Patents

Literature

80results about How to "Simple," patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

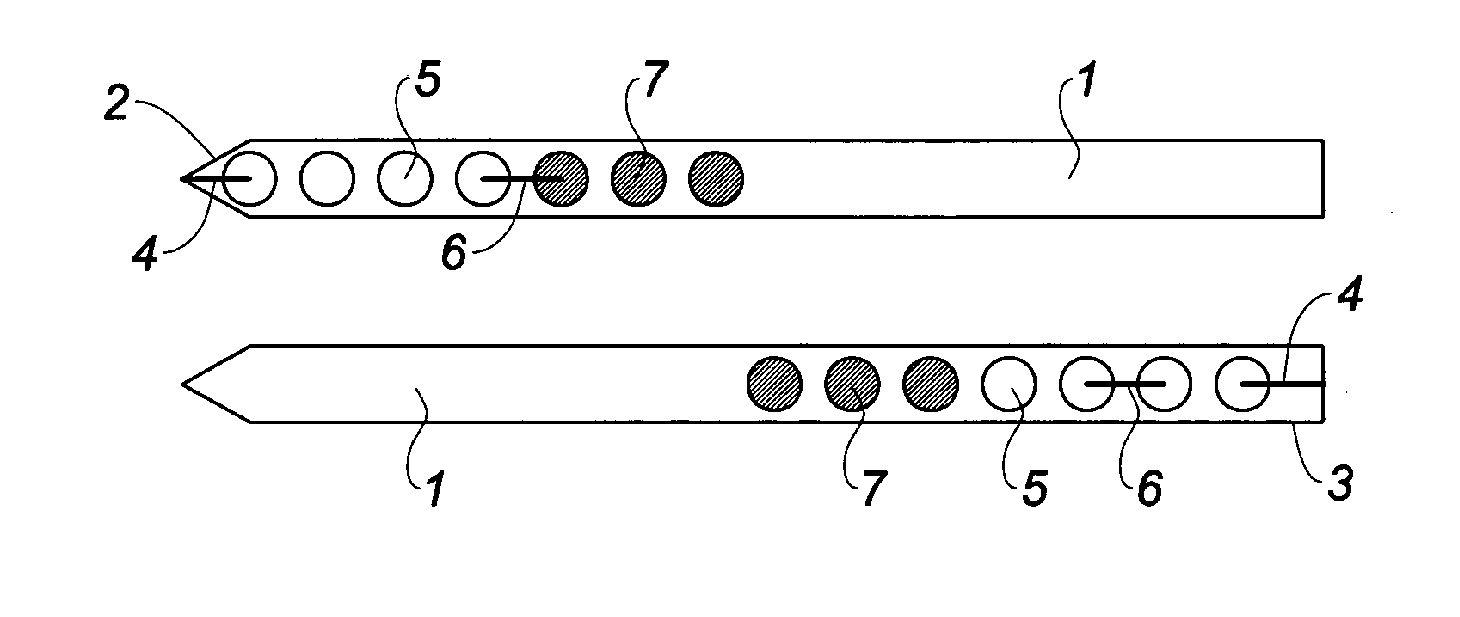

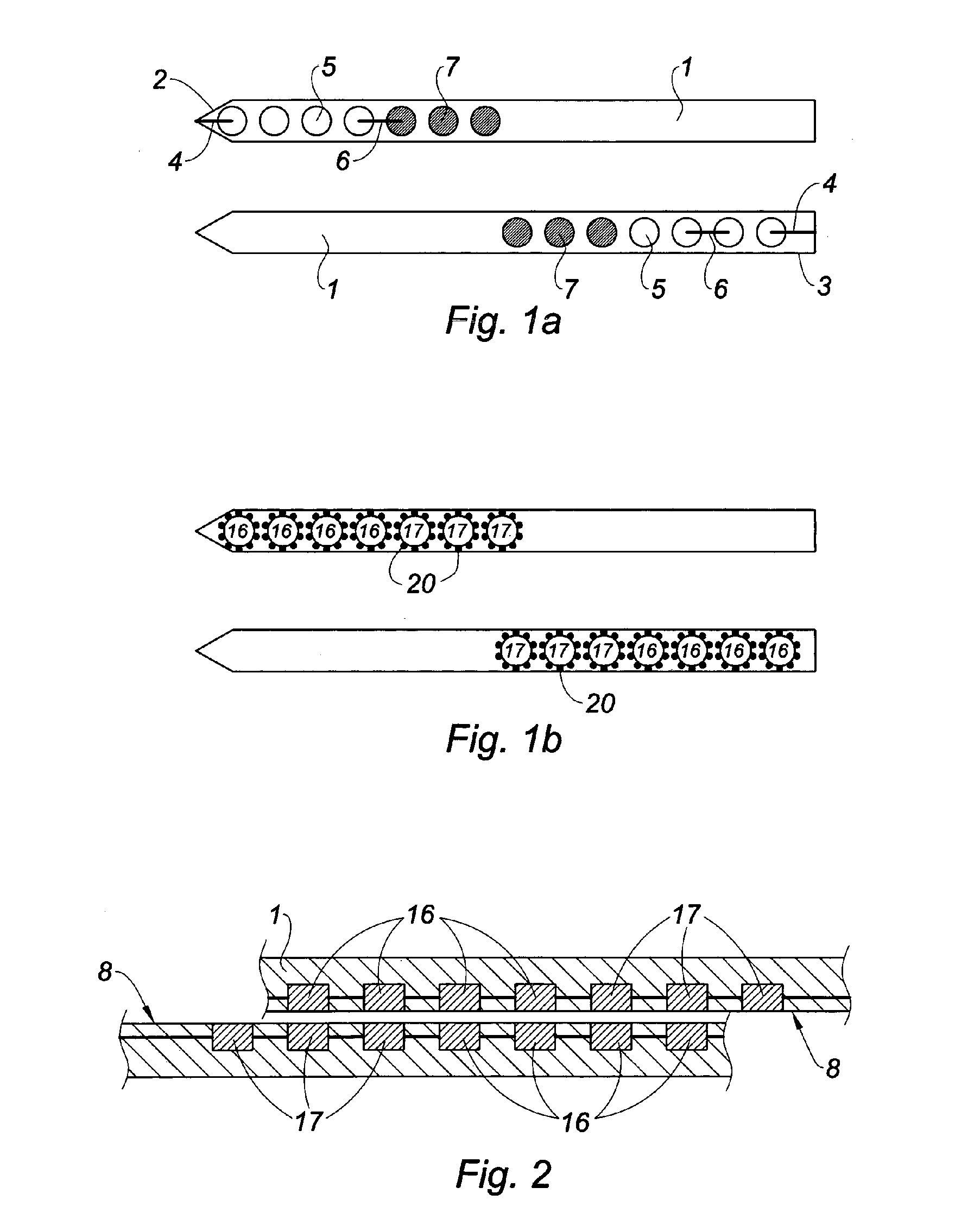

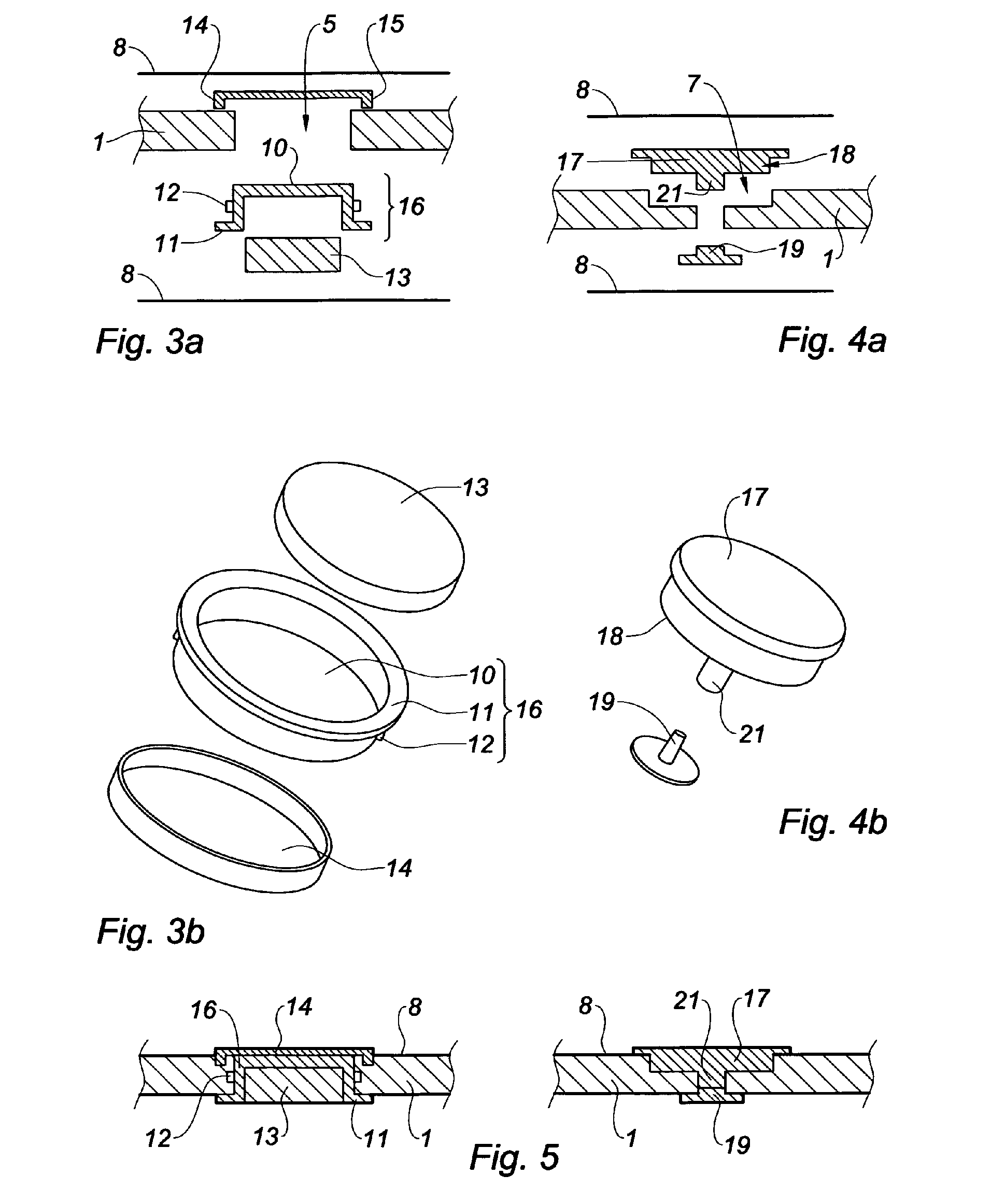

Magnetic clasp device for clothing accessories

ActiveUS20120216374A1SimpleThe process is simple and fastSnap fastenersPermanent magnetsElectrical and Electronics engineeringMagnetic field

The invention relates to a device for magnetic clasping at a plurality of points for a clothing accessory such as a belt, characterised in that said device includes at least one permanently magnetised assembly (13) arranged at one end of one surface of the accessory, while a plurality of ferromagnetic elements (17) and / or permanently magnetised assemblies (13) are arranged longitudinally on the other surface of the accessory at the opposite end thereof (3), the permanently magnetised assemblies of one surface being suitable for attracting a permanently magnetised assembly of the other surface, the permanently magnetised assemblies (13) and / or ferromagnetic elements (17) of each surface being arranged such that, by placing the ends of the two surfaces of the clothing accessory vertically adjacent to one another, a plurality of adjustment positions of the two surfaces are obtained relative to the position of the permanently magnetised assemblies (13) and ferromagnetic elements (17), representing a plurality of possible tightness levels, each permanently magnetised assembly of one surface engaging with a permanently magnetised assembly or a ferromagnetic element of the other surface in each one of the adjustment positions, in order to close any magnetic field.

Owner:MANUELLO GERARLD

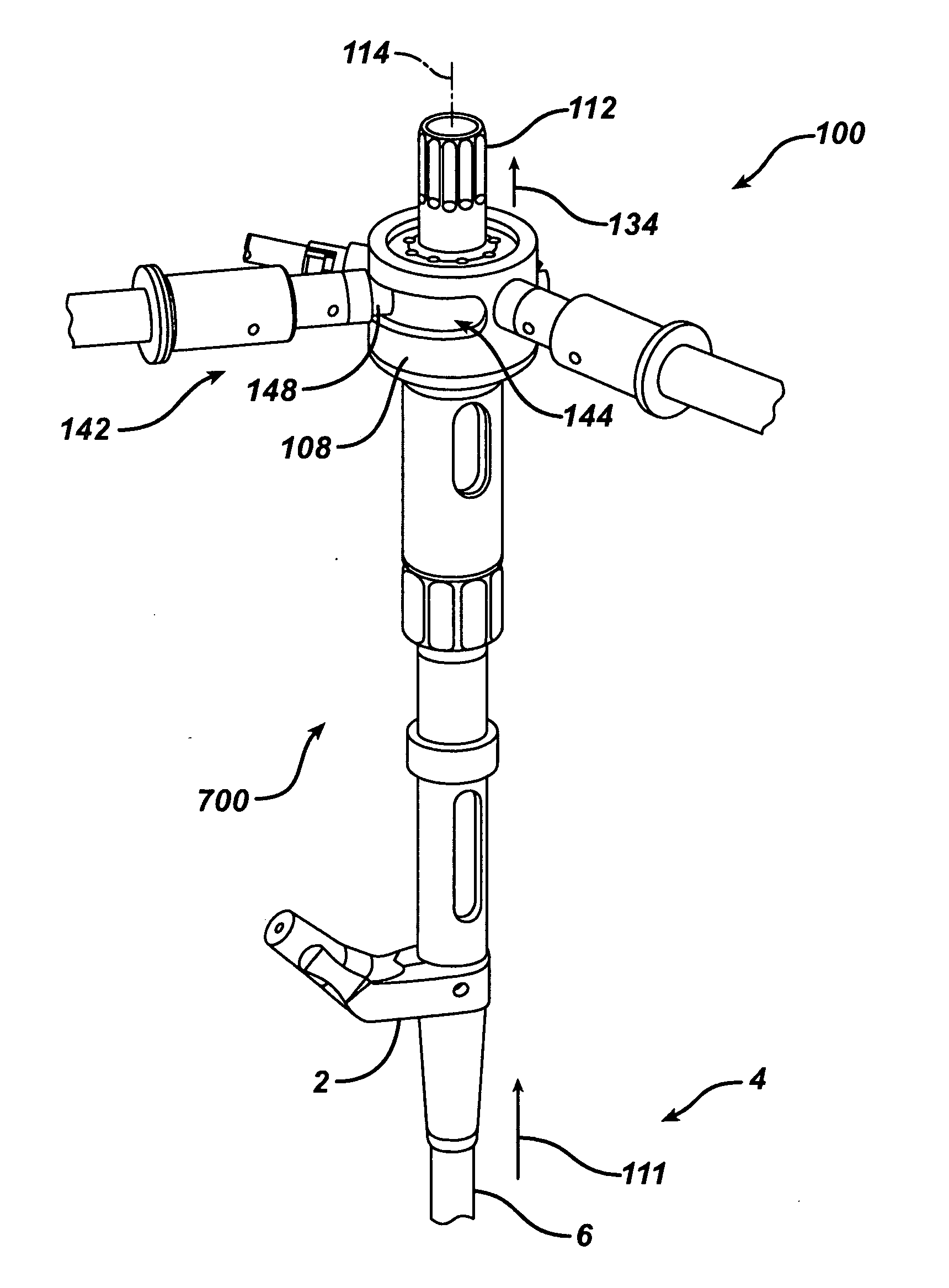

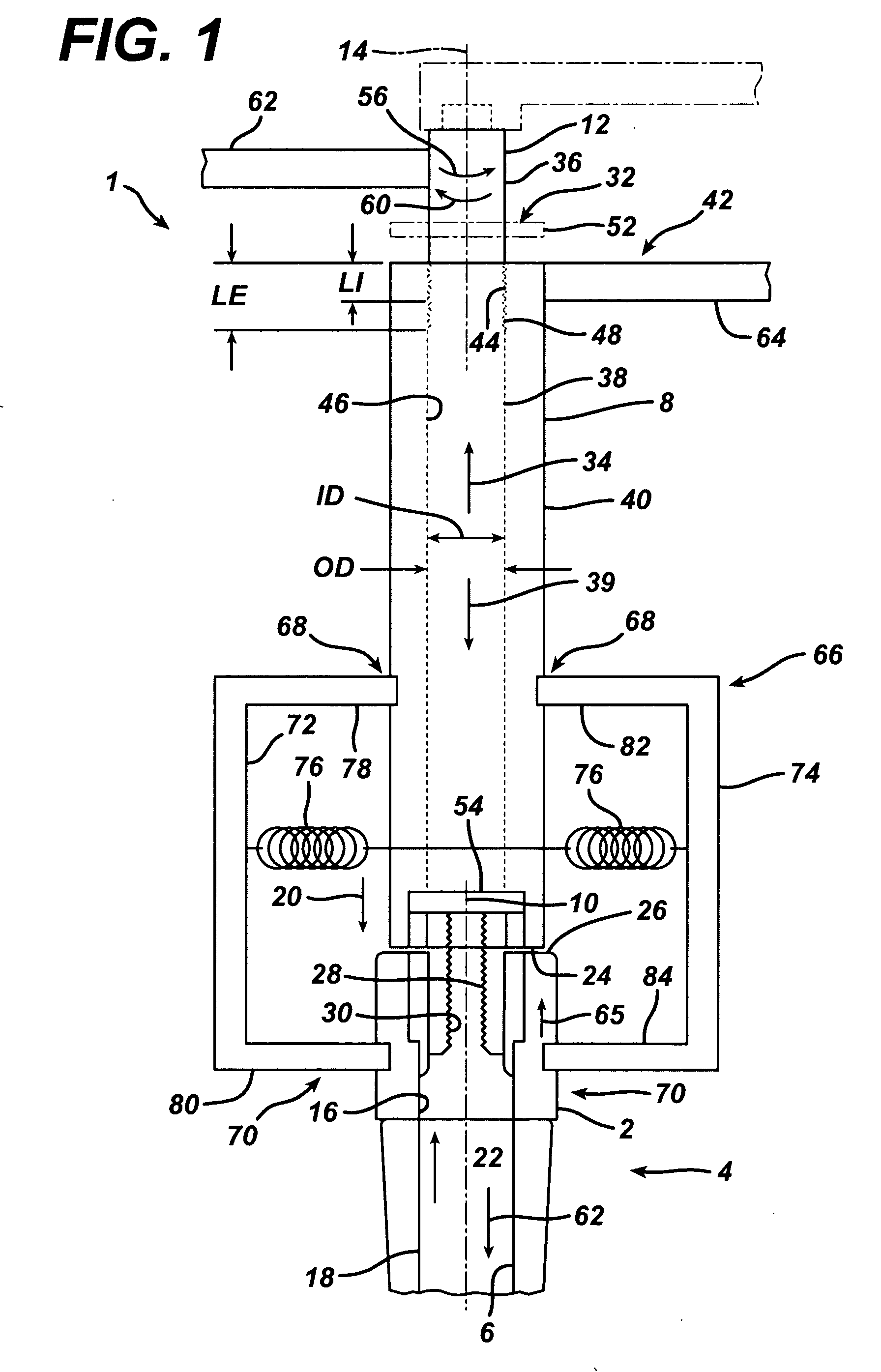

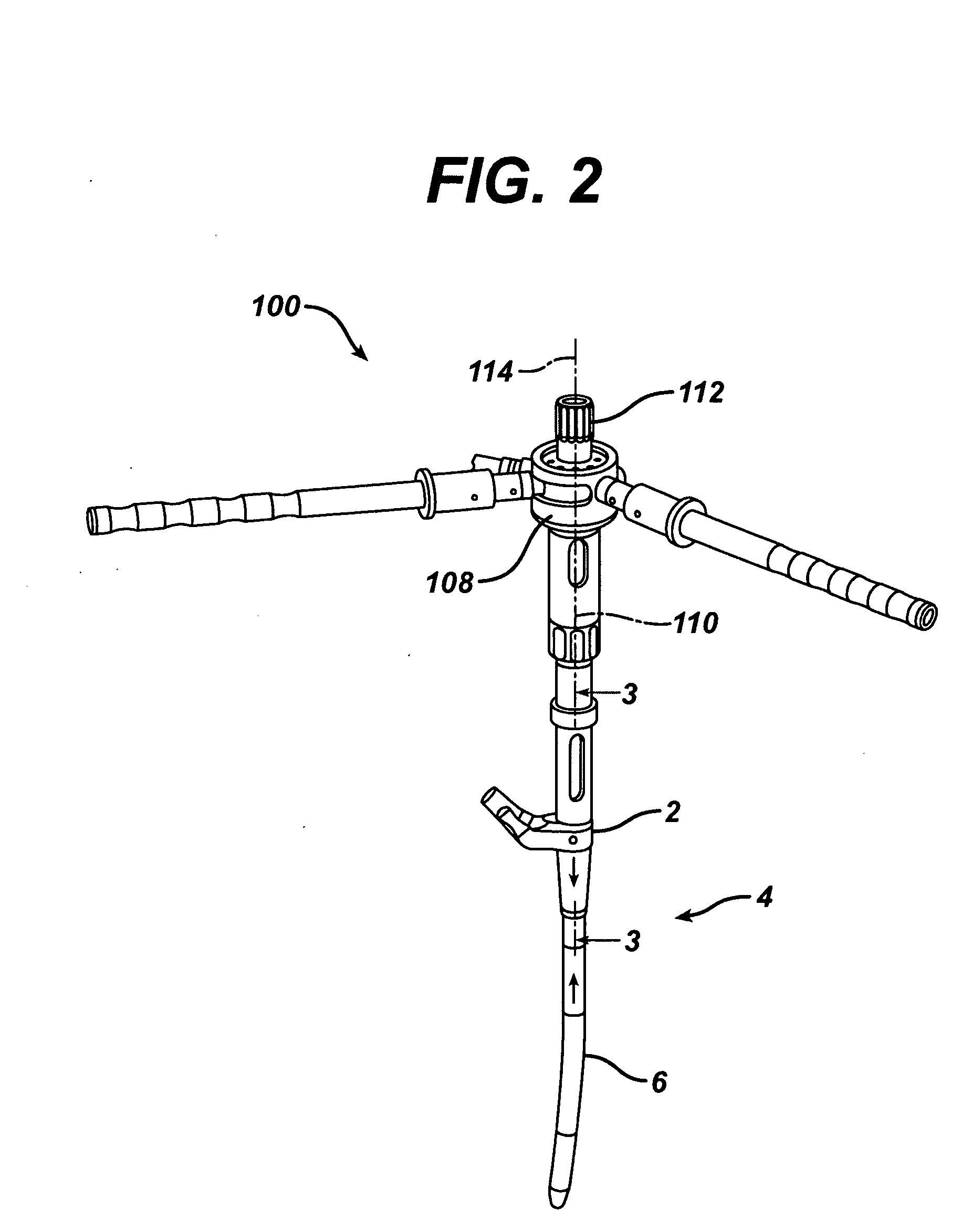

Assembly tool for modular implants and associated method

An assembly tool for assembly of a first component of a prosthesis to a second component of the prosthesis for use in joint arthroplasty is provided. The tool includes a first member operably associated with the first component and a second member. The second member is operably associated with the second component. At least one of the first member and the second member are adapted to provide for the assembly of the first component of the prosthesis to the second component of the prosthesis. The second member is operably associated with the first member for relative motion between the first member and the second member for assembly of the first component of the prosthesis to the second component. The tool also includes an angular orientation feature cooperating with at least one of the first member and the second member for at least one of replicating and measuring the relative angular orientation of the first component with respect to the second component.

Owner:DEPUY PROD INC

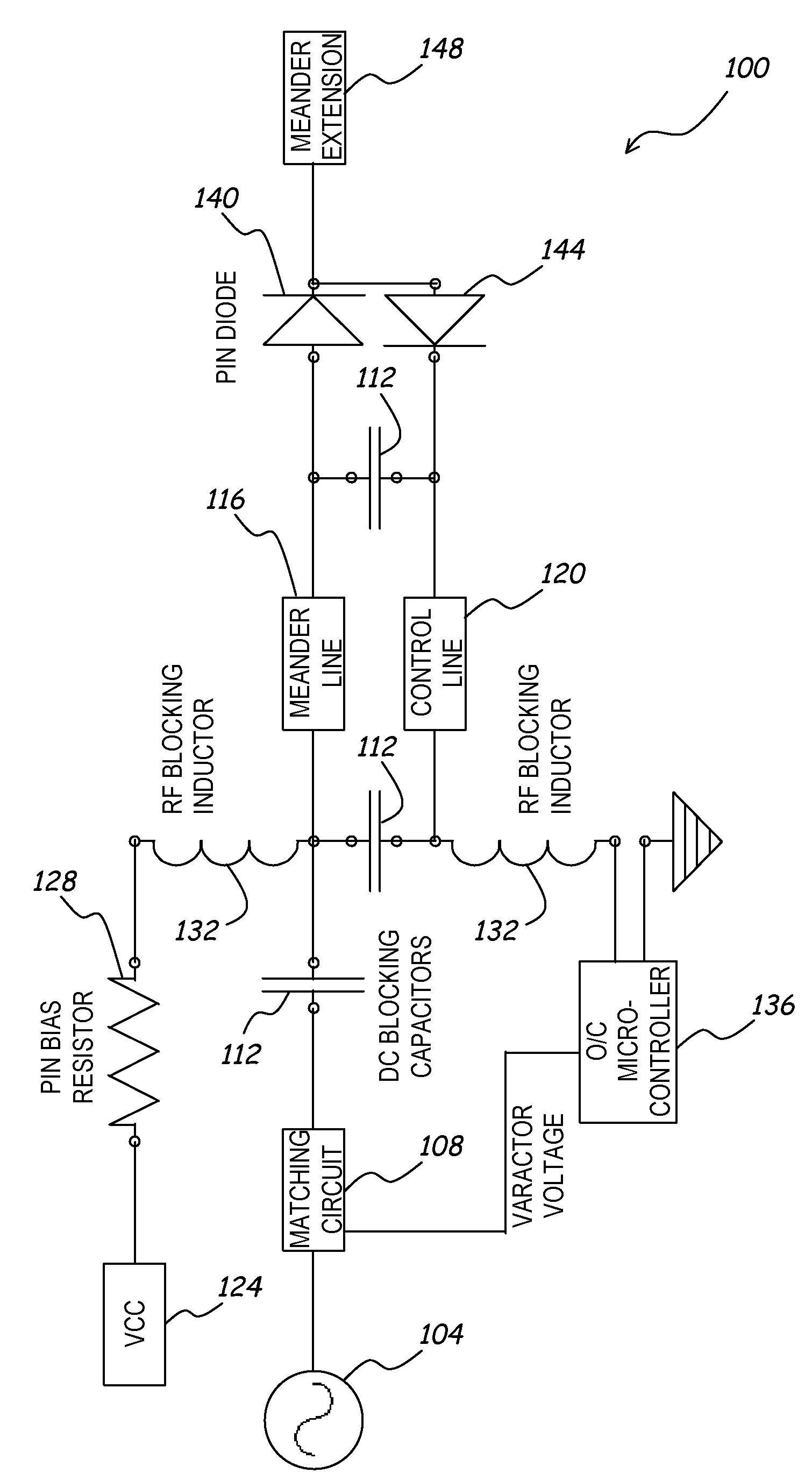

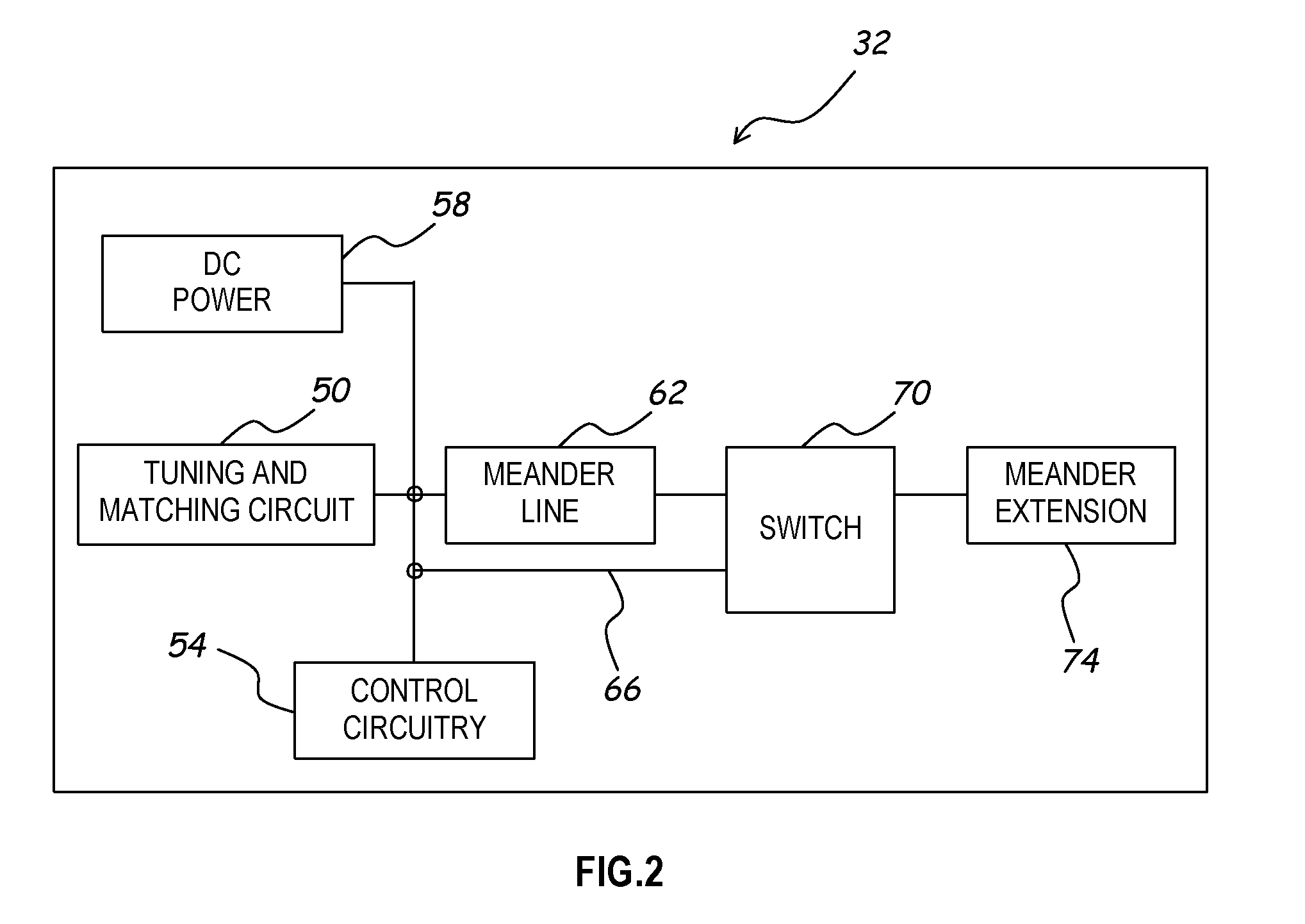

Selectable length meander line antenna

InactiveUS7129894B1Simple (Simultaneous aerial operationsRadiating elements structural formsPolygonal lineControl signal

A single antenna element with a switchable extension may be used to change the size of the radiating surface and provide an antenna that has two or more separate center frequencies. The range of frequencies that may be tuned by the antenna is enhanced, while maintaining relatively low complexity tuning and matching circuitry. Switching for the extension is performed by a switching element that is located at the point of connection of the extension to the antenna element. A control line supplies a control signal to the switching element to enable and disable the extension. The control line is positioned in close proximity to the antenna element to enhance coupling between the antenna element and the control line.

Owner:CENTURION WIRELESS TECH INC

Traditional Chinese medicine antibiotic skincare hand cleanser and preparation method thereof

InactiveCN102423291AGood antibacterial effectDelicate and not dryCosmetic preparationsToilet preparationsMonilinia laxaIrritation

The invention relates to a traditional Chinese medicine antibiotic skincare hand cleanser prepared from mixed materials of a traditional Chinese medicine extract, a surfactant, an antiseptic, glycerin, an essence and water. The traditional Chinese medicine extract is prepared from raw materials of, by weight: 35-45 parts of lightyellow sophora root, 15-25 parts of amur corktree bark, 15-25 parts of Chinese gentian, 5-15 parts of common cnidium fruit, and 5-15 parts of belvedere fruit. The raw materials are extracted by using water, and the density d of the obtained traditional Chinese medicine extract is 1.5-1.8g / ml. The traditional Chinese medicine antibiotic skincare hand cleanser provided by the invention has certain inhibitive effects against escherichia coli, staphylococcus aureus, and candida albicans, and provides certain preventive effects against eczema, skin pruritus, and the like. The hand cleanser is also advantaged in small dosage, high decontamination capability, good sterilization effect, and low irritation. The hands are delicate and not dry after washing. According to the invention, the formula of the hand cleanser is simple. With the hand cleanser, modern market requirements on naturalness, environment-friendliness, and high antibiotic efficiency can be satisfied.

Owner:SHANXI ZHENDONG PHARMA

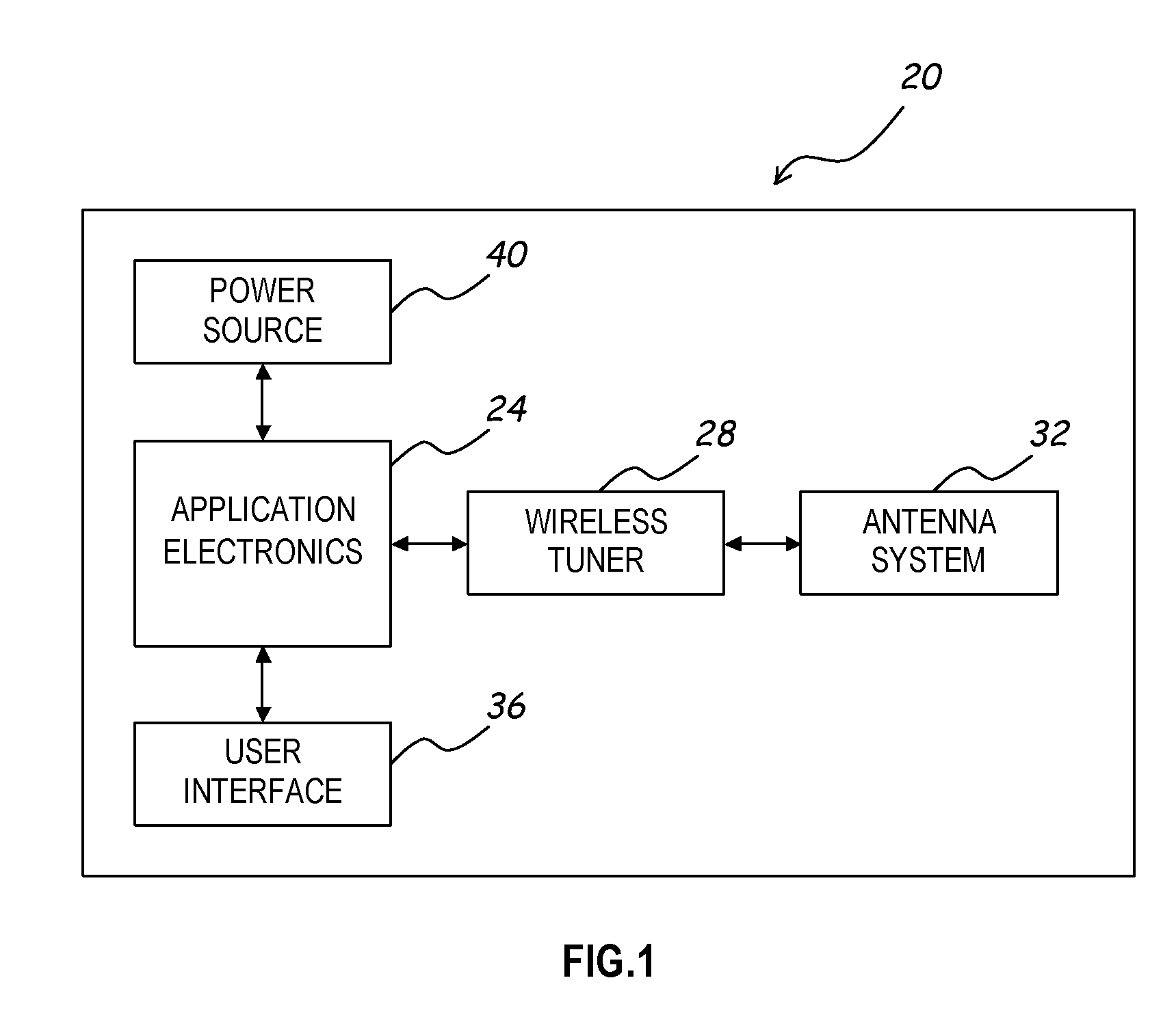

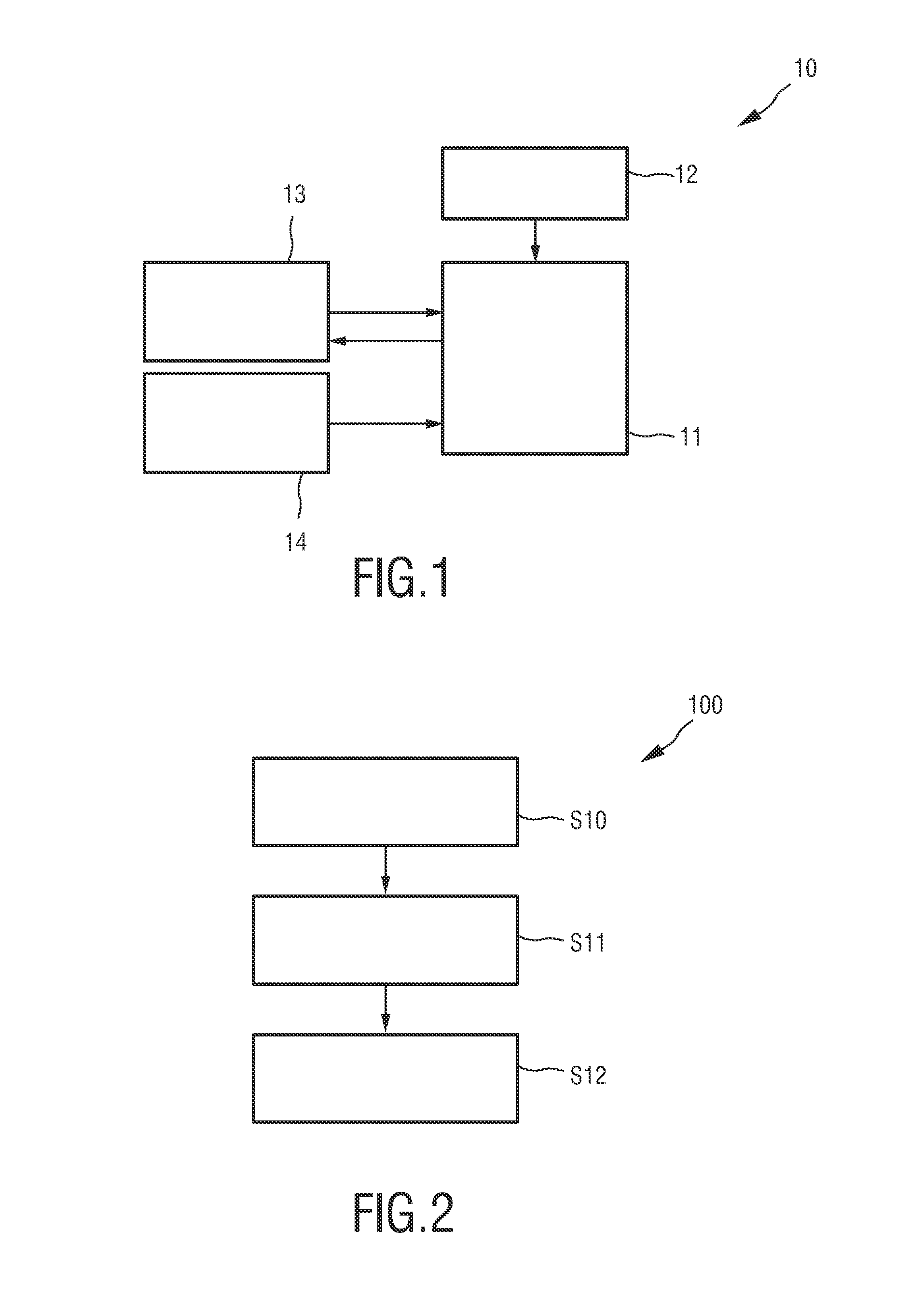

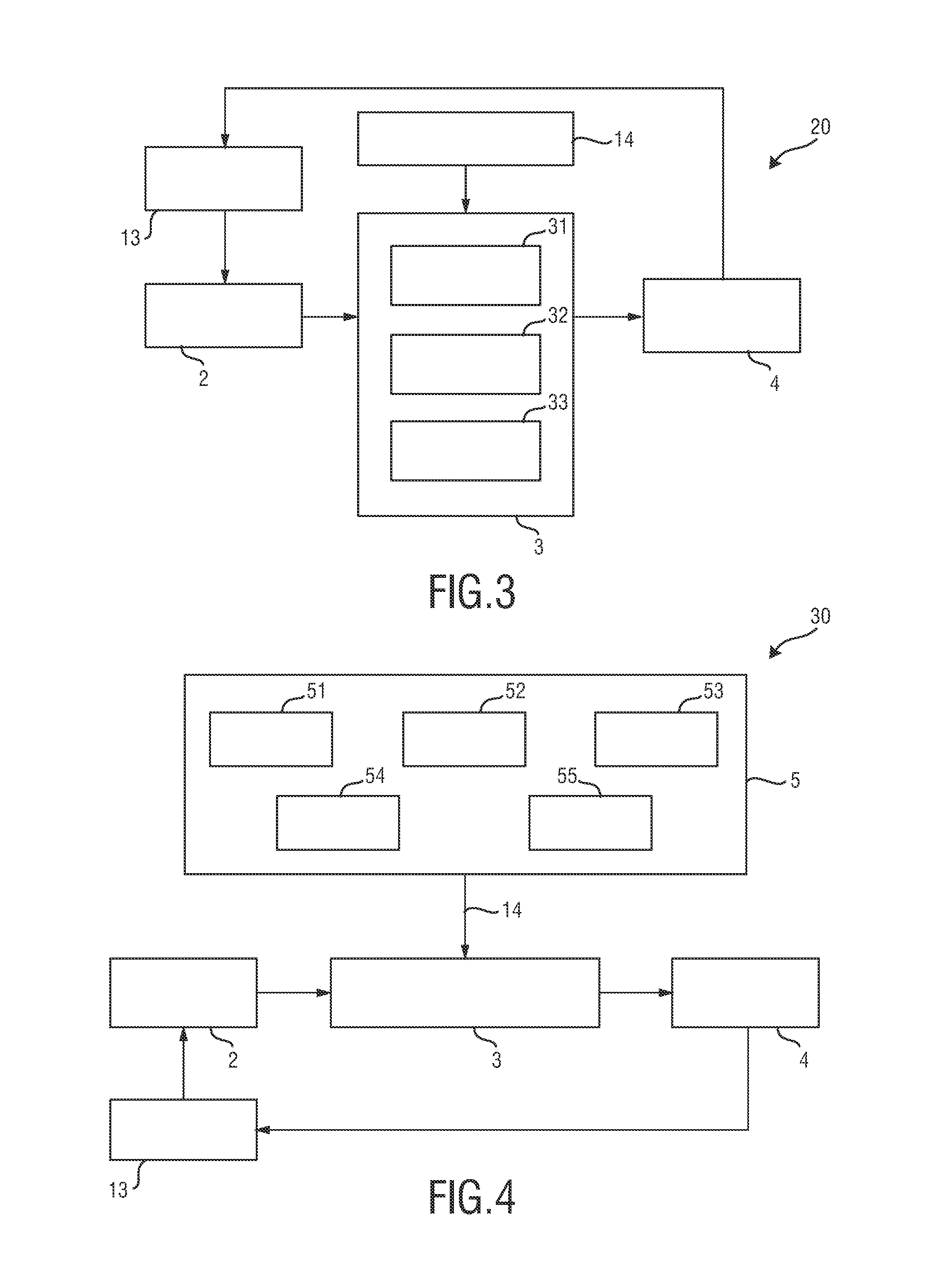

Healthcare system and method for adjusting a personalized care plan of a user

InactiveUS20150088536A1Good motivation and adherenceEasy to controlPhysical therapies and activitiesData processing applicationsPlan of carePersonalization

The present invention relates to a healthcare system (10, 20) comprising a care plan unit (2) for obtaining a personalized care plan (13) for a user, said care plan defining a plurality of prescribed care plan elements to be adhered to by the user, a compliance score calculation unit (3) for calculating the user's compliance score indicating the user's compliance to his care plan based on measurements (14) of the user's adherence to prescribed care plan elements, and a care plan adjustment unit (4) for dynamically adjusting the user's care plan based on the user's calculated compliance score.

Owner:KONINKLJIJKE PHILIPS NV

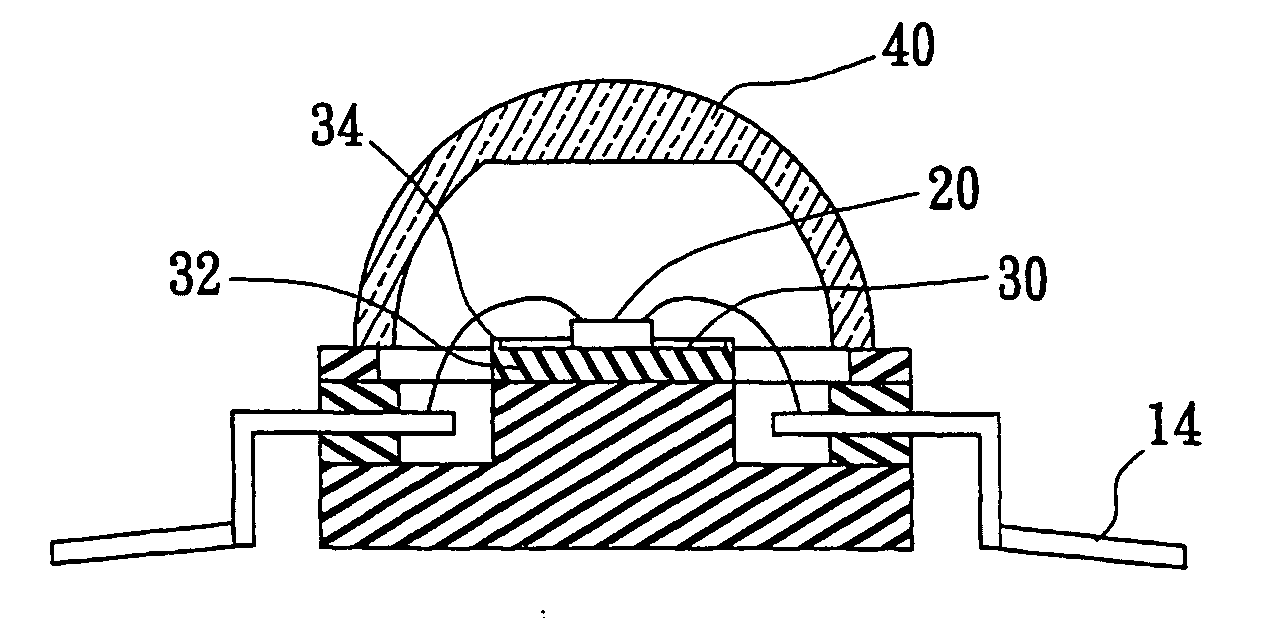

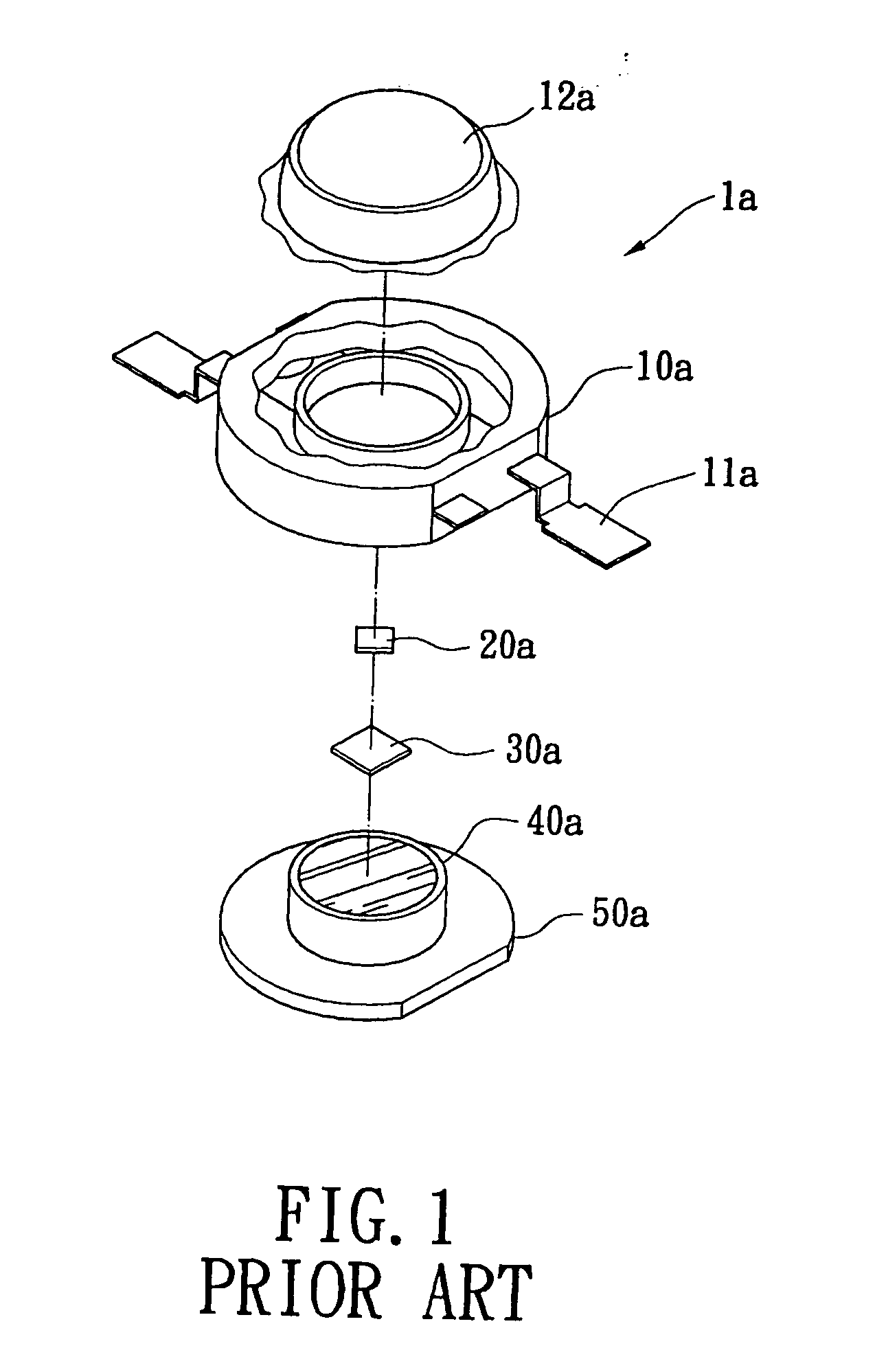

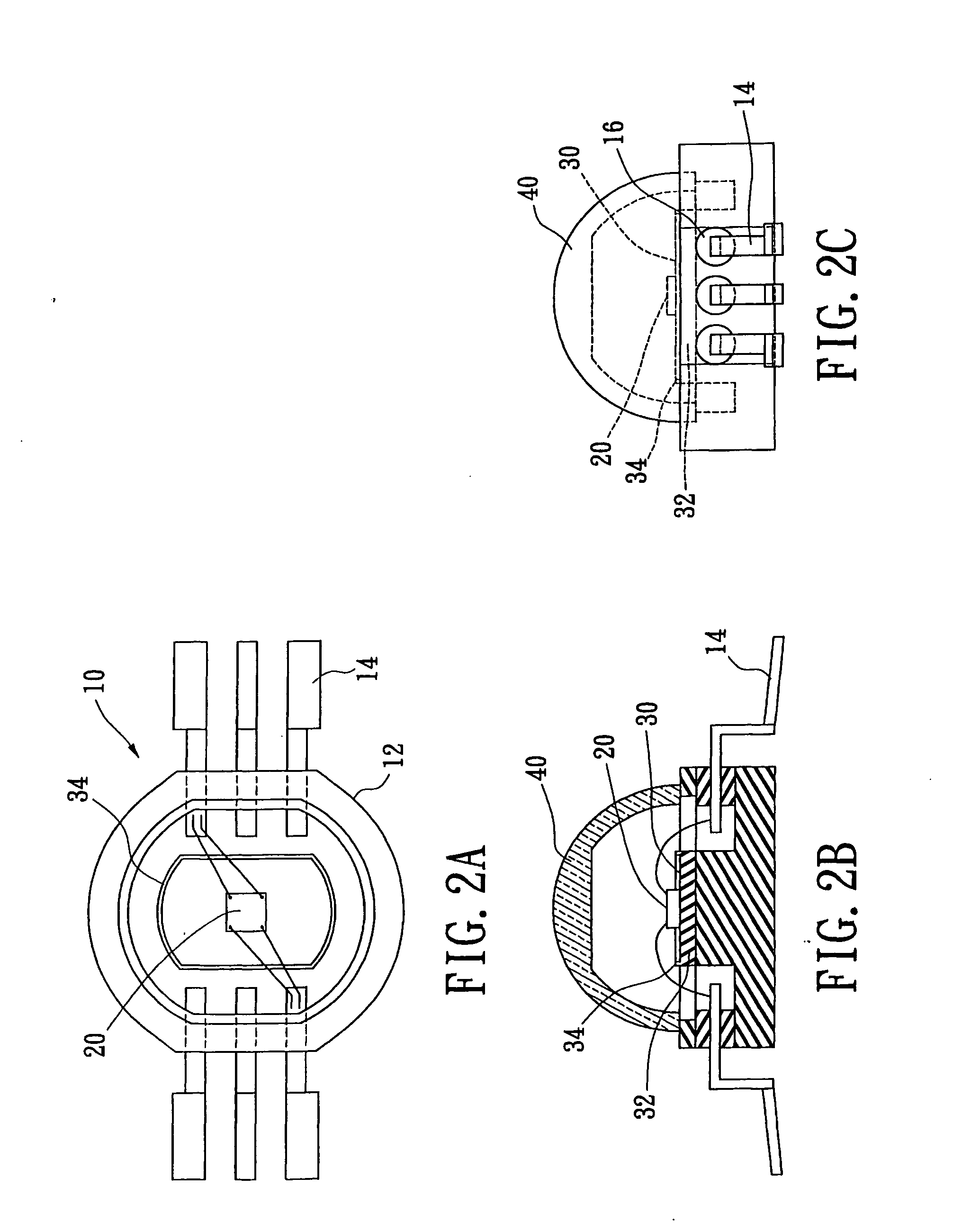

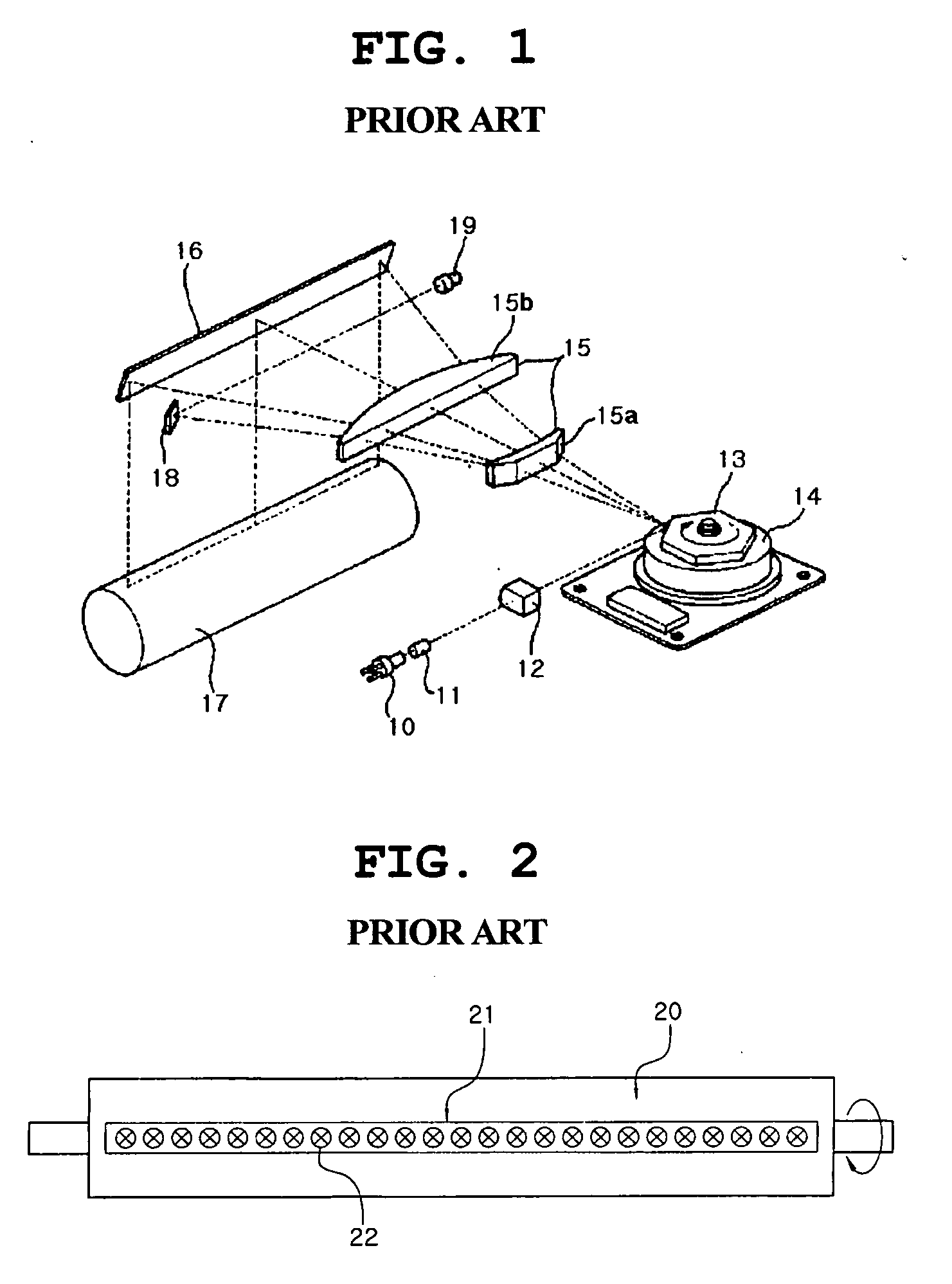

Package structure for optical-electrical semiconductor

InactiveUS20060086945A1SimpleCheap and high quality mass productionSolid-state devicesSemiconductor devicesEngineeringFault rate

A package structure for an optical-electrical semiconductor is described. The package structure has a thermal conductive structure for heat transfer and is integrally formed in one piece to improve the structural strength thereof, while the thermal conductive structure prevent over-heating of the LED device for greater longevity. The package structure reduces the failure rate in production and has improved quality. When the present invention is applied in light-emitting diode packages, the special requirement can be reached and has better properties than the prior art.

Owner:HARVATEK CORPORATION

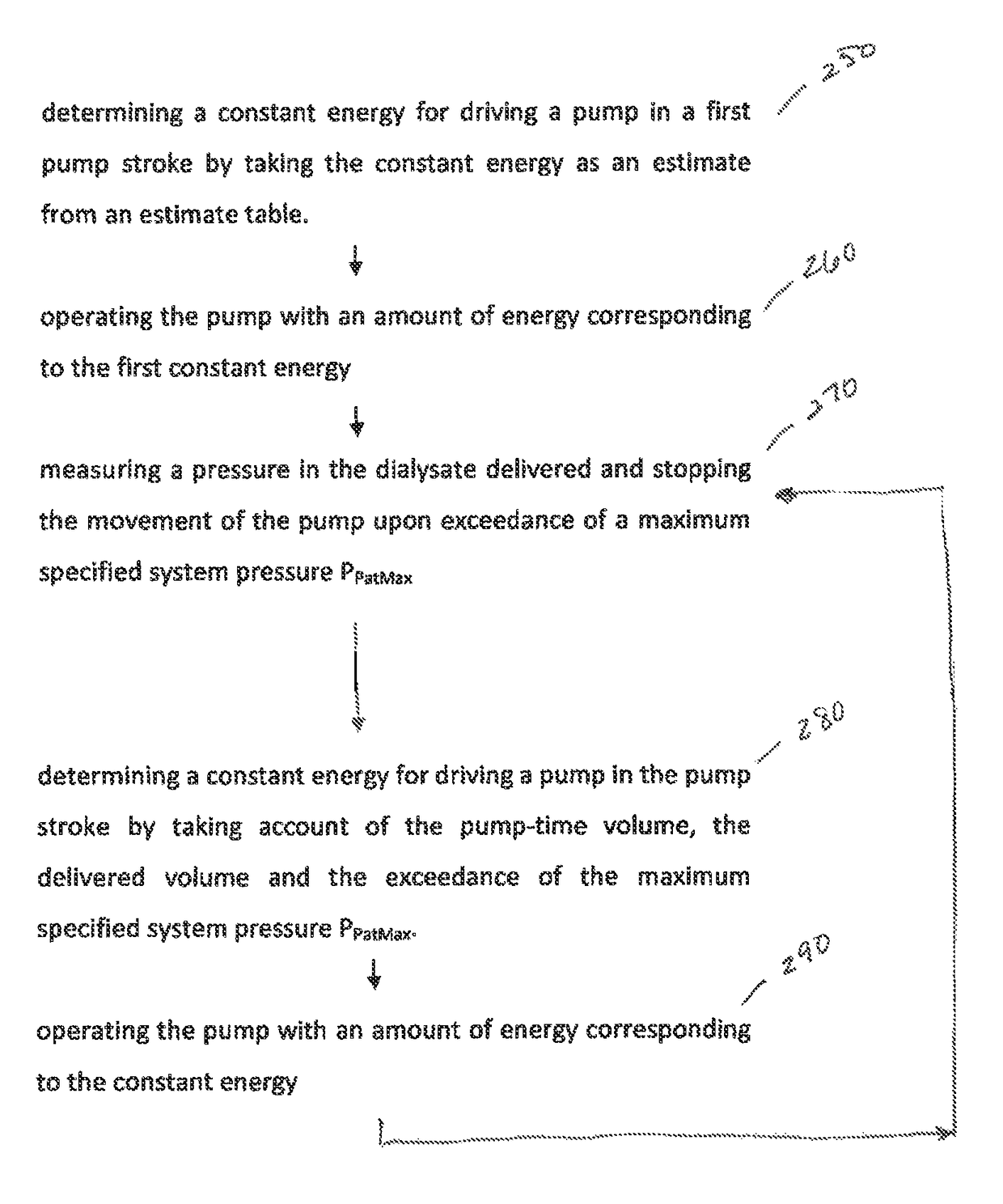

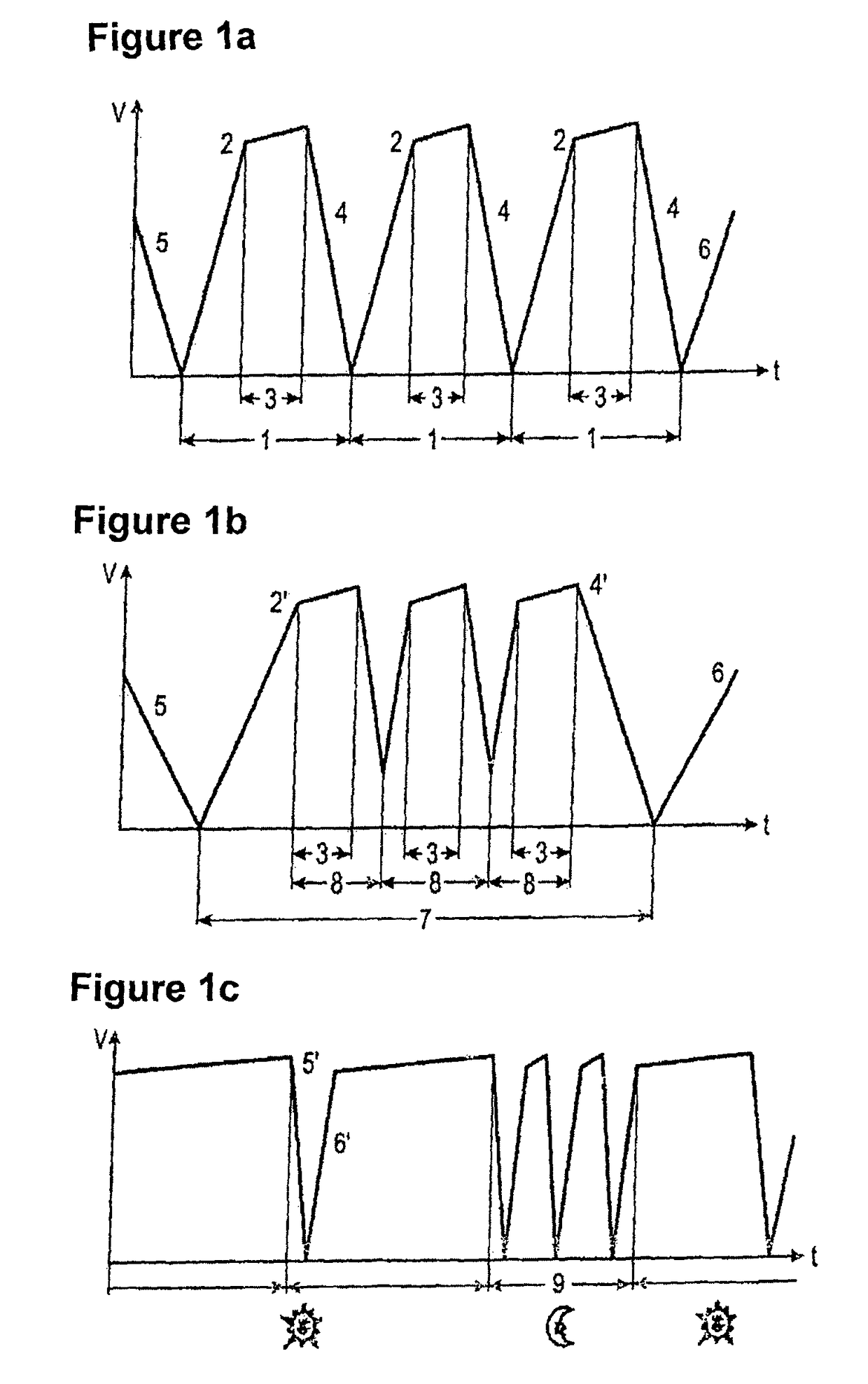

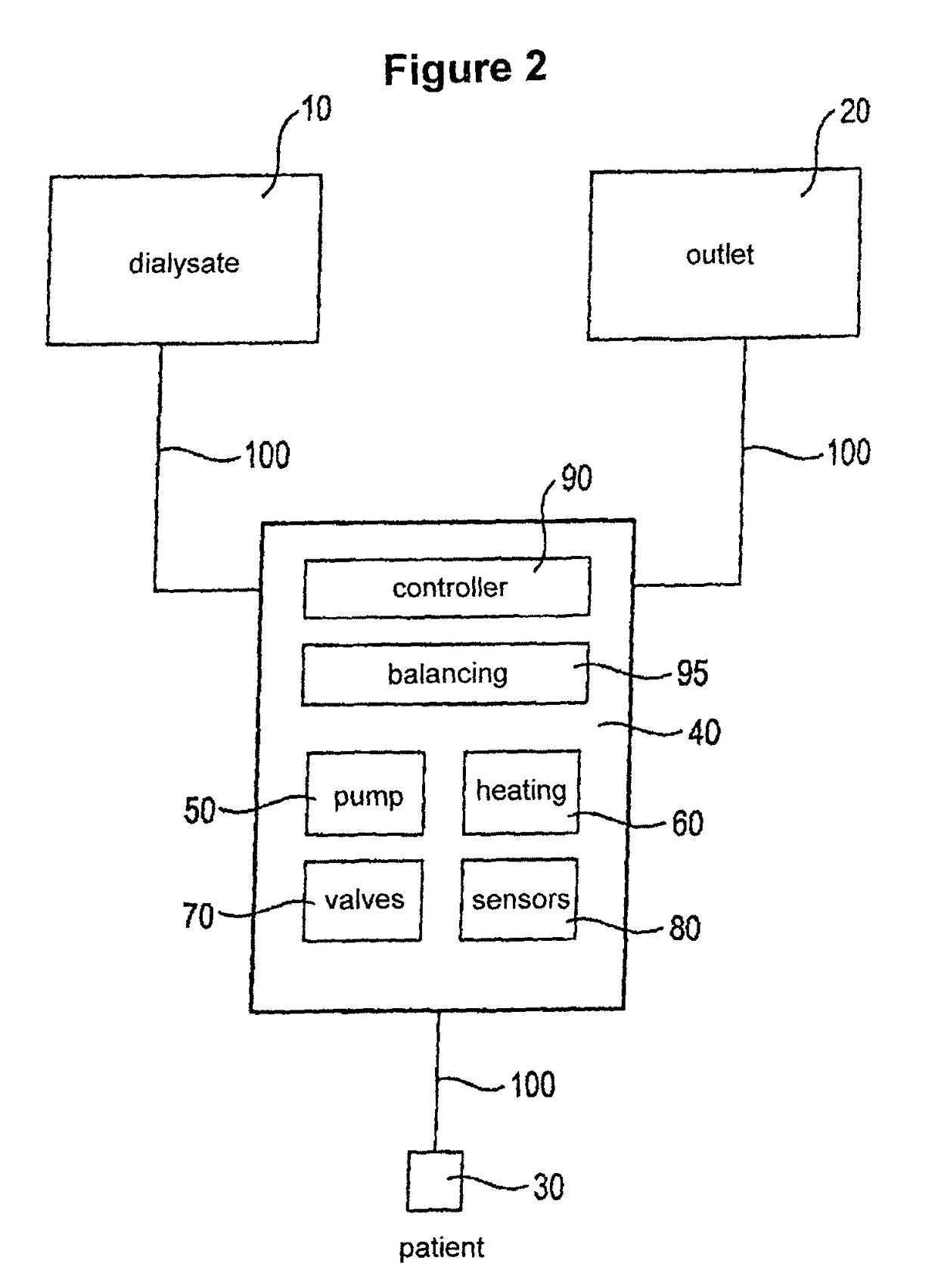

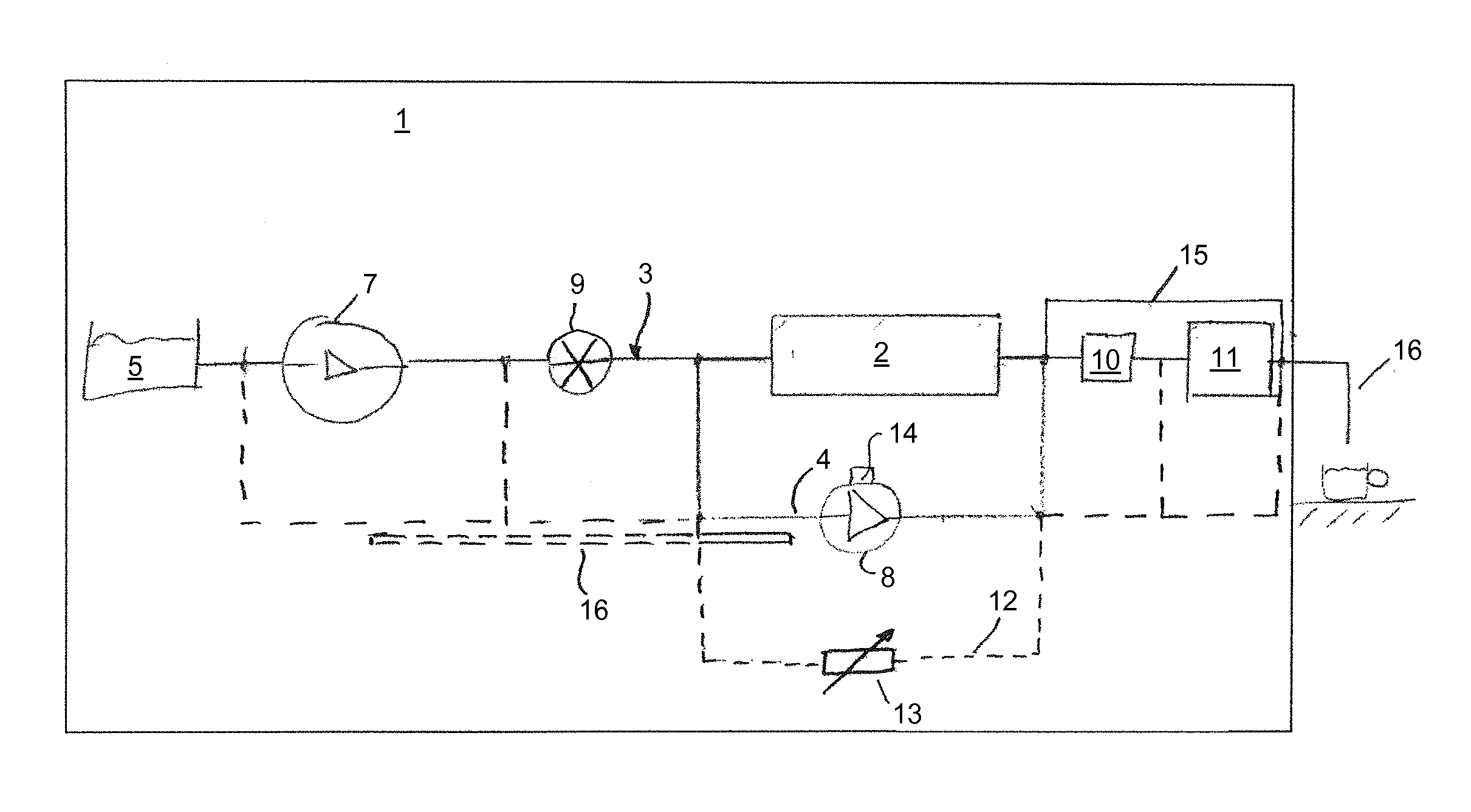

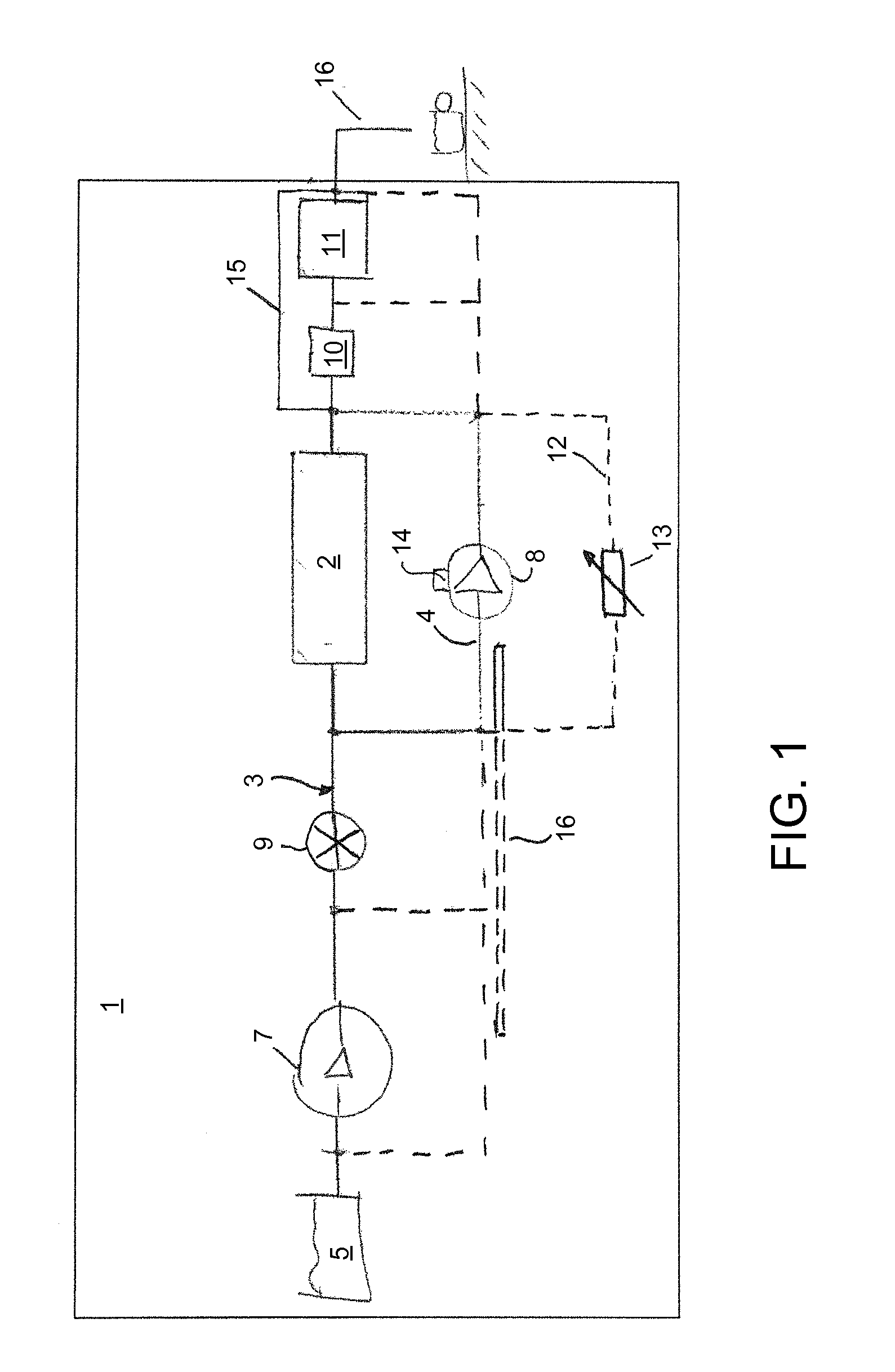

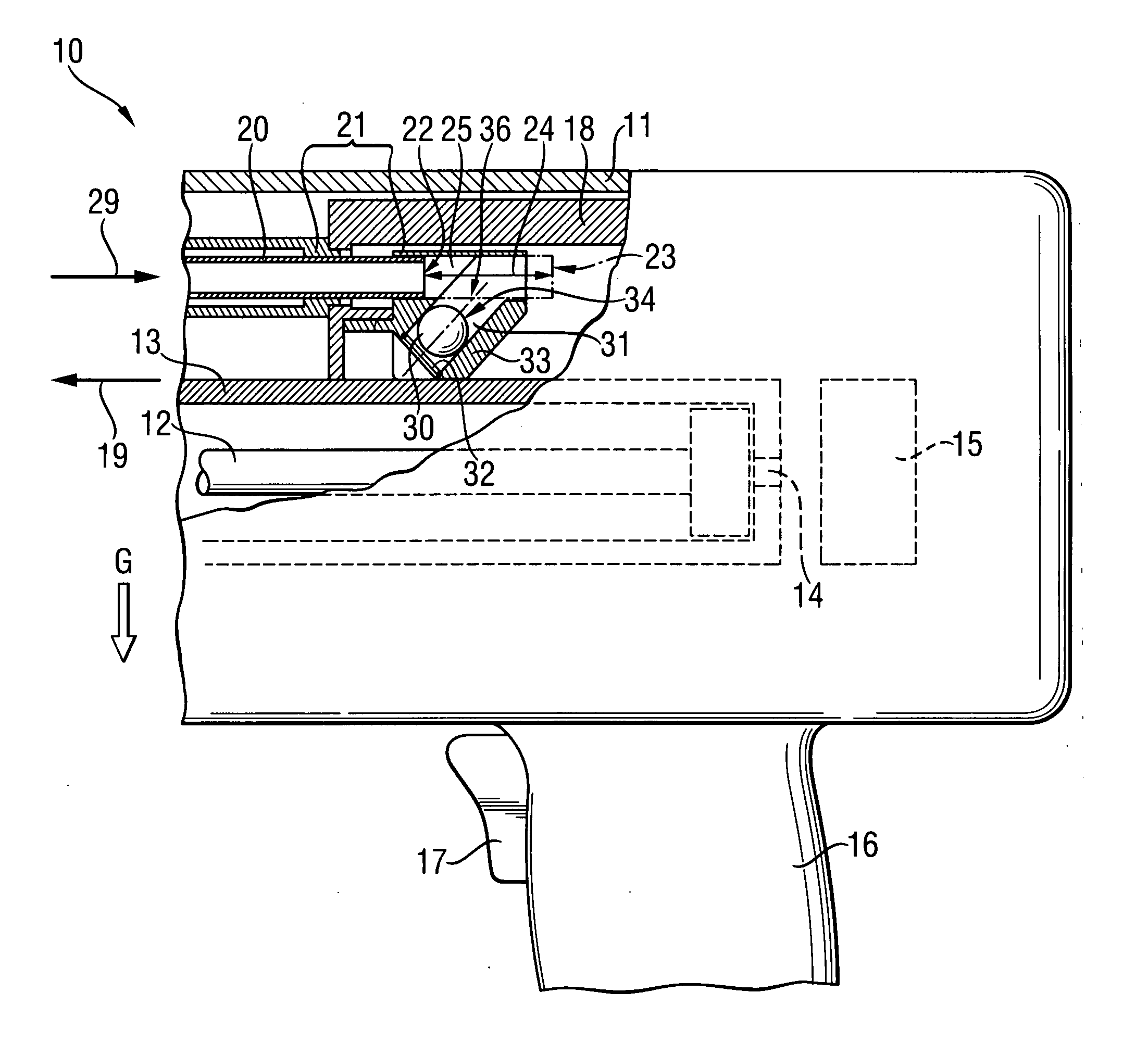

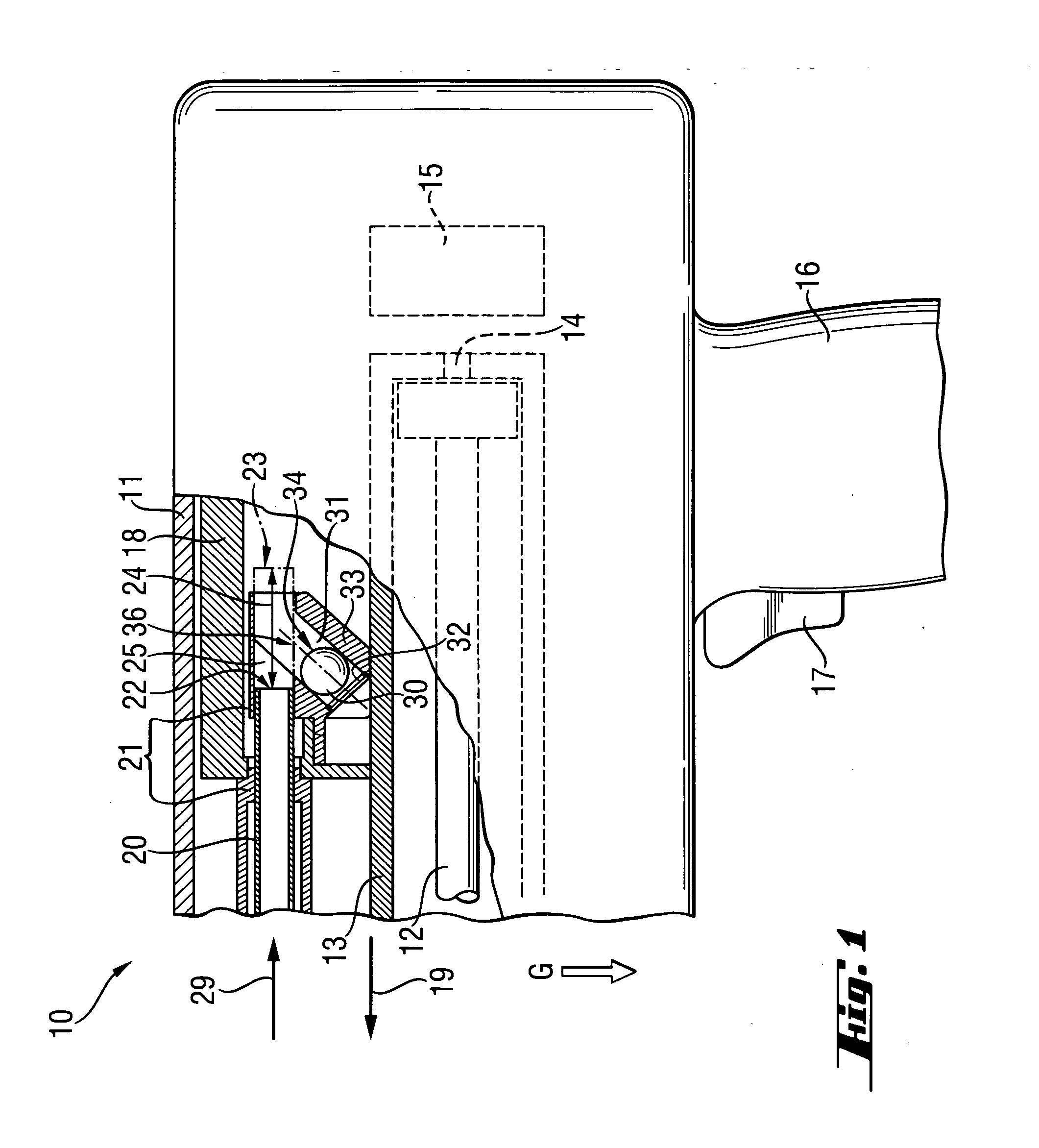

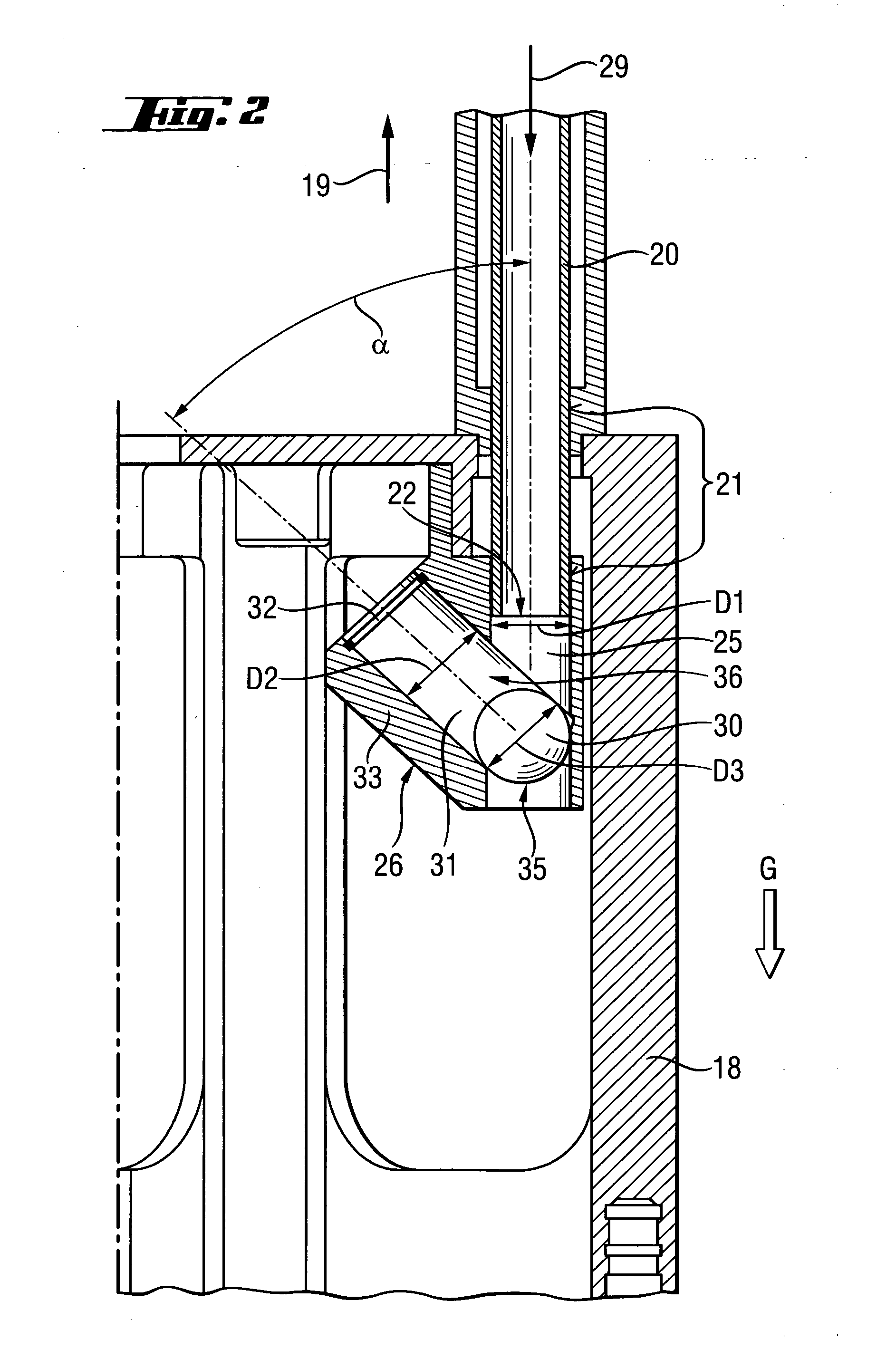

Method for adjusting a continuous dialysate volume flow in a dialysis machine and dialysis machine

ActiveUS9694126B2SimpleReduce requirementsMedical devicesPeritoneal dialysisDialysis fluidBiomedical engineering

A method is provided for adjusting a continuous dialysate volume flow in a dialysis machine with at least two discontinuous pumps and a controller for generating a desired volume flow of the dialysate. The energy for driving the pumps is set to be constant with a value determined corresponding to the pump-time volume of the respective pump stroke and the delivered volume. A dialysis machine for carrying out the aforementioned method is also provided.

Owner:FRESENIUS MEDICAL CARE DEUTSCHLAND GMBH

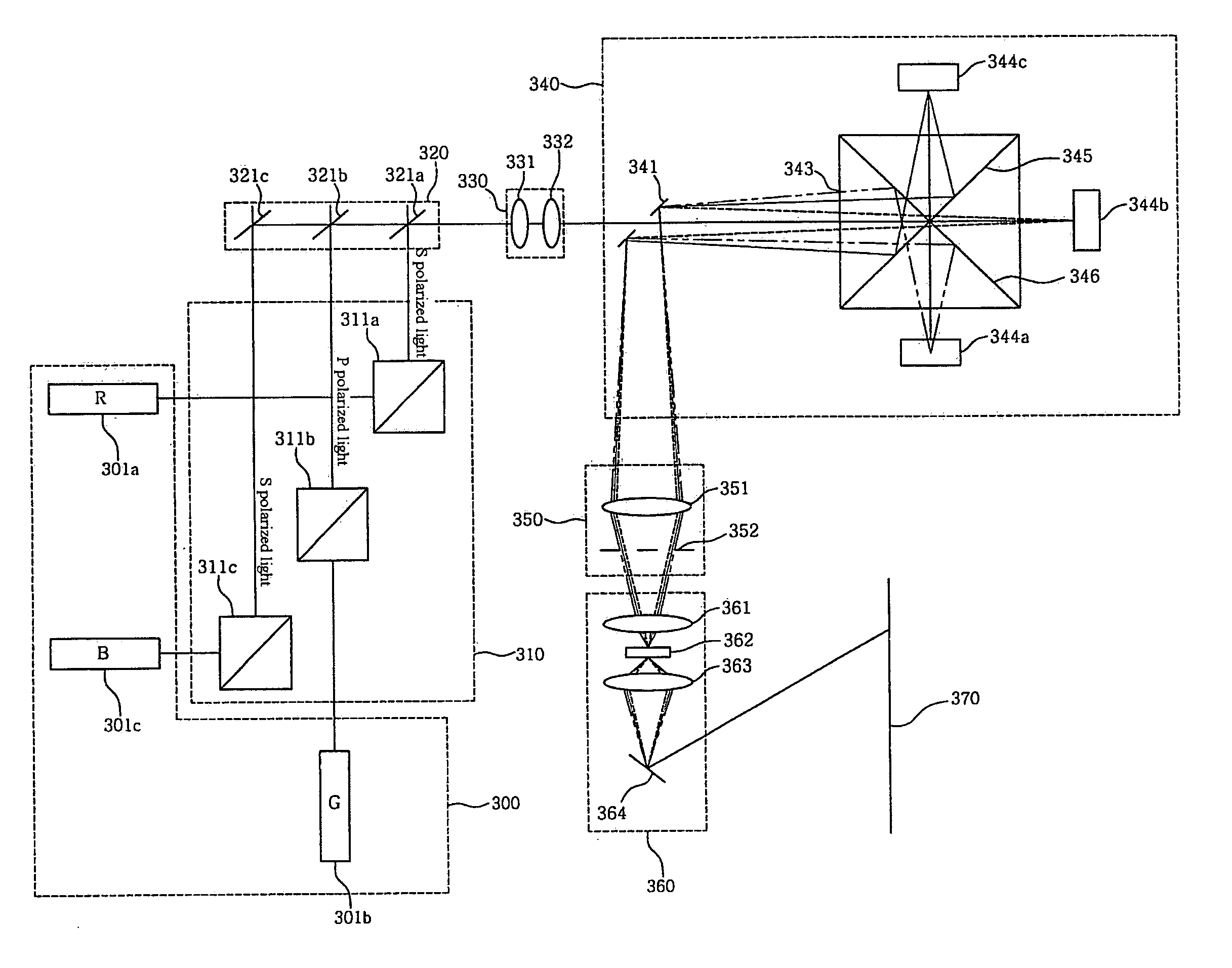

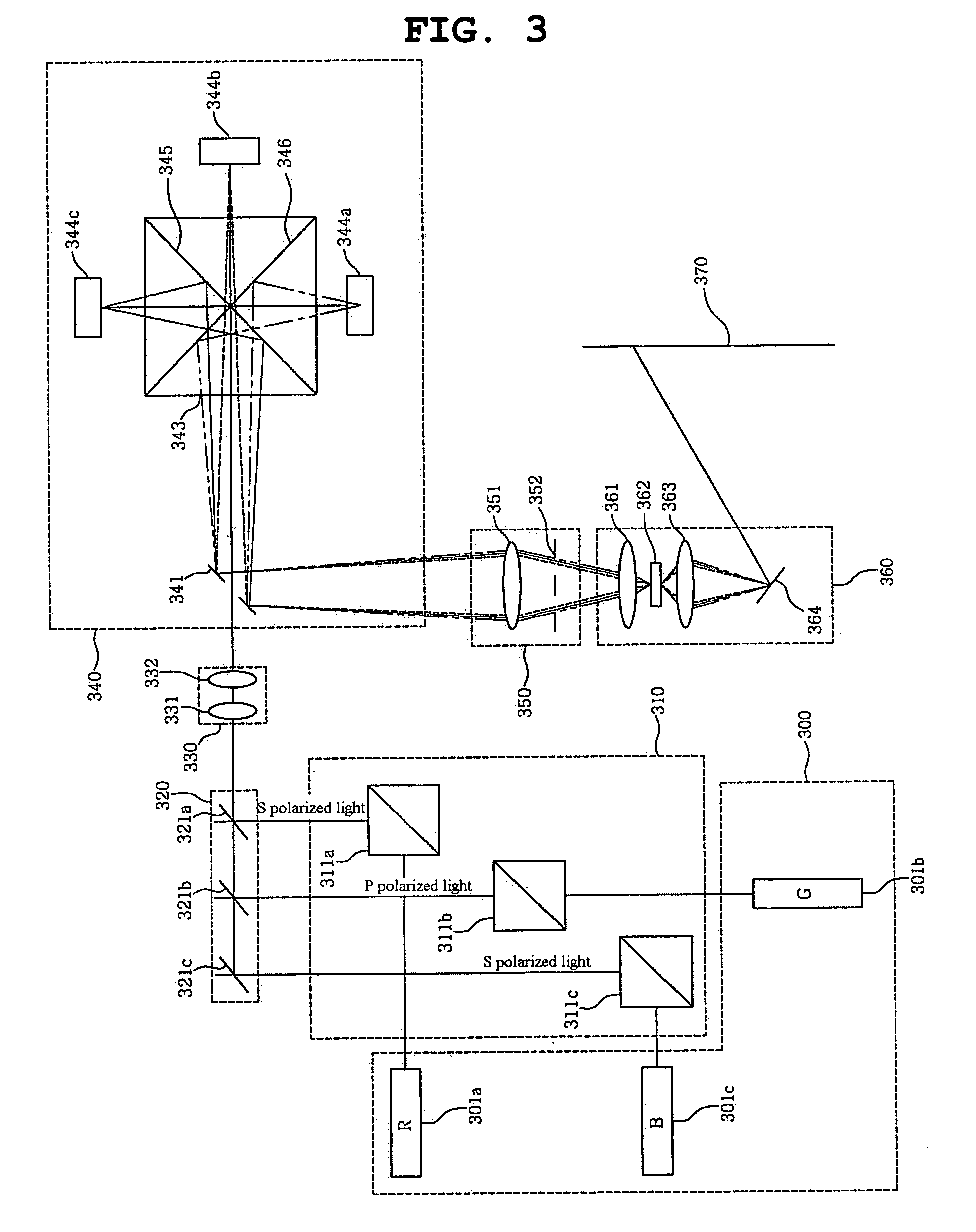

Color display device using separate diffracted light and illumination light

InactiveUS20060119941A1SimpleSimple optical systemTelevision system detailsProjectorsProjection systemLight beam

A display device is disclosed. The display device includes a condenser unit, an illumination lens system, a plurality of diffractive light modulators, a mirror for separating illumination light from diffracted light, a polarized beam separator, a filter unit and a projection unit. The condenser unit converges polarized light, and outputs the converged polarized light. The illumination lens system converts the polarized light into linear parallel light. The diffractive light modulators produce diffracted light beams having a plurality of diffraction orders. The mirror passes the polarized light therethrough using slits, and reflects the diffracted light beams toward a filter system. The polarized beam separator separates the polarized light on a wavelength basis and then allows the separated beams to be incident on corresponding diffractive light modulators, and converges the diffracted light beams and then outputs the converged light to the mirror. The filter system selects the diffracted light beams having desired diffraction orders from among diffracted light beams using a spatial filter. The projection system focuses the diffracted light beams, and projects the focused light beams onto a screen.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

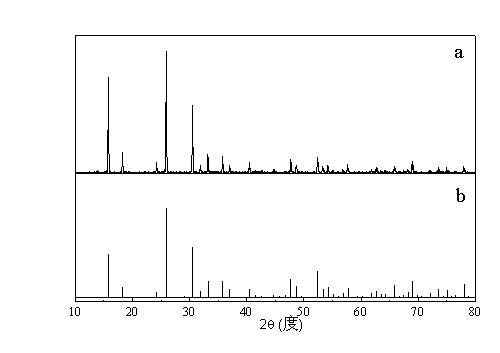

Method for hydrothermally synthesizing analcime monocrystal

InactiveCN103572362ALow priceSimplePolycrystalline material growthFrom normal temperature solutionsMineralogySodium aluminate

The invention belongs to the technical field of artificial synthesis of natural minerals and particularly relates to a synthetic method of an isometric system analcime monocrystal. The synthetic method is characterized by comprising the following steps of: (1) preparation of a sodium silicate solution, namely dissolving 3.865 grams of solid NaOH into 160mL of distilled water, then adding 1.201 grams of Si powder, carrying out water-bath reaction at 90 DEG C for 5 hours; (2) preparation of a sodium metalluminate solution, namely dissolving 1.947 grams of the solid NaOH into 50mL of the distilled water, and then adding 0.576 gram of Al powder, and sufficiently reacting under the condition of room temperature; (3) preparation of a precursor: respectively filtering the solutions, mixing, stirring, carrying out microwave heating, and carrying out stirring reaction for 0.5 hours; (4) placing the precursor in a high-pressure kettle, and carrying out thermostatic reaction at 200 DEG C for 3-6 days; (5) washing a product with distilled water to be neutral, and drying to obtain the analcime monocrystal with the size of about 120 micrometers.

Owner:UNIV OF JINAN

Beverage machine

ActiveUS20120291634A1Improve efficiencyLong running lifeBeverage vesselsTeaWaste managementWater tanks

A beverage machine (1), in particular to a coffee machine, has a main flow path (3), that leads through a heating device (2), and a bypass flow path (4) that circumvents the heating device (2). The bypass flow path (4) branches off from the main flow path (3) upstream of the heating device (2). The main flow path (3) is connected to a water tank (5) at the input side and to a dispensing location (6) at the output side. A main flow pump (7) is arranged in the main flow path (3) between the water tank (5) and the heating device (2). Thus a bypass pump (8) is arranged in the bypass flow path (4) to provide a cost-efficient and accurate admixing of cold water.

Owner:WMF WURTTEMBERGISCHE METALLWARENFABRIK AG

Color metallic pigment, method for producing same, and coating composition and cosmetic containing same

ActiveUS20130131187A1Excellent obliterate powerSimpleBiocideCosmetic preparationsSilicon oxideMaterials science

A color metallic pigment according to the present invention contains at least a metallic pigment, an amorphous silicon oxide film layer that is formed on the surface of the metallic pigment, a metal oxide layer that is formed on the surface of the amorphous silicon oxide film layer and contains a metal oxide other than silicon oxide, and metal particles that are formed on the surface of the metal oxide layer, wherein the metal particles are so formed as to directly cover a part of the metal oxide layer.

Owner:TOYO ALUMINIUM KK

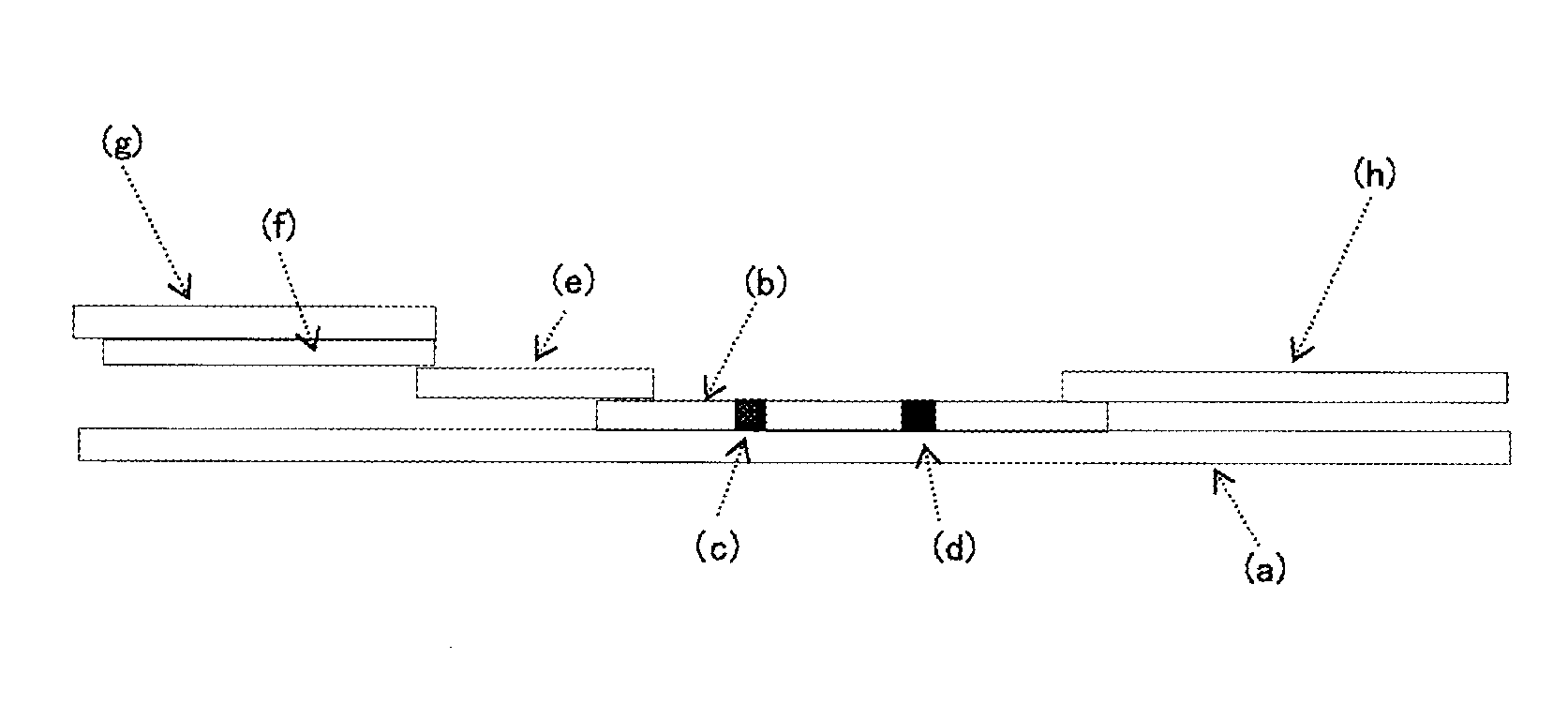

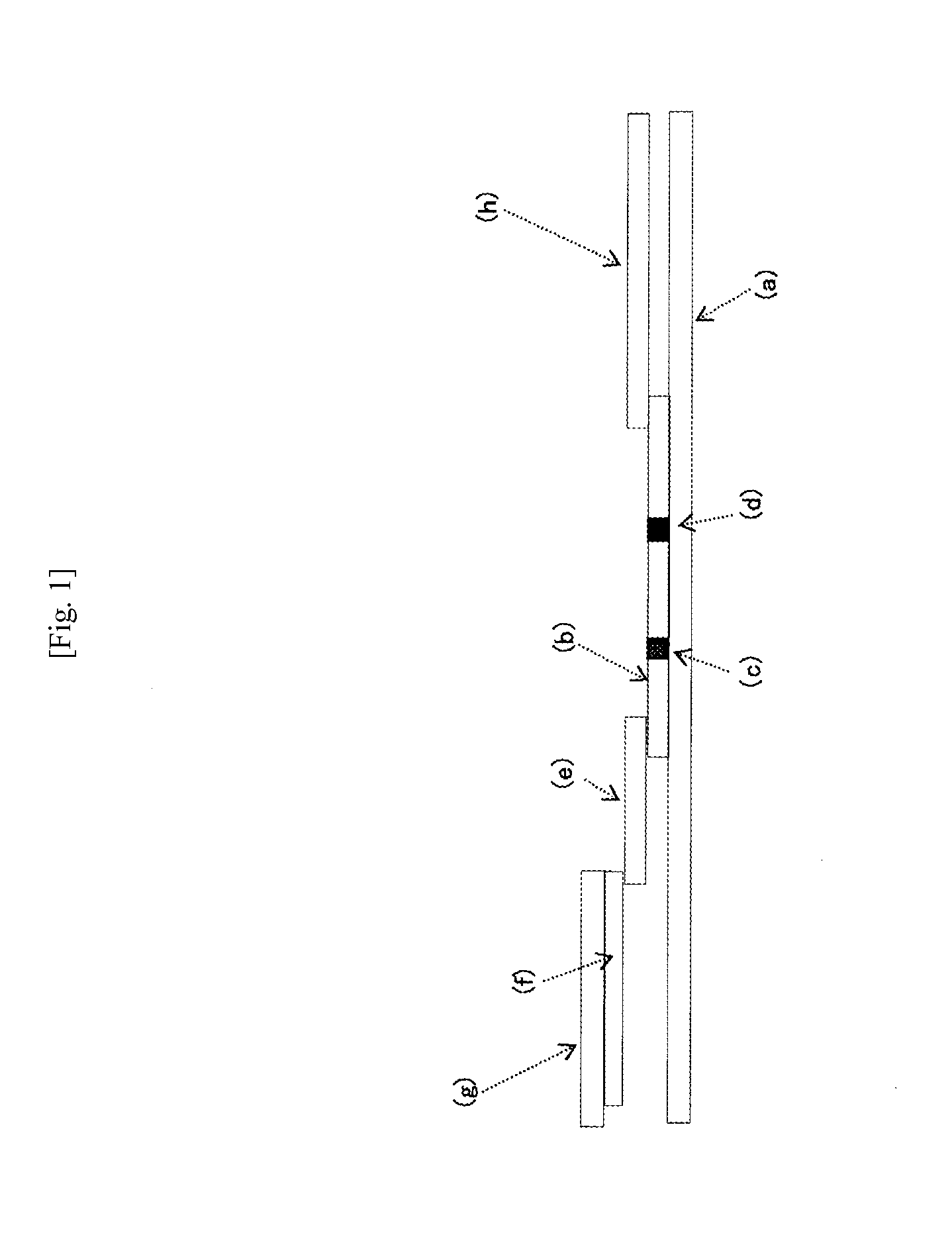

Immunochromatographic test strip and detection method using immunochromatography for detecting target in red blood cell-containing sample

ActiveUS20150086974A1Suppress aggregationSimpleBioreactor/fermenter combinationsAnalysis using chemical indicatorsChemistryImmunochromatographic test

A problem to be solved by the present invention is to provide an immunochromatographic test strip and a detection method using immunochromatography avoiding aggregation of colloidal gold conjugates while red blood cells in whole blood are agglutinated and then separated and removed in the case of using polybrene as a blood-agglutinating agent and the colloidal gold conjugates as a detection reagent. To solve the problem, the present inventers reviewed a past reagent configuration itself from a completely different viewpoint rather than selecting type and amount of polyanions and, as a result of extensive study on each element, the inventers surprisingly found that aggregation of colloidal gold can be suppressed by using a certain buffer solution without using neutralization by polyanions.

Owner:SEKISUI MEDICAL CO LTD

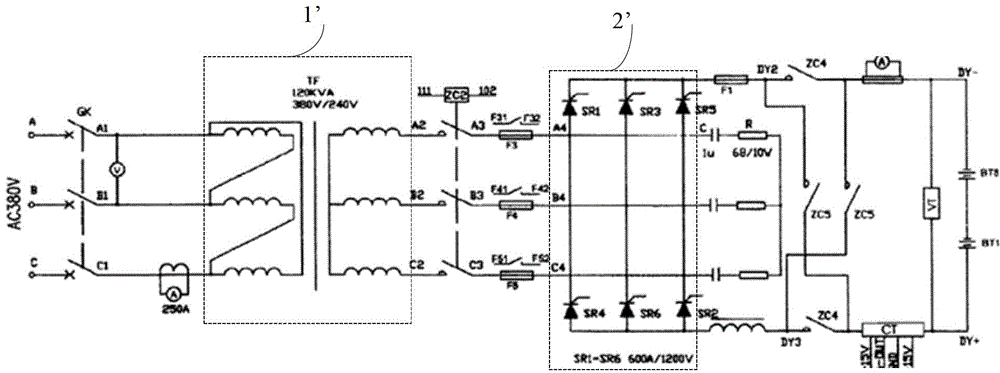

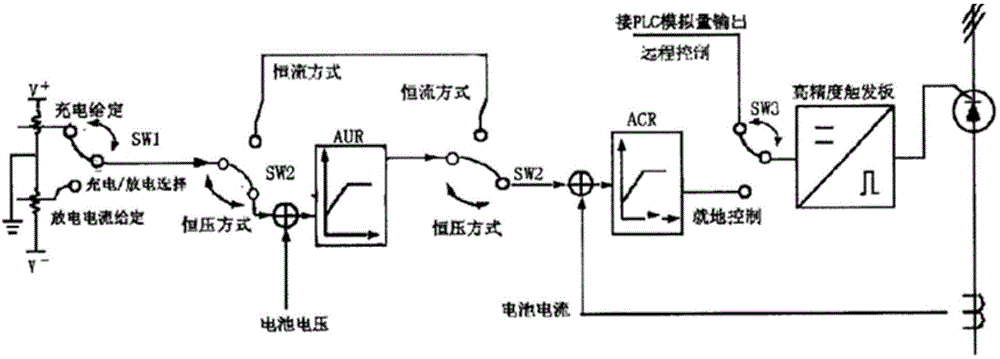

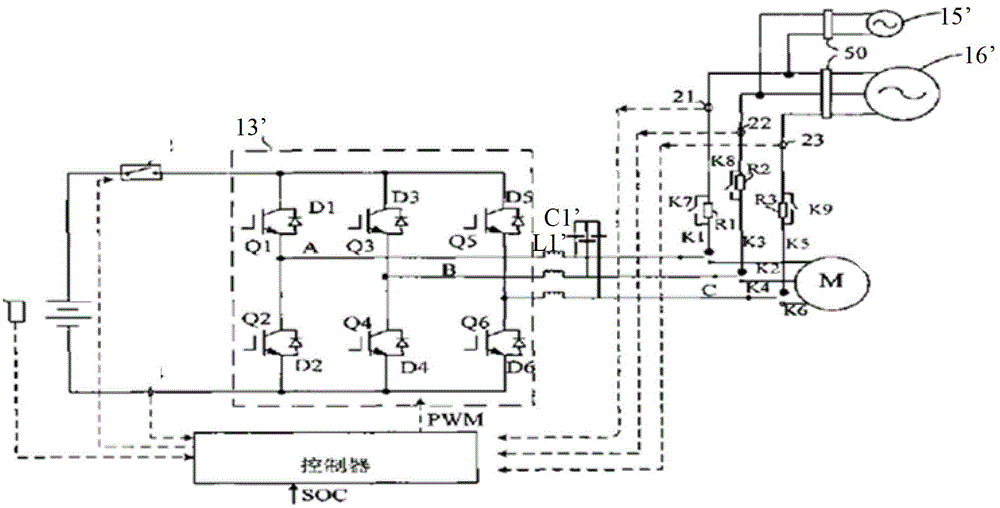

Electric automobile and discharging device thereof

The invention discloses a discharging device of an electric automobile. The discharging device comprises an alternating current charging port, a meter, a controller, a battery manager and a power battery, wherein the alternating current charging port is connected with a charging pile which is connected with a power grid, and is used for delivering output alternating current electricity to the power grid through the charging pile; the meter is used for sending out a discharging preparation command when a trigger signal is received; the controller is used for detecting whether the alternating current charging port is connected with the charging post after the discharging preparation command is received, is used for detecting whether a pulse width modulation (PWM) wave with preset voltage exists inside the controller or not, and is switched to be in an external discharging mode if the PWM wave with preset voltage exists inside the controller; the battery manager is used for controlling an external discharging loop in a high-voltage distribution cabinet which is used for actuating the electric automobile after the controller is switched to be in the external discharging mode; and the power battery is used for providing direct current electricity through the external discharging loop in the high-voltage distribution cabinet. The discharging device of the electric automobile has the advantages of simple model, high efficiency and applicability. The invention also provides the electric automobile.

Owner:BYD CO LTD

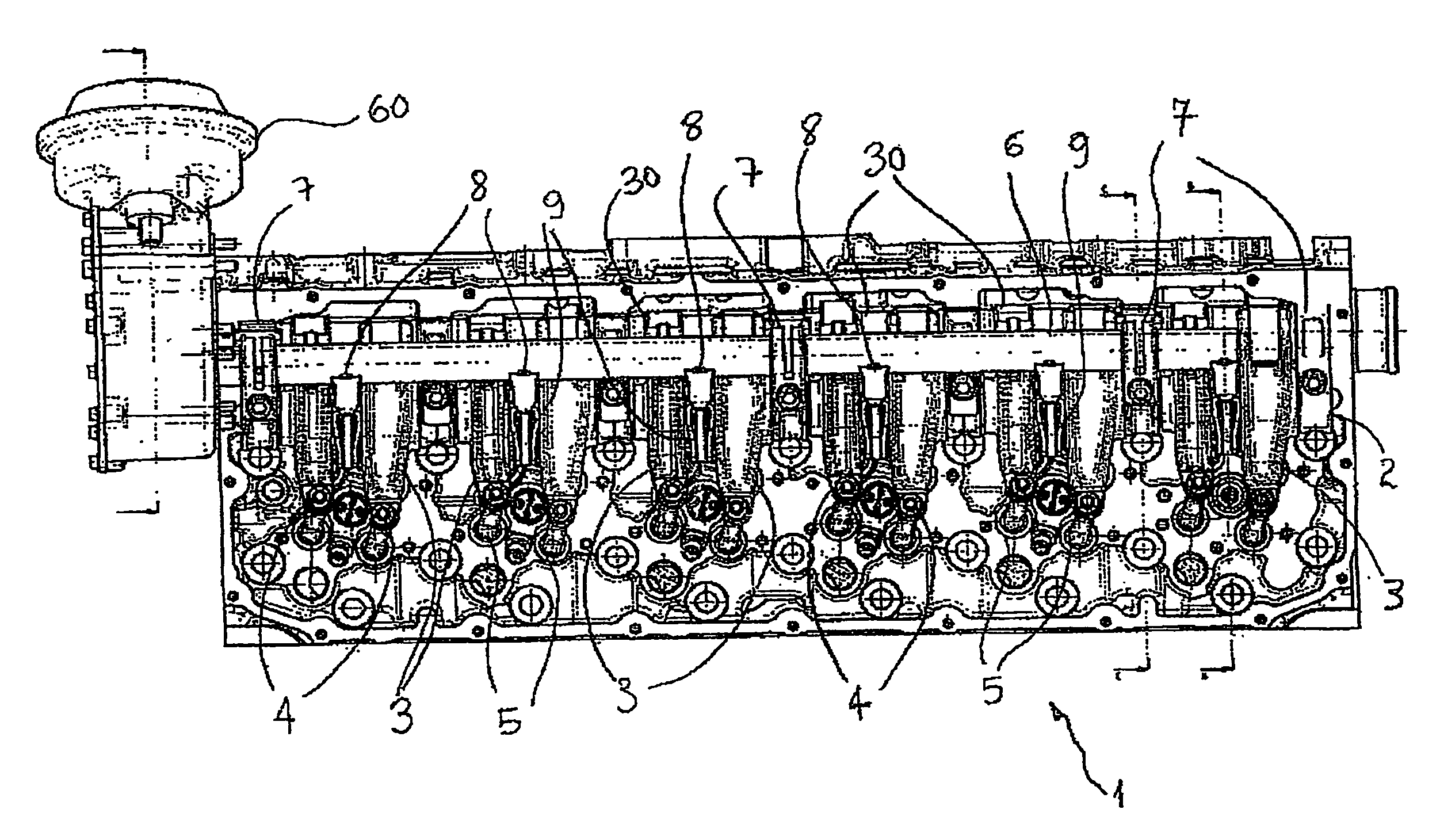

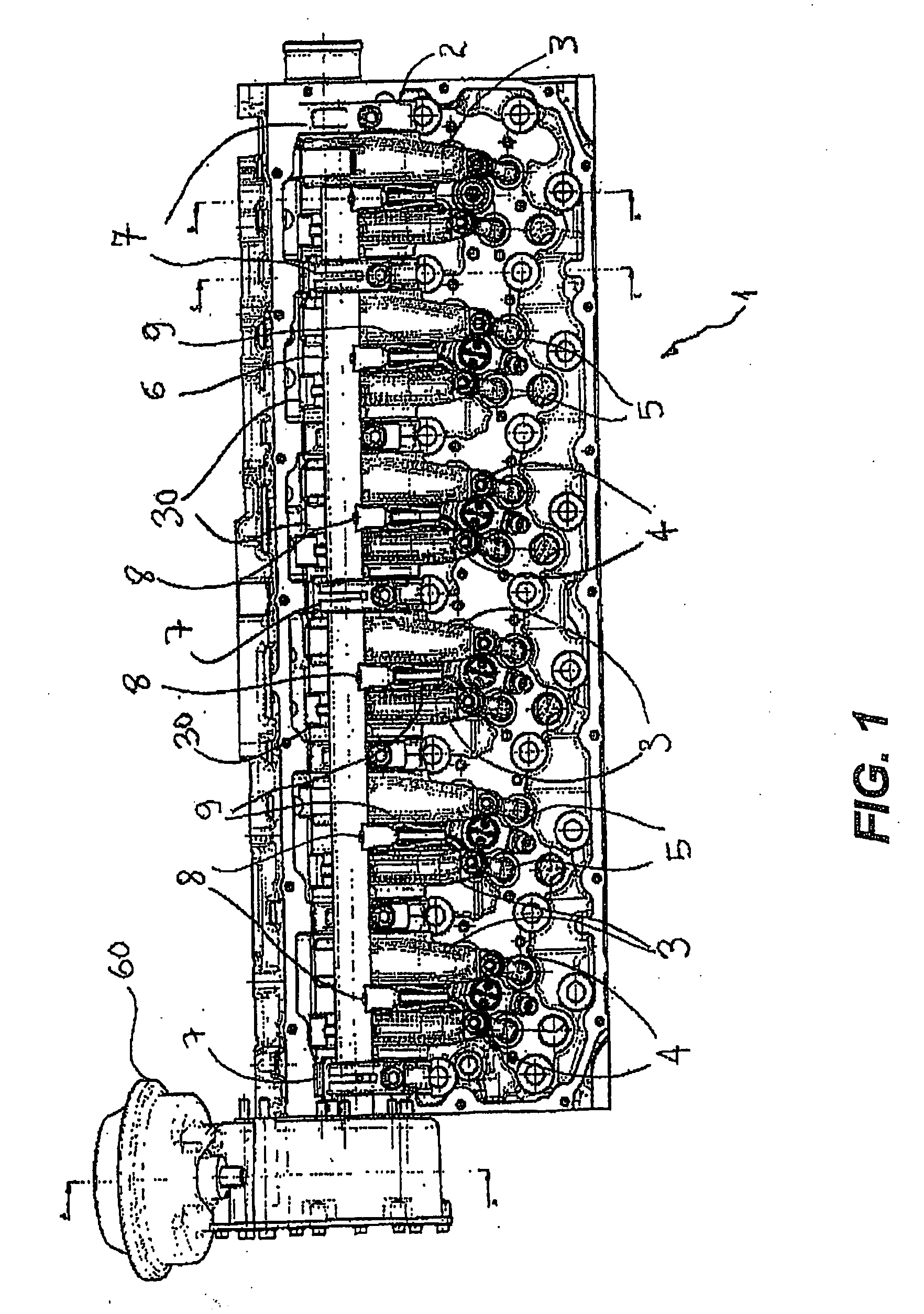

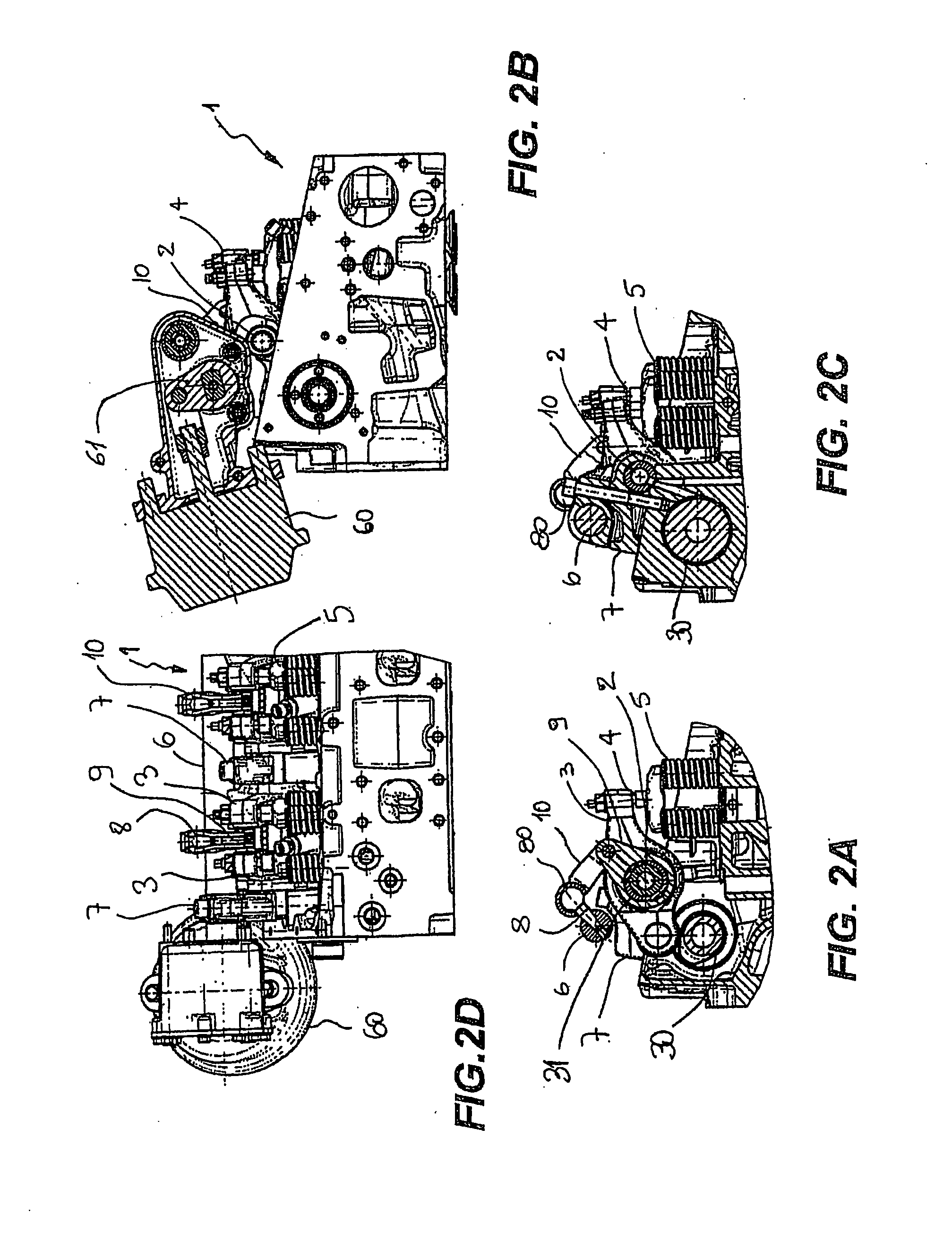

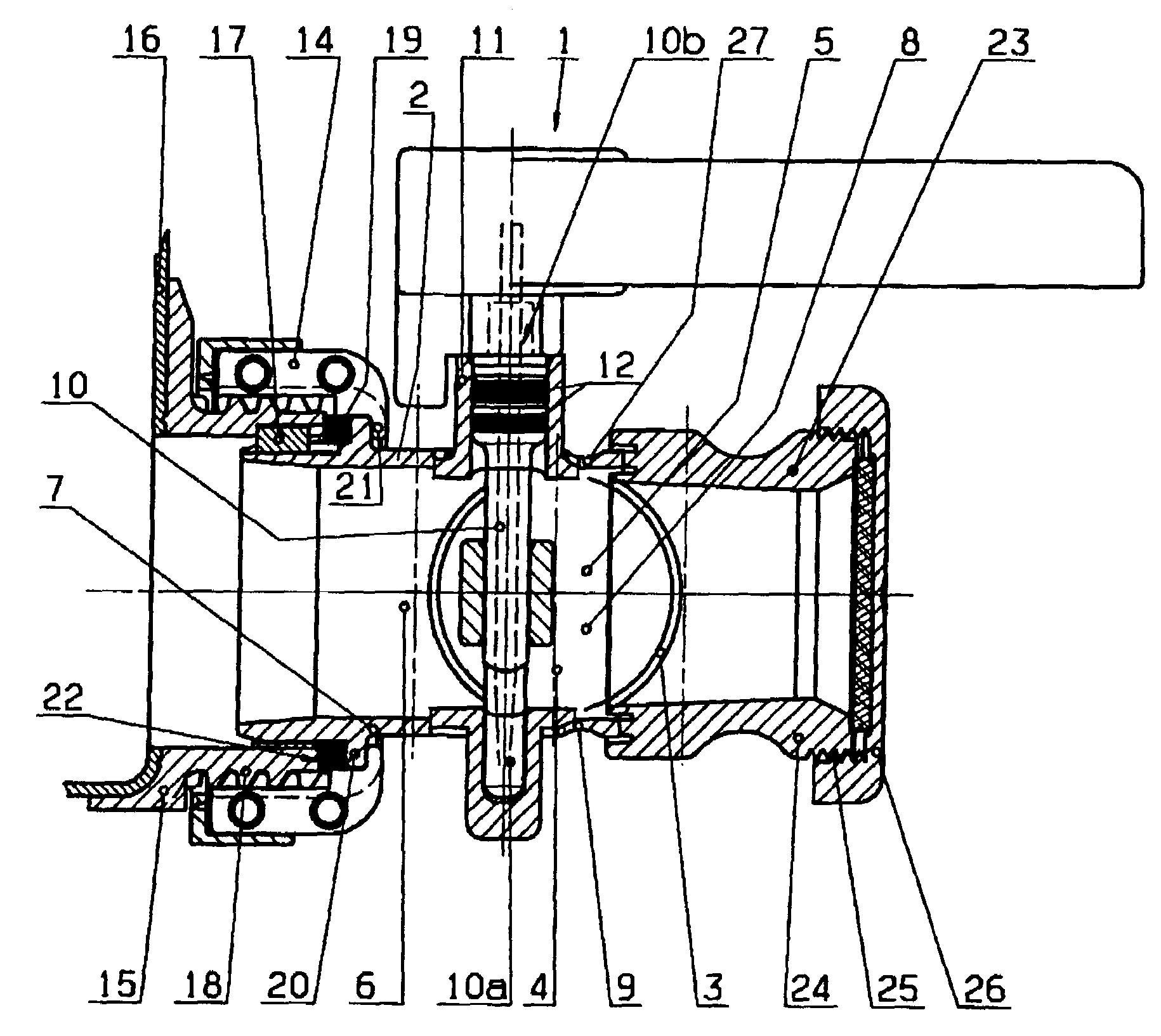

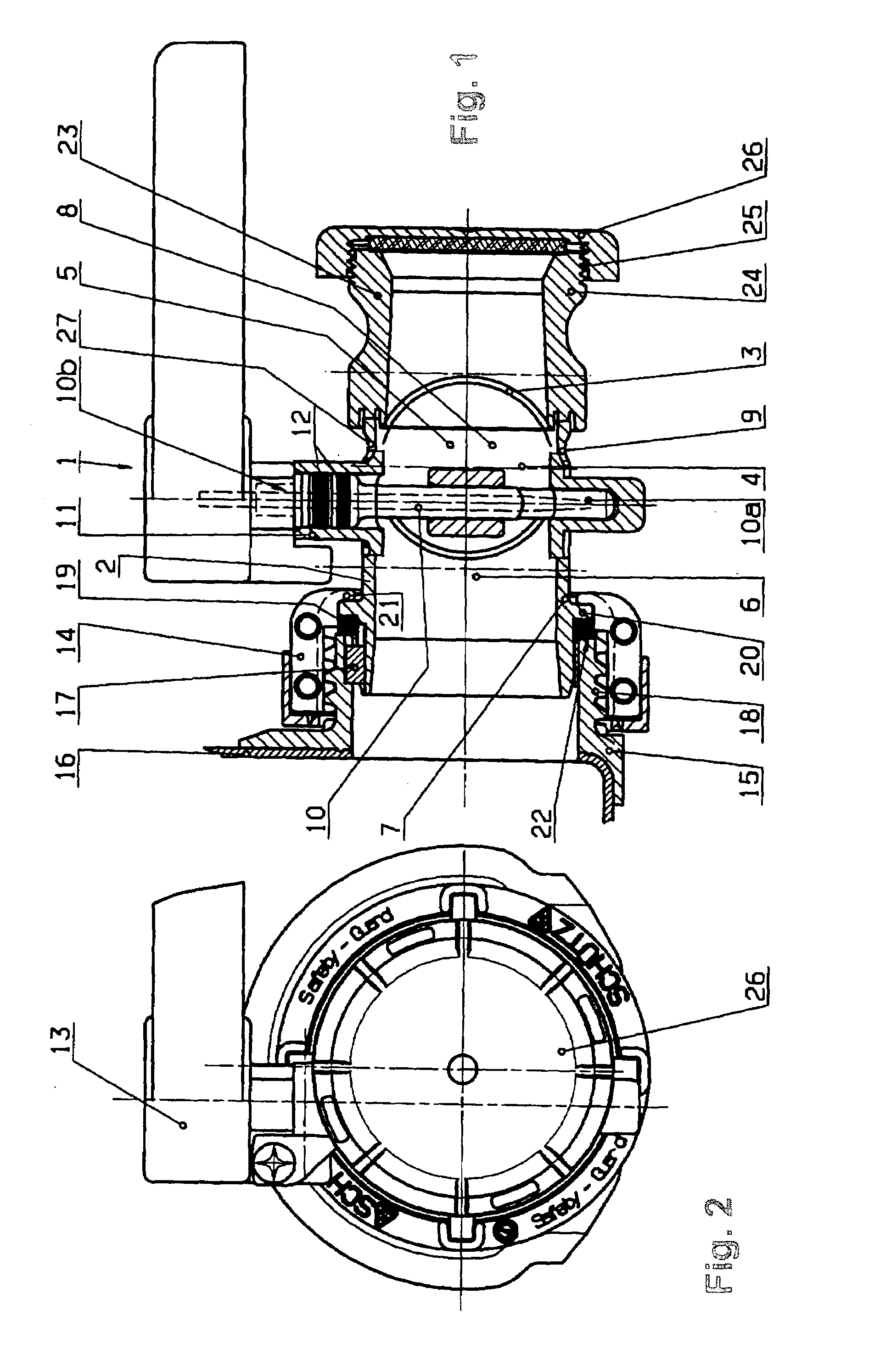

Decompression braking device in endothermic engines

InactiveUS20080121477A1Increased complexitySimpleValve arrangementsOutput powerEngineeringExhaust valve

A decompression braking device in an endothermic engine (1) is provided of the type comprising a lever axle (2) on which a plurality of eccentric bushings (31) of a corresponding plurality of levers (3) provided with tappets (4) are rotationally and eccentrically mounted for actuating a plurality of exhaust valves (5), and a camshaft (30) for actuating said plurality of levers (3), the device is characterised in that it comprises an actuating member (6, 61) mounted externally to said lever axle (2) and connected to the latter by means of linkages (8, 9, 10), such that a respective rotation of said bushings (31) by a predetermined angular value (□), with consequent displacement of the hinging axis of said levers (3), corresponds to each excursion of said actuating member (6, 60).

Owner:IVECO SPA

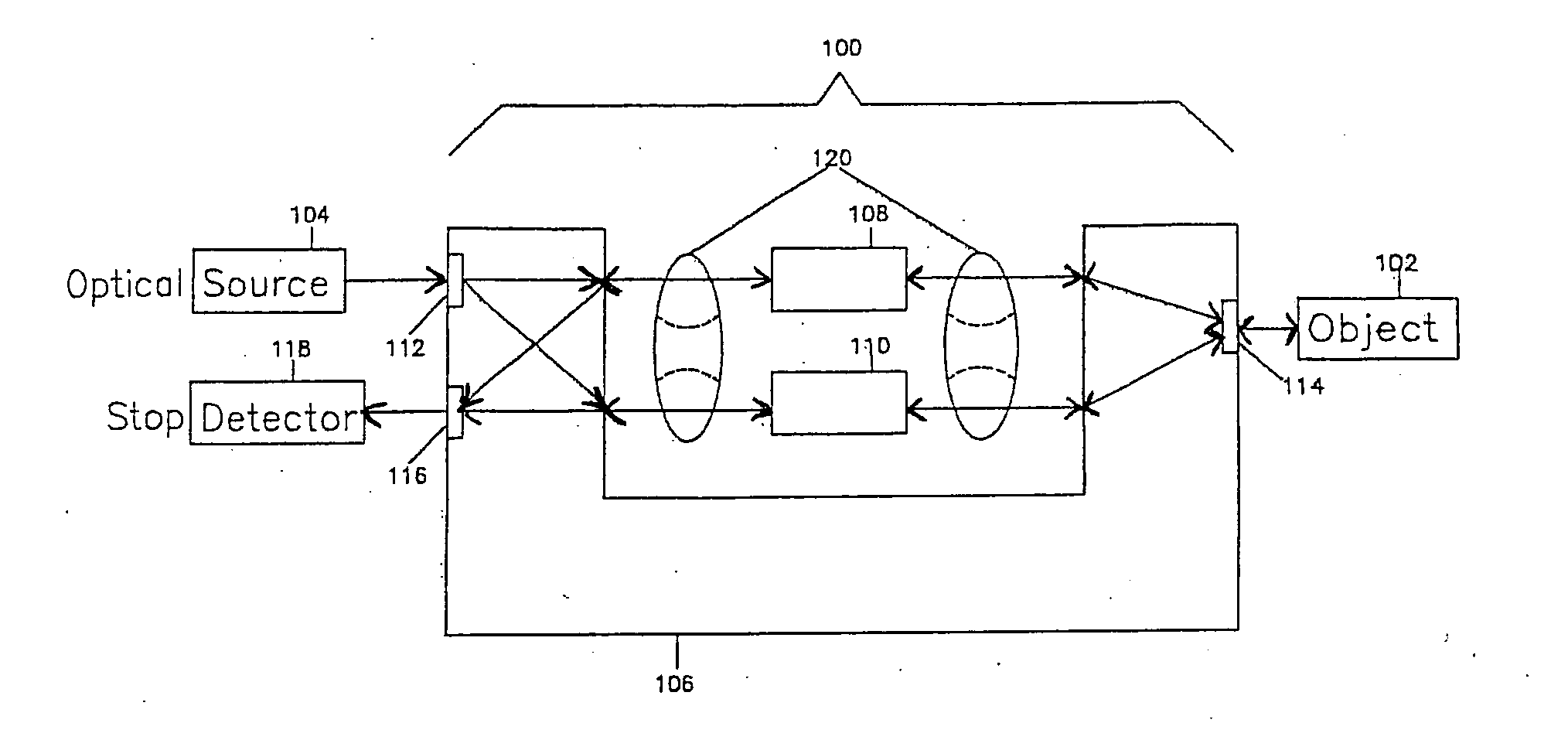

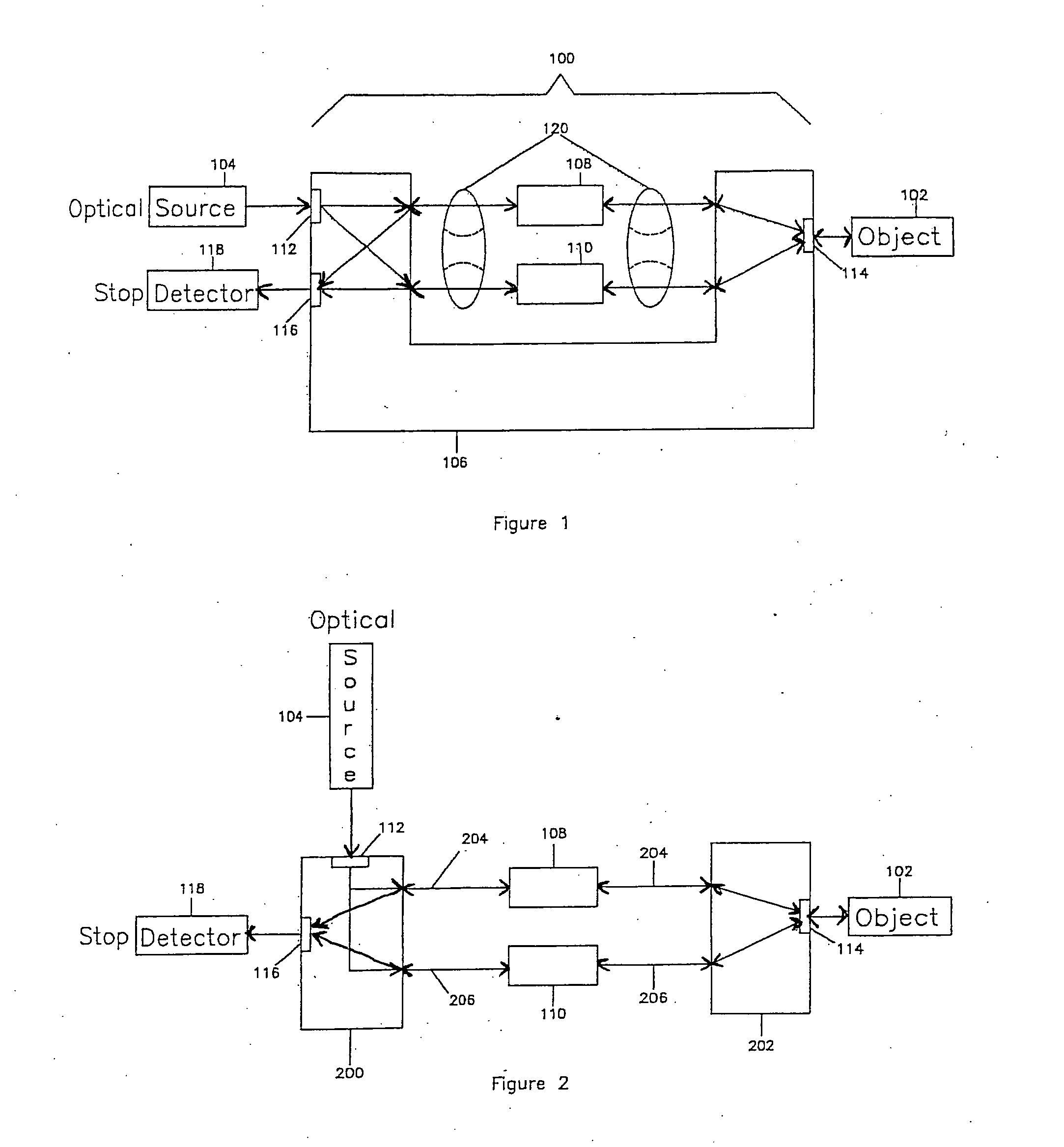

Optical element, measuring apparatus and measuring method

InactiveUS20060232762A1SimpleSmall measuring headWave based measurement systemsOptical rangefindersPhysicsMeasurement device

The optical element comprises a beam transformer and at least two non-reciprocal components for propagation-direction-dependent polarization operations such that an entrance aperture of the transmission direction, a common two-directional aperture for an exit in the transmission direction and for an entrance in the reception direction, and an exit aperture of the reception direction can be used in the beam transformer. The beam transformer both transmits an optical beam towards an object and receives the reflected optical beam through the common aperture. The beam transformer outputs the received optical beam through the exit aperture of the reception direction different from the entrance aperture of the transmission direction.

Owner:SPECIALITY MINERALS (MICHIGAN) INC

Hand-held setting tool

Owner:HILTI AG

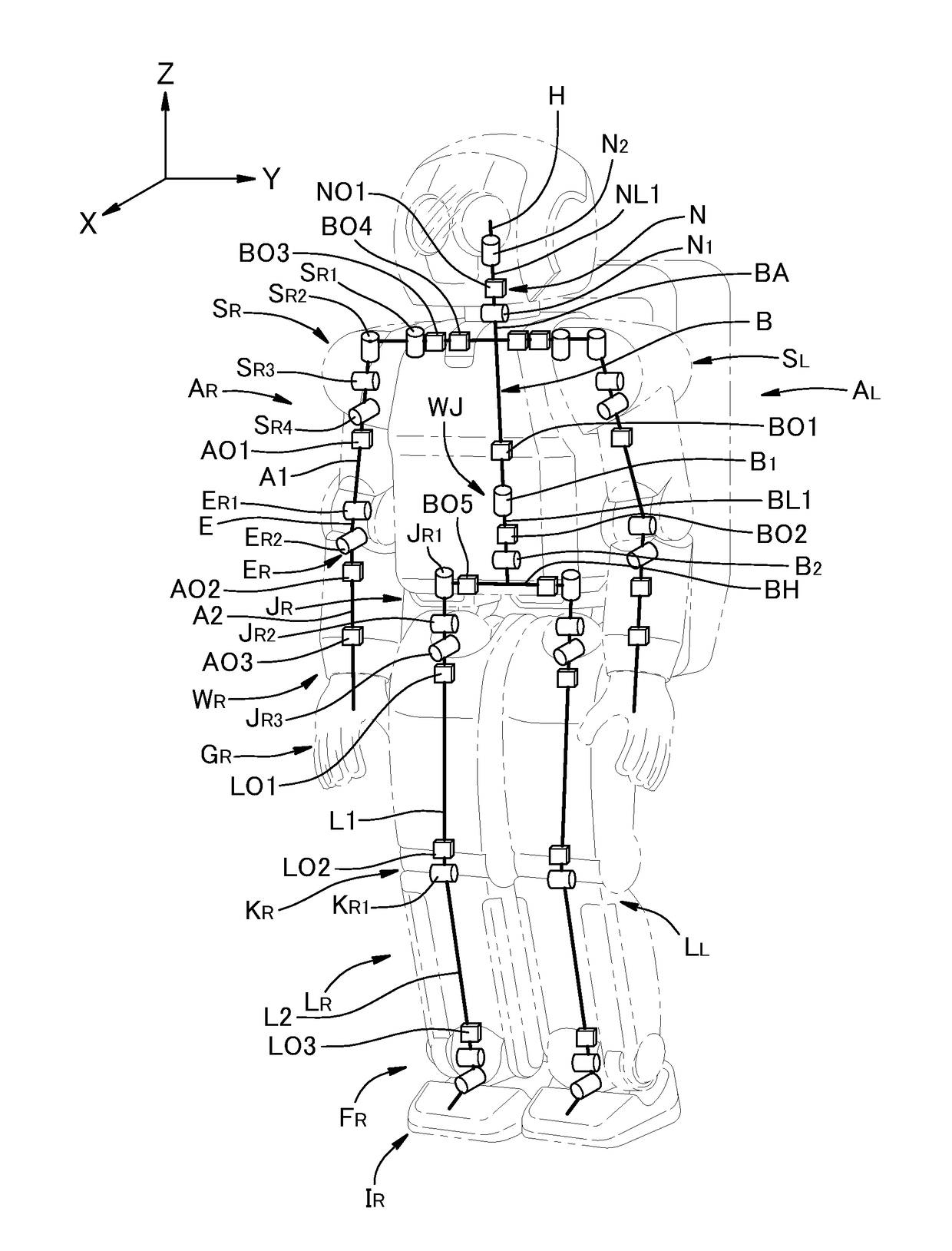

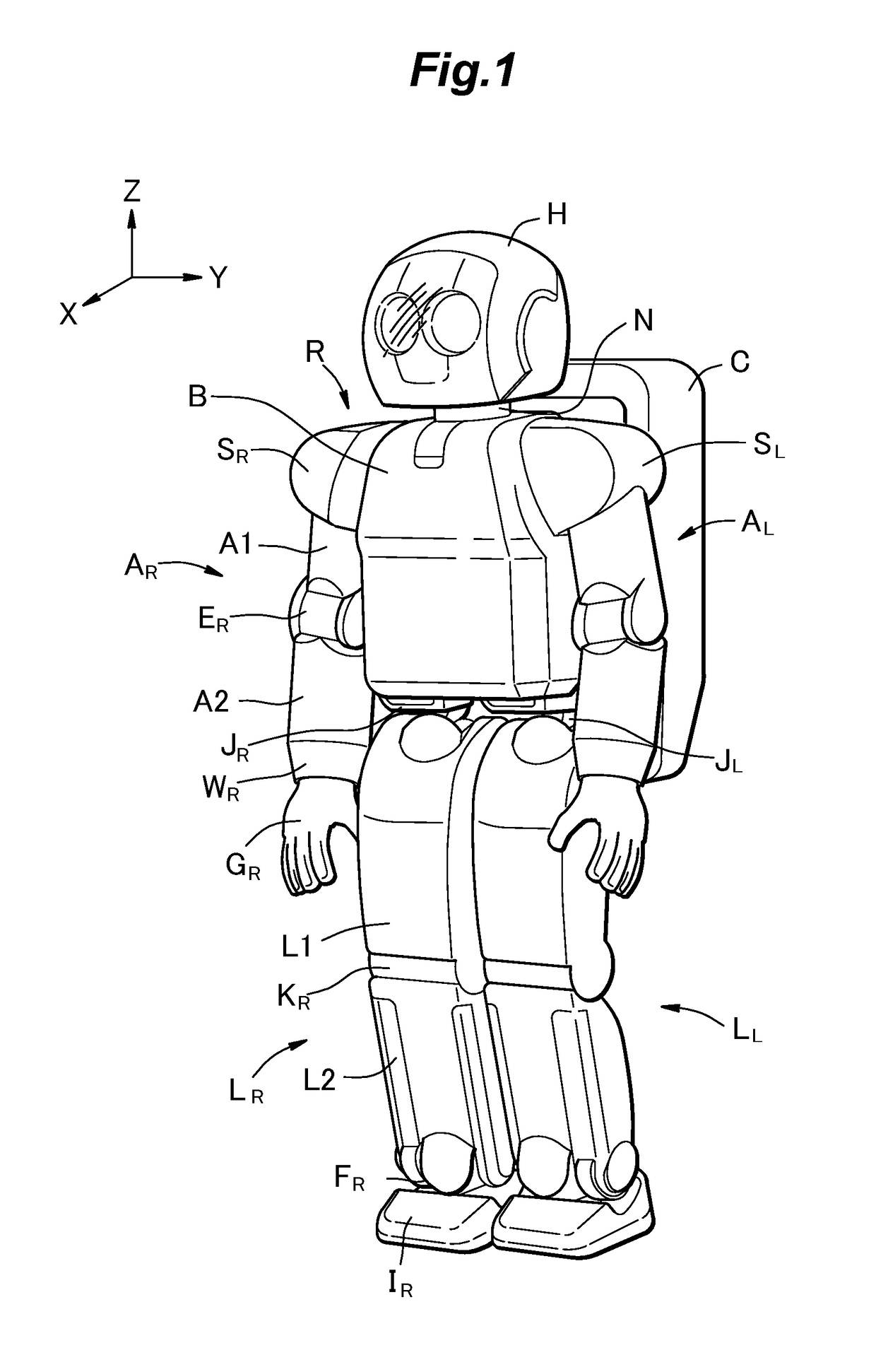

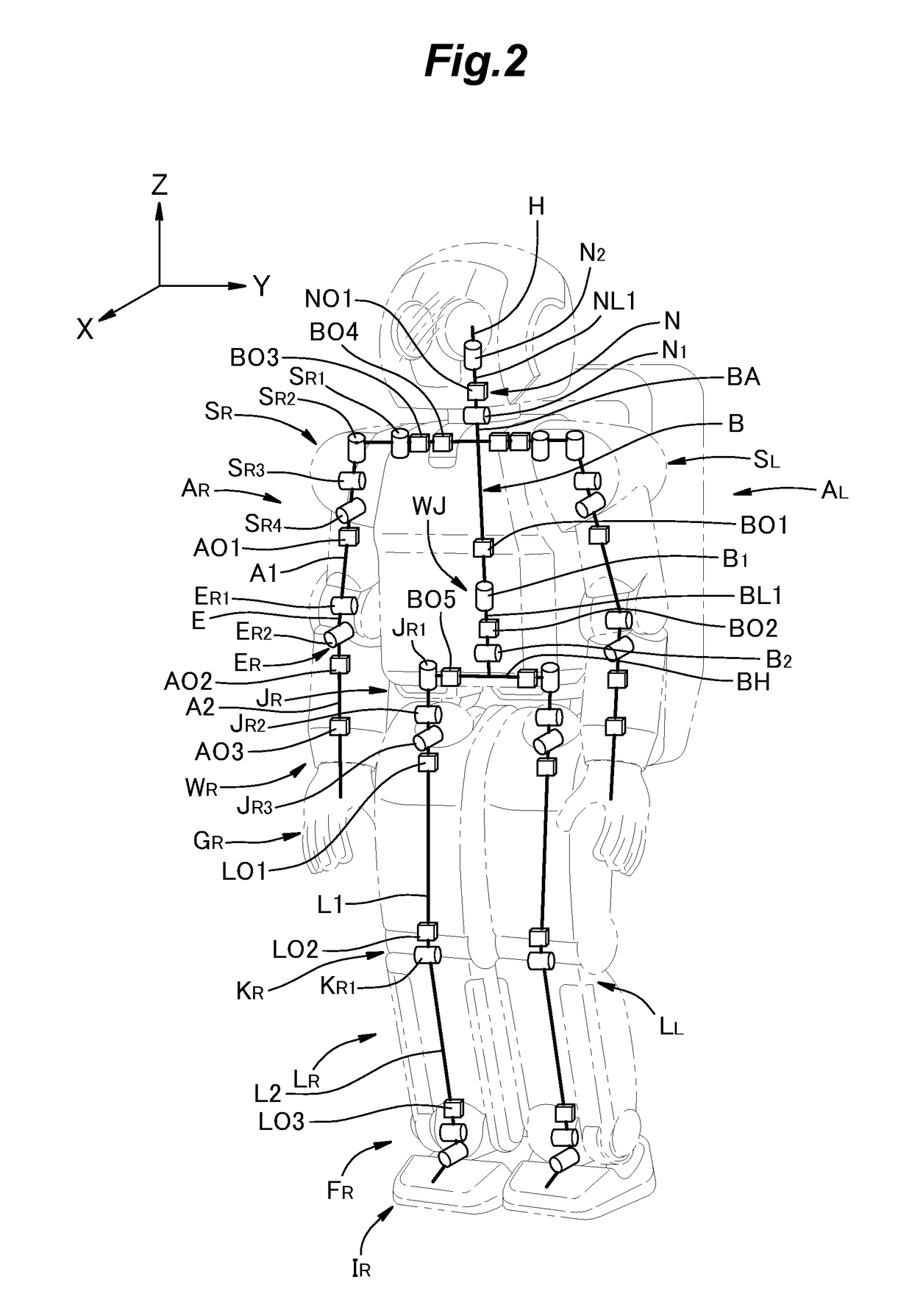

Optical fiber network for transmitting signals in a robot

ActiveUS20170309169A1SimpleTransmission loss becomes largeProgramme-controlled manipulatorNon-electrical signal transmission systemsVIT signalsTransceiver

In an optical fiber network for transmitting optical signals in a robot having three or more joints connecting a plurality of links in series such that the links include two end links located at either end and intermediate links provided between the two end links, and the links connected by the joints are moveable relative to each other, a plurality of optical transceiver modules are provided on the links such that at least one optical transceiver module is provided on each link; and a plurality of optical fiber cables connect the optical transceiver modules in a ring; wherein at least one end of each optical fiber cable connecting the optical transceiver modules provided on different links is connected to one of the optical transceiver modules provided on the intermediate links.

Owner:HONDA MOTOR CO LTD

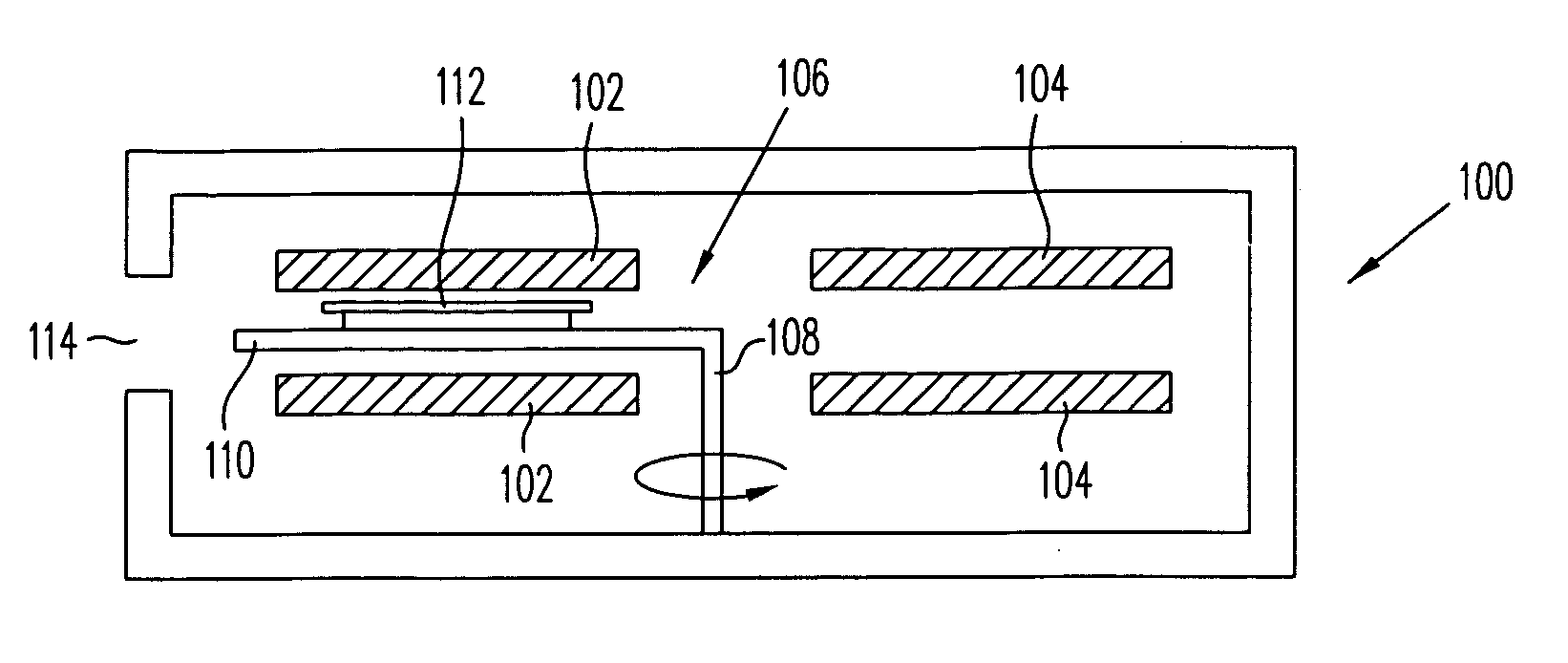

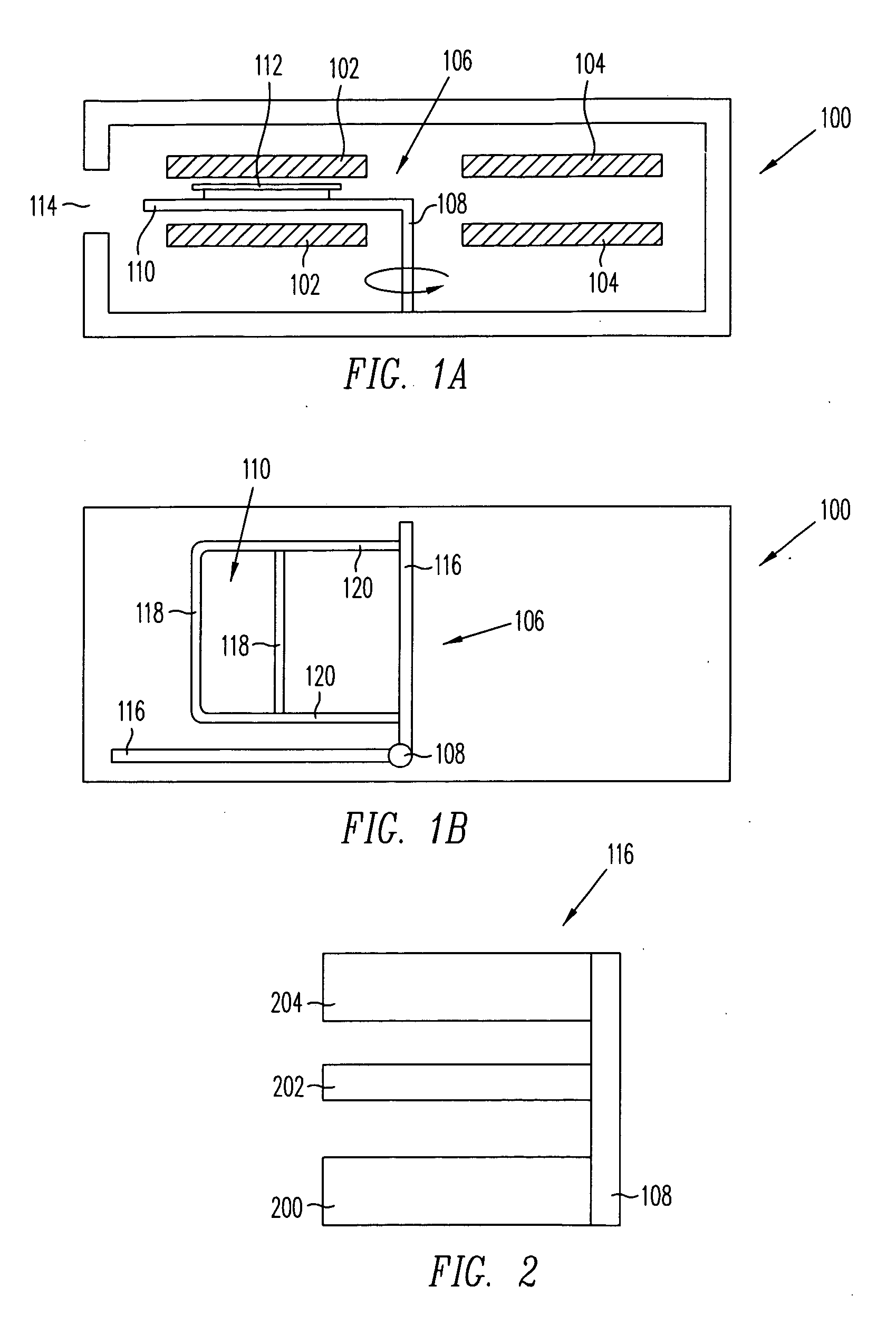

Stacked annealing system

InactiveUS20060291830A1Low costSimpleSemiconductor/solid-state device manufacturingHigh-frequency/infra-red heating bakingElectrical and Electronics engineeringHot plate

A process chamber includes an opening, two or more stacked cold plates adjacent the opening, two or more stacked hot plates adjacent the cold plates, and a rotatable wafer transport capable of moving a wafer between the cold plates and between the hot plates for processing of the wafer. The wafer can be rapidly heated while between the hot plates. The wafer transport has perpendicular walls about a pivot such that when the wafer is between the cold plates or between the hot plates, one of the walls separates the cold and hot portions, thereby increasing the efficiency of cooling and heating.

Owner:WAFERMASTERS

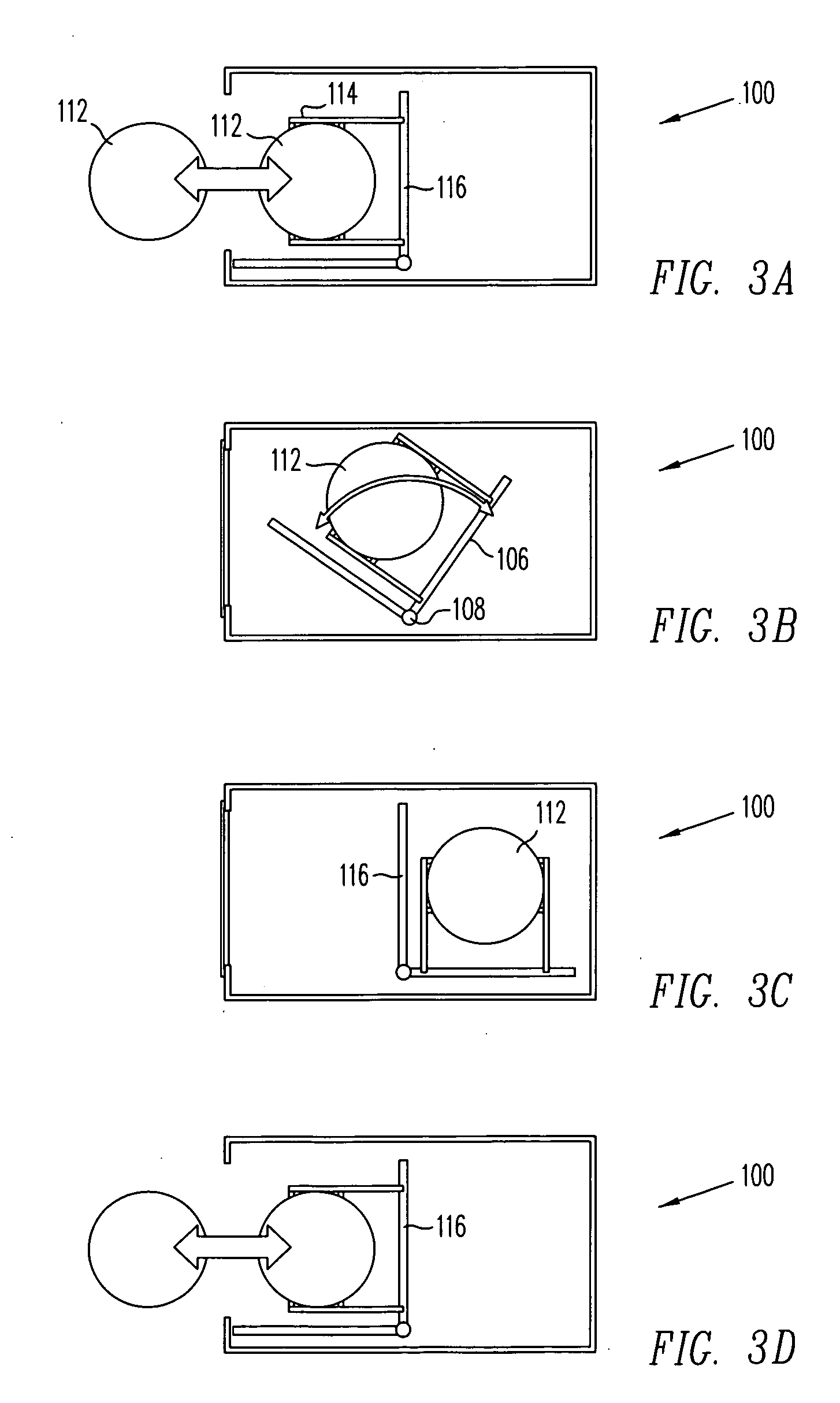

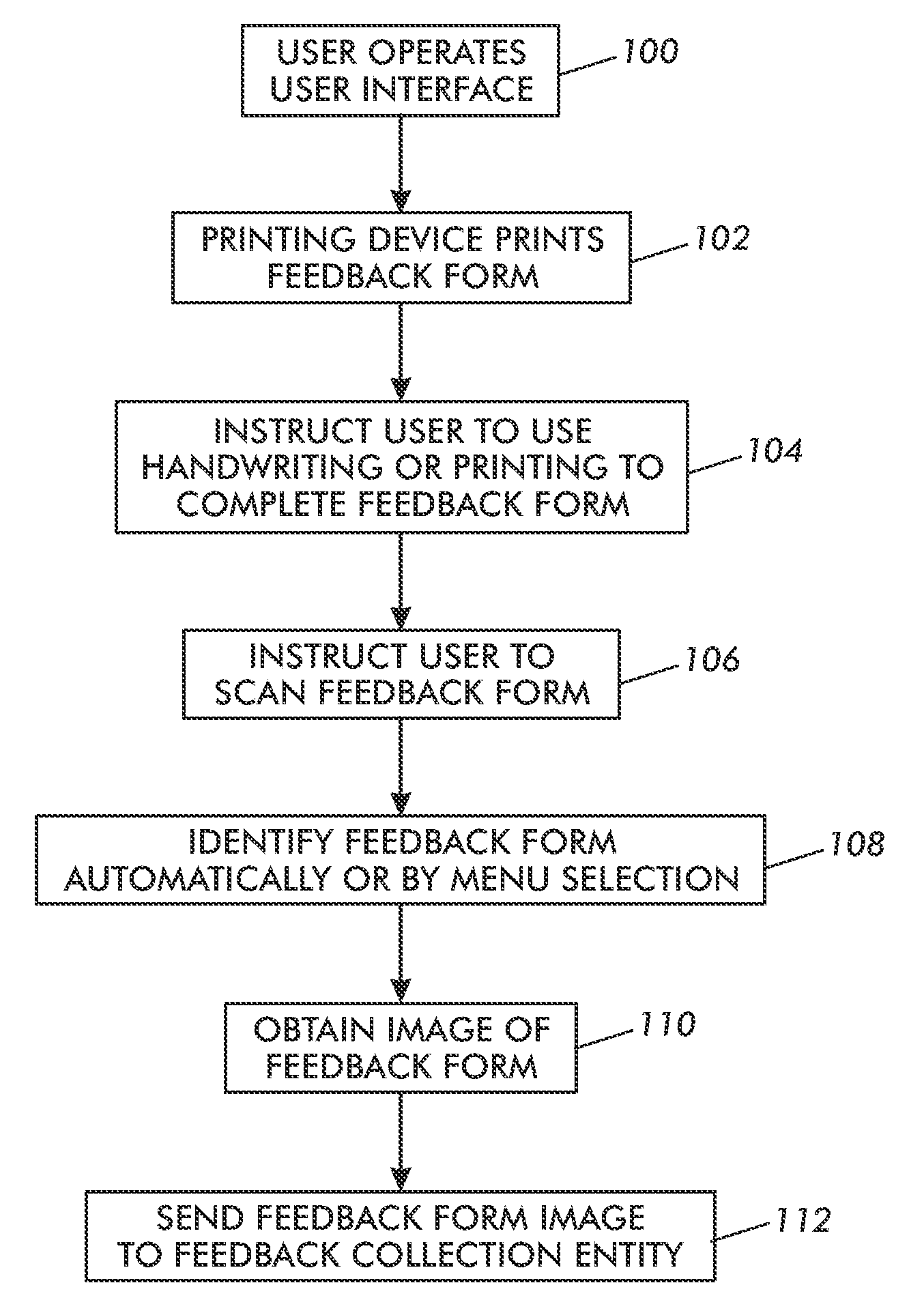

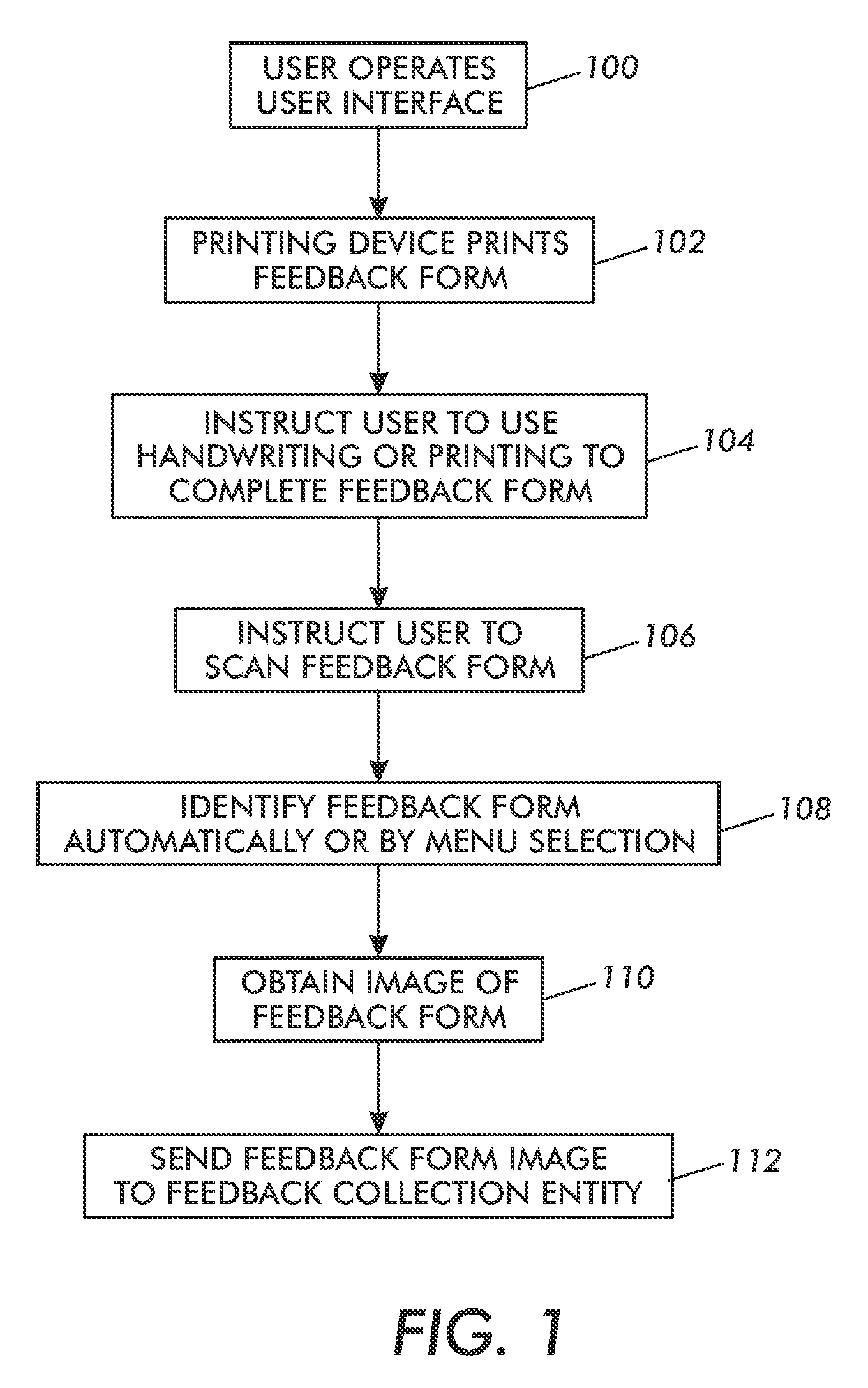

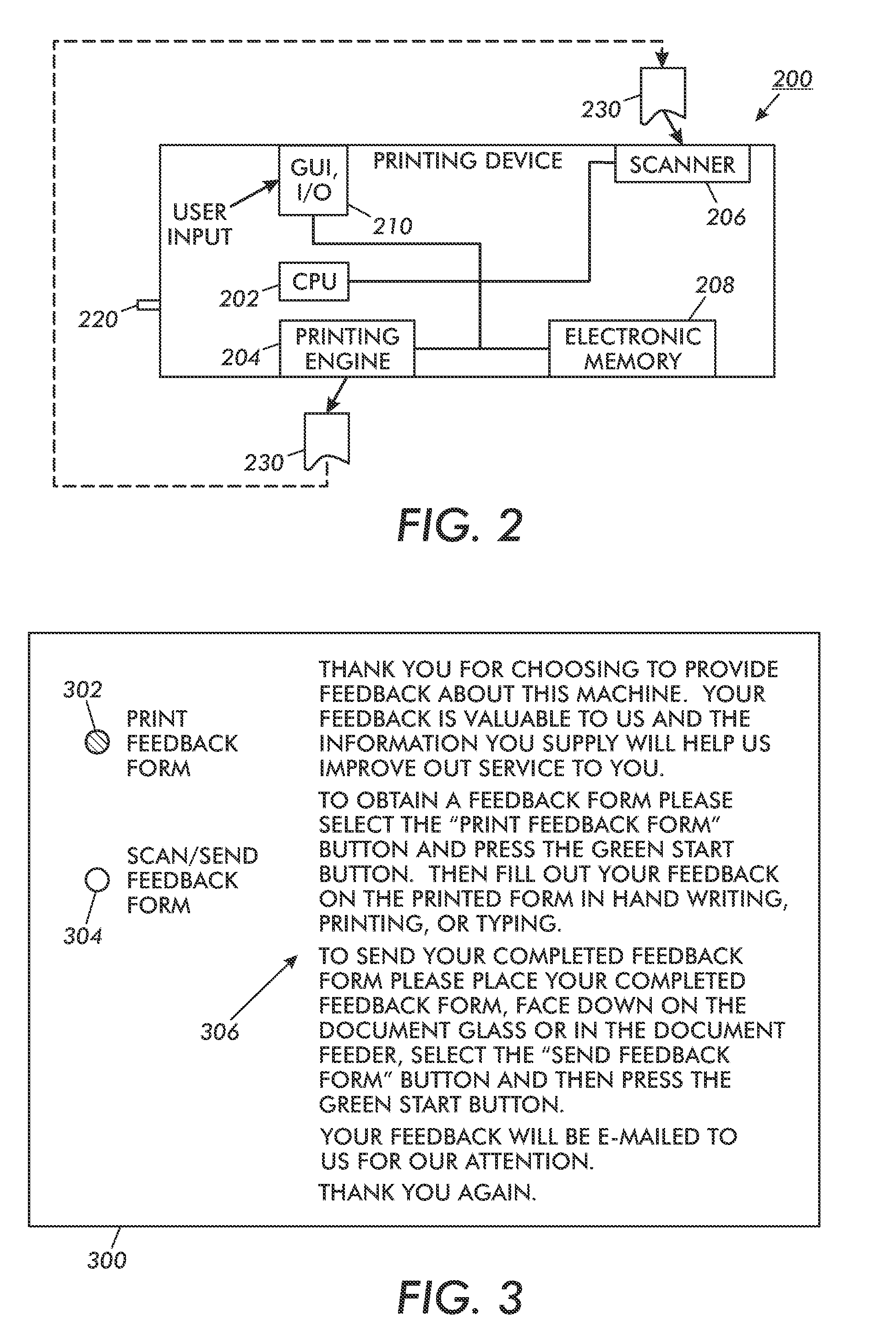

Automated user feedback

InactiveUS20090141302A1SimpleSimplified user interfaceDigitally marking record carriersPictoral communicationEngineeringFeedback form

A method and printing device print a feedback form in response to activation of a customer feedback option of the printing device. The printing device and the feedback form instruct the user to supply feedback comments on the feedback form and cause the feedback form to be scanned using the printing device. The method and printing device identifying the feedback form in response to the scanning of the feedback form and capture the feedback form as a feedback form image. The method and printing device transmit the feedback form image from the printing device to a feedback collection entity.

Owner:XEROX CORP

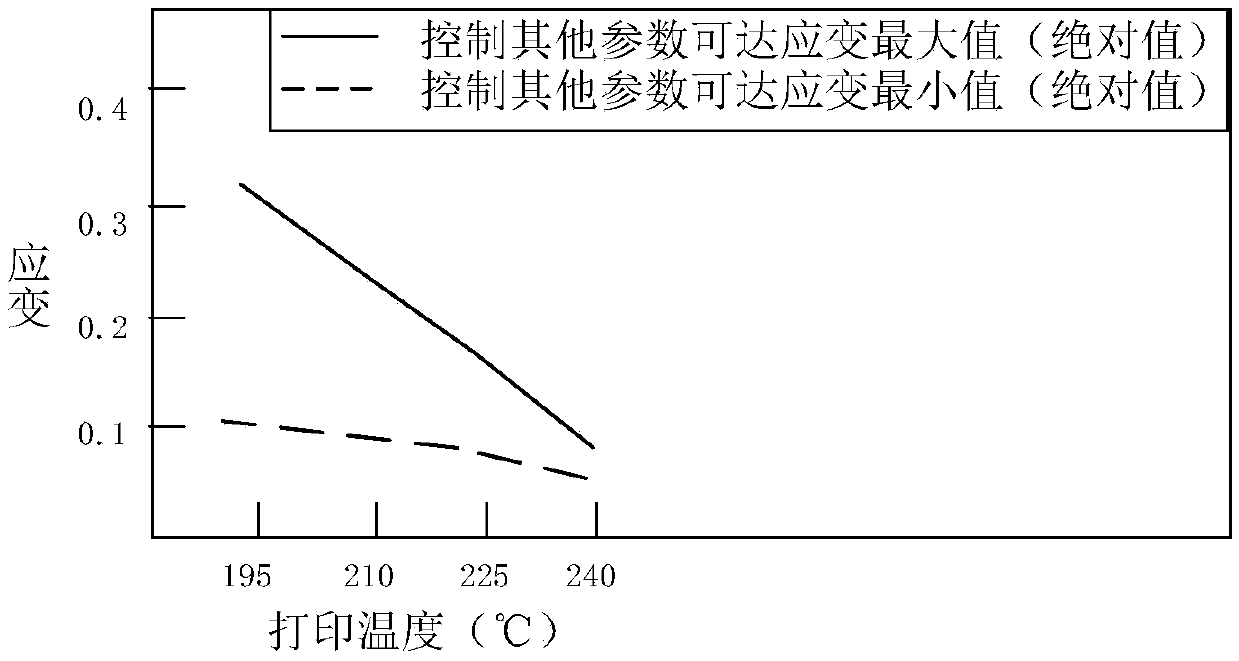

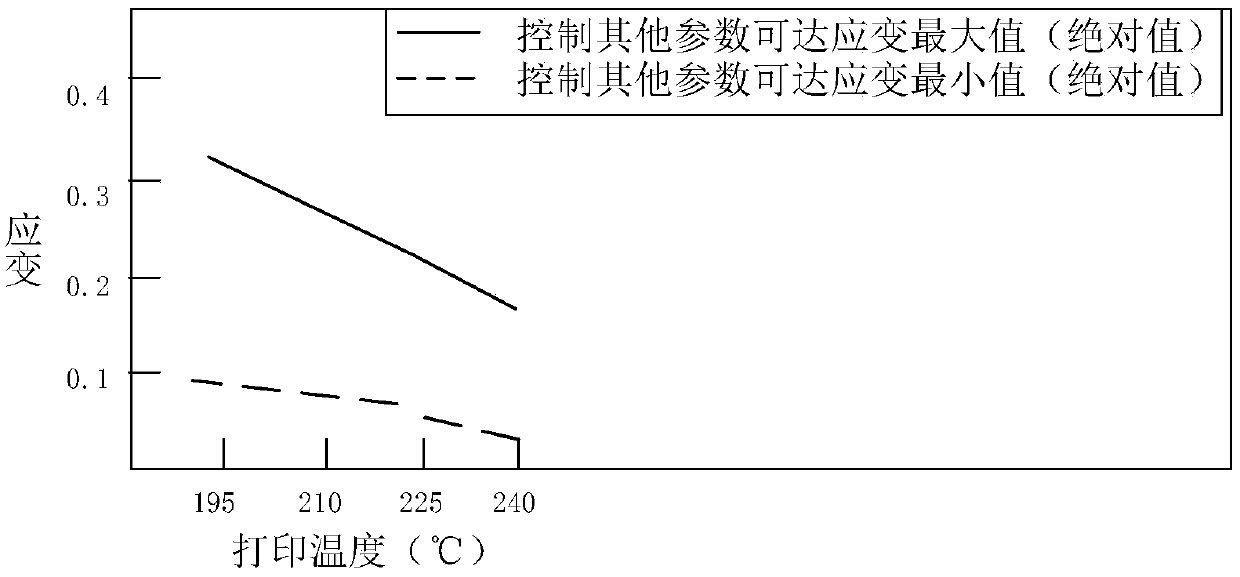

Transverse-netlike double-layer structure 4D printing method based on temperature response

InactiveCN109664499ASimpleFunctionalAdditive manufacturing apparatus3D object support structuresTemperature responseMaterials preparation

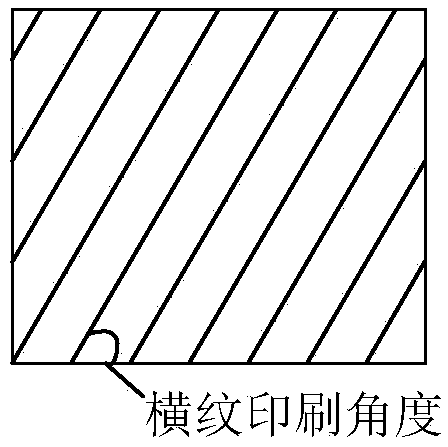

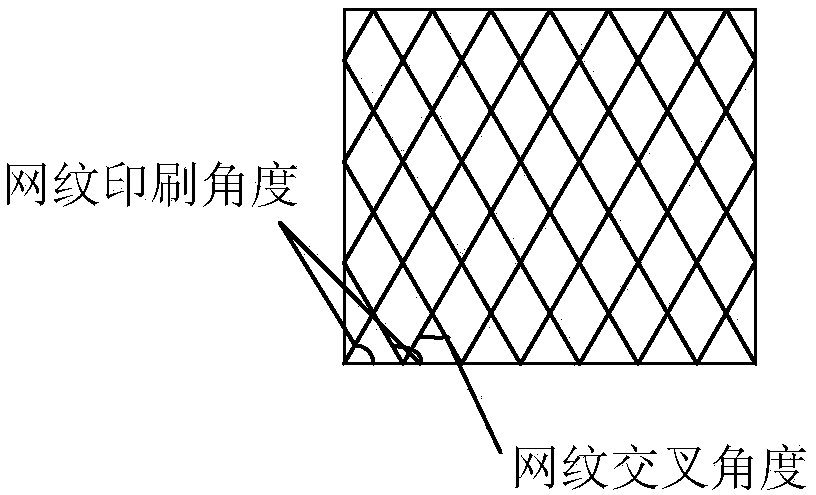

The invention discloses a transverse-netlike double-layer structure 4D printing method based on temperature response. The method comprises the steps that shape memory polymer materials are selected toperform repeating cascading printing from bottom to top with a double-layer structure as a unit, wherein the double-layer structure is formed by performing cascading printing and arranging on two groups of different fill pattern layers up and down, all single layers in the groups of fill pattern layers are printed to be the same fill patterns, fill pattern layers above and below are transverse grain patterns and netlike grain patterns correspondingly, the transverse grain patterns and the netlike grain patterns are textured patterns formed by arranging one group of straight line arrays and two groups of straight line arrays in a crossed mode, and the straight line arrays are composed of a plurality of straight lines arranged in parallel; and rough products are made to deform through precise temperature heating, and 4D deformation is completed. By means of the 4D printing method, the problems that currently, temperature-driven 4D printing material preparation is difficult, and the degree of response to low-power deformation is small are solved, the fused deposition 4D printing method that special wires do not need to be manufactured through design parameter programming is achieved,and limitations of the tedious process of material preparation of the 4D printing technology are broken through.

Owner:ZHEJIANG UNIV

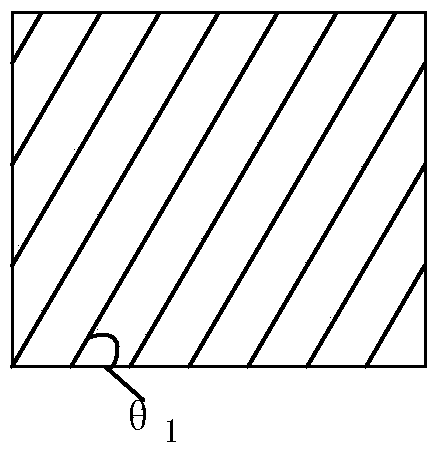

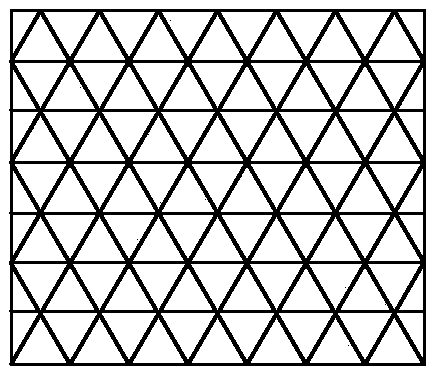

Transverse-triangular double-layer structure 4D printing method based on temperature response

InactiveCN109664498ASimpleFunctionalAdditive manufacturing apparatus3D object support structuresEngineeringMaterials preparation

The invention discloses a transverse-triangular double-layer structure 4D printing method based on temperature response. The method comprises the steps that shape memory polymer materials are selectedto perform repeating cascading printing from bottom to top with a double-layer structure as a unit, wherein the double-layer structure is formed by performing cascading printing and arranging on twogroups of different fill pattern layers up and down, all single layers in the two groups of fill pattern layers are printed into the same fill patterns, fill pattern layers above and below are transverse grain patterns and triangular grain patterns, the transverse grain patterns and the triangular grain patterns are textured patterns formed by arranging one group of straight line arrays and threegroups of straight line arrays in a crossed mode, and the straight line arrays are composed of a plurality of straight lines arranged in parallel; and finally, through precise temperature heating, rough products are made to deform, and 4D deformation is completed. By means of the 4D printing method, the problems that currently, temperature-driven 4D printing material preparation is difficult, andthe degree of response to low-power deformation is small are solved, the fused deposition 4D printing method that special wires do not need to be manufactured through design parameter programming is achieved, and limitations of the tedious process of material preparation of the 4D printing technology are broken through.

Owner:ZHEJIANG UNIV

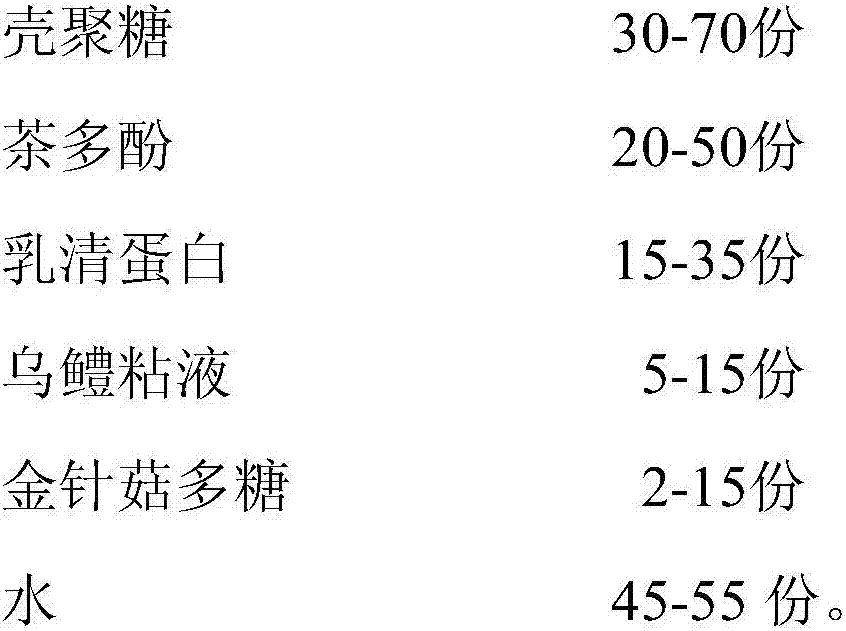

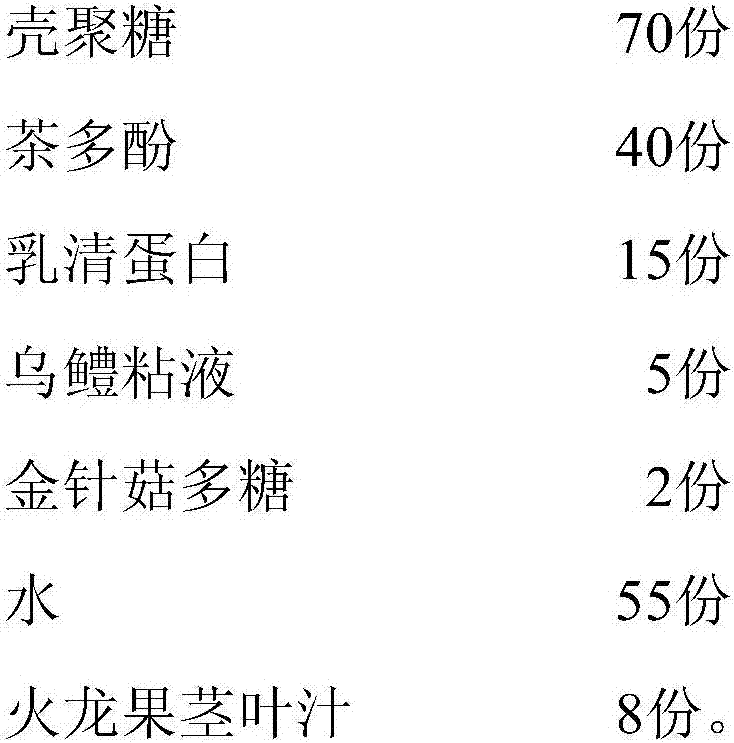

Novel fish paste preservative as well as preparation method and application thereof

InactiveCN107439667ASimpleAbundant resourcesMeat/fish preservation using chemicalsUltra high pressure food processesMushroomChemistry

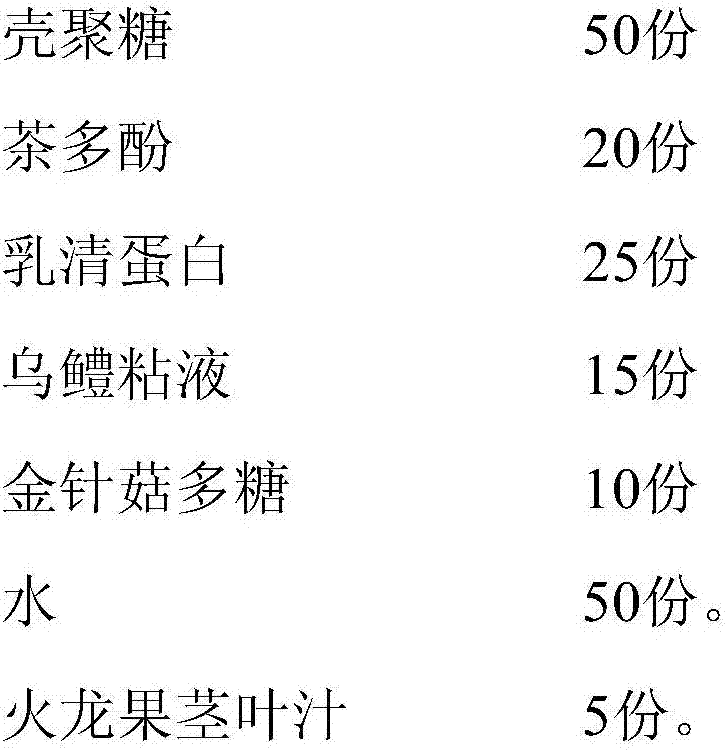

The invention belongs to the technical field of meat product preservation methods and discloses a novel fish paste preservative as well as a preparation method and application thereof. The preservative comprises the following raw material substances in parts by weight: 30-70 parts of chitosan, 20-50 parts of tea polyphenol, 15-35 parts of whey protein, 5-15 parts of snakehead mucus, 2-15 parts of needle mushroom polysaccharide and 45-55 parts of water; and the preservative also can comprise 5-10 parts of pitaya stem and leaf juice. The preparation method comprises the following steps: uniformly mixing chitosan, tea polyphenol, whey protein, snakehead mucus, needle mushroom polysaccharide and water by virtue of ultrasonic treatment of ultrasonic waves, carrying out ultra high pressure treatment on the uniformly mixed liquid, and uniformly mixing the solution in combination with micro-jet high pressure homogenization treatment, thereby obtaining the novel fish paste preservative.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI

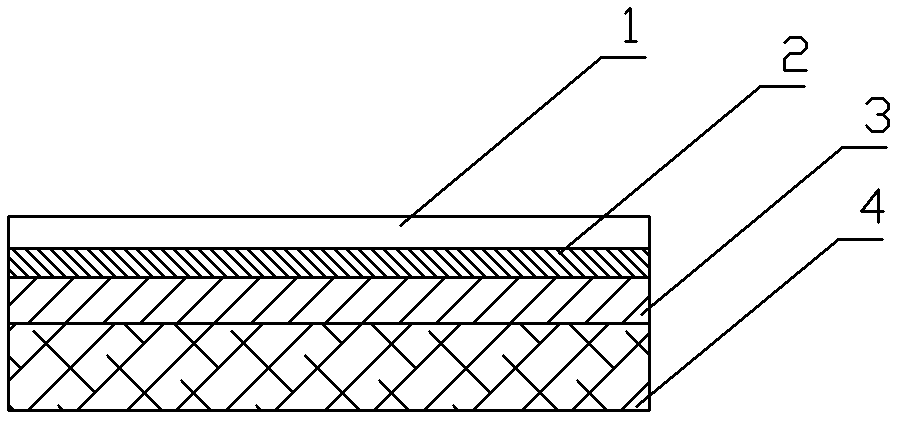

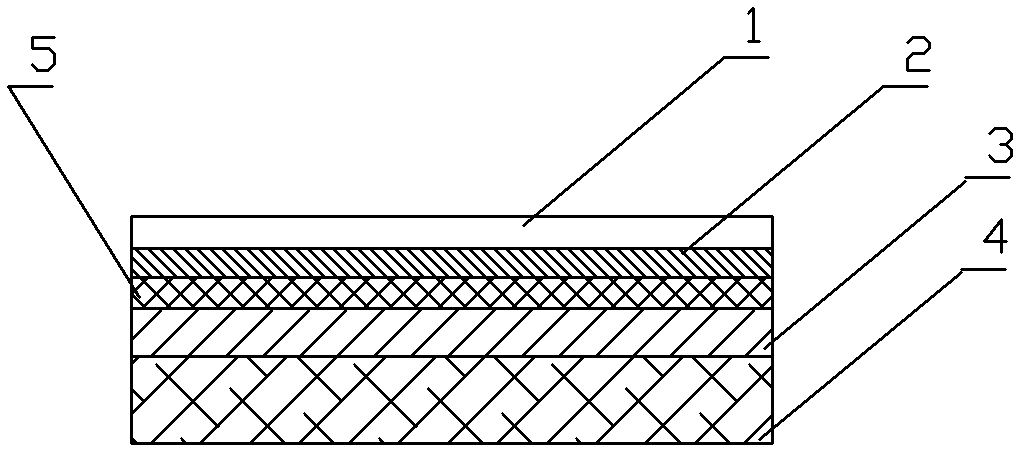

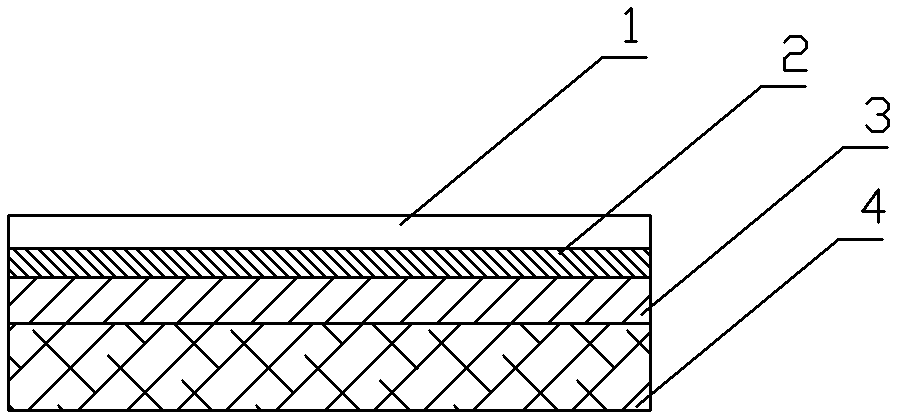

Surface treatment method by directly sticking transfer film to ultrafine fiber napped leather

The invention discloses a surface treatment method by directly sticking a transfer film to ultrafine fiber napped leather, which is characterized in that the method comprises the following processing steps: 1) preparing transfer film coiled material, ultrafine fiber napped leather coiled material and a hot-pressing laminating machine; 2) pulling the transfer film and ultrafine fiber napped leather aligned into a double-roll of the hot-pressing laminating machine, and performing hot pressing and rolling, wherein a carrier layer of the transfer film contacts a hot roller and an adhesive layer of the transfer film contacts the ultrafine fiber napped leather; 3) continuously pulling the ultrafine fiber napped leather and the transfer film out of the double-roll, thereby sticking the transfer film to the ultrafine fiber napped leather at this time; and 4) peeling the carrier layer to obtain the finished product. The product obtained by the treatment method of the invention has soft and smooth handfeel, and can be kept on subsequent processes such as lacquering, silk-screen printing, transfer printing, embossing and the like. The surface treatment method of the invention has a simple process and no environmental issues of solvent consumption and recovery, saves a great amount of equipment investment and energy consumption, and improves the site working conditions. Therefore, the surface treatment method of the invention is a desirable substitute of the prior art.

Owner:张放

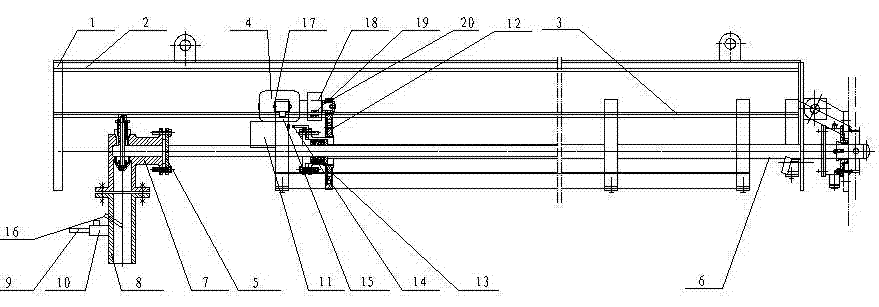

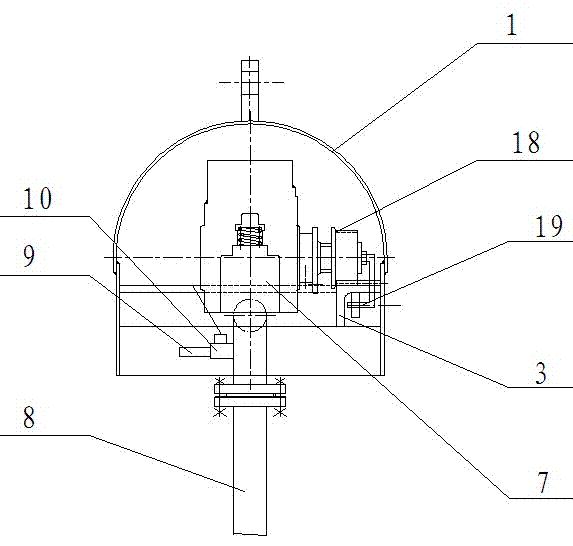

Leakage-free synchronous long-telescopic steam ash blower

The invention discloses a leakage-free synchronous long-telescopic steam ash blower and relates to the technical field of industrial heating furnaces and boiler energy conservation, and specifically relates to a leakage-free synchronous long-telescopic steam ash blower; the leakage-free synchronous long-telescopic steam ash blower comprises a cover shield, a structural beam, a support rail, a synchronous drive device, an ash blowing pipe inner pipe, an ash blowing pipe, an ash blowing steam electromagnetic valve, an external-connected steam pipe, a heating pipe waste connecting pipe, a heating pipe electromagnetic valve and an electric control device, wherein the upper surface of the structural beam is provided with a support rail; the synchronous drive device is supported on the support rail; a driven gear is mounted on the ash blowing pipe; one end of the ash blowing pipe inner pipe perforates into the ash blowing pipe; the other end of the ash blowing pipe inner pipe is connected with the outlet end of the ash blowing steam electromagnetic valve; and the synchronous drive device is mounted on one side of the structural beam. According to the invention, the leakage-free synchronous long-telescopic steam ash blower has advantages of energy conservation, high efficiency, convenient operation, simple mounting, a simple structure and the like; simultaneously, manufacture working time and material consumption are reduced; in addition, the leakage-free synchronous long-telescopic steam ash blower is characterized by intelligent / automatic / soft control, simple manufacture and low power consumption.

Owner:和荣扬州环保科技有限公司

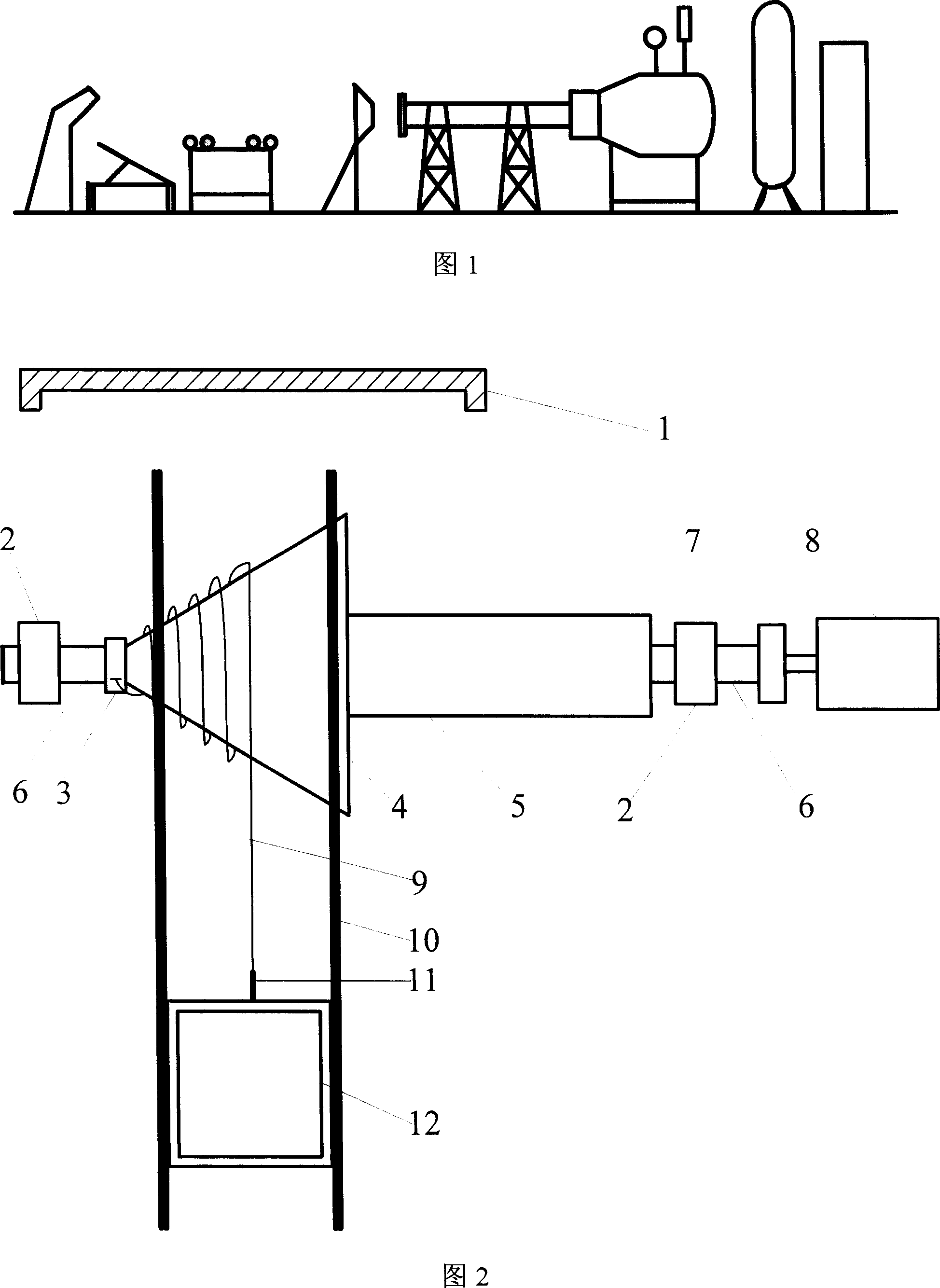

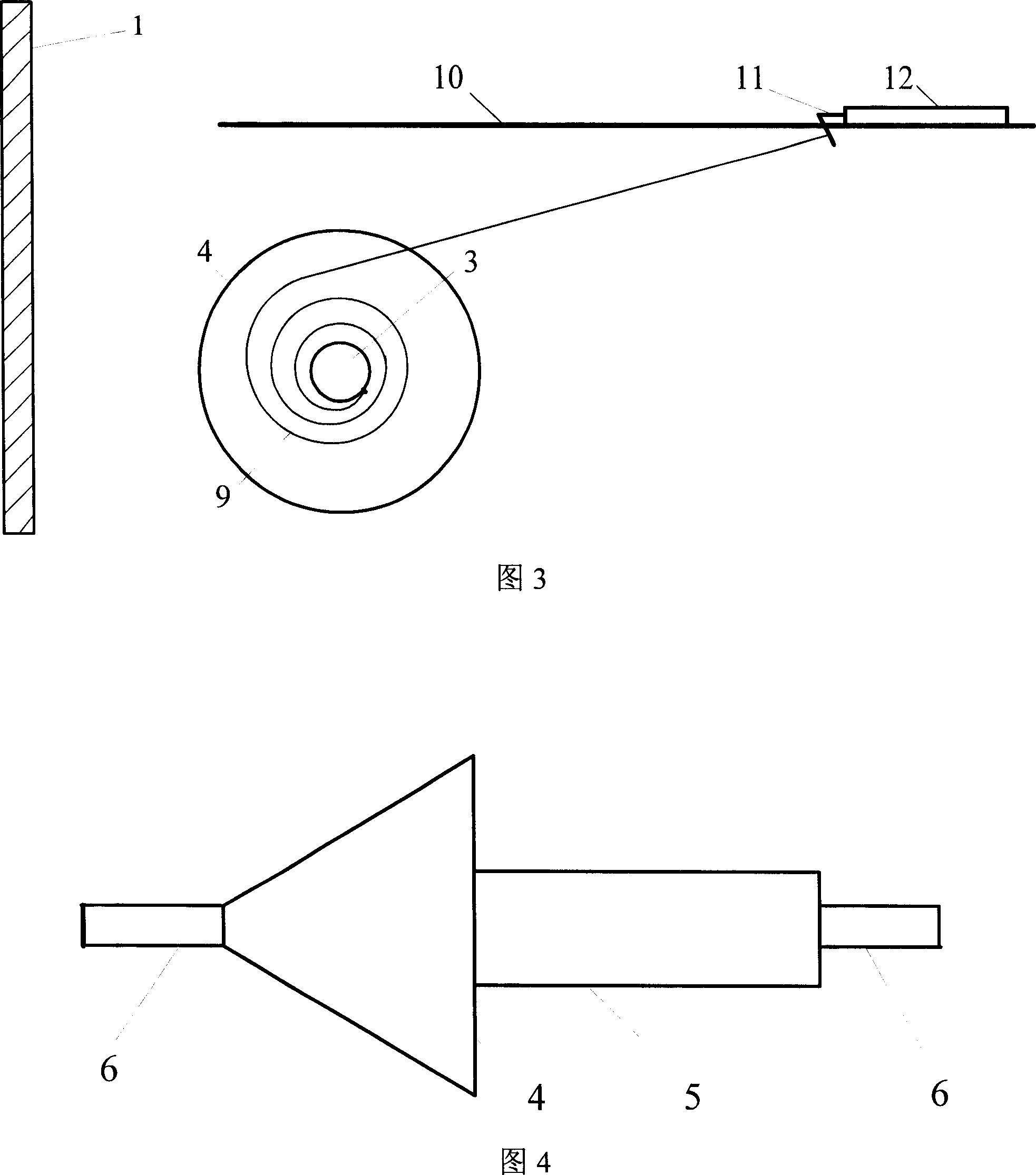

High-speed acceleration apparatus

InactiveCN101025381ASimpleEasy to implementShock testingStrength propertiesElectric machineryImpact test

The invention relates to a high speed hasten device, which is a hasten device to accelerate the object to the high speed status in the high speed impact experimentation. It uses the electric energy of the common use electromotor to replace rocket or high pressure gas in the traditional method; in the meantime bobbin with special design keeping the object invariable acceleration in the accelerate process, consequently, keeping cord and bracket equipment endure the equal stress, eliminating the impact function; the harmony work of the whole device can guarantee the equal accelerate experimental effect with the traditional method. Compared with the existing technology, its advantages are that it is simple in structure and easy to implement, low cost, safety and reliability, while the low price of experiment, can save a lot of energy consumption, and can be more controllable and stable acceleration, reduces the restrictions of the corresponding performance requirements, making more extensive equipment selection. In short, this device has high controllable, fully meet the requirements of impact test, and save a lot of manpower, material and financial resources.

Owner:TSINGHUA UNIV

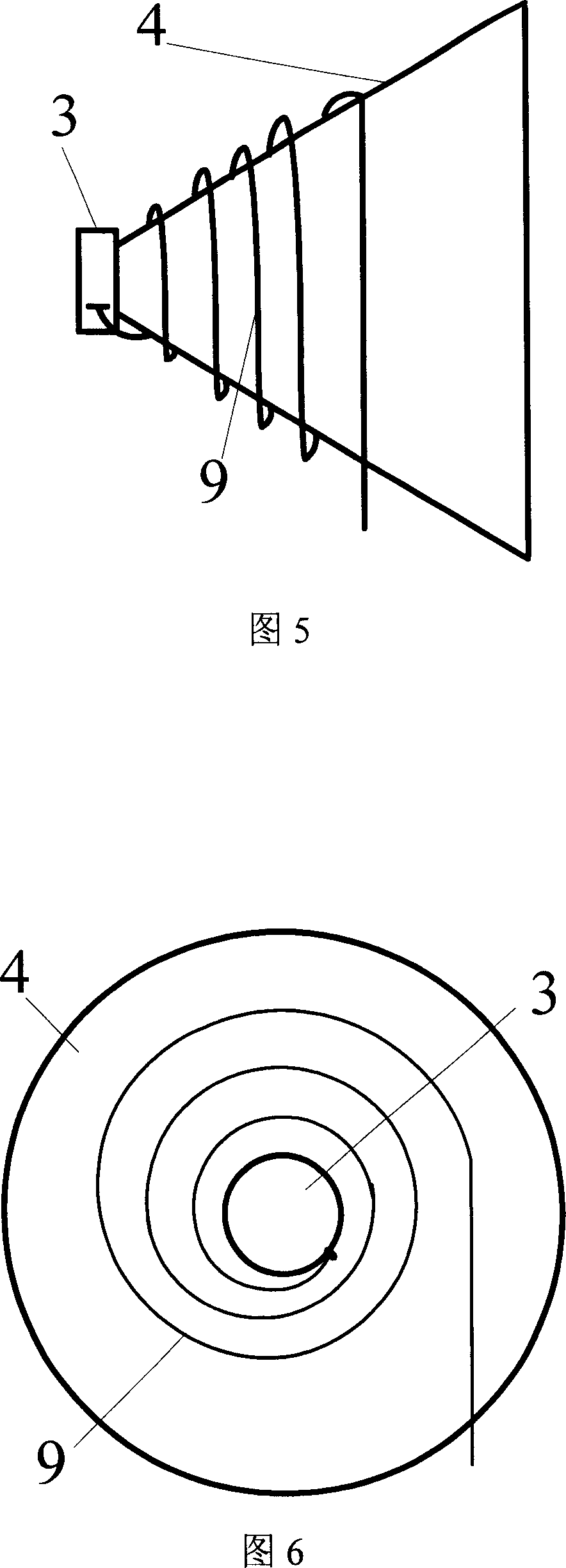

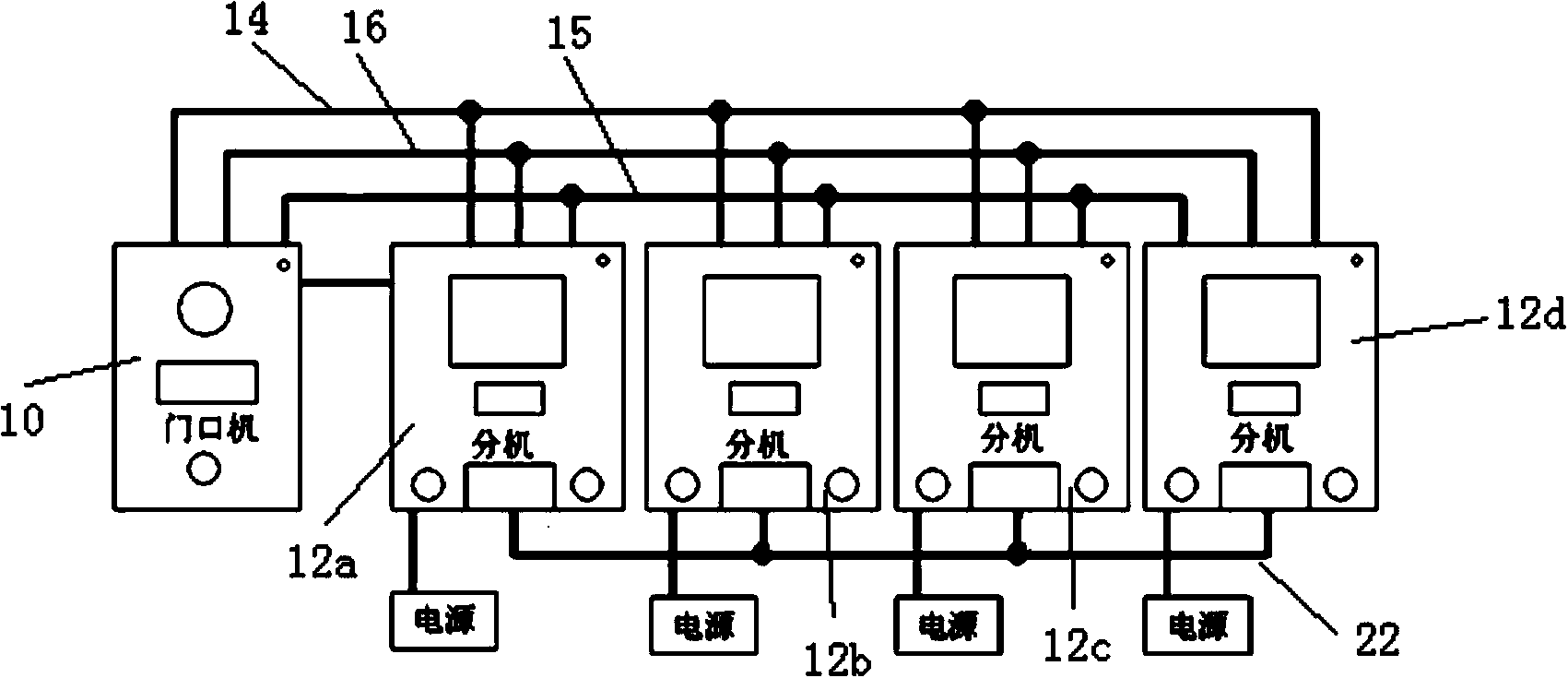

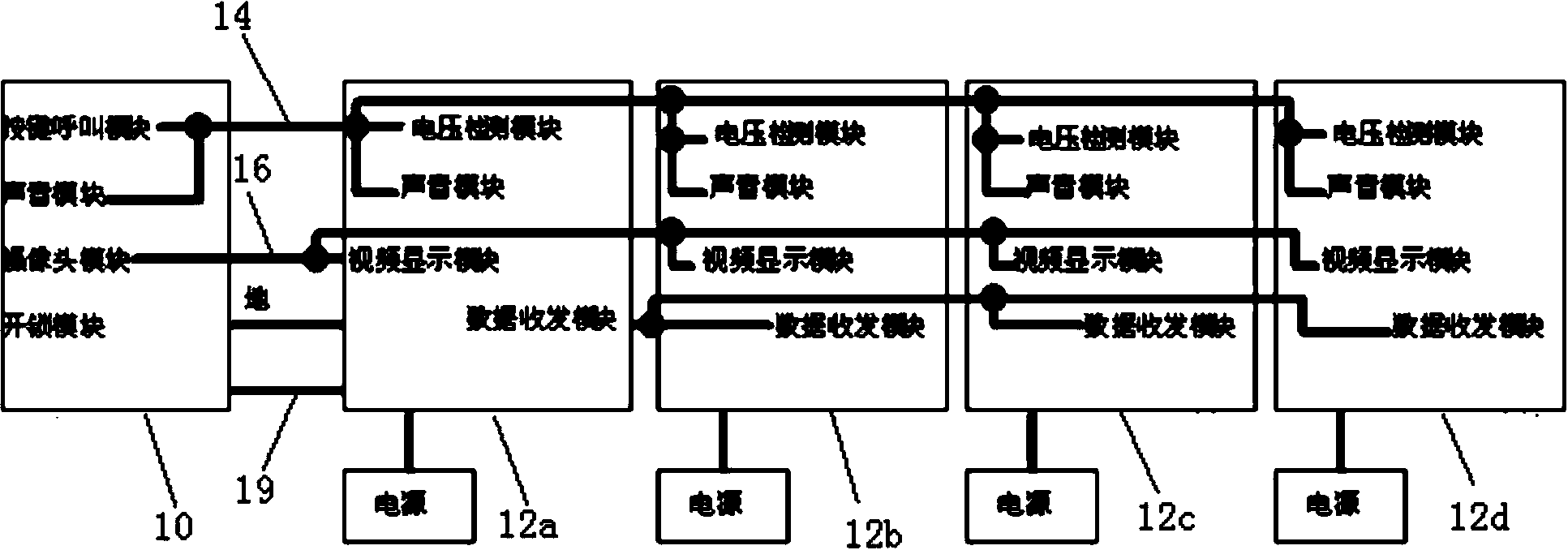

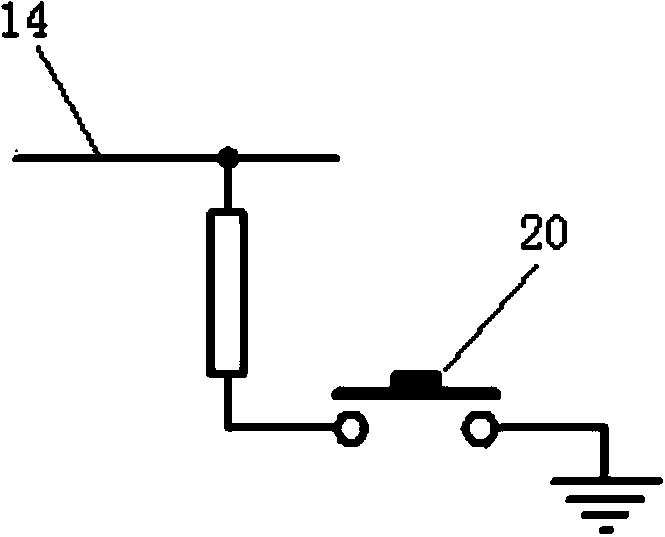

Building video doorphone system and method

ActiveCN103888728ASimpleSave energyClosed circuit television systemsStations for two-party-line systemsExtension setComputer module

The invention discloses a building video doorphone system and method. A doorphone of the system is connected with extension sets through an audio wire, a ground wire and a video wire. The extension sets are connected with power sources. The extension set which supplies power to the doorphone is the first extension set. After the audio wire is connected with a call key, the call key is grounded. After the audio wire is connected with a voltage detection circuit, the audio wire is connected with extension set micro-control units of the extension sets. The call key is connected with the audio line, when the call key is pressed, the voltage of the audio wire is changed, the voltage detection circuit detects the change of the voltage at this time and feeds back a detection result to the extension set micro-control units of the extension sets, and the first extension set supplies power to the doorphone, a video module is started, rings are given out, and a user is reminded to make a response.

Owner:GUANGDONG ANJUBAO DIGITAL TECH

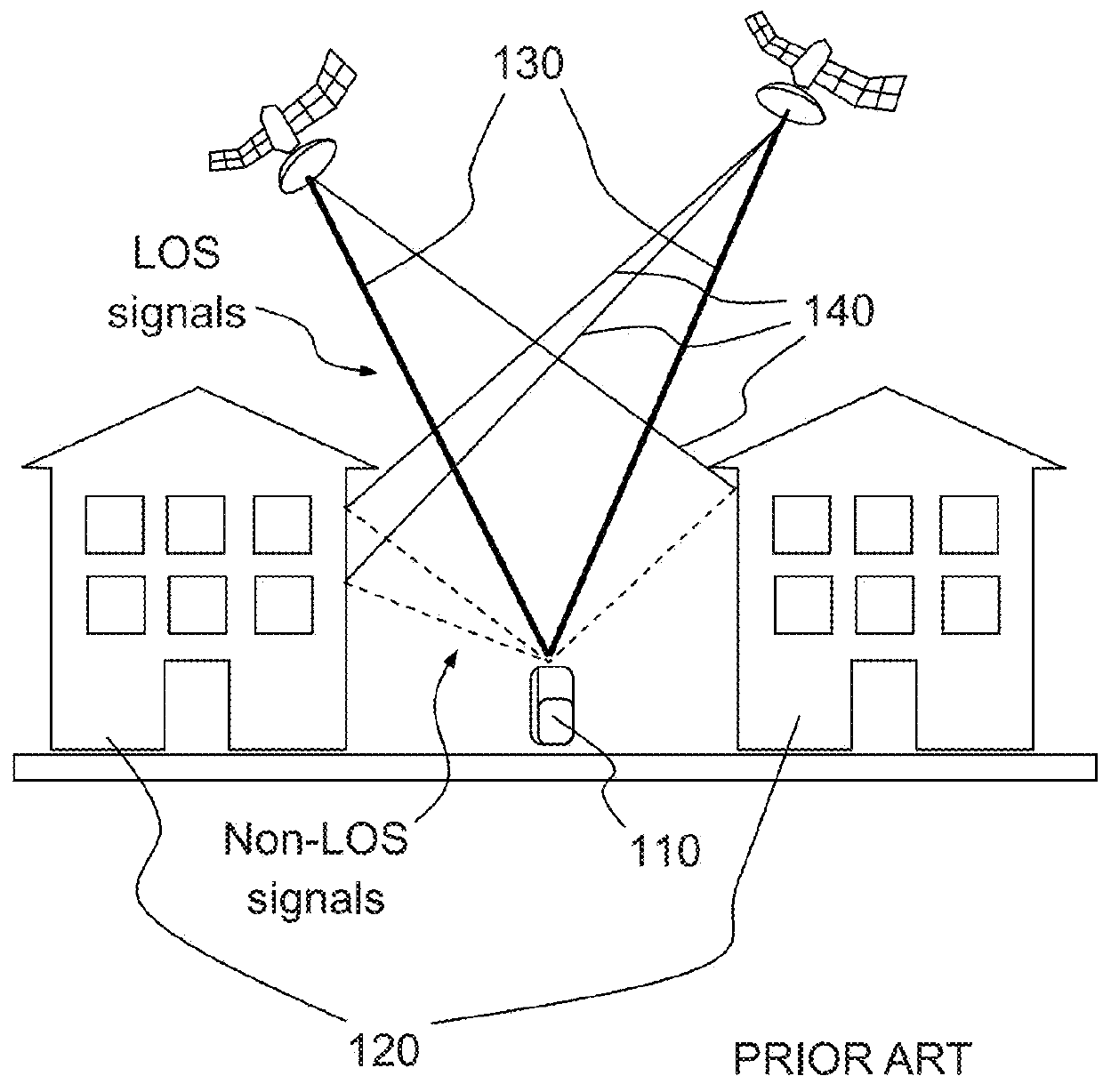

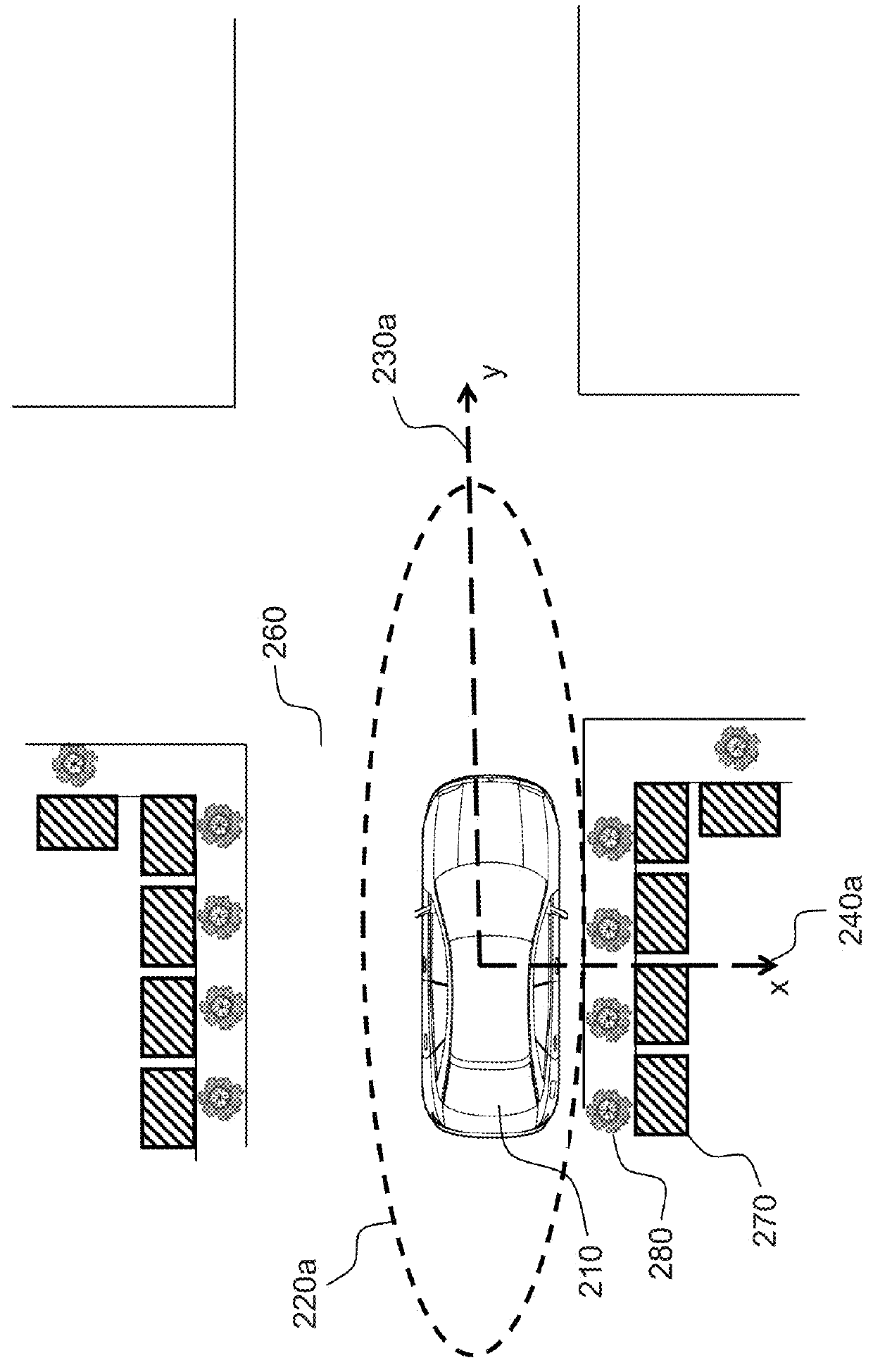

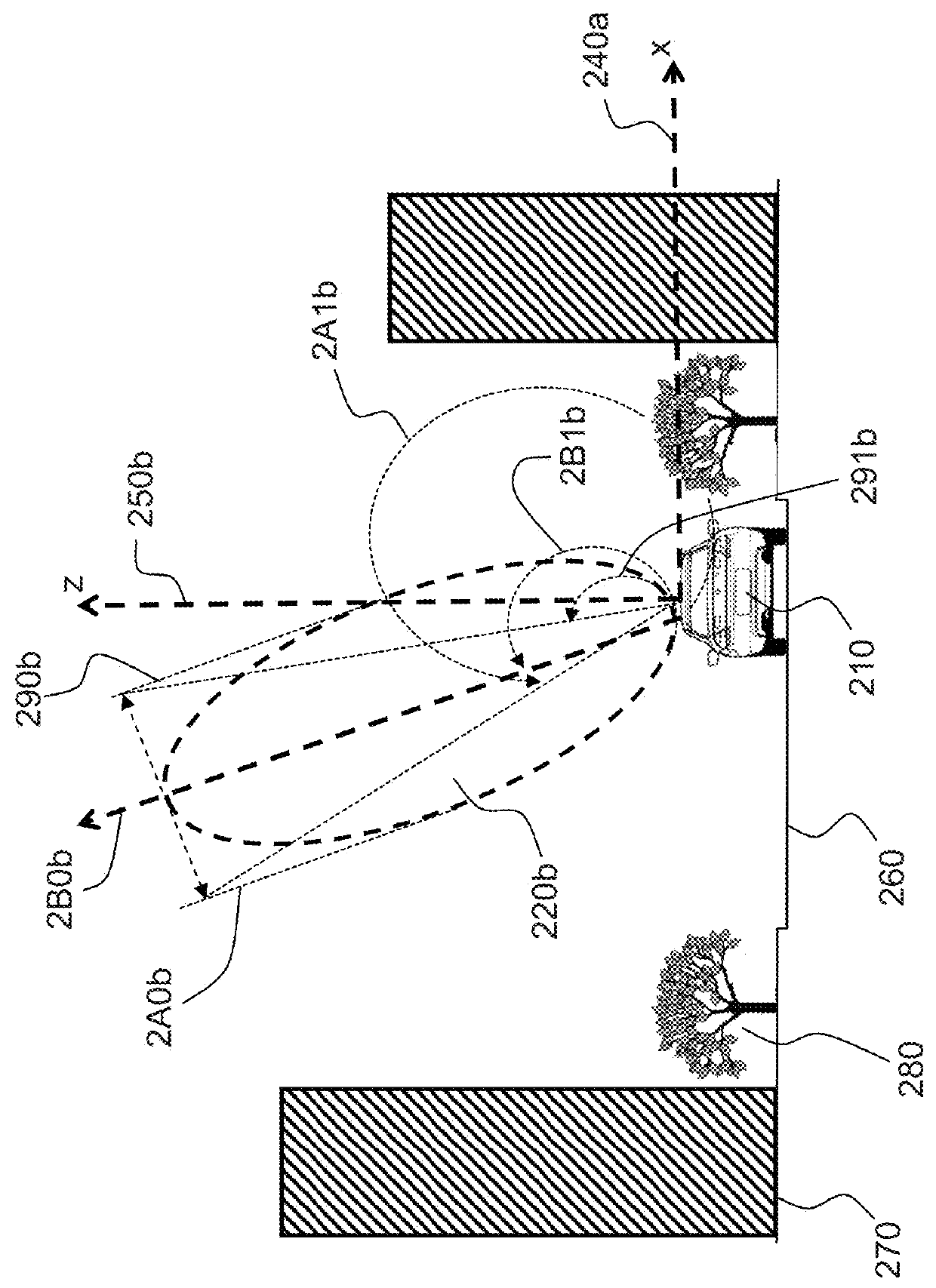

Simplified GNSS receiver with improved precision in a perturbated environment

InactiveUS20180180741A1SimpleSimpler and compact and cost-effective solutionAntenna adaptation in movable bodiesSatellite radio beaconingVIT signalsPrevalence

The invention discloses an antenna assembly that may be connected to a standard GNSS receiver. The antenna assembly comprises antenna elements that are configured to shape a radiating pattern which is directional in a direction of movement of the GNSS receiver and which has a FOV above the receiver that may be limited. The signals received in LOS will then have a much better C / N0 than the Non-LOS signals. In some embodiments, the FOV may be twisted leftwards or rightwards depending on a configuration of a vehicle carrying the receiver. In some embodiments, the antenna assembly is capable of operating in a plurality of modes that will differ notably by the FOV of the radiating pattern above the receiver. Switching between modes may be triggered manually or automatically and may be based on a determination of the prevalence and / or type of multipath reflections in the area where the rover moves. This determination may be based on sensor processing or a determination of a coarse position that will give to an index of multipath reflections from a database and / or a map.

Owner:CENT NAT DETUD SPATIALES C N E S

Tapping valve of plastics material for transport and storage containers for liquids

A tapping valve of plastics material for transport and storage containers for liquids, which is constructed as a flap valve or ball valve, includes a valve housing with an inlet connection connectable to an outlet connection of the liquid container and an outlet connection, wherein the outlet connection of the valve body is welded to the male part of a Kamlok coupling for connecting a discharge hose. The valve housing is of a polyethylene of high density and the male part of the Kamlok coupling is of a glass fiber-reinforced polyethylene of high density.

Owner:PROTECHNA SA

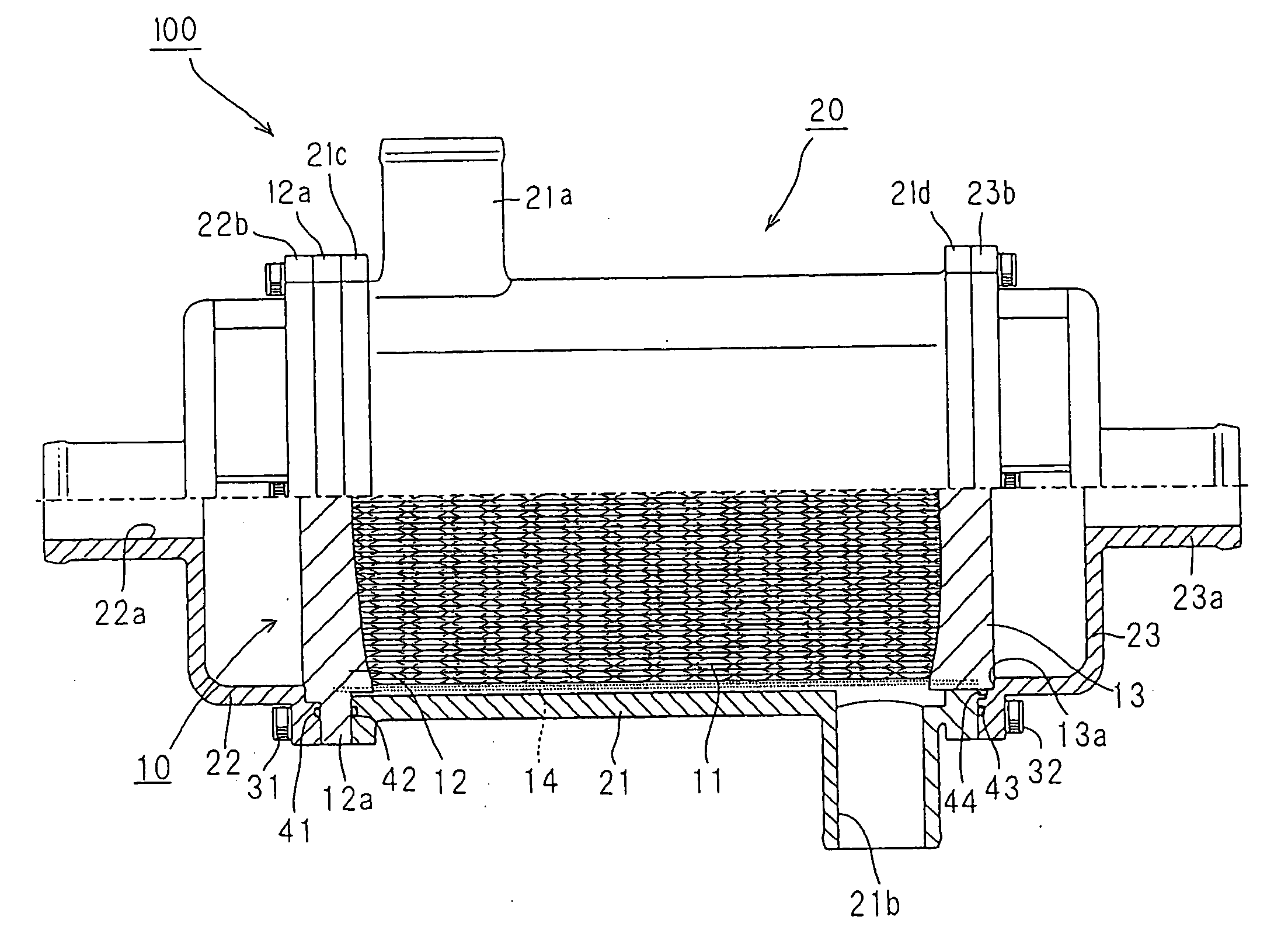

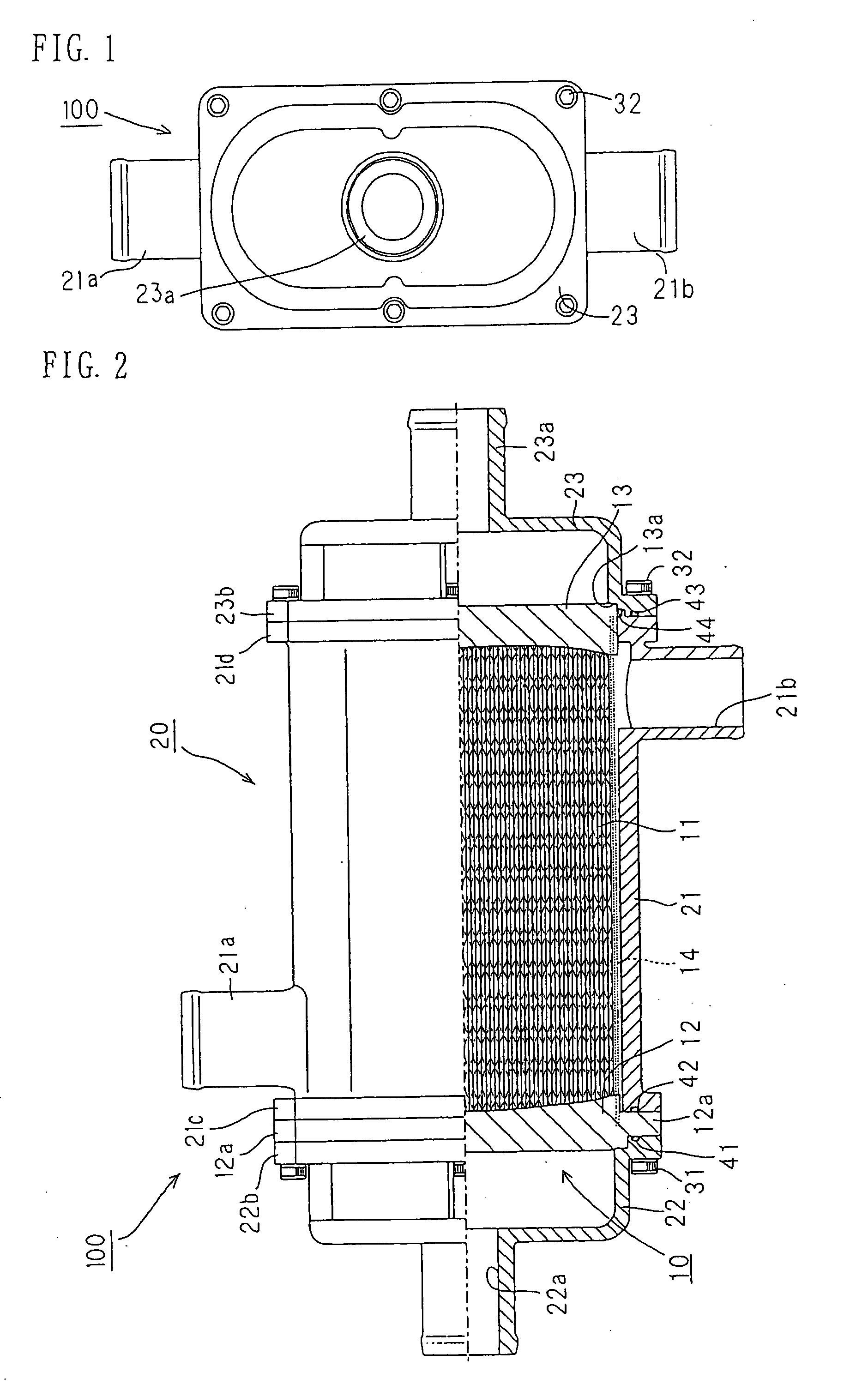

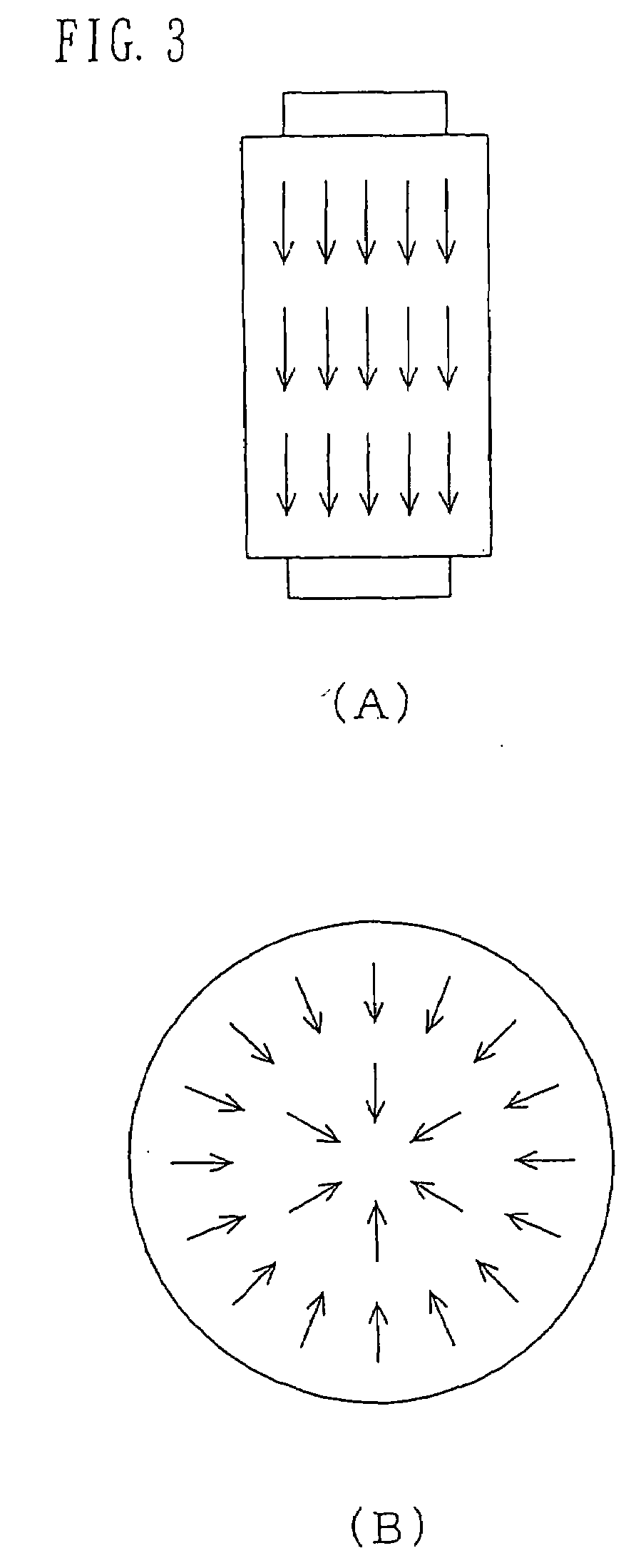

Hollow Fiber Membrane Module, and Method for Producing the Hollow Fiber Membrane Module

InactiveUS20090039010A1SimpleSimple structureSemi-permeable membranesMembranesHollow fibre membraneEngineering

The structure can be made simple, and the reuse of a housing can be attained.A hollow fiber membrane module 100 including a hollow fiber membrane unit 10 which has plural hollow fiber membranes 11, and a first seal-fixing section 12 and a second seal-fixing section 13 for seal-fixing both ends of these hollow fiber membranes 11 to make the insides of the hollows therein open, and which is constructed in a state that outer wall faces of these seal-fixing sections are uncovered, and a housing 20 for containing the hollow fiber membrane unit 10, wherein the housing 20 has first ports 22a and 23a constituting a channel leading to the insides of the hollows in the hollow fiber membranes 11, and second ports 21a and 21b constituting a channel leading to the side of outer wall faces of the hollow fiber membranes 11, and the hollow fiber membrane unit 10 is constructed to be freely put on and taken off from the housing 22.

Owner:NOK CORP

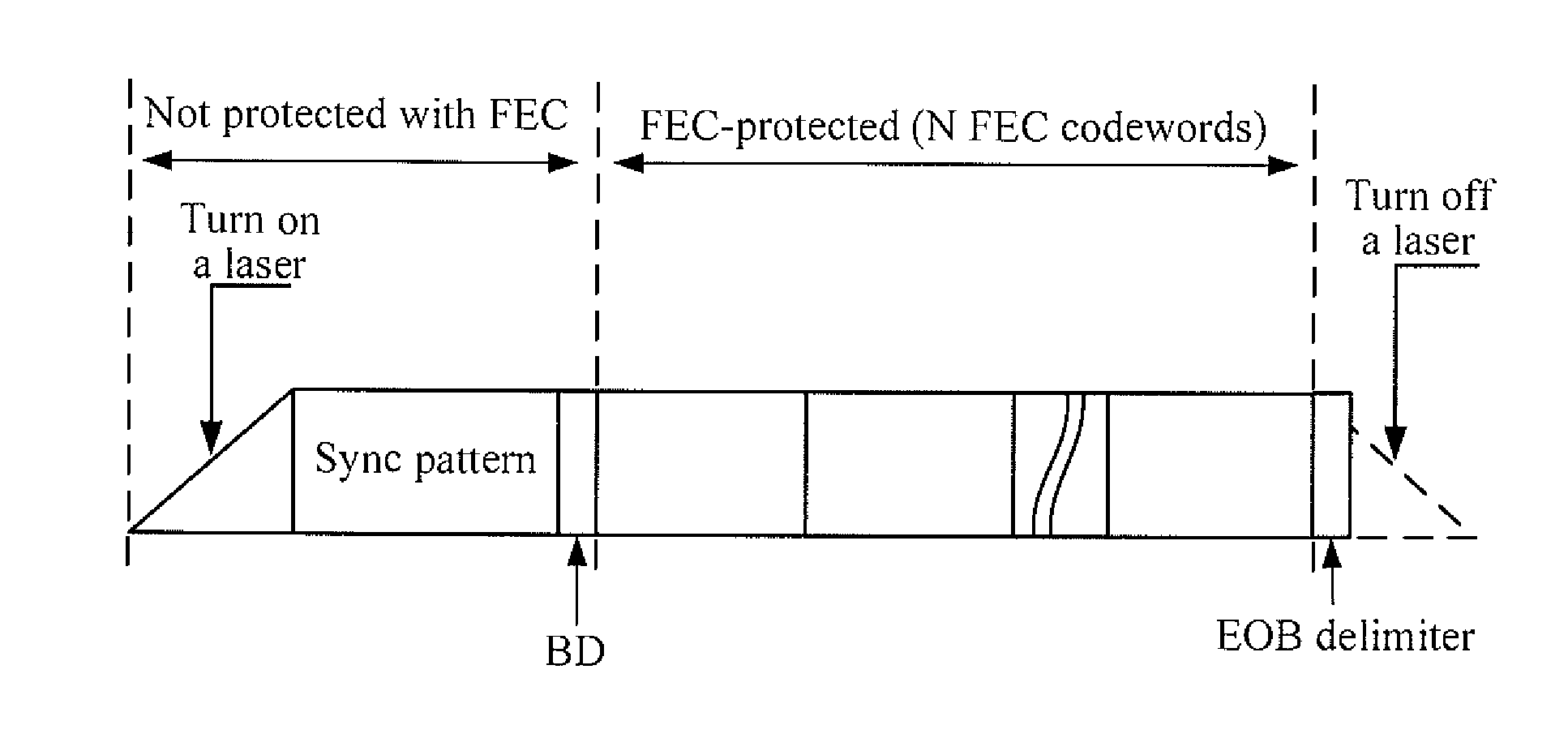

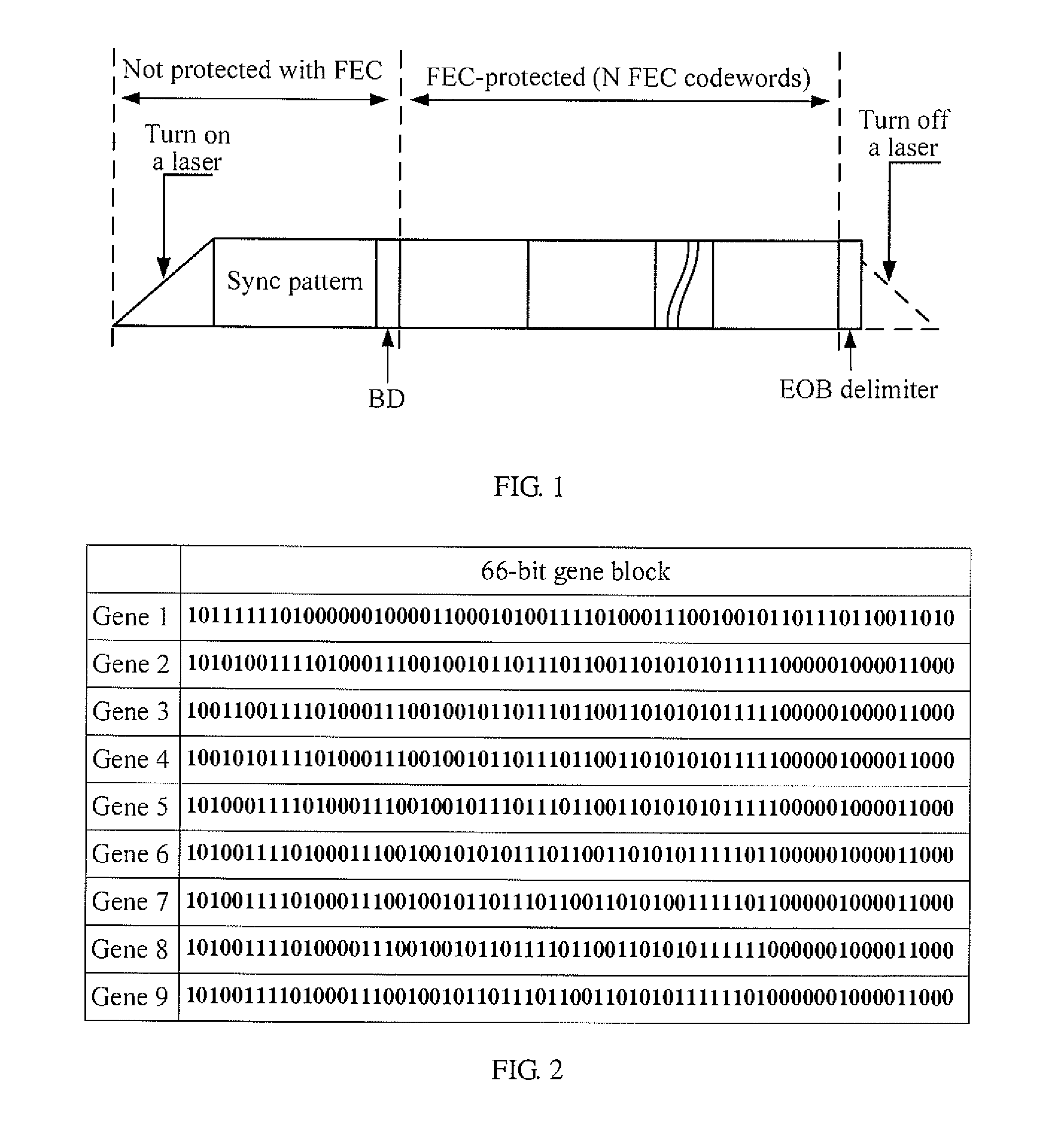

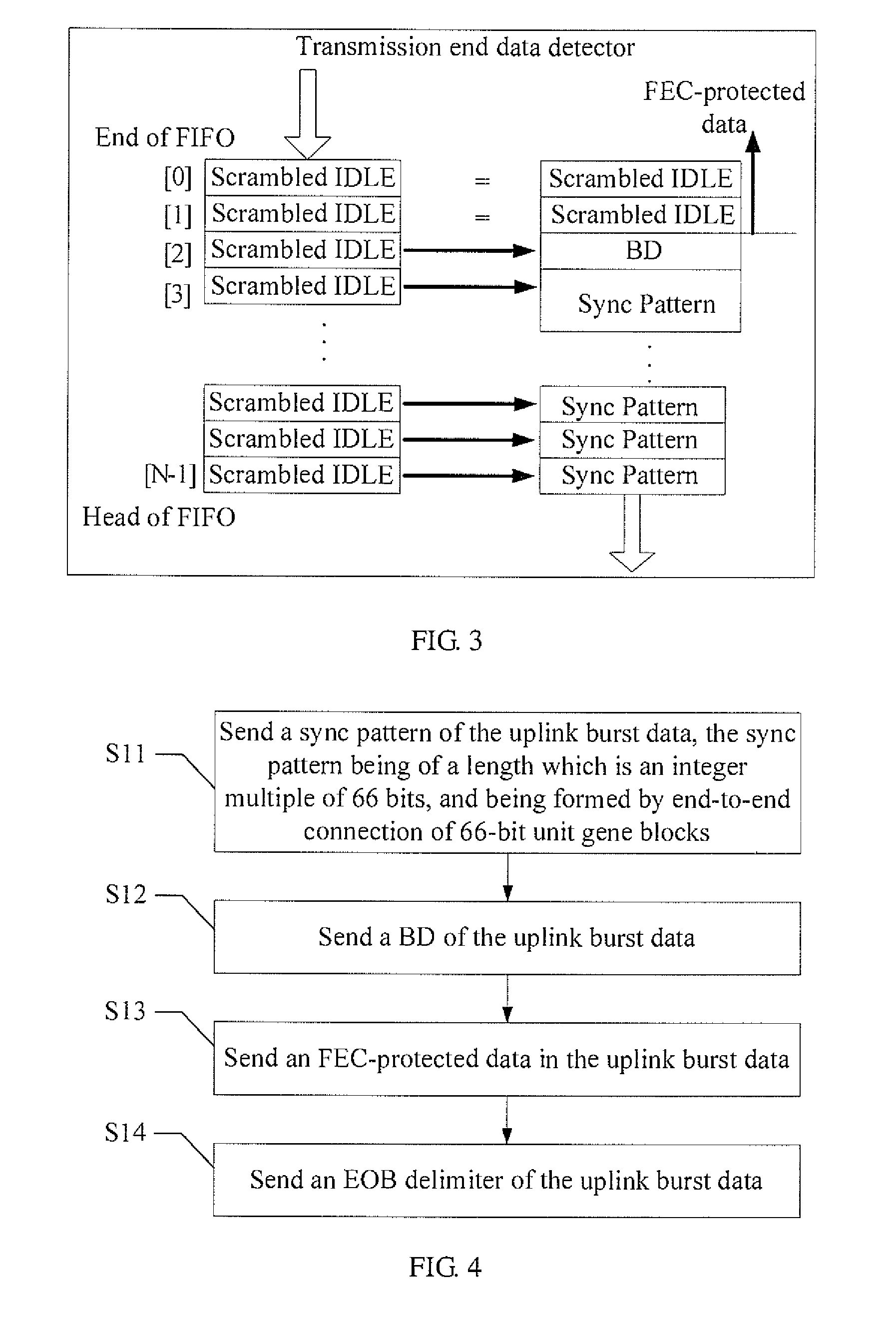

Method and device for sending uplink burst data in passive optical network system

A method for sending uplink burst data in a passive optical network (PON) system includes: sending a synchronization pattern of the uplink burst data, the synchronization pattern being of a length, which is an integer multiple of 66 bits, and being formed by connection of 66-bit unit gene blocks; sending a burst delimiter (BD) of the uplink burst data; sending a forward error correction (FEC)-protected data in the uplink burst data; and sending an end of burst (EOB) delimiter of the uplink burst data. The technical solutions in the embodiments allow the use of a less complex equalizer at the reception end of a high-speed PON system.

Owner:HUAWEI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com