Multifunctional 3D printer

A 3D printer, multi-functional technology, applied in the direction of 3D object support structure, printed circuit, printed circuit manufacturing, etc., can solve the problem that the structure and functional integration of customized electronic products cannot be satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

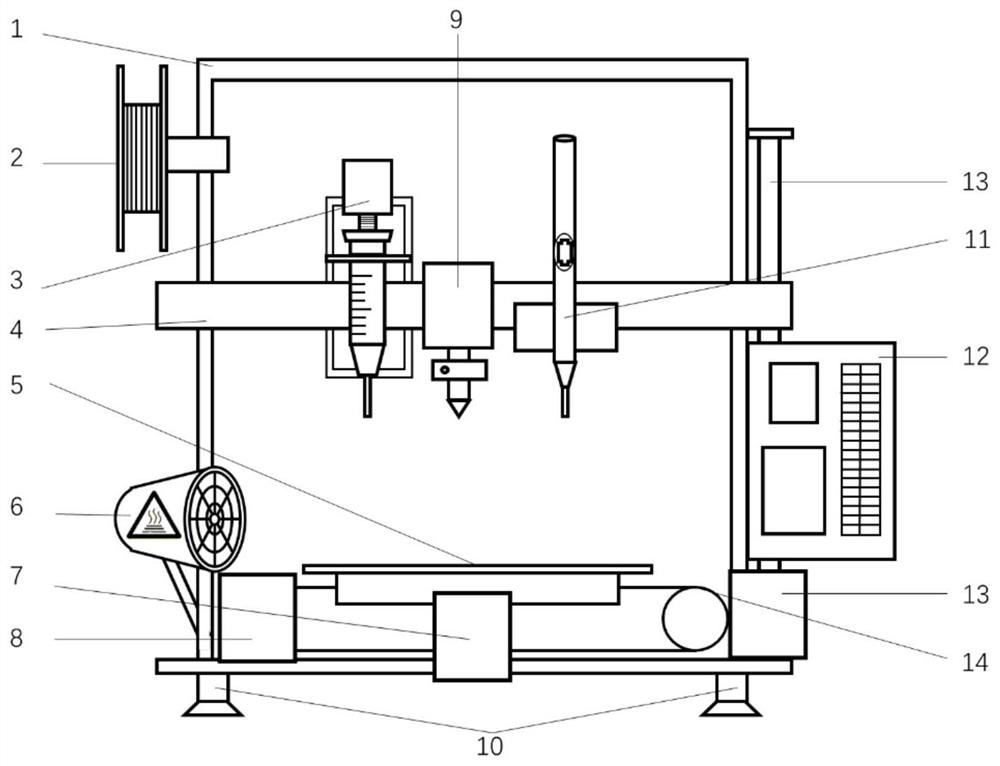

Embodiment 1

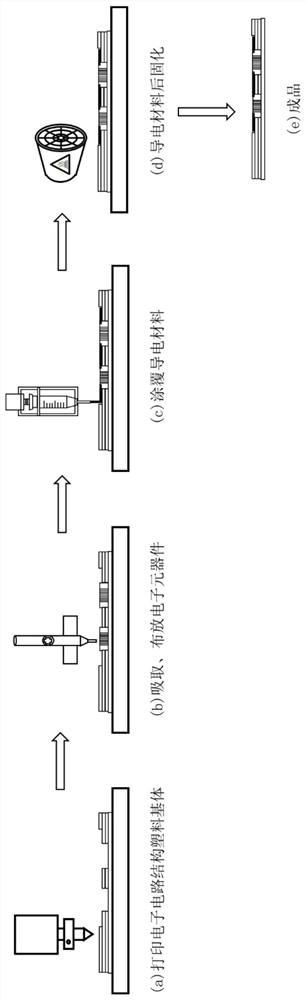

[0031] Embodiment 1, the molten plastic extruding mechanism 9 is composed of a plastic wire extruder driven by a stepping motor; the conductive material coating mechanism 3 is composed of a screw extruder; the conductive material pre-curing module 6 is composed of a heat gun. Blow hot air to pre-cure the conductive adhesive.

[0032] Such as image 3 As shown, the process of manufacturing the two-dimensional circuit structure in this embodiment is as follows: first, use computer-aided design software (CAD) to design the model of the electronic circuit; then, set the printing parameters in the 3D printing slicing software (such as: Slicer3R), and Carry out slicing processing to obtain the CNC programming language code (such as: G-Code code) that drives the hybrid 3D printing device to work; the computer control system 12 drives the X, Y, Z axis ball screw to move according to the CNC programming language code, and controls the plastic wire The material extruder prints the plas...

Embodiment 2

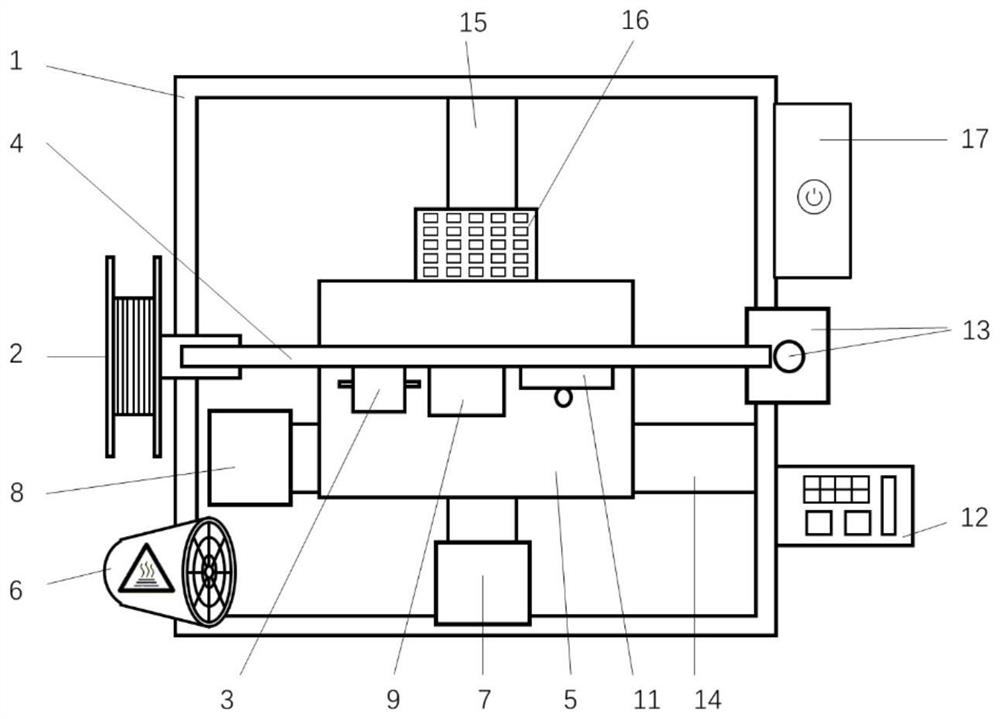

[0033] Embodiment 2, the molten plastic extruding mechanism 9 is composed of a pellet screw extruder driven by a stepping motor; the conductive material coating mechanism 3 is composed of a jet printing head; the conductive material pre-curing module 6 is composed of a UV lamp, and is passed The light curing method enables the conductive ink to be pre-cured.

[0034] Such as Figure 4As shown, the method for manufacturing a three-dimensional circuit structure in this embodiment is as follows: first, use computer-aided design software (CAD) to design the model of the electronic circuit; set the printing parameters in the 3D printing slicing software (such as: Slicer3R), and perform slicing Processing, to obtain the CNC programming language code (such as: G-Code code) that drives the work of the hybrid 3D printing device; then, the computer control system 12 drives the X, Y, Z axis ball screw to move according to the CNC programming language code, and controls the granular mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com