Production device of hollow fiber membrane element and method thereof

A production device and production method technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of poor applicability, inconvenient use, and high investment, achieve production automation, reduce wire transportation, and improve utilization. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

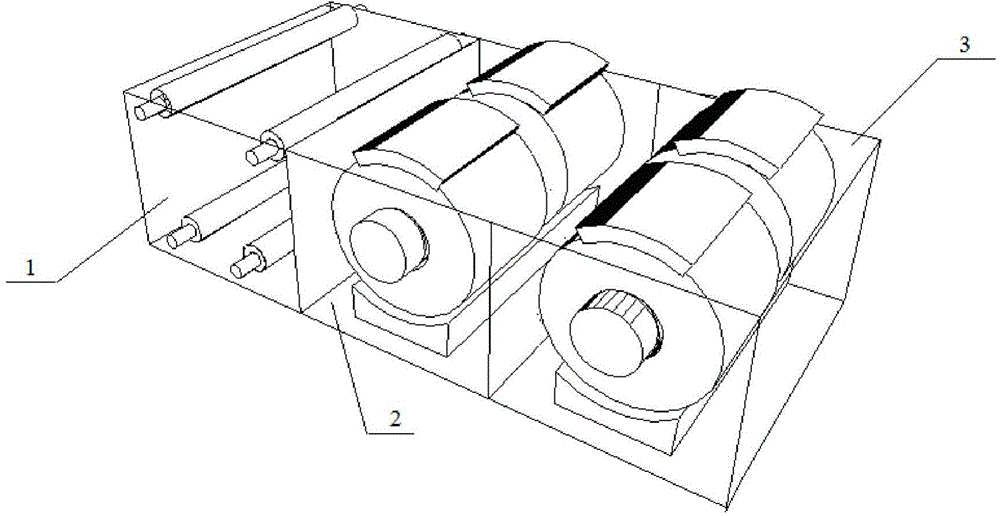

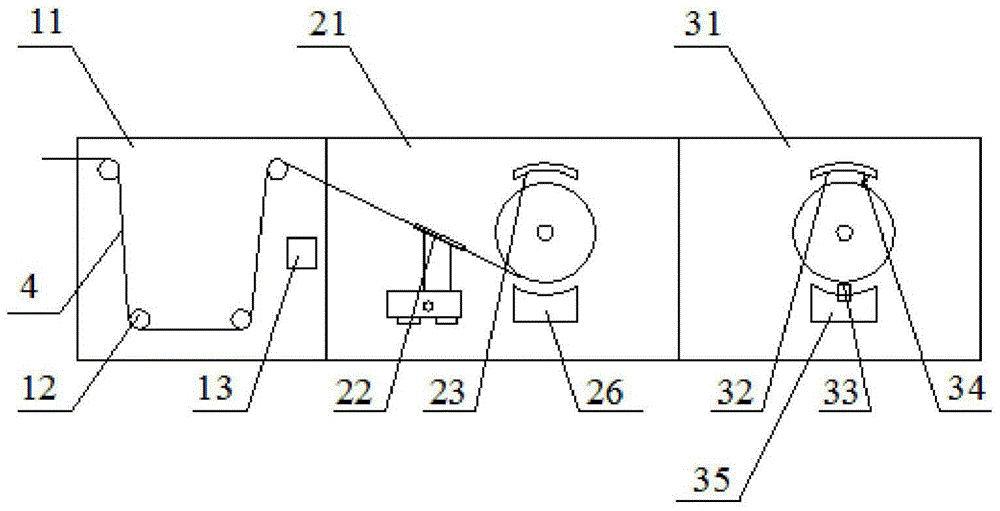

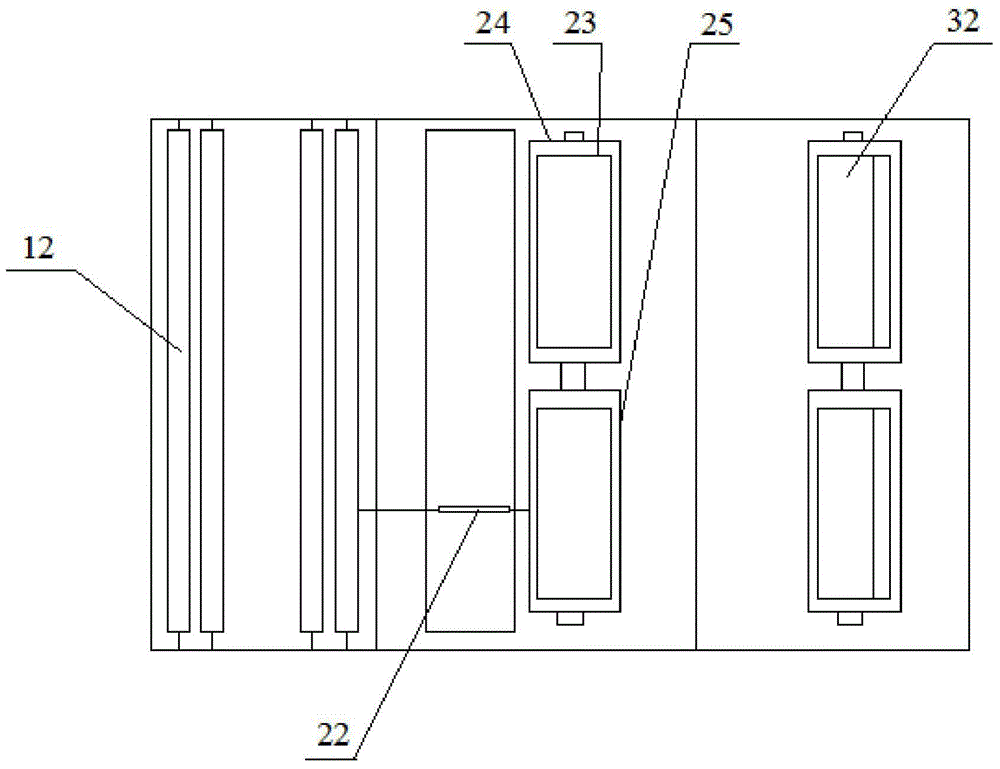

[0038] Such as Figure 1-3 A production device for hollow fiber membrane elements is shown, which includes a pre-drying unit 1, a positioning unit 2 and a packaging unit 3 that are sequentially and continuously discharged. , positioning unit 2, and packaging unit 3 complete the three processes of initial drying, positioning winding and continuous drying, cutting membrane filaments and completing membrane element packaging; the specific production process is as follows:

[0039]The pre-drying unit 1 mainly includes a first box body 11, a guide roller group 12 and an air-drying mechanism 13, the guide roller group 12 and the air-drying mechanism 13 are respectively arranged in the first box body 11, and the film filament 4 is wound around the guide roller group 12, The air-drying mechanism 13 is placed on the bottom s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com