Pretreatment method for refractory gold ore with antimony and arsenic

A refractory gold ore pretreatment technology, applied in the field of metallurgy, can solve problems such as hidden safety hazards, difficult wastewater treatment, and difficult treatment, and achieve good economic and social benefits, small flue gas treatment system, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

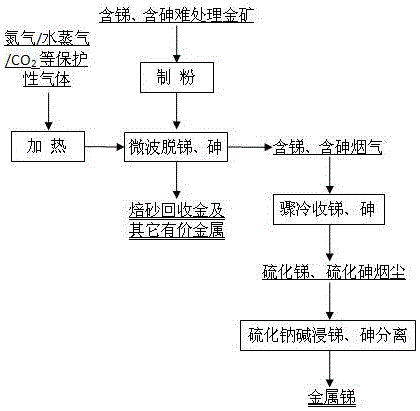

Method used

Image

Examples

Embodiment 1

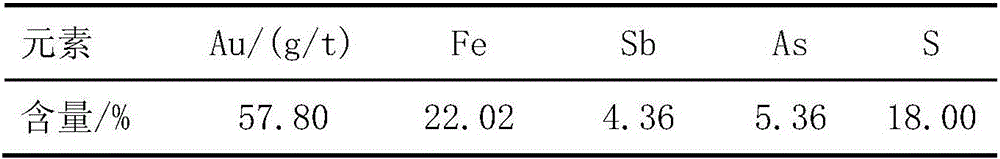

[0049] What this example chooses is a gold concentrate containing antimony and arsenic in Gansu Province. The material composition is shown in Table 1. The specific implementation steps are as follows:

[0050] Table 1 Element composition list of an antimony-containing and arsenic-containing gold concentrate in Gansu (%)

[0051]

[0052] Take 300g of arsenic-containing antimony-gold concentrate powder in Gansu Province, the particle size-0.075μm accounts for 70%, put it into a corundum crucible, put the crucible containing the material into the quartz riser of a closed riser-type microwave heating furnace, and cover the riser tightly. End cover, connect the air inlet and outlet pipelines, pass in protective gas nitrogen, microwave roasting temperature is about 1000°C, roasting time is 0.5 hours, after reaching the temperature, nitrogen protection is cooled to below 100°C, and the calcination yield is 75%. The contents of Sb, As and S in calcine were detected to be 0.055%, ...

Embodiment 2

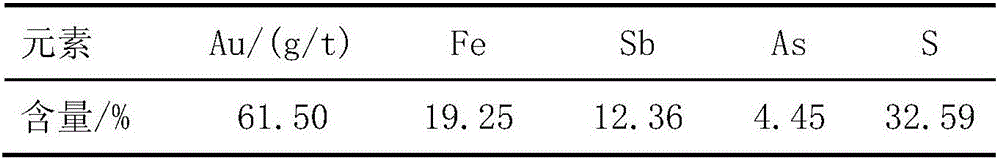

[0054] This example selects a high-antimony gold concentrate in Xiangxi, Hunan. The material composition is shown in Table 2. The specific implementation steps are as follows:

[0055] Table 2 Element composition list of a high-antimony gold concentrate in Xiangxi, Hunan (%)

[0056]

[0057] Take 300g of a high-antimony gold concentrate powder in Xiangxi, Hunan, the particle size-0.075μm accounts for 80%, put it into a corundum crucible, put the crucible into the material tube of a closed tubular resistance heating furnace, and cover the end cap tightly. Connect the air inlet and outlet pipelines, feed in protective gas water vapor, roast at a temperature of about 1150°C, and roast for 80 minutes. After reaching the temperature, nitrogen protection is used to cool down to room temperature, and the calcined sand is weighed. The calcined sand yield is 70%. Take the calcined sand The contents of Sb, As and S were detected to be 0.076%, 0.025% and 25.50% respectively, and the ...

Embodiment 3

[0059] This example selects a refractory gold mine containing antimony and arsenic in Xinjiang. The material composition is shown in Table 3. The specific implementation steps are as follows:

[0060] Table 3 Element composition list of a refractory gold mine containing antimony and arsenic in Xinjiang (%)

[0061]

[0062] Take 400g of refractory gold ore powder containing antimony and arsenic in Xinjiang, the particle size-0.075μm accounts for 82%, put it into a corundum crucible, put the crucible containing the material into the quartz riser of a closed vertical tube microwave heating furnace, and cover it tightly. Seal the end cover of the standpipe, connect the air inlet and outlet pipes, and pass in the protective gas carbon dioxide. The microwave roasting temperature is about 870°C, and roast for 0.5 hours. After reaching the temperature, pass carbon dioxide to protect and cool to room temperature. The yield was 78%. Sb, As, and S were detected by calcined sand, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com