Array substrate, manufacturing method thereof, and display device

A manufacturing method and array substrate technology, which are applied in the fields of semiconductor/solid-state device manufacturing, electrical components, transistors, etc., can solve the problems of low process integration and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

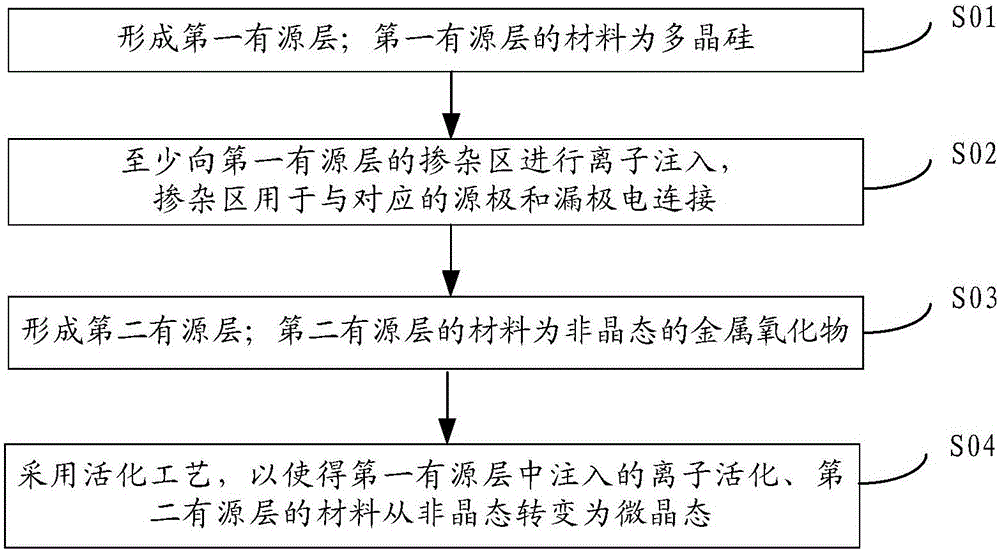

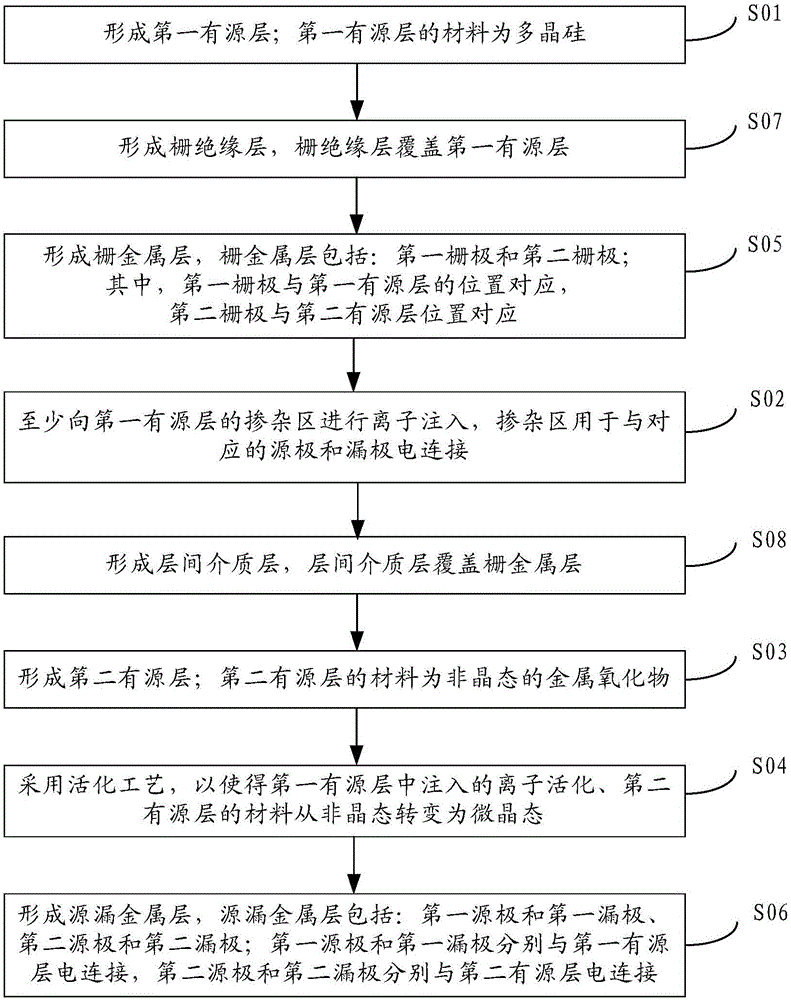

[0038] An embodiment of the present invention provides a method for manufacturing an array substrate, the method comprising:

[0039] S01, forming the first active layer; the material of the first active layer is polysilicon; the specific method for forming the first active layer is not limited here, as an example, an amorphous silicon film can be formed first, and then the amorphous silicon The film is irradiated with laser light to crystallize amorphous silicon (a-silicon) into polysilicon (p-silicon), forming a polysilicon film.

[0040] S02. Perform ion implantation at least into the doped region of the first active layer, the doped region is used for electrical connection with the corresponding source and drain; here, the method and type of implanted ions are not limited. As an example, boron ions can be implanted into the first active layer by plasma bombardment to form a P-type TFT; or, phosphorus ions can also be implanted into the first active layer by plasma bombardm...

Embodiment 2

[0060] An embodiment of the present invention provides an array substrate, which is formed by using any one of the manufacturing methods provided in the first embodiment. The array substrate has the characteristics of high process integration and low production cost. The array substrate may be a common array substrate or a COA (Color Filter on Array) substrate. The COA substrate refers to a substrate with a color filter layer on the array substrate, which is not limited here.

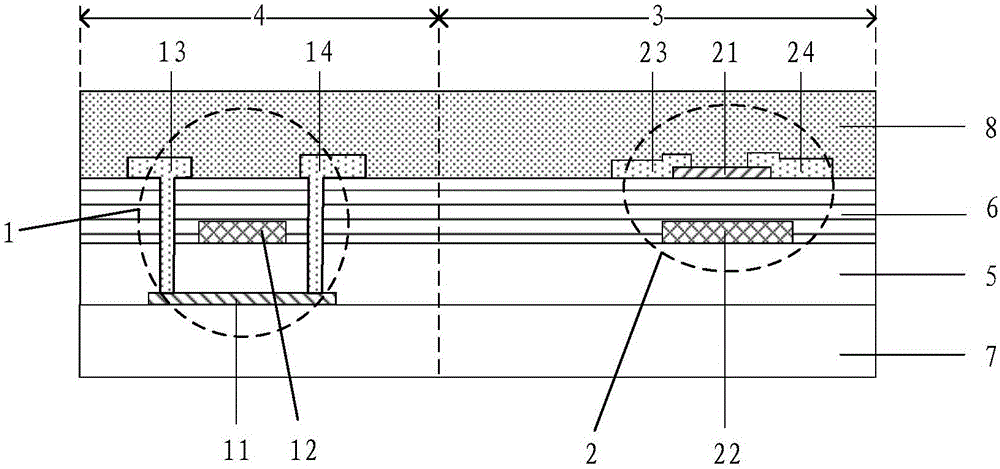

[0061] By adjusting the sequence of the fabrication method in Embodiment 1, array substrates with various structures can be formed. An array substrate with a specific structure is provided below. refer to figure 2 As shown, the array substrate includes: a substrate 7, a first active layer 11 sequentially arranged on the substrate 7, a gate insulating layer 5 covering the first active layer 11, a gate metal layer (the first gate 12 and The second gate 22), the interlayer dielectric layer 6 covering t...

Embodiment 3

[0063] An embodiment of the present invention provides a display device, including: the array substrate provided in Embodiment 2. The above-mentioned display device can be a display device such as a liquid crystal display, an electronic paper, an OLED (Organic Light-Emitting Diode, organic light-emitting diode) display, and any product with a display function such as a TV, a digital camera, a mobile phone, a tablet computer, etc. that include these display devices, or part. The display device has the characteristics of high process integration, low production cost, low power consumption and high stability. In addition, the size and application scenarios of the display device are not limited here; it can be a large-size display device, or a small-size, wearable display device, such as a bracelet, etc.; it can be applied indoors or Outdoors, since the display device has the characteristics of low power consumption, it is more advantageous to be applied outdoors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com