Patents

Literature

152results about How to "Realize integrated manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

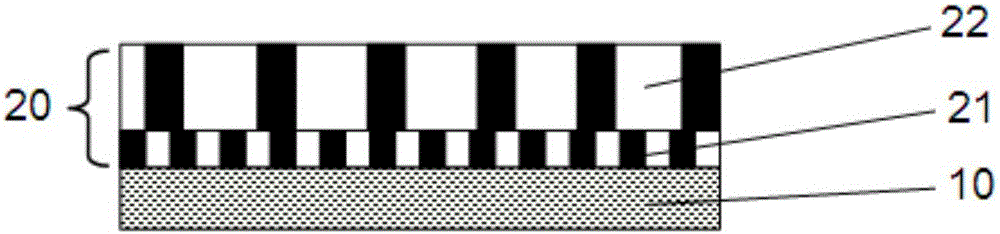

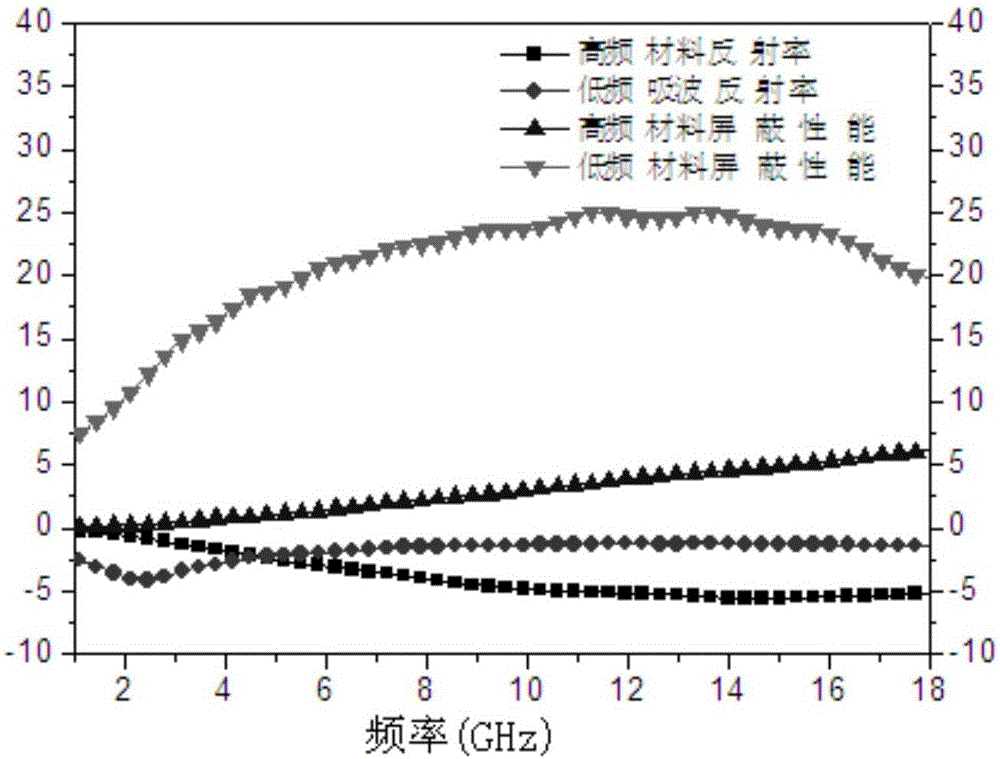

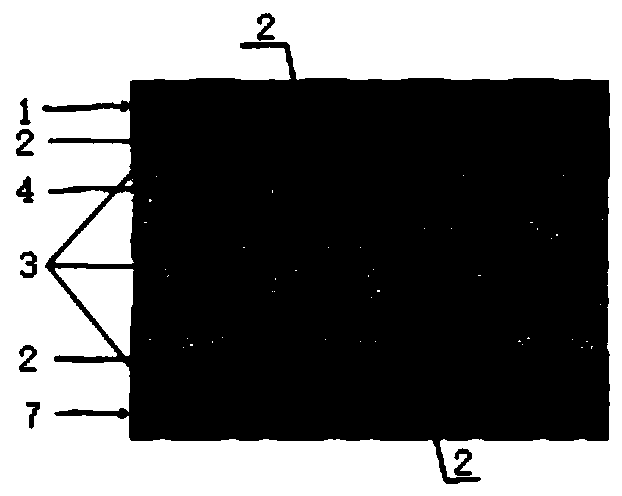

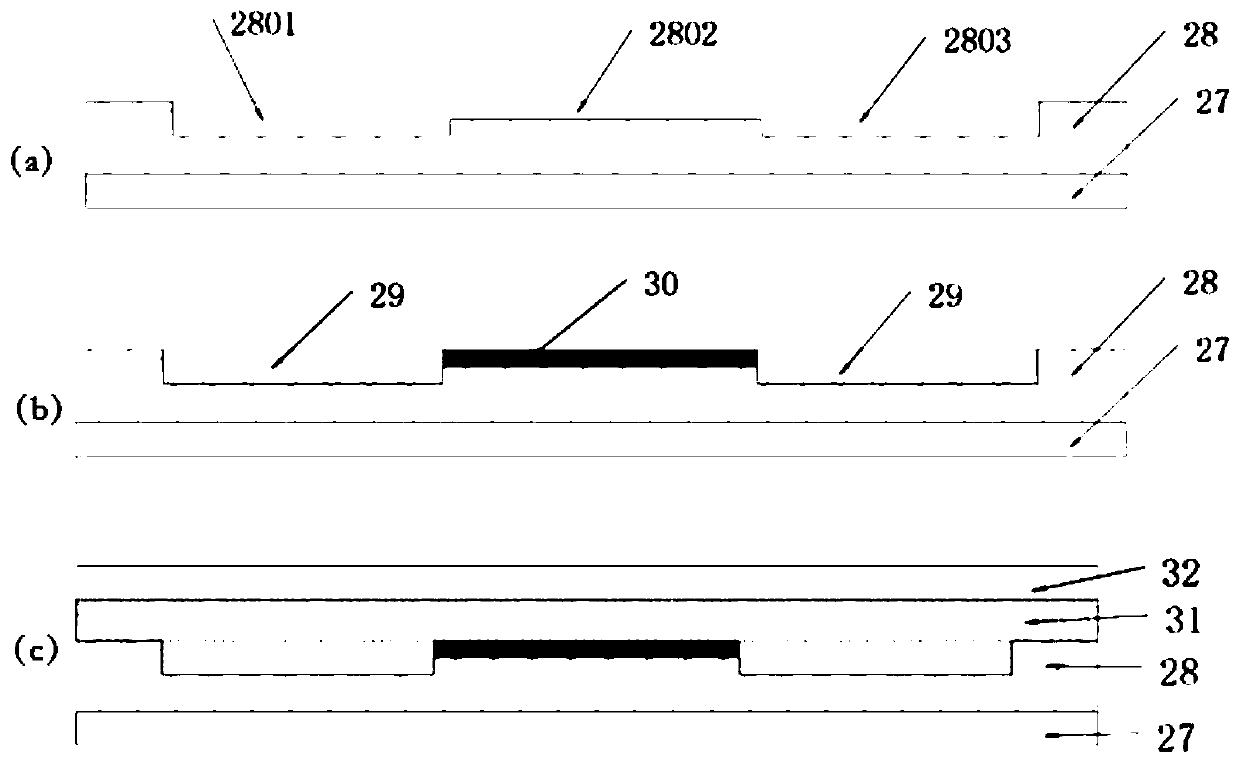

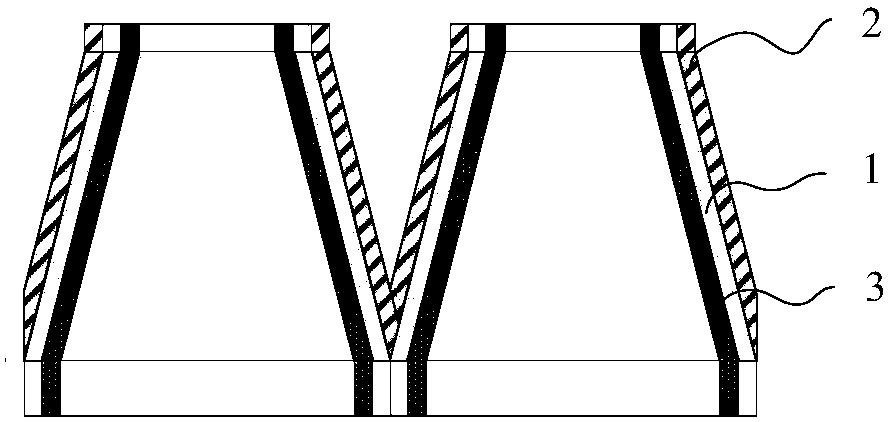

Broadband wave-absorbing material and preparation method thereof

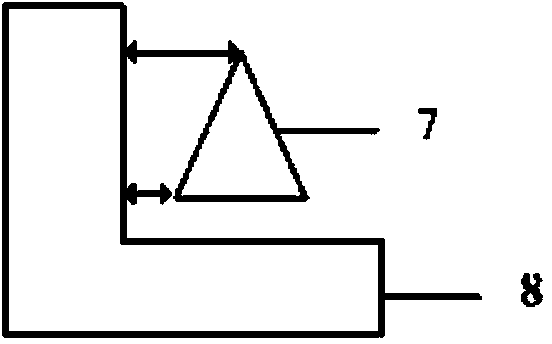

The invention discloses a broadband wave-absorbing material and a preparation method thereof. The broadband wave-absorbing material is composed of a low frequency wave-absorbing material bottom layer and a high frequency wave-absorbing material surface layer. The high frequency wave-absorbing material surface layer comprises a plurality of high frequency wave-absorbing layers with different concentrations. FeSi or FeSiAl particles are taken as the additive of the low frequency wave-absorbing material, and carbonyl iron particles are taken as the additive of the high frequency wave-absorbing material. A rolling method is adopted to prepare the low frequency wave-absorbing material bottom layer, and a three-dimensional moulding technology is adopted to prepare the high frequency wave-absorbing material surface layer. The multilayer lamination manufacturing method combines a multi-rolling technology and three-dimensional moulding together and has the advantages that the binding force between layers can be ensured, multiple repeated mould pressing is avoided, the thickness of each layer, the internal structure, and particle distribution can be adjusted so as to satisfy the predetermined electromagnetic property requirements; the broadband wave-absorbing performance of the wave-absorbing material and designable performance of a shielding material can be realized; the integrated manufacturing of space structure of the wave-absorbing material is achieved, and the preparation cost is low at the same time.

Owner:SHANGHAI RADIO EQUIP RES INST

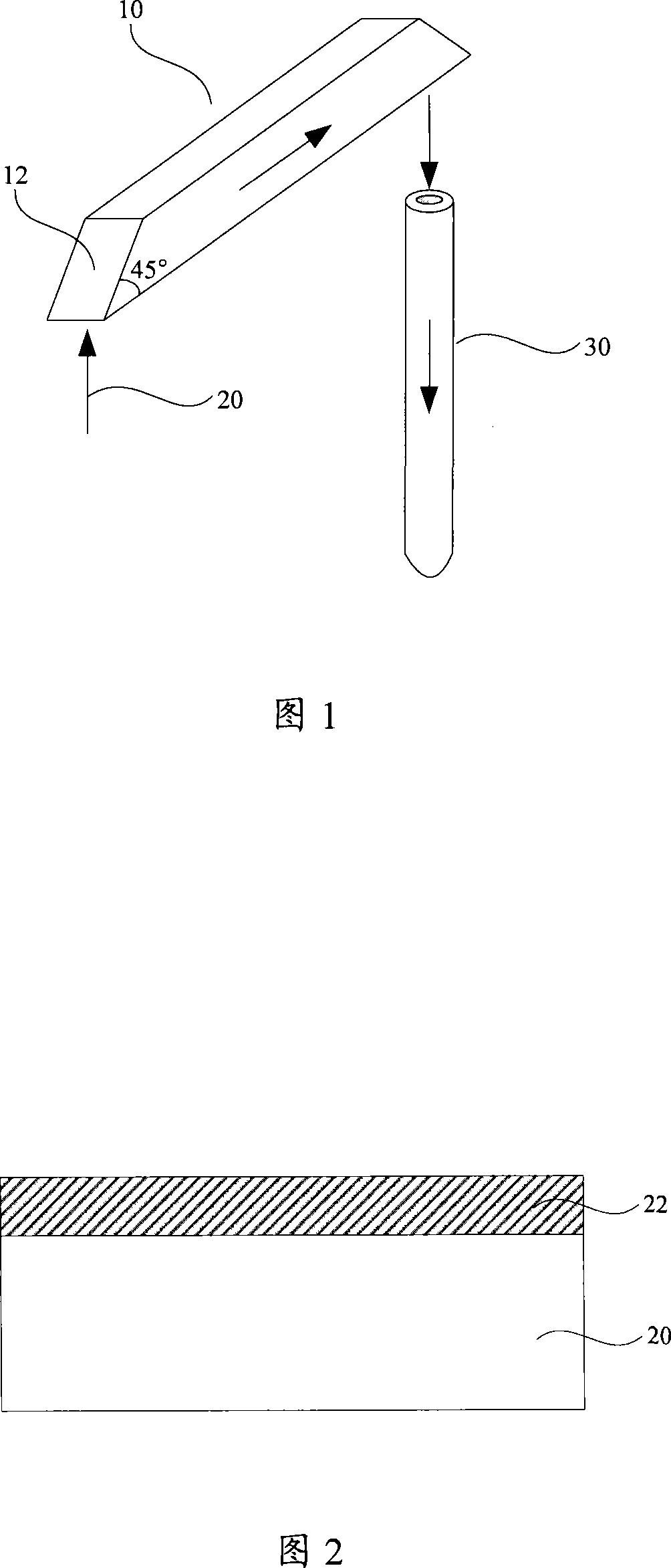

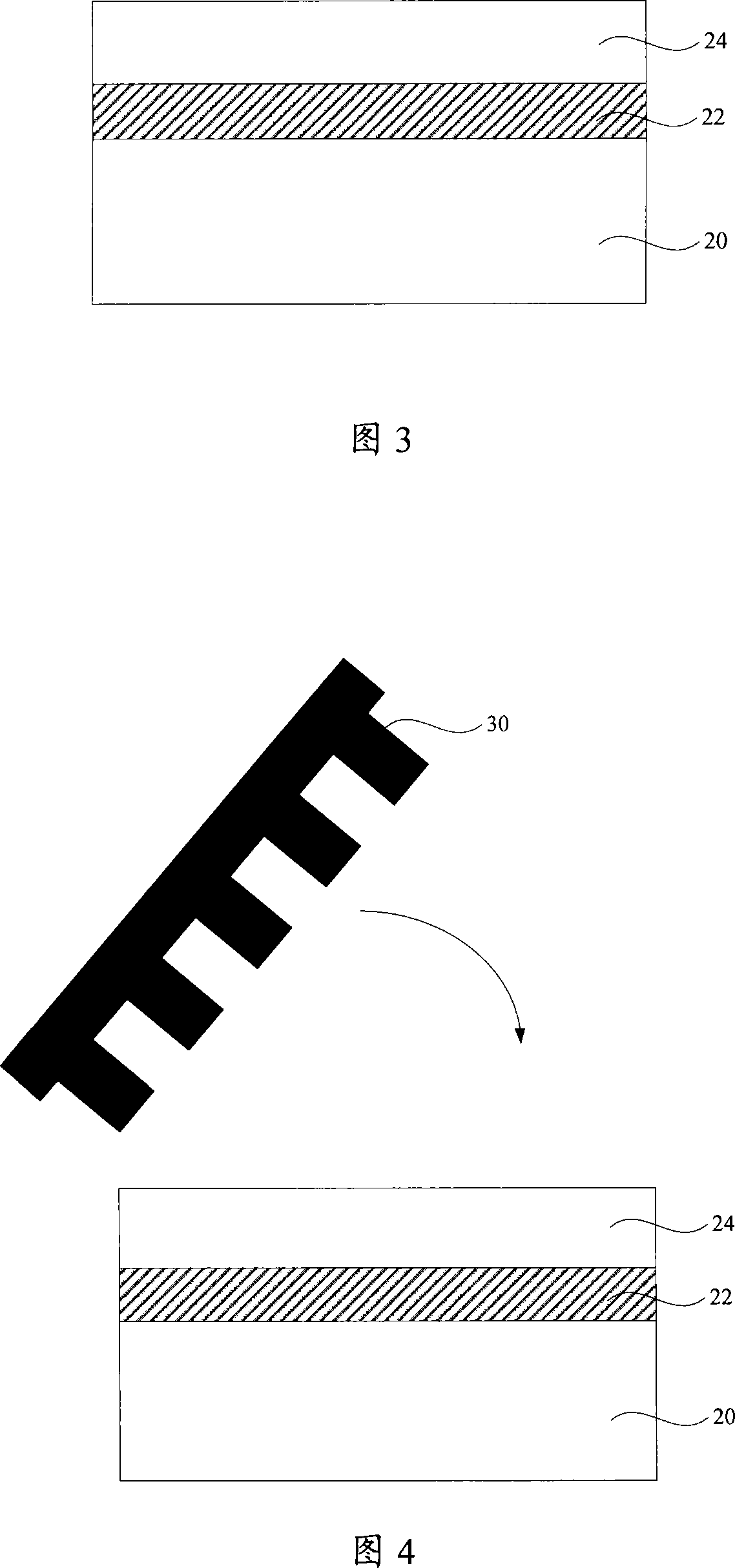

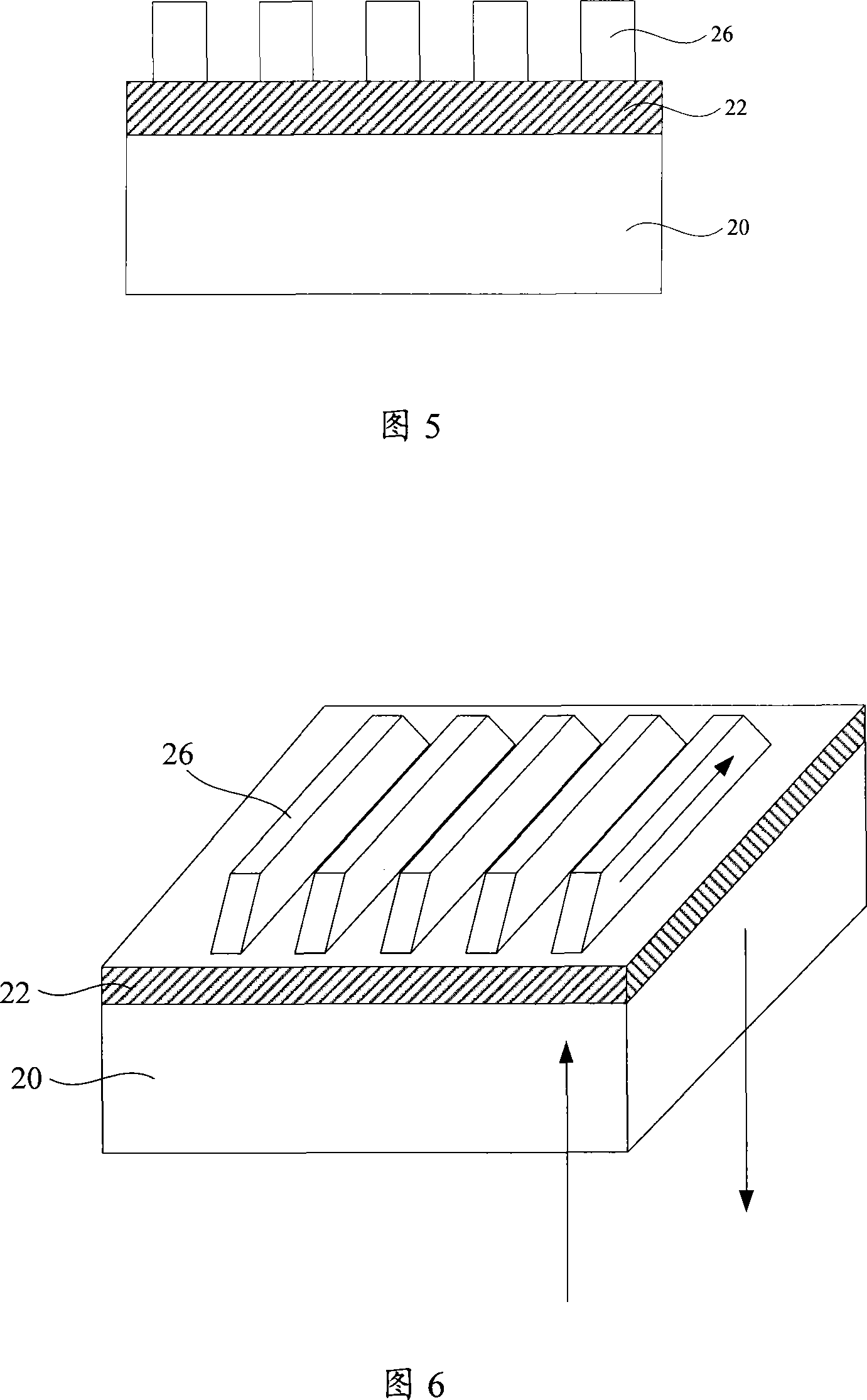

Optical waveguide and its manufacture method thereof

ActiveCN101122655ASimple preparation processReduce lossSemiconductor/solid-state device manufacturingCoupling light guidesIntegrated circuit manufacturingEngineering

The invention provides a wafer-level optical waveguide and a manufacturing method. The invention adopts the semiconductor integrated circuit manufacturing process to manufacture micron optical waveguide with smooth contact surface, uniform thickness and an arbitrary angle mirror on end face, and significantly reduce the manufacturing cost.

Owner:CHINA WAFER LEVEL CSP

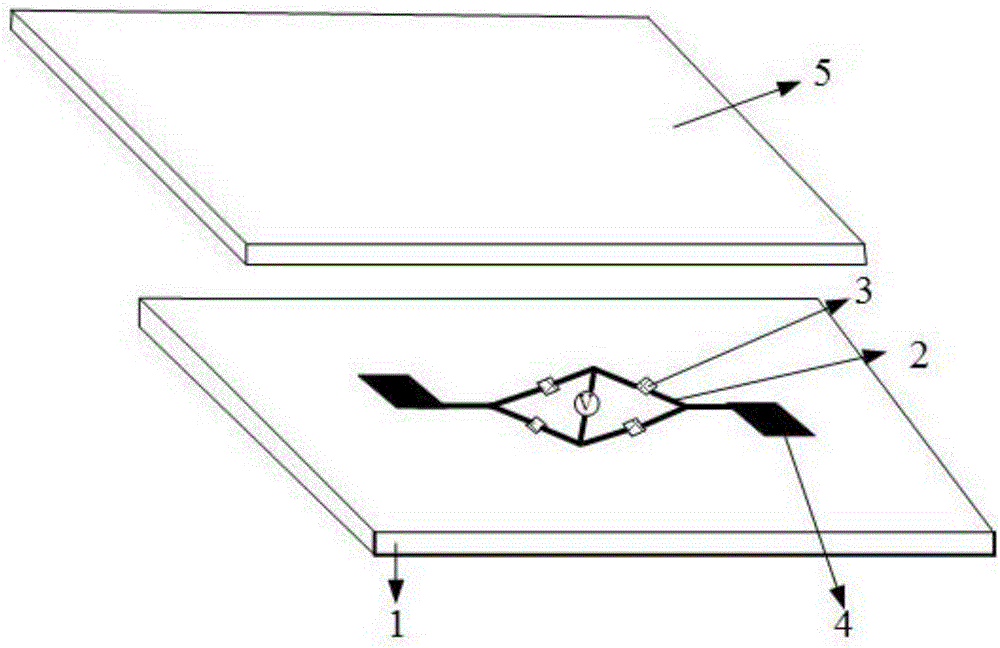

Flexible pressure sensor and preparation method thereof

ActiveCN106441646ARealize integrated manufacturingSimple preparation processForce measurement using piezo-resistive materialsMicro nanoElectrical resistance and conductance

The invention provides a flexible pressure sensor. The flexible pressure sensor comprises a flexible substrate, a flexible upper cover and electrodes arranged between the flexible substrate and the flexible upper cover at intervals. A circuit with semiconductor resistors and conductive channels is arranged between the electrodes. The micro-nano processing technology is combined with the modern printing electronic technology, so the Wheatstone bridge type pressure sensor can be built on the pure flexible substrate, the defects that the process of a technology for preparing a hard substrate (like silicon) pressure sensor through a traditional semiconductor technology is complex, and influences of the high-temperature technology are large are avoided, and integrated preparation of the flexible sensor is achieved. The micro-nano processing technology, the modern printing electronic technology, nano-carbon materials, polymer materials and the like are combined, so the flexible pressure sensor of a Wheatstone bridge structure is prepared on the flexible substrate, and the pressure sensor is simple in preparation process, low in cost, good in performance and suitable for large-scale production.

Owner:江苏科华智能控制设备有限公司

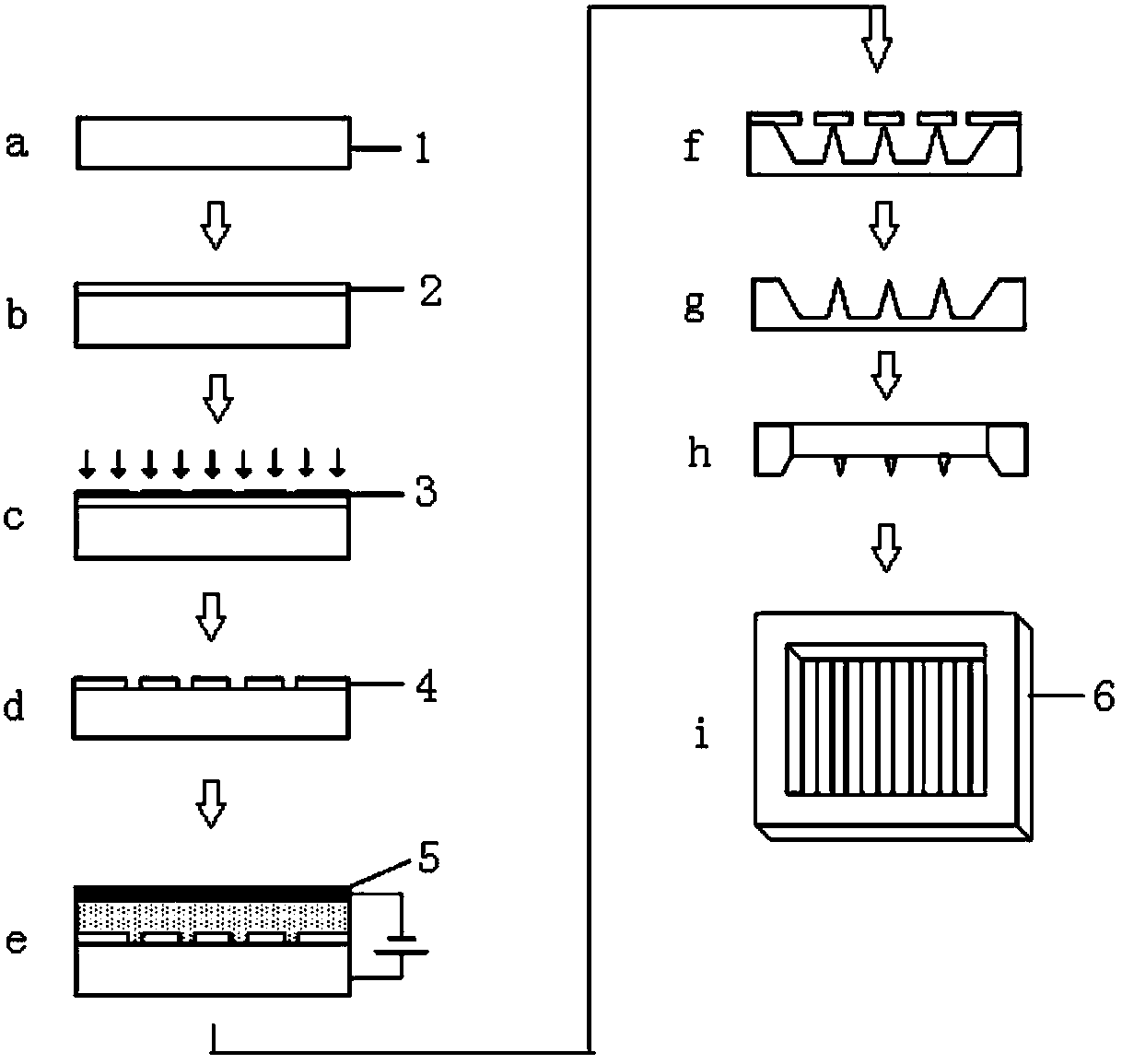

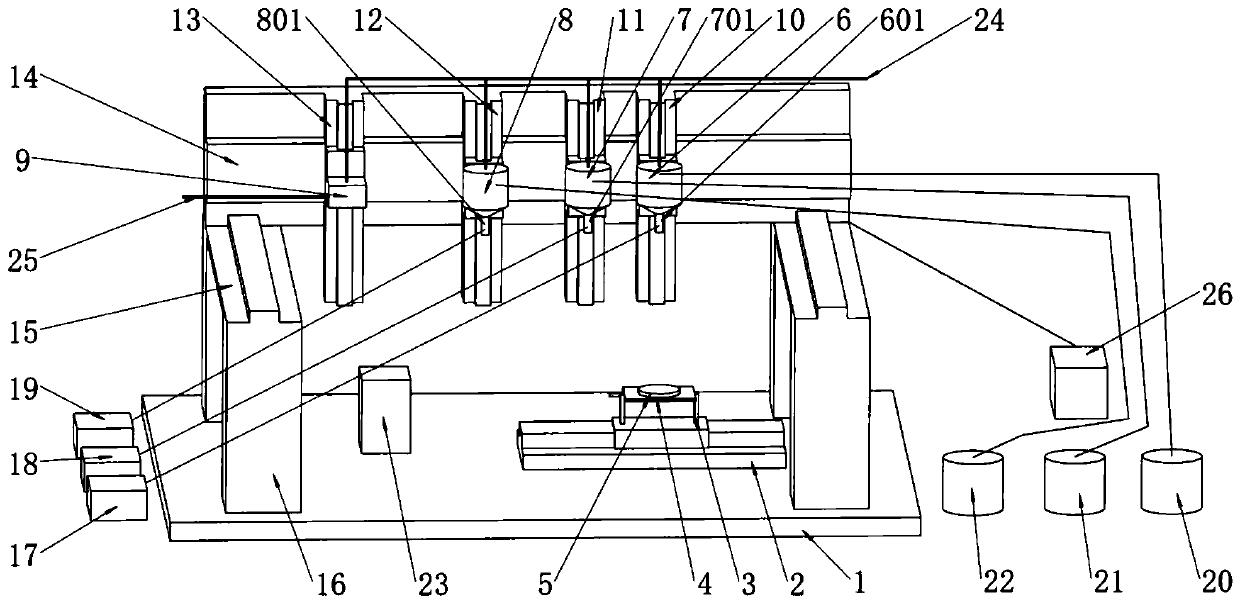

Wire electrode array structure preparation method for micro-electrochemical machining

ActiveCN103706899AEfficient preparationReduce the impactMachining electrodesElectrical-based machining electrodesElectrolysisElectrode array

The invention discloses a wire electrode array structure preparation method for micro-electrochemical machining. The wire electrode array structure preparation method includes the steps of 1), pretreating a metal base; 2), manufacturing a graphical masking film; 3), subjecting the masking film to profound electrolytic corrosion, namely taking the metal base with the graphical surface as a positive electrode for electrolytic machining to obtain a tool negative electrode in a wire electrode template machined and manufactured in the profound electrolytic corrosion, and determining electrolytic corrosion time according to photoresist pattern width and electrolysis current density till to obtain a metal gate line array pattern with the point top; 4), removing back materials, namely removing the back materials corresponding to the manufactured metal gate lines to obtain a wire electrode array integrated with a frame. By means of the method, the metal microstructure array with cross sections different in shapes like square, rectangle and rhombus can be manufactured, so that the metal microstructure array with large depth-to-width ratio, high density and high machining quality can be efficiently realized.

Owner:江苏蔚之领域智能科技有限公司

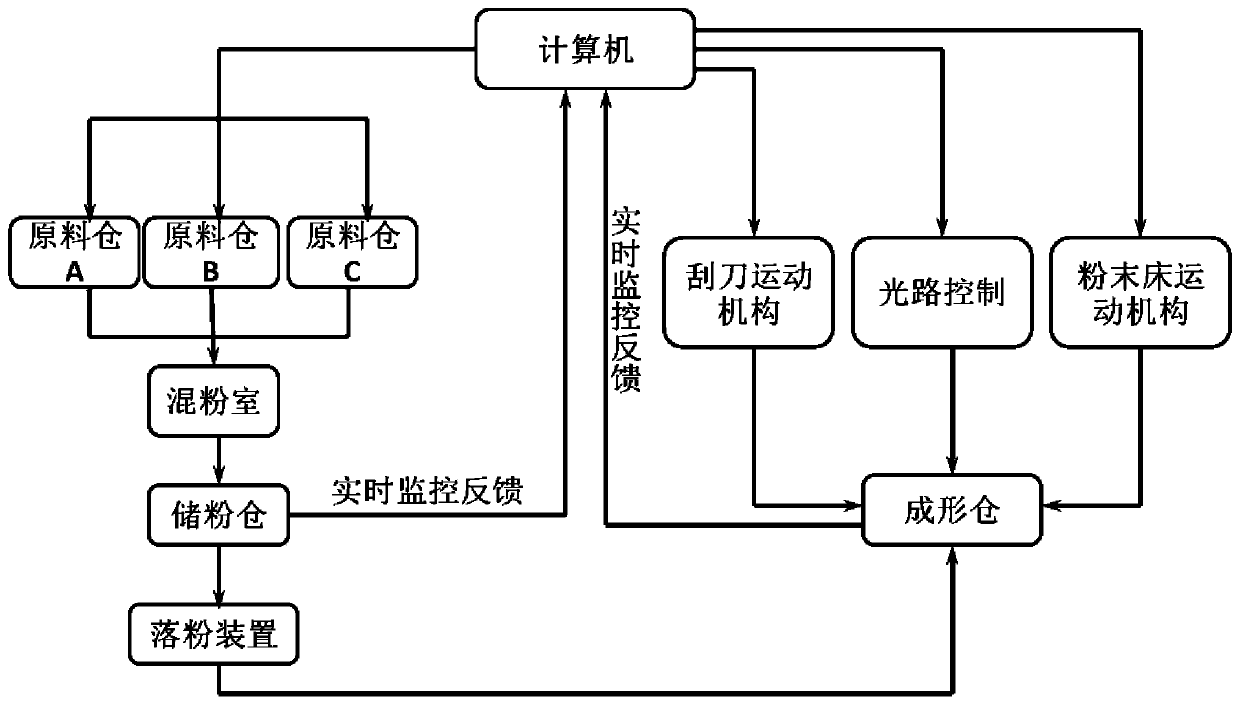

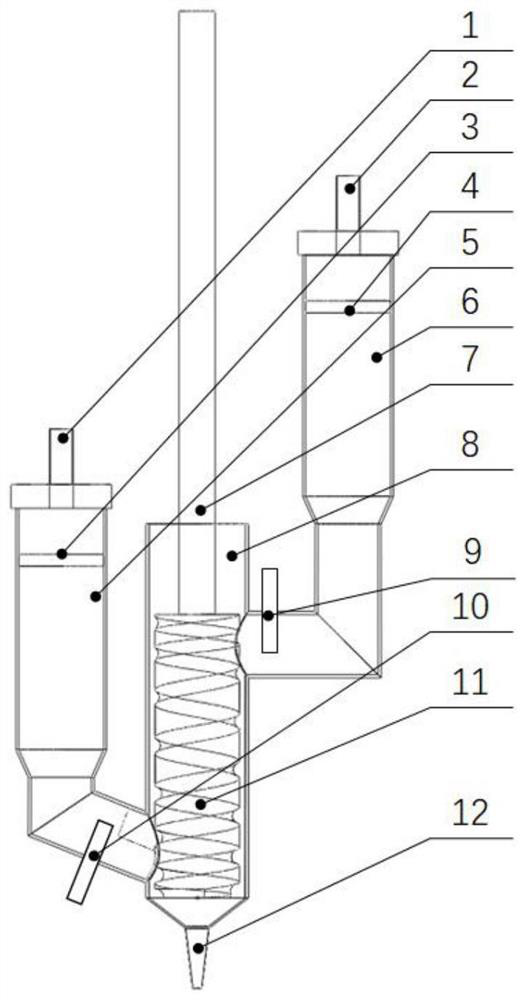

Selective laser melting device and preparation method for gradient material

InactiveCN110369715ARealize integrated manufacturingReduce the use effectAdditive manufacturing apparatusIncreasing energy efficiencyMelting tankSelective laser melting

The invention discloses a selective laser melting device and a preparation method for a gradient material. The device is provided with 2-5 raw material bins, and each raw material bin, a powder mixingroom, a powder storage bin, a powder dropper and a control valve define a powder feeding system with 2-5 channels, and an outlet of the powder storage bin communicates with an inlet of the powder dropper. Alloy powder needed for each slice layer is mixed in proportion, and is printed and formed through processes of raw material bin powder-feeding, mixing room powder-mixing, powder storage bin powder storage and powder dropper powder-dropping, so that preparation for the gradient material with components continuously changing in a vertical direction is realized; and the obtained formed part issmoothly transited in component and texture in macro-scale, so that component and performance mutation caused by metallurgical bonding, formed by layer-by-layer alternated printing of various powderin the prior art, of molten pool scale are eliminated, and therefore, integrated integral manufacturing of structure and function is realized. Uniform transition performance indexes in space scale canavoid the problems of discordant deformation and stress concentration, so that using performance of the formed part is favorably improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

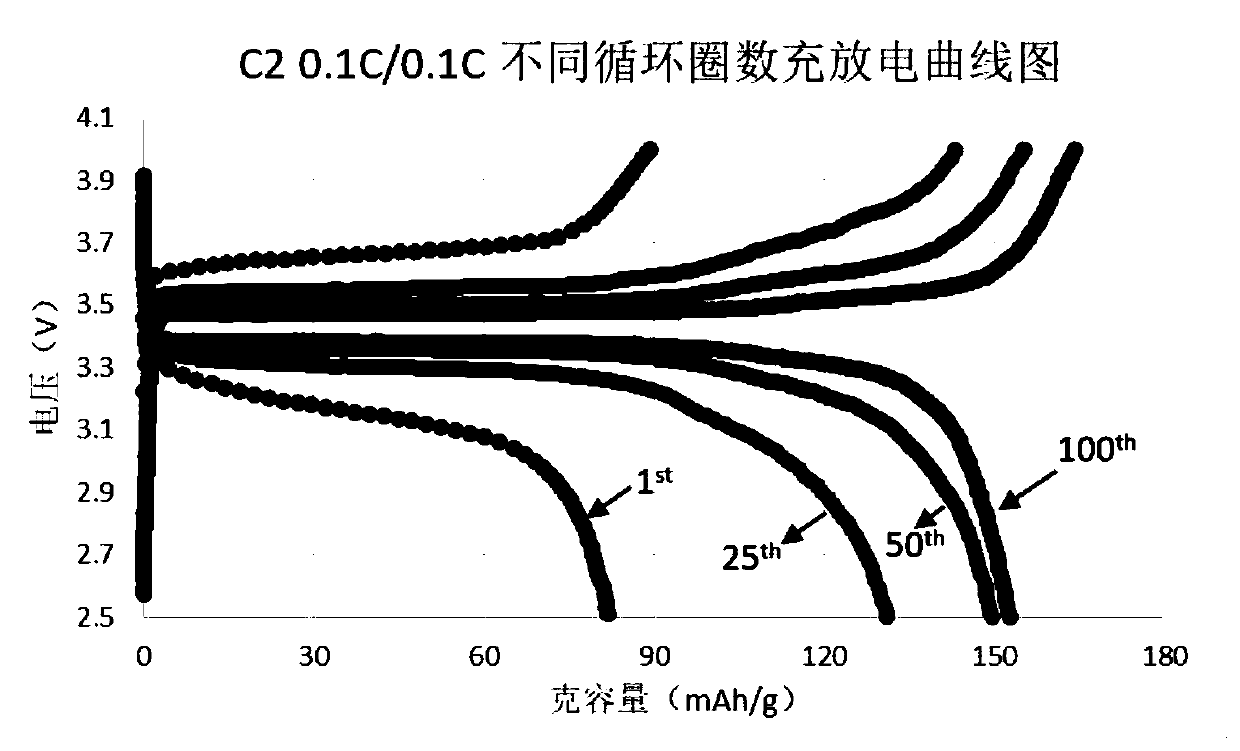

Preparation method of novel all-solid-state lithium ion battery

ActiveCN110233298AReduce interface impedanceWeaken polarizationCell electrodesFinal product manufactureSolid-state batteryChemistry

The invention relates to a preparation method of a novel all-solid-state lithium ion battery, belonging to the technical field of lithium ion batteries. The preparation method comprises the steps of:mixing and uniformly dispersing a cathode active substance, a conductive agent and Li3OX as a cathode ingredient; mixing and uniformly dispersing an anode active substance, the conductive agent and Li3OX as an anode ingredient; mixing and uniformly dispersing a main body solid electrolyte and Li3OX as a solid electrolyte layer ingredient; coating the cathode ingredient on a cathode current collector, coating the anode ingredient on the anode current collector, stacking the anode current collector, the anode ingredient, the solid electrolyte layer ingredient, the cathode ingredient and the cathode current collector in order layer by layer to form a solid battery laminated cell, performing sintering of the solid battery laminated cell at a temperature of 282-400 DEG C while applying the pressure to the solid battery laminated cell, packaging the sintered solid battery laminated cell by adopting a battery membrane shell to obtain a novel all-solid-state lithium ion battery. The preparation method is simple, friendly in preparation environment, and is suitable for large-scale production.

Owner:ZHUHAI COSMX BATTERY CO LTD

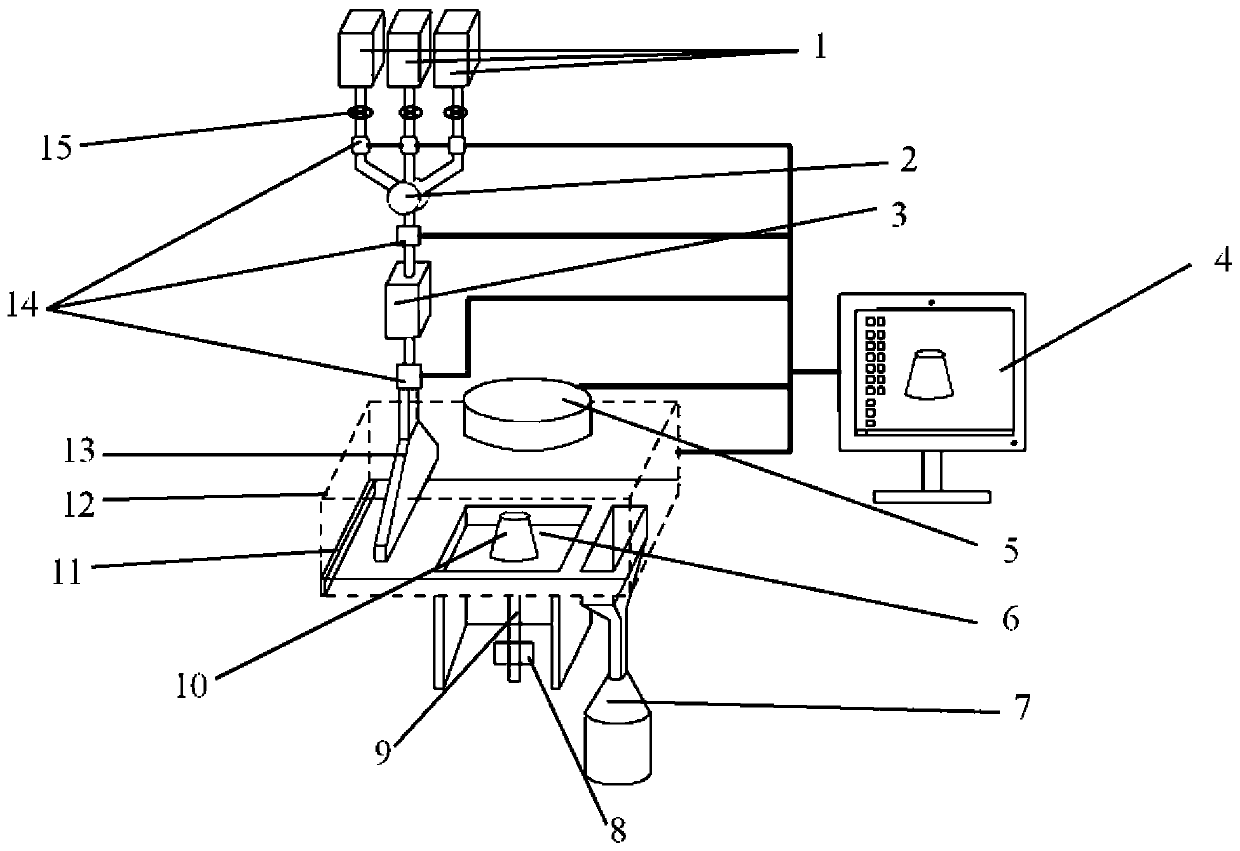

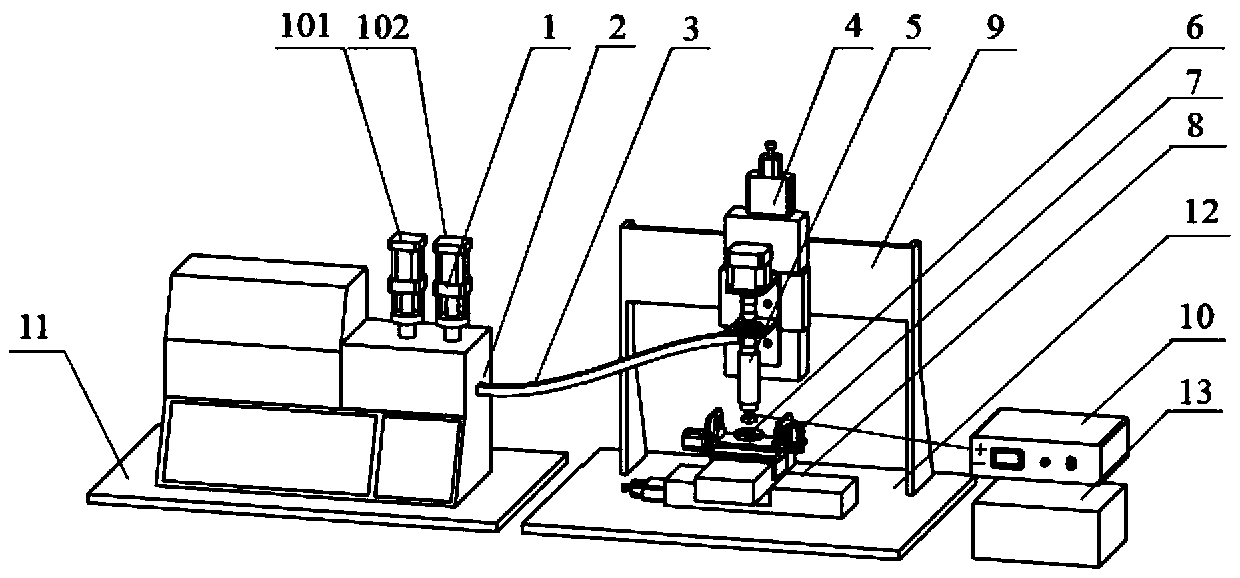

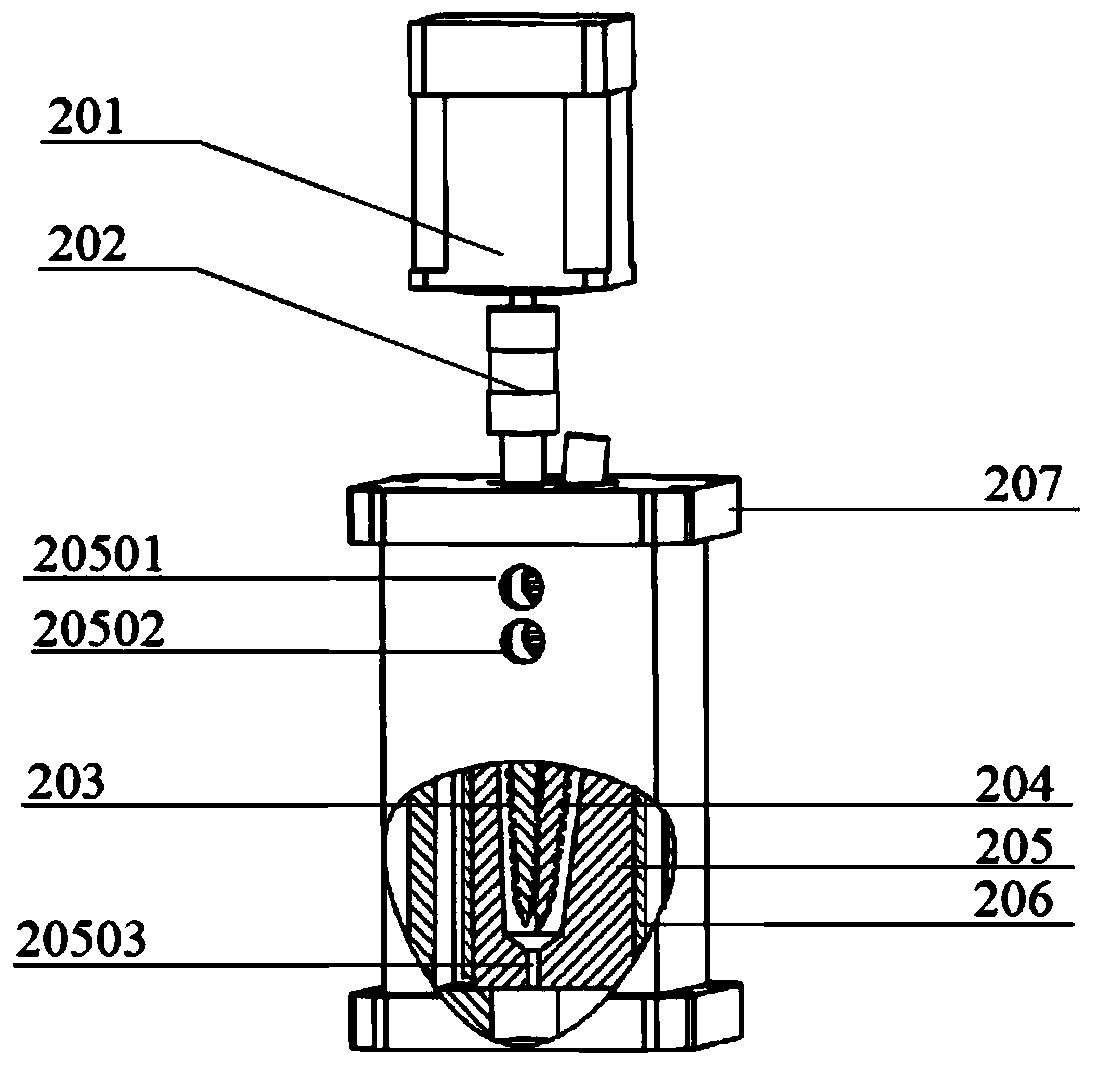

3D printer for integral manufacturing of functionally graded material and forming structure, and working method thereof

PendingCN109732905APrecise Controlled ExtrusionContinuous and stable printingAdditive manufacturing apparatus3D object support structuresImage resolutionEngineering

The invention provides a 3D printer for integral manufacturing of a functionally graded material and a forming structure, and a working method thereof. A feeding module, a mixing module and a printingsprayer are split; and through ingenious arrangement of the components, integral manufacturing of the continuous functionally graded material and the complex three-dimension structure can be achieved. The 3D printer has the characteristics and outstanding advantages of active, efficient and uniform mixing of various materials, high print resolution (due to micro-nano microscale characteristic structure printing), diverse applicable materials, high production efficiency, low cost and simple structure; and particularly, the 3D printer can achieve integral manufacturing of the continuous functionally graded material and the complex three-dimension structure based on material composition and microstructures.

Owner:QINGDAO 5D INTELLIGENT ADDITIVE MFG TECH CO LTD

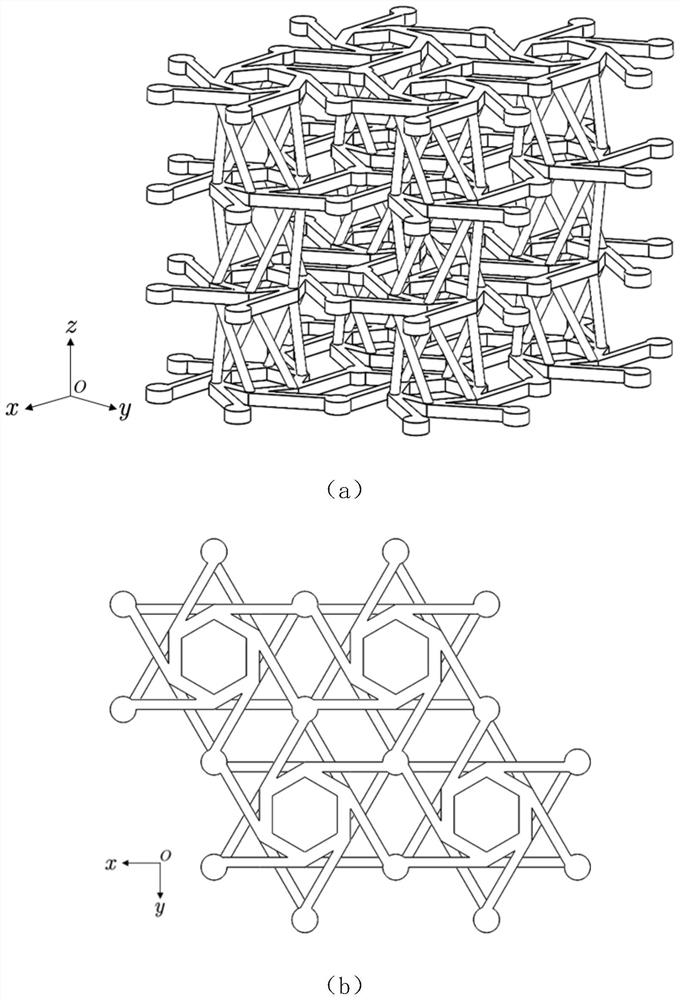

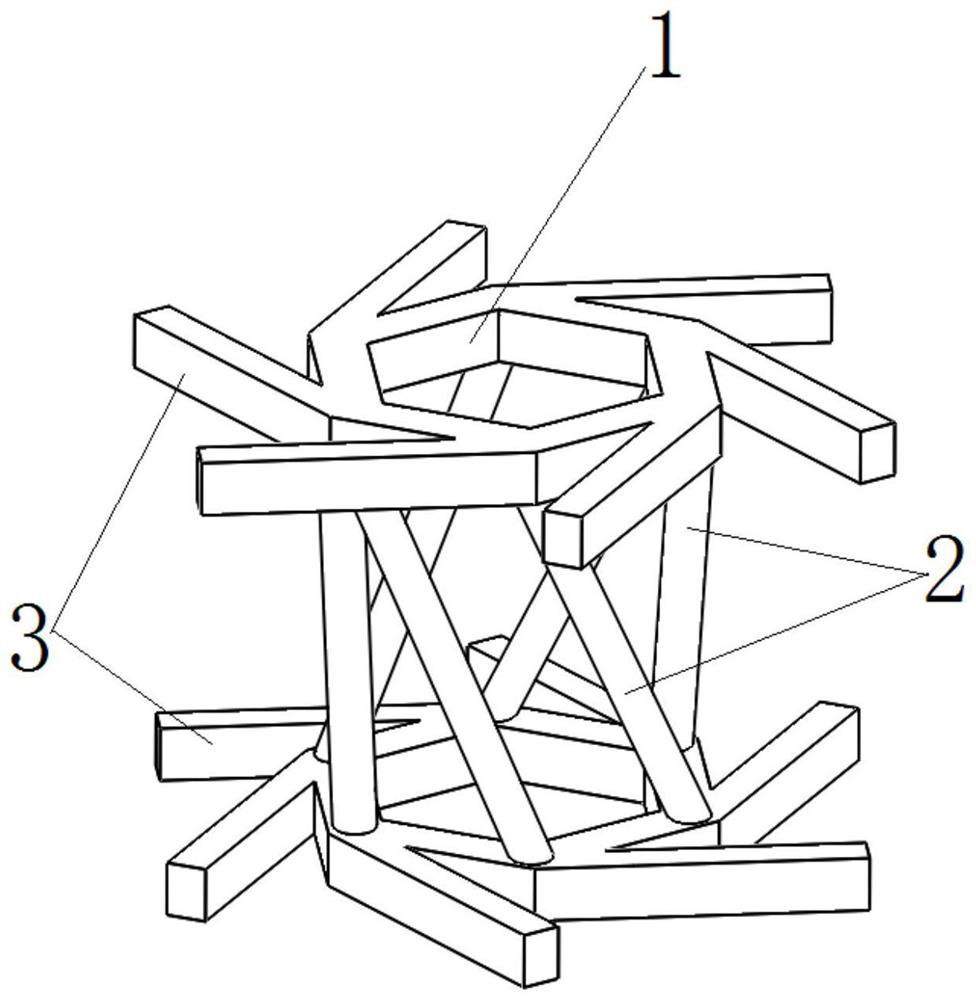

Chiral auxetic metamaterial structure with tension-torsion coupling characteristics and preparation method thereof

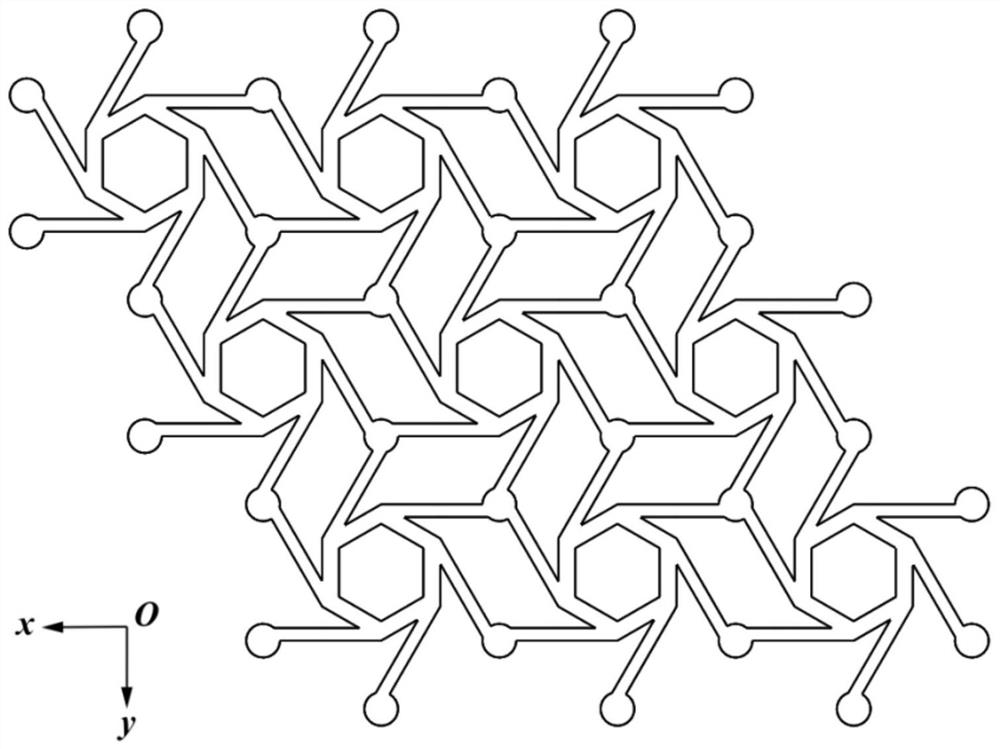

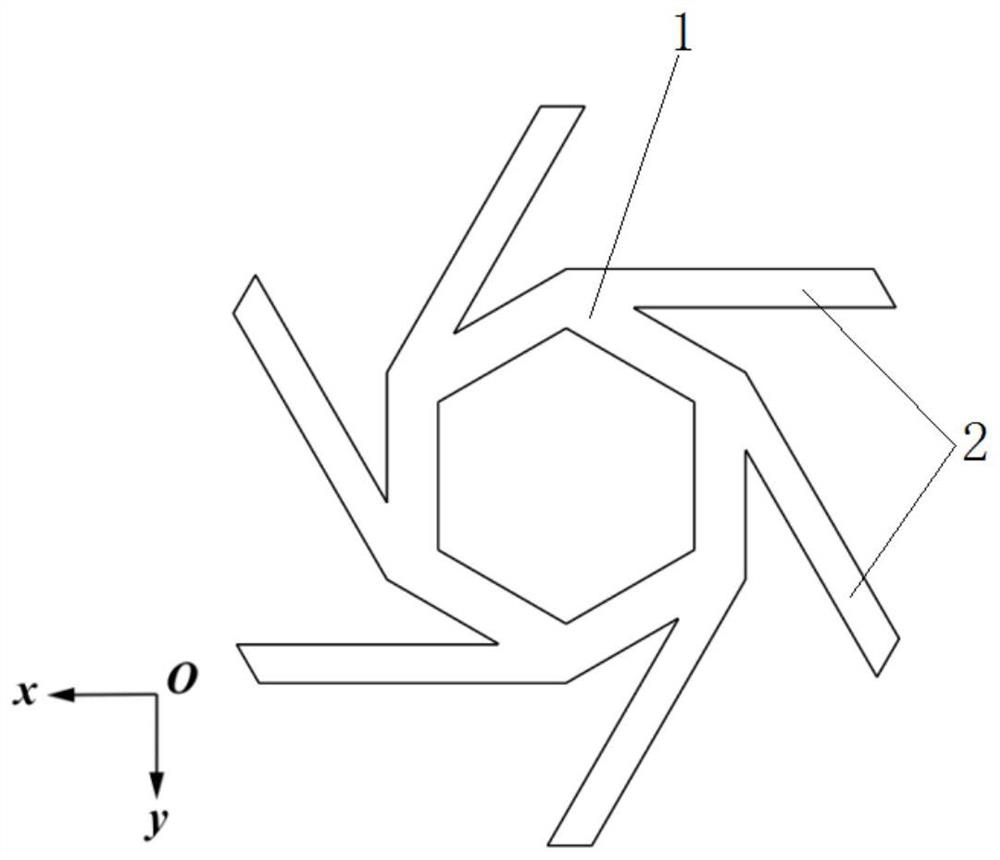

ActiveCN112049886AWith tension torsion coupling characteristicsImprove carrying capacityAdditive manufacturing apparatusIncreasing energy efficiencyStructural engineeringMechanical engineering

The invention discloses a chiral auxetic metamaterial structure with tension-torsion coupling characteristics and a preparation method thereof. The chiral auxetic metamaterial structure comprises a plurality of three-dimensional unit cell structures, each three-dimensional unit cell structure comprises two polygonal annular structures arranged up and down, and the vertexes of the upper and lower polygonal annular structures are connected through correspondingly-arranged inclined cylinders; a plurality of inclined cylinders are arranged in a staggered mode in the same direction, connecting rodsused for being connected with the adjacent three-dimensional unit cell structures are arranged at the vertexes of the two polygonal annular structures respectively, the plurality of three-dimensionalunit cell structures are arranged in a spatial array mode, and the chiral auxetic metamaterial structure with the tension-torsion coupling characteristics is formed by connecting the corresponding connecting rods.

Owner:XI AN JIAOTONG UNIV +1

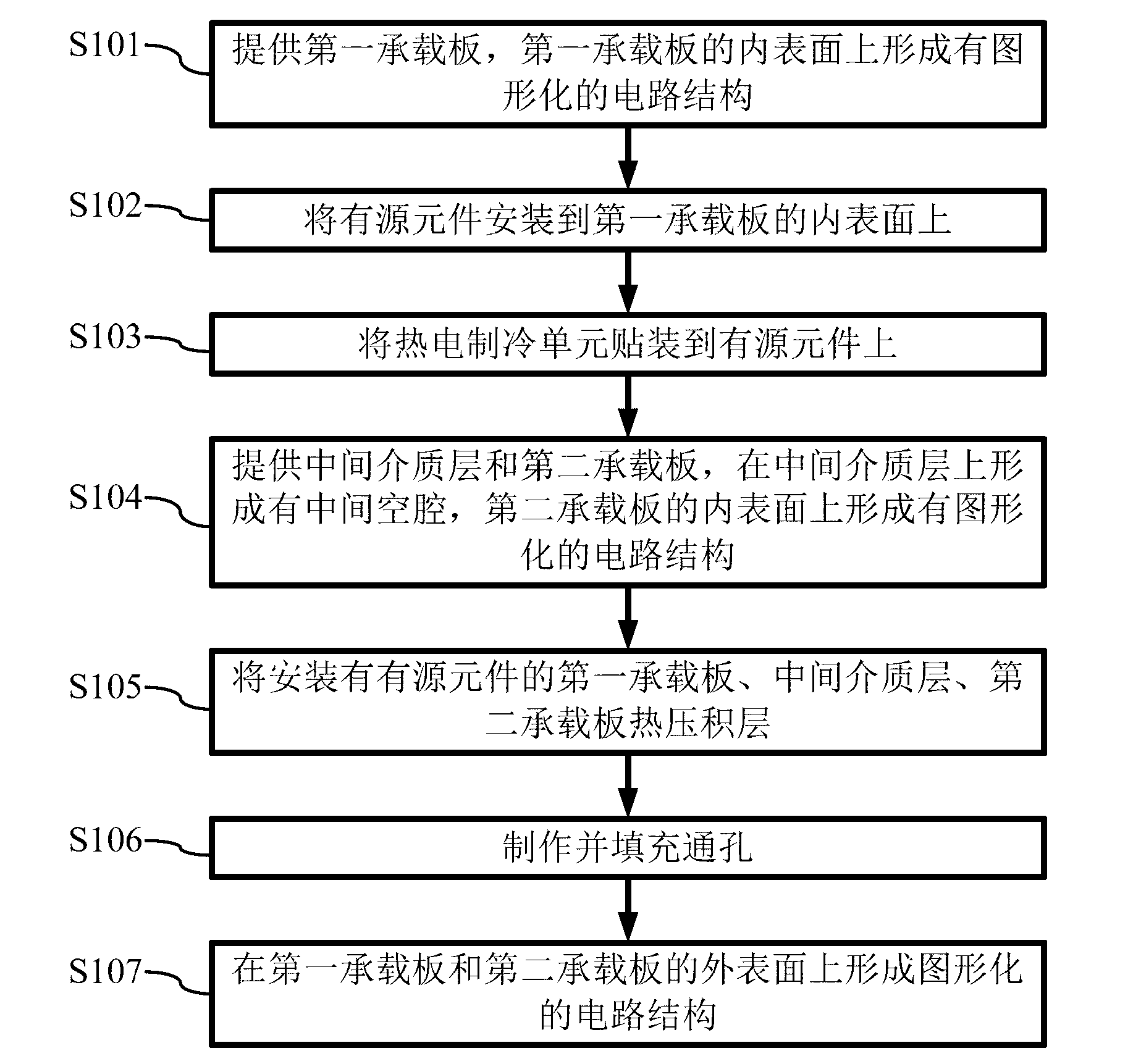

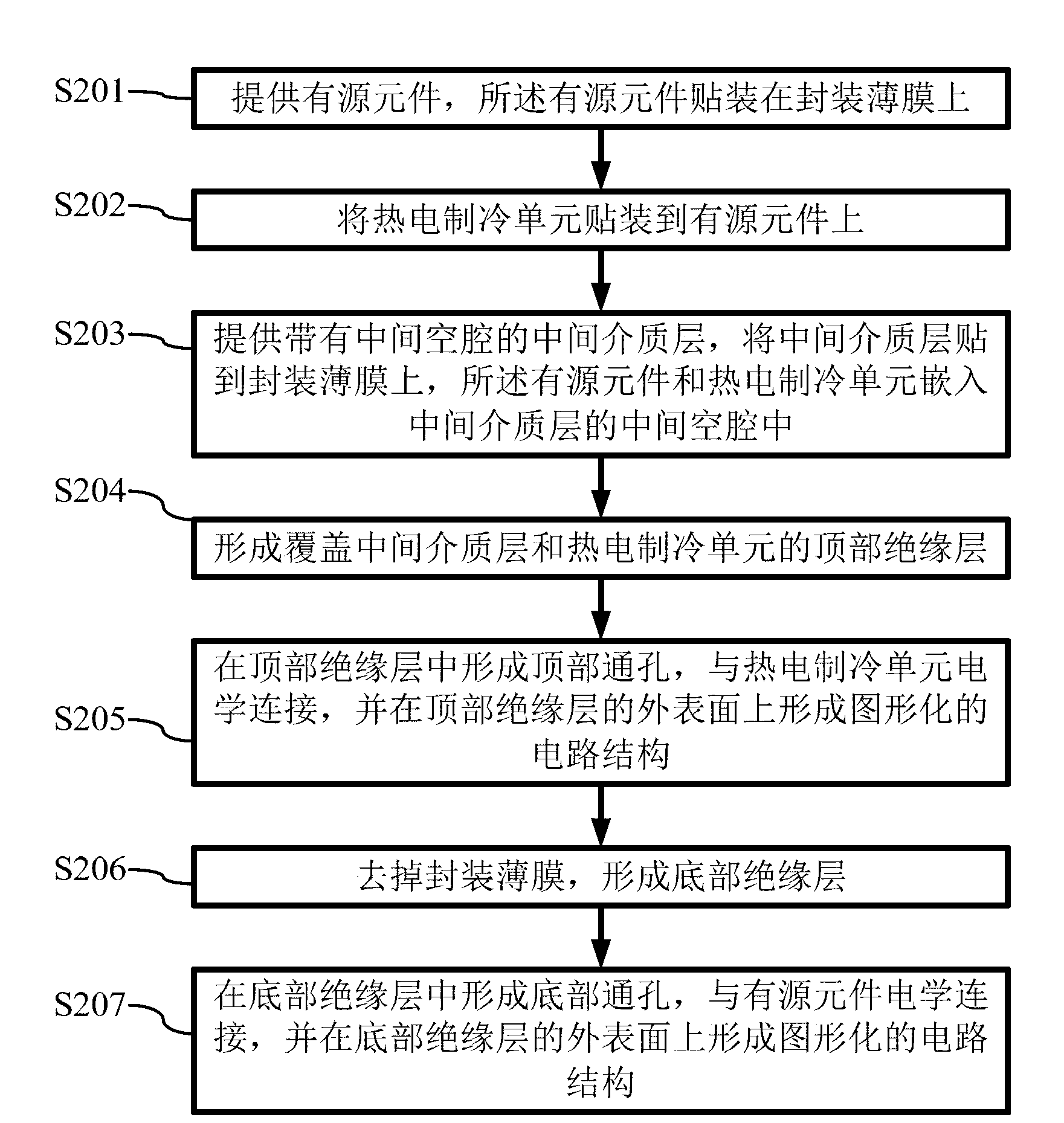

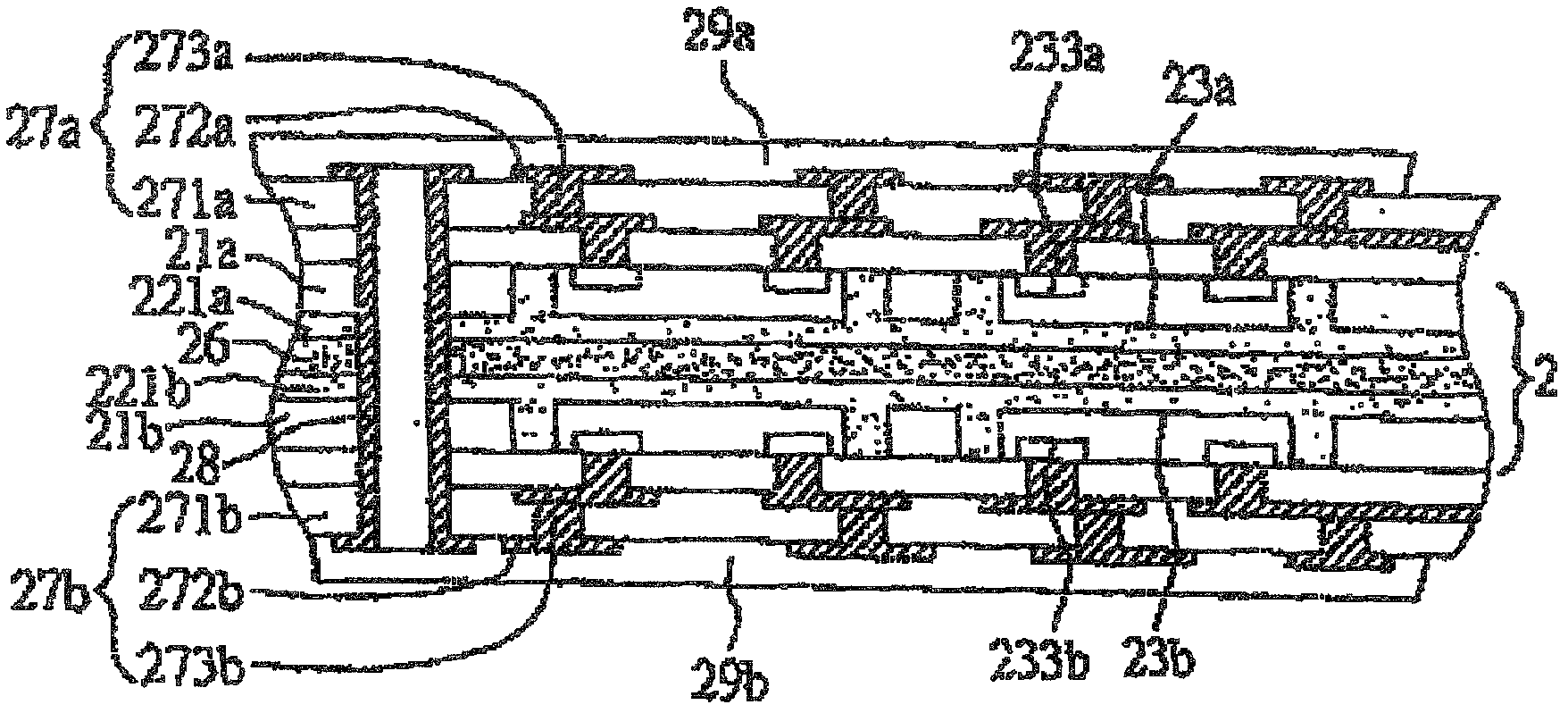

Electronic component package and manufacturing method thereof

ActiveCN102800636AControllable cooling efficiencyFlexible embedding positionSemiconductor/solid-state device detailsSolid-state devicesActive componentThermoelectric refrigeration

The invention discloses an electronic component package and a manufacturing method thereof, wherein, the electronic component package comprises a thermoelectric refrigeration unit and an active component, which are positioned in the package and are coupled together. The thermoelectric refrigeration unit comprises at least one N-type refrigeration element and at least one P-type refrigeration element which are connected in series. Correspondingly, the invention also provides the manufacturing method for two electronic component package structures. A single thermoelectric refrigeration unit or a plurality of the thermoelectric refrigeration units are embedded in a multilayered packaging baseplate in series, so that effective heat dissipation is provided to active component embedding technology. The electronic component package and the manufacturing method thereof can solve the problem of dimensional system packaging and especially the problem that the heat quantity cannot be brought out in the active component embedding packaging technology, and the heat dissipation performance can be improved.

Owner:NAT CENT FOR ADVANCED PACKAGING

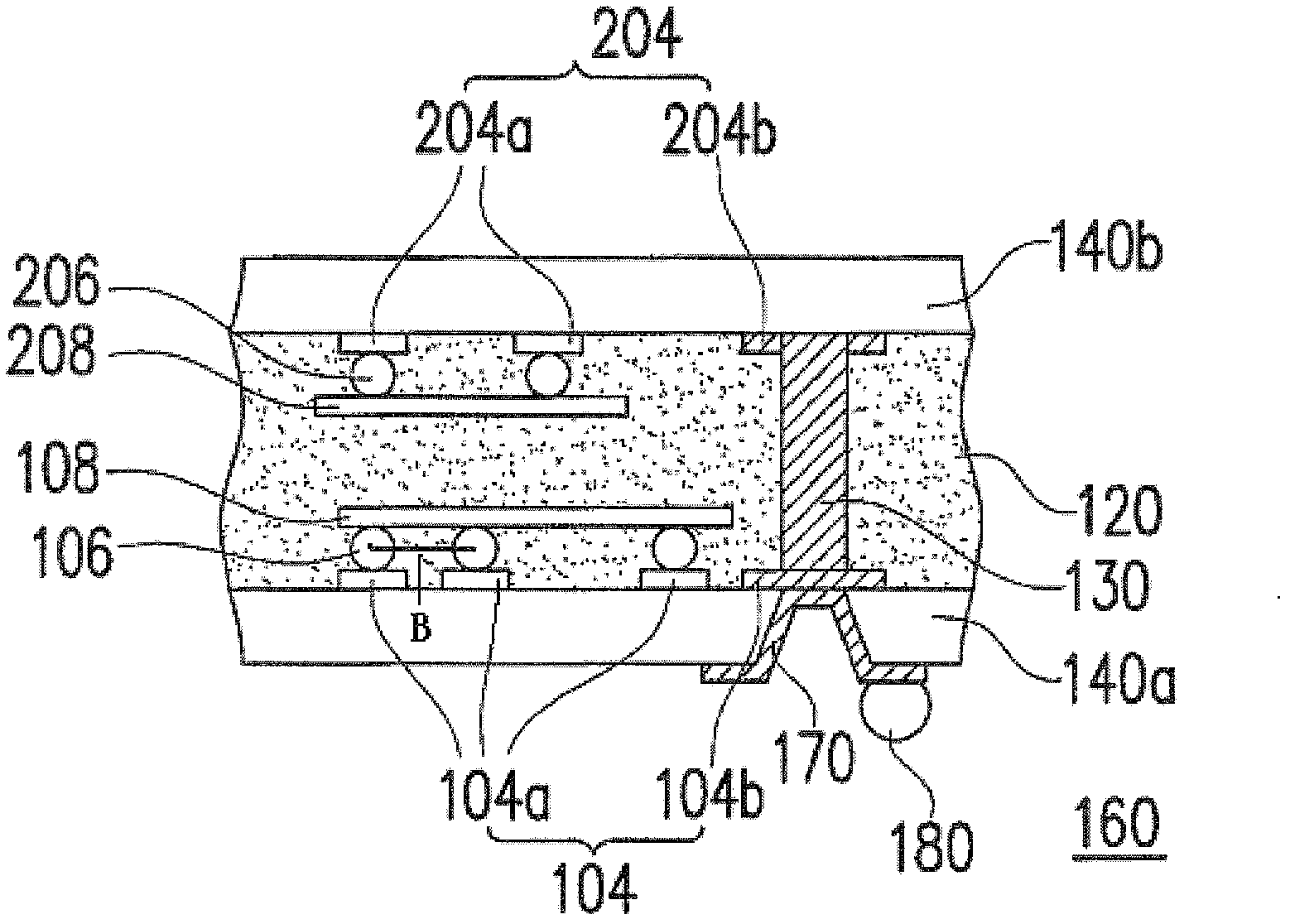

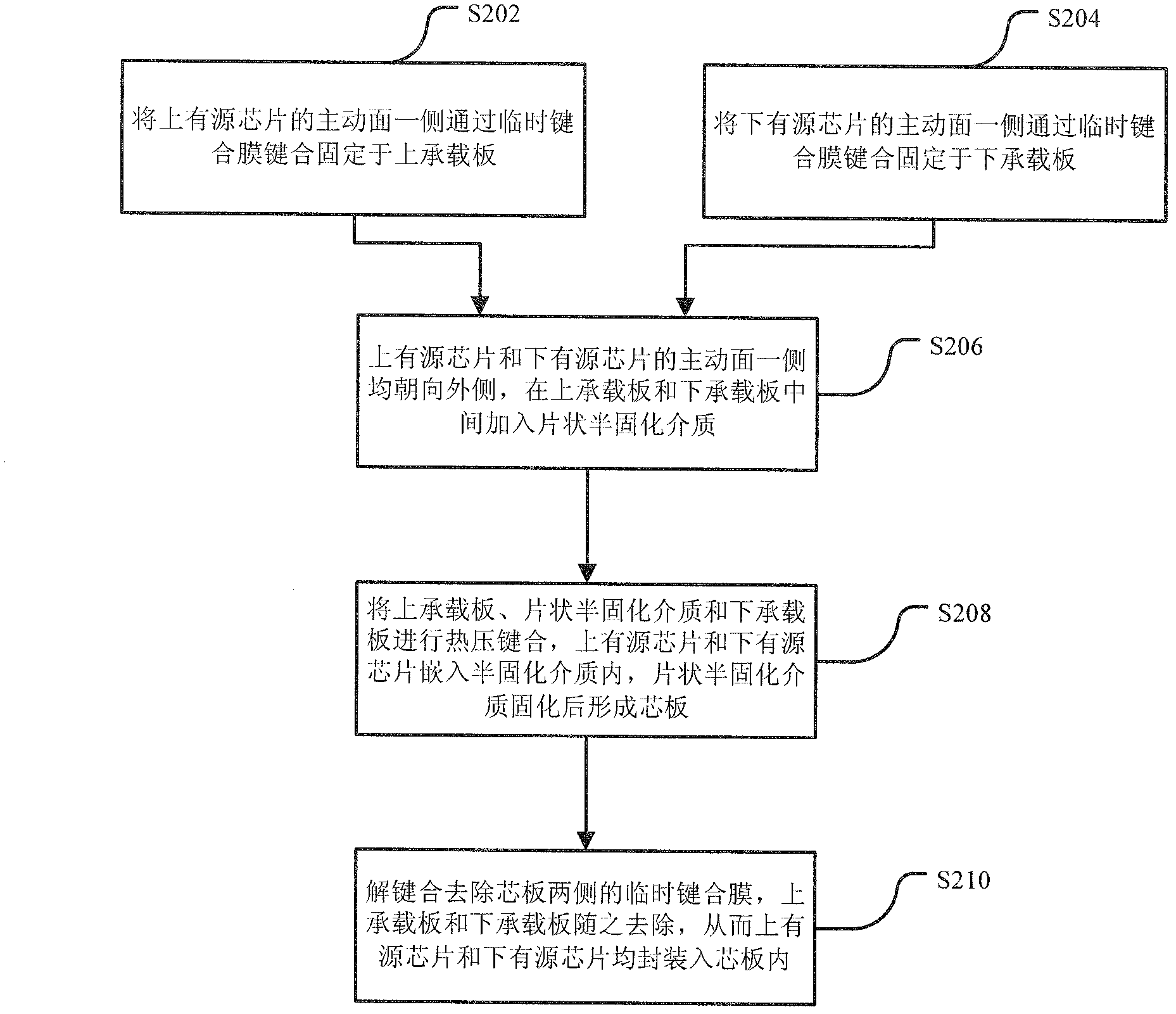

Package substrate of active chip and preparation method thereof

ActiveCN103137613AMiniaturizationAchieve lightweightSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrical connection

The invention provides a package substrate of an active chip and a preparation method of the package substrate of the active chip. The package substrate of the active chip comprises a core plate. The core plate comprises at least one upper active chip, and at least one lower active chip. The upper active chip is embedded into the core plate, an active face faces toward the lower surface of the core plate, and the upper active chip is an active unpacked chip. The lower active chip is embedded into the core plate, an active face faces toward the upper surface of the core plate and the lower active chip is an active unpacked chip. Due to the fact that the active chips are not packed before being embedded, thinning processing is carried out on the active chips, so that microminiaturization and light weight of the package structure are achieved, and therefore the manufacturing technology of the substrate is simplified. In addition, a plurality of the unpacked chips are simultaneously embedded into two faces of the substrate, and integrality is improved. Meanwhile, the freedom degree and the space on the two faces of the substrate are large, multi-layer wiring can be continuously carried out, and therefore process quality and reliability of electrical connection are improved.

Owner:NAT CENT FOR ADVANCED PACKAGING

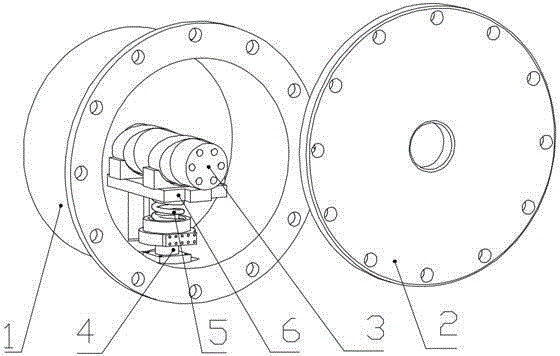

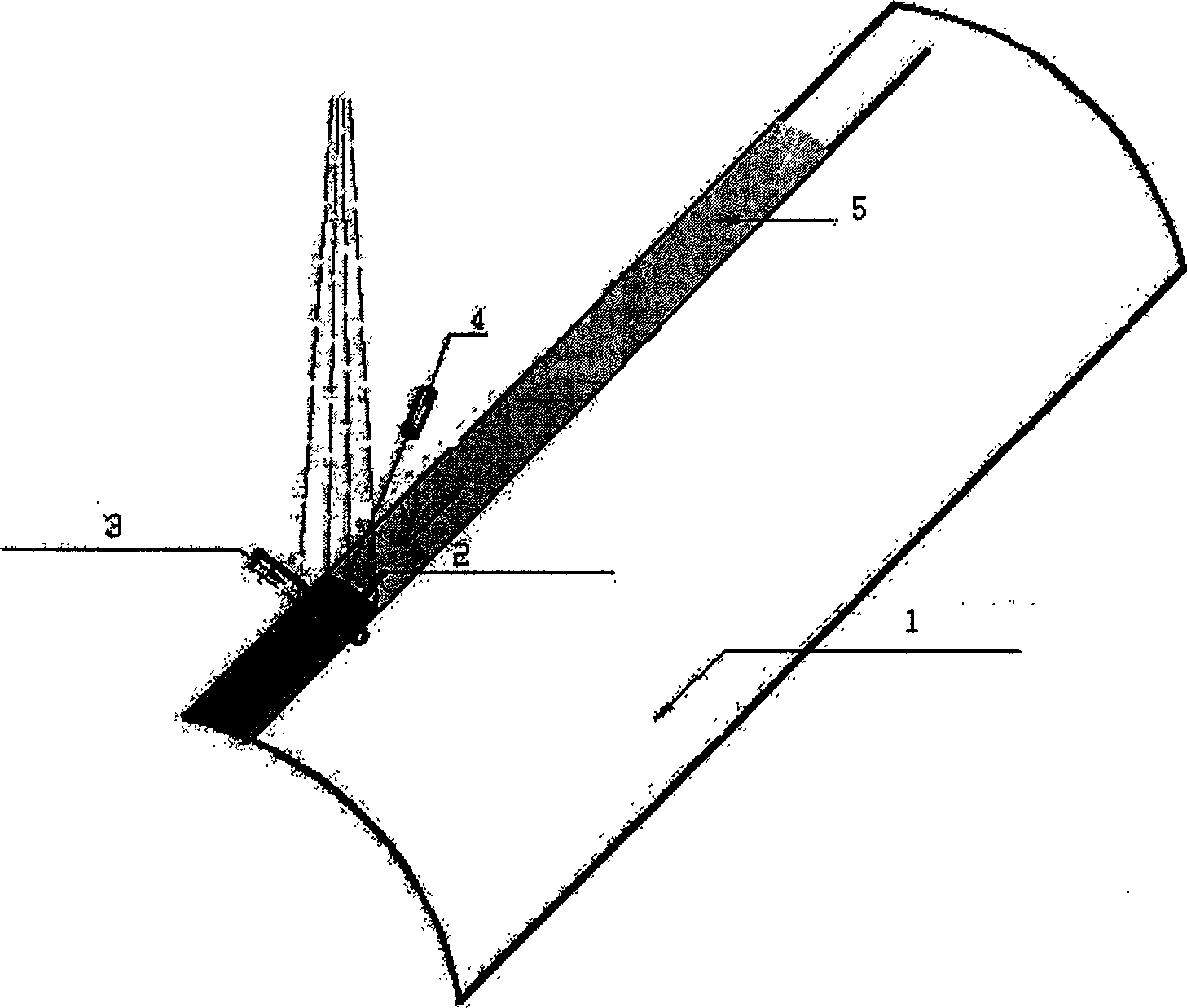

Integrated manufacturing method of composite material cavity member

InactiveCN104742383AGuaranteed quality and accuracyGuaranteed dimensional accuracyWater solubleTheoretical models

The invention discloses an integrated manufacturing method of a composite material cavity part. The integrated manufacturing method comprises the following steps: manufacturing a standard mould according to a theoretical model of the part, wherein a cavity of the standard mould is coincident to that of the part; coating the surface in the cavity with one layer of water-soluble surface filling material and then injecting a water-soluble core material, compacting, closing, curing an upper mould and a lower mould, removing the standard mould after curing to form a water-soluble core mould of the part; spreading a composite material prepreg on the surface of the water-soluble core mould and curing; and finally, washing the water-soluble core mould by using water to form the composite material cavity part.

Owner:XIAN AIRCRAFT BRANCH OF XIAN AIRCRAFT INT

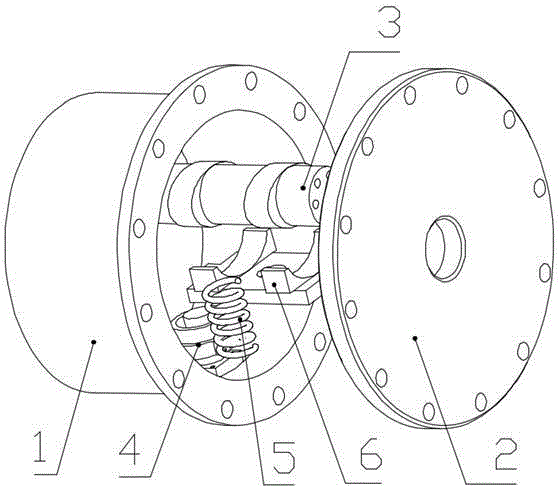

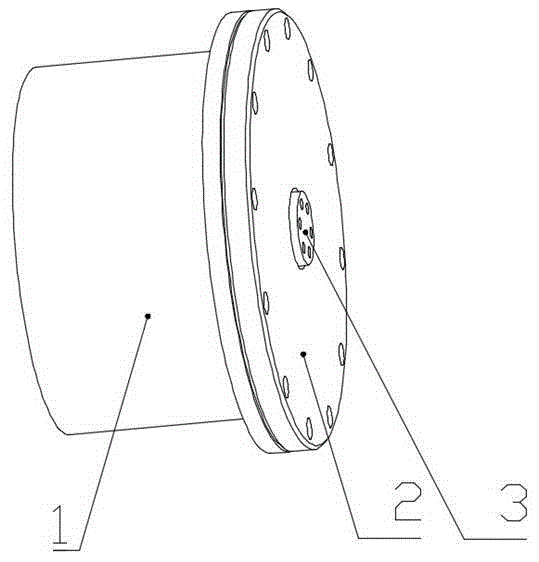

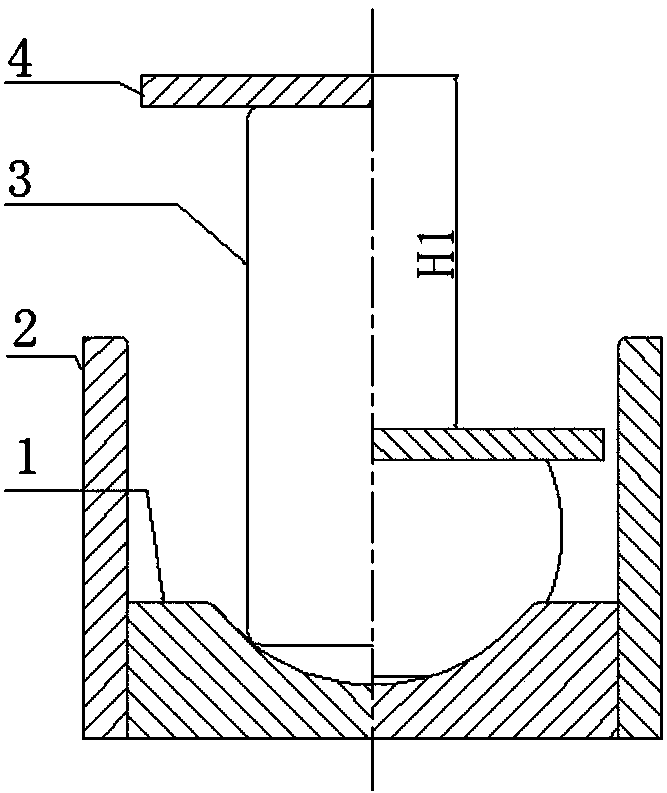

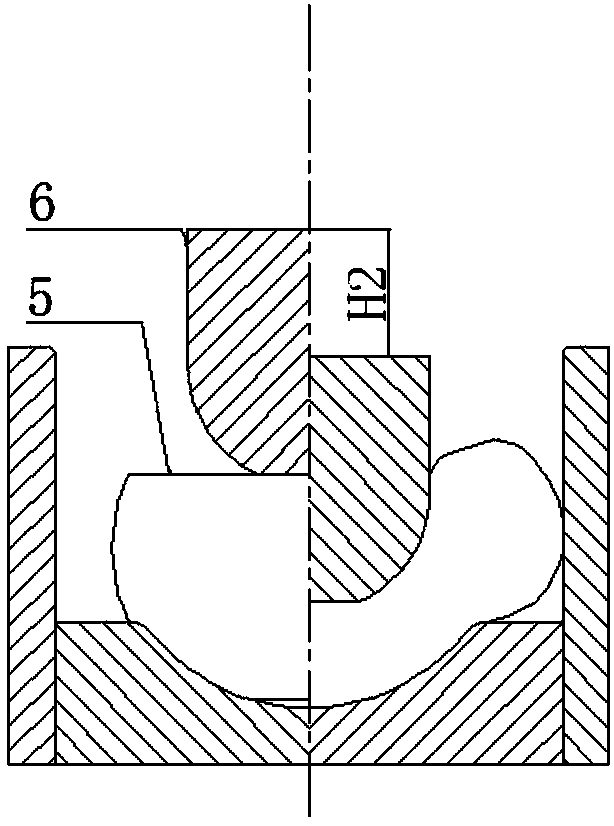

Machine safety variable-rigidity elastic joint and rigidity adjustment method

ActiveCN105171770AOvercome the disadvantage of limited rotation angleUndamagedJointsElasticity measurementEngineeringCam

The invention discloses a machine safety variable-rigidity elastic joint. The machine safety variable-rigidity elastic joint concretely comprises a first joint output shaft, a second joint output shaft, a linear motor, a spring and a push disc. The machine safety variable-rigidity elastic joint is characterized in that a motor installation base is arranged on the inner side face of the first joint output shaft, the linear motor is fixed to the motor installation base, a moving component of the linear motor is fixedly connected with the spring, the other end of the spring is fixedly connected with the push disc, the second joint output shaft is a cam shaft and is in cam shaft transmission with the push disc, and the second joint output shaft is in revolute pair connection with the first joint output shaft.

Owner:SICHUAN UNIV

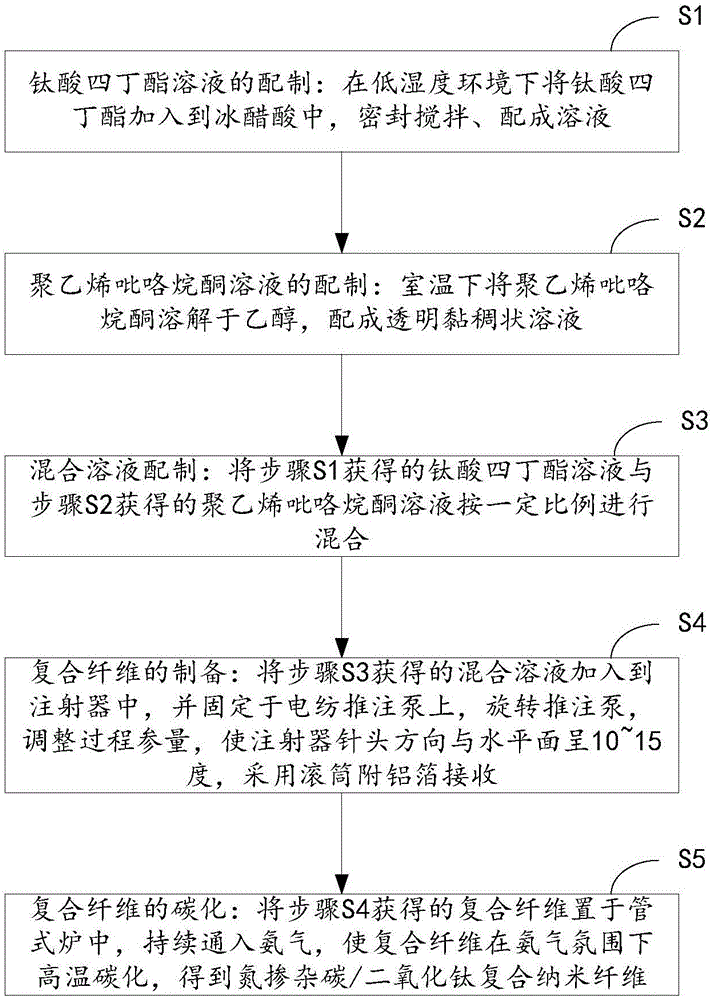

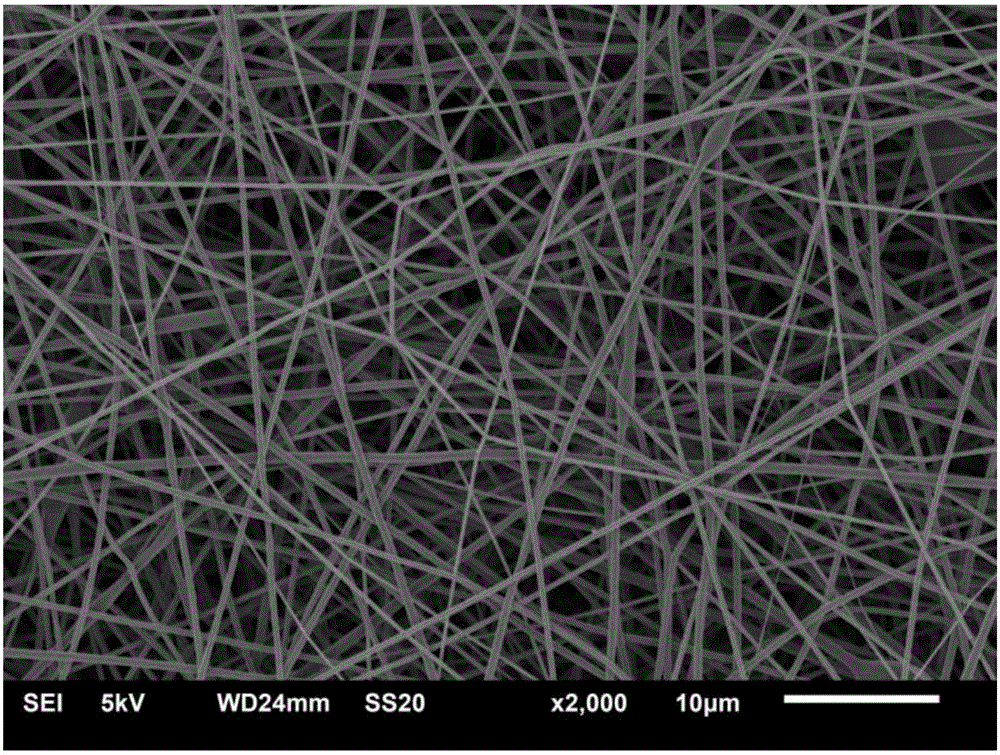

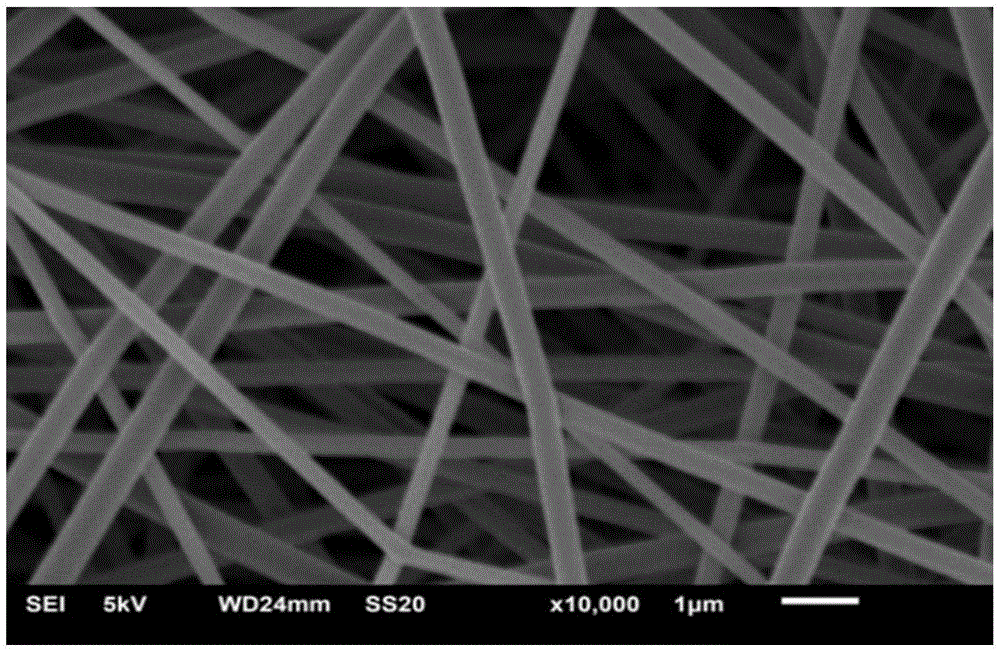

Nitrogen-doped carbon/titanium dioxide composite nanofibers carrier preparation method

InactiveCN106245158ARealize integrated manufacturingHigh surface areaCatalyst carriersCell electrodesFiberPorosity

The invention reveals a nitrogen-doped carbon / titanium dioxide composite nanofibers carrier preparation method. The preparation method comprises the following steps: mixing an acetate acid gracial solution of tetrabutyl titanate and an ethanol solution of polyvinylpyrrolidone according to a proper proportion, preparing a composite fibrous material through a static spinning technology, and performing high-temperature carbonization on the fibrous material under ammonia gas atmosphere to obtain the nitrogen-doped carbon / titanium dioxide composite nanofibers. According to the invention, integrated preparation of titanium dioxide, carbon and the composite nanofibers is realized, and organic fusion of a carbon material and titanium dioxide is realized. The composite material has high specific surface and porosity, charge characteristics of the composite material can be adjusted through doping of the nitrogen atoms, corrosion resistant performance and conductivity of a catalyst carrier is increased, the catalyst carrier is excellent, material transmission is improved, and the method has good application prospect in a proton exchange membrane fuel cell.

Owner:XUZHOU NORMAL UNIVERSITY

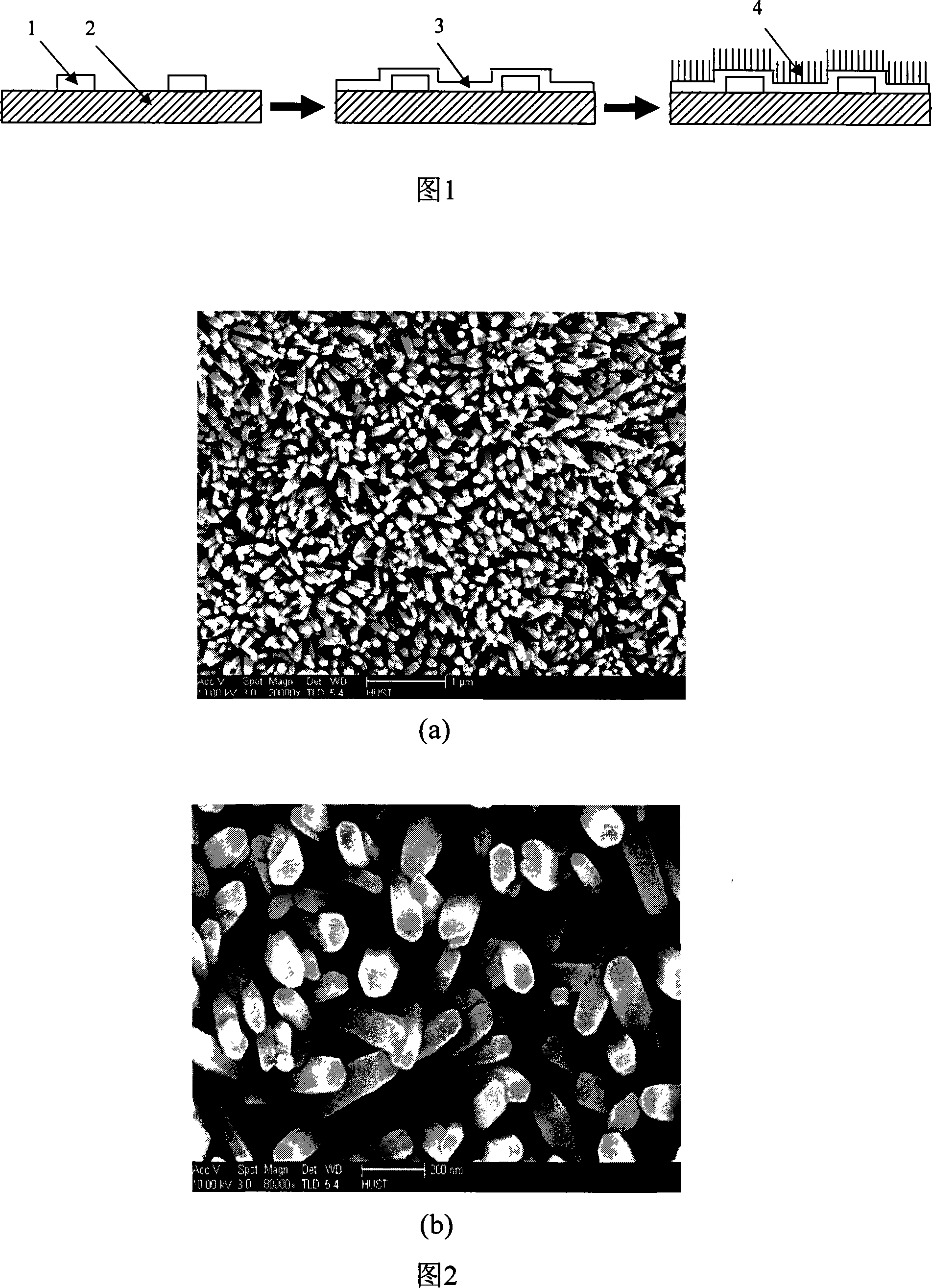

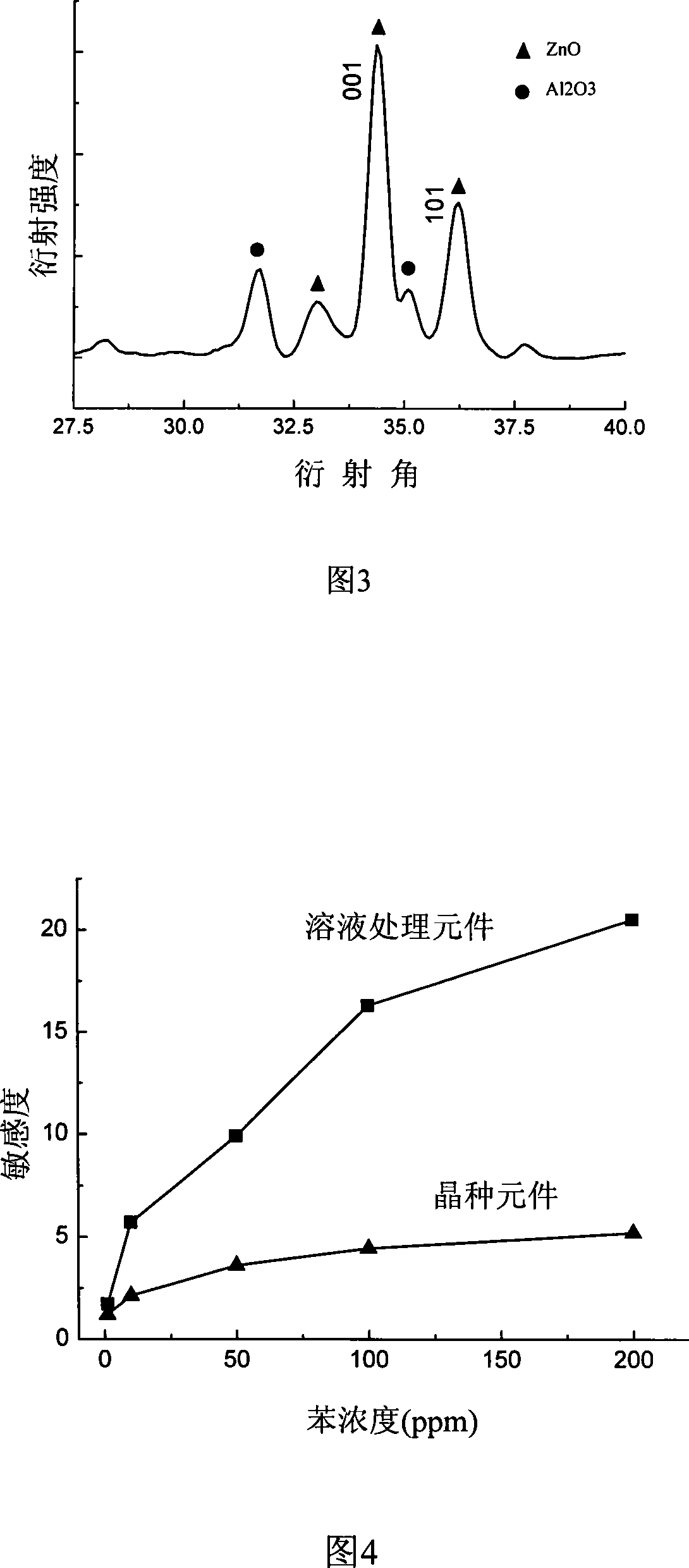

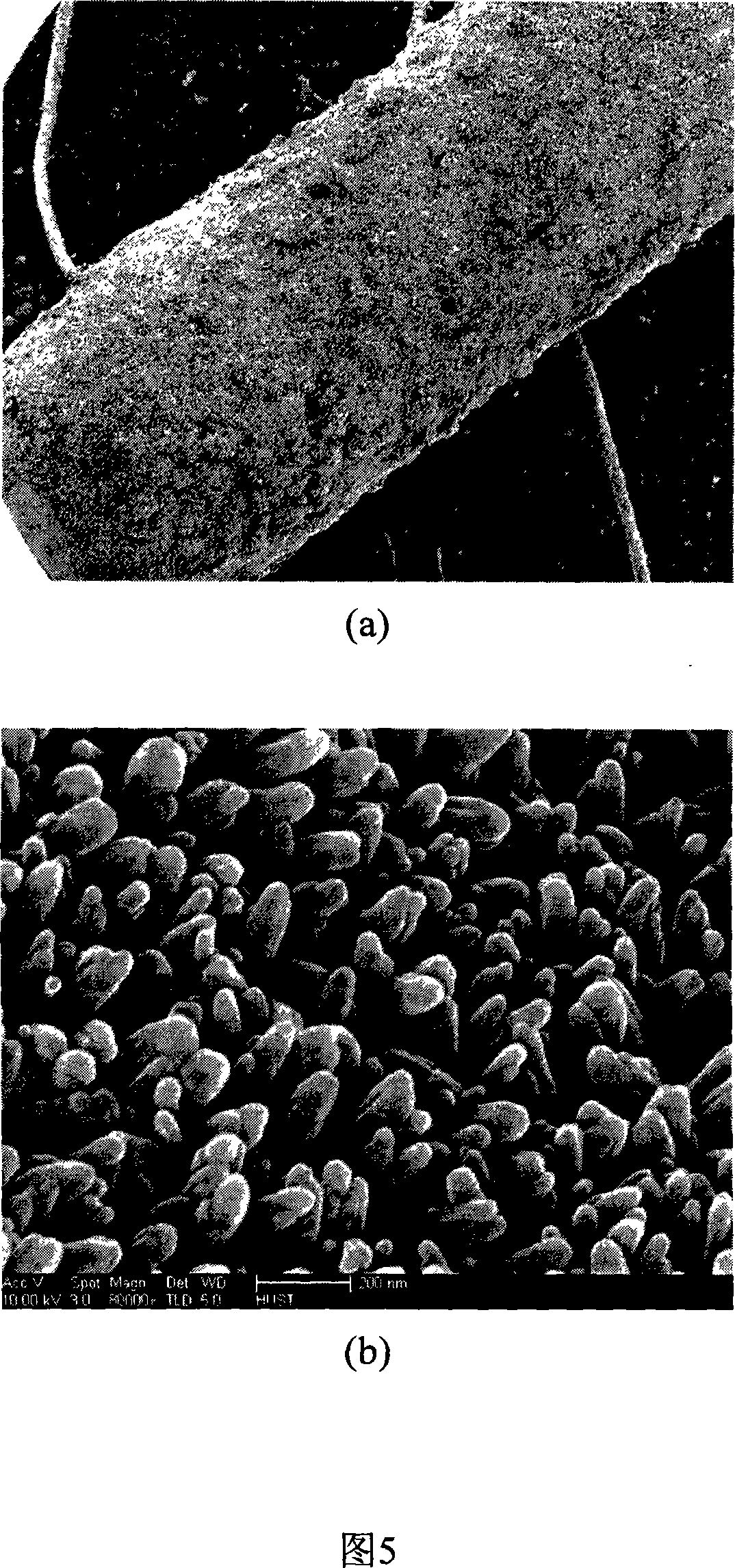

Semi-conductor oxidate gas sensor preparation method

InactiveCN101158661ARealize integrated manufacturingEffective control of grain morphologySolid-state devicesMaterial resistanceSolventIon

The invention discloses a semiconductor oxide gas sensor component preparation method. (1)The invention cleans and dries a substrate printed with heating electrode and a measuring electrode, lays the substrate into water or alcohol solution with the soluble metal salts soaking, then dries, heats and decomposes the substrate, finally forms the seed crystal; (2) matches the water or the alcoholic solution with the homogeneous metallic ion soluble salt, adopts the same solvent dispensing precipitant solution, drips the solvent into the water or the alcoholic solution and mixes the solution evenly, then hangs and soaks the substrate in the solution, seals and heats up;(3) removes, washes, and sinters the substrate to obtain the gas sensor component. The traditional technique preparation of materials and components produced are separated. The invention utilizes simple technique preparing the high-sensitivity nanometer semiconductor oxide gas sensor component to overcome the shortcomings, and realizes the effective regulation to the surface sensitive components microstructure. The preparation method has the advantages that low requirements to the production equipment and environment, energy conservation, low cost, and mass production, therefore the invention is expected to be widely applied in the field of gas sensor.

Owner:HUAZHONG UNIV OF SCI & TECH

Laser reinforcing process of the intake side of turbine vane

InactiveCN1740350ARealize integrated manufacturingEasy to operateHeat treatment process controlSolution treatmentLaser power density

The laser reinforcing process is for treating the intake side of turbine vane made of super high strength stainless steel. The laser reinforcing process includes the following steps: cleaning the surface of the intake side to be treated; painting light absorbing alloy material; laser solid solution treatment of the selected area with proper laser beam after the alloy layer dries, with the laser solid solution treatment parameters including laser power density of 500-1200 w / sq cm, layer moving speed of 50-300 mm / min and solid solution treatment temperature of 1150-1600 deg.c; cooling while laser solid solution treatment; and final ageing treatment at temperature of 400-570 deg.c for 2.0-5.0 hr.

Owner:ZHEJIANG UNIV OF TECH

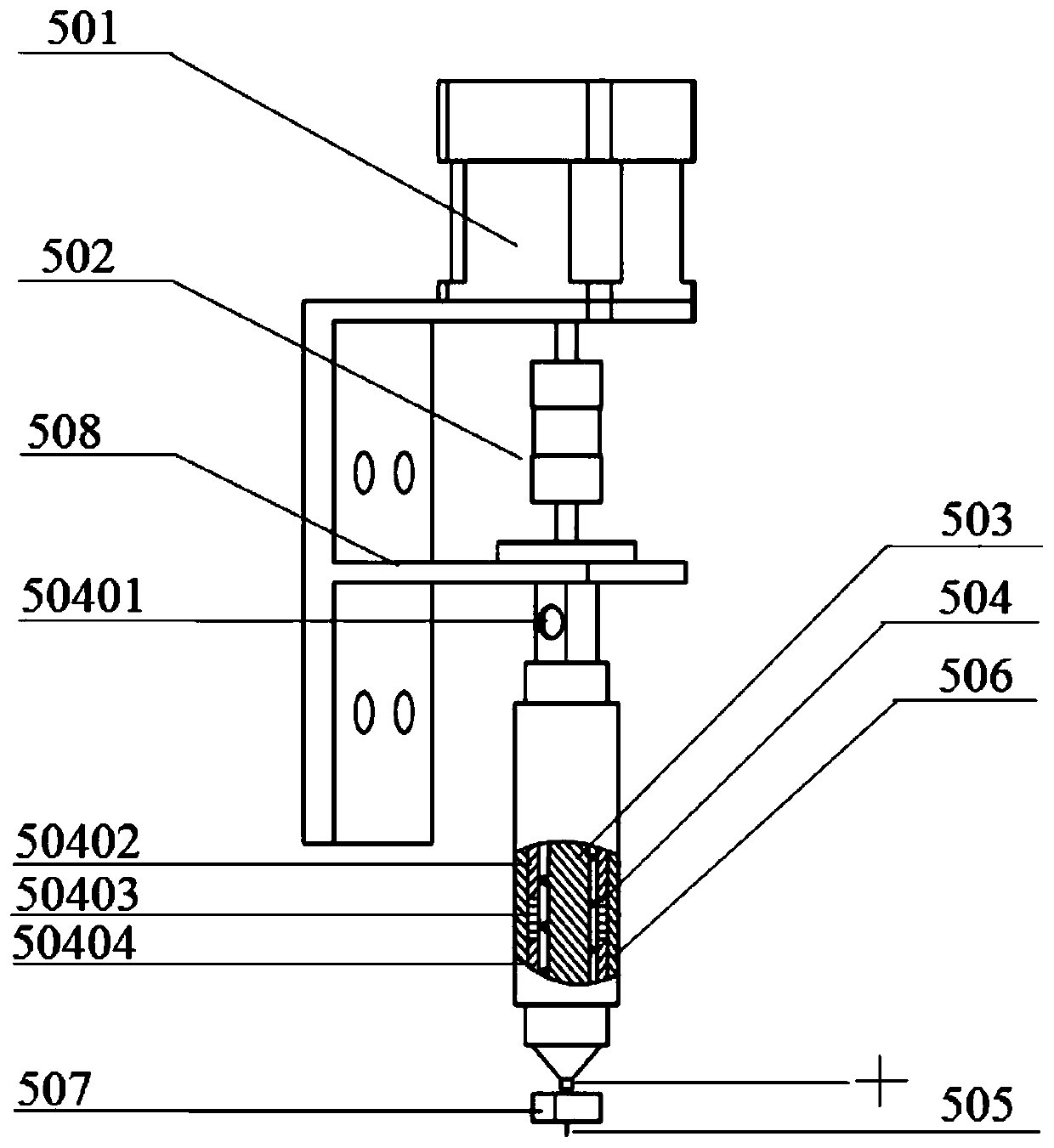

Multi-material 3D printing device for integrally manufacturing stretchable electronic product and working method

PendingCN109732900AAchieving heat curingReduce printing timeManufacturing platforms/substratesManufacturing heating elementsStretchable electronicsMulti material

The invention provides a multi-material 3D printing device for integrally manufacturing a stretchable electronic product and a working method. The device comprises a base and a control module; the base is provided with a three-dimensional workbench, a placing platform, a swing table and a printing bed, wherein the printing bed is arranged on the swing table, and the swing table drives the printingbed with vacuum adsorption and electric heating functions to swing and rotate; and the three-dimensional workbench comprises at least four Z-direction workbenches, the first Z-direction workbench isprovided with a mechanical arm used for grabbing and placing electronic elements, and each of the remaining Z-direction workbenches is provided with a printing nozzle. Movement of the three-dimensional workbench, the swinging table, the mechanical arm and a feeding module are controlled, each printing nozzle executes printing of a flexible base plate, a protective layer, a connecting circuit, an embedded electronic element and a packaging layer of the stretchable electronic product according to a set sequence, and thus integrated manufacturing is realized.

Owner:QINGDAO 5D INTELLIGENT ADDITIVE MFG TECH CO LTD

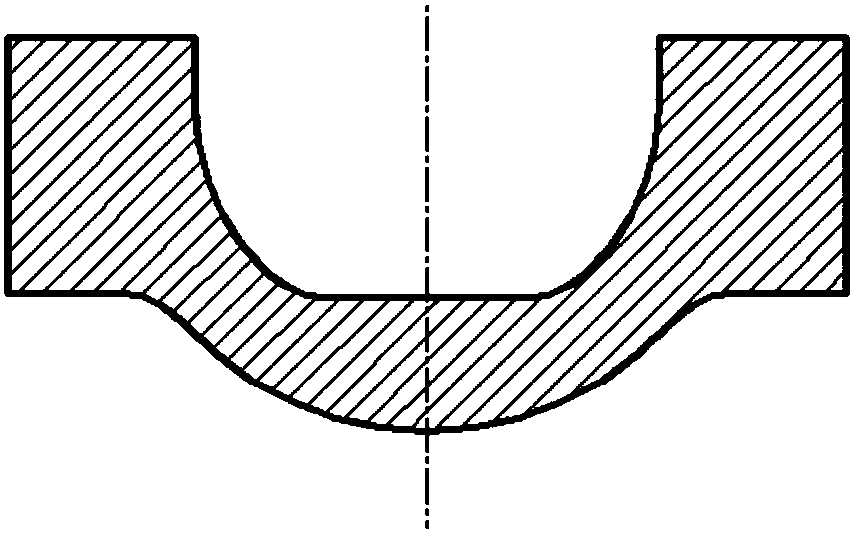

Integral forging method of variable-wall-thickness thick-wall end socket of high flange

The invention discloses an integral forging method of a variable-wall-thickness thick-wall end socket of a high flange. The method comprises the following steps that shape sizes of forging blanks andforging molds are determined through calculation according to relevant data of the target end socket, corresponding molds are manufactured, after steel ingots are heated to a forging temperature, thesteel ingots are subjected to upsetting and drawing to obtain cylindrical blanks conforming to calculation, the cylindrical blanks are put into a set concave die and a cylindrical die, and are subjected to upsetting and deforming to a set height by using a circular flat plate, after the upset blanks are heated again, the blanks are put back into the concave die and the cylindrical die, a rotary punching head is used for carrying out punching deformation on the blanks, the punched blanks are re-heated and are put back into the concave die and the cylindrical die, an annular inner pressing ringand an annular outer pressing ring are used for compressing and deforming upper end metal of the extruded blanks to a set height, and therefore the required size of a forged piece is met. According tothe integral method, in-mold forming is adopted, and the obtained forged piece is regular in shape and good in performance; and the method is short in technological process, does not have special requirements on forging devices, and is convenient to popularize and apply.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

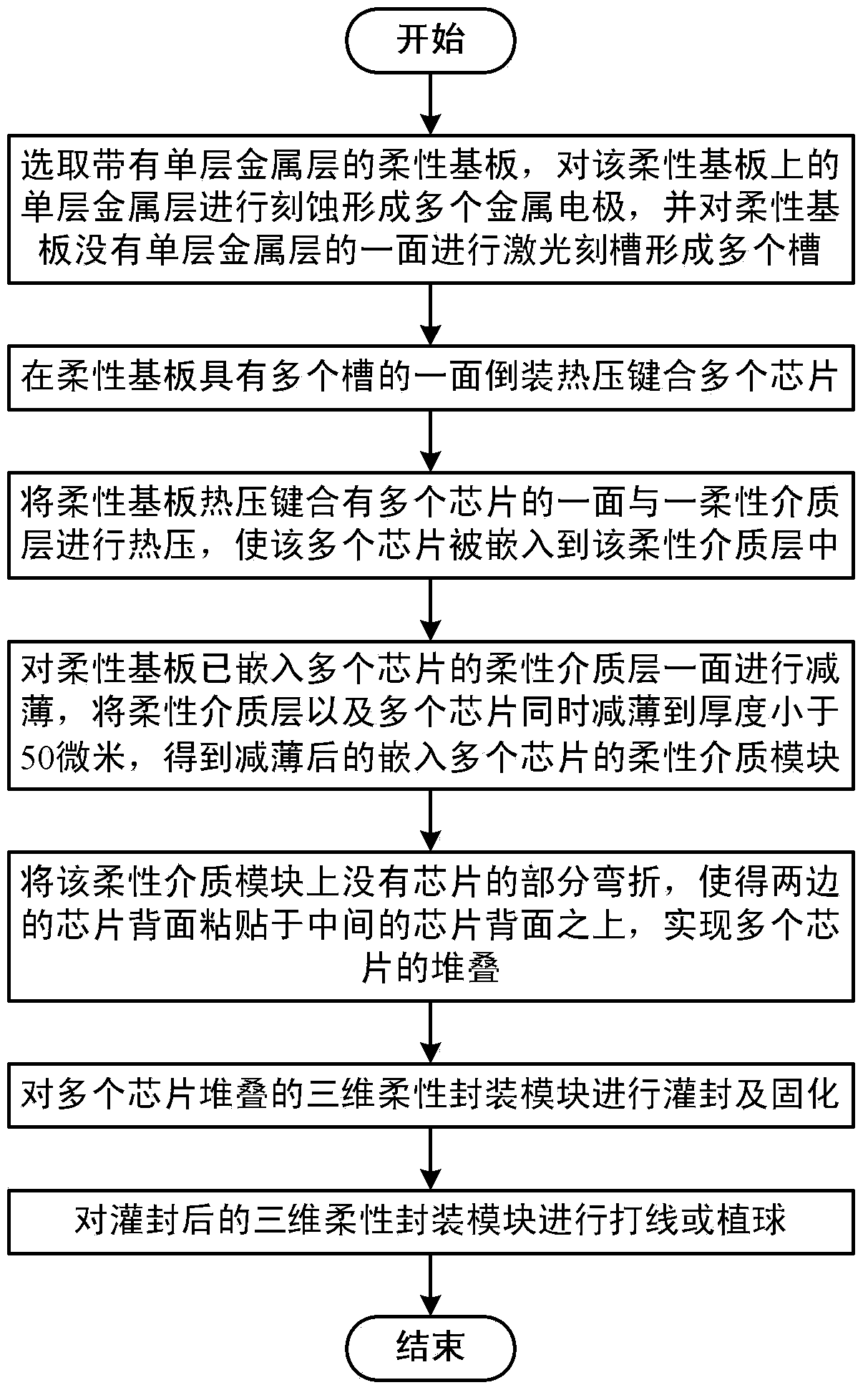

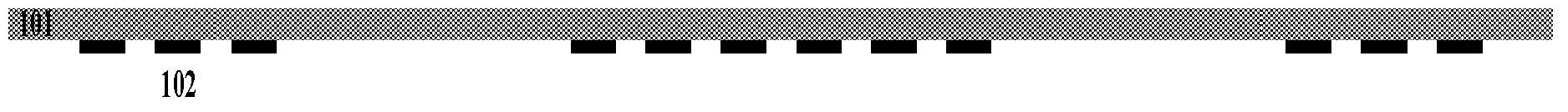

Method for manufacturing three-dimensional flexible stacked encapsulating structure of embedded ultrathin chip

ActiveCN103681458AEfficient use ofEffective coolingSolid-state devicesSemiconductor/solid-state device manufacturingComputer moduleEngineering

The invention discloses a method for manufacturing a three-dimensional flexible stacked encapsulating structure of an embedded ultrathin chip. The method comprises choosing a flexible substrate with a single-layer metal layer, etching the single-layer metal layer on the flexible substrate to form a plurality of metal electrodes, conducting laser grooving on one side of the flexible substrate without the single-layer metal layer to form a plurality of grooves, conducting flipped thermocompression bonding with a plurality of chips on one side of the flexible substrate, provided with the plurality of grooves, thermally compressing the side of the flexible substrate, provided with the plurality of chips through thermocompression bonding and a flexible medium layer to embed the plurality of chips into the flexible medium layer, thinning one side of flexible medium layer embedded with the plurality of chips of the flexible substrate to obtain a thinned flexible medium module embedded with the plurality of chips, bending a part of the flexible medium module without the chips to stack the chips, encapsulating and curing a three-dimensional flexible encapsulating module with the plurality of stacked chips, and routing or reballing the encapsulated three-dimensional flexible encapsulating module.

Owner:NAT CENT FOR ADVANCED PACKAGING

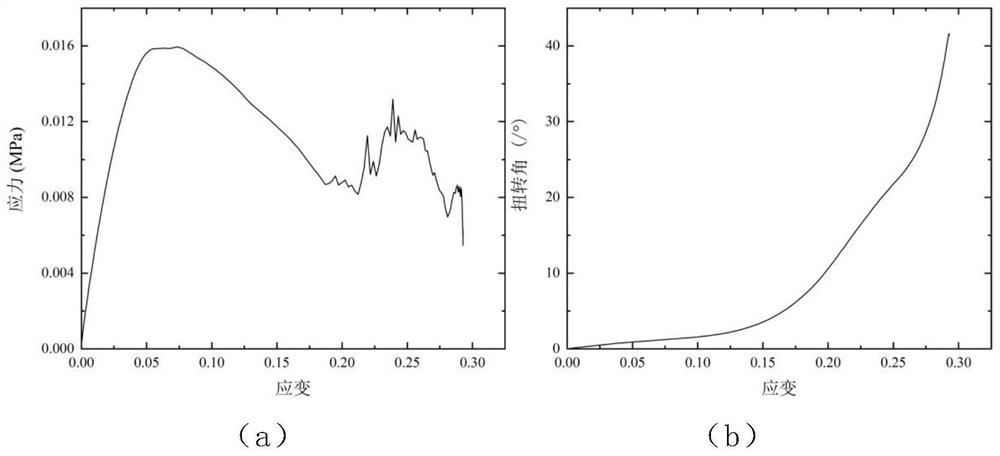

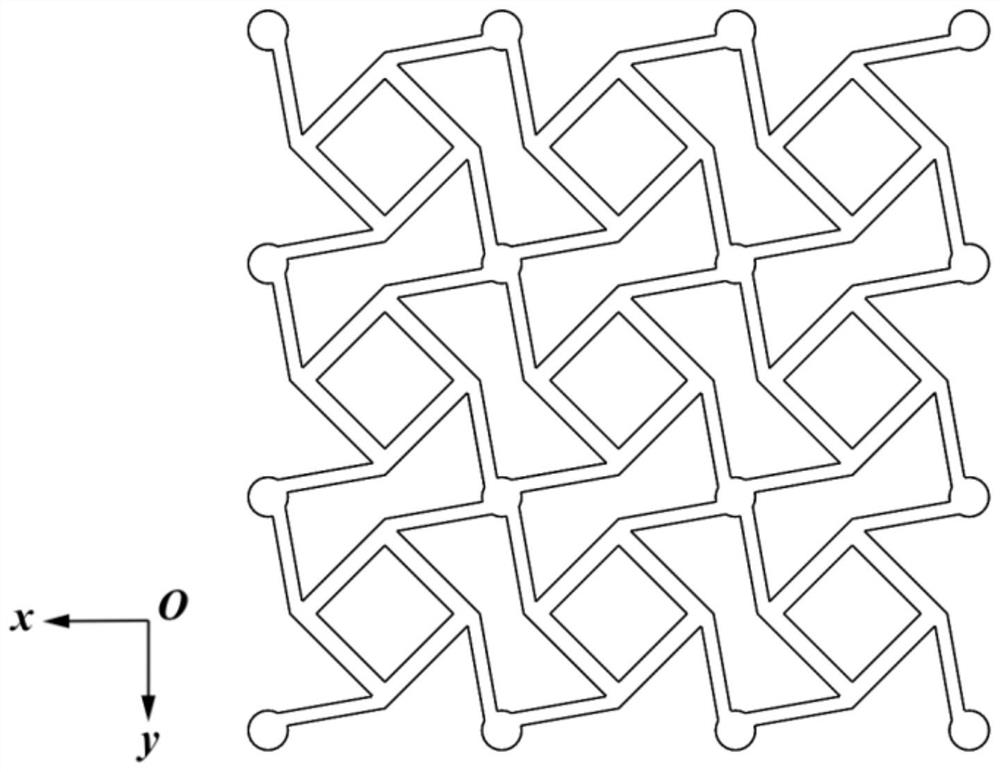

Chiral auxetic metamaterial structure with compression-shear coupling characteristic and preparation method thereof

ActiveCN112045990AStrong energy absorption and impact resistanceBroaden your optionsAdditive manufacturing apparatusElastic dampersCrystallographyEnergy absorption

The invention discloses a chiral auxetic metamaterial structure with a compression-shear coupling characteristic and a preparation method thereof. Polygonal chiral structures with different shapes areperiodically arranged and connected with each other, so that the chiral auxetic metamaterial structure simultaneously has excellent compression-shear coupling characteristic and auxetic characteristic; and as the intersections of connecting rods are connected in a circular manner, negative Poisson's ratio behaviors are generated through two deformation mechanisms of indenting and rotation when aload is borne, so that very strong energy absorption and impact resistance characteristics are formed. Simulation results show that the chiral auxetic metamaterial structure with the compression-shearcoupling characteristic has remarkable compression-shear coupling and auxetic characteristics and has a wide prospect in industrial application.

Owner:XI AN JIAOTONG UNIV +1

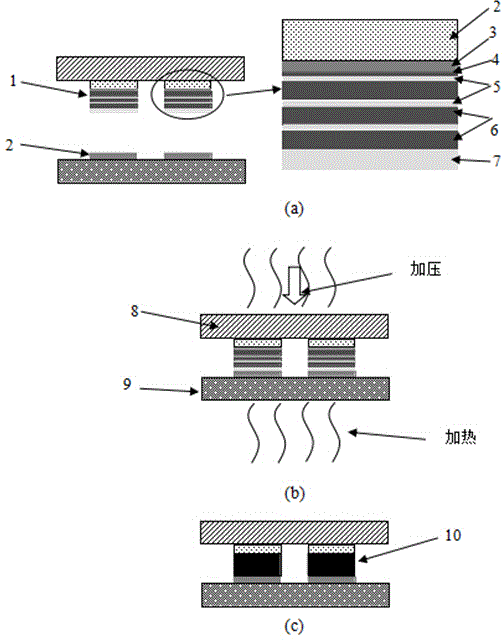

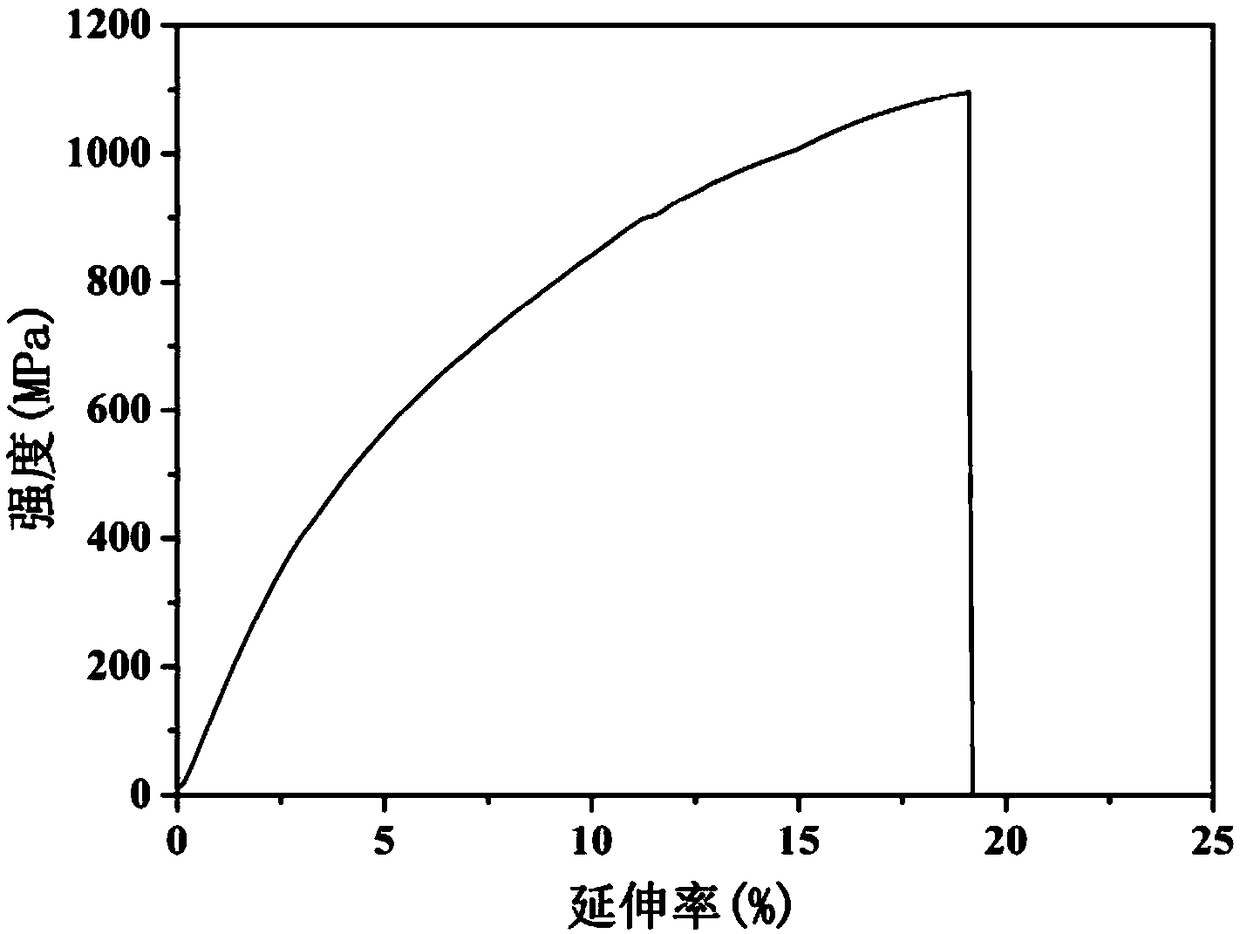

Method for fast preparing high-temperature service total IMC microscale solder joint through multi-layer micron and submicron film

ActiveCN104862701AImprove performanceRealize integrated manufacturingVacuum evaporation coatingSputtering coatingMembrane surfaceThin membrane

A method for fast preparing a high-temperature service total IMC microscale solder joint through a multi-layer micron and submicron film comprises the following steps that a Cu or Ag film is prepared on the surface of a bonding pad of a wafer or a chip, Sn / (Cu or Ag) with the micron-level or submicron-level thickness is sequentially deposited, the deposition step of the Sn / (Cu or Ag) film can be repeatedly executed according to the height of the needed solder joint, and after the needed thickness is reached, a Sn film is prepared on the surface of the multi-layer micron and submicron film; a multi-layer film structure of the wafer or the chip is aligned with a connecting bonding pad needed by a substrate or other wafers or other chips, and pressure is applied; the system is placed in a reflow oven, the preheating stage, the insulating stage, the reflowing stage and the cooling stage are carried out, and finally preparation of the total IMC solder joint is achieved. The total IMC solder joint preparing technology can be well compatible with a traditional brazing filler metal reflow soldering technology or a hot pressure soldering technology, and preparation of the IMC solder joint at the low temperature and within the short time can be achieved. The low-temperature bonding high-temperature service of the solder joint is achieved on the premise that cost is low, and the production efficiency is high.

Owner:HARBIN INST OF TECH

3D-printing in-situ rare earth doped titanium matrix composite material activated bone implant and forming method

ActiveCN108705092AImprove service performanceImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyTitanium matrix compositesArgon atmosphere

The invention discloses a 3D-printing in-situ rare earth doped titanium matrix composite material activated bone implant. The implant comprises an in-situ rare earth doped titanium matrix composite material formed by in-situ rare earth Re2O3, an in-situ TiB ceramic phase and a hydroxyapatite ceramic phase. A preparation method comprises the steps that B2O3 powder and rare earth Re powder are subjected to ball-milling mixing by adopting a high-energy ball milling technology under inert gas shielding, and B2O3 / Re mixed powder is obtained; the B2O3 / Re mixed powder, hydroxyapatite powder and 3D-printing dedicated spherical titanium alloy powder are weighed, a low-energy ball milling technology under inert gas auxiliary shielding is adopted, and titanium alloy composite material powder is obtained; and under the argon atmosphere, the in-situ rare earth Re2O3, in-situ TiB ceramic and hydroxyapatite ceramic reinforced titanium matrix composite material activated bone implant is formed by means of laser 3D-printing. According to the method, the service performance of the titanium alloy bone implant is improved through rare earth in-situ doping, and precision manufacturing of the high-performance complex-structure titanium alloy activated bone implant can be achieved.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

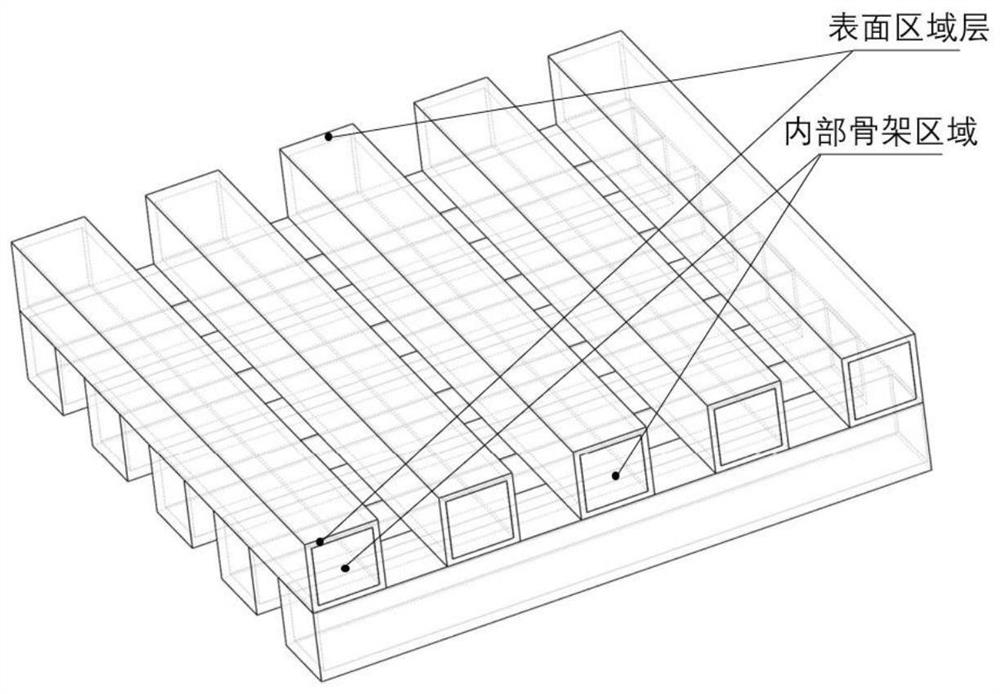

Method for 3D printing of monolithic catalyst

ActiveCN112058317ARealize integrated manufacturingReduce macerationAdditive manufacturing apparatusCatalyst activation/preparation3d printPtru catalyst

The invention relates to a method for 3D printing of a monolithic catalyst. The method comprises the following steps: simulating a designed three-dimensional model of the monolithic catalyst for different catalytic reactions, and optimally designing the three-dimensional model according to the simulation effect; slicing the optimized three-dimensional model, introducing the sliced three-dimensional model into a screw extrusion 3D printer, carrying out 3D printing on a surface region layer of the monolithic catalyst by adopting catalytic active component slurry, and carrying out 3D printing onan internal skeleton region by adopting ceramic slurry; carrying out constant-temperature and constant-humidity drying on the integral catalyst primary blank obtained by 3D printing; and finally, carrying out a high-temperature sintering process on the monolithic catalyst initial blank to obtain the 3D printing monolithic catalyst. According to the invention, the advantages of multi-material printing of 3D printing, easiness in tight combination with structure simulation and capability of preparing a complex porous structure can be brought into full play, and integrated, low-cost and rapid manufacturing of the monolithic catalyst with the complex structure is realized.

Owner:陕西斐帛思凯科技发展有限公司

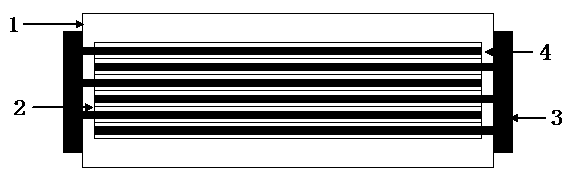

Graphite paper-barium titanate/polymide integrated composite thin-film capacitor

ActiveCN104036957ADirectly Test Dielectric PropertiesImprove thermal stabilityLiquid surface applicatorsThin/thick film capacitorBarium titanateGraphite

The invention relates to a graphite paper-barium titanate / polymide integrated composite thin-film capacitor. The graphite paper-barium titanate / polymide integrated composite thin-film capacitor comprises one or more layers of graphite-paper inner electrodes, dielectric layers among the inner electrodes and end electrodes at two ends. The graphite-paper-barium titanate / polymide integrated composite thin-film capacitor is characterized in that tatanate / polymide composite films are used as the dielectric layers, and the dielectric layers are integrally manufactured by graphite paper as carriers by means of the Czochralski method; the polymide is used as shell packing materials. The graphite-paper-barium titanate / polymide films are made by the Czochralski method, and solvent is removed and air microbubbles easy to cause breakdown are eliminated by reaction of vacuum heat imidization, so that dielectric constant is increased and the graphite paper-barium titanate / polymide integrated composite thin-film capacitor high in dielectric performance is manufactured. The manufactured thin-film capacitor has higher thermal stability, small thickness, high dielectric constant and low dielectric loss, energy loss caused by high-temperature sintering is avoided, and large-area manufacturing is realized.

Owner:OCEAN UNIV OF CHINA

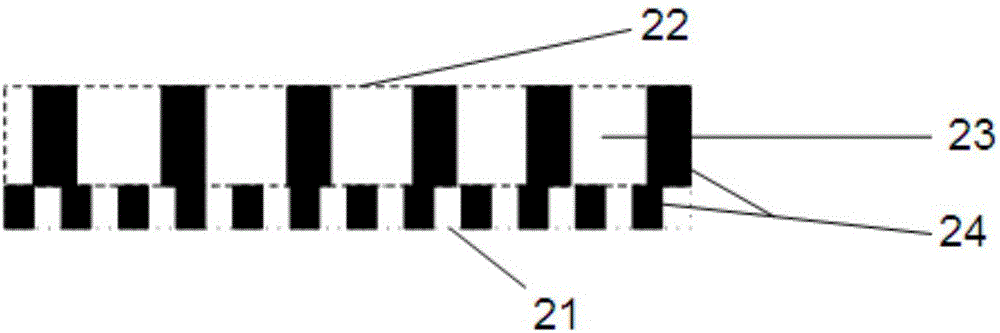

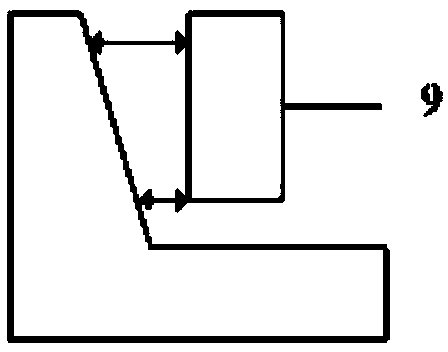

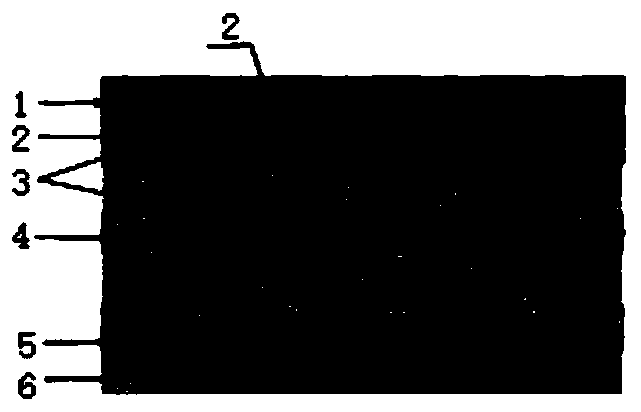

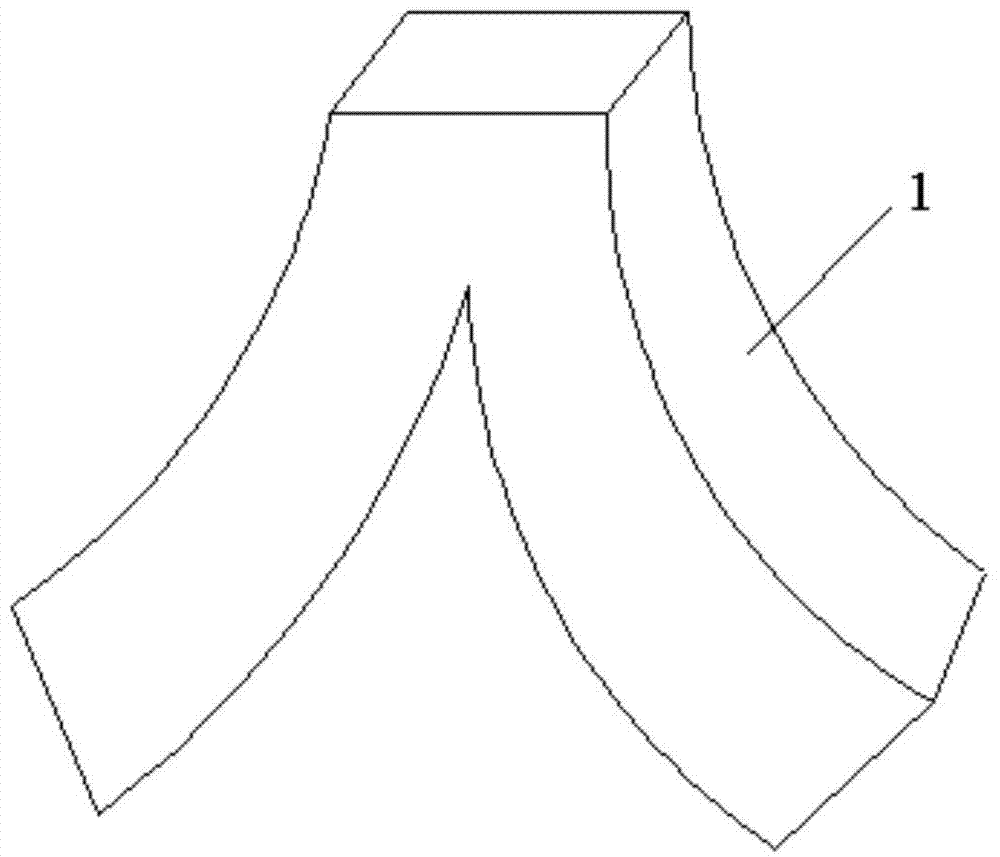

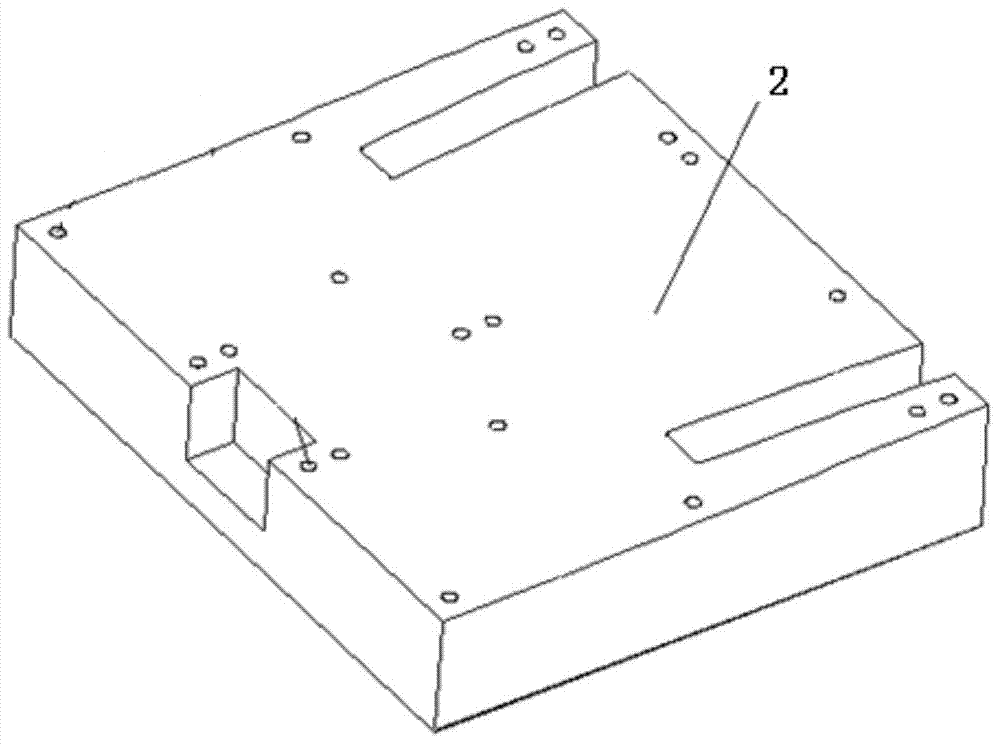

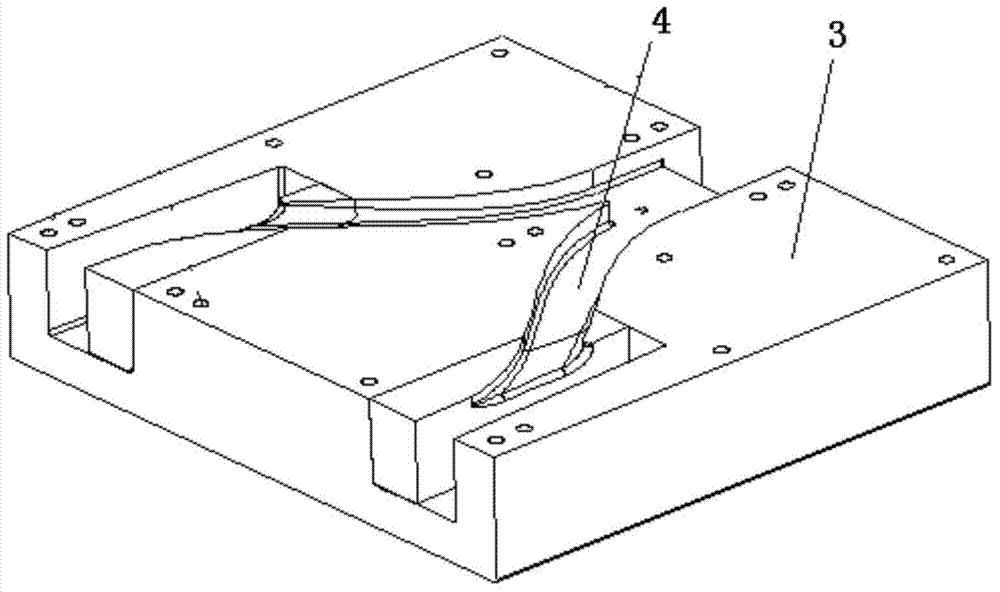

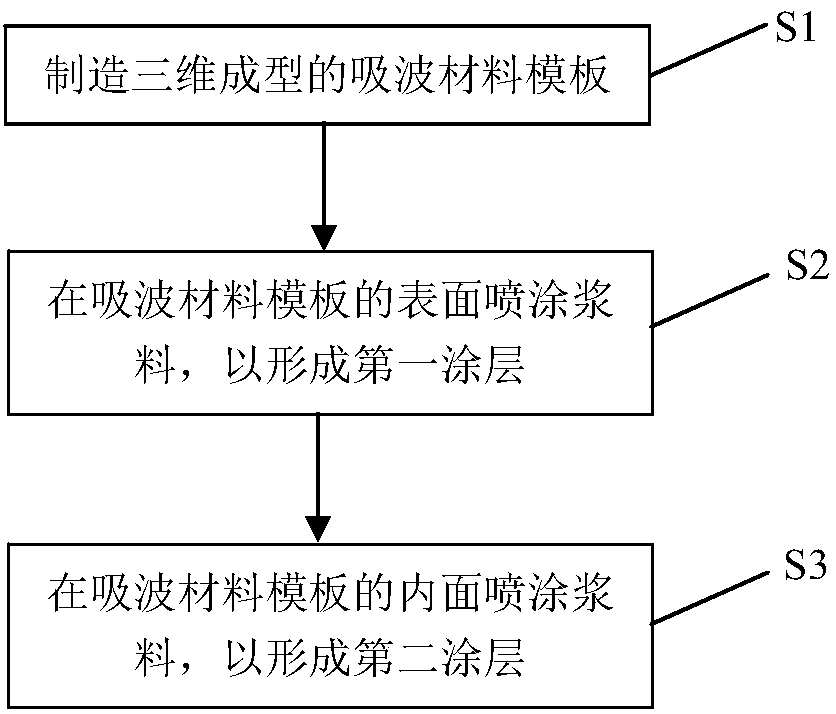

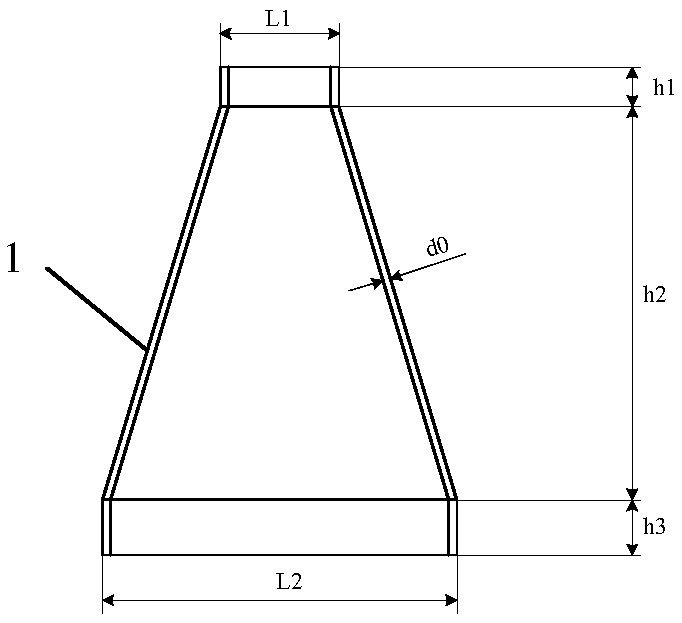

Three-dimensional molding based microwave absorbing body preparing method and corresponding microwave absorbing body

ActiveCN108097560APromote absorptionImprove shielding effectAdditive manufacturing apparatusCoatingsMicrowaveSlurry

The invention discloses a three-dimensional molding based microwave absorbing body preparing method. The three-dimensional molding based microwave absorbing body preparing method comprises the following steps that S1, a three-dimensional molding microwave absorbing material mold plate is manufactured; S2, the surface of the microwave absorbing material mold plate is sprayed with slurry to form a first coating; and S3, the inner face of the microwave absorbing material mold plate is sprayed with slurry to form a second coating. The three-dimensional molding based microwave absorbing body preparing method has the beneficial effect that the excellent electromagnetic wave absorbing or shielding effect can be achieved, and meanwhile, the three-dimensional molding based microwave absorbing bodypreparing method has the beneficial effects of being small in thickness, resistant to oxidation, small in mass, low in cost and the like.

Owner:SHANGHAI RADIO EQUIP RES INST

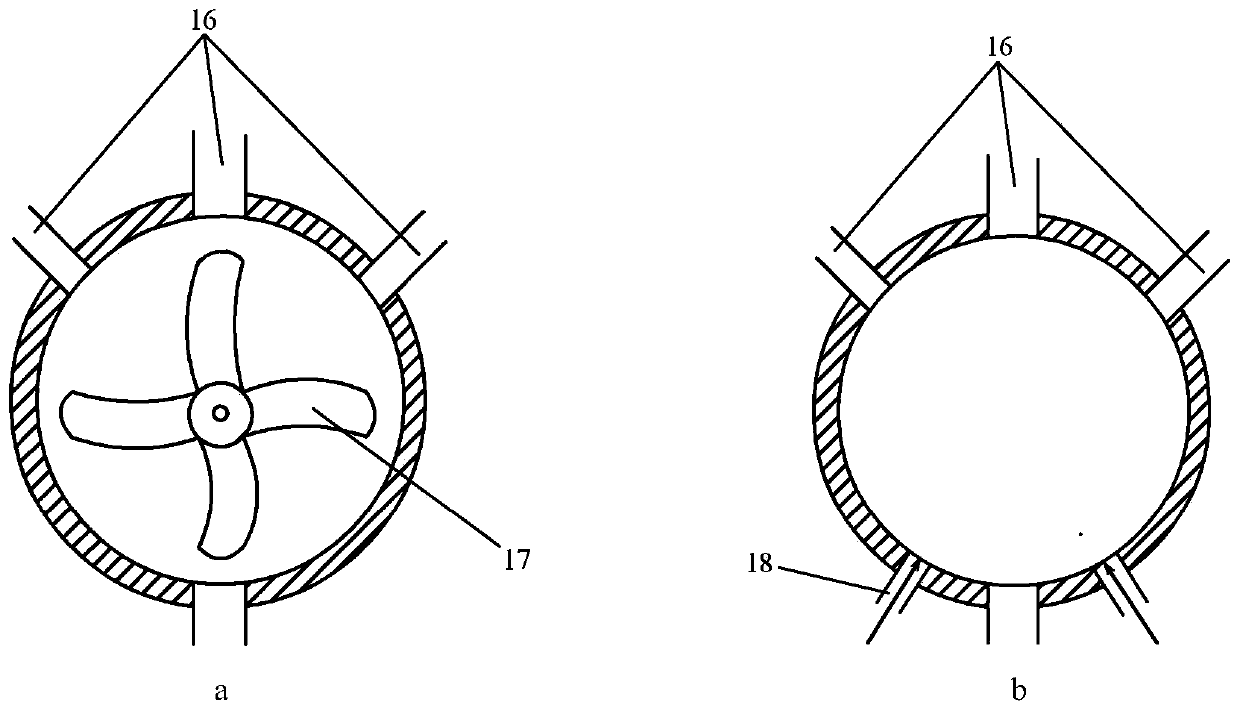

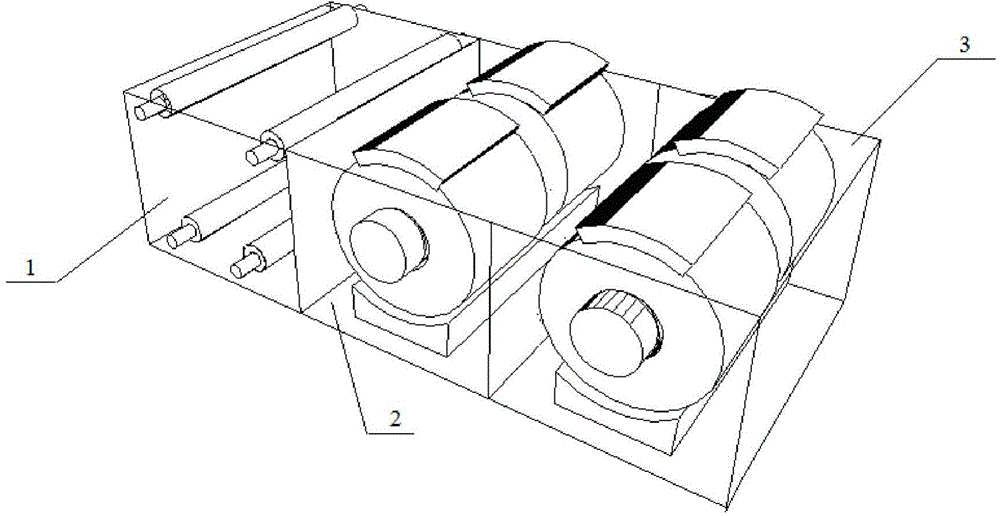

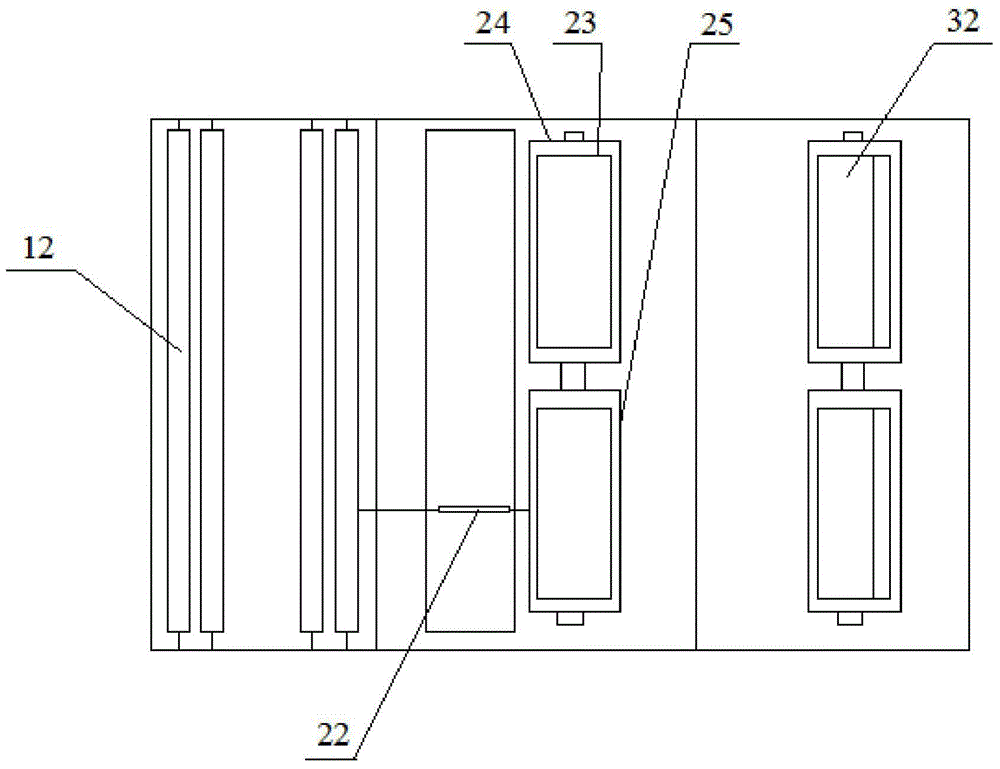

Production device of hollow fiber membrane element and method thereof

ActiveCN104815557ARealize integrated manufacturingReduce wire runSemi-permeable membranesBiomedical engineeringMethods of production

The invention discloses a production device of hollow fiber membrane element and a method thereof. The production device comprises a pre-drying element, a locating element and a packaging element which are sequentially arranged in a membrane fiber forward direction, wherein the pre-drying element is a closed element, and the locating element is communicated with the packaging element; the production device further comprises a control part which is respectively connected with the pre-drying element, the locating element and the packaging element. According to a production method provided by the invention, the initial drying of the membrane fiber, the membrane fiber drying of a packaging section and an online membrane fiber casting can be respectively completed by the pre-drying element, the locating element and the packaging element, and a spinning head can be directly and automatically casted and packaged through the rinsed membrane fiber, so as to realize a process from fiber distribution to casting and cutting head, realize the automatic production process and reduce the dependence to manual factors caused by the process; furthermore, the produced membrane elements have the characteristics of being regular to arrange and high in membrane fiber volumetric proportion, and the quality can be significantly improved.

Owner:BEIJING ORIGIN WATER FILM TECH

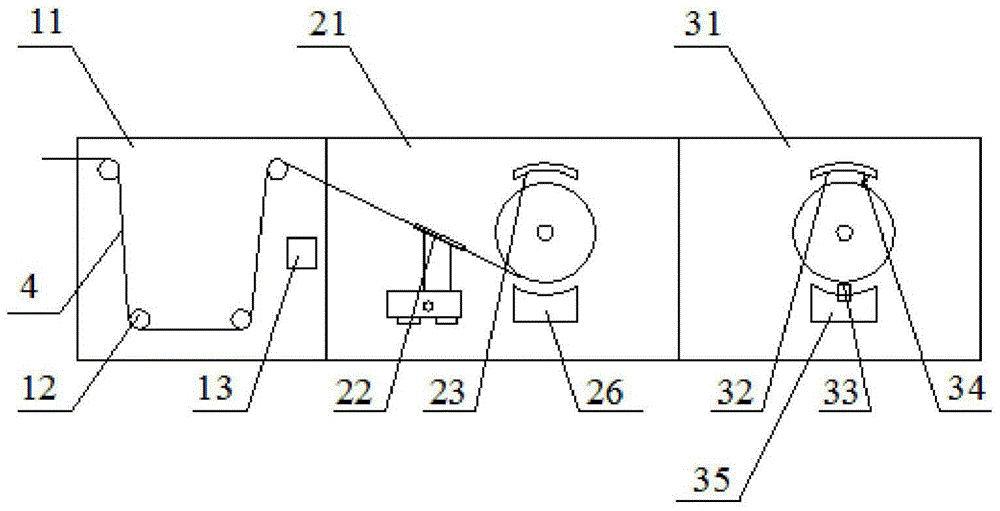

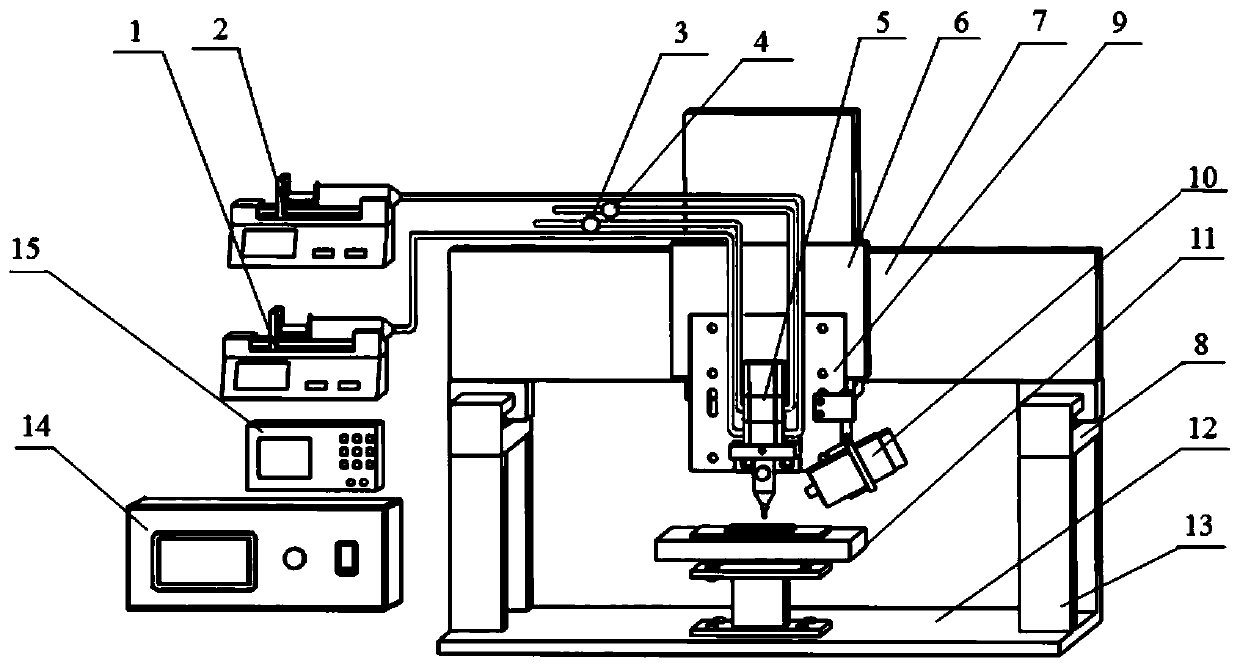

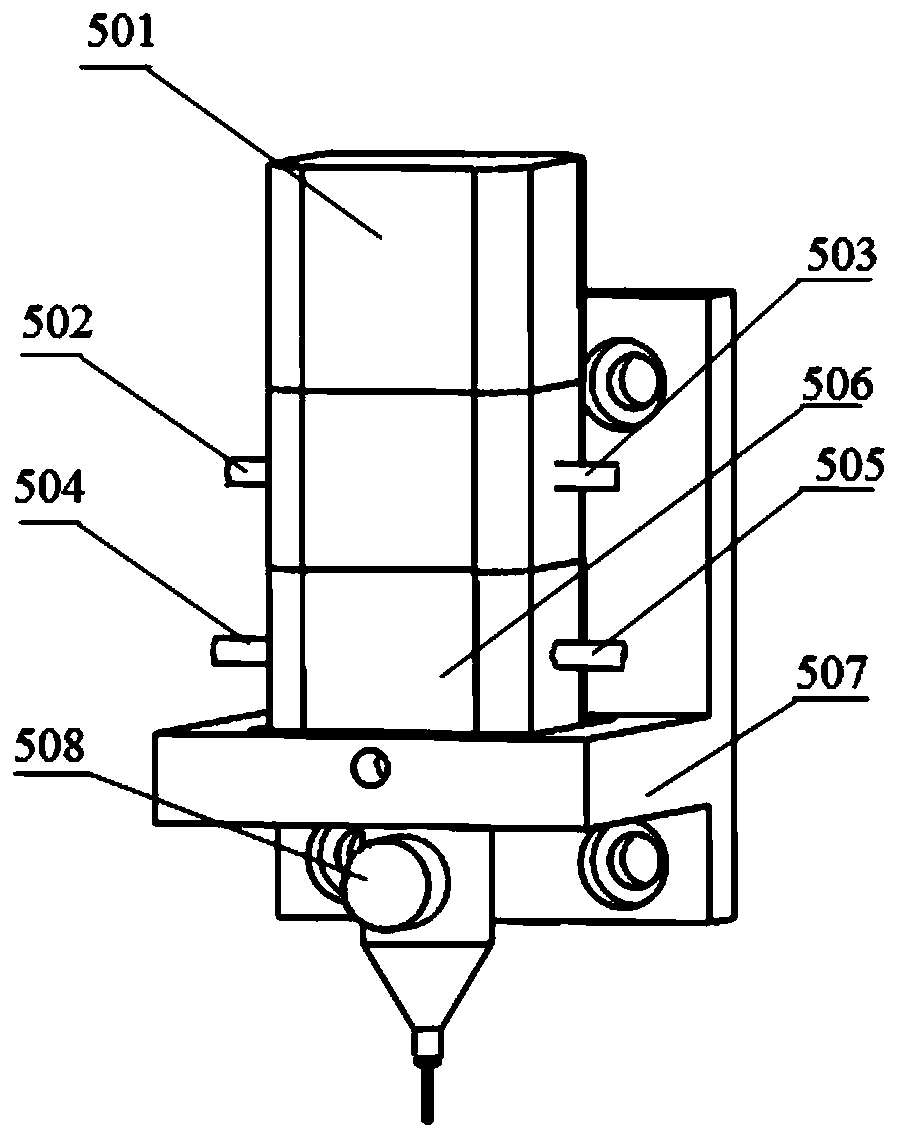

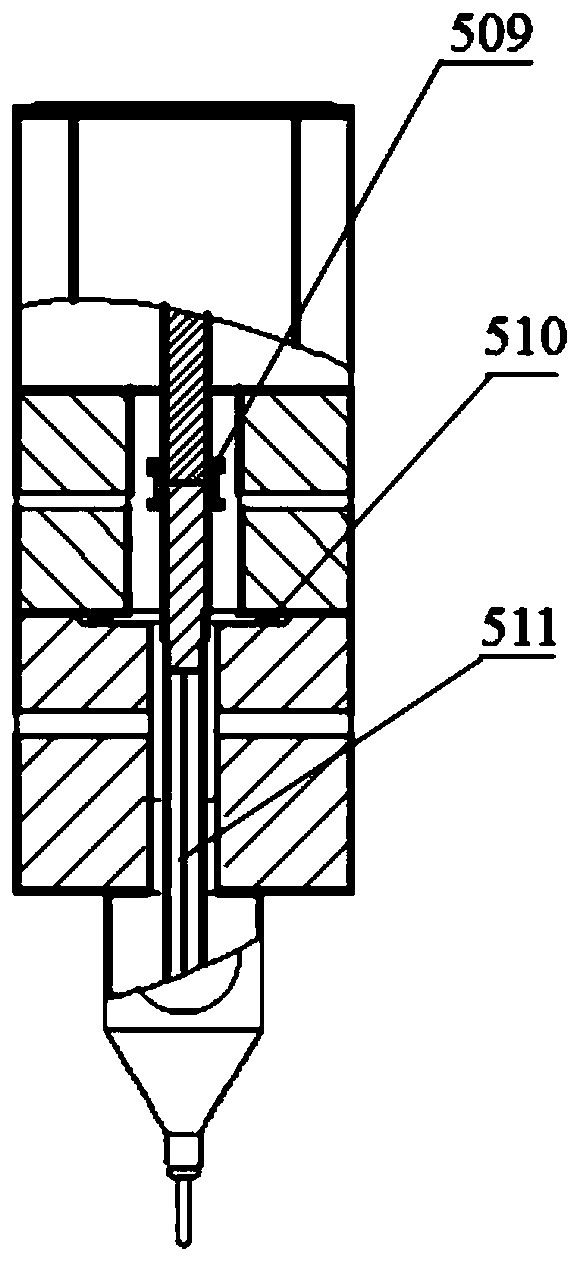

Function gradient material and structure integrated manufacturing 3D printing device and printing method

ActiveCN111284004AImprove the mixing effectAvoid mixing dead endsAdditive manufacturing apparatus3D object support structuresGradient materialSpray nozzle

The invention discloses a function gradient material and structure integrated manufacturing 3D printing device and printing method. The 3D printing device comprises a three-dimensional moving supportand a printing nozzle mounted on the three-dimensional moving support and including a stepping motor, a stirring paddle, a shell and a spray nozzle, the stepping motor is mounted at the end of the shell, one end of the stirring paddle is connected with an output shaft of the stepping motor through a coupling, the other end of the stirring paddle extends into a mixing chamber in the shell, the output shaft of the stepping motor and the shell are sealed, the spray nozzle and the stepping motor are oppositely mounted at the other end of the shell, the position, between the nozzle and the mixing chamber, of a material runner is provided with a control valve, a printing material I inlet and a printing material II inlet are formed in the side wall of the mixing chamber and are connected with a printing material I supply pump and a printing material II supply pump correspondingly, and a gas path I opening and a gas path II opening are formed in the position, between the mixing chamber and thestepping motor, of the side wall of the shell, and are connected with a gas source and a vacuum pump.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

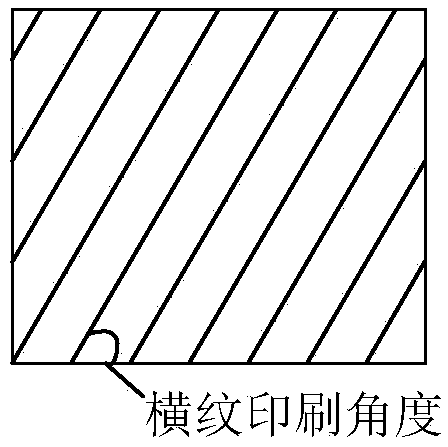

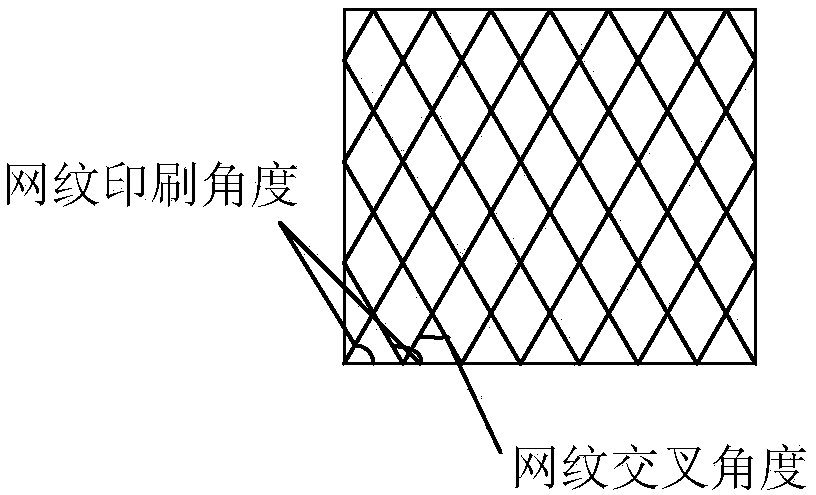

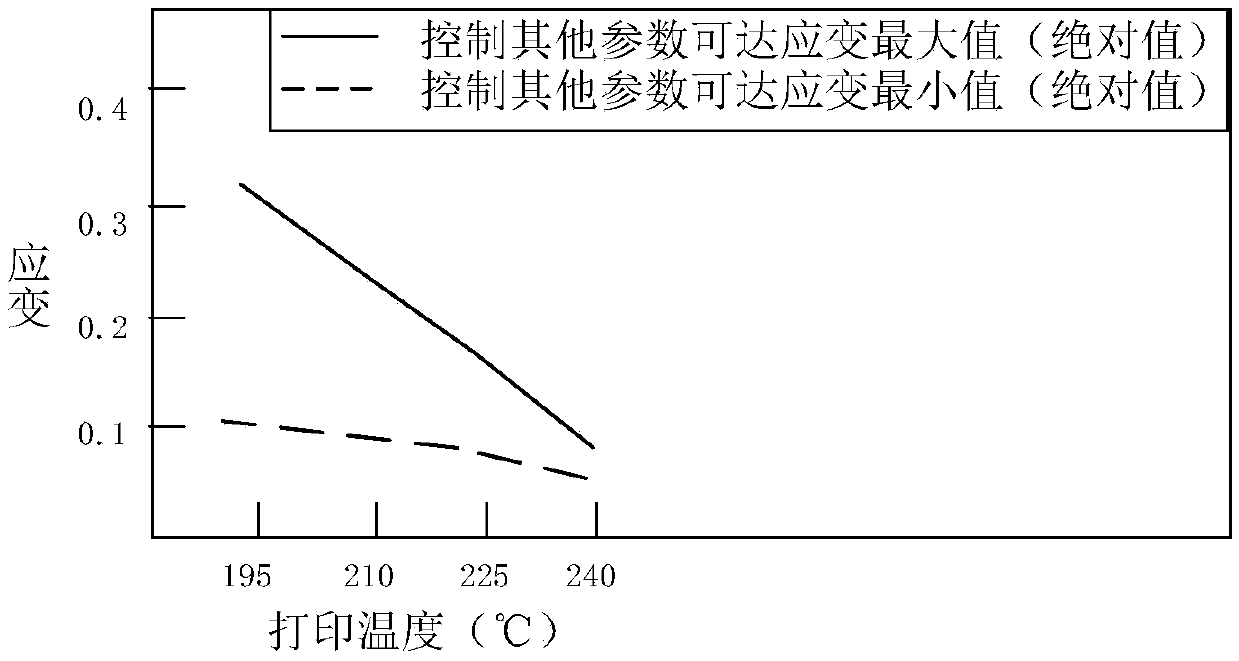

Transverse-netlike double-layer structure 4D printing method based on temperature response

InactiveCN109664499ASimpleFunctionalAdditive manufacturing apparatus3D object support structuresTemperature responseMaterials preparation

The invention discloses a transverse-netlike double-layer structure 4D printing method based on temperature response. The method comprises the steps that shape memory polymer materials are selected toperform repeating cascading printing from bottom to top with a double-layer structure as a unit, wherein the double-layer structure is formed by performing cascading printing and arranging on two groups of different fill pattern layers up and down, all single layers in the groups of fill pattern layers are printed to be the same fill patterns, fill pattern layers above and below are transverse grain patterns and netlike grain patterns correspondingly, the transverse grain patterns and the netlike grain patterns are textured patterns formed by arranging one group of straight line arrays and two groups of straight line arrays in a crossed mode, and the straight line arrays are composed of a plurality of straight lines arranged in parallel; and rough products are made to deform through precise temperature heating, and 4D deformation is completed. By means of the 4D printing method, the problems that currently, temperature-driven 4D printing material preparation is difficult, and the degree of response to low-power deformation is small are solved, the fused deposition 4D printing method that special wires do not need to be manufactured through design parameter programming is achieved,and limitations of the tedious process of material preparation of the 4D printing technology are broken through.

Owner:ZHEJIANG UNIV

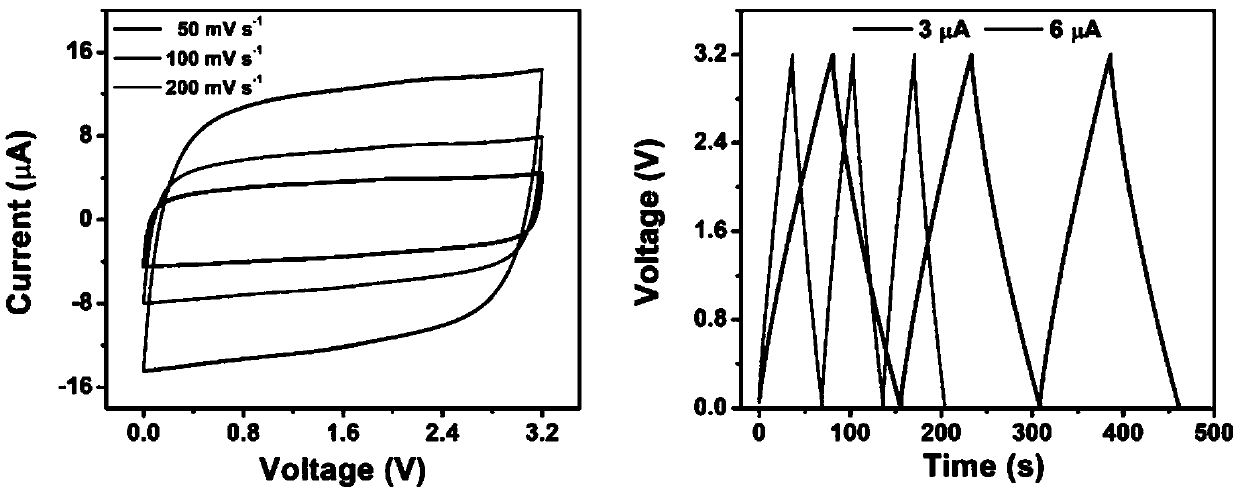

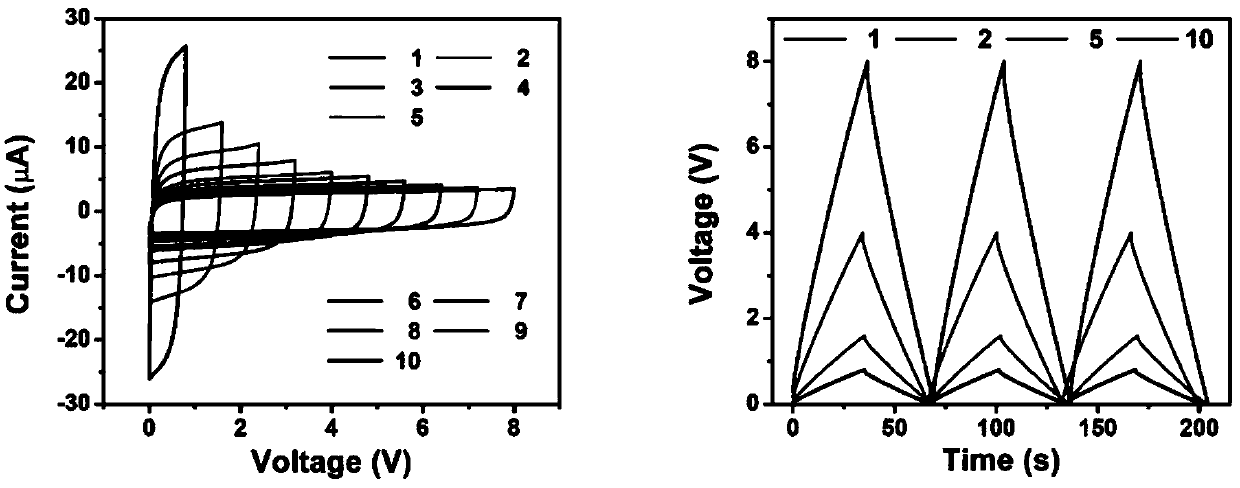

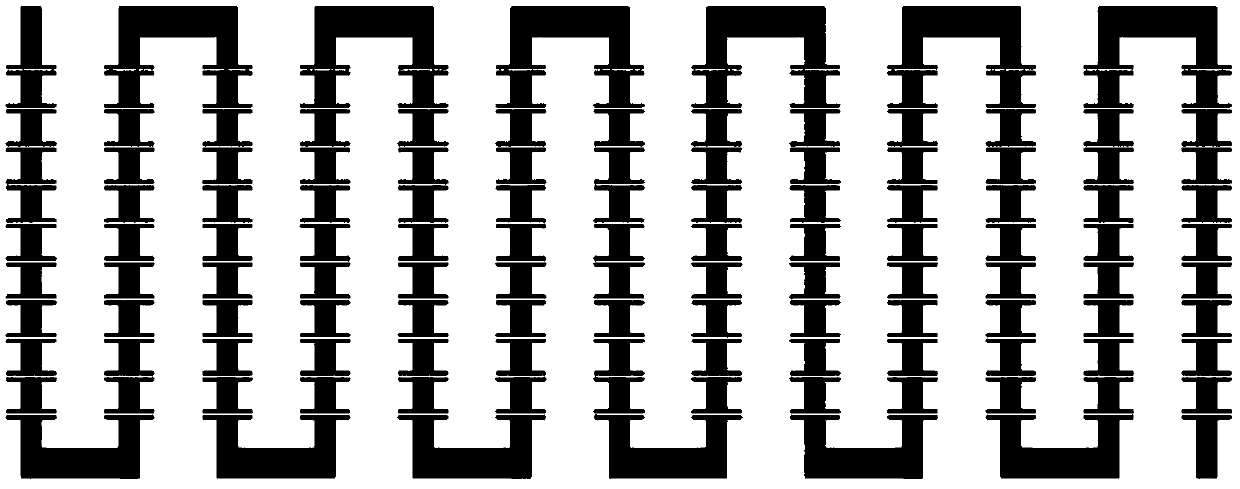

High-voltage planar supercapacitor as well as preparation method thereof

InactiveCN109637846ARealize integrated manufacturingRealize concatenationHybrid capacitor electrodesMultiple hybrid/EDL capacitorsCarbon nanotubePrinting ink

The invention discloses a high-voltage planar supercapacitor as well as a preparation method thereof. Specifically, a dispersion system containing electrode materials (graphene, carbon nano tubes, polymers, oxides, hydroxides, sulfides, nitrides and the like) and additives is taken as printing ink, a printing method is adopted, and a planar supercapacitor with high voltage is prepared on any insulated substrate by virtue of a one-step process. The obtained planar supercapacitor realizes integration preparation of electrodes, a current collector and a connector as well as series integration ofmultiple plane supercapacitors, has a high output voltage, can be combined with a printable electronic device to be taken as a power source of the printable electronic device and has a broad market prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

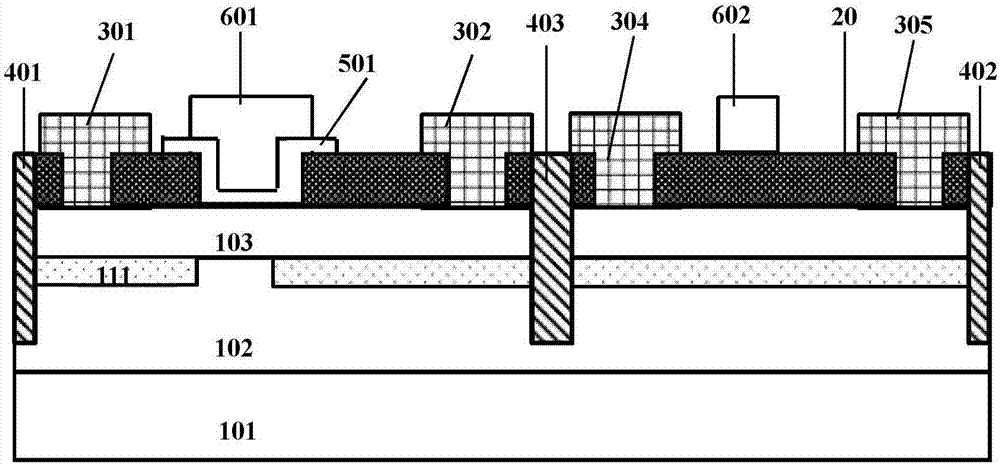

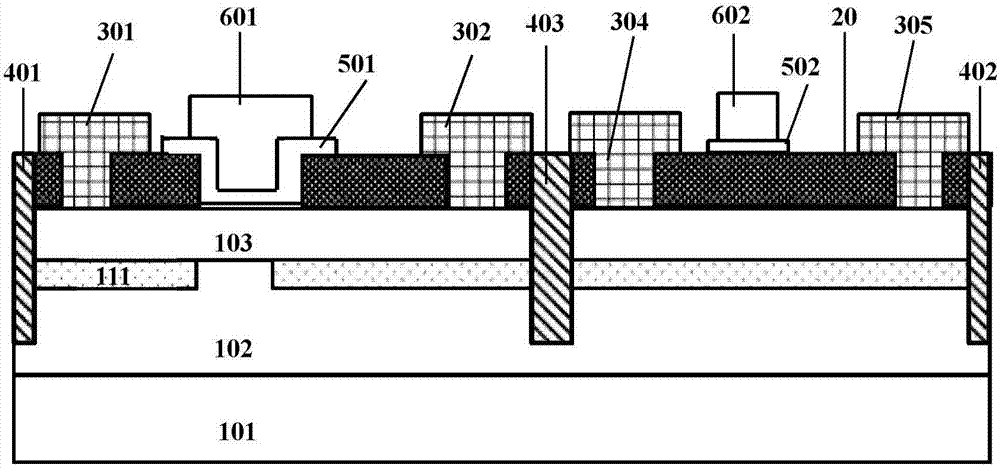

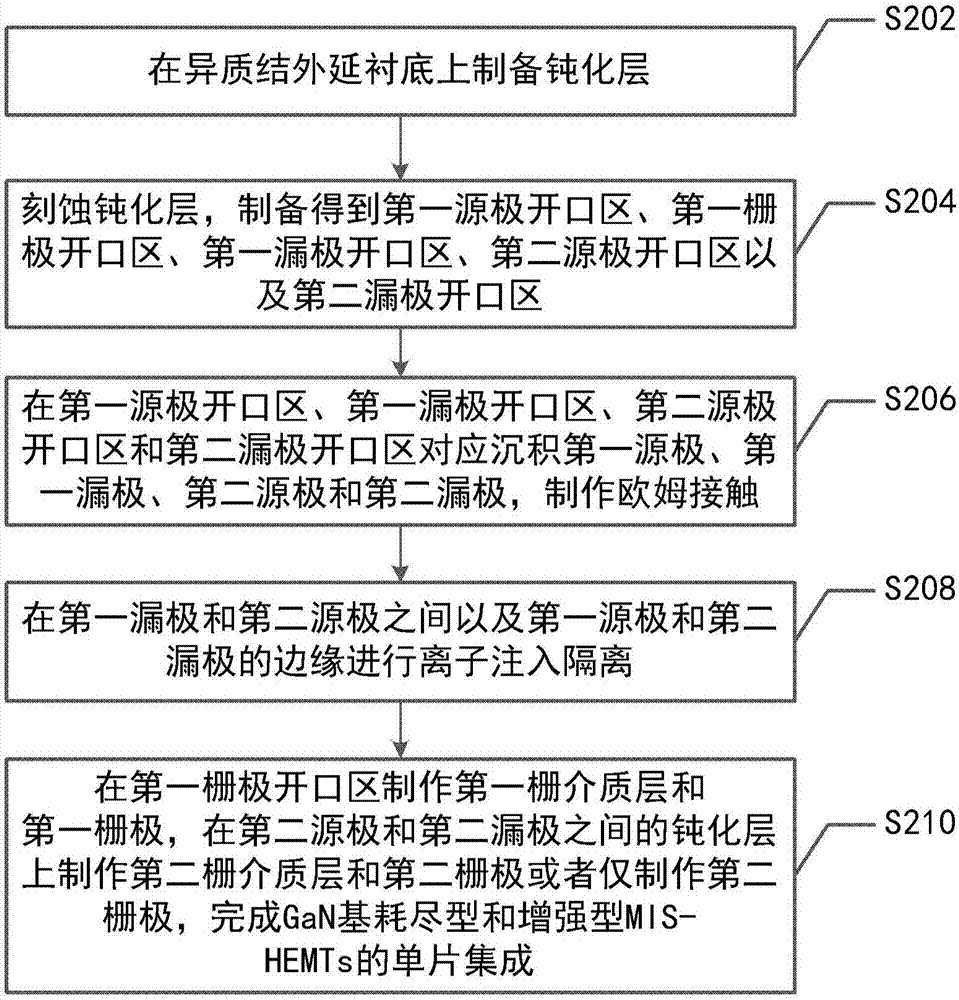

GaN based monolithic power inverter and manufacturing method thereof

ActiveCN107887383AReduce manufacturing difficultyImprove yieldTransistorEfficient power electronics conversionPower inverterHeterojunction

The present invention discloses a GaN based monolithic power inverter and a manufacturing method thereof. The power inverter comprises: a heterojunction epitaxial substrate; passivation layers formedon the heterojunction epitaxial substrate and provided with a plurality of hollow areas between the passivation layers; a normally OFF power triode structure formed in the hollow areas in the plurality of the hollow areas and comprising a first source electrode, a first drain electrode and a first grid electrode, wherein the first source electrode and the first drain electrode both achieve Ohmic contact with a thin barrier layer, and the first grid electrode and the thin barrier layer achieve insulation through a first gate dielectric layer located at the lower portion the first grid electrode; and an normally ON power triode structure formed at the other hollow areas in the plurality of hollow areas and comprising a second source electrode, a second drain electrode and a second grid electrode, wherein the second source electrode and the second drain electrode both achieve Ohmic contact with the thin barrier layer, and the second grid electrode and the passivation layers achieve insulation through a second gate dielectric layer located at the lower portion the second grid electrode or the second grid electrode is in direct contact with the passivation layers. The preparation technology of the power converter is simple, the structure is diversified, and the device yield is improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

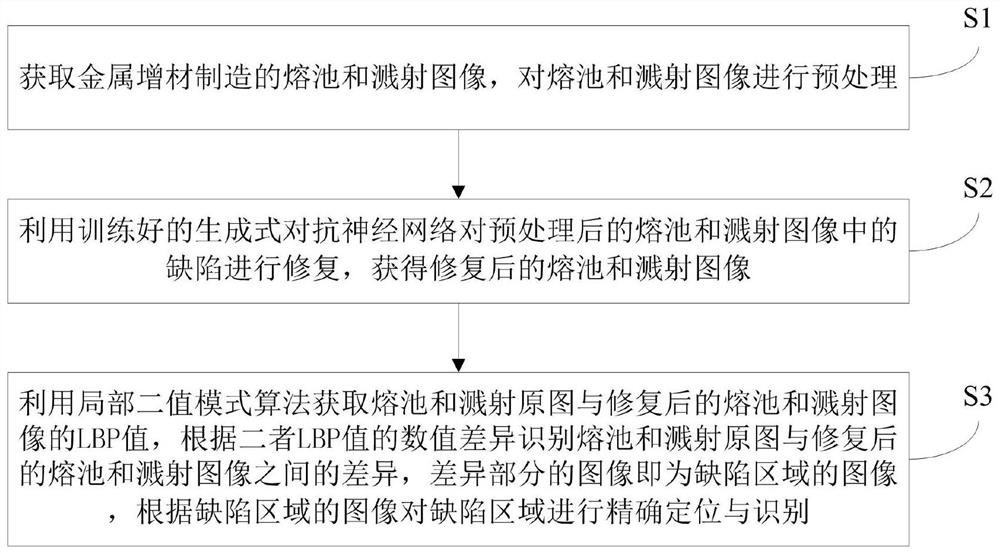

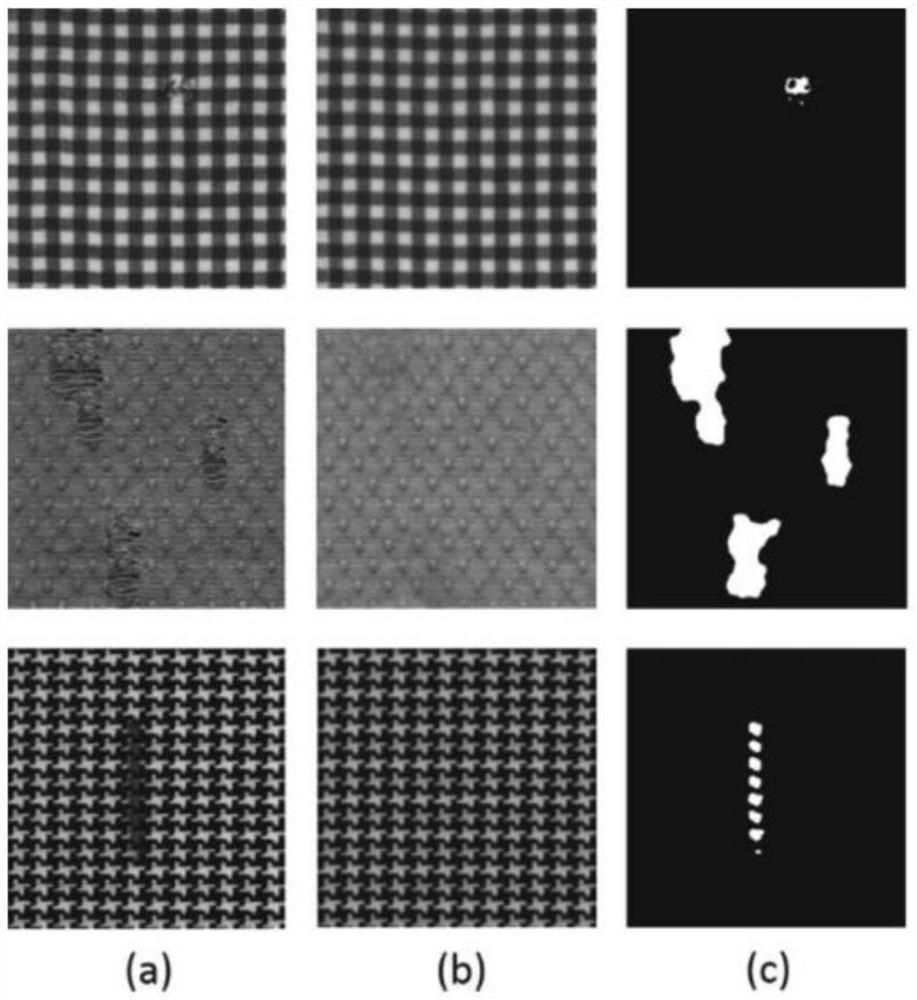

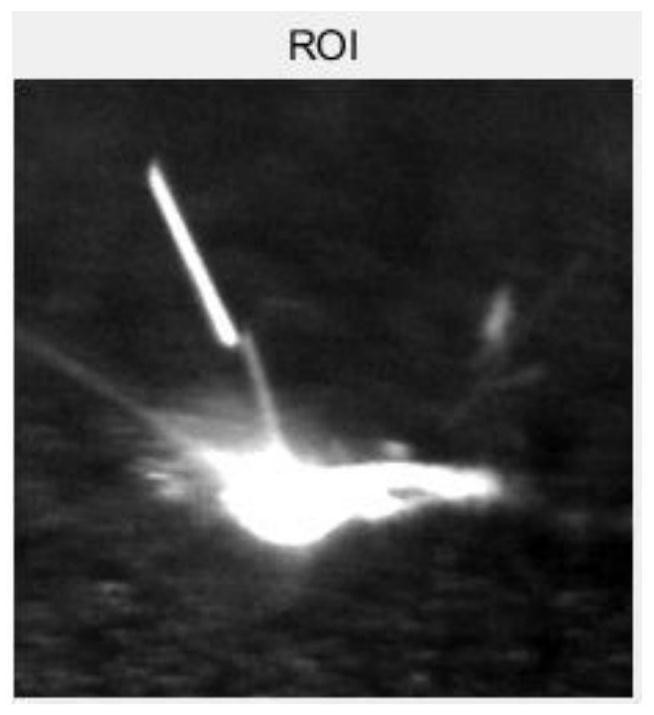

Metal additive manufacturing image detection method and device combining adversarial neural network with local binary value

PendingCN111815555AImprove yield rateReal-time adjustment of manufacturing process parametersImage enhancementAdditive manufacturing apparatusMetallurgyImage detection

The invention provides a metal additive manufacturing image detection method and device combining an adversarial neural network with local binary. The method comprises the steps: obtaining a molten pool and a sputtering image of metal additive manufacturing, and carrying out the preprocessing of the molten pool and the sputtering image; utilizing the trained generative adversarial neural network to repair defects in the preprocessed molten pool and sputtering image to obtain a repaired molten pool and sputtering image; utilizing a local binary pattern algorithm to obtain LBP values of the molten pool, the sputtering original image and the repaired molten pool and sputtering image; and the difference between the molten pool and the sputtering original image and the repaired molten pool andthe sputtering image is identified according to the numerical difference of the LBP values of the molten pool and the sputtering original image, the image of the difference part is the image of the defect area, and the defect area is accurately positioned and identified according to the image of the defect area. Defects in a molten pool and a sputtering image in the metal additive manufacturing process can be positioned and recognized, so that manufacturing process parameters are adjusted in real time, and the part manufacturing yield is increased.

Owner:SHENZHEN RES INST OF WUHAN UNIVERISTY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com