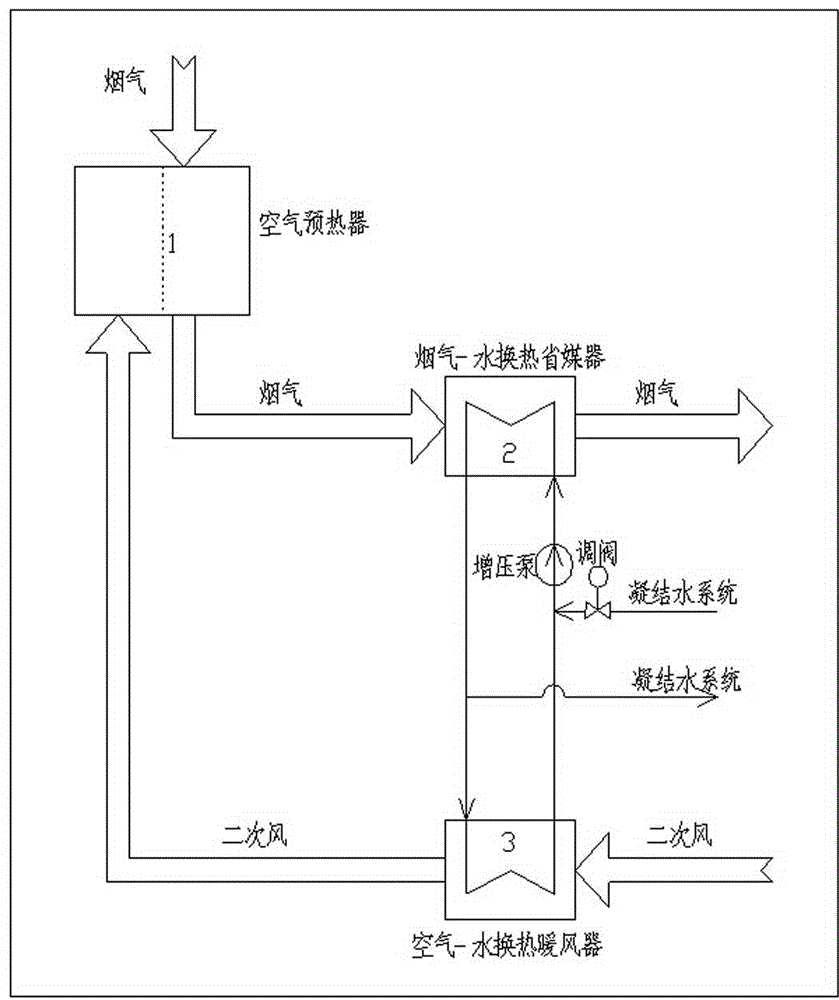

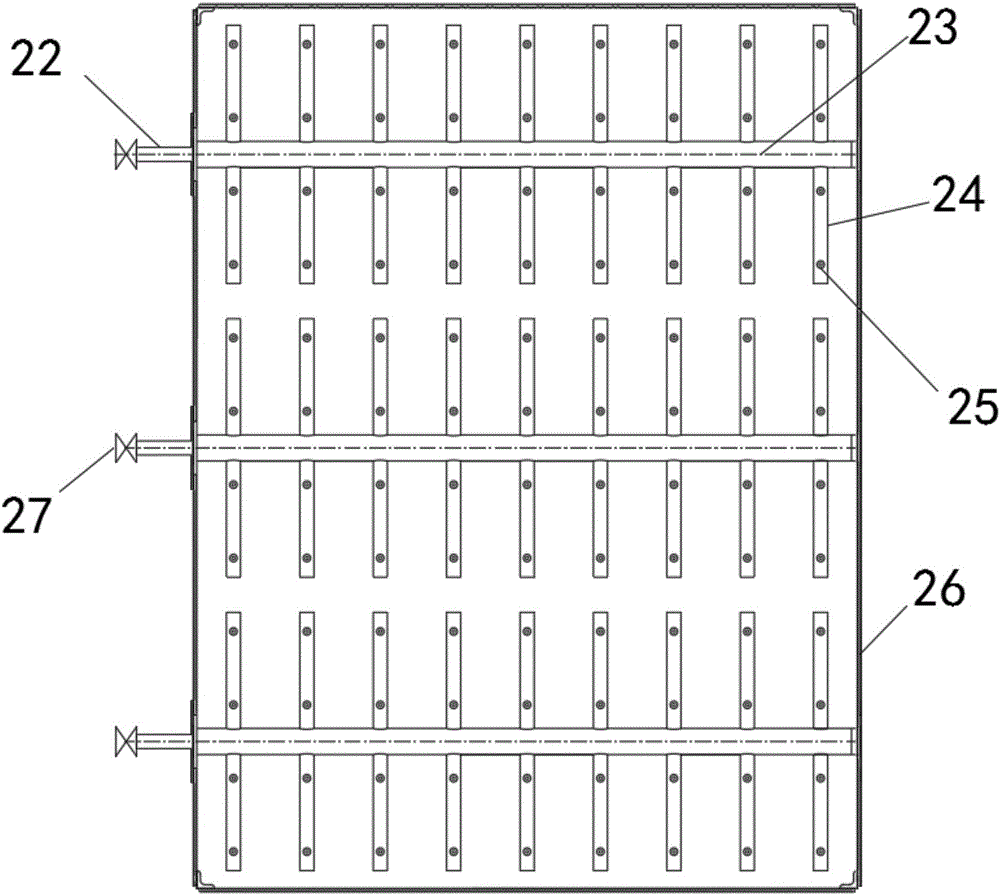

Composite utilization system for waste heat of exhaust fume of boiler

InactiveCN104456611AIncrease temperatureImprove efficiencyCombustion processIndirect carbon-dioxide mitigationAir preheaterCold air

The invention provides a composite utilization system for the waste heat of the exhaust fume of a boiler. The system comprises at least one air preheater, at least one fume-water heat exchange coal economizer, at least one air-water heat exchange air heater, and a connecting pipe for connecting the air preheater and the heat exchanger, wherein the fume-water heat exchange coal economizer is arranged behind the air preheater, fume is exhausted after the heat of the fume from an outlet of the air preheater is absorbed through the fume-water heat exchanger, and the waste heat of the fume is utilized to raise the temperature of the cold air and the temperature of the condensation water; the air-water heat exchange air heater is used for heating the cold air through water media. The system has the characteristics that the temperature of the cold air is raised, the deposition of ammonium bisulfate is relieved, the flue exhaust temperature is reduced, the efficiency of the boiler is improved, the condensation water is heated, and the water usage for a desulfurization system is saved.

Owner:ZHEJIANG ELECTRIC POWER DESIGN INST

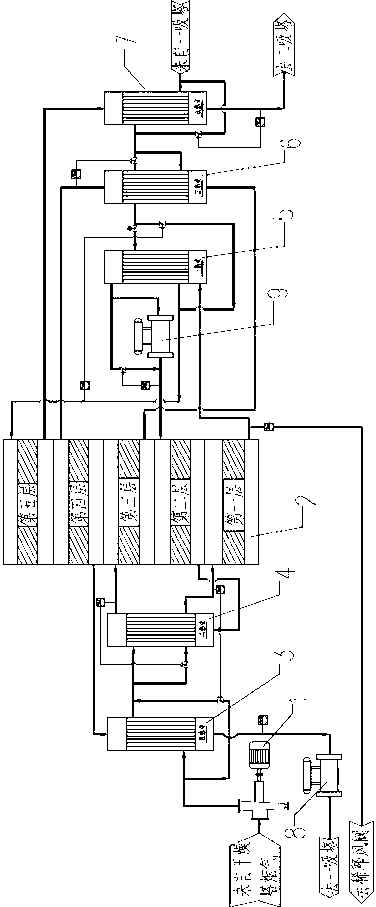

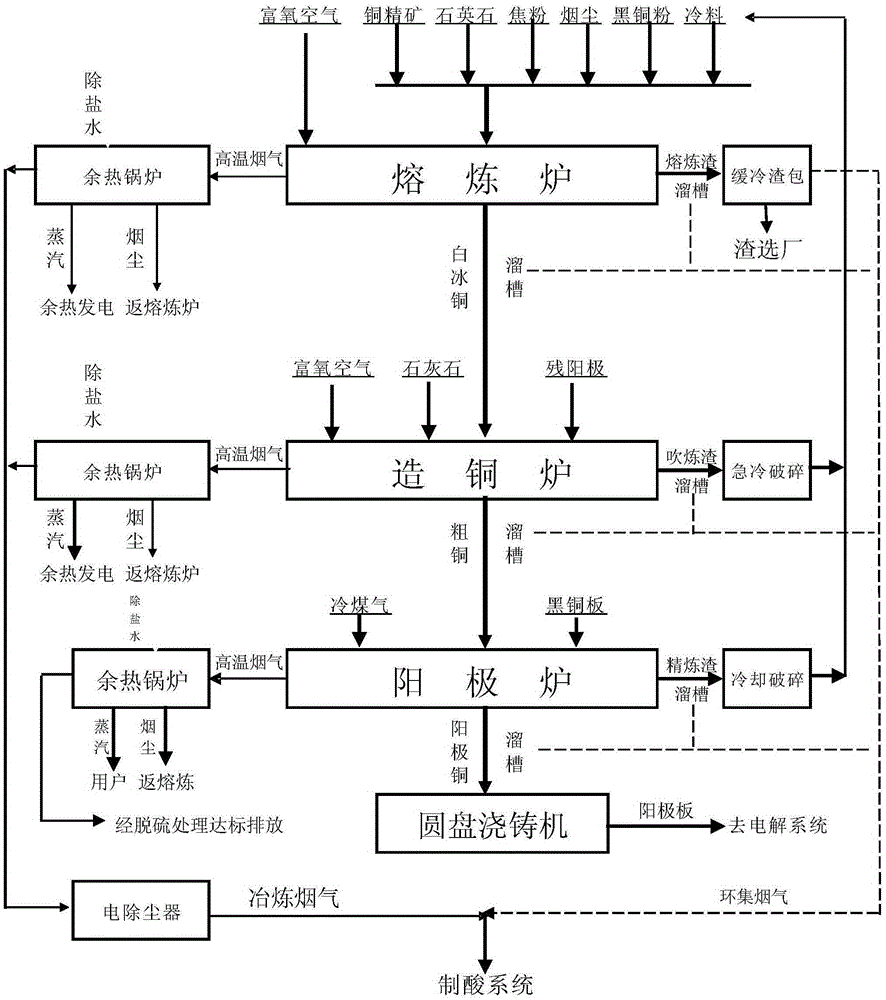

Three continuous furnace technology for continuous production of anode copper with copper concentrate

InactiveCN105238938AReduce metallurgical equipment and plant investmentAvoid sensible heat lossRotary drum furnacesCrucible furnacesSlagContinuous operation

The invention provides a three continuous furnace technology for continuous production of anode copper with copper concentrate. The technology is particularly characterized in that a smelting furnace, a copper making furnace and an anode furnace are in tandem arrangement successively, and kilns are connected by chutes. The technology comprises the steps that the copper concentrate and flux enter the smelting furnace and react with oxygen-enriched air to generate white matte, smelting slag and high-temperature smoke; the smelting slag overflows continuously; a slow cooling slag ladle is put through the chutes for floatation and depletion; the white matte continuously flows into the copper making furnace via siphon through the chute and reacts with the flux and the oxygen-enriched air to generate raw copper, copper converting slag and high-temperature smoke; the raw copper continuously or intermittently flows into the anode furnace via siphon through the chute; the anode furnace alternately operates and produces the anode copper via oxygenation and reduction; and the converting slag is regularly discharged, chilled, broken and returned to the smelting furnace. The technology achieves continuous operation of smelting production of the raw copper with the copper concentrate.

Owner:CHIFENG JINFENG METALLURGICAL TECH DEV

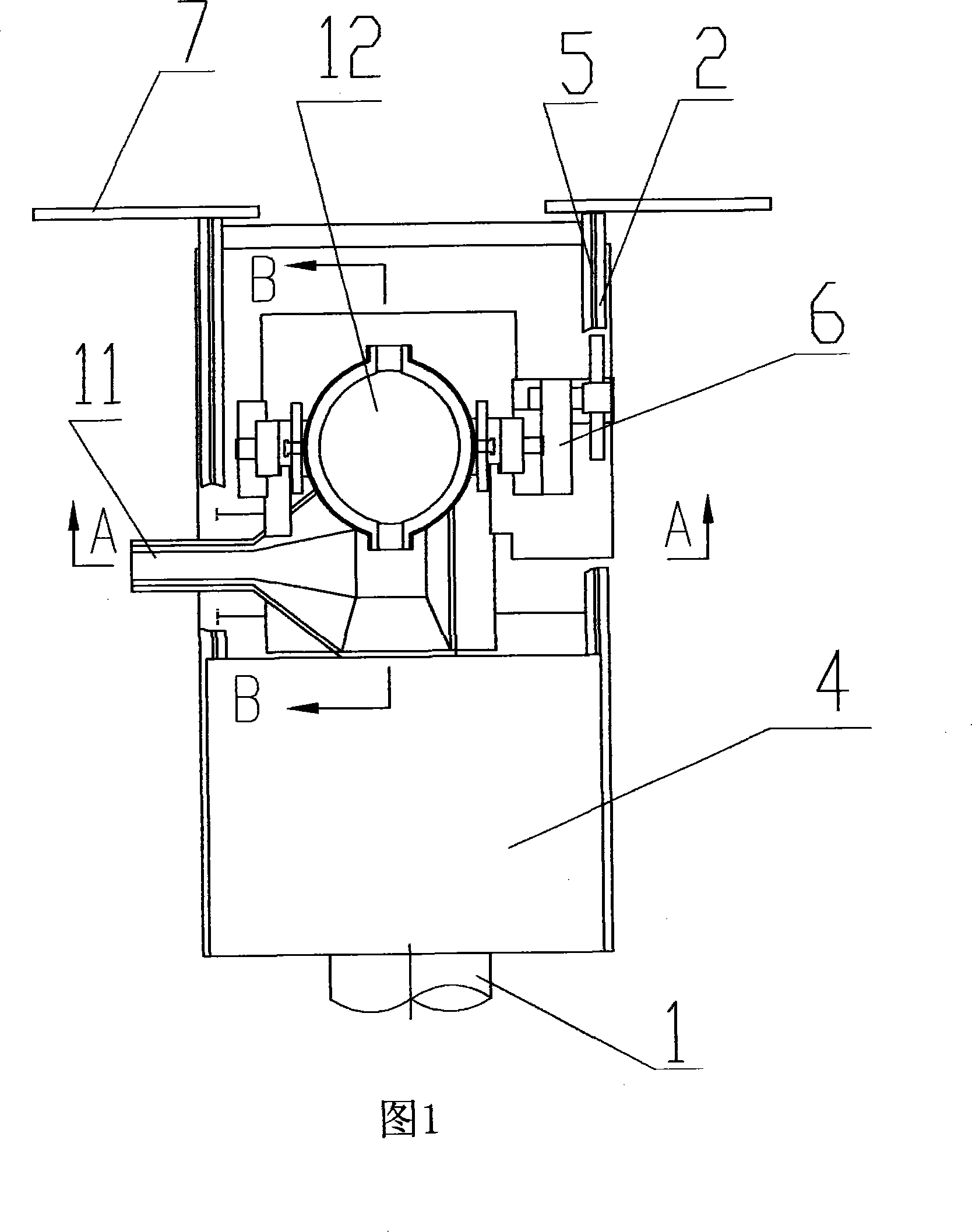

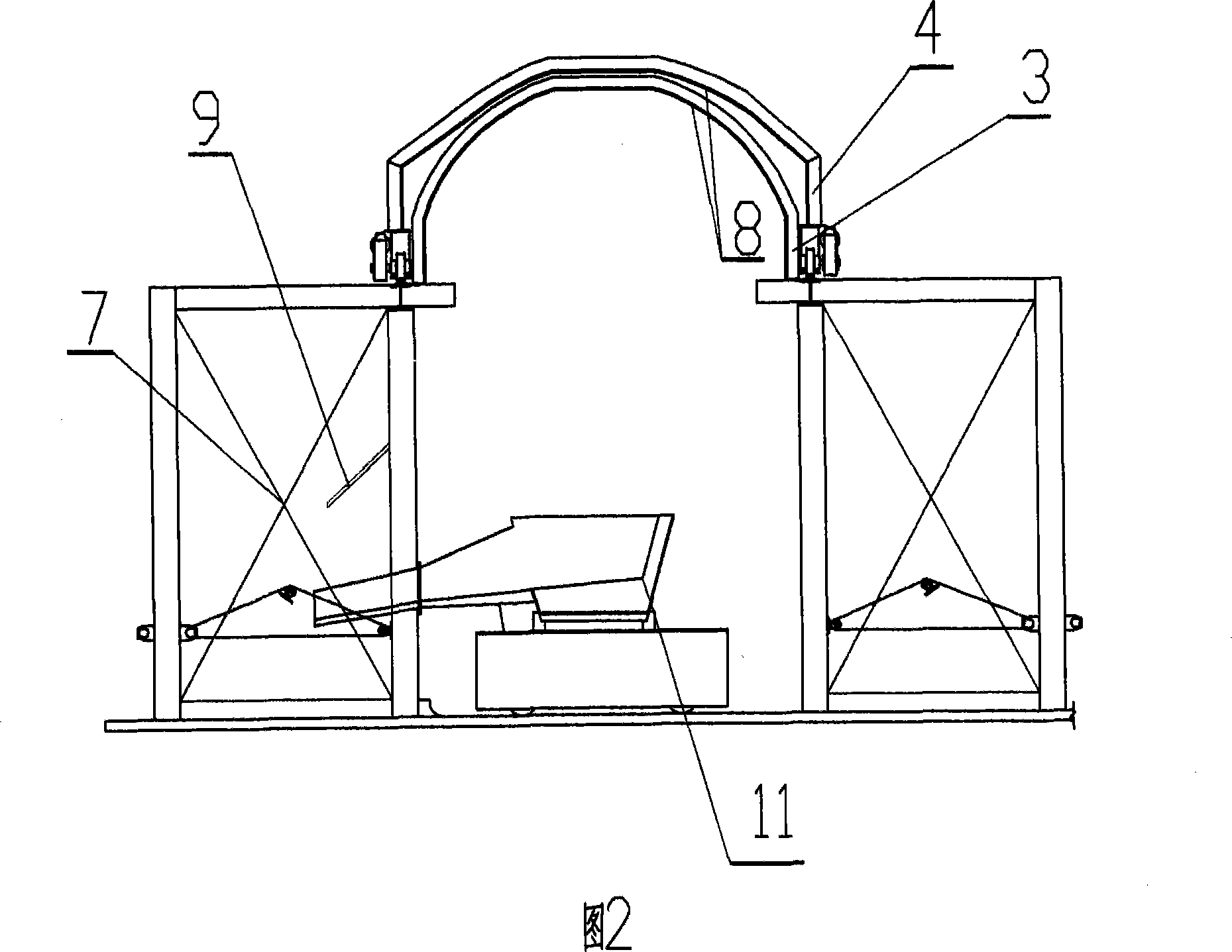

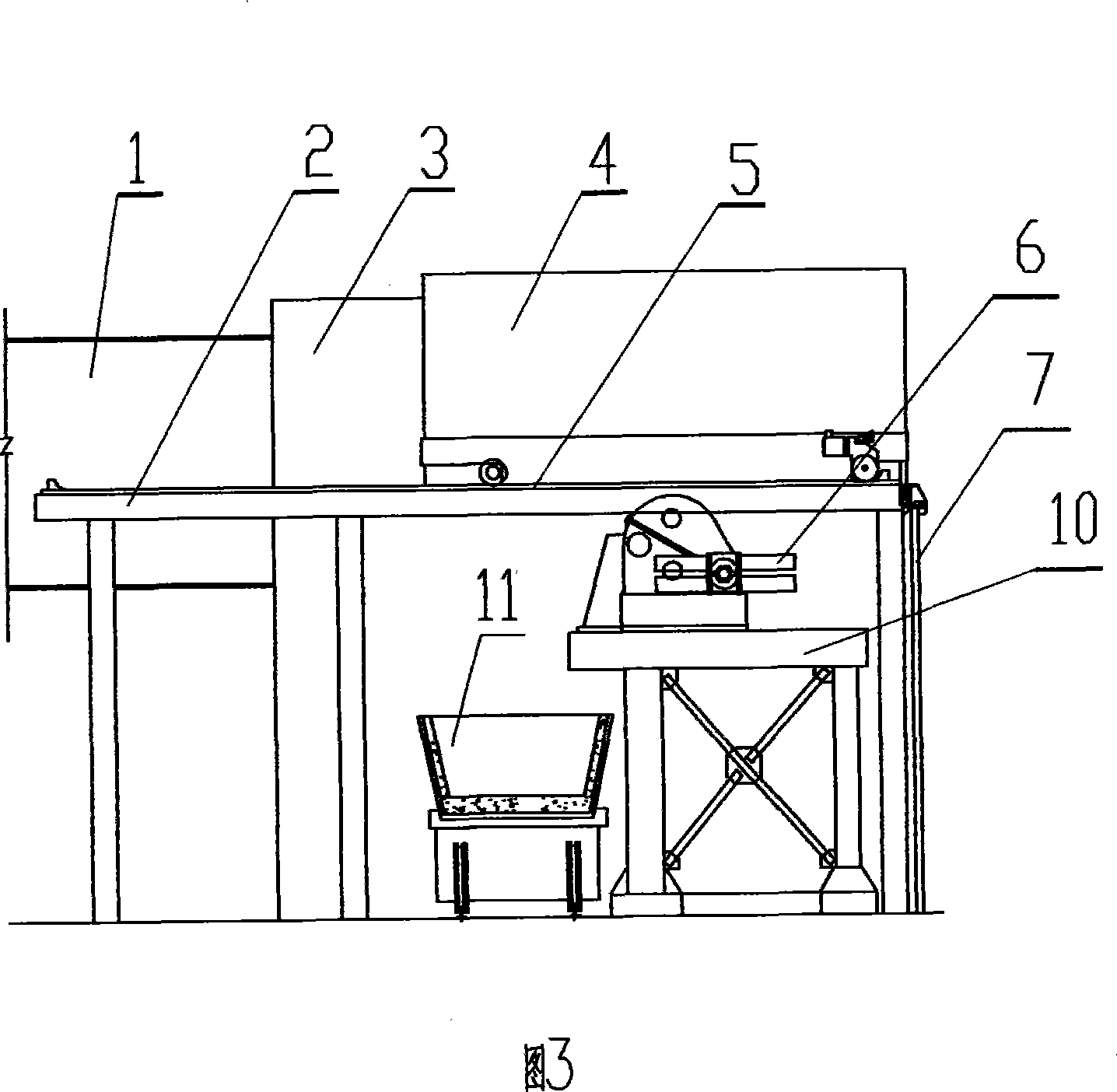

Mobile smoke blast trapping device for furnace mixer

The invention discloses a movable dust arrestment device used for a metal iron mixer, comprising a dedust pipe (1), a support (2), a fixed smoke cover (3) and a movable smoke cover (4). The movable dust arrestment device is characterized in that: the fixed smoke cover (3) and a guide way (5) are arranged on the support (2), and the movable smoke cover (4) can move along the guide way (5), and can be combined with the fixed smoke cover (3) to form a sealed dedust cover; a pig-iron ladle dumping device (6) is arranged on the support (2), and the dedust pipe (1) is arranged on one side of the fixed smoke cover (3). The movable dust arrestment device used for the metal iron mixer has the advantages of convenient usage, ensuring high dust arrestment rate and good dedust effect in the iron receiving process of metal mixer, being energy-saving, reducing running cost, improving the working environment of operating staffs and reducing the operating rate of cranes in workshop.

Owner:HUATIAN ENG & TECH CORP MCC

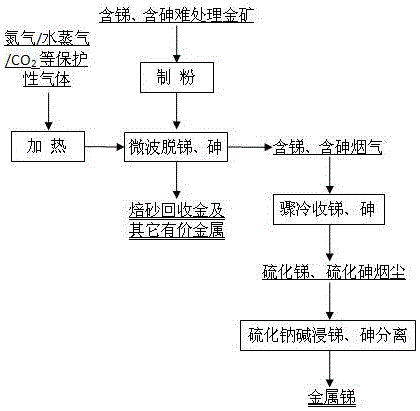

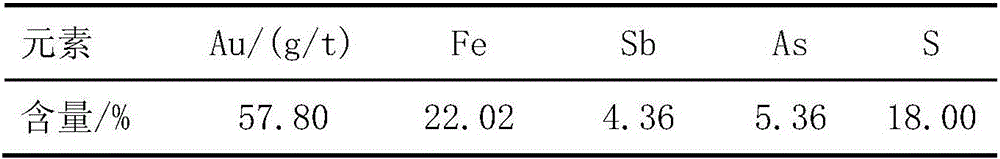

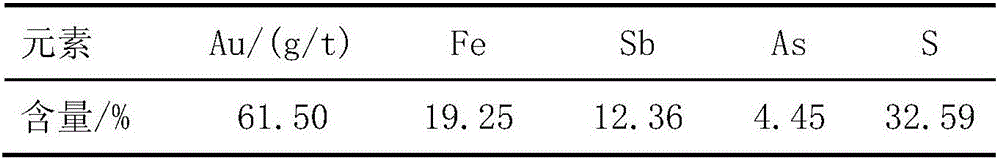

Pretreatment method for refractory gold ore with antimony and arsenic

The invention relates to the technical field of metallurgy, in particular to a pretreatment method for refractory gold ore with antimony and arsenic. The method comprises the steps that 1, the refractory gold ore with antimony and arsenic is broke and subjected to ball milling to form powder; 2, the powder obtained in the step 1 is added into a hermetic vertical pipe type heating furnace, neutral protective gas is introduced in, roasted ore is obtained after roasting and cooling are carried out, produced tail gas enters a tail gas collection device, collected smoke dust is leached through a mixed solution of Na2S with the concentration of 50-200 g / L and NaOH with the concentration of 20-100 g / L, solid-liquid separation is carried out, a filter residue with arsenic and a leaching solution with antimony are obtained, and the leaching solution is electrodeposited to produce metal antimony, wherein leaching time is 30-180 min, and leaching temperature is 20-95 DEG C. The pretreatment method has the advantages that the technological process is simple, operation is flexible, roasting time is short, energy consumption is low, antimony and arsenic can be synchronously removed, smoke gas is low in toxicity and small in amount, and economic and social benefits are good.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

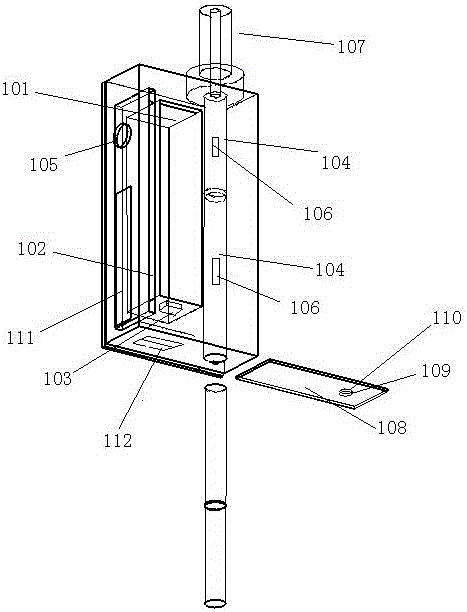

Multifunctional smoking tool

The invention provides a multifunctional smoking tool. An atomizer unit is combined with a smoking tool body, and a user obtains more smoke experiences accordingly; meanwhile, as the atomizer unit is directly connected with straight-cylinder-type heating cavities, tobacco rods are more conveniently filled, a path of smoke is shortened, and the smoke amount is increased; as the multiple heating cavities are formed, subsection control heating can be achieved, even heating and full heating of flue-cured tobacco can be guaranteed, and the quality of smoke of the flue-cured tobacco is improved; as the atomizer unit is matched, the smoking quality of the user is improved; as the atomizer unit is detachably connected with the smoking tool body, maintaining and replacing are convenient, and the service life is prolonged; the portable-power-source function is further added, a 5V direct-current power source is externally output through a USB in a key mode or a wireless-operation-selection mode, the function is more complete, and the user conveniently uses.

Owner:SHENZHEN JINJIA TECH

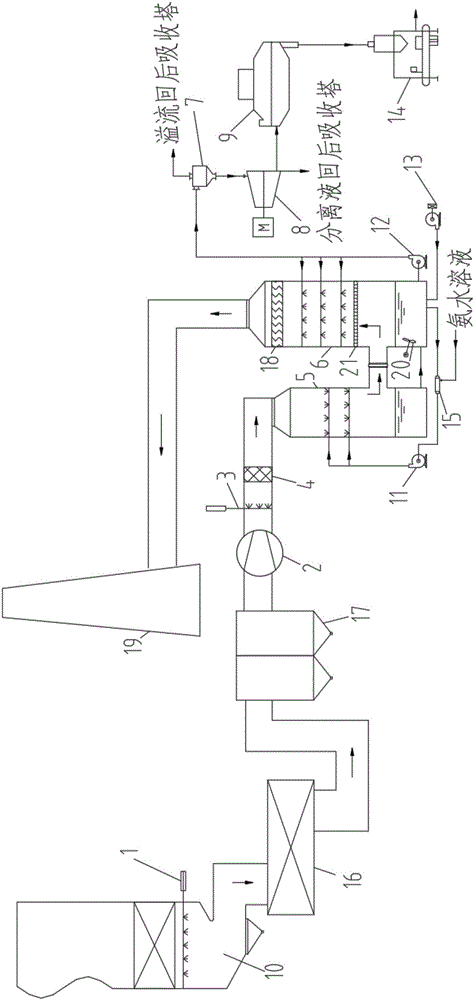

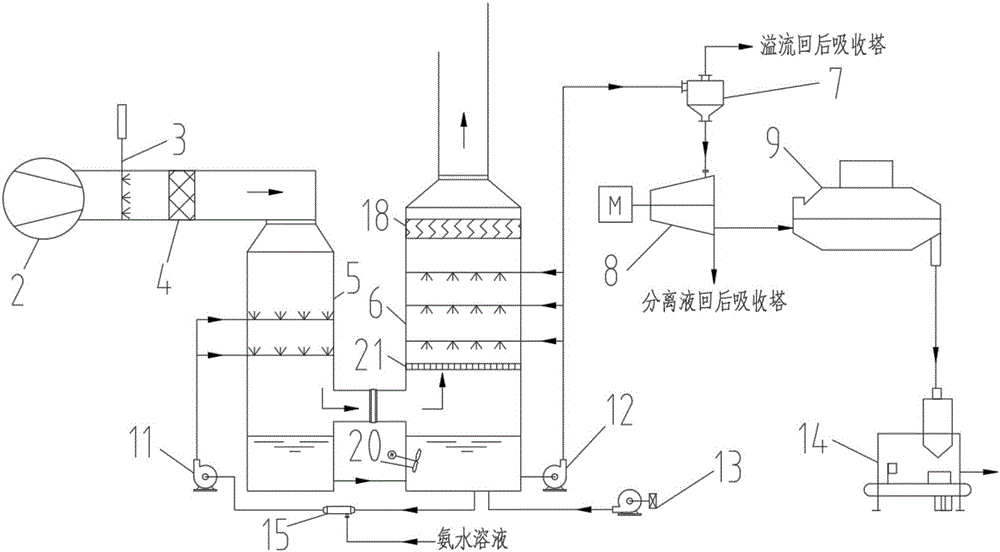

Desulfurization and denitration technology and system by ozone oxidation double-tower ammonia method

ActiveCN106166434AHigh process integrationReduce resistanceDispersed particle separationAir preheaterFlue gas

The invention relates to a desulfurization and denitration system by an ozone oxidation double-tower ammonia method. The desulfurization and denitration system sequentially comprises a hydrogen peroxide spraying device, a draught fan, an ozone spraying device, a flue gas mixing device, a front adsorption tower, a rear adsorption tower, a cyclone separator, a centrifugal separator and a drier, wherein the hydrogen peroxide spraying device is arranged at an outlet of a boiler coal economizer, the outlet of the boiler coal economizer is connected to the draught fan through an air preheater and a dust remover and is connected to the front adsorption tower; the ozone spraying device is mounted in front of an inlet flue of the front adsorption tower; and the flue gas mixing device is arranged between the ozone spraying device and the inlet flue of the front adsorption tower. The desulfurization and denitration system disclosed by the invention has the beneficial effects that the integration degree of a technology is high, the desulfurization and the denitration are integrated, the double-tower structure are stable in properties, the desulfurization efficiency and the denitration efficiency are high, the source of an adsorption tower machine is reliable, the added value of by-products is high, little secondary pollution exists, and the operation cost is low.

Owner:ZHEJIANG TIANDI ENVIRONMENTAL PROTECTION TECH CO LTD

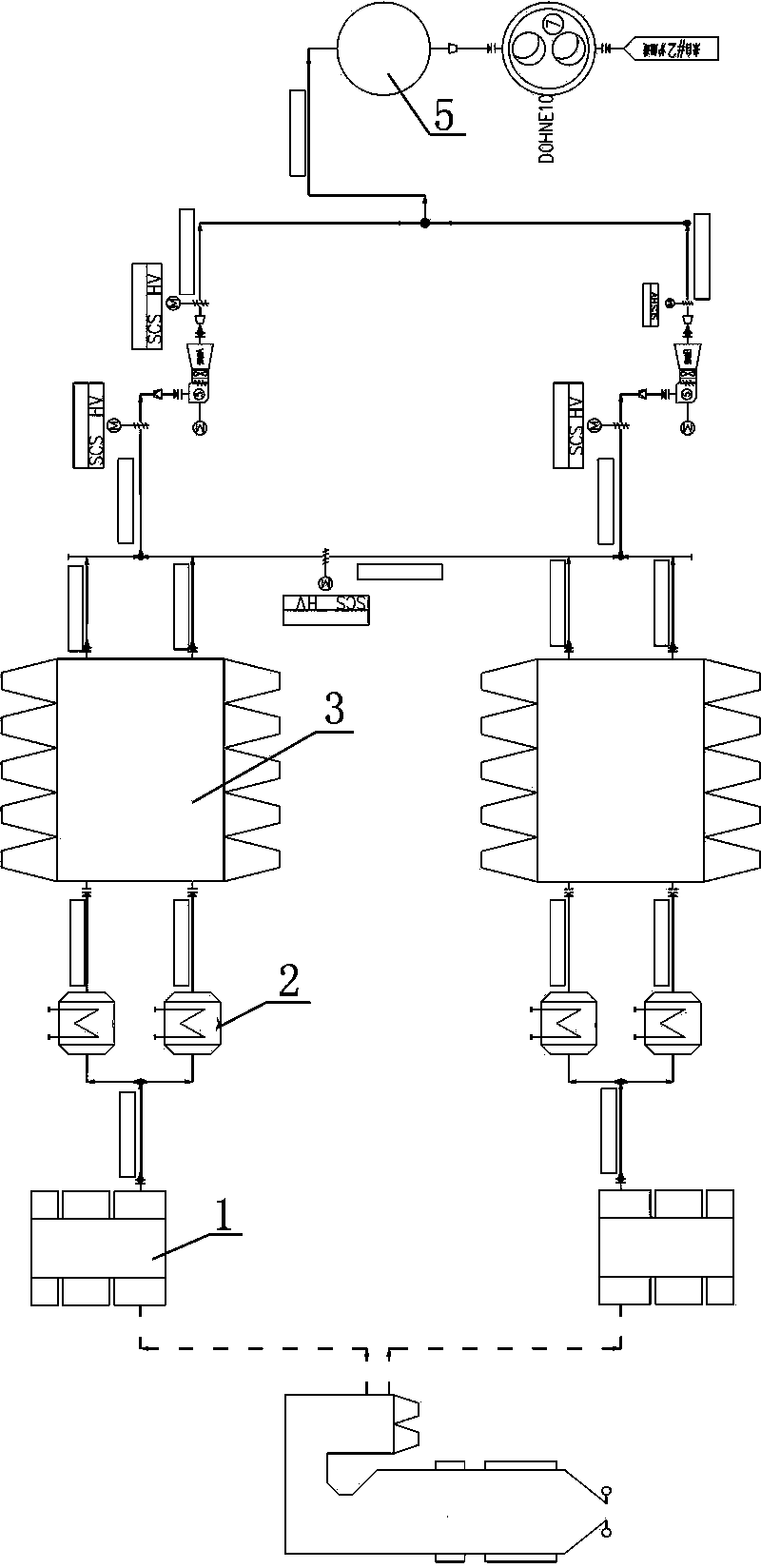

Medical waste incinerator applied with oxygen-enriched combustion technology

ActiveCN104006391AAvoid low temperatureBurn completelyIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberCombustible gas

The invention discloses a medical waste incinerator applied with the oxygen-enriched combustion technology, and belongs to the field of environmental-friendly and energy-saving devices. The medical waste incinerator comprises an incinerator body, a second combustion chamber, a combustion air fan, an oxygen-enriched air supply system and a smoke tail processing system. Combustible components of medical waste are decomposed into combustible gas (smoke) in the incinerator body, and combustible gas enters a second combustion chamber body and flows downwards; the combustion air fan delivers combustion air into the incinerator body and the second combustion chamber body; the oxygen-enriched air supply system is used for generating oxygen-enriched gas and leading the oxygen-enriched gas into the second combustion chamber body; the smoke is contacted with the common combustion air and the oxygen-enriched gas which enters into the second combustion chamber respectively, turbulence and perturbation are formed in a main combustion zone by the smoke, and therefore the fact that waste gas burns out is facilitated. According to the medical waste incinerator applied with the oxygen-enriched combustion technology, the burning temperature of the waste gas of the incinerator is guaranteed to the maximum extent through oxygen-enriched equipment and a secondary air system, the second combustion chamber is facilitated to form turbulent flow, the staying time of the smoke in the second combustion chamber is prolonged, and therefore dioxin is decomposed.

Owner:路宁 +1

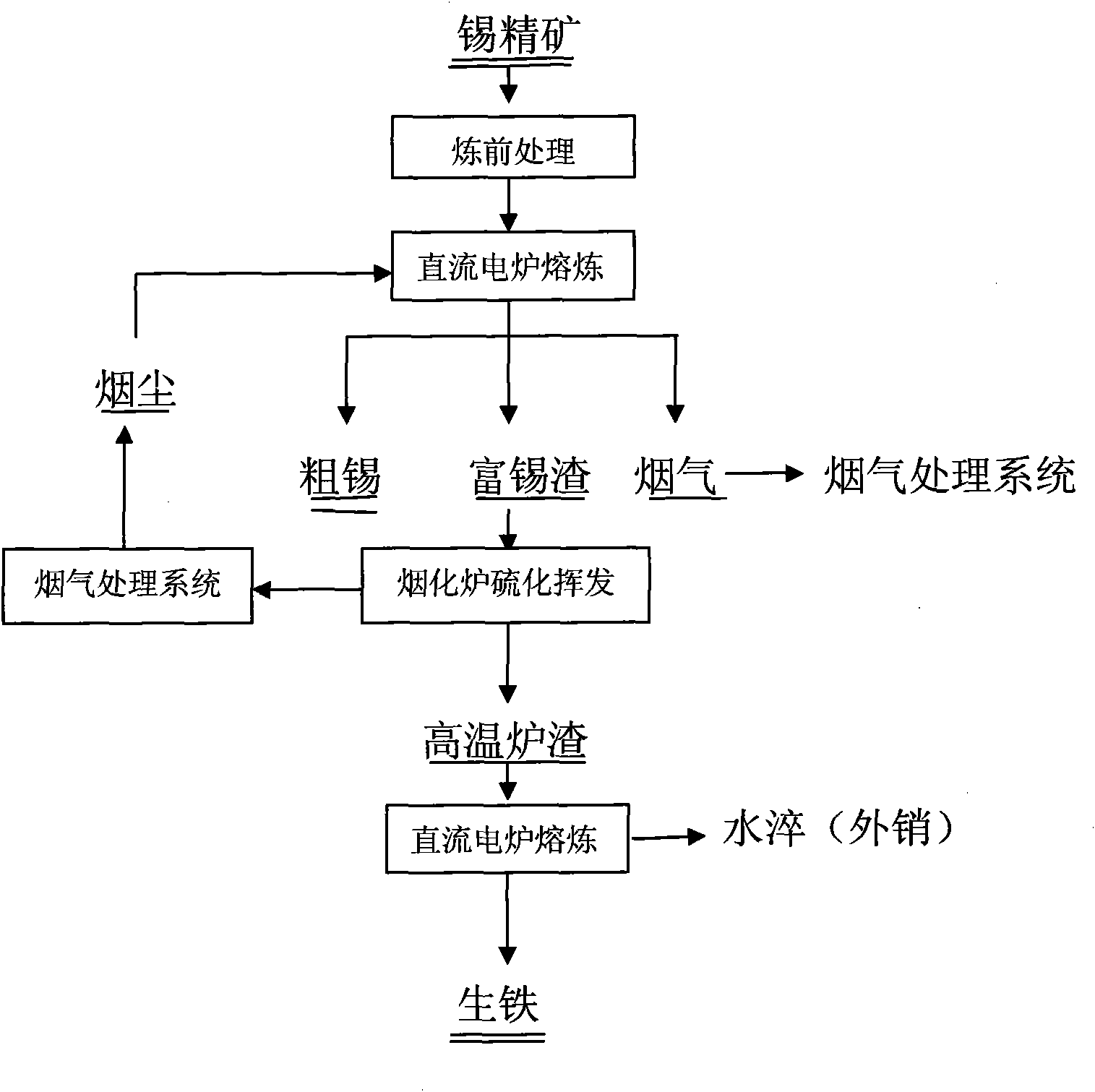

DC electric furnace-fuming furnace combined tin-smelting method

InactiveCN101787445AIncrease production capacityFast meltingProcess efficiency improvementElectric arc furnaceLiquid state

The invention relates to a tin-smelting process, in particular to a method for tin smelting by combining a DC electric furnace and a fuming furnace and for comprehensively recycling iron. The steps of the invention are as follows: reducing agent is added according to the components of tin concentrate, and then, the mixture is put in the DC electric furnace for reduction and smelting to generate metallic tin; and vulcanizing agent and slagging flux are added to liquid slag according to components of the liquid slag, and then, the mixture is put in the fuming furnace to be vulcanized to volatilize the tin in the slag; meanwhile, the mixture is recycled in the form of tin oxide fume; the fumed slag is put in the DC electric furnace in the liquid state, and then, the reducing agent and the flux are added to the fumed slag to be smelted to generate pig iron; meanwhile, the residual sulphur contained in the slag is utilized to continually volatilize the residual tin, and the water-quenched slag can be used as the raw material for building. The method is suitable for processing various tin-containing materials; compared with the traditional tin-smelting method, the tin-smelting method provided by the invention has the advantages of less investment and high tin recovery rate and can comprehensively recycle iron and other valuable metals.

Owner:YUNNAN TIN GROUP HLDG

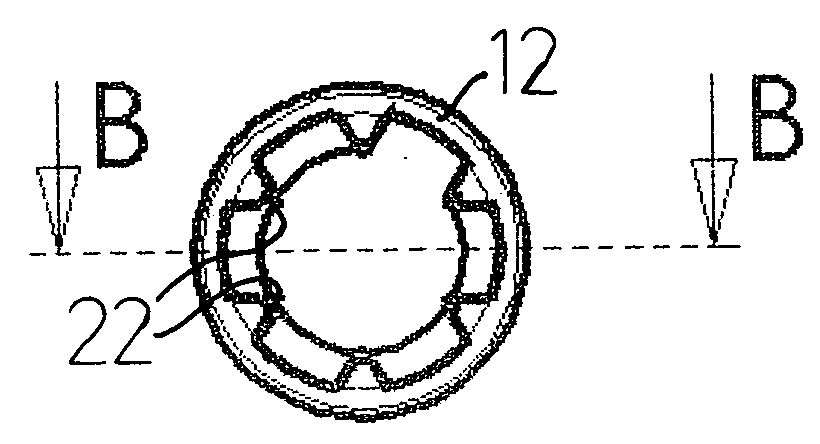

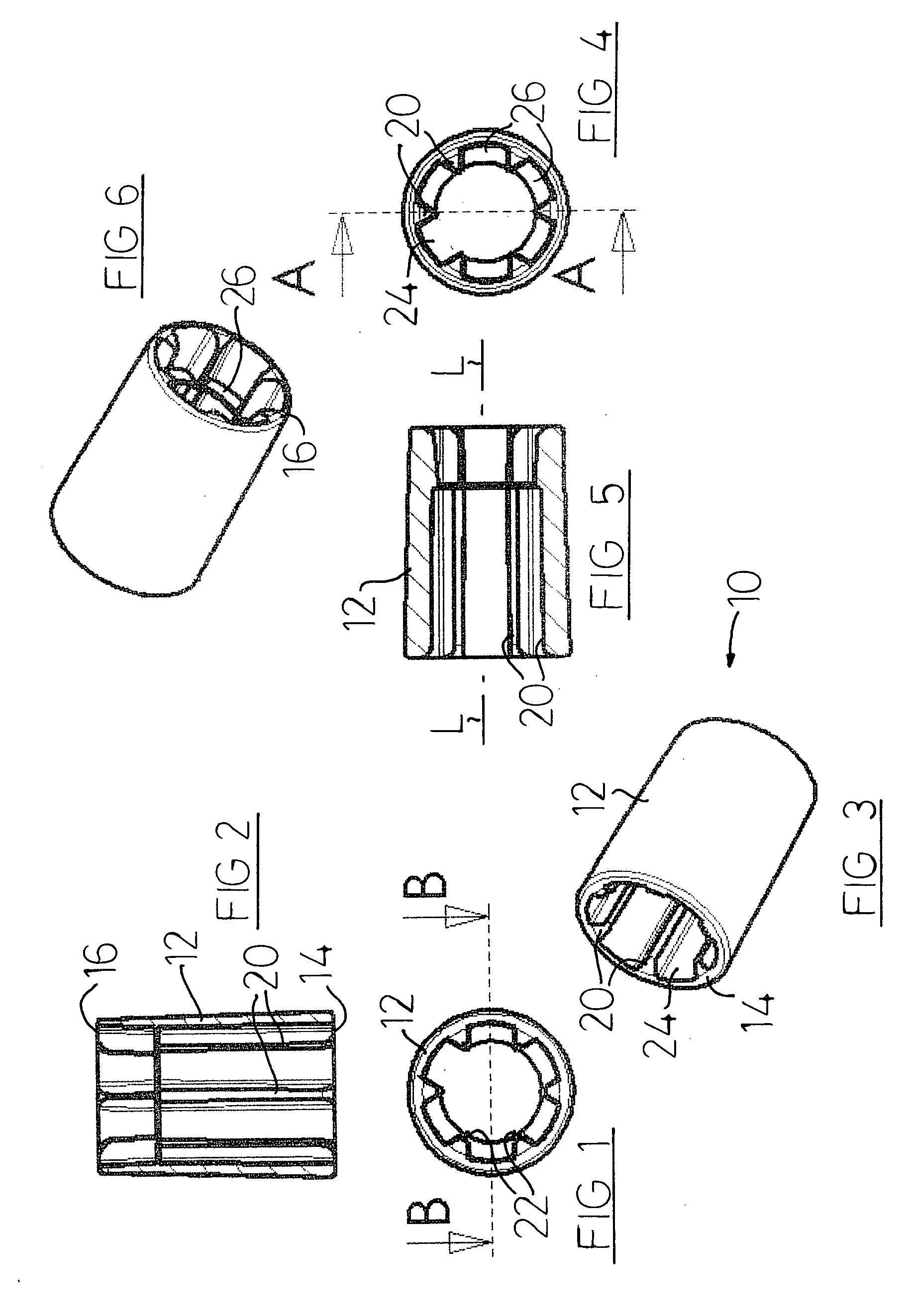

Anti-smoking device

InactiveUS20090320864A1Reduce the amount of smokeLess smokeTobacco pipesTobacco devicesEngineeringInternal dimension

This invention relates to a device which functions as a cigarette holder and can reduce the intake of cigarette smoke into the lungs of a user. The holder is substantially tubular and has a first end (14) for mounting a cigarette, the first end having an annular wall (12) with an internal dimension larger than the diameter of the cigarette, the annular wall carrying a plurality of inwardly-directed longitudinal ribs (20) adapted to engage and support the cigarette. Between the ribs are passageways which can allow the flow of air along the outside of the cigarette into the mouth of the user, so that the volume of smoke breathed in by the user can be reduced.

Owner:ROWLEY THOMAS J

Front semidry desulphurization system and desulphurization technology

InactiveCN102716658AReduce corrosionImprove dust removal conditionsDispersed particle separationFlue gasTower

The invention discloses a front semidry desulphurization system which comprises a desulphurization system, a dust removing system and an exhaust system, wherein the desulphurization system is arranged at the front end of the dust removing system, and comprises a desulfurizing tower, a cyclone separator and a recycling material box; the inlet end of the desulfurizing tower is connected with a flue which is not dedusted; the outlet end of the desulfurizing tower is connected with the inlet end of the cyclone separator; a first outlet end of the cyclone separator is connected with the dust removing system which is then connected with the exhaust system; a second outlet end of the cyclone separator is connected with the inlet end of the recycling material box; the outlet end of the recycling material box is communicated with the desulfurizing tower; and the desulfurizing tower is provided with a jet apparatus used for spraying a desulfurizing agent into the desulfurizing tower. The desulfurizing tower is connected with the flue which is not dedusted, and flue gas is firstly desulfurized and then dedusted, so that the dust removal condition of the dust removing system can be improved; a stage of dust removing system is only needed to be arranged in the whole system, so that one-time construction cost is lowered; and the running cost of the semidry desulphurization system is greatly reduced.

Owner:无锡高达环境科技有限公司

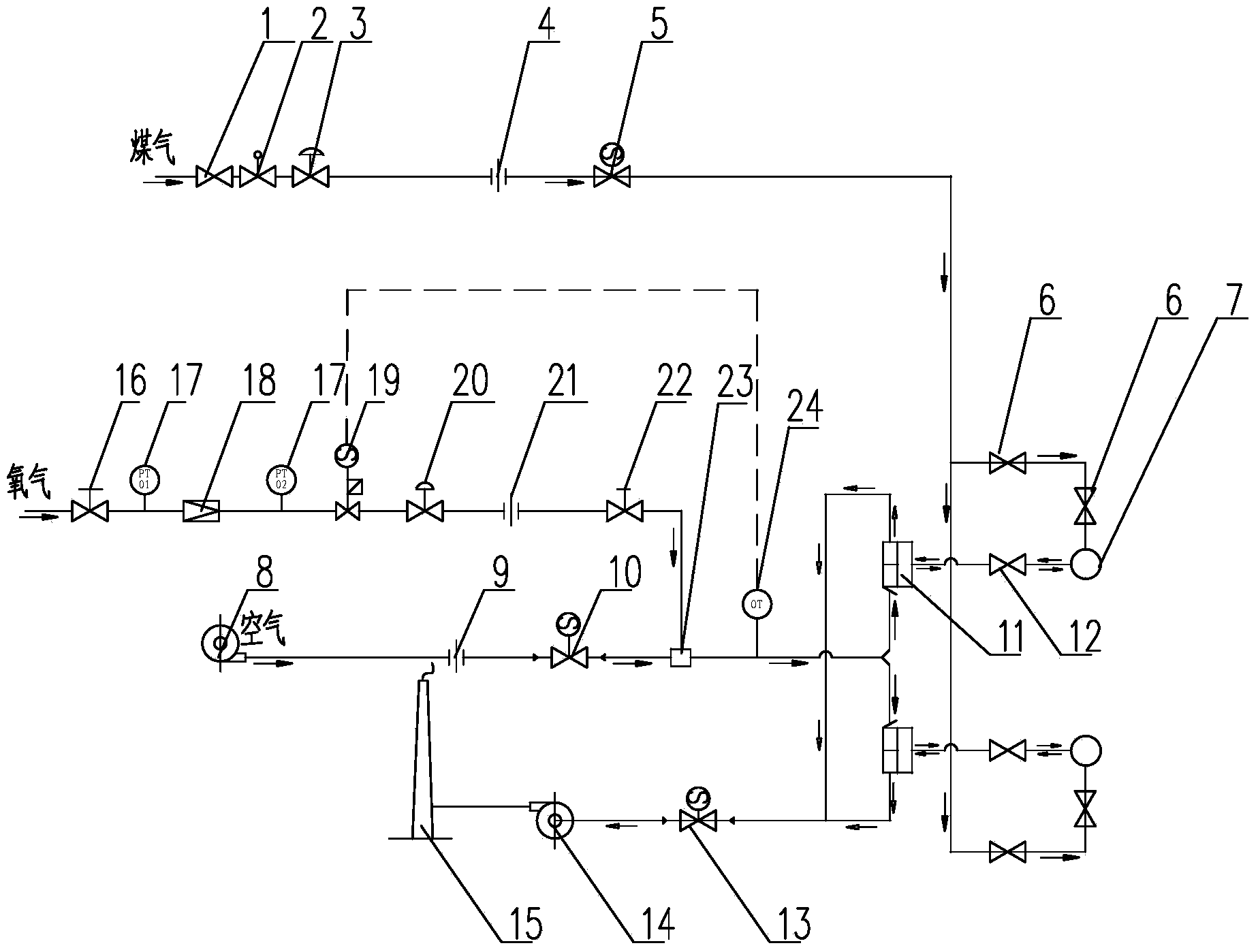

Cold crude gas heat accumulating type oxygen-enriched combustion method and cold crude gas heat accumulating type oxygen-enriched combustion system

InactiveCN103953920AReduce generationPromote environmental protectionDirect carbon-dioxide mitigationIndirect carbon-dioxide mitigationCombustion systemOxygen system

The invention relates to a cold crude gas heat accumulating type oxygen-enriched combustion method and a cold crude gas heat accumulating type oxygen-enriched combustion system. The combustion method comprises the steps of transmitting cold crude gas, generating and transmitting mixed oxygen-enriched air, reversing the oxygen-enriched air by an air-smoke reversing valve, heating the reversed oxygen-enriched air in a heat accumulating type burner, mixing the oxygen-enriched air with gas for burning, discharging smoke, and the like; the combustion system comprises a gas system, an air-smoke system and an oxygen system, wherein the tail end of a pipeline of the oxygen system is connected with a dynamic mixer of the air-smoke system; the tail end of a branch behind the air-smoke reversing valve in the air-smoke system is connected with the heat accumulating type burner of the gas system. Compared with the prior art, the method and the system have the beneficial effects that (1) the burning velocity is increased, the tempering is avoided, and the combustion safety is improved; (2) the ignition temperature of fuel and the burn out time are reduced; (3) the excess air coefficient is reduced, and the amount of the smoke after combustion can be reduced; (4) the production of CO2 and NOX can be effectively reduced, so that the environmental protection can be better realized; (5) the system is simple in structure, convenient to operate and high in degree of automation.

Owner:辽宁向导科技发展有限公司

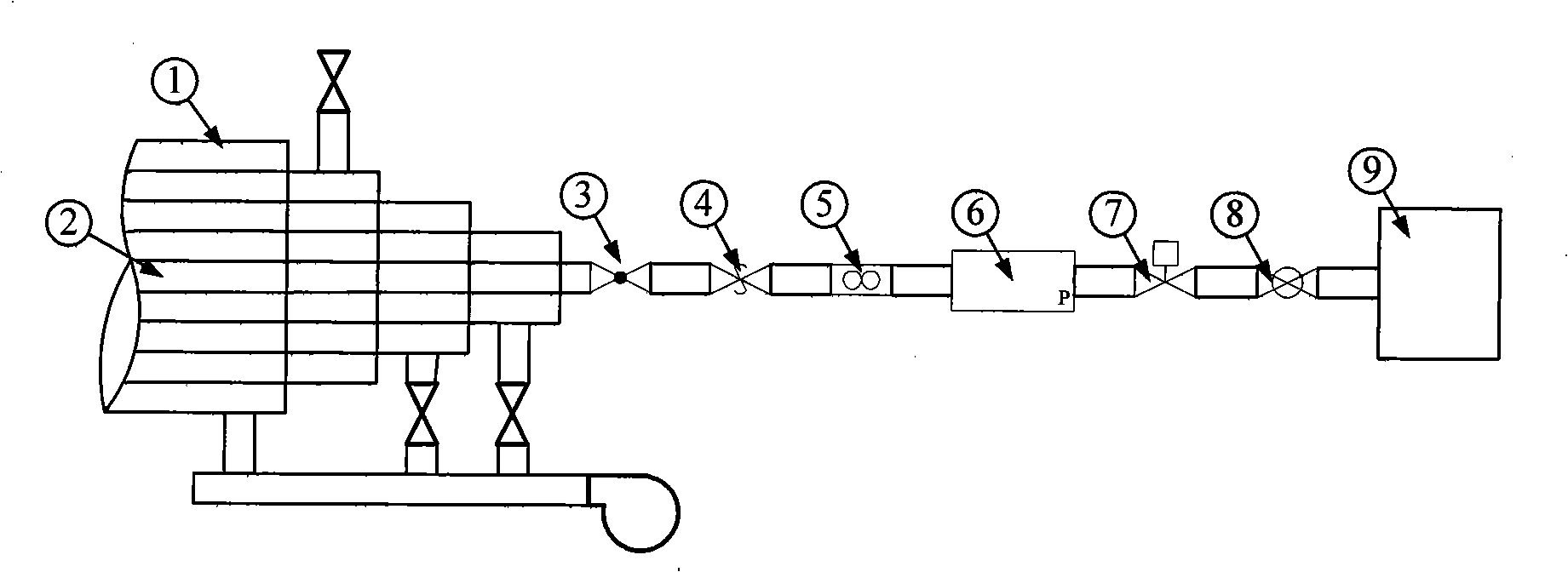

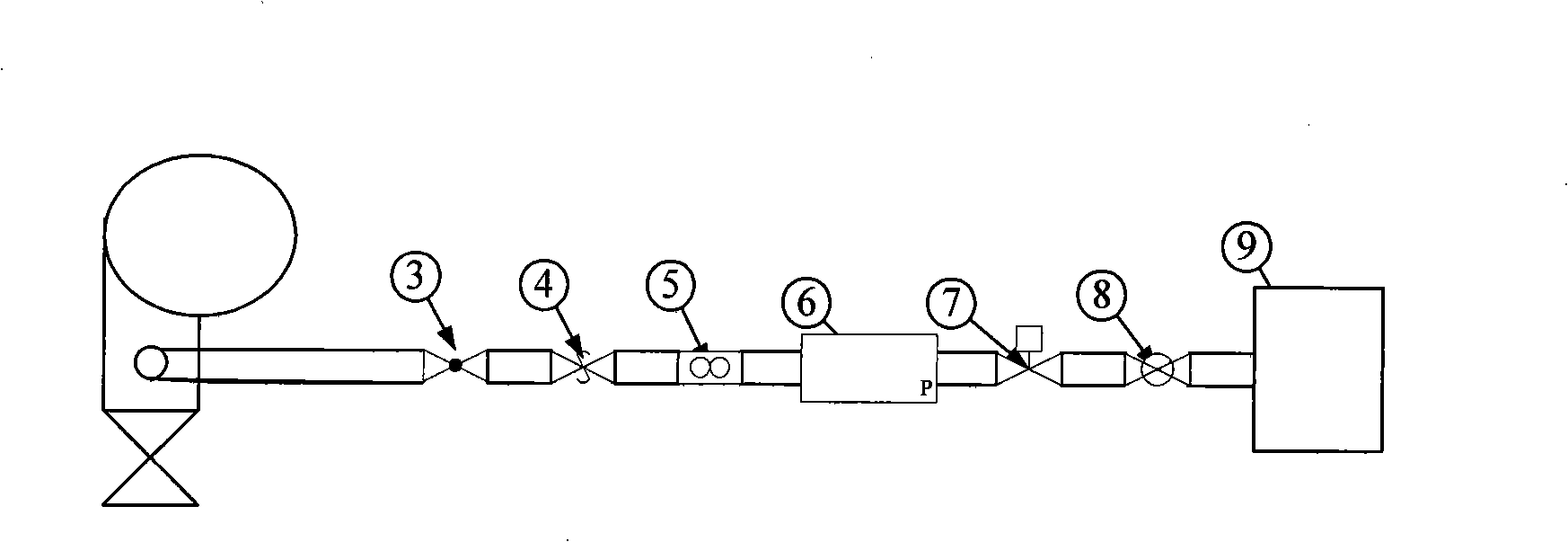

Oxygen-enriched combustion process for improving cement kiln clinker calcining temperature and apparatus thereof

InactiveCN101407381AQuality assuranceRaise the ignition temperatureTemperature resistanceCement kiln

The invention relates to an oxygen-enriched combustion technical method for improving heating power of a cement kiln and a device thereof. During the process of cement clinker calcination, the invention is characterized in that: 1) a pure oxygen (over 90 percent) feeding device is added at a coal dust combustion zone of the cement kiln so as to lead the combustion zone to form a local thermonuclear area, and with the gradual diffusion of high temperature at the thermonuclear area, the heating power of the whole cement kiln is further improved and stably controlled; and 2) an oxygen feeding device is added at a combustion area of the cement kiln so as to improve and stably control the oxygen content in combustion air within the range of 21.8-33 percent at the combustion area. In a coal supplying system and an air supplying system of the cement kiln, an oxygen-enriched combustion system is formed by arranging at least one high temperature resistance oxygen jet, a pipeline for transmitting oxygen, an oxygen generation device, an oxygen supply-quantity regulating device, a DCS control device and the like inside each independent combustion area of the cement kiln. The invention has the advantages of improving combustion efficiency of faulty coal and the heating power of the cement kiln, and stabilizing thermal regulation of the kiln so as to enhance the quality of the cement and prolong the service life of various heating equipment of the cement kiln.

Owner:昆明阳光基业股份有限公司

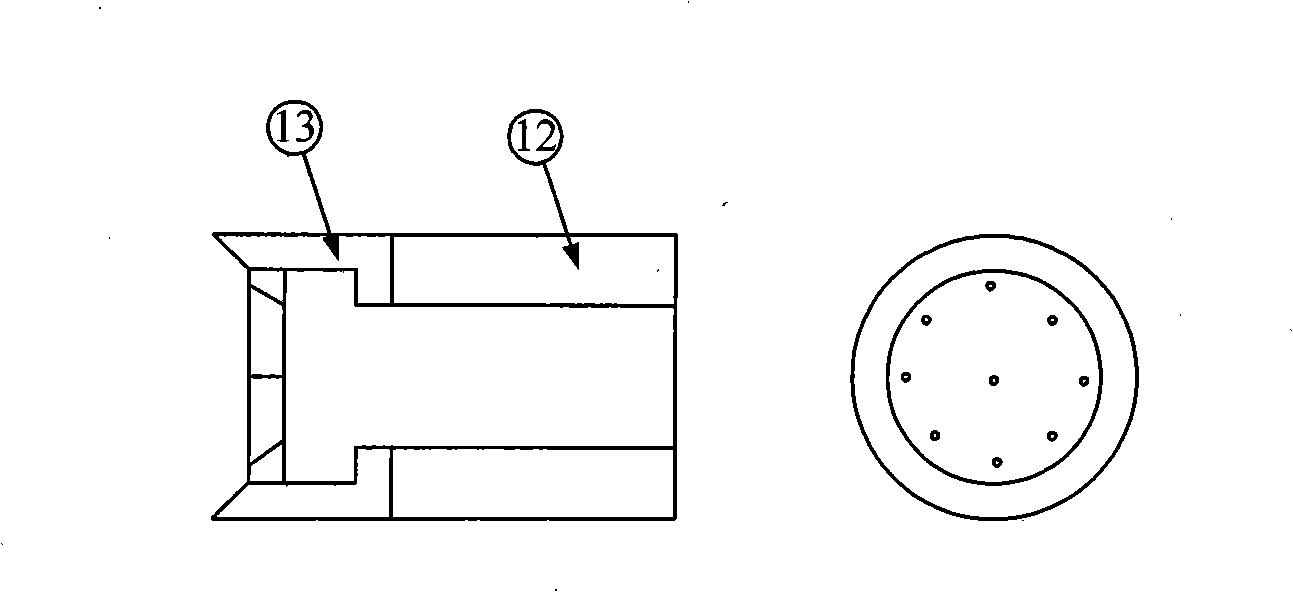

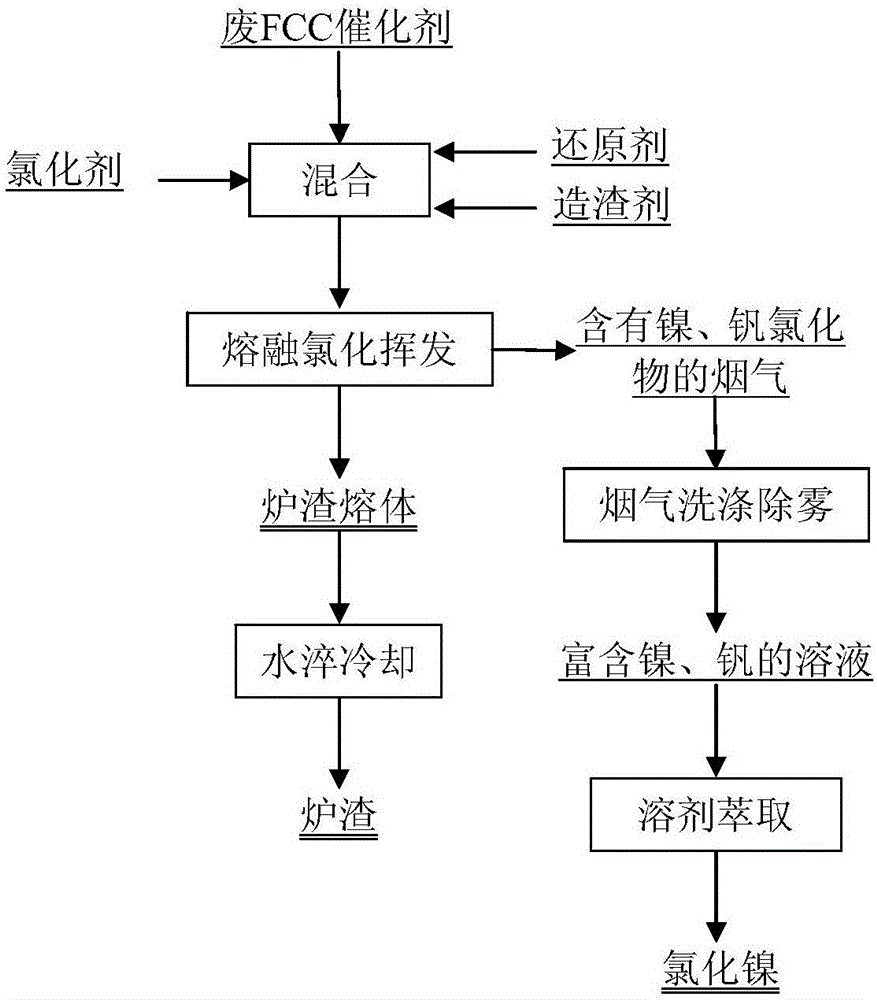

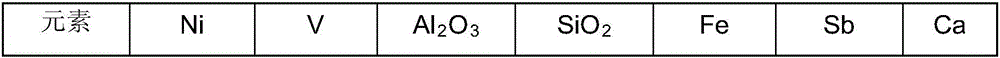

Method for recovering nickel and vanadium from waste FCC (Fluid Catalytic Cracking) catalyst through molten chlorination volatilizing

The invention discloses a method for recovering nickel and vanadium from a waste FCC (Fluid Catalytic Cracking) catalyst through molten chlorination volatilizing. The method comprises the following steps: adding a chlorinating agent, a reducing agent and a slag forming constituent to the waste FCC catalyst, and uniformly mixing to obtain a mixture to be molten; performing molten chlorination on the mixture to be molten through a melting furnace for 30 to 300 minutes at the temperature of 1250 to 1700 DEG C so as to obtain smoke containing nickel and vanadium chloride; charging the smoke containing the nickel and vanadium chloride into a smoke washing system to wash and defog the smoke so as to obtain a solution rich in nickel and vanadium; and then separating nickel and vanadium from the solution rich in nickel and vanadium by a solvent extraction method so as to obtain vanadium pentoxide and nickel chloride. With the adoption of the method, the recovery rate of nickel and vanadium can be greatly increased; in addition, the method is simple in technology, short in process, flexible to operate, high in recycling rate, and high in geographical adaptability; the produced wastewater, waste gas and slag are nontoxic and harmless, so that the environment is influenced a little.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com