Diaphragm coating device and diaphragm coating method

A technology for coating devices and diaphragms, which is applied to devices, coatings, and electrical components that apply liquid to the surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

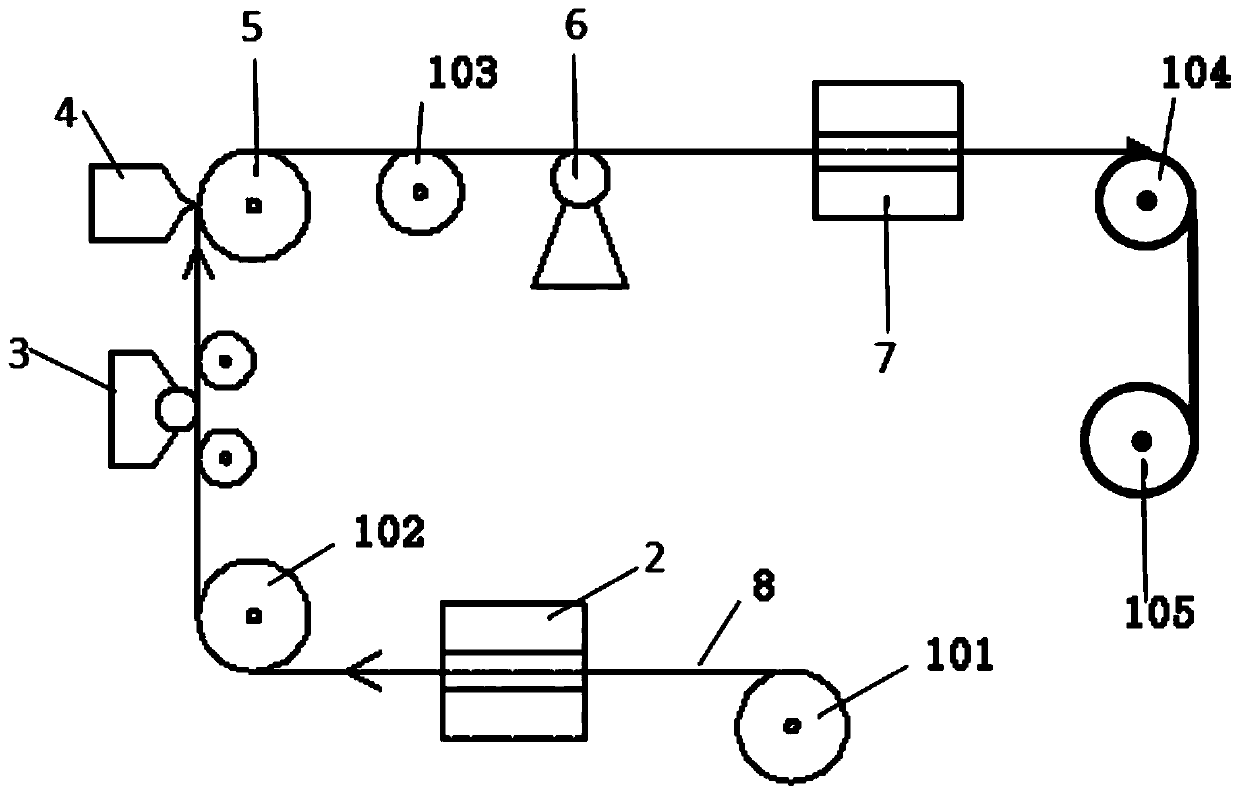

[0056] This embodiment provides a diaphragm coating device, the diaphragm coating device such as figure 1 As shown, it includes a preheating device 2, a first coating device 3, a second coating device 4 (the second coating device 4 also has a back roller 5), a third coating device 6 and a post-treatment Device 7.

[0057] Wherein, the preheating device 2 is a preheating oven, the first coating device 3 is a micro-gravure coating device, the second coating device 4 is an extrusion coating device, and the third coating device 6 is a wire rod coating device, and the post-processing device 7 is a drying oven. In addition, the coating head of the first coating device 3 and the coating head of the second coating device 4 are located on one side of the base film 8, and the coating head of the third coating device 6 is located on the other side of the base film 8.

[0058] The diaphragm coating device also includes a transmission device for transmitting the base film 8 to be processed. T...

Embodiment 2

[0063] This embodiment provides a method for coating a diaphragm using the diaphragm coating device of embodiment 1, which is specifically:

[0064] After the base film 8 (PE film) is preheated at 20°C through the preheating device 2, it passes through the first coating device 3 but does not turn on the first coating device 3 (that is, the first coating device is not used for coating), The adhesive coating (aqueous PVDF layer) is extruded and coated on one side of the base film 8 by the second coating device 4, and the wire rod is coated and bonded on the other side of the base film 8 by the third coating device 6 The coating (aqueous PVDF layer) is then dried by the post-processing device 7 at 20° C. to obtain a separator. Among them, the tension of the coating head region of the second coating device 4 and the third coating device 6 are both 5N.

[0065] The diaphragm of this embodiment has undergone both extrusion coating and wire rod coating, and has a layer of coating on both...

Embodiment 3

[0067] After the base film 8 (PE film) is preheated by the preheating device 2 at 70°C, the first coating device 3 is used for micro-gravure coating of alumina coating, and the second coating device 4 The bond coat (aqueous PVDF layer) is extrusion coated on the coating, passes through the third coating device 6 but does not turn on the third coating device 6 (that is, does not use the third coating device for coating), and then passes through post-processing The device 7 is dried at 70°C to obtain a diaphragm. Among them, the tension of the coating head regions of the first coating device 3 and the second coating device 4 are both 35N.

[0068] The diaphragm of this embodiment has undergone both microgravure coating and extrusion coating, and has two layers of coating on one side of the base film 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com