Pretreatment process of landfill leachate

A landfill leachate and pretreatment technology, which is applied in filtration treatment, contaminated groundwater/leachate treatment, sedimentation treatment, etc., can solve the problems of inability to meet the requirements of biochemical treatment, large amount of reagent addition, high ammonia nitrogen content, etc., and achieve improvement Biodegradability, simple process, and high process integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

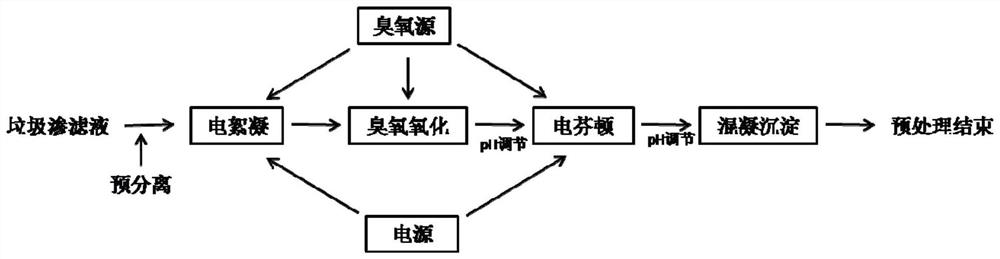

[0044] A pretreatment system for landfill leachate, comprising the following steps:

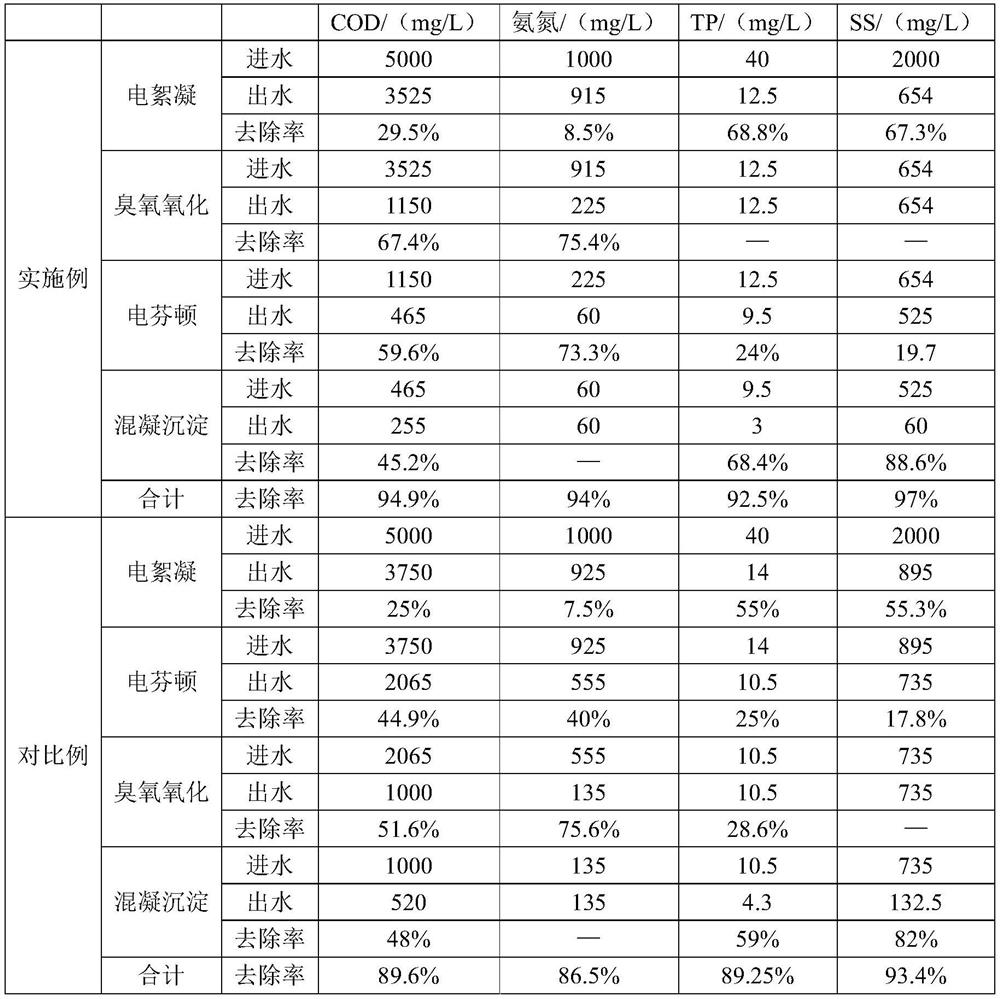

[0045] (1) Electro-flocculation: take the landfill leachate with COD concentration of 5000mg / L, ammonia nitrogen concentration of 1000mg / L, TP concentration of 40mg / L and SS concentration of 2000mg / L, first through screen treatment and then sent to the electro-flocculation device , the COD concentration of the landfill leachate is 5000mg / L, the ammonia nitrogen concentration is 1000mg / L, and the TP concentration is 40mg / L. Electroflocculation is carried out under the action of DC power supply and iron-iron cathode and anode plates. The flocculant generated by , complexation, etc. removes suspended solids, COD, total phosphorus, heavy metal ions and other pollutants, and the current density of electroflocculation is 15mA / cm 2 , the distance between the plates is 1cm, the electrolysis reaction is 30min, and after the electroflocculation reaction, the scum is removed by a slag scraper, and the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com