Patents

Literature

70results about How to "High process integration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

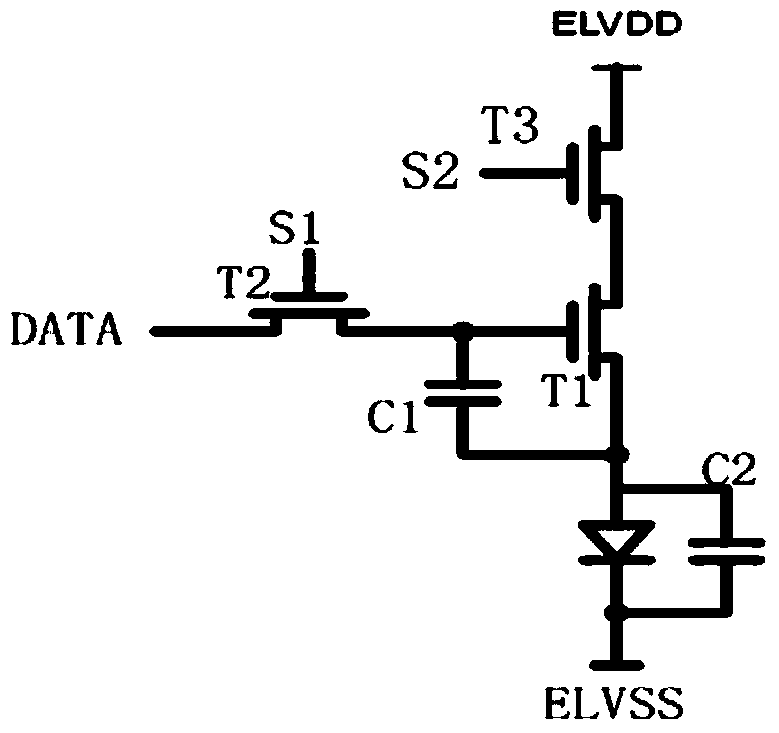

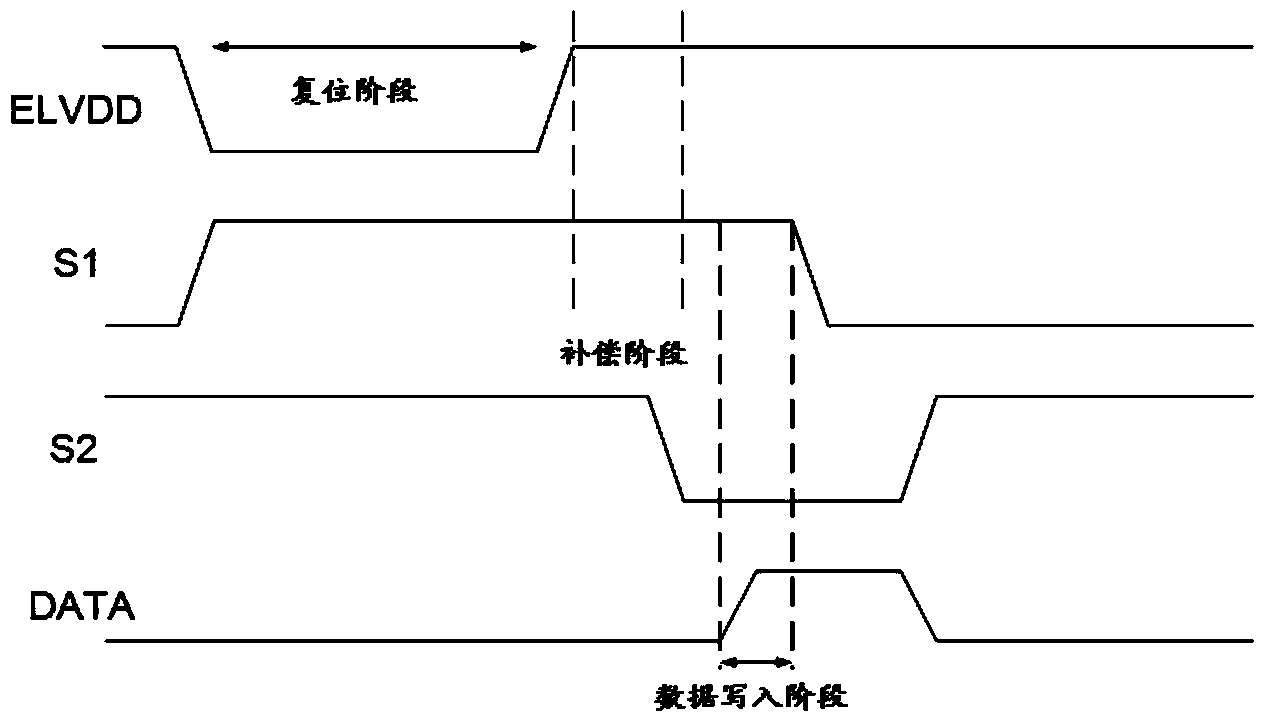

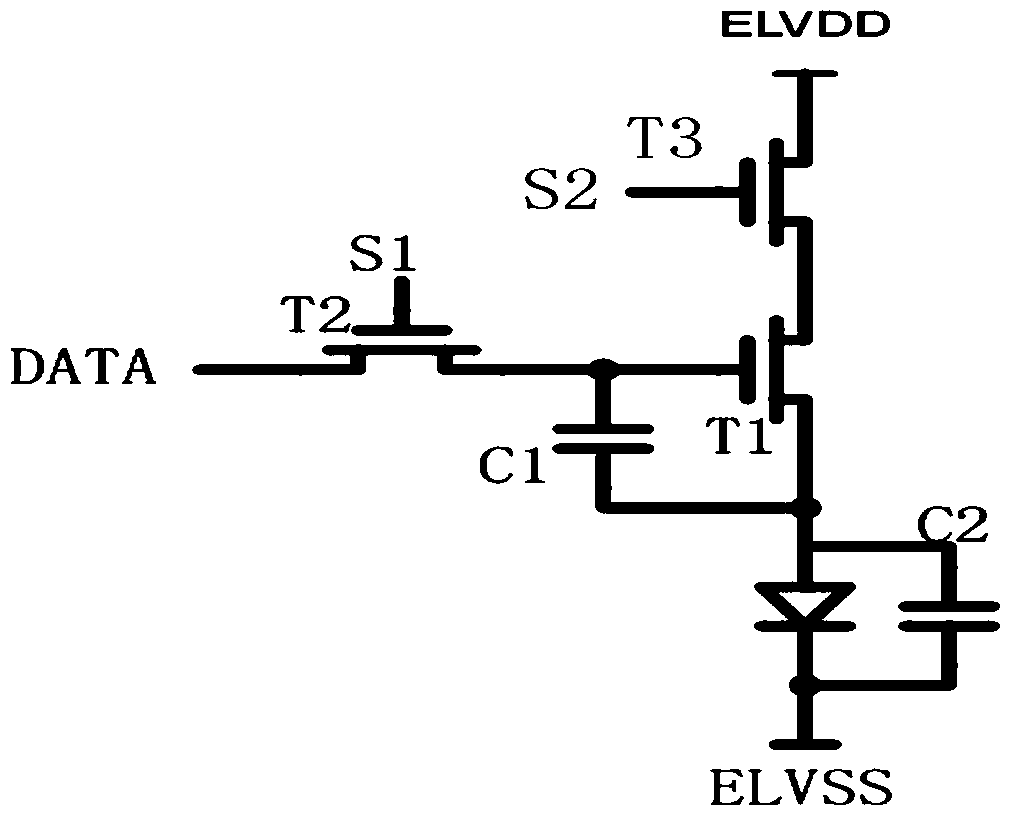

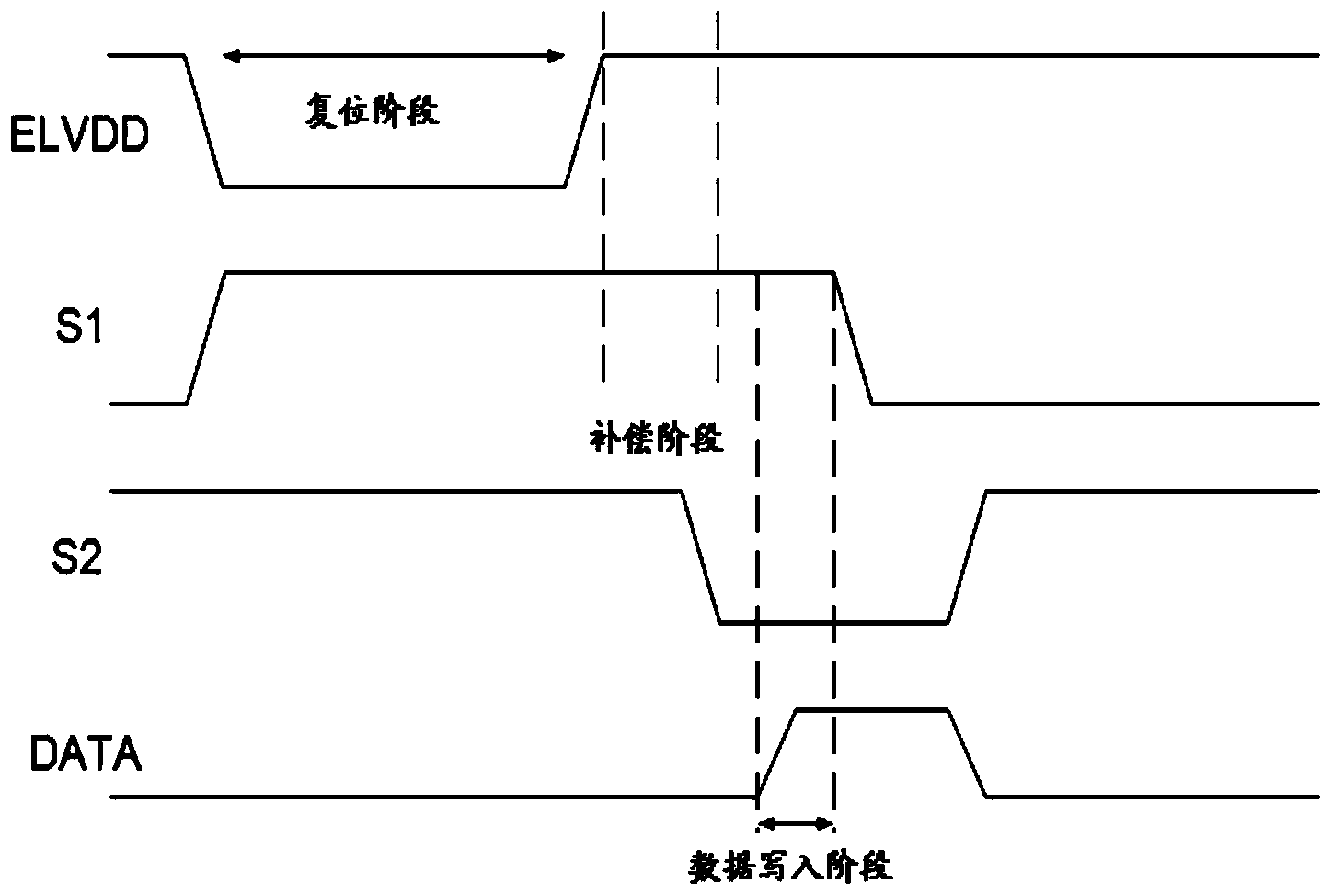

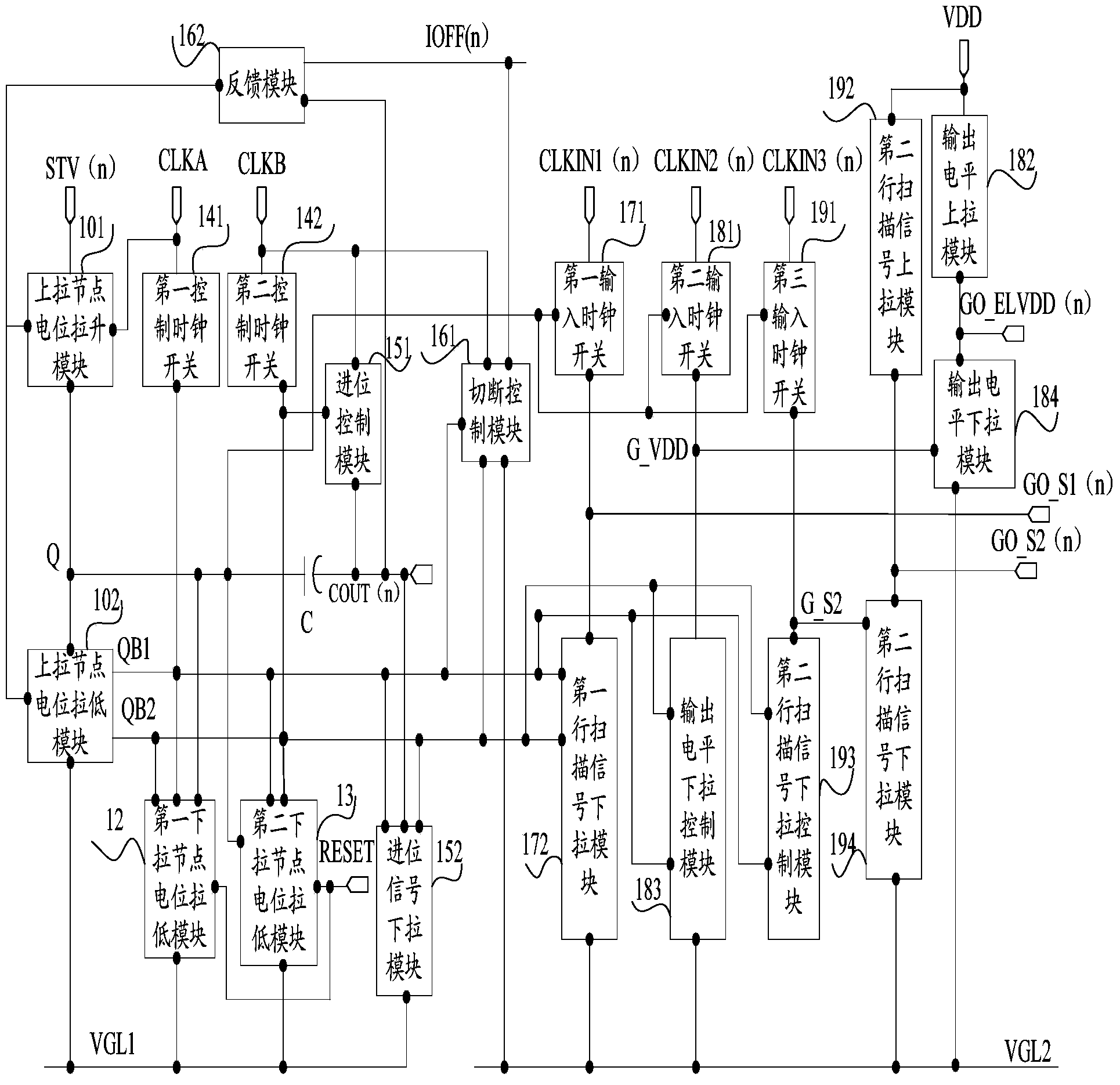

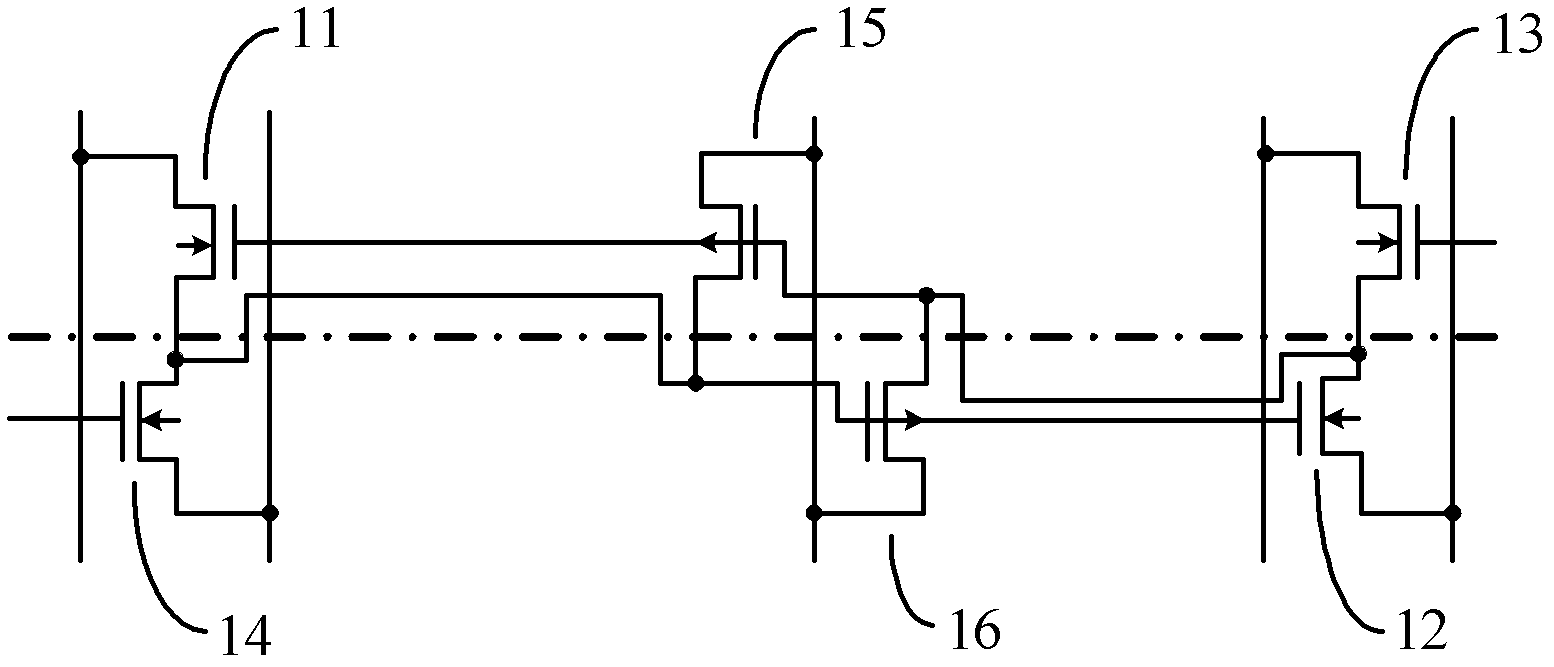

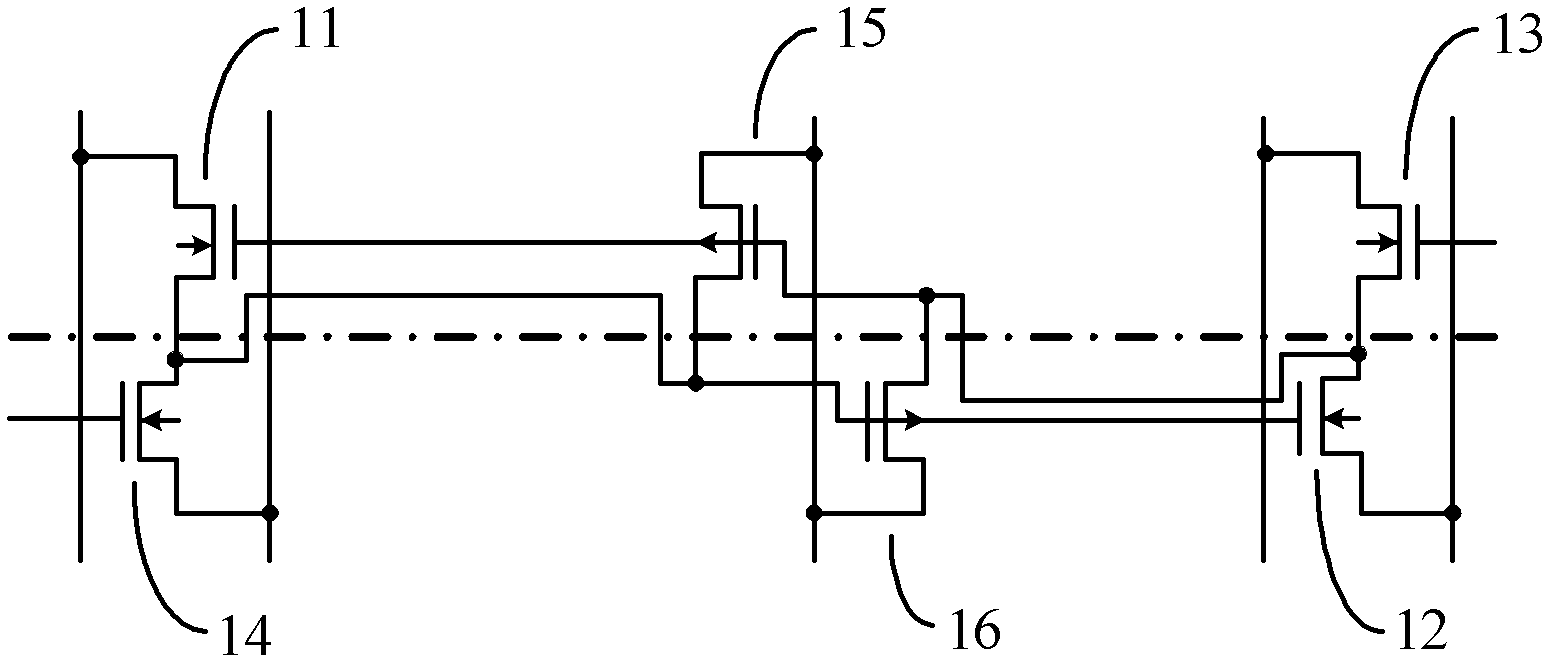

Grid driving circuit and method, array substrate line driving circuit and display device

ActiveCN103730089AHigh process integrationLow costStatic indicating devicesDriver circuitDisplay device

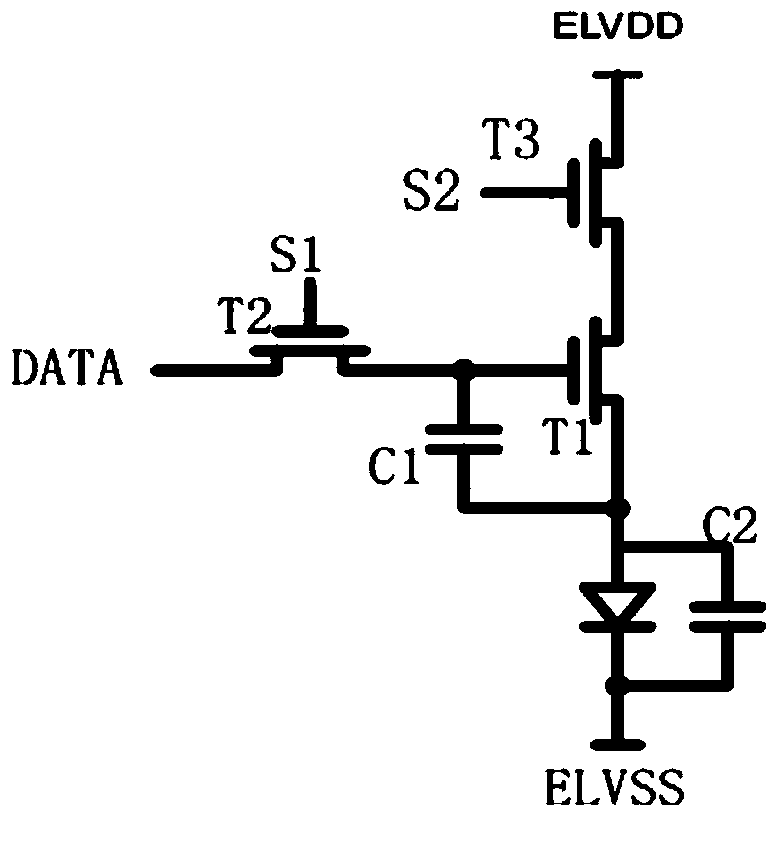

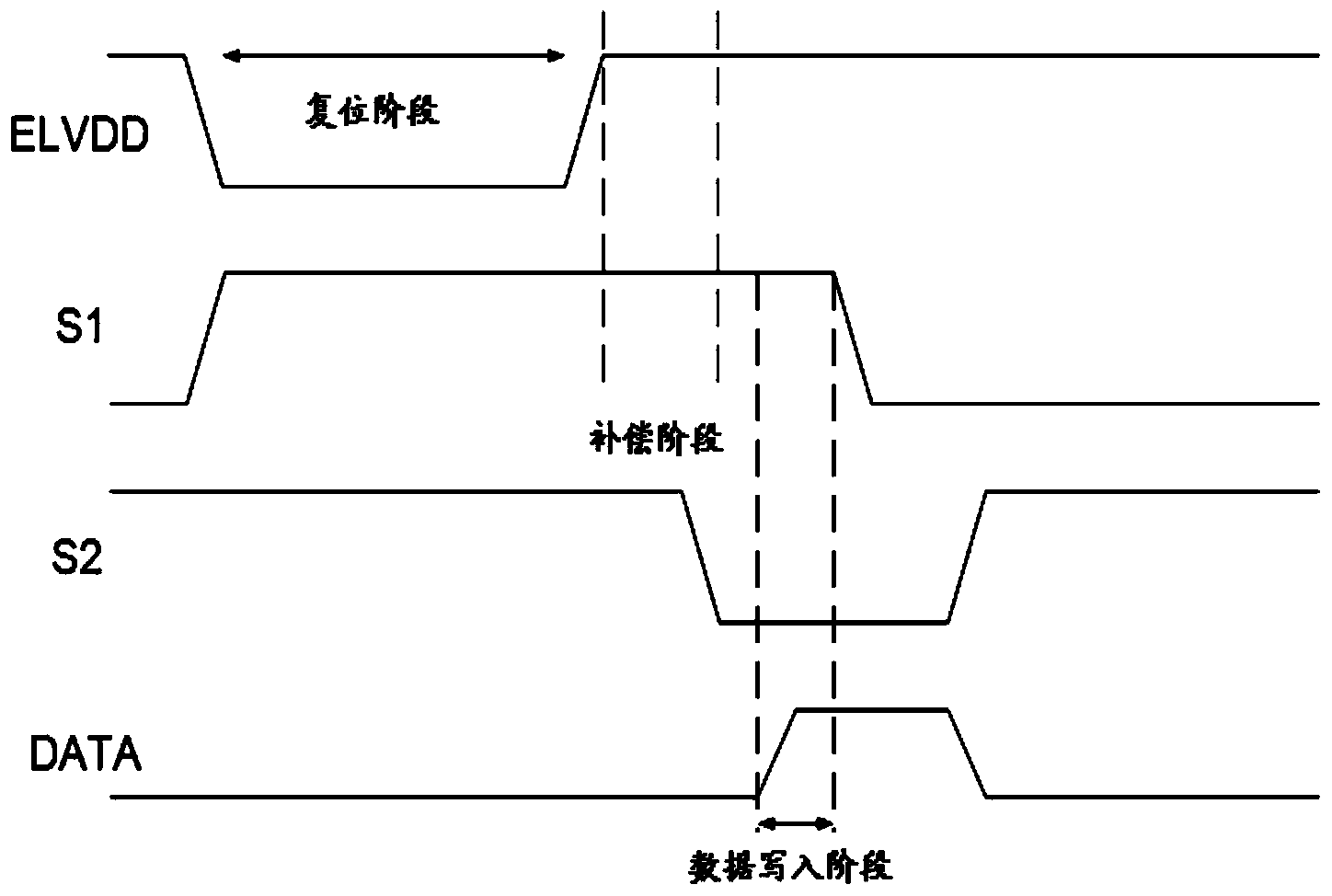

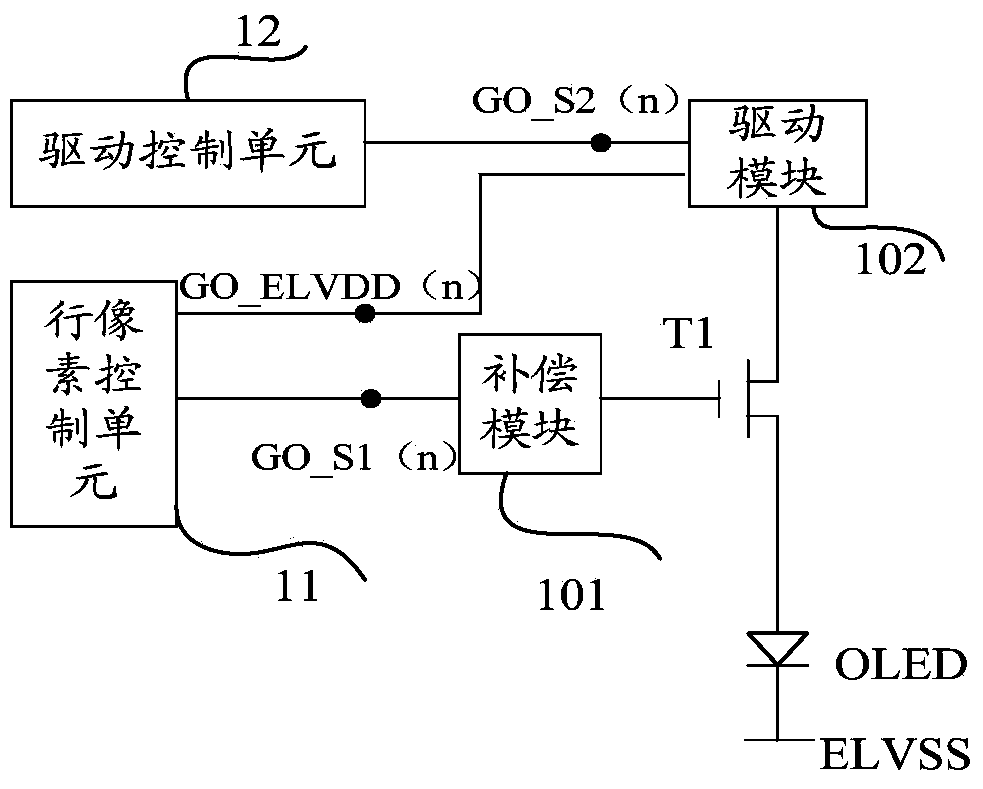

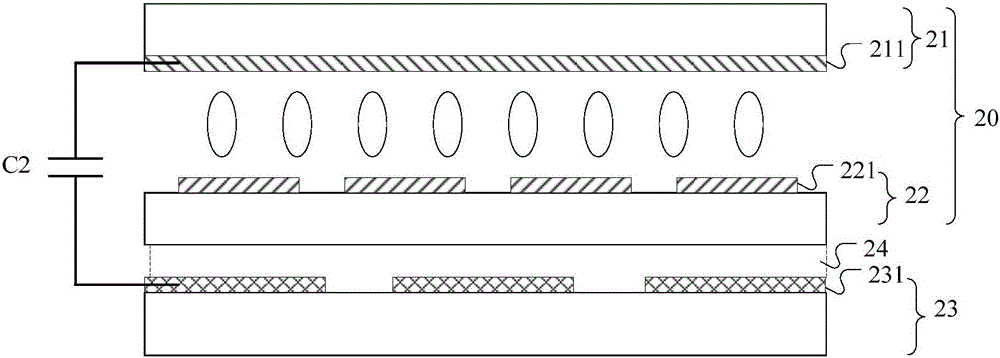

The invention provides a grid driving circuit and method, an array substrate line driving circuit and a display device. The grid driving circuit is connected with a line pixel unit, wherein the line pixel unit comprises a line pixel driving module and a light-emitting element, the line pixel driving module and the light-emitting element are connected with each other, the line pixel driving module comprises a driving transistor, a driving module and a compensation module, a grid scanning signal is connected to the compensation module, and a driving level is connected to the driving module. The grid driving circuit further comprises a line pixel control unit, wherein the line pixel control unit is used for providing grid scanning signals for the compensation module and providing the driving level for the driving module to further control the compensation module to compensate for the threshold voltage of the driving transistor and control the driving module to drive the light-emitting element. According to the grid driving circuit and method, the array substrate line driving circuit and the display device, the pixel threshold voltage and the driving pixel can be compensated at the same time, and the integration level is improved.

Owner:BOE TECH GRP CO LTD

Grid driving circuit and method, array substrate row driving circuit and display device

ActiveCN103714781AHigh process integrationLow costStatic indicating devicesControl signalComputer module

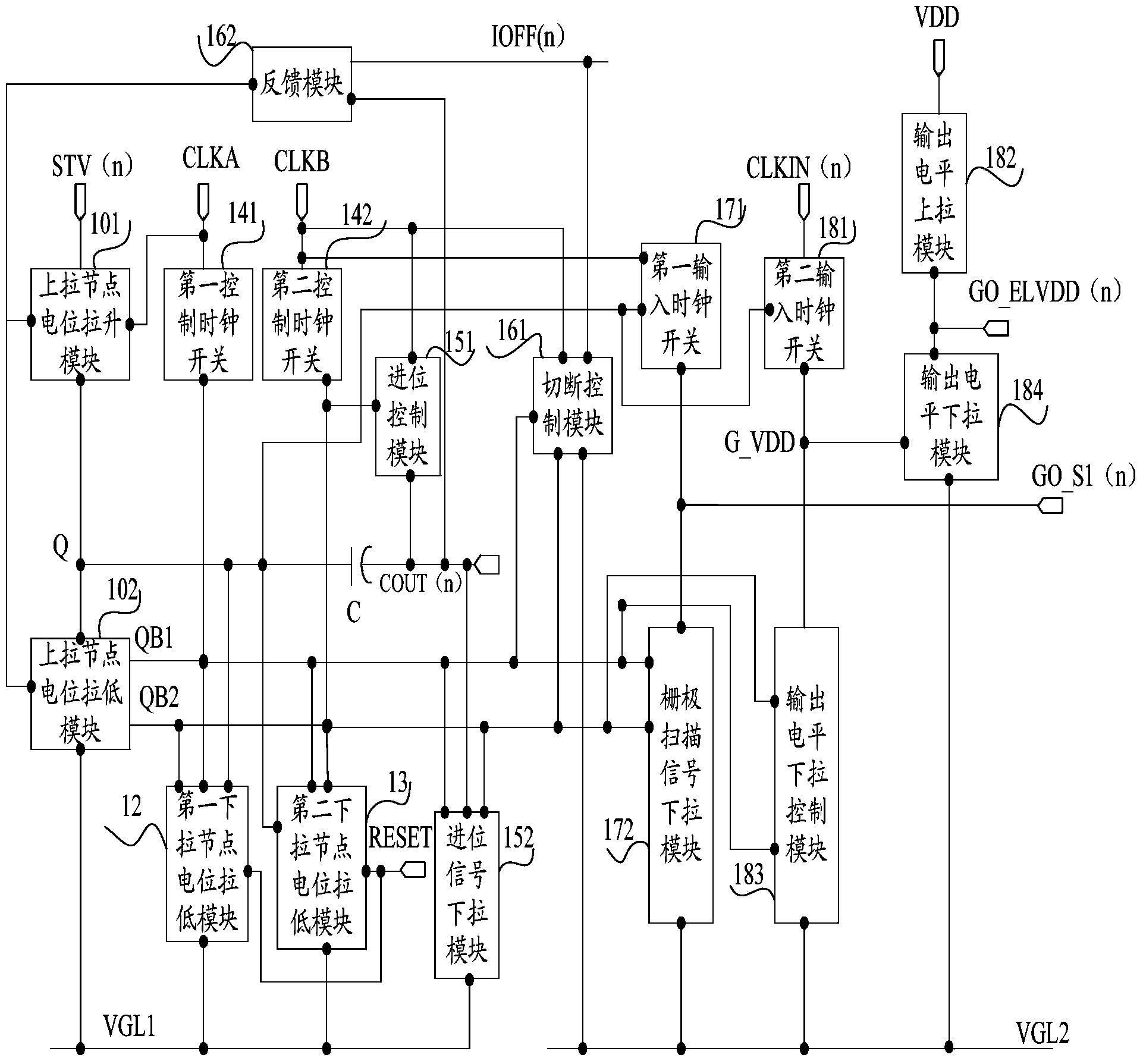

The invention provides a grid driving circuit and method, an array substrate row driving circuit and a display device. The grid driving circuit is connected with a row pixel unit, and the row pixel unit comprises a row pixel driving module and a light emitting element which are connected with each other. The row pixel driving module comprises a driving transistor, a driving module and a compensation module. A grid scanning signal is connected into the compensation module. A driving control signal and a driving level are connected into the driving module. The grid driving circuit comprises a row pixel control unit and a driving control unit, wherein the row pixel control unit is used for providing the grid scanning signal for the compensation module and providing the driving level for the driving module so as to control the compensation module to compensate for the threshold voltage of the driving transistor , and the driving control unit is used for providing a driving control signal for the driving module so as to control the driving module to drive the light emitting element. The pixel threshold voltage and the driving pixels can be compensated for at the same time, and thus the integration is improved.

Owner:BOE TECH GRP CO LTD

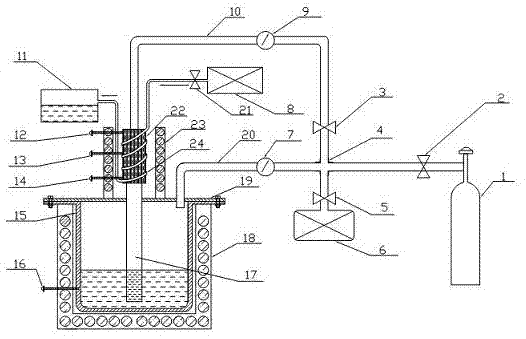

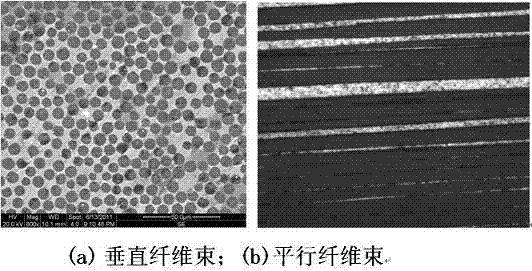

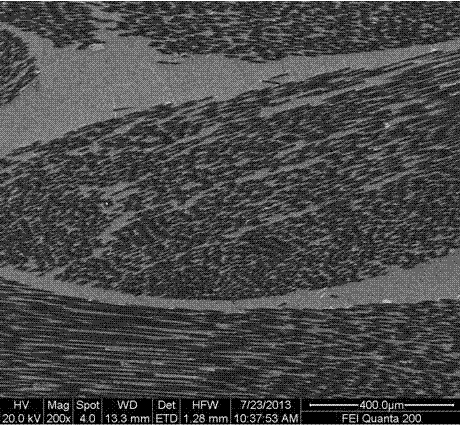

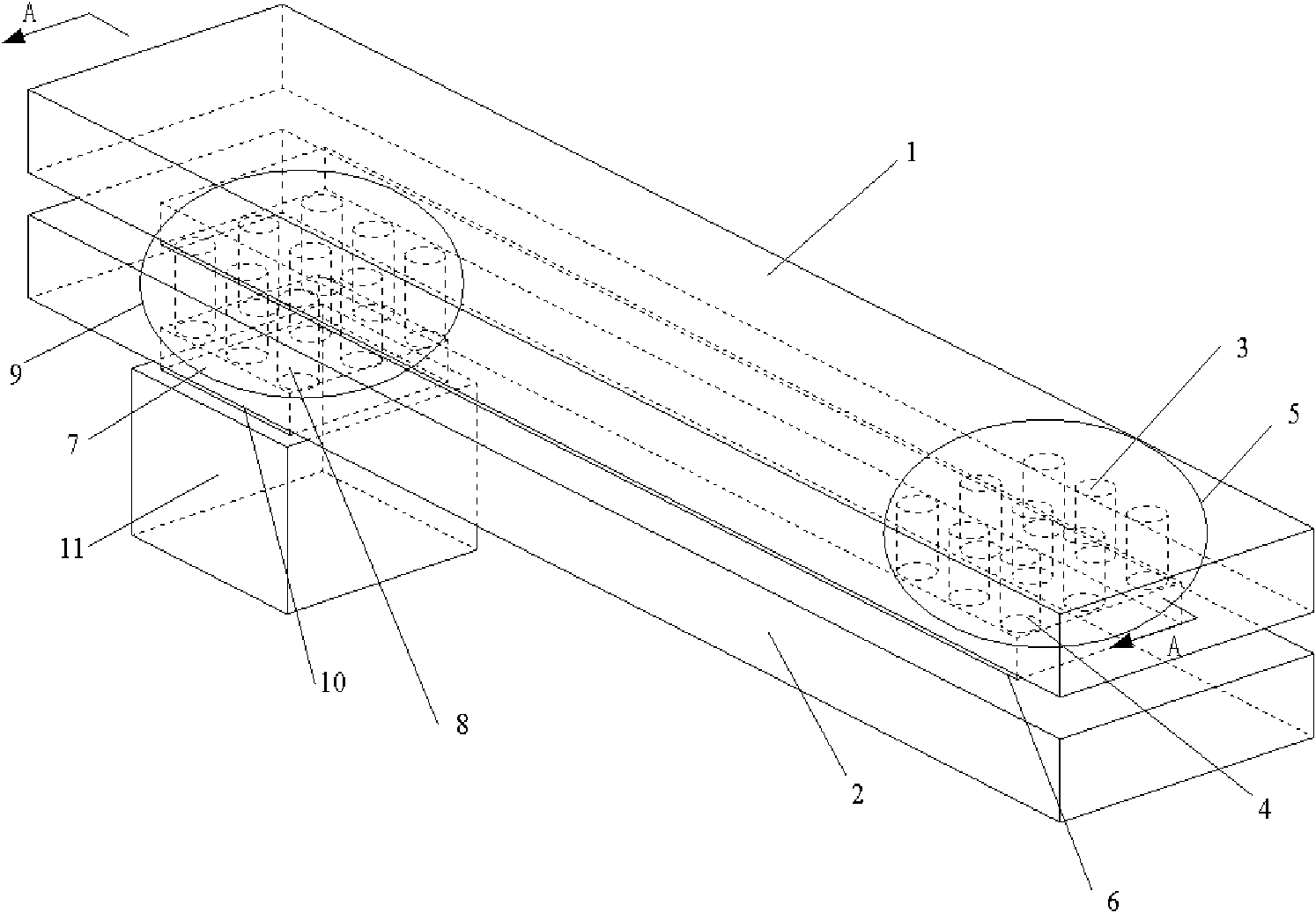

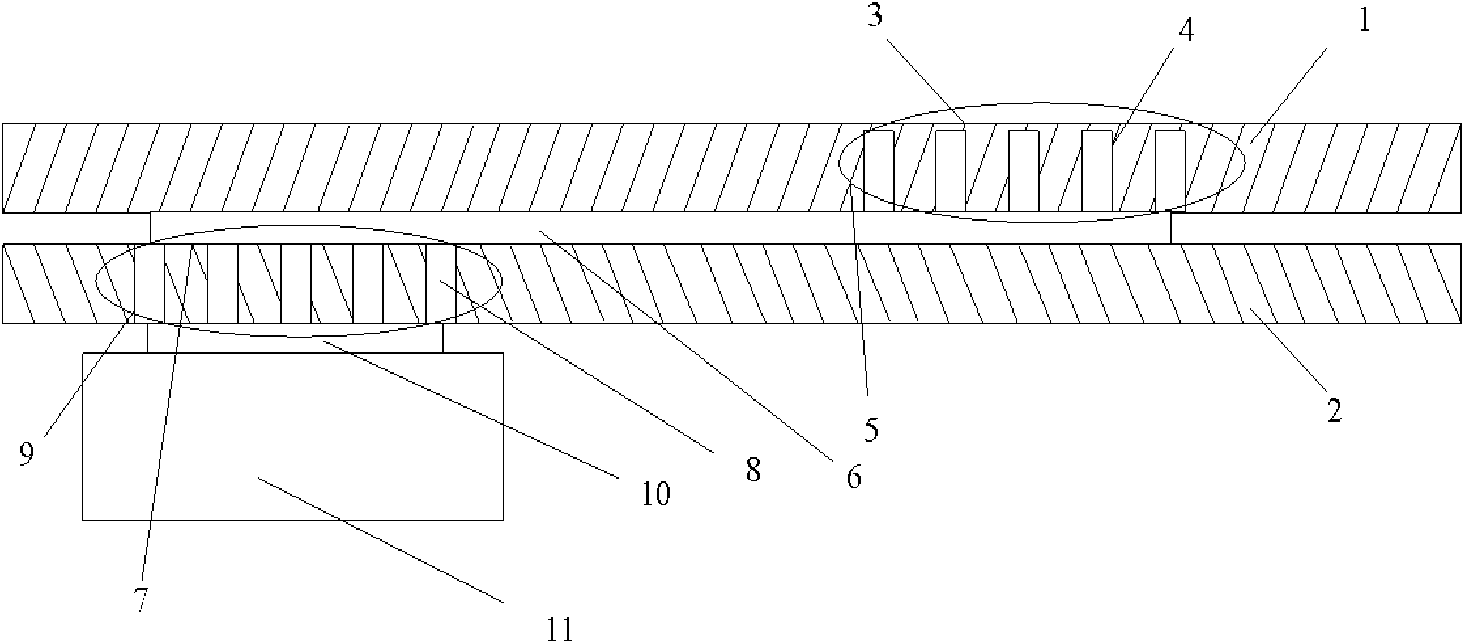

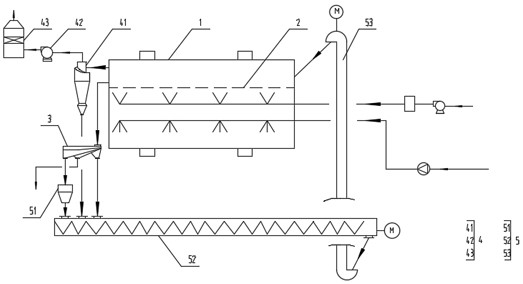

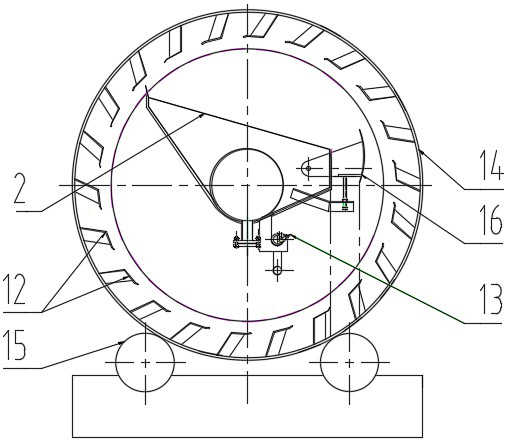

Liquid-state near-net forming method and device for continuous carbon fiber enhanced aluminum-based composite material

InactiveCN103540873ARealize hypoxic temperature control preheatingAchieve cooling rate controlFiberCarbon fibers

The invention discloses a liquid-state near-net forming method and device for a continuous carbon fiber enhanced aluminum-based composite material, namely a vacuum-assisted pressure-adjusting and infiltration casting method and device. The method comprises four procedures of smelting an alloy and pre-heating fibers, carrying out vacuum-assisted pressure-adjusting and infiltration, condensing at a high pressure and cooling rapidly. The device is composed of an alloy smelting device, a vacuum-assisted pressure-adjusting and infiltration device and a casting rapid cooling device. The liquid-state near-net forming method and device have the characteristics that (1) low-oxygen and temperature-controllable pre-heating of nickel-plated carbon fibers is realized; (2) low-pressure infiltration and high-pressure condensation of the aluminum-based composite material are realized; (3) the control of a cooling speed in the condensation of a composite material casting is realized. According to the liquid-state near-net forming method and device for the continuous carbon fiber enhanced aluminum-based composite material, oxidization and burning loss caused by pre-heating the carbon fibers, prefabricated body deformation in the infiltration process and interface reaction problems in the condensation process of the composite material are solved. The liquid-state near-net forming of the continuous carbon fiber enhanced aluminum-based composite material can be realized and the prepared composite material has the advantages of dense tissues, few interface reactions, high mechanical properties and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

Grid driving circuit, grid driving method, array substrate row driving circuit and display device

ActiveCN103714780AHigh process integrationLow costStatic indicating devicesDigital storageDisplay deviceComputer module

The invention provides a grid driving circuit, a grid driving method, an array substrate row driving circuit and a display device. The grid driving circuit is connected with a row pixel unit, the row pixel unit comprises a row pixel driving module and a light emitting component which are mutually connected, wherein the row pixel driving module comprises a driving transistor, a driving module and a compensation module, the compensation module is connected with the first row scanning signal, the driving module is connected with the second row scanning signal and a driving level, the grid driving circuit further comprises a row pixel control unit used for providing the first row scanning signal for the compensation module and used for providing the second row scanning signal and the driving level for the driving module, so the compensation module is controlled to compensate threshold voltage of the driving transistor, and the driving module is controlled to drive the light emitting component. The grid driving circuit can compensate the pixel threshold voltage and a driving pixel and improves an integration level.

Owner:BOE TECH GRP CO LTD

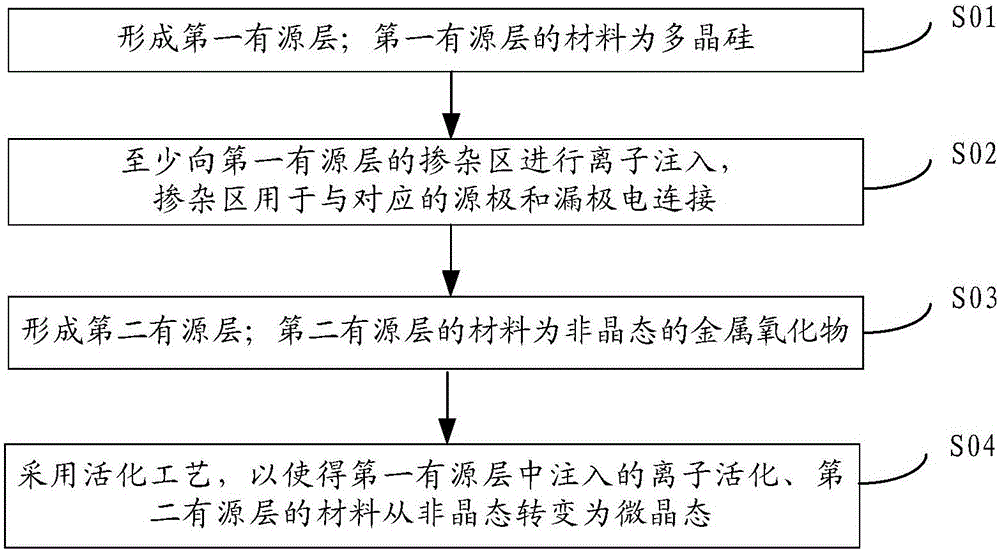

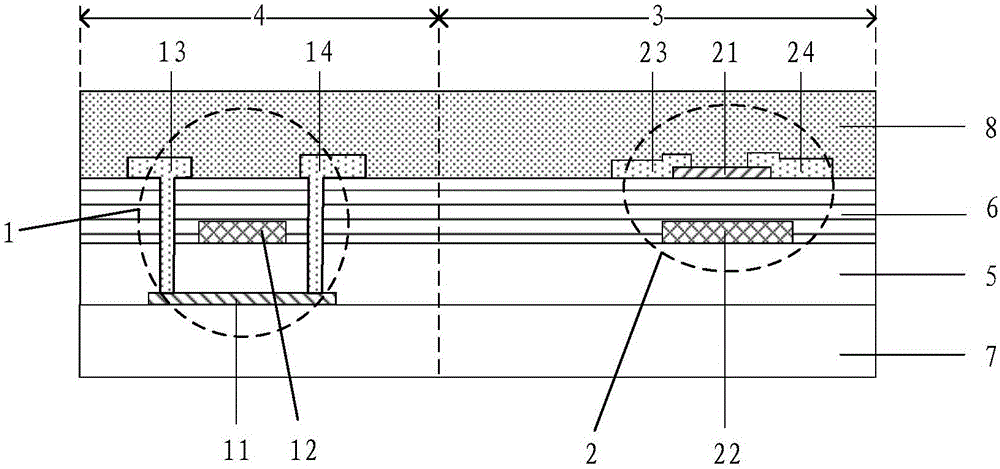

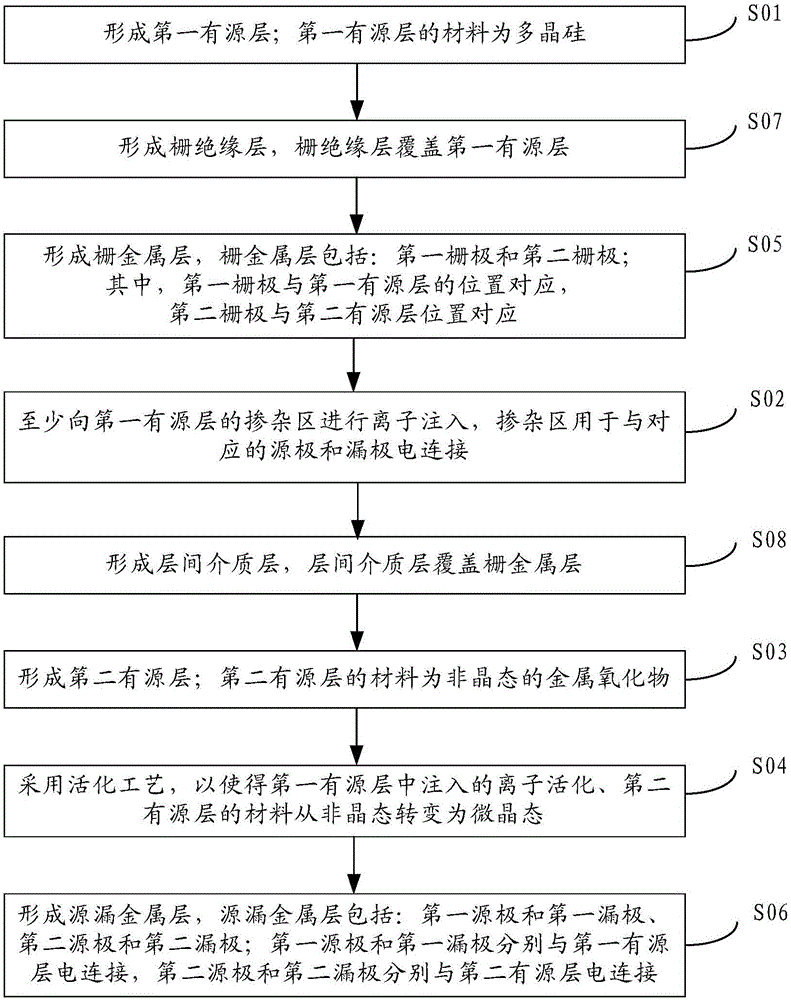

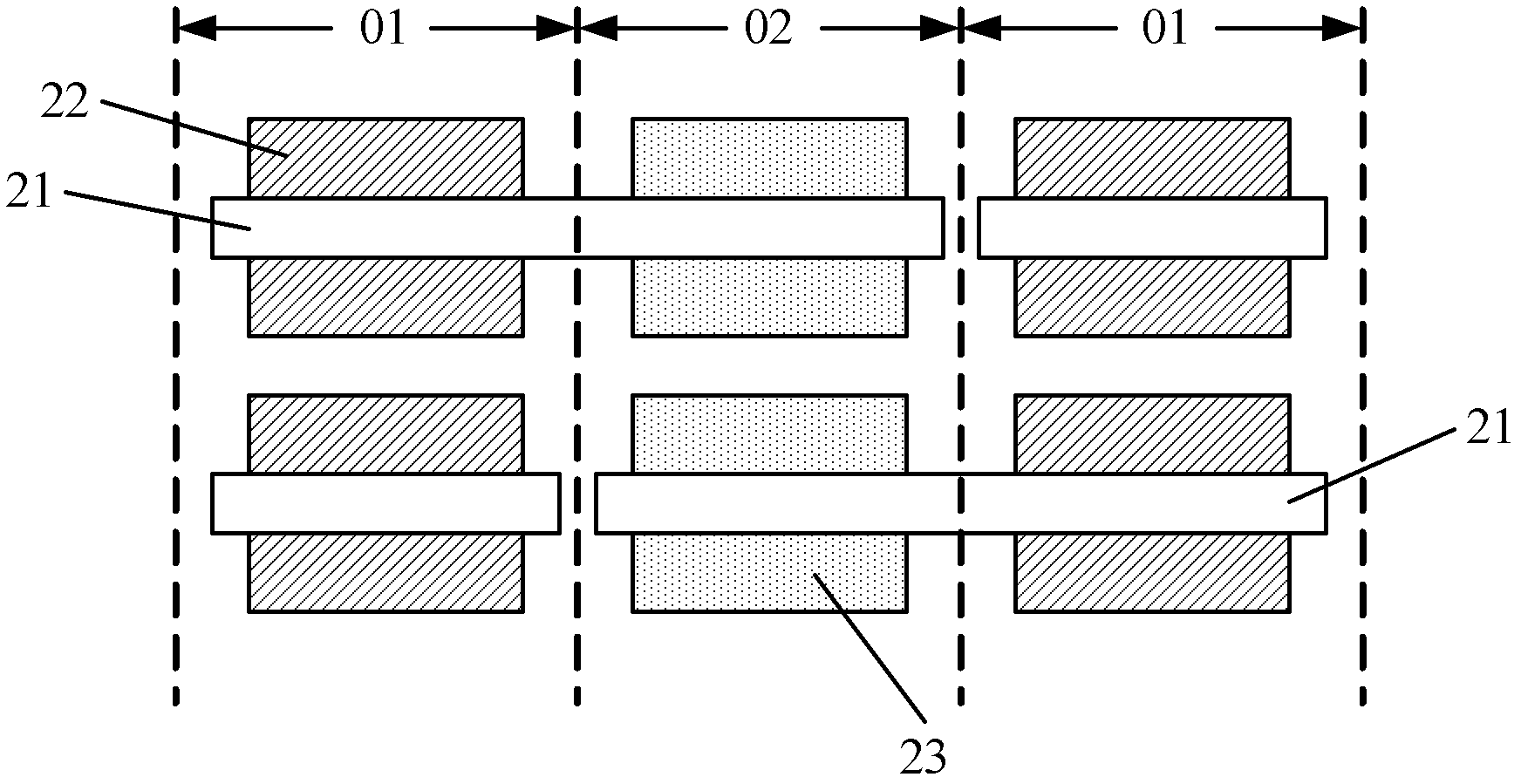

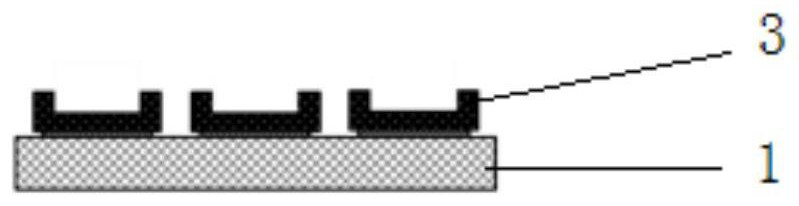

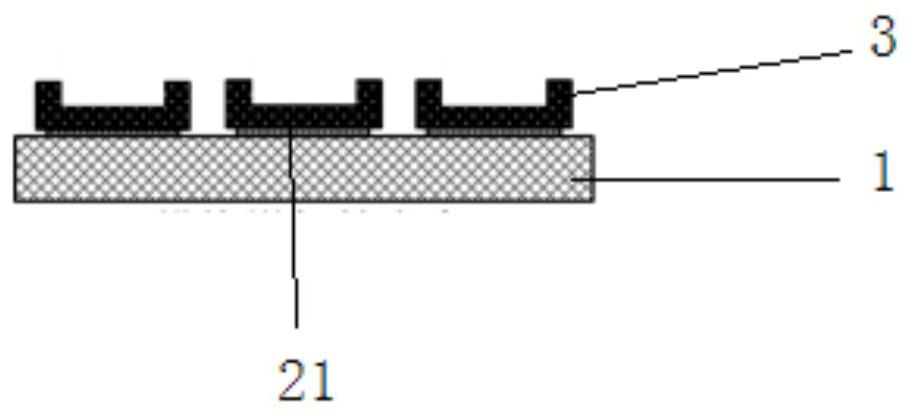

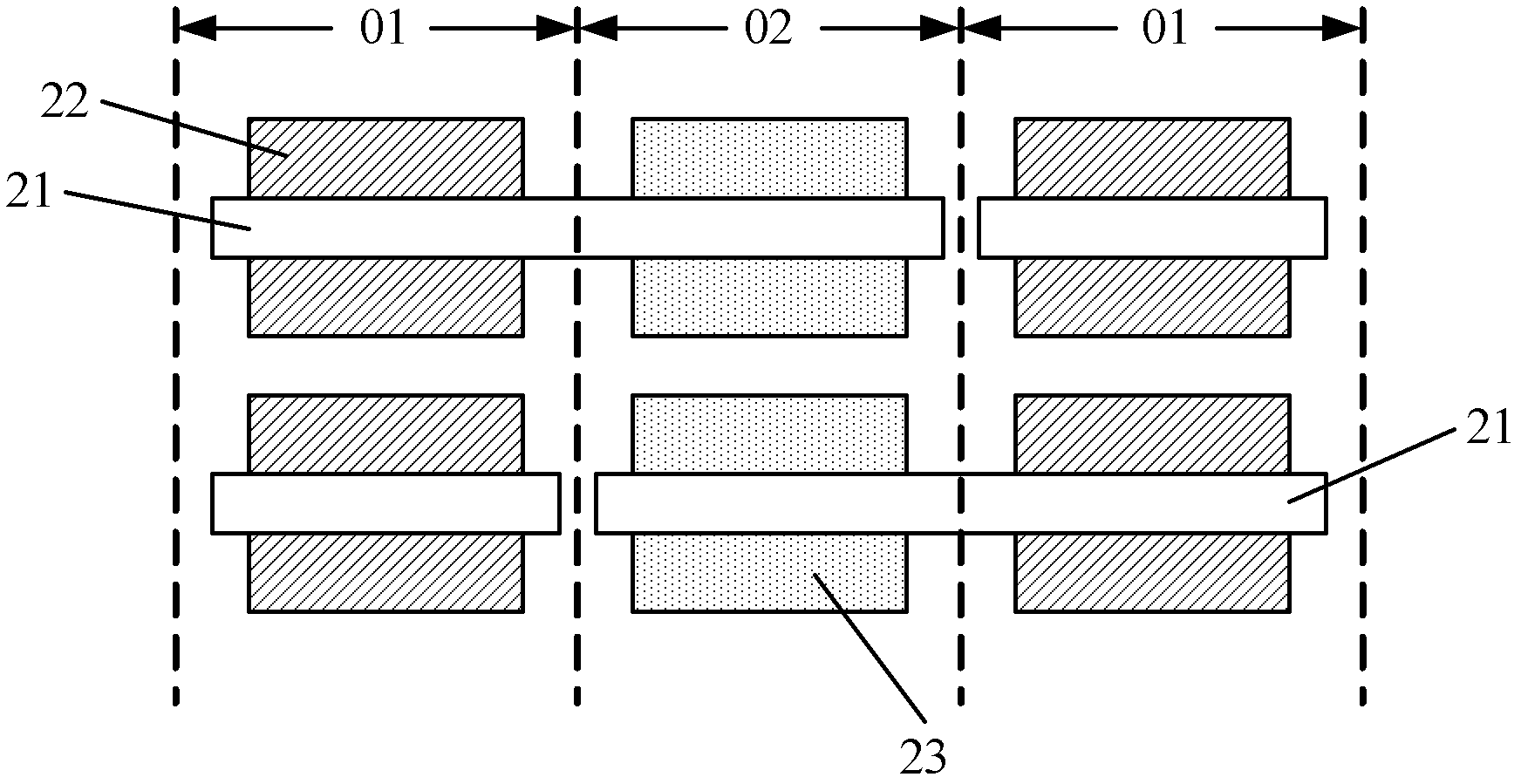

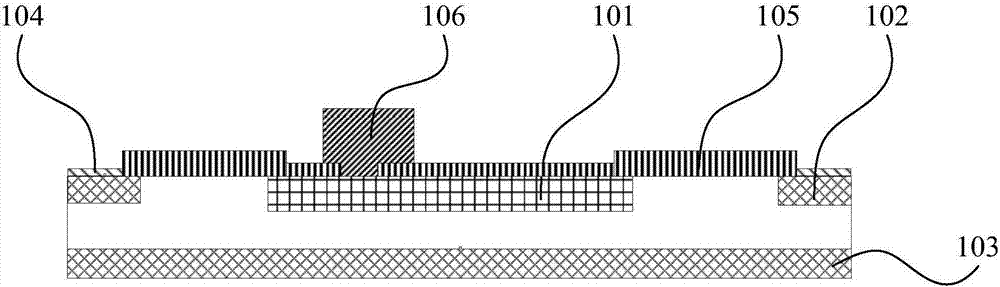

Array substrate, manufacturing method thereof, and display device

InactiveCN106298648AHigh process integrationReduce manufacturing costTransistorSolid-state devicesBiochemical engineeringDisplay device

The invention provides an array substrate, a manufacturing method thereof, and a display device, which relate to the technical field of display. Through the manufacturing method of the array substrate, an ion activation process of LTPS TFT (Thin Film Transistor) and a process of converting an amorphous state of Oxide TFT into a mini-crystal state are integrated into a whole. The manufacturing method of the array substrate comprises the steps of forming a first active layer, wherein the material of the first active layer is polycrystalline silicon; at least carrying out ion implantation into a doping area of the first active layer, wherein the doping area is used for being electrically connected with a corresponding source electrode and a corresponding drain electrode; forming a second active layer, wherein the material of the second active layer is amorphous metallic oxide; after at least carrying out ion implantation into the doping area of the first active layer, and forming the second active layer, adopting an activation process so as to activate ion implanted into the first active layer and turn the material of the second active layer from the amorphous state to the mini-crystal state. The manufacturing method provided by the invention is applicable to manufacturing the array substrate and the display device comprising the array substrate.

Owner:BOE TECH GRP CO LTD

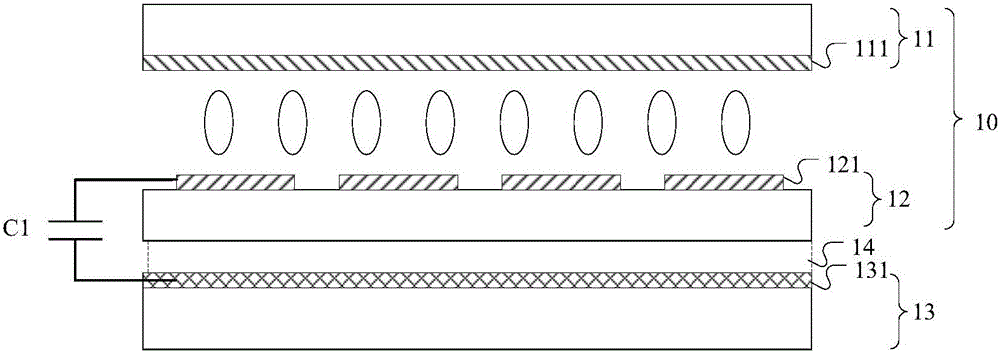

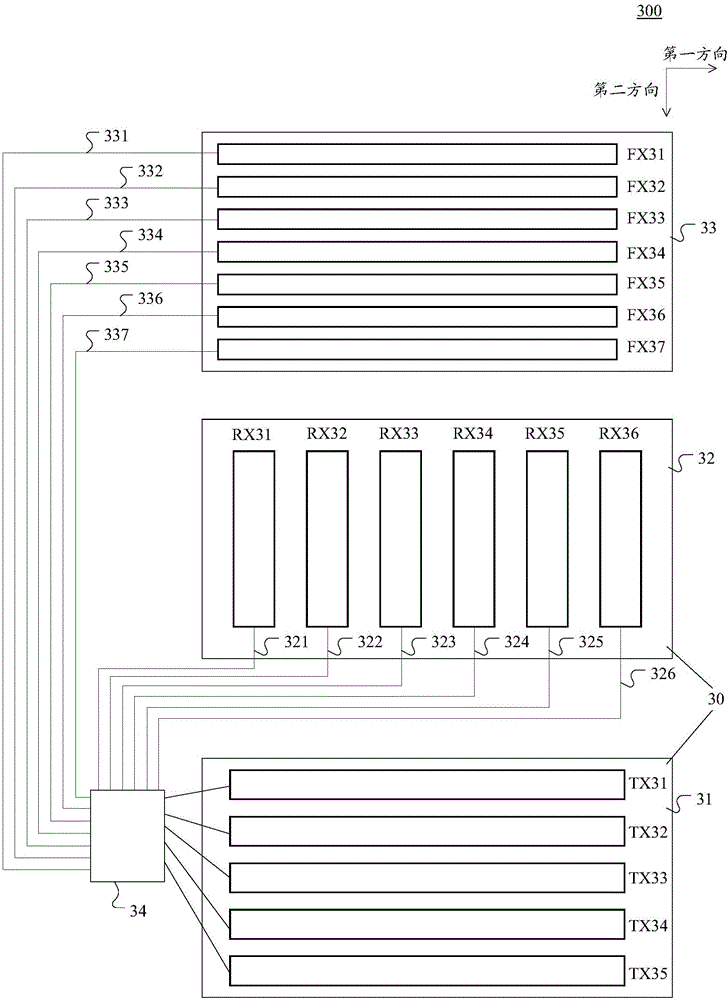

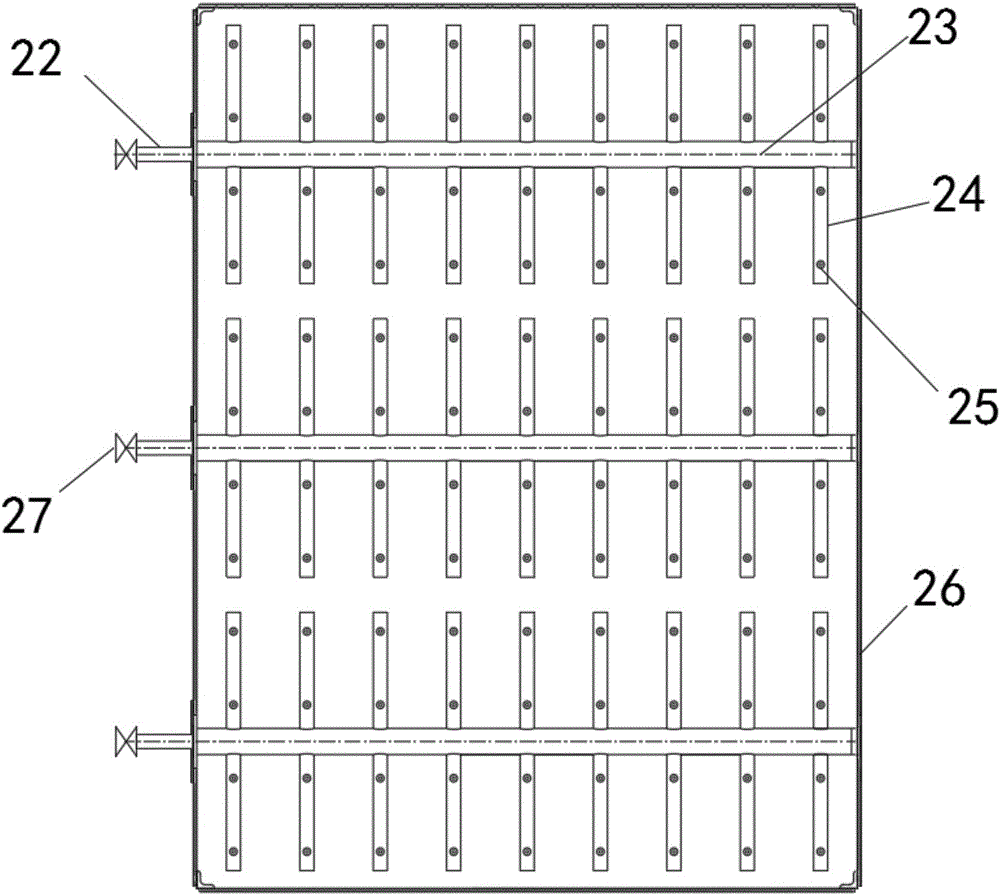

Integrated touch display device

InactiveCN106125976AThe production process is simpleHigh process integrationInput/output processes for data processingDisplay deviceComputer science

The application discloses an integrated touch display device. The display device comprises a display panel and a backlight module, wherein the display panel comprises a first substrate and a second substrate which are opposite to each other, one of the first substrate and the second substrate is provided with strip-shaped touch emission electrodes arranged in parallel, and the other of the first substrate and the second substrate is provided with strip-shaped touch receiving electrodes arranged in parallel; the extension directions of the strip-shaped touch emission electrode and the strip-shaped receiving electrode are intersected; the strip-shaped touch emission electrode or the strip-shaped receiving electrode is multiplexed as a first pressure electrode; the backlight module comprises a second pressure electrode; a gap is formed between the display panel and the backlight module; the first pressure electrode, the second pressure electrode and the gap form a pressure capacitor; the pressure capacitor is used for sensing the pressure exerted on the integrated touch display device. The integrated touch display device is capable of realizing pressure detection function, and capable of simplifying the manufacture process and reducing the cost.

Owner:XIAMEN TIANMA MICRO ELECTRONICS +1

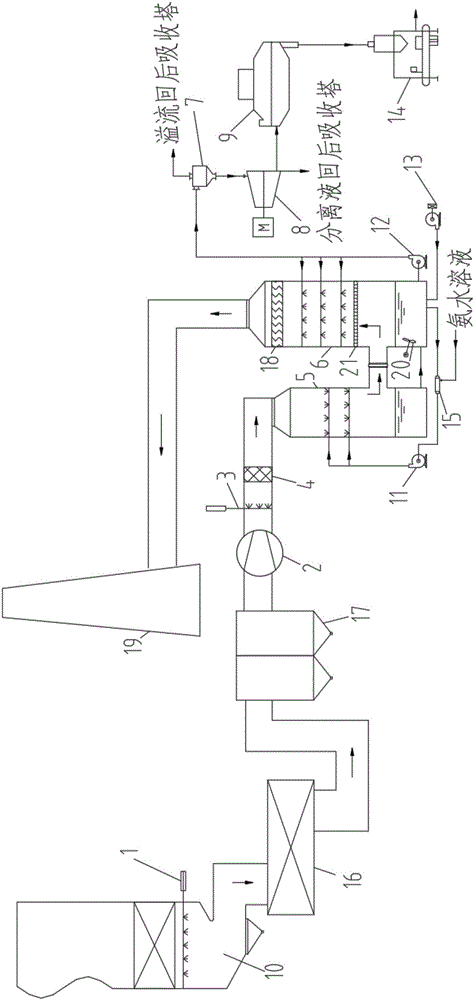

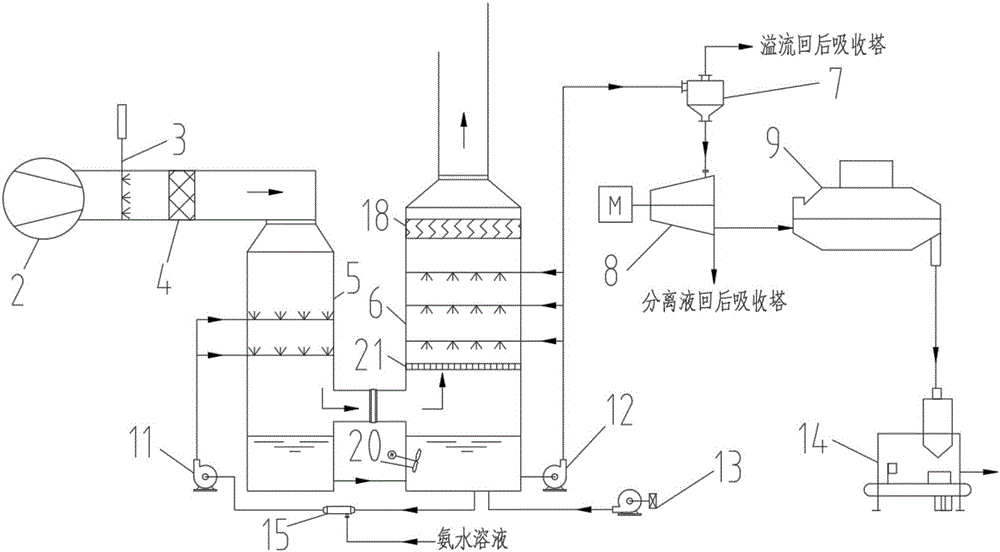

Desulfurization and denitration technology and system by ozone oxidation double-tower ammonia method

ActiveCN106166434AHigh process integrationReduce resistanceDispersed particle separationAir preheaterFlue gas

The invention relates to a desulfurization and denitration system by an ozone oxidation double-tower ammonia method. The desulfurization and denitration system sequentially comprises a hydrogen peroxide spraying device, a draught fan, an ozone spraying device, a flue gas mixing device, a front adsorption tower, a rear adsorption tower, a cyclone separator, a centrifugal separator and a drier, wherein the hydrogen peroxide spraying device is arranged at an outlet of a boiler coal economizer, the outlet of the boiler coal economizer is connected to the draught fan through an air preheater and a dust remover and is connected to the front adsorption tower; the ozone spraying device is mounted in front of an inlet flue of the front adsorption tower; and the flue gas mixing device is arranged between the ozone spraying device and the inlet flue of the front adsorption tower. The desulfurization and denitration system disclosed by the invention has the beneficial effects that the integration degree of a technology is high, the desulfurization and the denitration are integrated, the double-tower structure are stable in properties, the desulfurization efficiency and the denitration efficiency are high, the source of an adsorption tower machine is reliable, the added value of by-products is high, little secondary pollution exists, and the operation cost is low.

Owner:ZHEJIANG TIANDI ENVIRONMENTAL PROTECTION TECH CO LTD

Refrigeration structure for three-dimensional encapsulation of micro-electronics and preparation method thereof

InactiveCN101667568AImprove cooling efficiencyHigh process integrationSemiconductor/solid-state device detailsSolid-state devicesMetallic materialsEngineering

The invention relates to a refrigeration structure for three-dimensional encapsulation of micro-electronics in the micro-electronic encapsulation field and a preparation method thereof. The refrigeration structure comprises two laminated chips, two longitudinal metal heat dissipation passage arrays and a transverse metal heat dissipation passage array, wherein the lower surface of an upper laminated chip and the upper surface of a lower laminated chip are respectively provided with one longitudinal metal heat dissipation passage array; the two longitudinal metal heat dissipation passage arraysare connected by the transverse metal heat dissipation passage array. The preparation method of the invention aiming at heat dissipation passages of local hot spots can selectively adopt metal material with high thermal conductivity as heat dissipation passages on one hand, and can adopt a feasible shortest heat dissipation route aiming at the local hot spots on the other hand, thus increasing the heat dissipation efficiency of the laminated high integration level chip to the largest extent. The invention has high technology integration level and is easy to realize.

Owner:SHANGHAI JIAO TONG UNIV

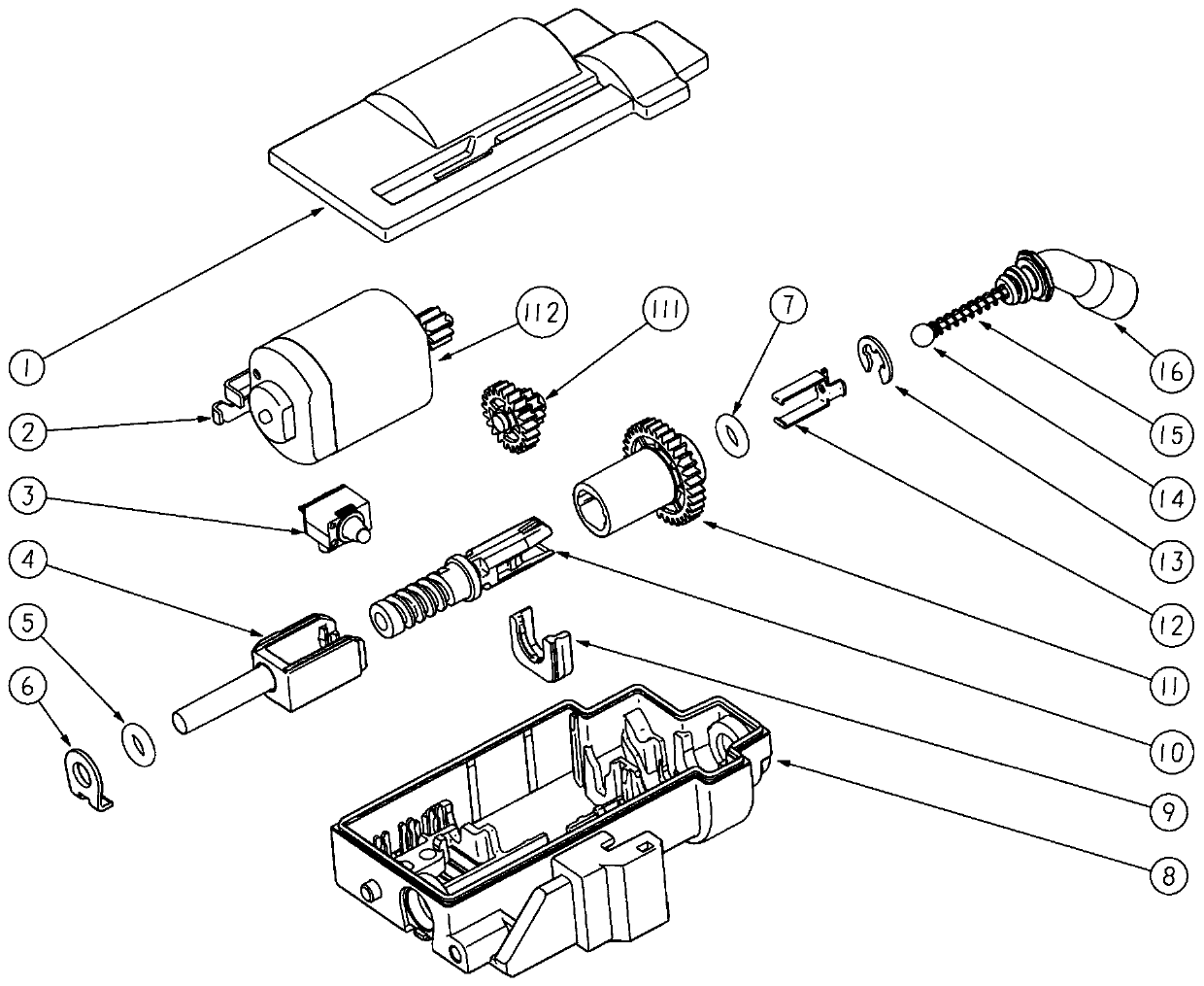

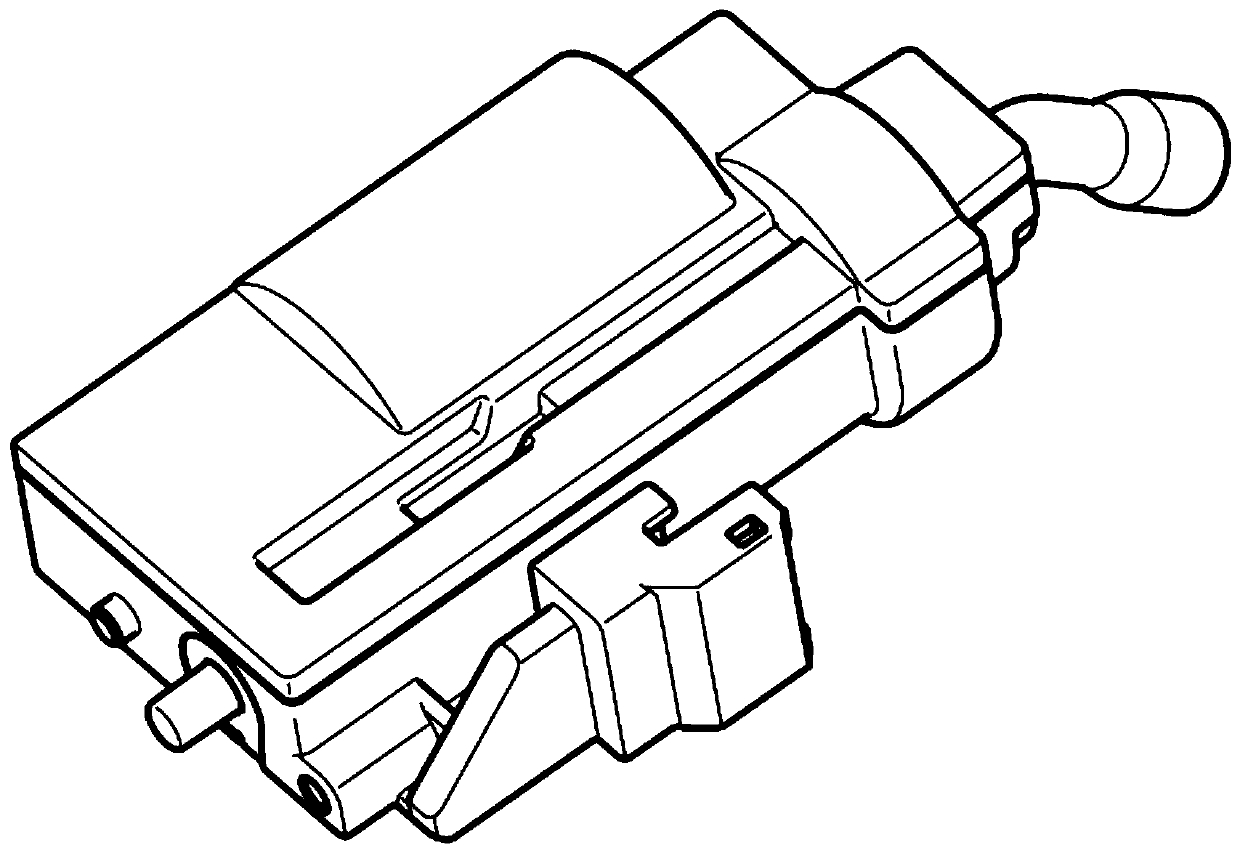

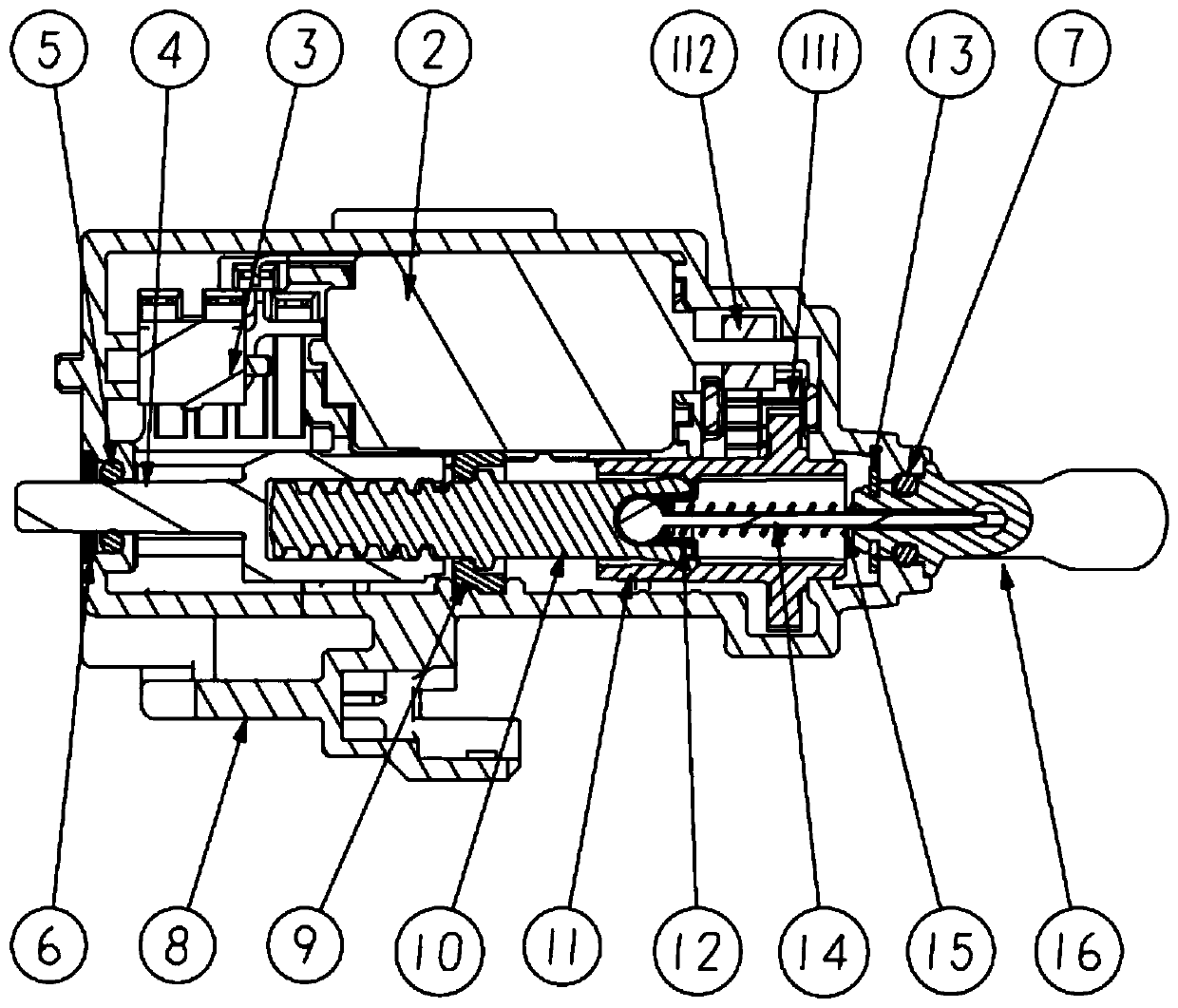

Electronic locking device

PendingCN110080636AWell thought outPrevent accidental unlockingElectrical locking actuatorsProcess integrationLocking mechanism

The invention discloses an electronic locking device. The electronic locking device comprises a shell, a power mechanism arranged in the shell, a transmission mechanism, a spring bolt sliding block, afeeding screw rod, a self-locking elastic piece, a reset mechanism and an unlocking action mechanism, wherein the power mechanism, the transmission mechanism, the spring bolt sliding block, the feeding screw rod, the self-locking elastic piece, the reset mechanism and the unlocking action mechanism are arranged in the shell. A locking mechanism provided by the invention is ingenious in concept, the transmission mechanism is ingenious in matching, the safety in a normal state is high, manual unlocking can be effectively prevented, and when emergency manual unlocking is needed, the transmissionmechanism of the electronic locking device can be safely and reliably unlocked; the electronic locking device is high in process integration level, higher in process automation degree, low in cost and higher in protection grade, compared with an former similar product, the structure is simple, the appearance size is small, the cost is low, and a high protection grade can be met; according to theelectronic locking device, the problems that a spring bolt is easily pulled out and the manual unlocking operation is partially followed are solved, and the system misjudgment probability in the charging and locking process is reduced, and the problem that manual unlocking mechanism with internal parts of an automobile body is interfered due to the rotation of an operation handle at the tail end of the manual unlocking mechanism when electric locking and unlocking at each time is avoided.

Owner:宁波均胜新能源汽车技术有限公司 +1

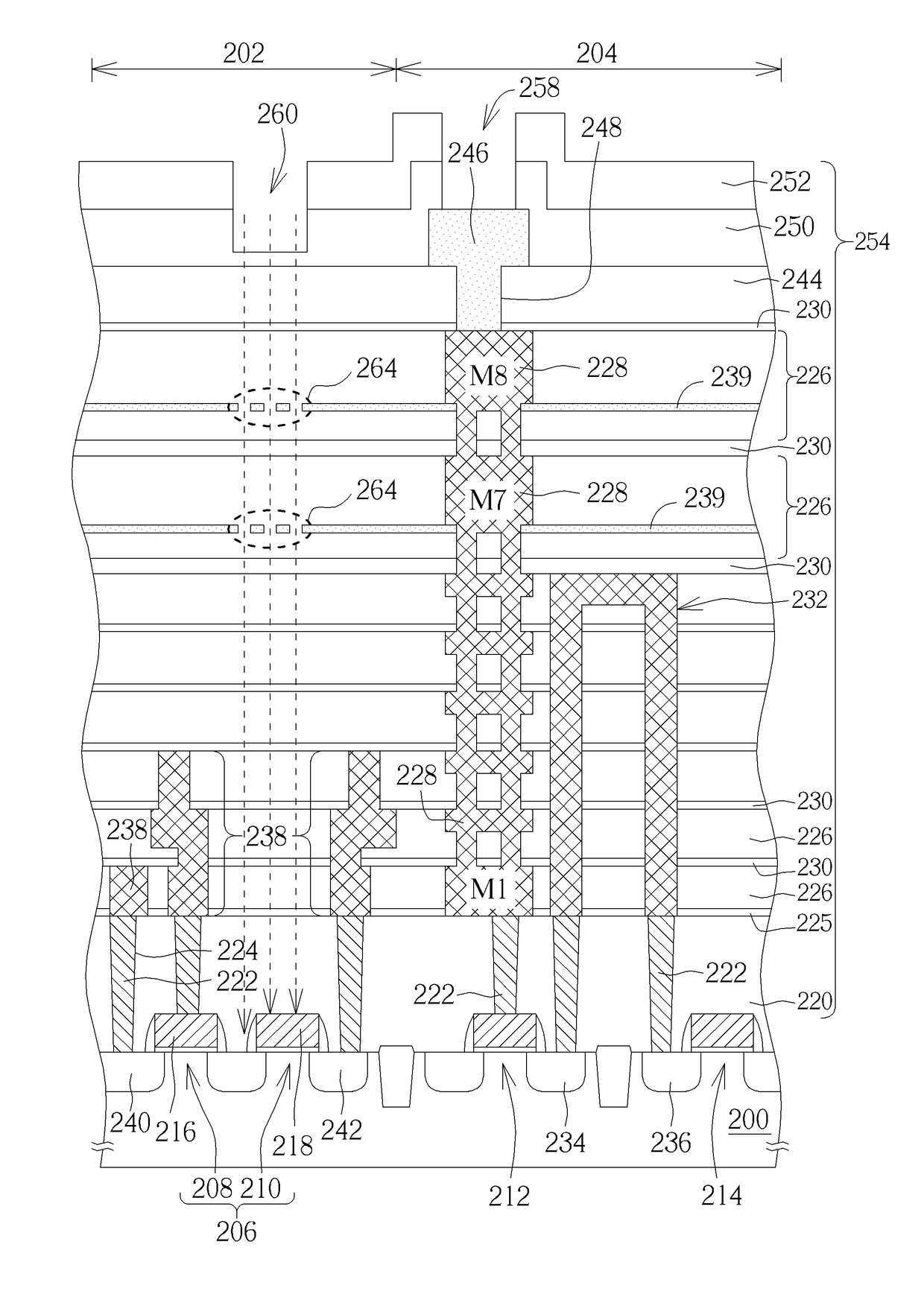

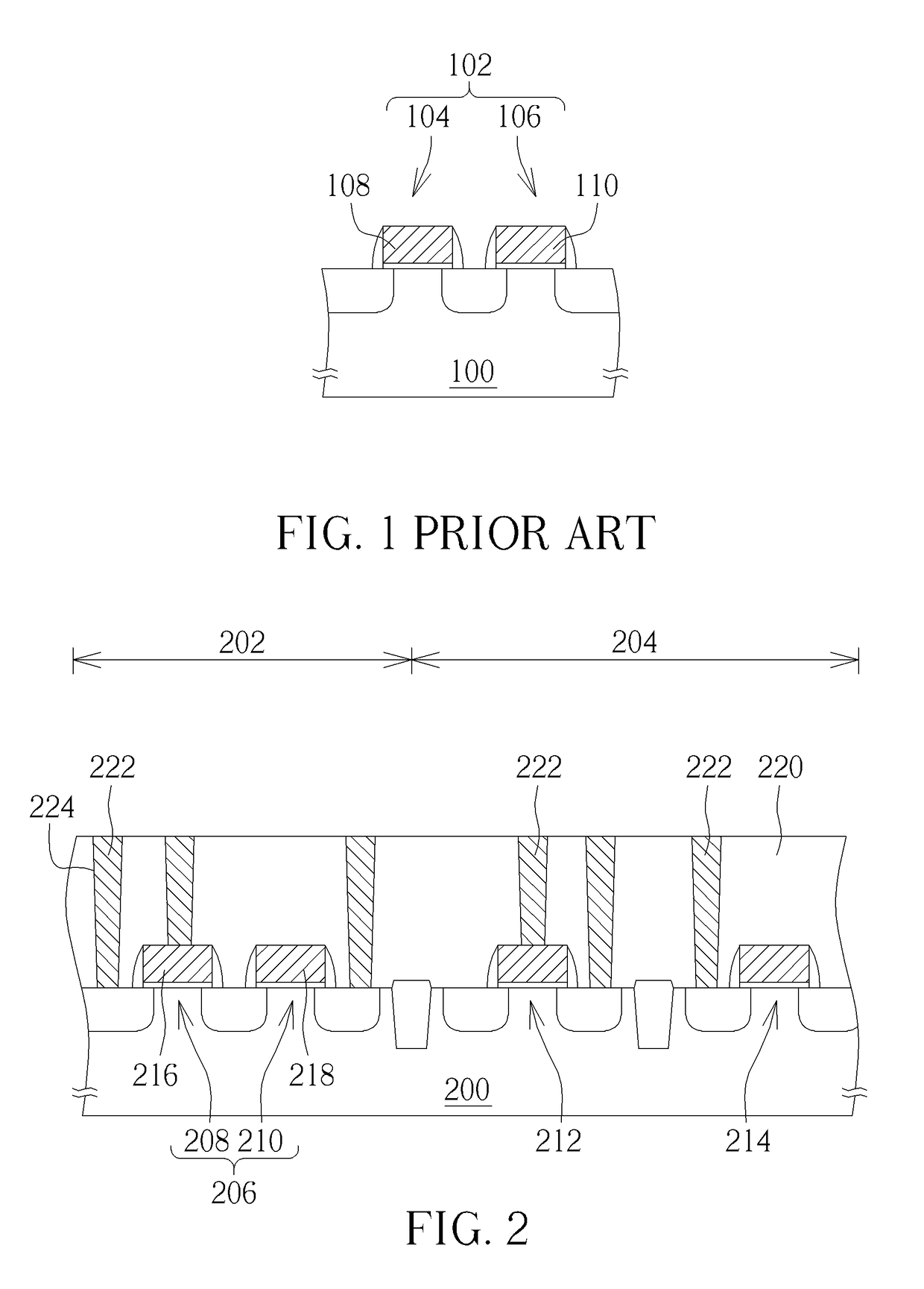

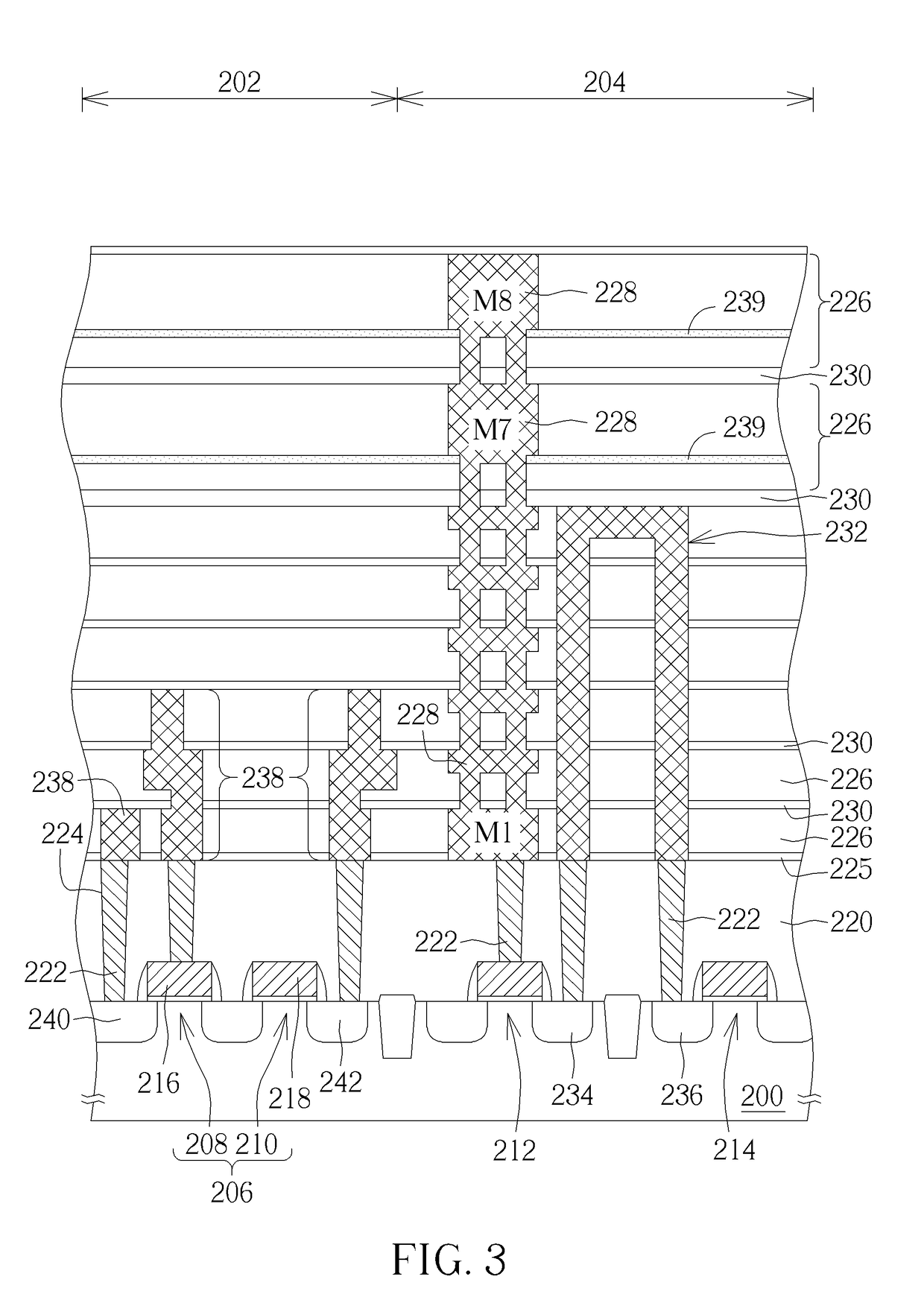

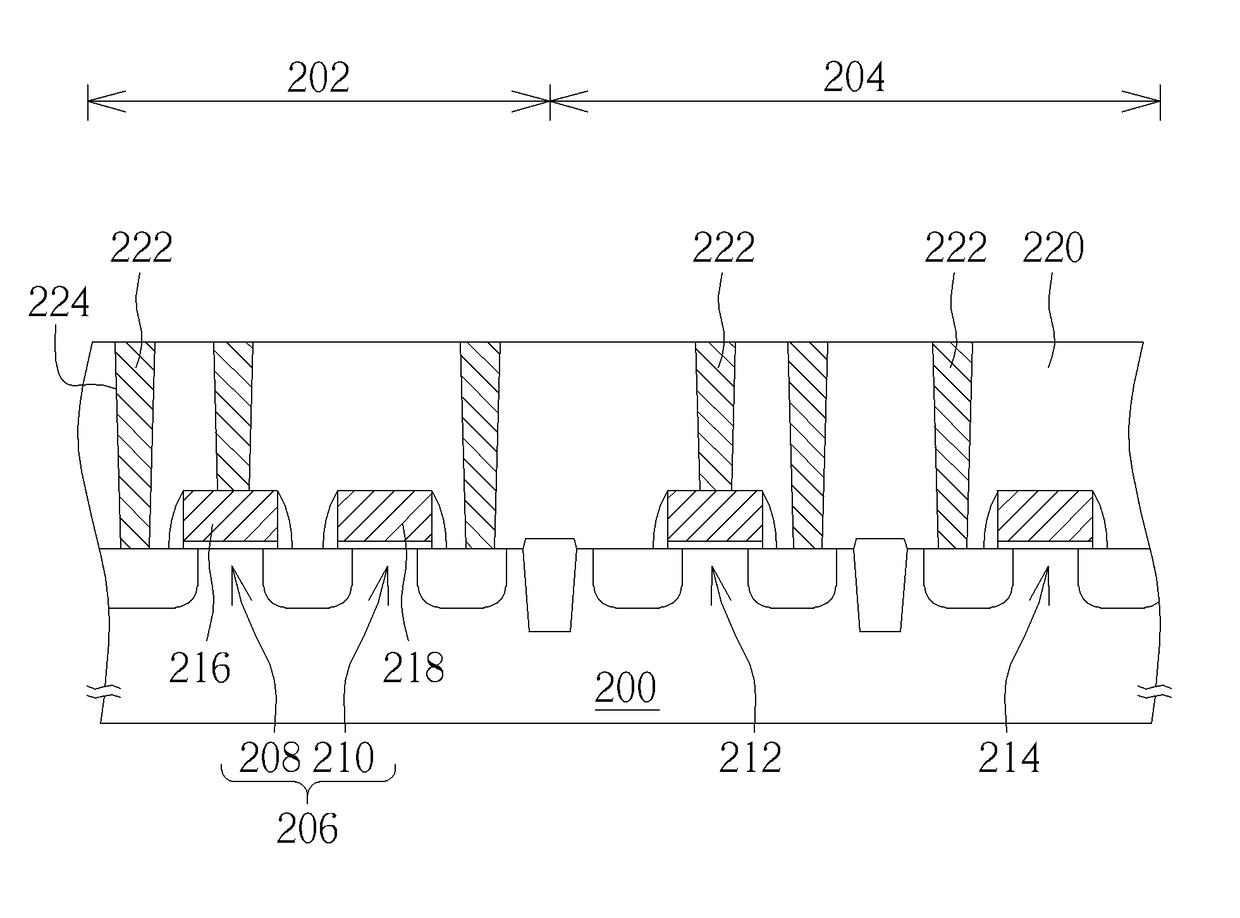

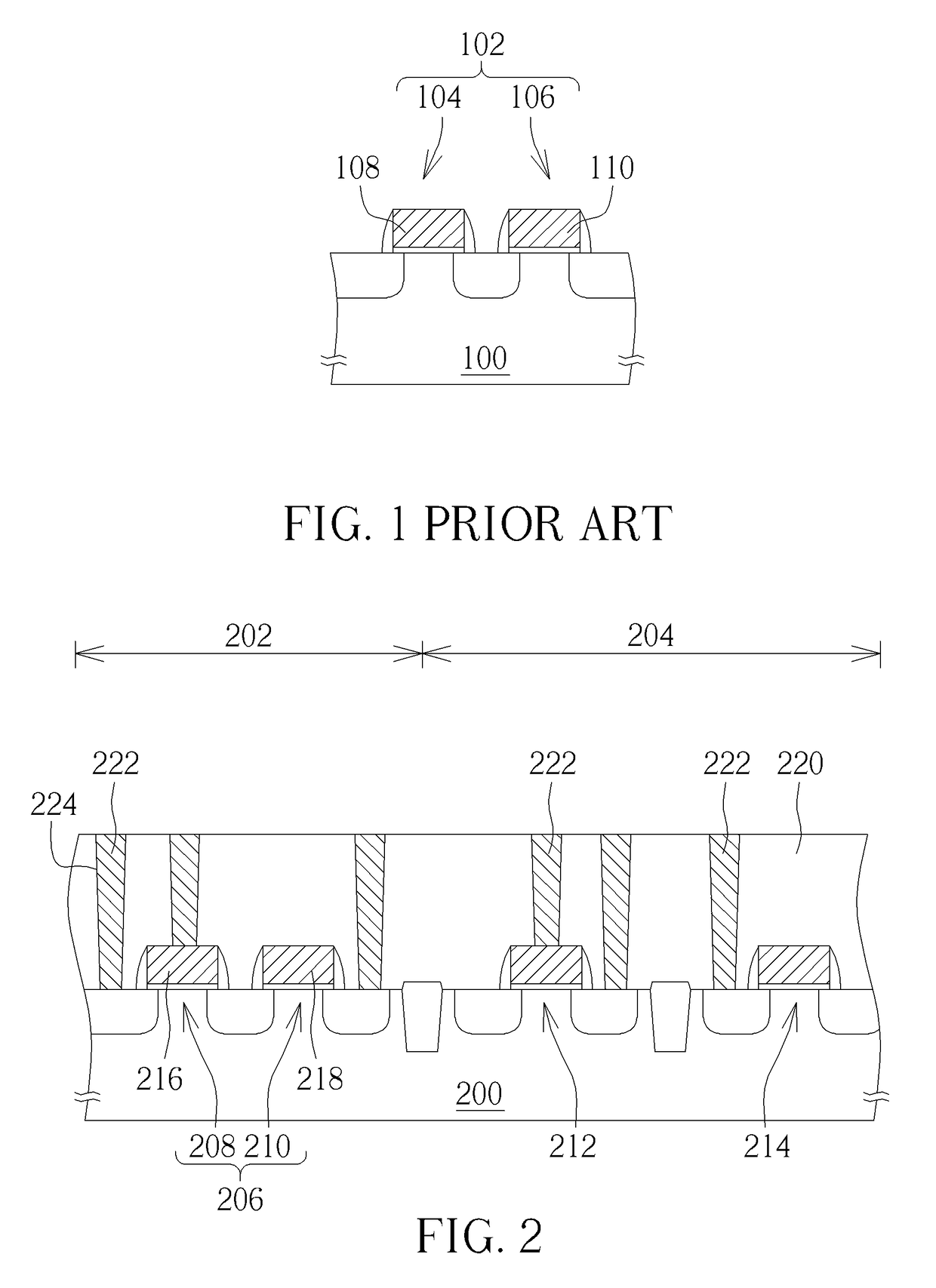

Light-erasable embedded memory device and method of manufacturing the same

ActiveUS9728260B1High process integrationLess costSemiconductor/solid-state device detailsSolid-state devicesEngineeringEmbedded system

A light-erasable embedded memory device and a method for manufacturing the same are provided in the present invention. The light-erasable embedded memory device includes a substrate with a memory region and a core circuit region, a floating gate on the memory region of the substrate, at least one light-absorbing film above the floating gate, wherein at least one light-absorbing film is provided with dummy via holes overlapping the floating gate, and a dielectric layer on the light-absorbing film and filling up the dummy via holes.

Owner:UNITED MICROELECTRONICS CORP

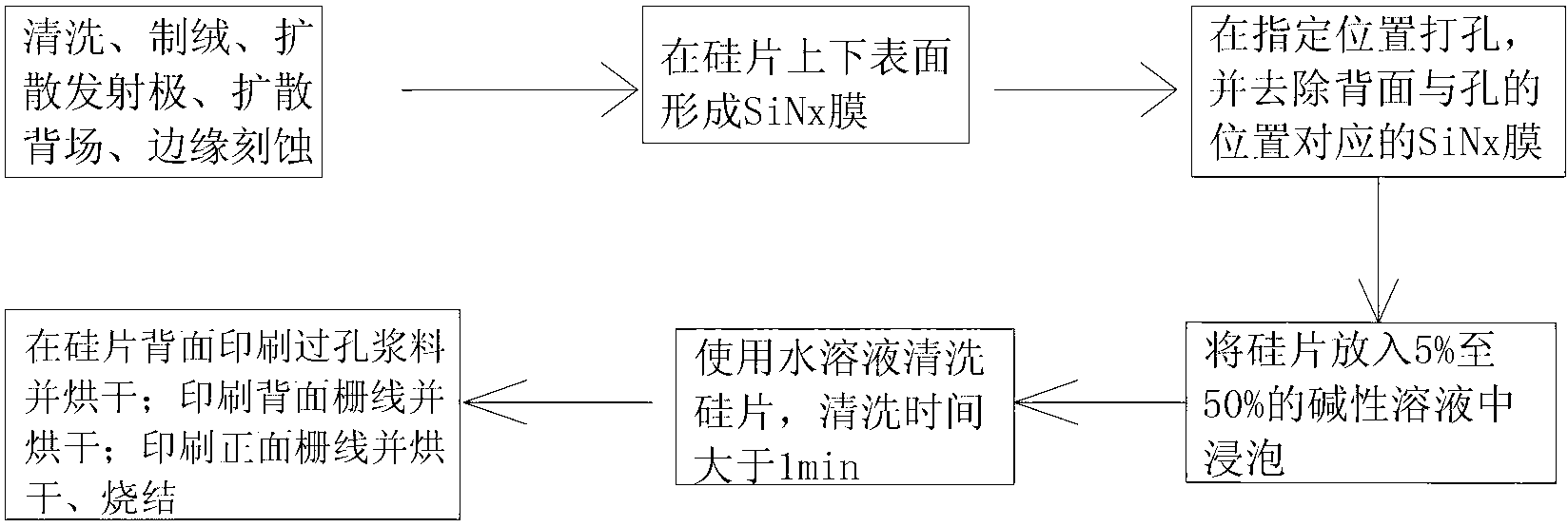

MWT solar battery and manufacturing method thereof

InactiveCN103258914AGuaranteed photoelectric conversion efficiencyHigh process integrationFinal product manufactureSemiconductor devicesProcess integrationEngineering

The invention provides an MWT solar battery and a manufacturing method of the MWT solar battery. The manufacturing method of the MWT solar battery comprises the following steps that antireflection films in a designated area on the back face of a substrate of the MWT solar battery are removed through laser to form an non-antireflection film area; the substrate of the MWT solar battery is placed into a strong alkaline solution to be cleaned, and the back field of the non-antireflection film area, laser damage and material passing hole interior damage are removed. In the manufacturing method of the MWT solar battery, the antireflection films which are needed in MWT solar battery production are used as masks, therefore other masks do not need to be manufactured additionally, and extra processes, equipment and materials do not need to be added. Compared with the prior art, the MWT solar battery is high in process integration degree, simple in process and beneficial to cost controlling.

Owner:YINGLI GRP

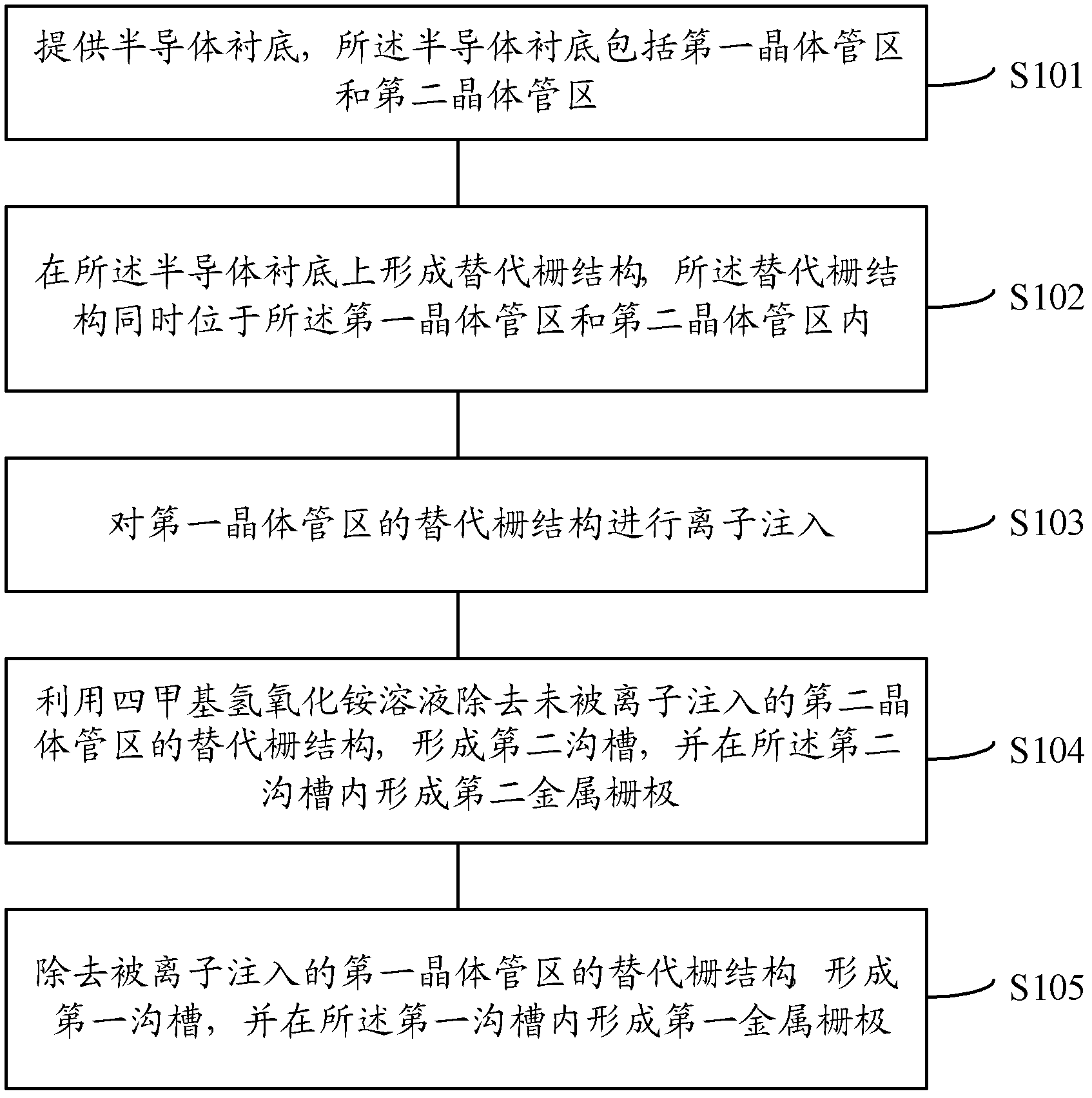

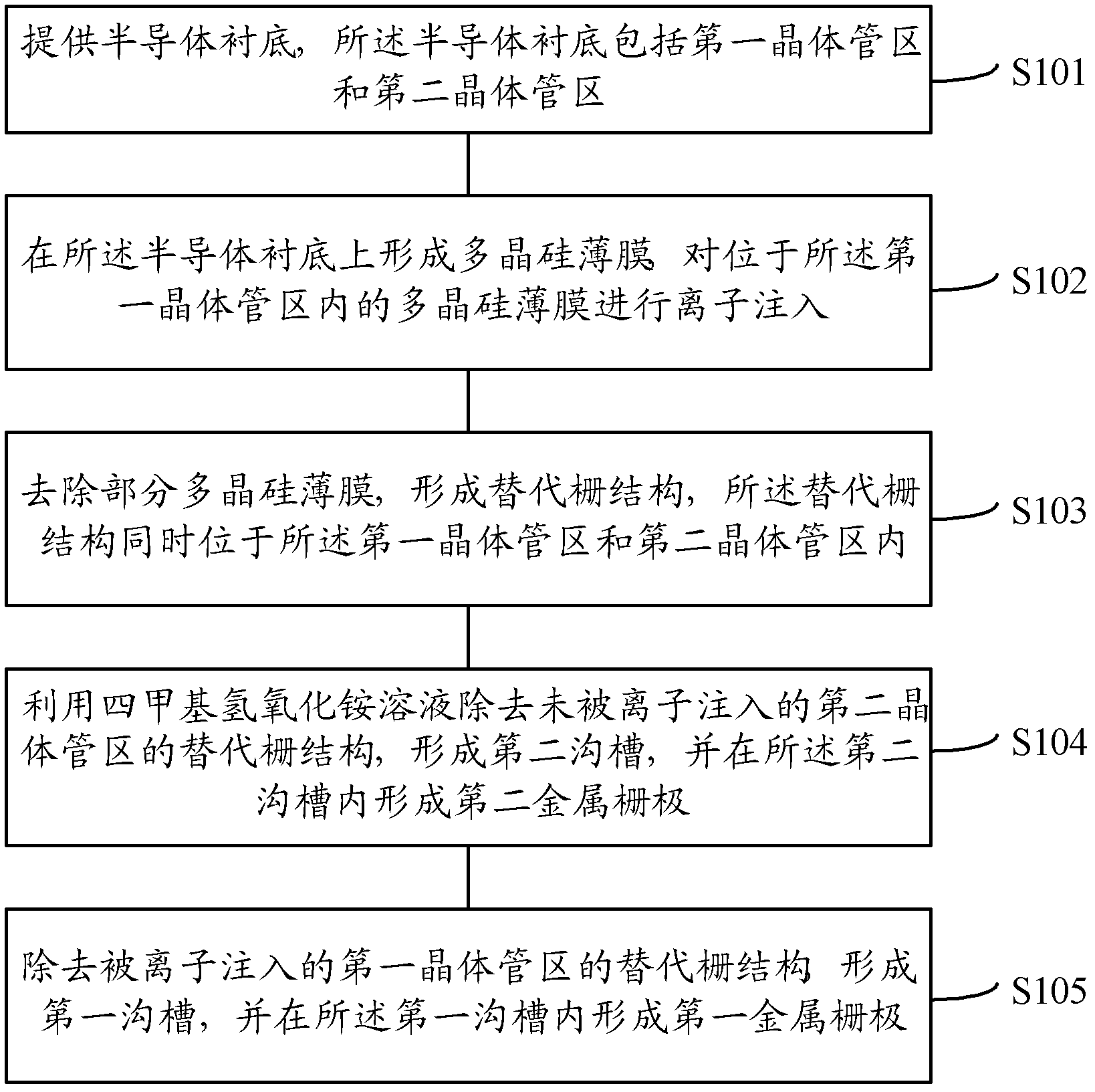

Formation method of metal grid electrode

ActiveCN103107073AReduce process stepsHigh process integrationSemiconductor/solid-state device manufacturingSemiconductor devicesTetramethylammonium hydroxideEngineering

Disclosed is a formation method of a metal grid electrode. The formation method of the metal grid electrode comprises that the formation method of the metal grid electrode is provided with a semi-conductor substrate. The semi-conductor substrate comprises a first transistor area and a second transistor area. A replacing grid electrode structure is formed on the semi-conductor substrate. The replacing grid electrode structure is arranged in the first transistor area and the second transistor area at the same time. Ion implantation is carried out in the replacing grid electrode structure of the first transistor area. Tetramethylammonium hydroxide liquor is used for eliminating the replacing grid electrode structure of the second transistor area. The ion implantation is not carried out in the second transistor area. A second groove is formed. A second metal grid electrode is formed in the second groove. The replacing grid electrode structure of the first transistor area is eliminated. The ion implantation is carried out in the first transistor area. A first groove is formed. A first metal grid electrode is formed in the first groove. Due to the fact that the replacing grid electrode structure is etched selectively by the tetramethylammonium hydroxide liquor, a perpendicular groove side wall can be achieved by taking advantage of injecting the ion, thus technological requirements can be met by the follow-up formed metal grid electrode.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Silica gel wastewater treatment method

ActiveCN110092519AAchieving zero emissionsHigh process integrationSilicaChemical industryUltrafiltrationChemistry

The invention discloses a silica gel wastewater treatment method which comprises the steps of two times of filter presses, two times of ultrafiltration, three times of nanofiltration, evaporation crystallization and the like which are interpenetrated with each other. The method has the beneficial effects the the process of the silica gel wastewater treatment method can be recyclable, zero emissioncan be realized, and water, silica gel and inorganic salts in silica gel wastewater can be recovered; in the process, except for adding of pH adjusting substances, no other medicaments are added, andno other impurities are introduced, so the the process integration level is high, and the cost is saved; the silica gel wastewater treatment method adopts an enhanced submerged ultrafiltration film to pretreat the silica gel wastewater, does not need to adjust the pH value of the silica gel wastewater in the early stage, and can achieve the purpose of pretreatment by adjusting the pH value of nanofiltration produced water.

Owner:SHANDONG JINHUI MEMBRANE TECH

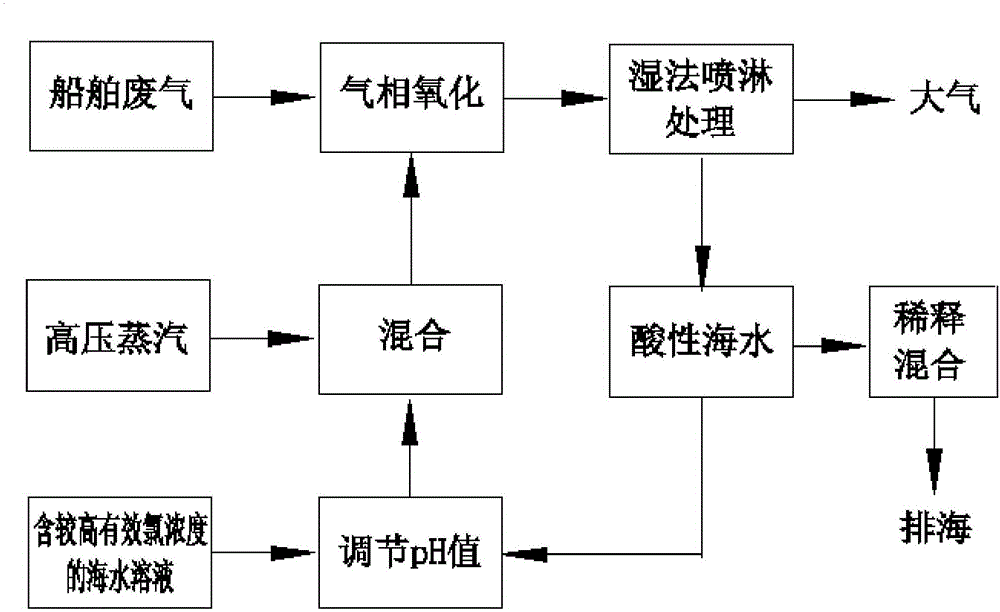

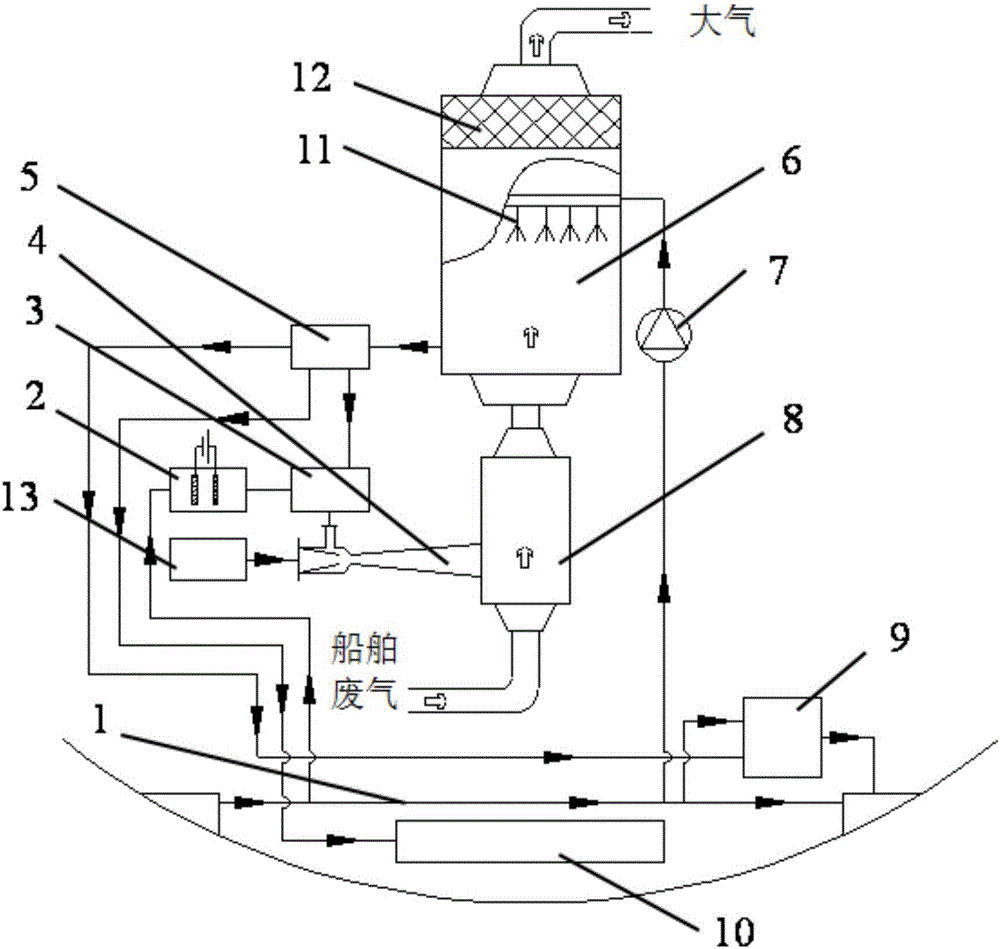

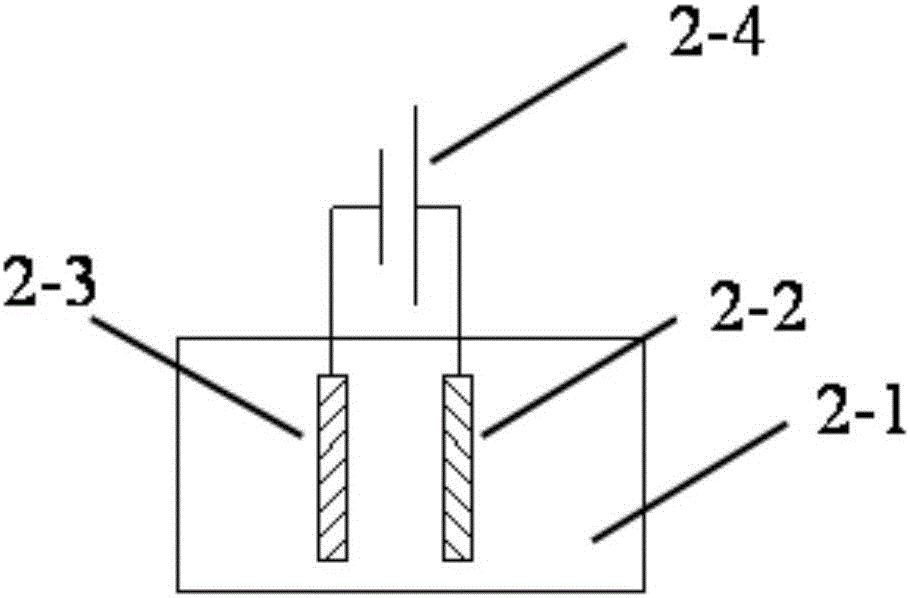

Comprehensive treatment method and device of waste gas of ship on basis of seawater electrolysis

InactiveCN105879678AImprove securityLow investment costSeawater treatmentUsing liquid separation agentParticulatesElectrolysis

The invention discloses a comprehensive treatment method of waste gas of a ship on the basis of seawater electrolysis. The comprehensive treatment method comprises the following steps: (S1) preparing a seawater solution containing higher and effective chloride concentration and mixing with acidic seawater solution; (S2) mixing high-pressure steam with the solution obtained in the step (S1) and mixing with the waste gas of the ship; (S3) carrying out wet-process spraying treatment and demisting on flue gas obtained by the step (S2), then discharging to atmosphere. The invention also discloses a comprehensive treatment device of the waste gas of the ship on the basis of seawater electrolysis. The comprehensive treatment method and device disclosed by the invention have the advantages that surplus electricity and steam resources of the ship are utilized, the potential ship-safety hazard and the additional investment cost caused by transportation and chemicals stored on the ship are reduced, the reaction time of waste gas treatment is shortened, the energy consumption such as an additional water pump needed for liquid-phase absorption is reduced, so that the operation cost of the treatment device of the waste gas of the ship is further reduced, the system economy is improved, a set of system is realized, and simultaneously, harmful components such as SOx, NOx and particulate impurities in the waste gas of the ship are removed; and the process is higher in integration level, and the device is smaller in occupied area.

Owner:DALIAN MARITIME UNIVERSITY

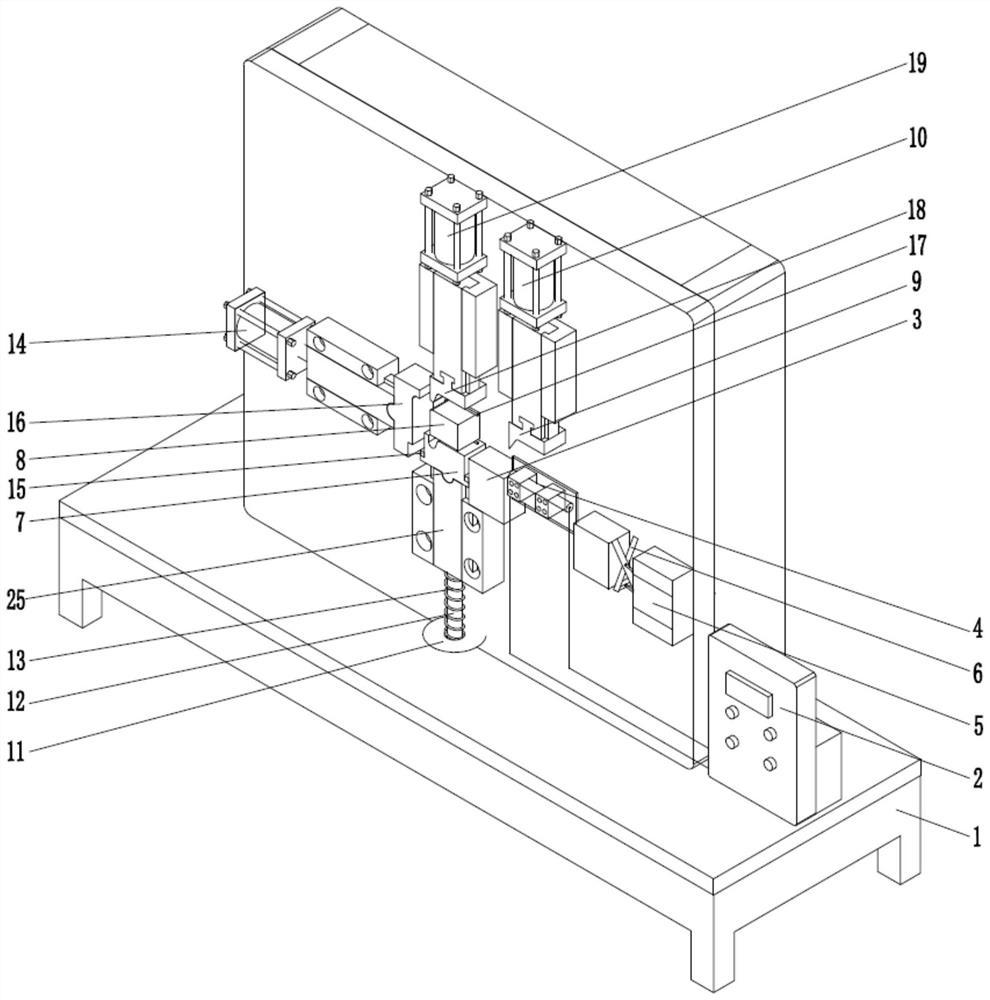

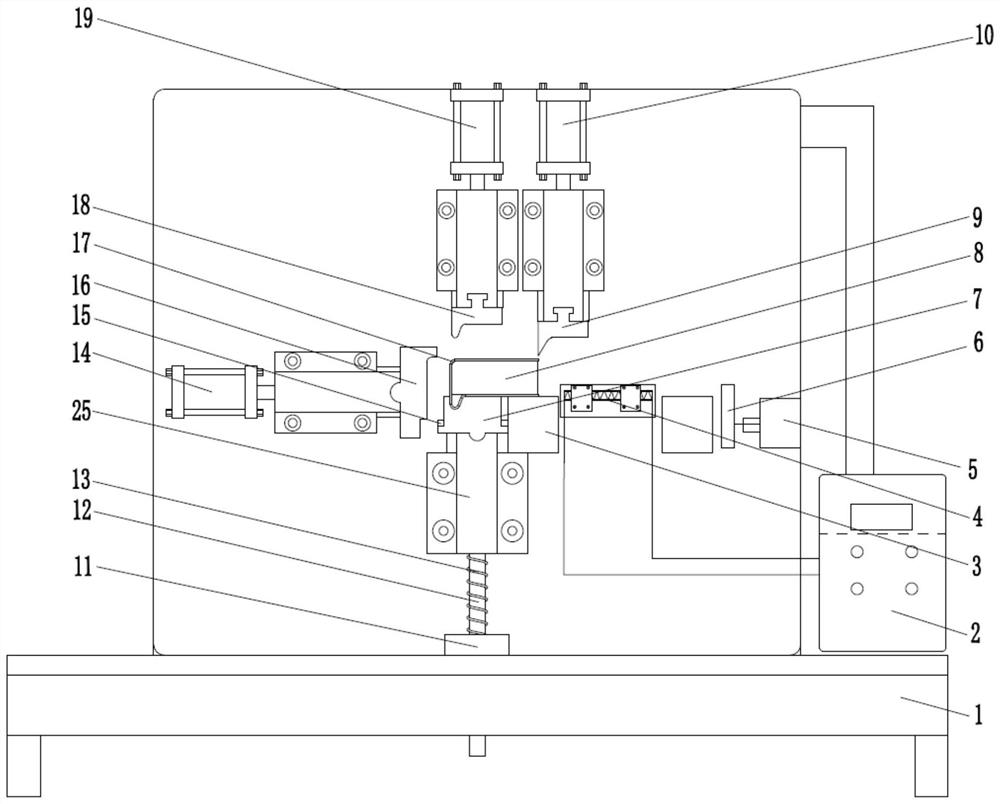

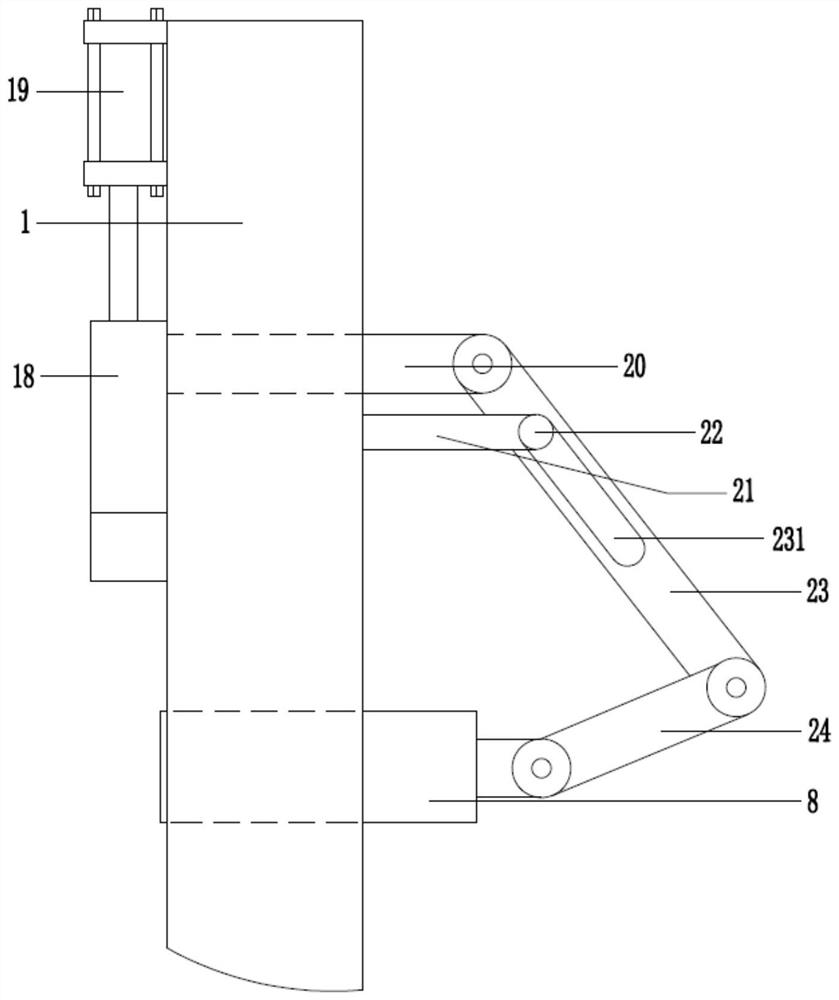

Automatic heating and bending device

PendingCN112238168ARealize one-time moldingIncrease productivityMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention discloses an automatic heating and bending device, and relates to the technical field of semiconductor part manufacturing. The device comprises a rack, a control cabinet, a feeding mechanism arranged at the feeding end of the rack, a bending assembly arranged on the rack and a heater arranged between the feeding mechanism and the bending assembly. According to the automatic heating and bending device, a connecting rod mechanism and a telescopic die core which are used for assisting in product bending forming are arranged on the back face of a stamping mechanism, and after the stamping mechanism completes stamping work and resets, the telescopic die core is automatically driven by the connecting rod mechanism to stretch out to press a workpiece to match a movable die to bend the workpiece again, therefore, one-time forming of workpiece manufacturing is achieved, production efficiency is improved, and procedure integration is high.

Owner:江苏实为半导体科技有限公司

Efficient ceramic packaging process

PendingCN111785649AAchieve preparationHigh process integrationSemiconductor/solid-state device detailsSolid-state devicesComposite materialCeramic materials

The invention relates to an efficient ceramic packaging process. The efficient ceramic packaging process comprises the following steps: coating the upper surface of a tube shell carrier with pyrolyticbond temporary bonding glue; mounting and pressing ceramic tube shells on the upper surface of the tube shell carrier in batches in an array manner through a pyrolytic bond temporary bonding adhesiveto form a ceramic tube shell array; baking the ceramic tube shell array, so that the pyrolytic bond temporary bonding glue is cured; mounting the ceramic sealing cap on the ceramic tube shell by taking the position of the ceramic tube shell as a reference to form a ceramic packaging body; performing heating at the bottom of the tube shell carrier, so that the adhesive force of the thermal decomposition bonding temporary bonding glue is reduced, and the de-bonding step of the ceramic packaging body and the tube shell carrier is completed; and sucking the ceramic packaging body by using a suction nozzle, so the ceramic packaging body is separated from the tube shell carrier. According to the invention, a single assembled ceramic tube shell is subjected to multi-tube combined arrangement, solarge-scale integrated machine type manufacturing is realized, the process integration degree is improved, the efficiency is improved, the output is increased, and the product yield and quality are improved.

Owner:WUXI ZHONGWEI GAOKE ELECTRONICS +1

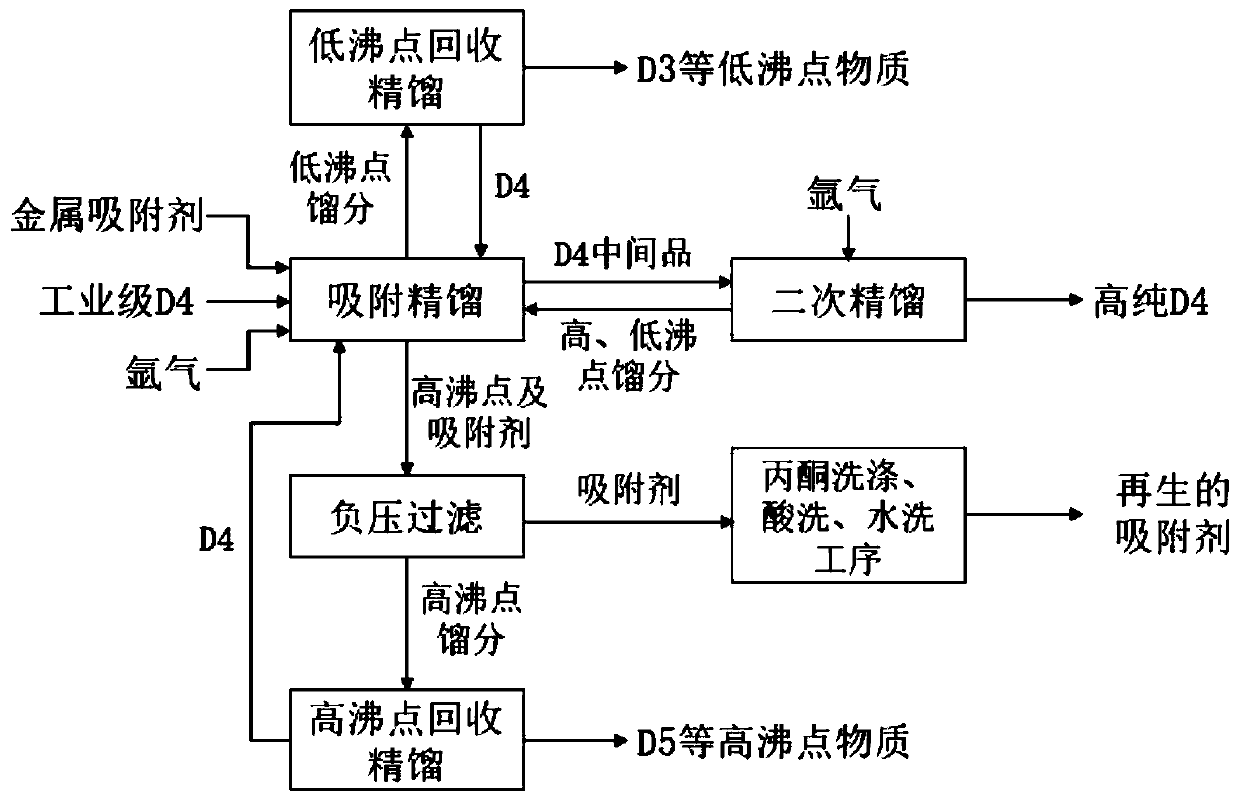

Purification process of octamethylcyclotetrasiloxane

PendingCN111574551ALow content of metal impuritiesHigh process integrationSilicon organic compoundsSiloxaneMetal impurities

The invention relates to a purification process of octamethylcyclotetrasiloxane. The purification process comprises the following steps: by using high-purity argon as a carrier gas, removing metal impurities in octamethylcyclotetrasiloxane by an adsorption reaction in a slight boiling state; carrying out rectification purification, separating octamethylcyclotetrasiloxane from the adsorbent, and removing organic impurities, water and oxygen to obtain an octamethylcyclotetrasiloxane intermediate product; and conducting secondary rectification to further purify an octamethylcyclotetrasiloxane intermediate product so as to obtain a pure octamethylcyclotetrasiloxane product with purity of greater than 99.999%. The pure octamethylcyclotetrasiloxane product meets the cladding deposition requirement of an optical fiber preform.

Owner:GRINM GUOJINGHUI NEW MATERIALS CO LTD

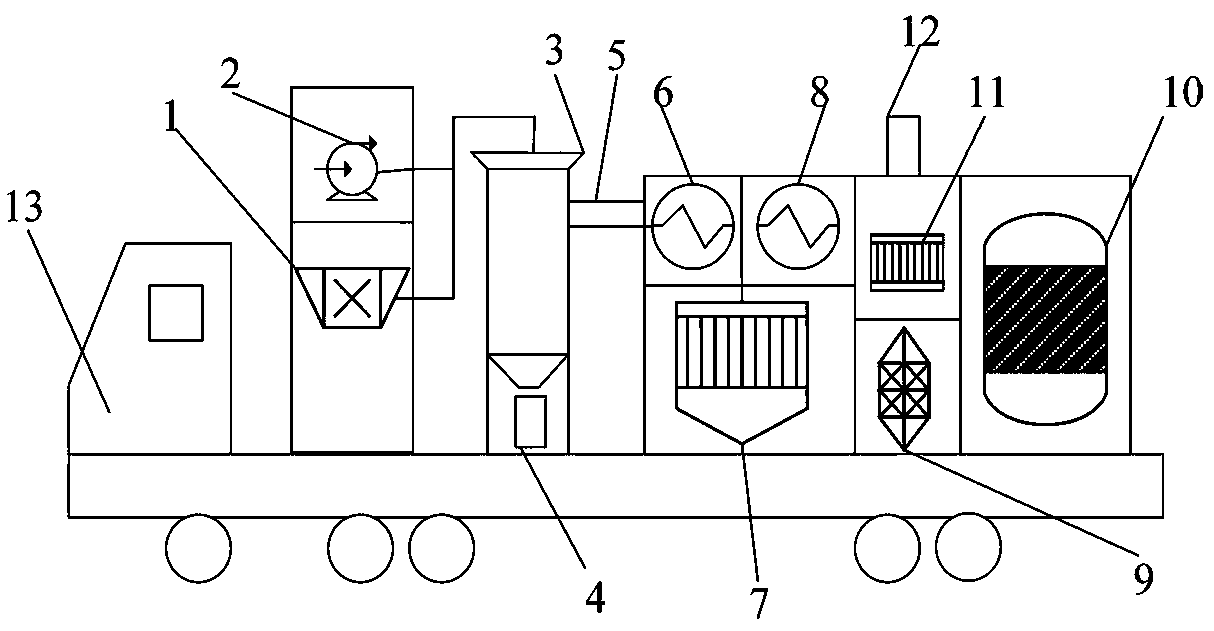

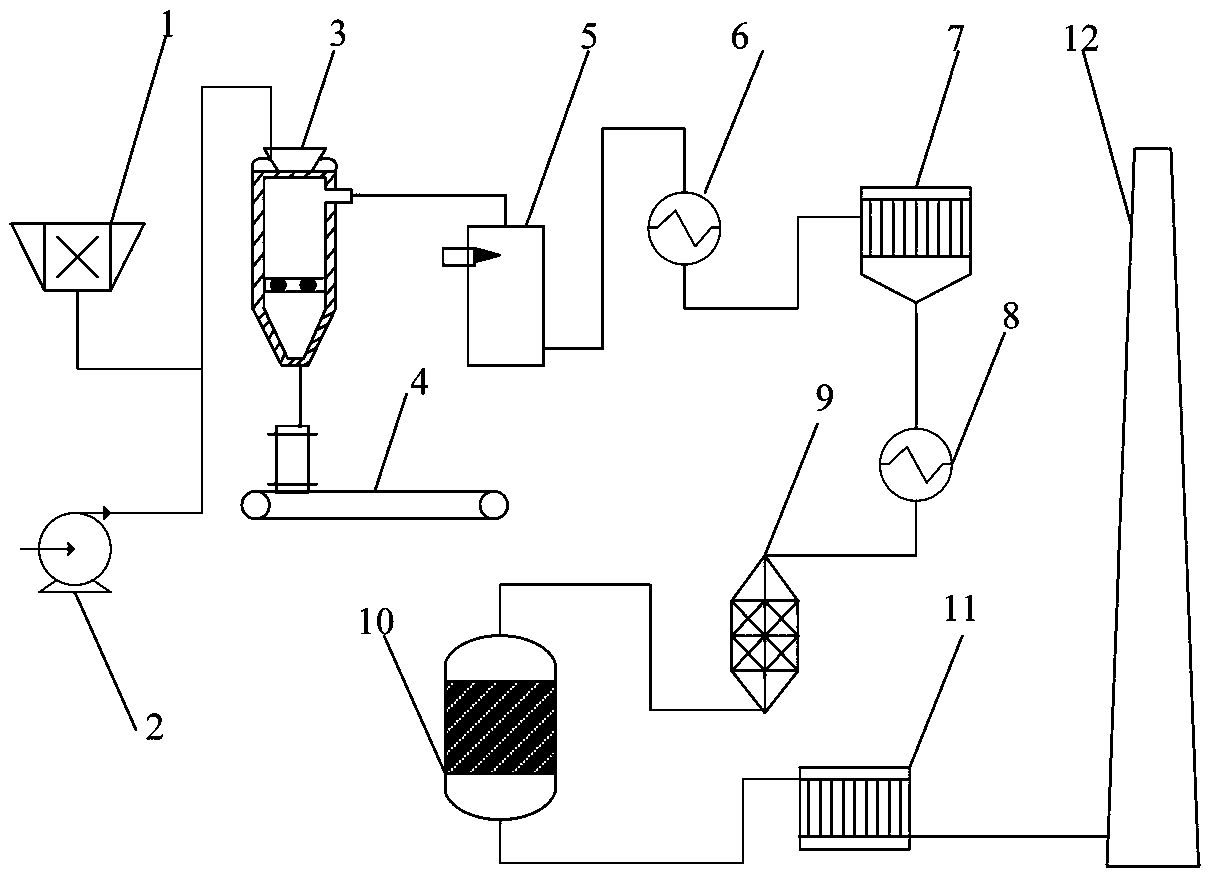

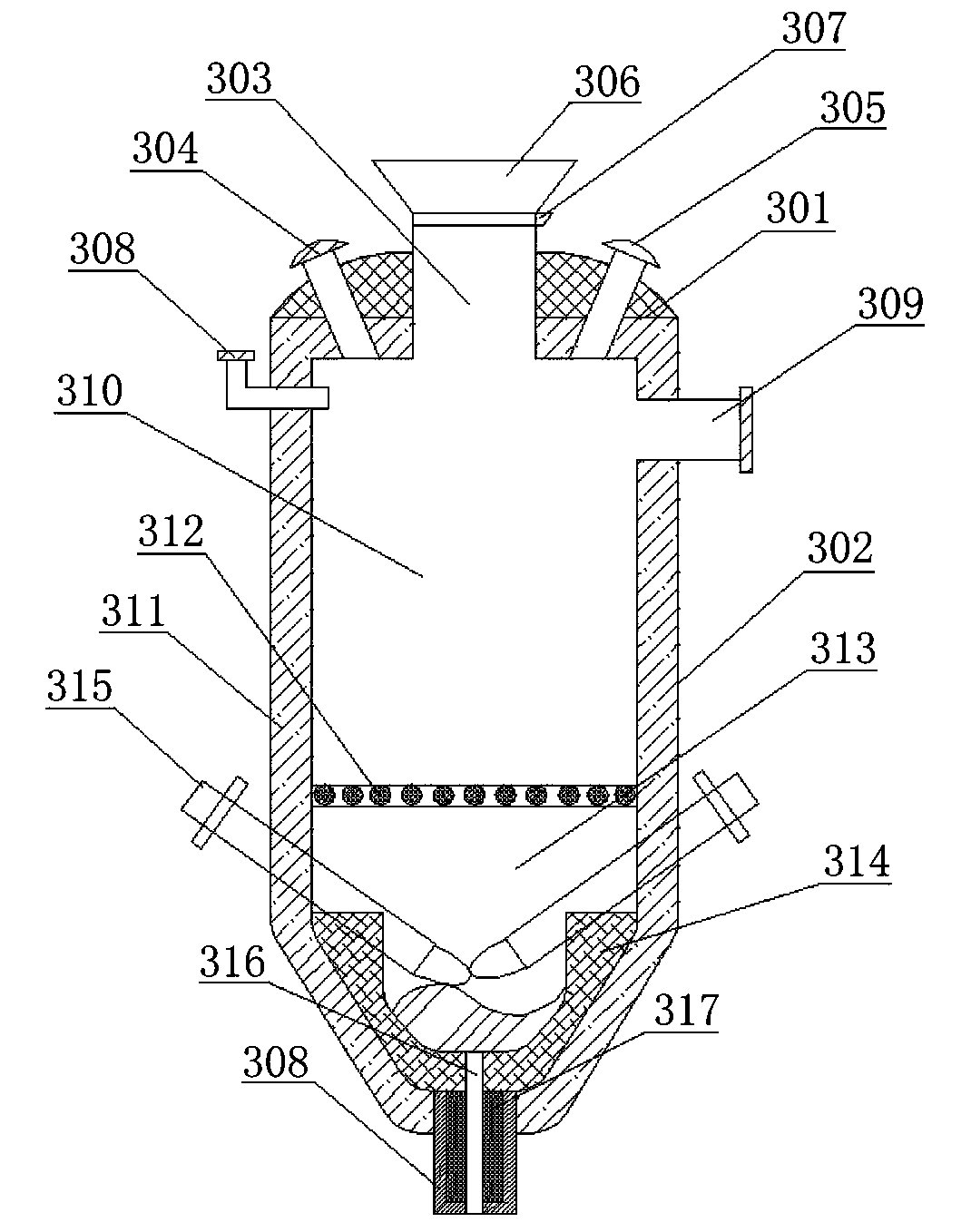

Movable minitype medium-low radioactive waste gasification and melting treatment system and method thereof

PendingCN110186052AIncrease energy densityReduce processing storage spaceIncinerator apparatusActivated carbonVolume reduction

The invention discloses a movable minitype medium-low radioactive waste gasification and melting treatment system and method thereof. The movable minitype medium-low radioactive waste gasification andmelting treatment system comprises a crusher, a pneumatic diaphragm pump, a plasma gasification and melting furnace, a melting vitreous body receiver, a burning chamber, a primary direct heat exchanger, a ceramic filter, a secondary direct heat exchange, an activated carbon adsorption tower, a deacidification washing tower, an efficient air filter, a chimney and mobile equipment. The waste is subjected to pretreatment and is conveyed into the plasma gasification and melting furnace, and then gasification reaction is carried out in an in-furnace gasification area so as to produce synthetic gas; the synthetic gas is introduced into the burning chamber, is fully burned and decomposed, and then is fed into a flue gas purification treatment system; ash residues enter into a melting area and are subjected to vitrification melting treatment so that radioactive nuclide is fixed in a melting vitreous body, and the vitreous body is cooled, is barreled and stored by an automatic receiving systemand is subjected to landfilling in a near surface area of a medium-low radioactive waste landfill. The movable minitype medium-low radioactive waste gasification and melting treatment system disclosed by the invention has the advantages of being good in volume reduction effect, high in safety and reliability, high in nuclide stability and high in process integration of the system.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD

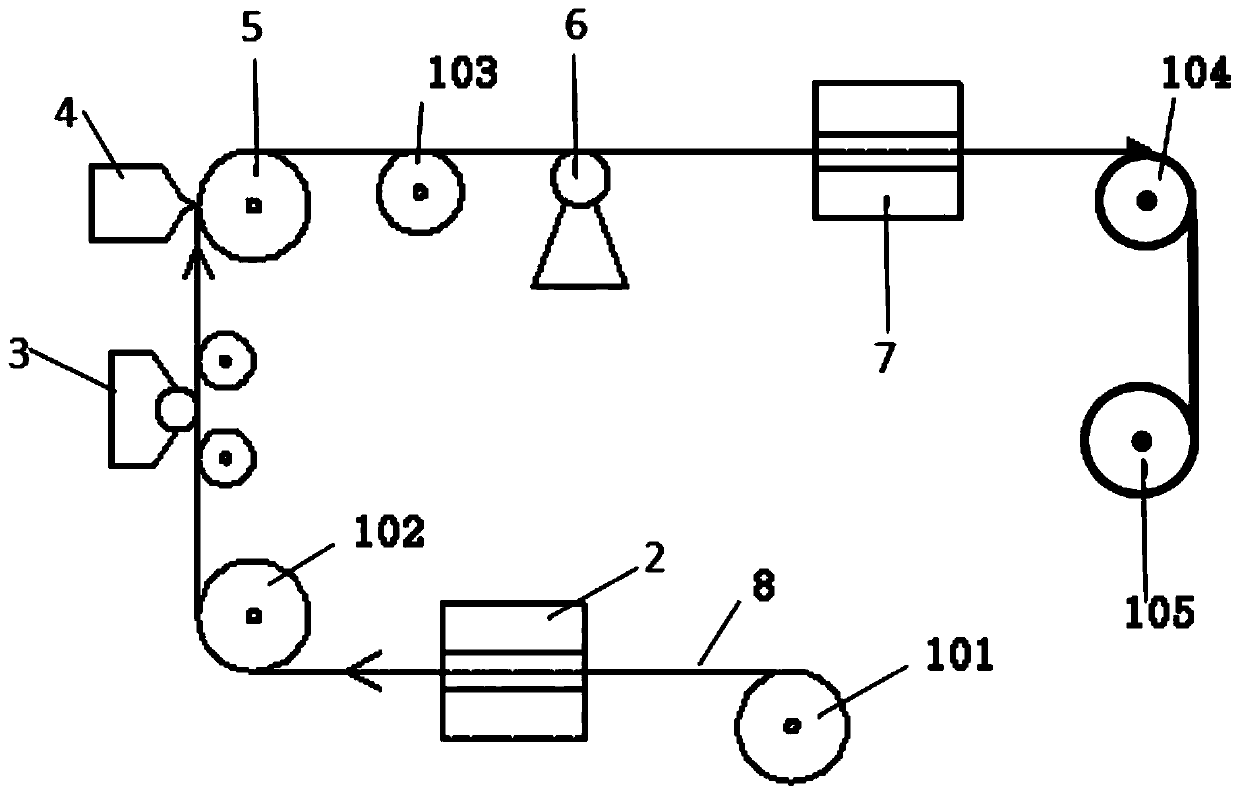

Diaphragm coating device and diaphragm coating method

InactiveCN111545397AReduce energy consumptionIncrease productivityPretreated surfacesSecondary cellsWire rodExtrusion coating

The invention provides a diaphragm coating device and a diaphragm coating method. The diaphragm coating device comprises a first coating device, a second coating device and a third coating device which are sequentially connected, wherein at least two of the first coating device, the second coating device and the third coating device are different in type; and the first coating device, the second coating device and the third coating device are independently a micro-gravure coating device, an extrusion coating device or a wire rod coating device. The method comprises the following steps of: enabling a base film to sequentially pass through the first coating device, the second coating device and the third coating device, and starting the corresponding coating devices to coat according to needs, thereby obtaining a diaphragm, wherein the number of coating layers is one, two or three. According to the device provided by the invention, three different coating modes can be integrated in the same equipment, so that one or more coatings can be simultaneously coated, the production efficiency of the coating equipment is improved, and the energy consumption of the equipment is reduced.

Owner:DONGGUAN TAFEL NEW ENERGY TECH CO LTD +2

Special-shaped titanium alloy capillary tube processing method

The invention discloses a special-shaped titanium alloy capillary tube processing method which comprises the following steps: coiling a titanium alloy capillary tube which is drawn to be a certain specifications on a reel; rotating the reel to release the capillary tube coiled on the reel; after the capillary tube is treated through a heating mechanism, feeding the capillary tube into a mold with a circular pore, reducing the diameter, and feeding the capillary tube into a cooling device; performing cold-drawing processing continuously by using molds of different pore shapes; selecting molds with different pore shape series according to the shape of a finished product special-shaped material to draw special-shaped materials with cross sections of a certain shapes. A product produced by using the method is high in quality stability, high in finished product rate, good in quality, excellent in mechanical property and elasticity, and good in subsequent processing property, and the processing method can be widely applied to the field of production and processing of intravascular stents and catheters for minimally invasive surgery.

Owner:QINGDAO MATE RUIOU NEW MATERIAL TECH CO LTD

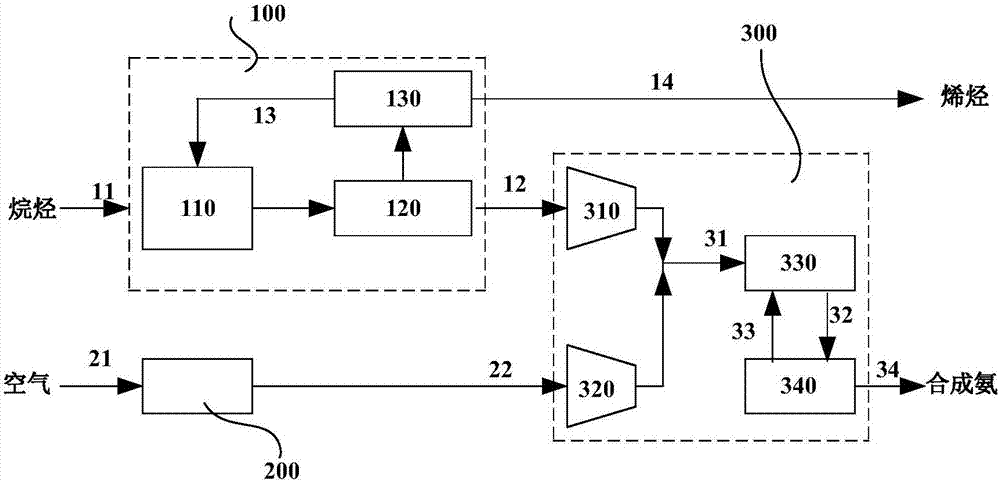

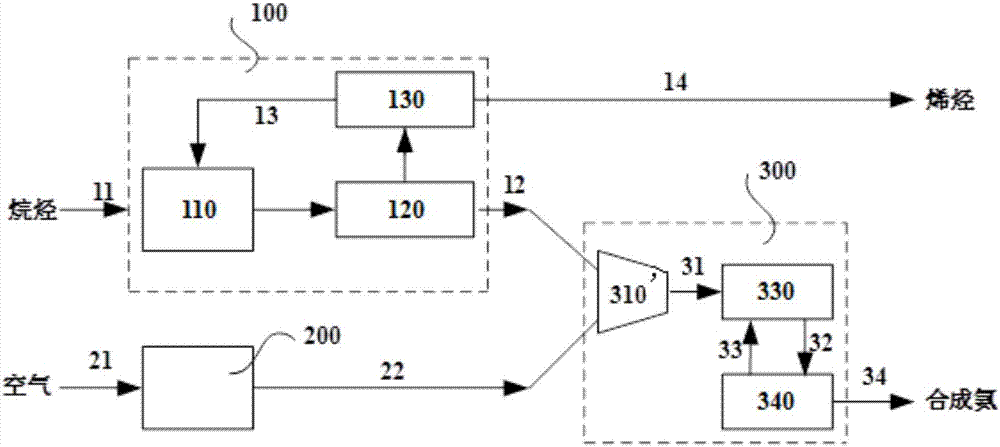

System and method for co-producing low carbon olefin and ammonia by low carbon alkane

InactiveCN107253895AShort processIncrease valueHydrocarbonsAmmonia preparation/separationAlkaneSocial benefits

The invention relates to a system and method for co-producing low carbon olefin and ammonia by low carbon alkane. The system comprises an alkane dehydrogenation device (100), an air separation unit (200) and an ammonia synthesis device (300). The alkane dehydrogenation device (100) is connected with the ammonia synthesis device (300) by a hydrogen conveying pipeline (12). The air separation unit (200) is connected with the ammonia synthesis device (300) by a nitrogen conveying pipeline (22). The low carbon alkane is reacted in the alkane dehydrogenation device so as to obtain the corresponding low carbon olefin and hydrogen, a low carbon olefin product with high purity and the hydrogen are obtained by the separation, the hydrogen is conveyed into the ammonia synthesis device, and reacts with the high-purity nitrogen obtained by the air separation unit, so the ammonia is generated. Compared with the current olefin uni-yield alkane dehydrogenation technology or coal-based synthesis ammonia technology, the method is capable of adequately using the byproduct hydrogen in the alkane dehydrogenation process to generate the ammonia, and has the advantages of short technological process, less waste discharge, and high economic and social benefit.

Owner:SHANGHAI JIAO TONG UNIV

A kind of silica gel wastewater treatment method

ActiveCN110092519BAchieving zero emissionsHigh process integrationSilicaChemical industryInorganic saltsUltrafiltration

Owner:SHANDONG JINHUI MEMBRANE TECH

Light-erasable embedded memory device and method of manufacturing the same

ActiveUS20170316830A1High process integrationFew stepsSemiconductor/solid-state device detailsSolid-state devicesEngineeringDielectric layer

Owner:UNITED MICROELECTRONICS CORP

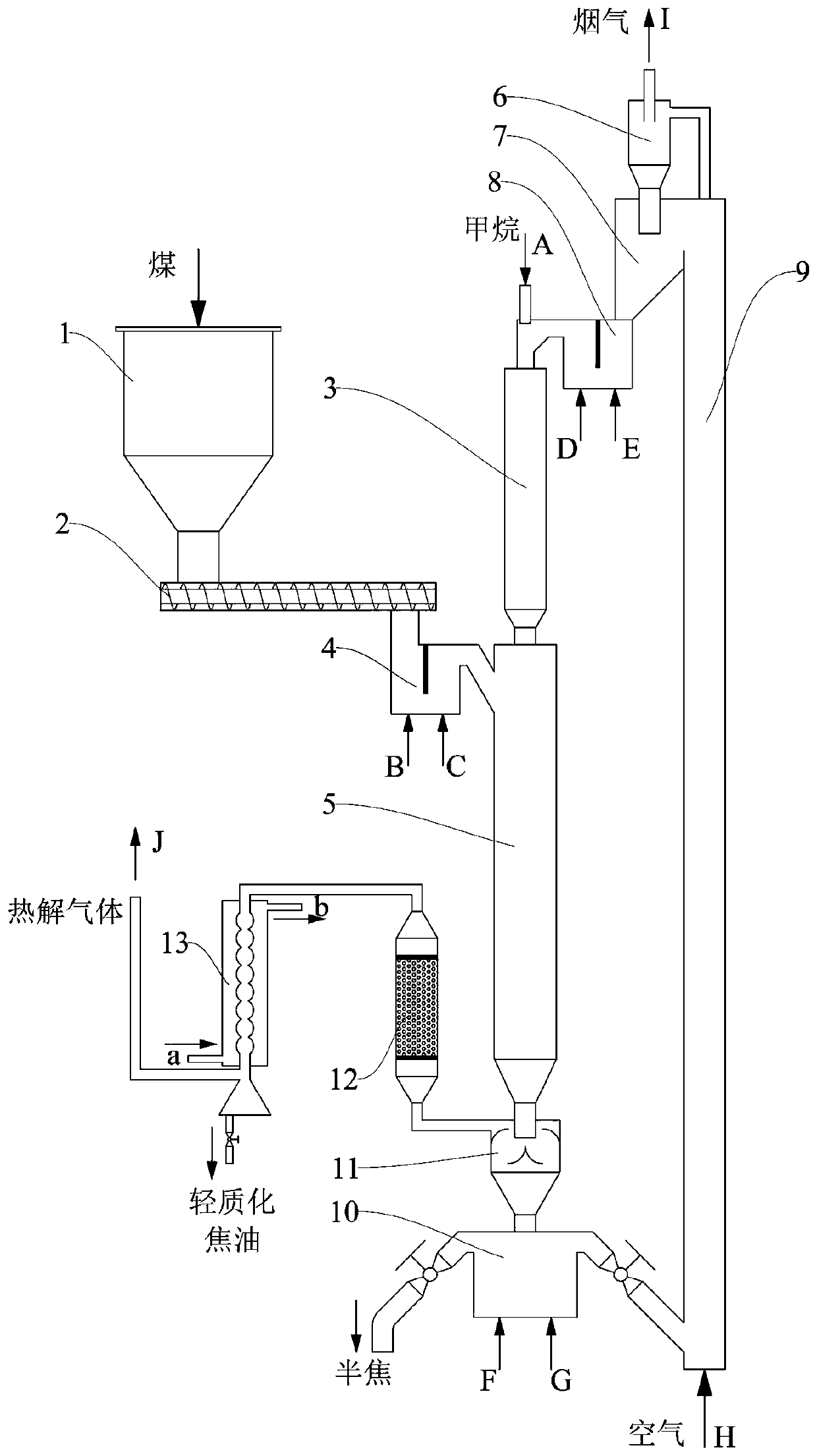

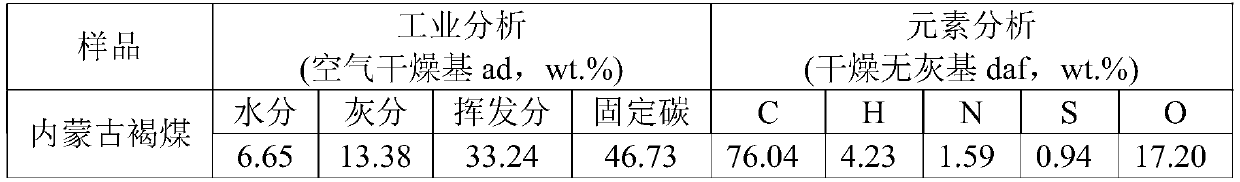

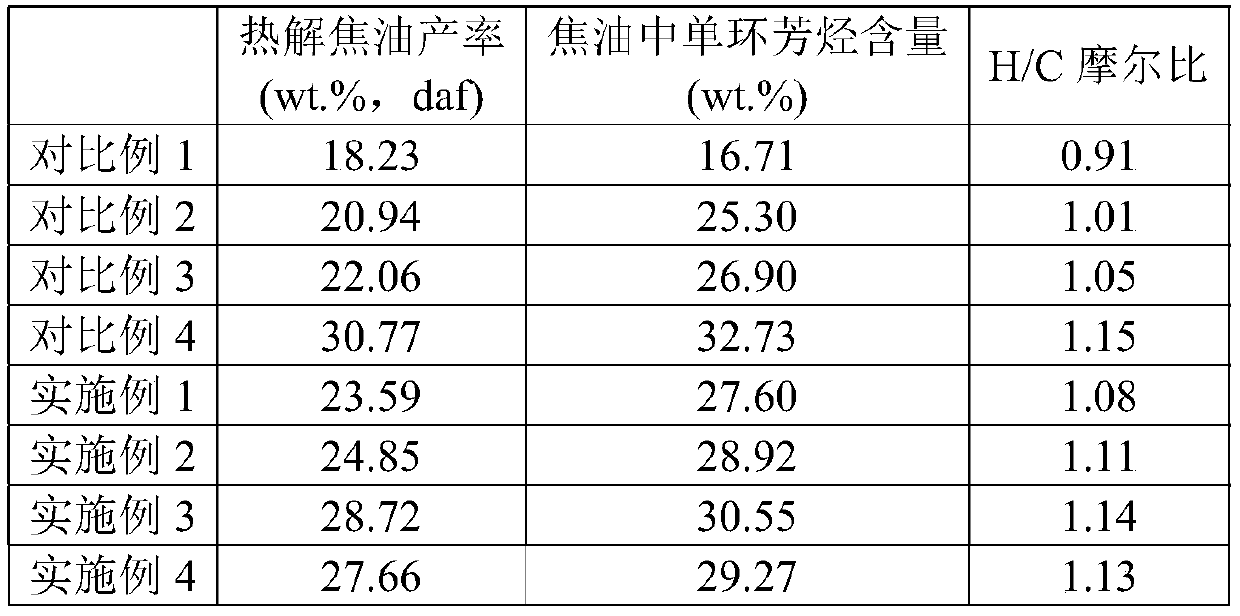

A method for producing light tar by catalytic co-refining of low-rank coal and methane

ActiveCN108219816BHigh mass and heat transfer efficiencyHigh process integrationLiquid hydrocarbon mixture productionChemical industryPtru catalyst

The invention belongs to the fields of energy and chemical industry, particularly provides a method for producing light tar by catalyzing and corefining low-rank coal and methane, and mainly solves the technical problem that the quality of pyrolytic tar of low-rank coal is increased is solved so as to increase the content of light aromatic hydrocarbon with important application values in tar. A down reactor, which is a riser coupling reactor, is adopted as a main body reaction unit, and the main body reaction unit is high in heat and mass transfer efficiency, simple in technological process, high in integration level and continuous and reliable in operation; high-temperature semicoke is taken as a catalyst, and methane is cracked into hydrogen, so that hydrogenation pyrolysis of coal is realized, the yield of tar and the content of light aromatic hydrocarbon inside tar are improved, and the cost of the catalyst and the hydrogen source is obviously reduced; moreover, the high-temperature semicoke is taken as a solid heat carrier, so that the heat efficiency of the process is greatly improved; moreover, an new approach for efficient clean utilization is developed for methane-rich rawmaterial gas such as traditional fossil energy coal and natural gas.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

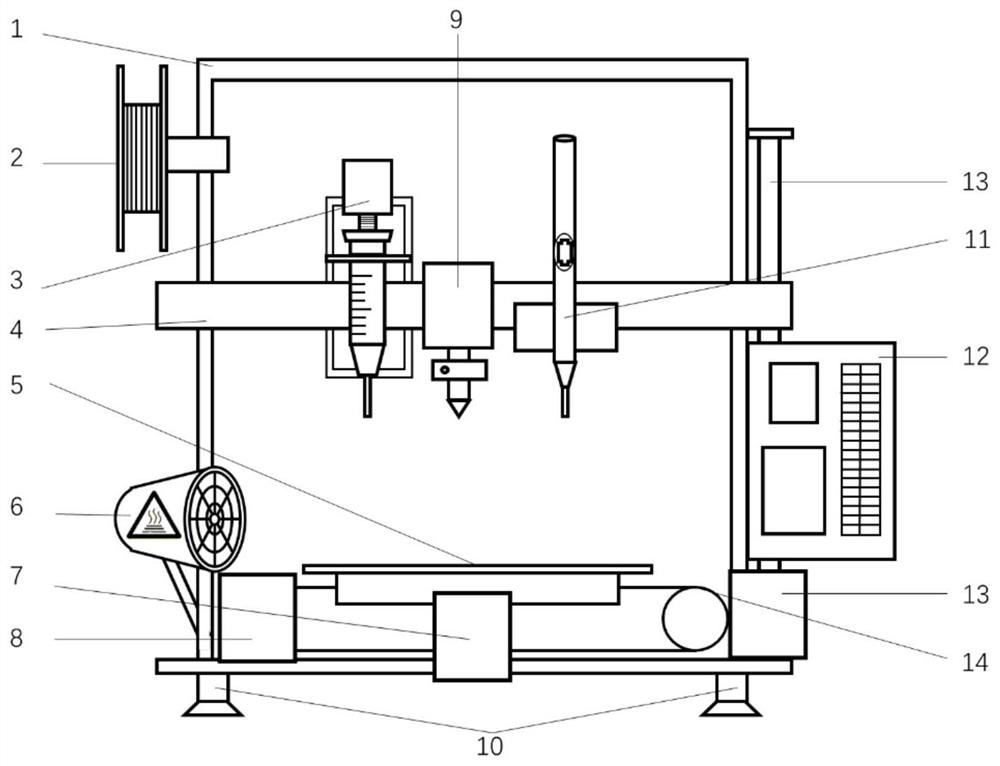

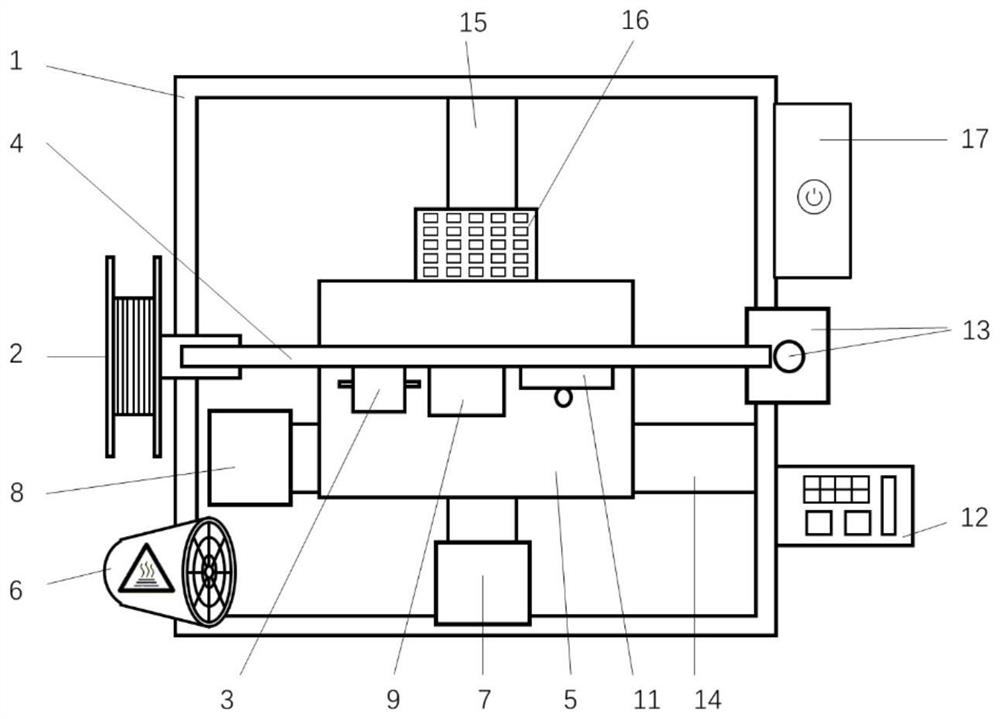

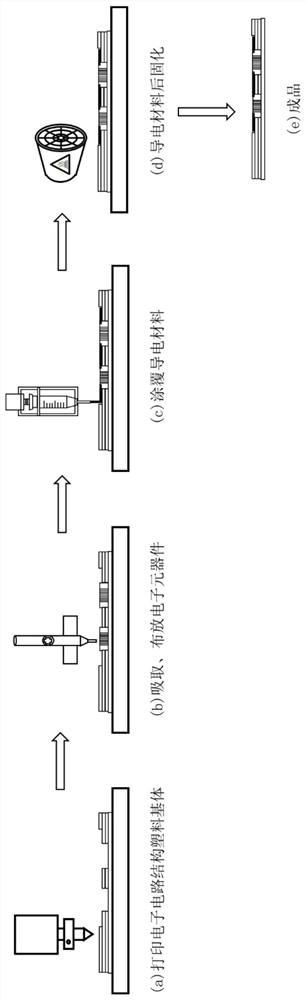

Multifunctional 3D printer

InactiveCN111823575AHigh process integrationRealize integrated manufacturingPrinted circuit assemblingAdditive manufacturing apparatusComputer printingHemt circuits

The invention discloses a multifunctional 3D printer. The printer includes a rack, an X-axis straight motion mechanism, a Y-axis straight motion mechanism, and a Z-axis straight motion mechanism are fixed on the rack, the Y-axis straight motion mechanism is connected with the X-axis straight motion mechanism in a transmission mode, a printing platform is fixed on the Y-axis straight motion mechanism, the Z-axis straight motion mechanism is connected with a horizontal shaft of the rack in a transmission mode, a melting plastic extrusion mechanism, a conducting material coating mechanism, and anelectronic component absorption-release mechanism are fixed on the horizontal shaft, and a conducting material pre-curing module is mounted on the lower part of the rack. According to the printer, all modules are integrated on one printer, the technology integration level is high, and integrated manufacturing can be achieved; electronic components can be embedded directly, the manual fabricationcan be saved, the labor cost can be lowered, and the efficiency can be improved; the design is simple, and the modification is simple; hybrid 3D printing can be used to manufacture an electronic product with a complex structure, the high-degree customization of the product can be achieved, and the product can be manufactured quickly according to the requirements; and circuits are implanted in a substrate of the electronic product, and the reliability and safety can be improved.

Owner:SOUTHEAST UNIV

Formation method of metal grid electrode

ActiveCN103107075AReduce process stepsHigh process integrationSemiconductor/solid-state device manufacturingSemiconductor devicesTetramethylammonium hydroxideIon implantation

Disclosed is a formation method of a metal grid electrode. The formation method of the metal grid electrode comprises that a semi-conductor substrate is provided. The semi-conductor substrate comprises a first transistor area and a second transistor area. A polycrystalline silicon thin film is formed on the semi-conductor substrate. Ion implantation is carried out on a polycrystalline silicon thin film in the first transistor area. Part of the polycrystalline silicon thin film is eliminated so that a replacing grid electrode structure is formed. The replacing grid electrode structure is arranged in the first transistor area and the second transistor area at the same time. Tetramethylammonium hydroxide liquor is used for eliminating the replacing grid electrode structure of the second transistor area. The ion implantation is not carried out in the second transistor area. A second groove is formed. A second metal grid electrode is formed in the second groove. The replacing grid electrode structure of the first transistor area is eliminated. The ion implantation is carried out in the first transistor area. A first groove is formed. A first metal grid electrode is formed in the first groove. Due to the fact that the replacing grid electrode structure is etched selectively by the tetramethylammonium hydroxide liquor, a perpendicular groove side wall can be achieved by taking advantage of the ion implantation, thus technological requirements can be met by the follow-up formed metal grid electrode.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Production process of spherical calcium chloride dihydrate

ActiveCN111908495AReduce chippingAvoid cakingCalcium/strontium/barium chloridesPhysical chemistryProcess engineering

The invention provides a spherical calcium chloride dihydrate production process. The production process comprises the following steps: 1) preparing seed crystals; 2) atomizing feed liquid; 3) performing rotary granulation; 4) performing fluidized drying; 5) screening and collecting. The problems that in the prior art, in a production process, crystals are prone to breakage, the yield is low, caking is prone to occurring in the production process, consequently, operation is unstable, and long-time continuous production cannot be achieved are effectively solved. According to the process, a fluidization air distribution plate is arranged in a rotary granulation device, granulation and drying processes are completed in the same equipment, particle fragmentation is effectively reduced, meanwhile, the drying and granulation processes are separately adjusted, caking is avoided, long-time continuous production can be guaranteed, the whole process is high in integration degree, and the production efficiency is greatly improved.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

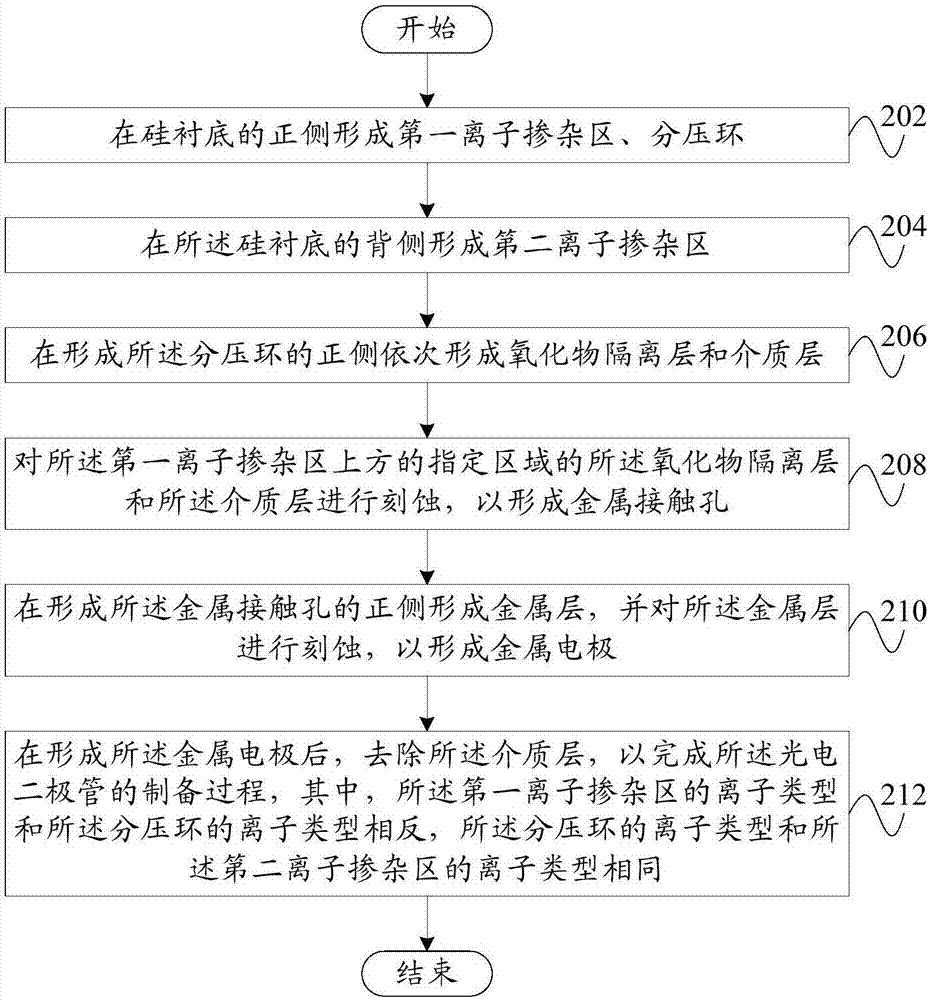

Photodiode preparation method and photodiode

The invention provides a photodiode preparation method and a photodiode. The preparation method comprises steps of forming a first ion doping region and a voltage dividing ring on the positive side of a silicon substrate; forming a second ion doping region at the back side of the silicon substrate; forming an oxide isolation layer and a dielectric layer on the positive side of the voltage dividing ring; etching the oxide isolation layer and the dielectric layer in a designated area above the first ion doping region to form a metal contact hole; forming a metal layer on the positive side of the metal contact hole and etching the metal layer to form a metal electrode; and after forming the metal electrode, removing the dielectric layer to complete the preparation process of the photodiode. With the technical scheme of the invention, the metal etching process reduces the pollution and ion damage to the oxide isolation layer, and the device reliability of the photodiode is improved.

Owner:FOUNDER MICROELECTRONICS INT

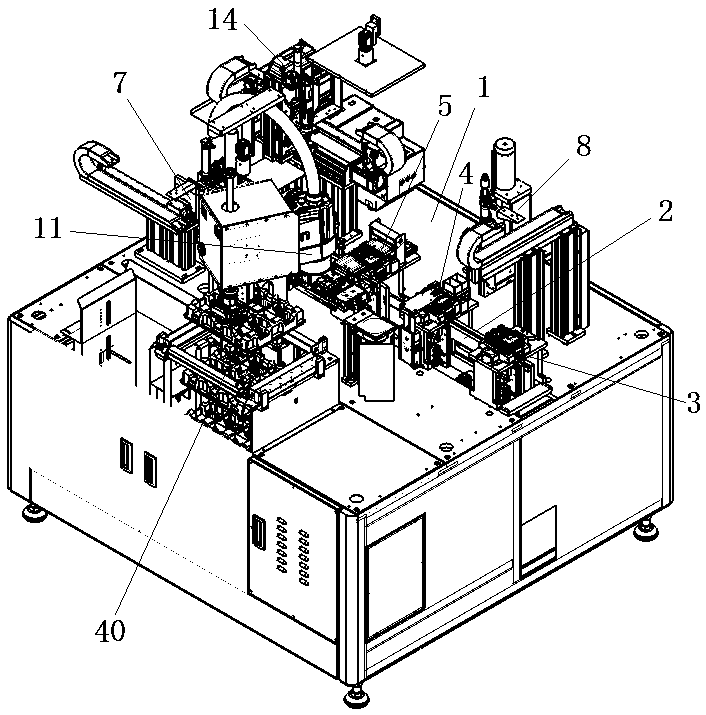

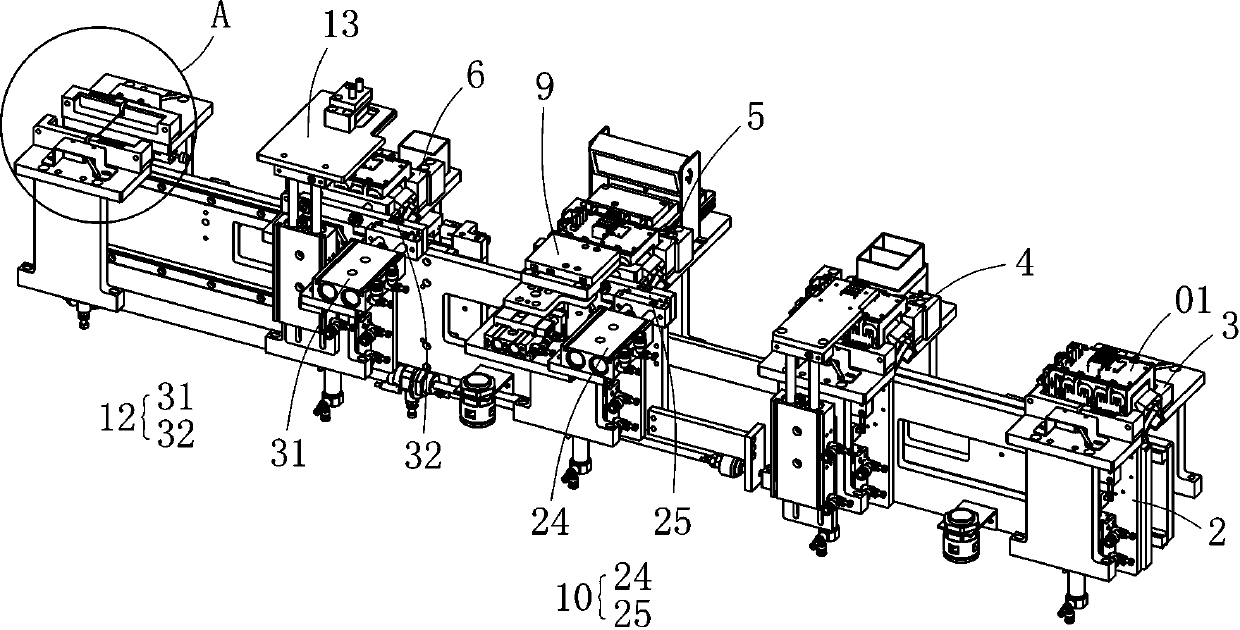

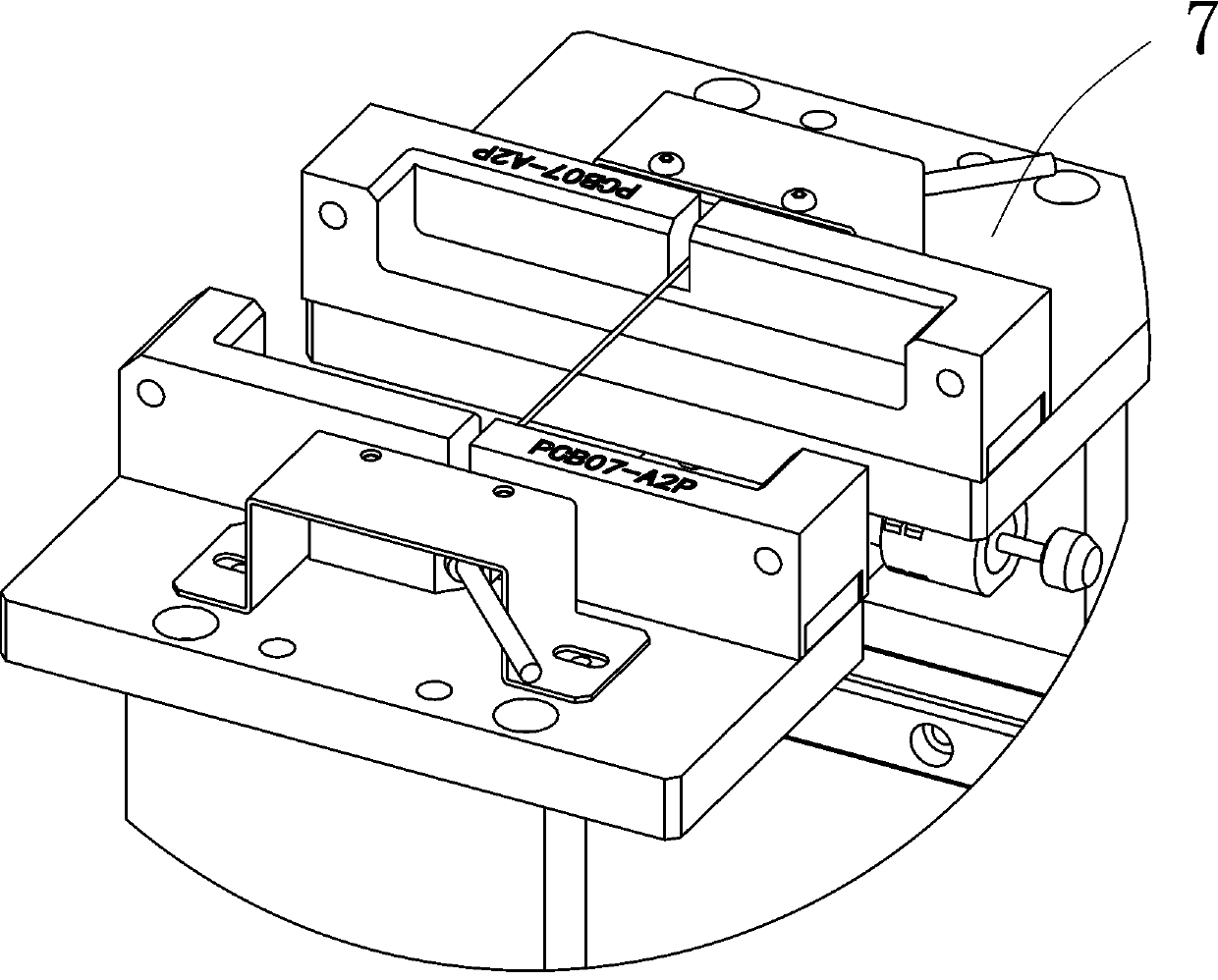

Automatic mounting equipment for small battery pack PCB

PendingCN110740608AHigh degree of automationIncrease productivityMounting boards securingCell component detailsProduction lineBattery cell

The invention relates to automatic mounting equipment for a small battery pack PCB. The automatic mounting equipment includes a frame body, a slideway, a feeding jig, a dispensing station jig, a nickel sheet station jig, a PCB station jig and a screw locking station jig, wherein the slideway is connected with the frame body in a sliding manner and is used for conveying a semi-finished battery pack, and the feeding jig, the dispensing station jig, the nickel sheet station jig, the PCB station jig and the screw locking station jig are sequentially arranged on the slideway and are used for clamping the semi-finished battery pack; a two-axis dispensing mechanism used for performing adhesive dispensing on the semi-finished battery pack is arranged beside the dispensing station jig; a nickel sheet positioning mechanism and a battery pack positioning mechanism I which are used for carrying out nickel sheet alignment and installation on the semi-finished battery pack are arranged beside the nickel sheet station jig; a four-axis mechanical arm, a battery pack positioning mechanism II and a pressing mechanism which are used for carrying out PCB alignment and installation on the semi-finishedbattery pack are arranged beside the PCB station jig; and a three-axis screw locking mechanism used for carrying out screw driving and locking on the semi-finished battery pack is arranged beside thescrew locking station jig. With the automatic mounting equipment for the small battery pack PCB adopted, labor cost can be decreased, the productivity of a production line can be improved, and product quality can be improved.

Owner:FORYOU MULTIMEDIA ELECTRONICS

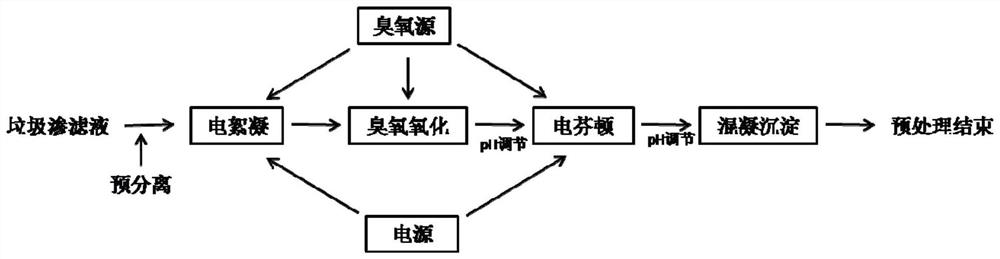

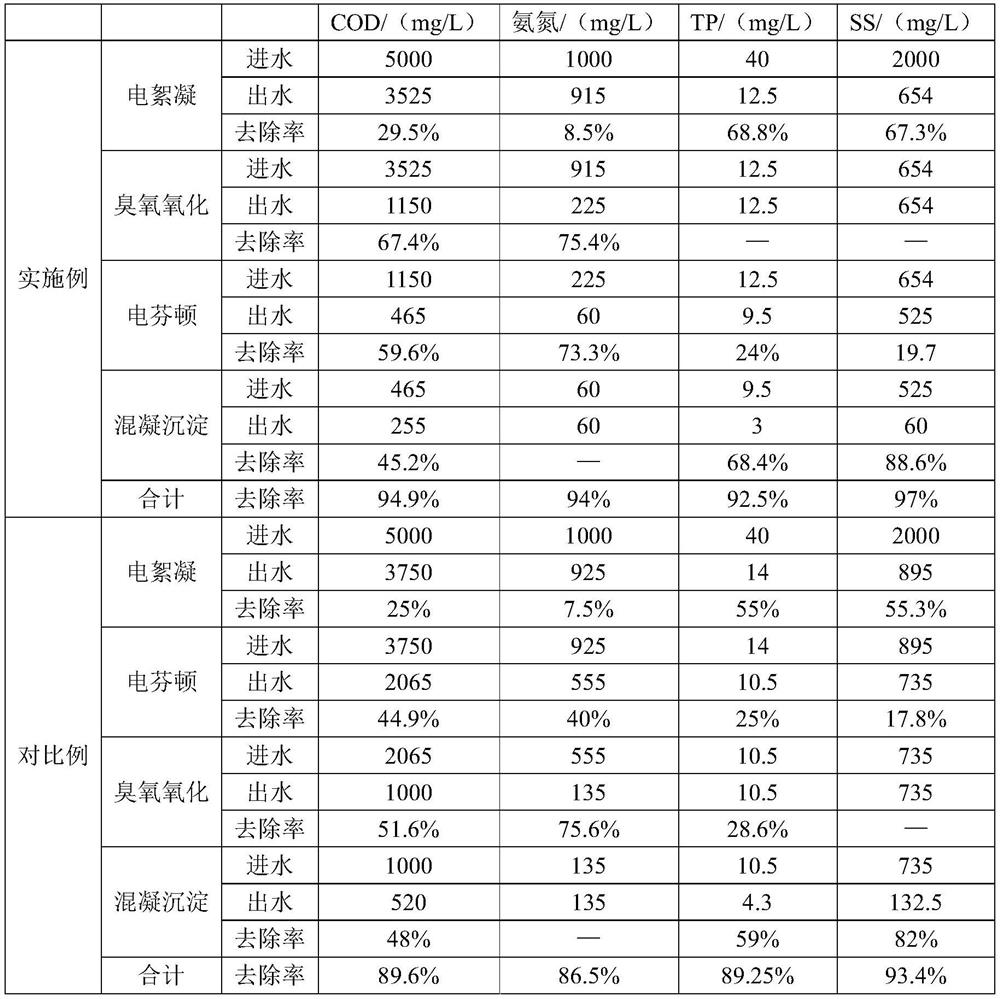

Pretreatment process of landfill leachate

PendingCN114524536AImprove biodegradabilityImprove conductivityWater treatment parameter controlWater treatment compoundsAmmoniacal nitrogenChemical oxygen demand

The invention discloses a landfill leachate pretreatment process which adopts a combined process of electric flocculation, electro-Fenton, ozone oxidation and coagulating sedimentation to pretreat landfill leachate, so that pollutants such as suspended solids, COD (Chemical Oxygen Demand), ammonia nitrogen, total phosphorus, turbidity and the like in wastewater can be synchronously removed, and the biodegradability of the wastewater can be improved; and the subsequent processing load is reduced.

Owner:长沙工研院环保有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com