Patents

Literature

88results about How to "Simple and inexpensive design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

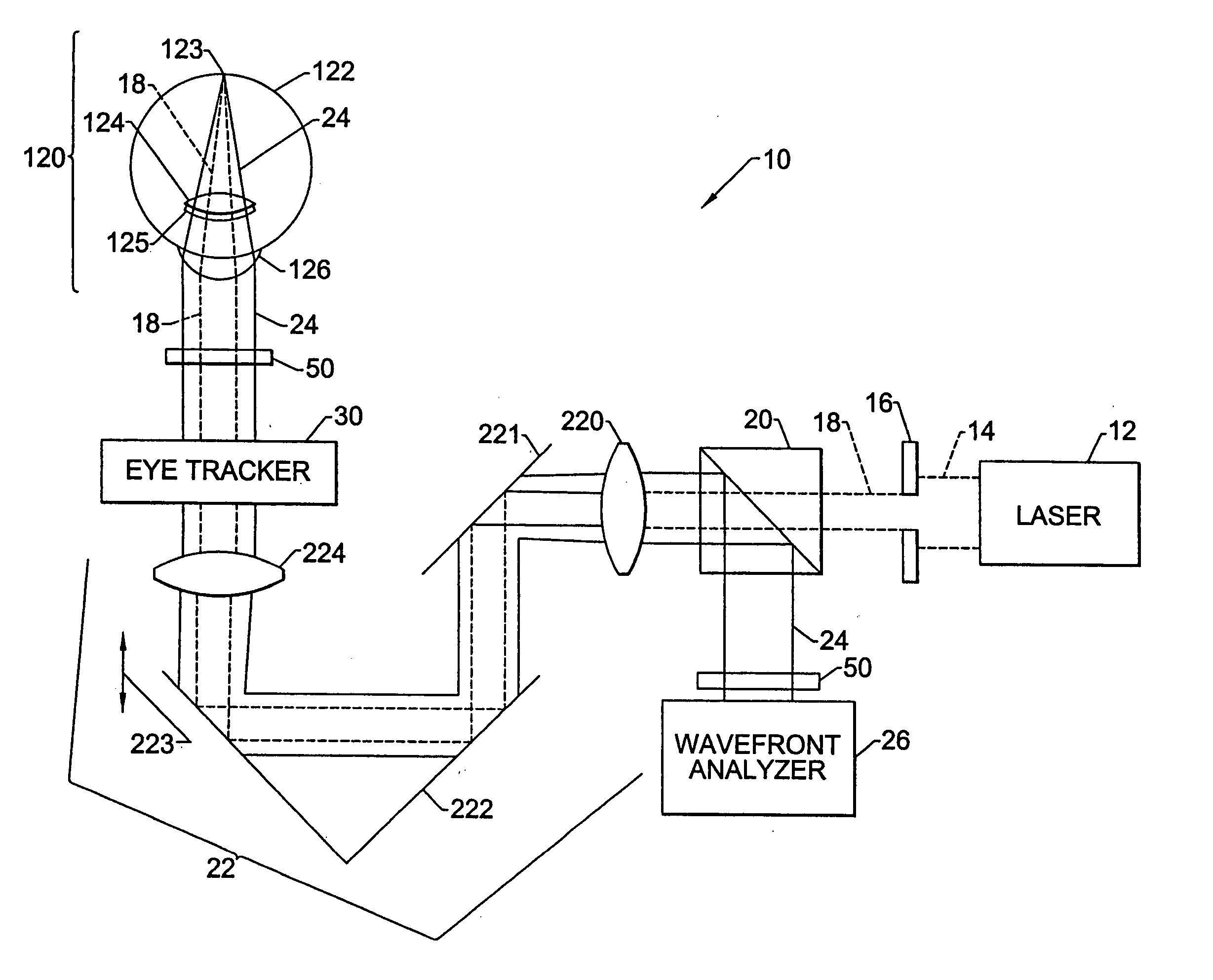

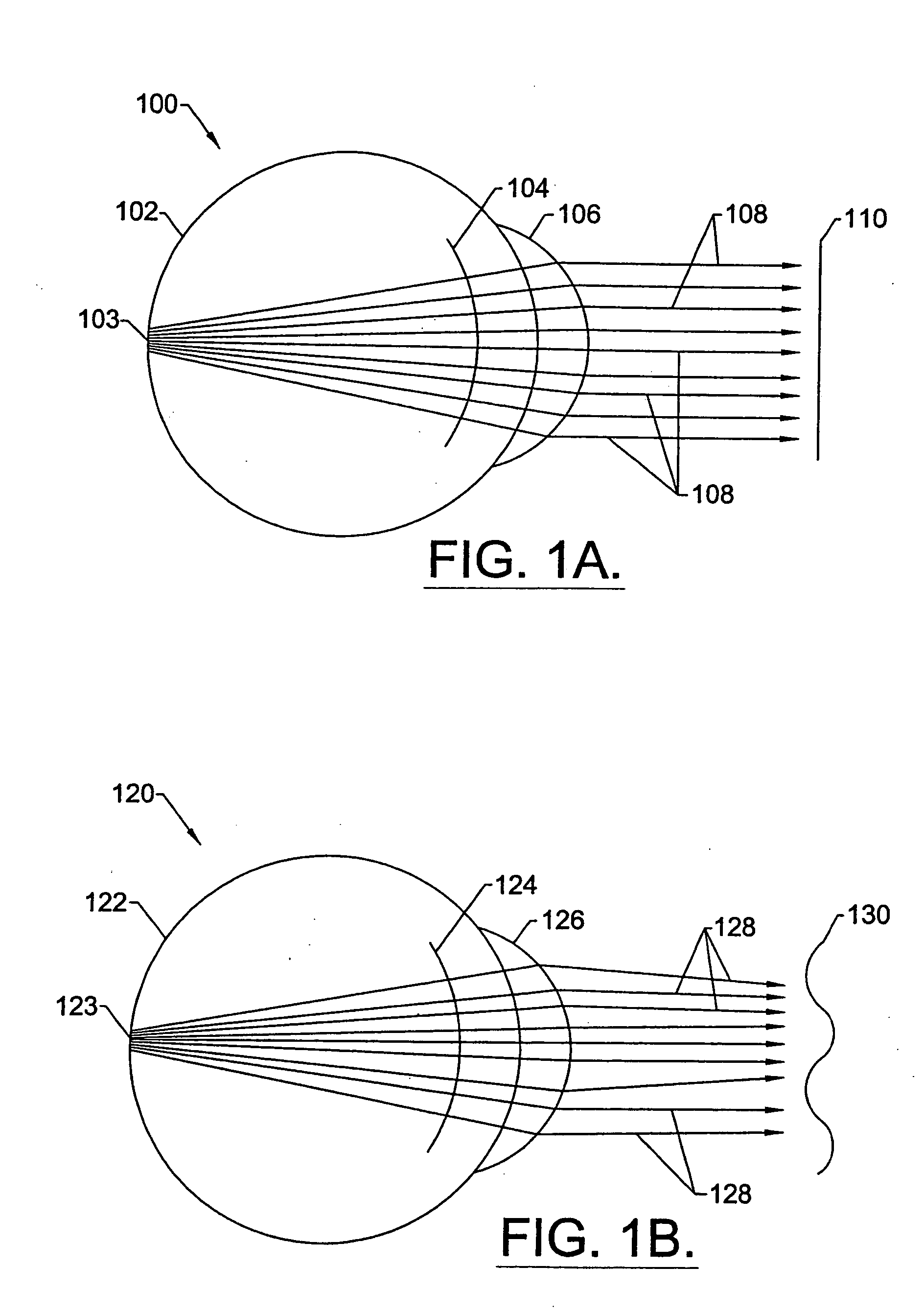

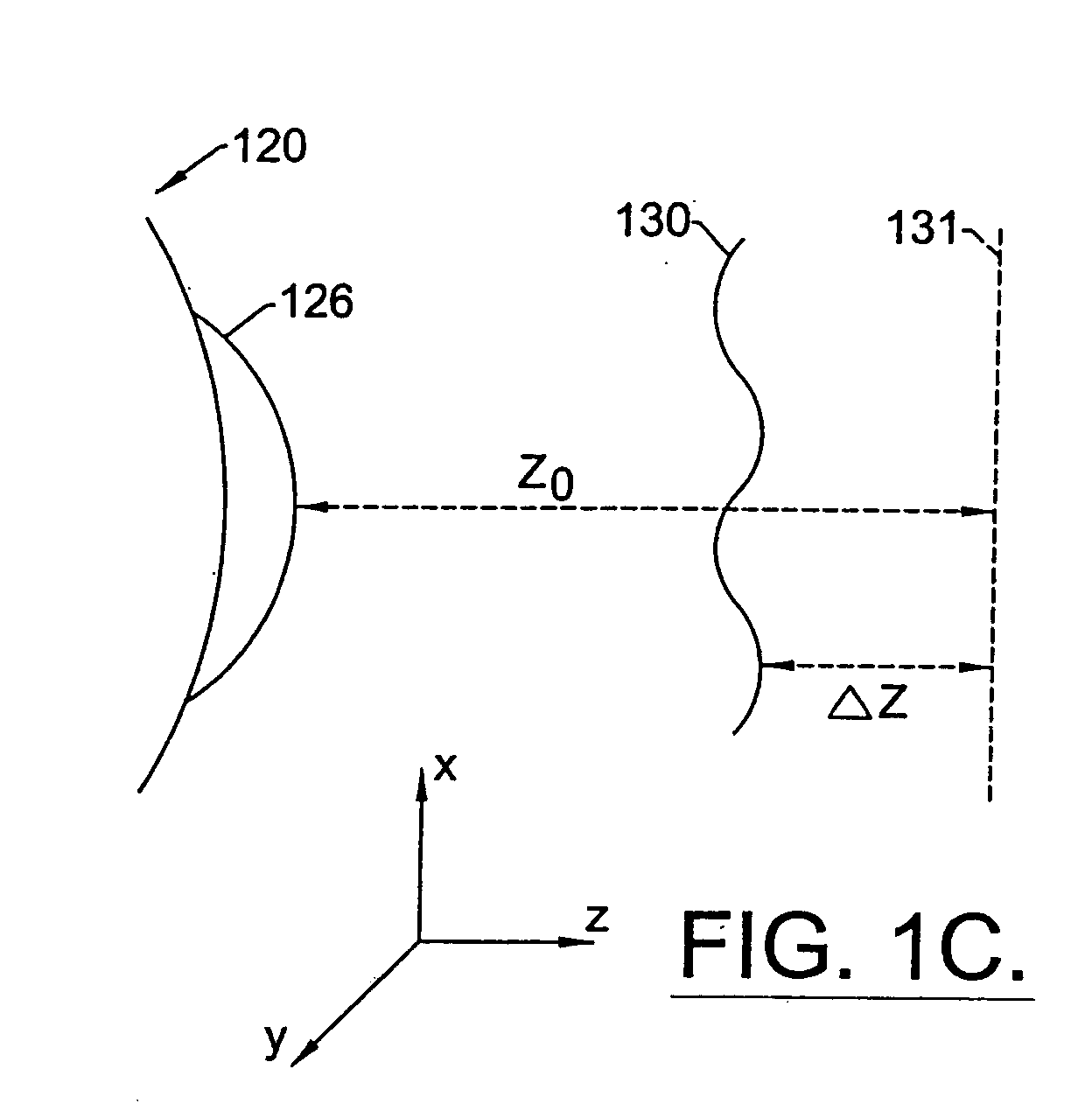

Method for determining and correcting vision

InactiveUS20050124983A1Simple and inexpensive designImprove visual effectsLaser surgerySurgical instrument detailsRefractive indexOptical path length

A method for enhancing vision of an eye includes a laser delivery system having a laser beam for ablating corneal material from the cornea of the eye. Measurements are made to determine an optical path difference between a plane wave and a wavefront emanating from the retina of the eye for a location at a surface of the cornea. An optical correction is provided to the laser delivery system for the location based on the optical path difference and refractive indices of media through which the wavefront passes. The optical correction includes dividing the optical path difference by a difference between an index of refraction of corneal material and an index of refraction of air. The laser beam is directed to the location on the surface of the cornea and corneal material ablated at the location in response to the optical correction to cause the wavefront to approximate the shape of the plane wave at that location.

Owner:FREY RUDOLPH W +4

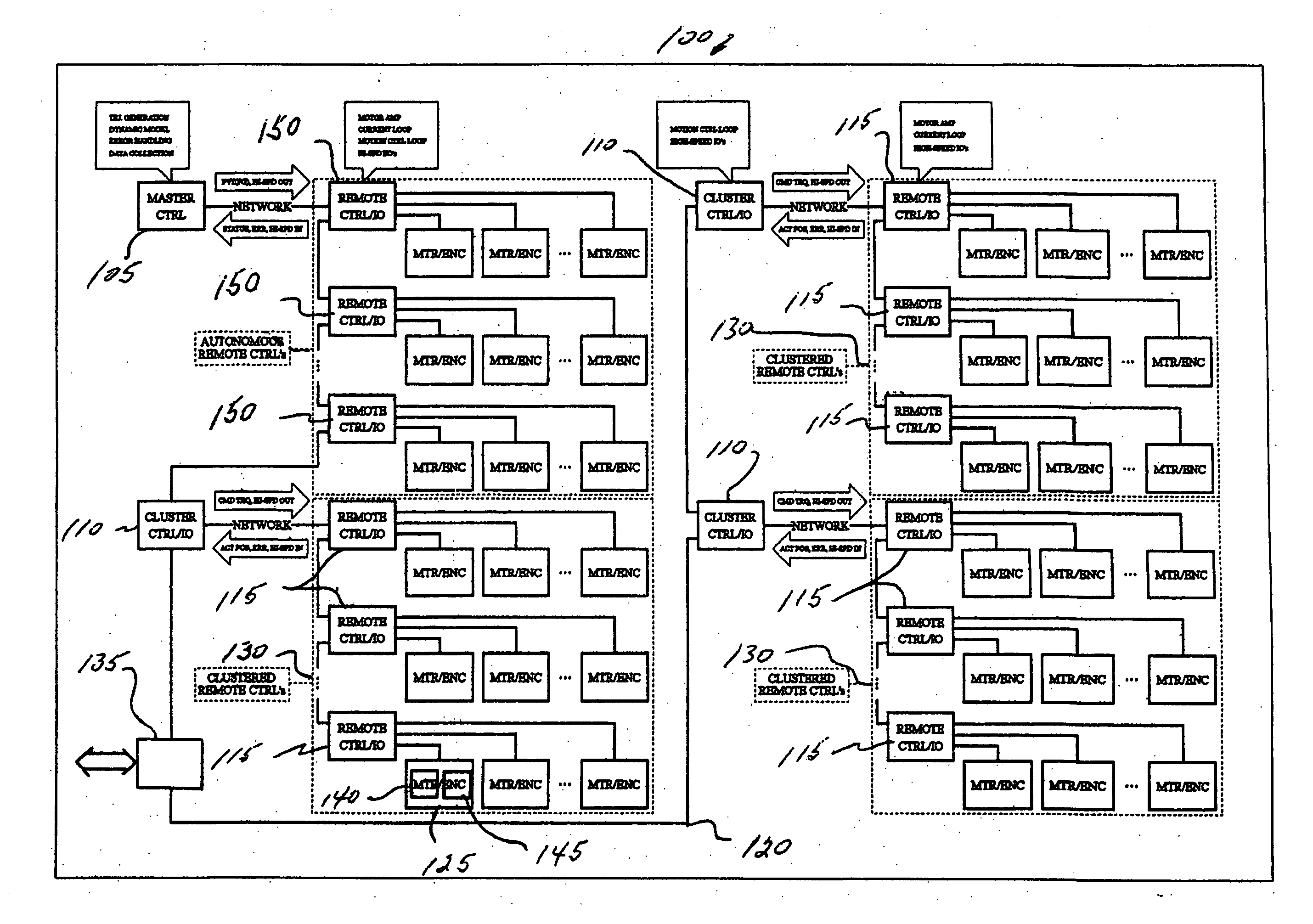

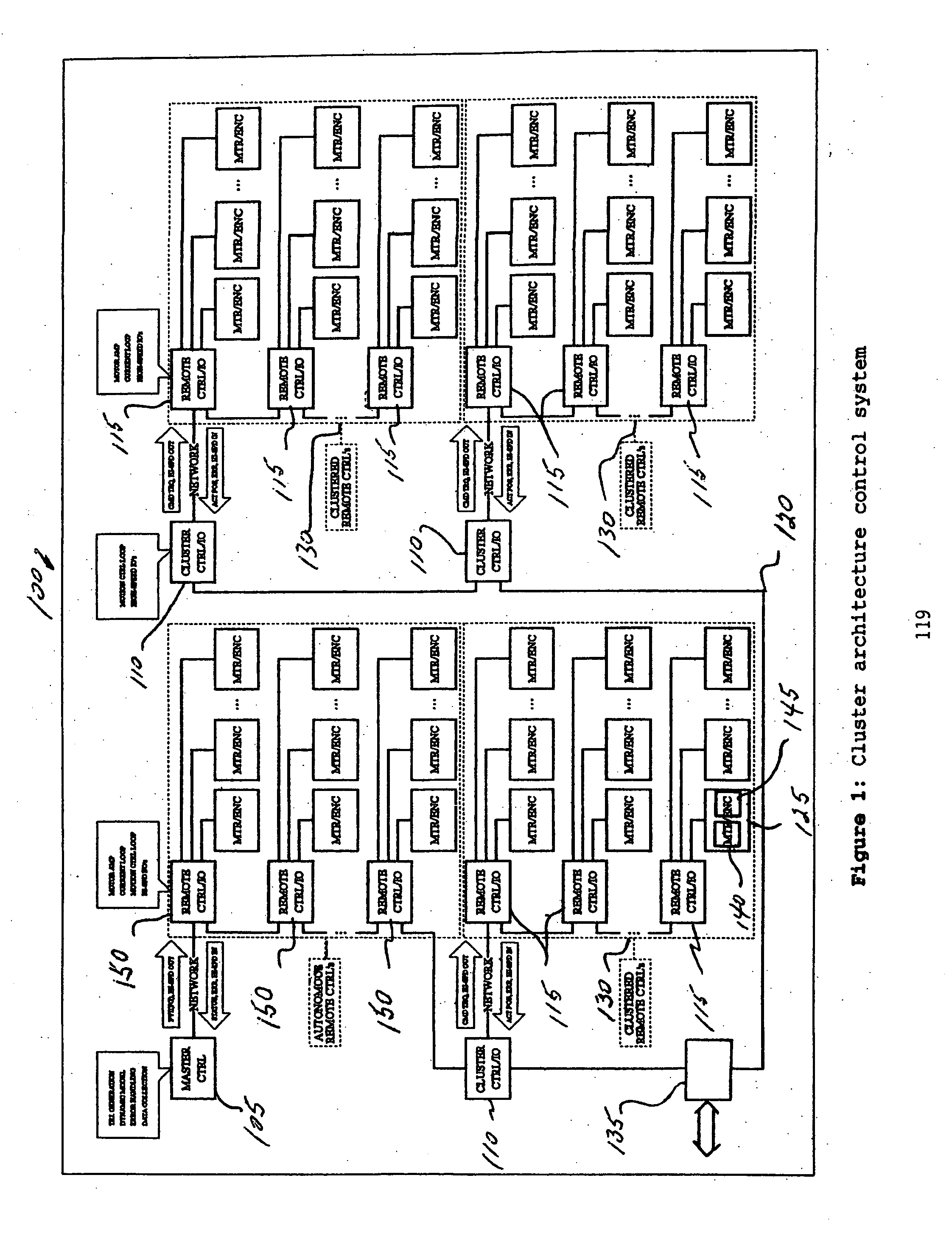

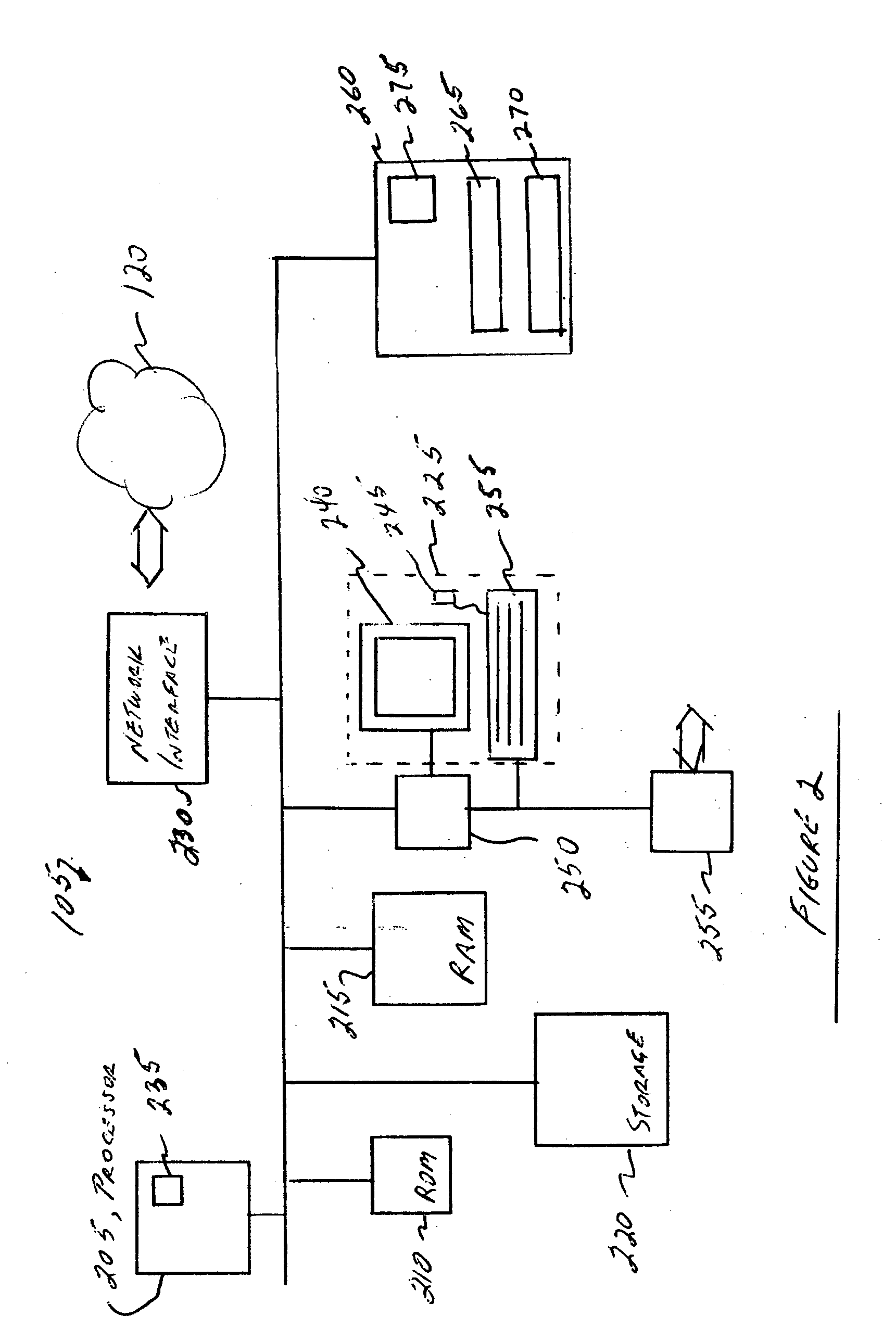

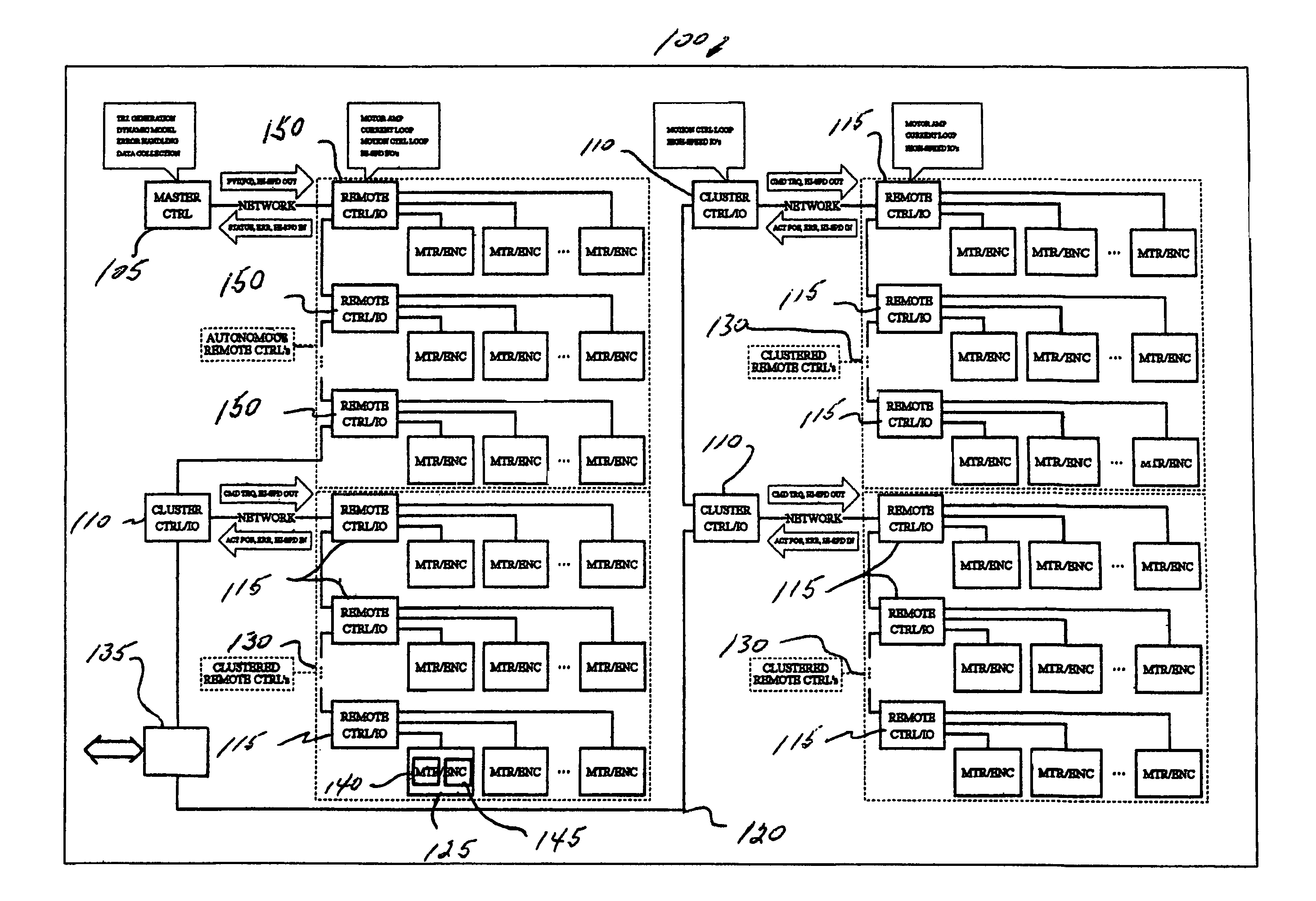

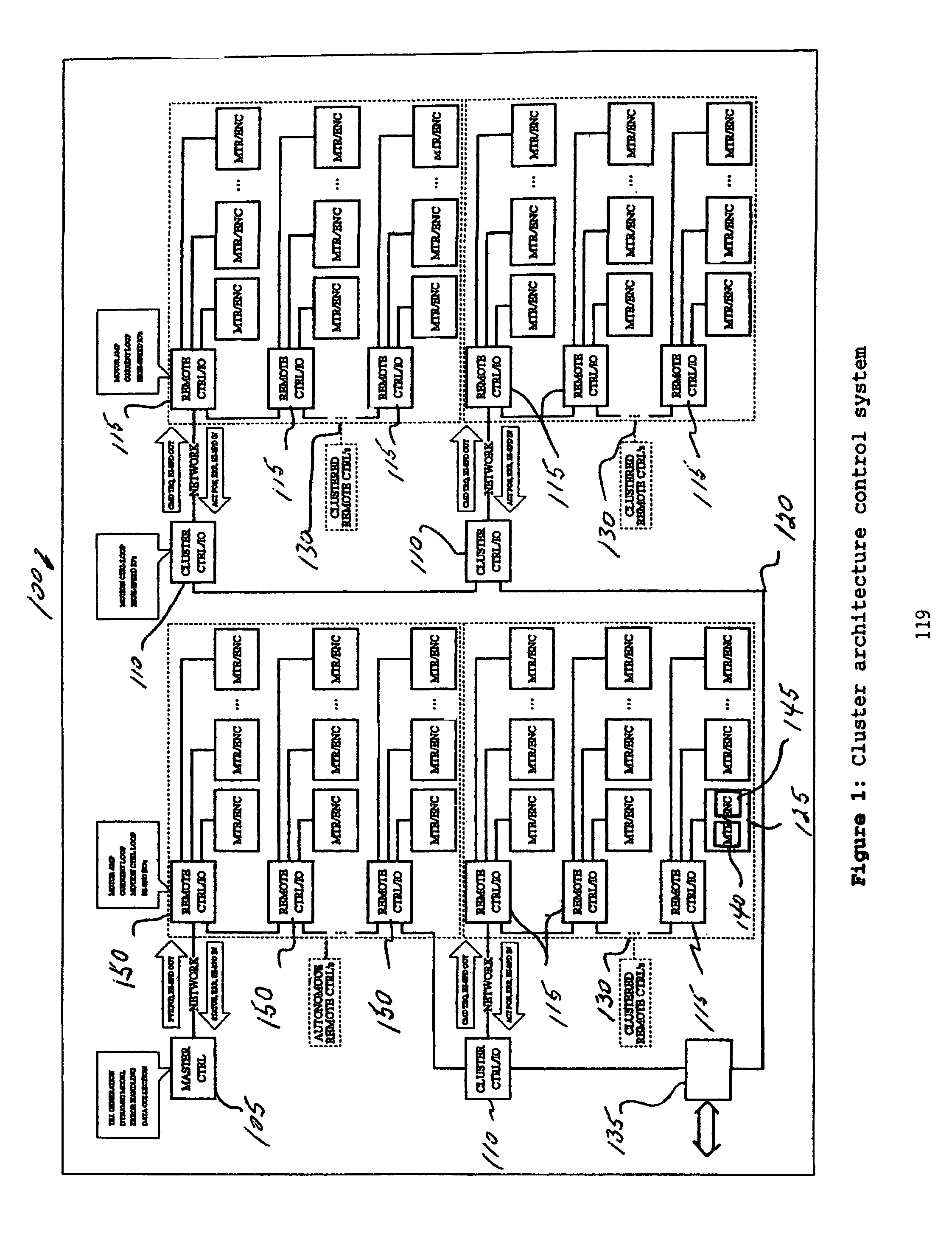

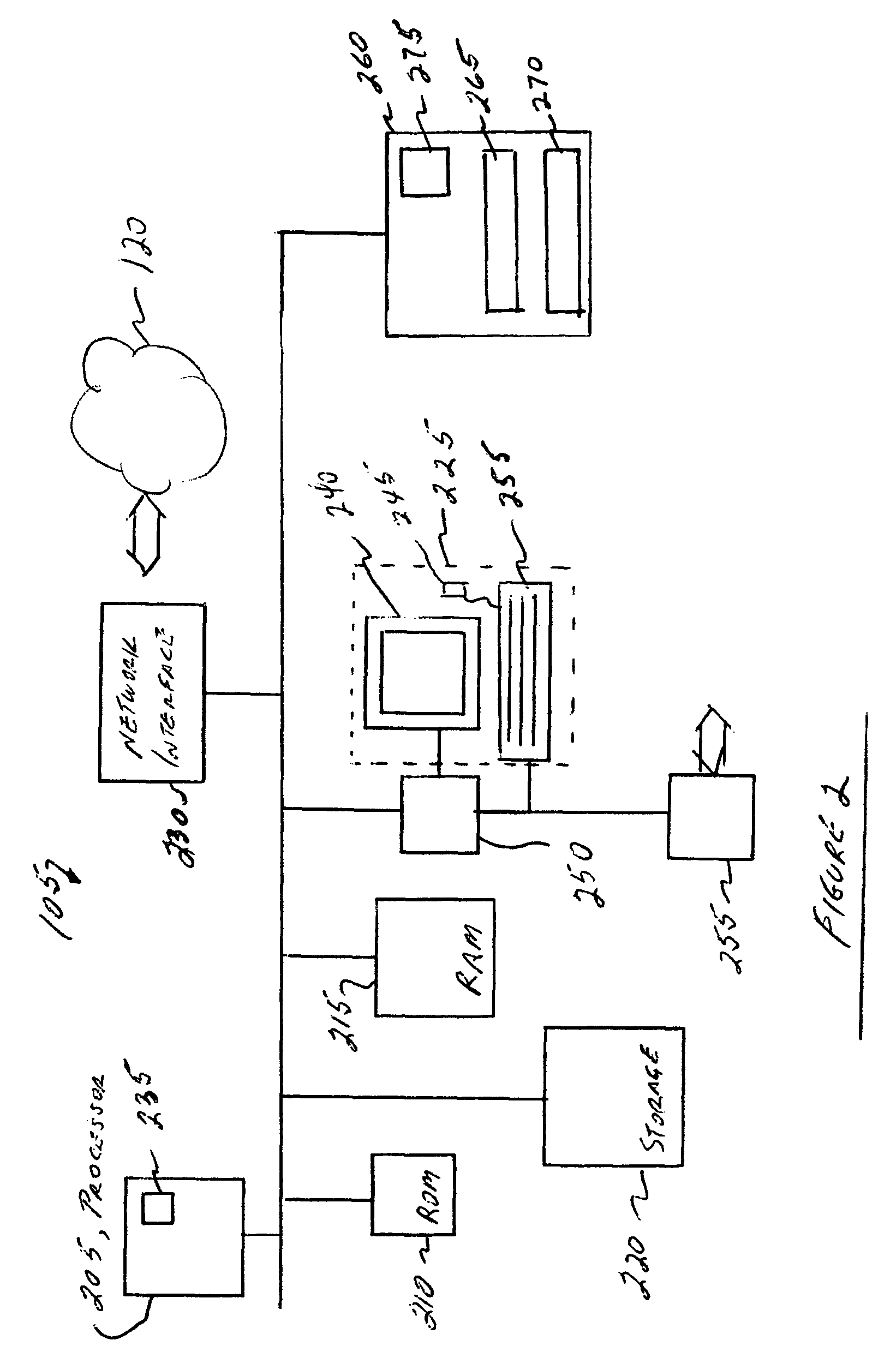

Scalable motion control system

ActiveUS20070010898A1Maintain integrityEasy to implementLiquid surface applicatorsComputer controlDirect controlMaster controller

A control system includes a clustered architecture having a master controller, a central control section including one or more first remote controllers under direct control of the master controller, and a distributed control section including a cluster controller controlled by the master controller. The cluster controller controls the activities of one or more second remote controllers. Each of the first and second remote controllers are utilized to drive one or more axes.

Owner:BOOKS AUTOMATION US LLC

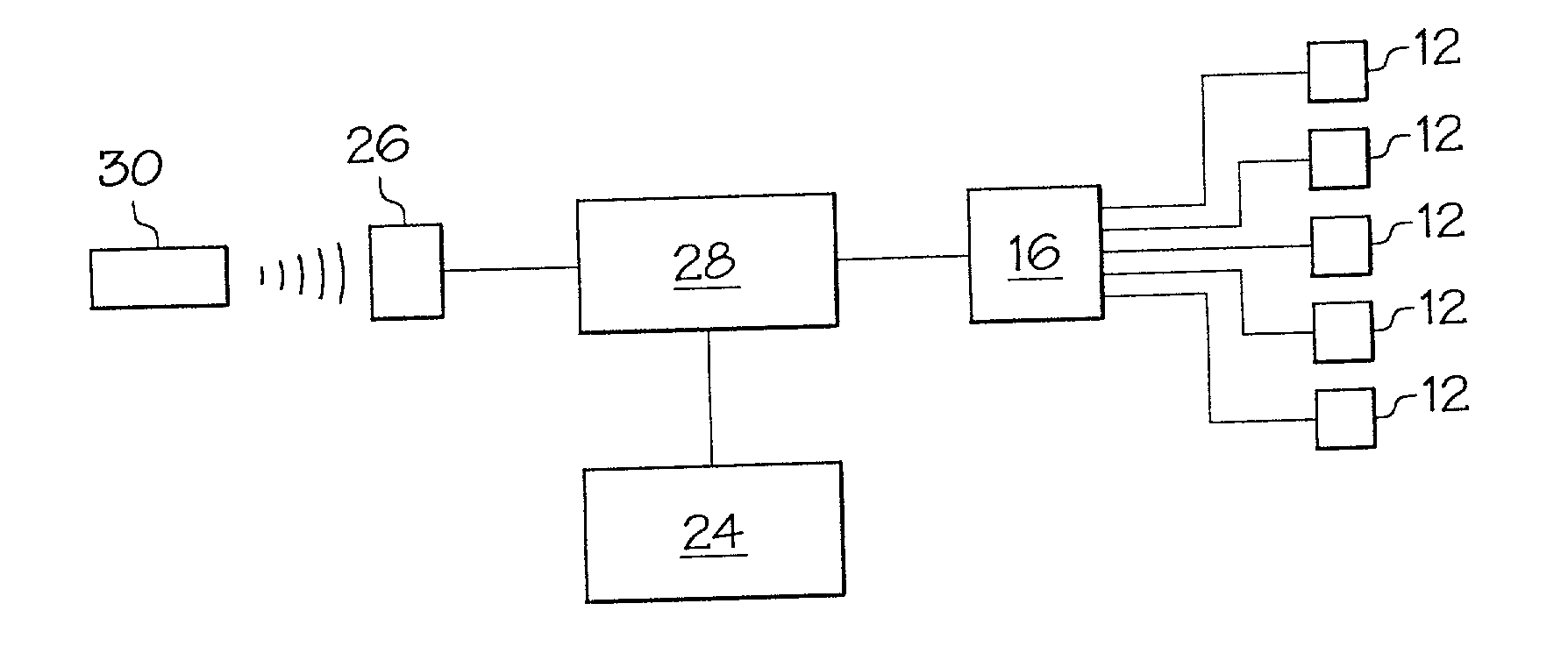

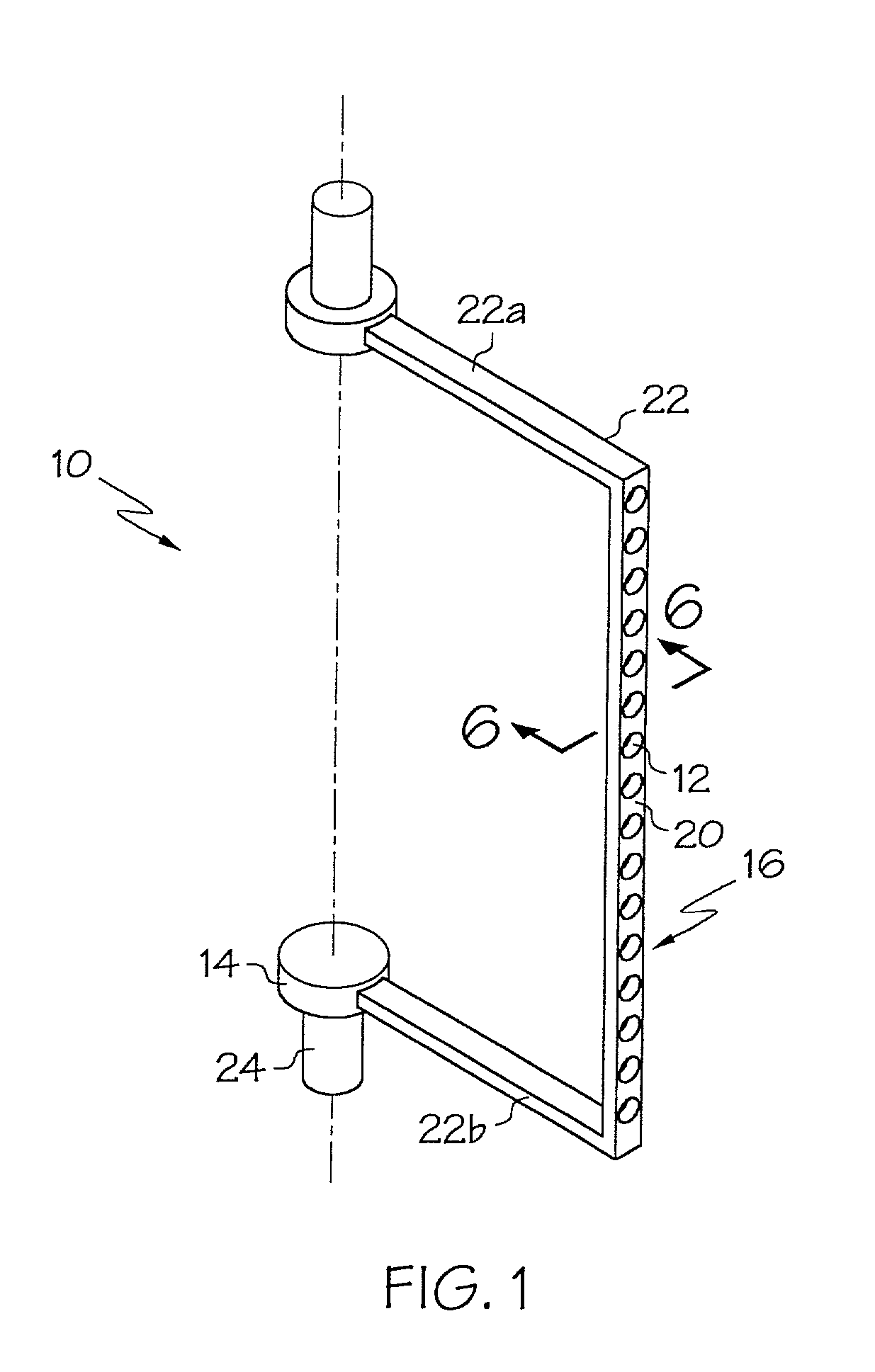

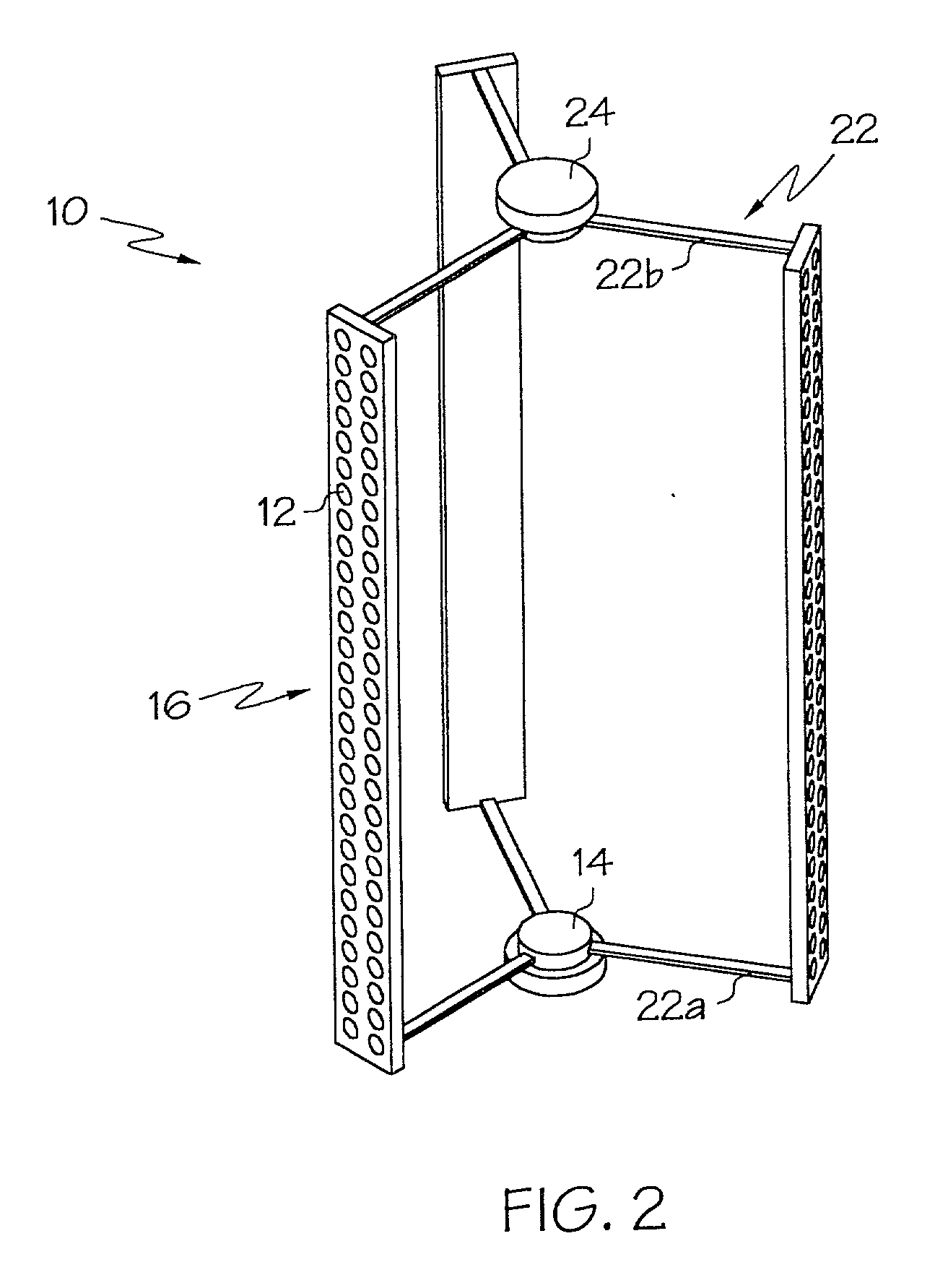

LED sign

InactiveUS20020005826A1Long life cycleSimple and inexpensive designStatic indicating devicesAircraft lightsElectricityEngineering

A system for displaying an image comprising at least one display apparatus. Each display apparatus including at least one light bar having a plurality of light emitting diodes mounted thereto. At least one support joining each light bar to a rotation mechanism. The rotation mechanism being constructed and arranged to rotate the light bars at a predetermined rate of rotation. The system also includes a controller in electrical communication with each of the plurality of light emitting diodes, and the rotation mechanism of each of the at least one display apparatus. The controller constructed and arranged to control the predetermined rate of rotation and selectively activate the light emitting diodes to produce at least one image capable of being perceived by a viewer.

Owner:E P SURVIVORS

Scalable motion control system

ActiveUS7904182B2Easy to implementLow computing performanceLiquid surface applicatorsComputer controlControl systemMaster controller

A control system includes a clustered architecture having a master controller, a central control section including one or more first remote controllers under direct control of the master controller, and a distributed control section including a cluster controller controlled by the master controller. The cluster controller controls the activities of one or more second remote controllers. Each of the first and second remote controllers are utilized to drive one or more axes.

Owner:BOOKS AUTOMATION US LLC

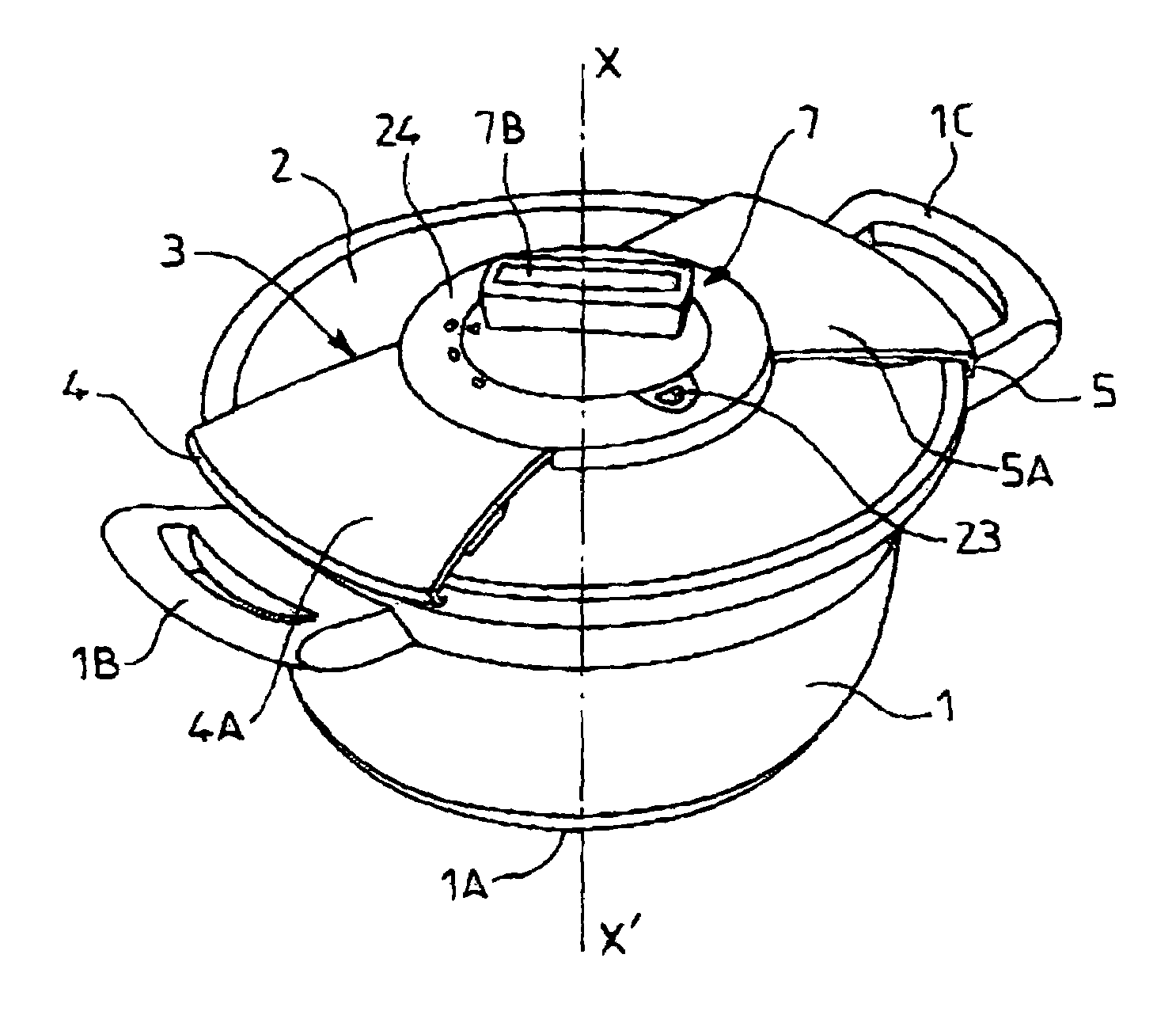

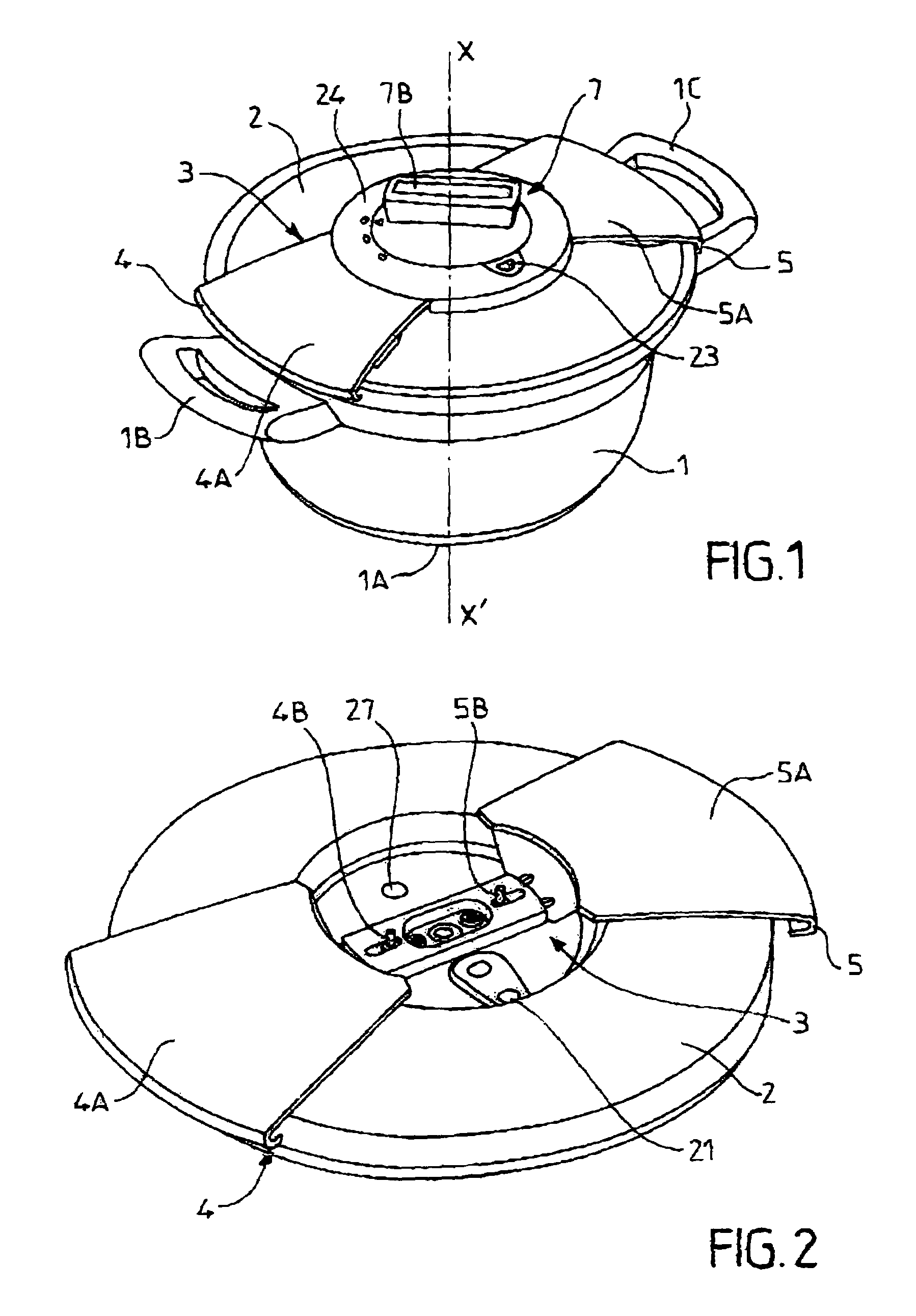

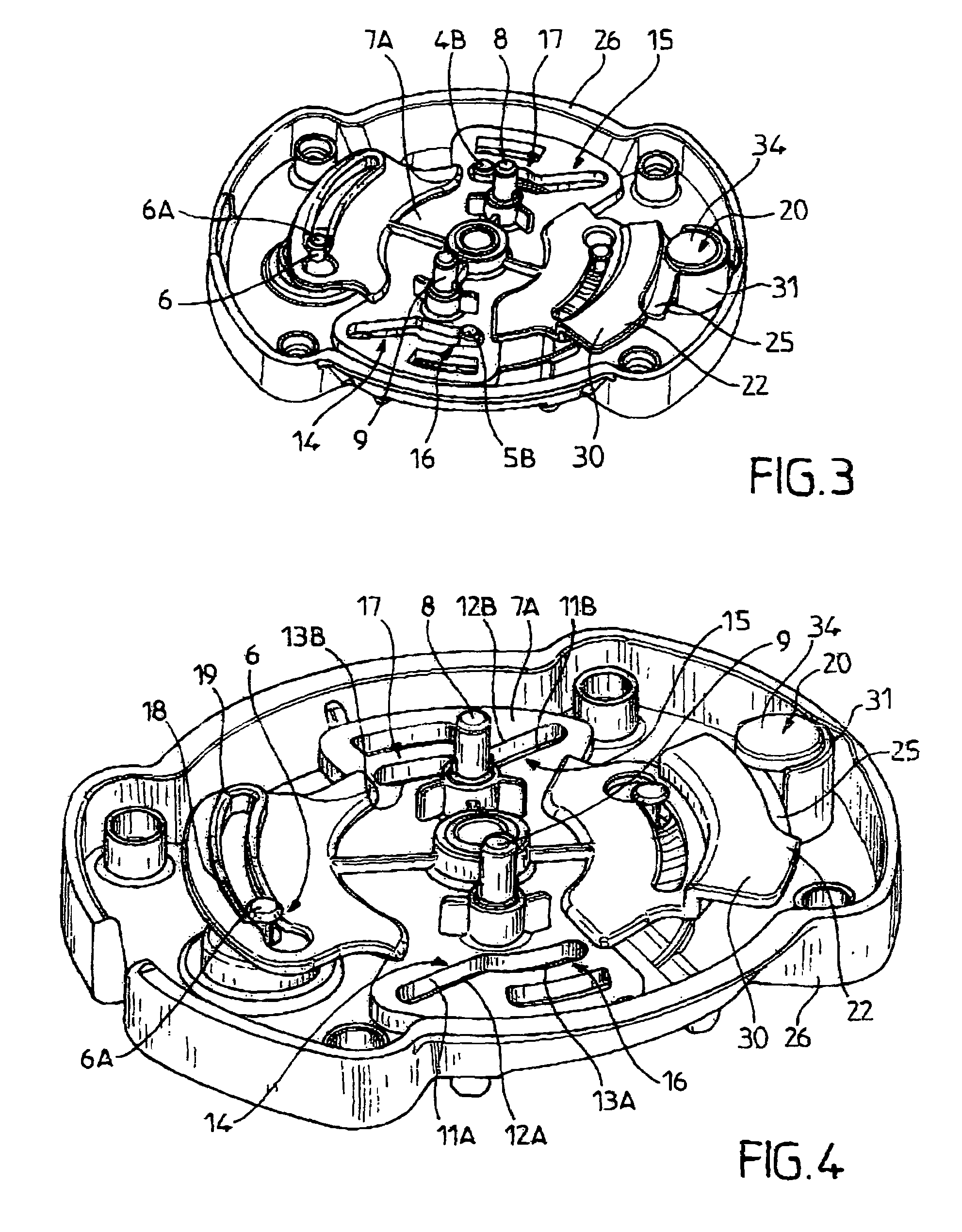

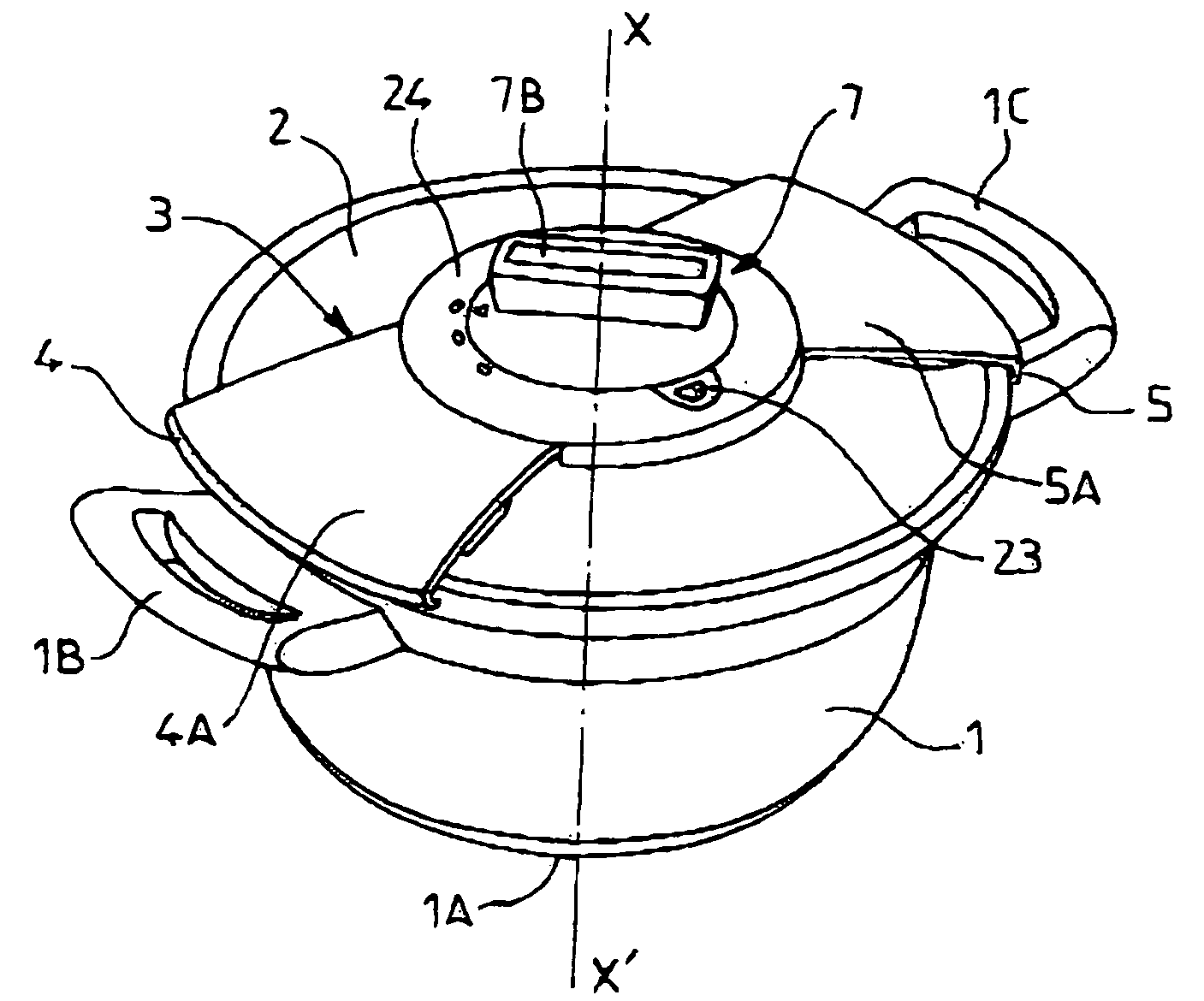

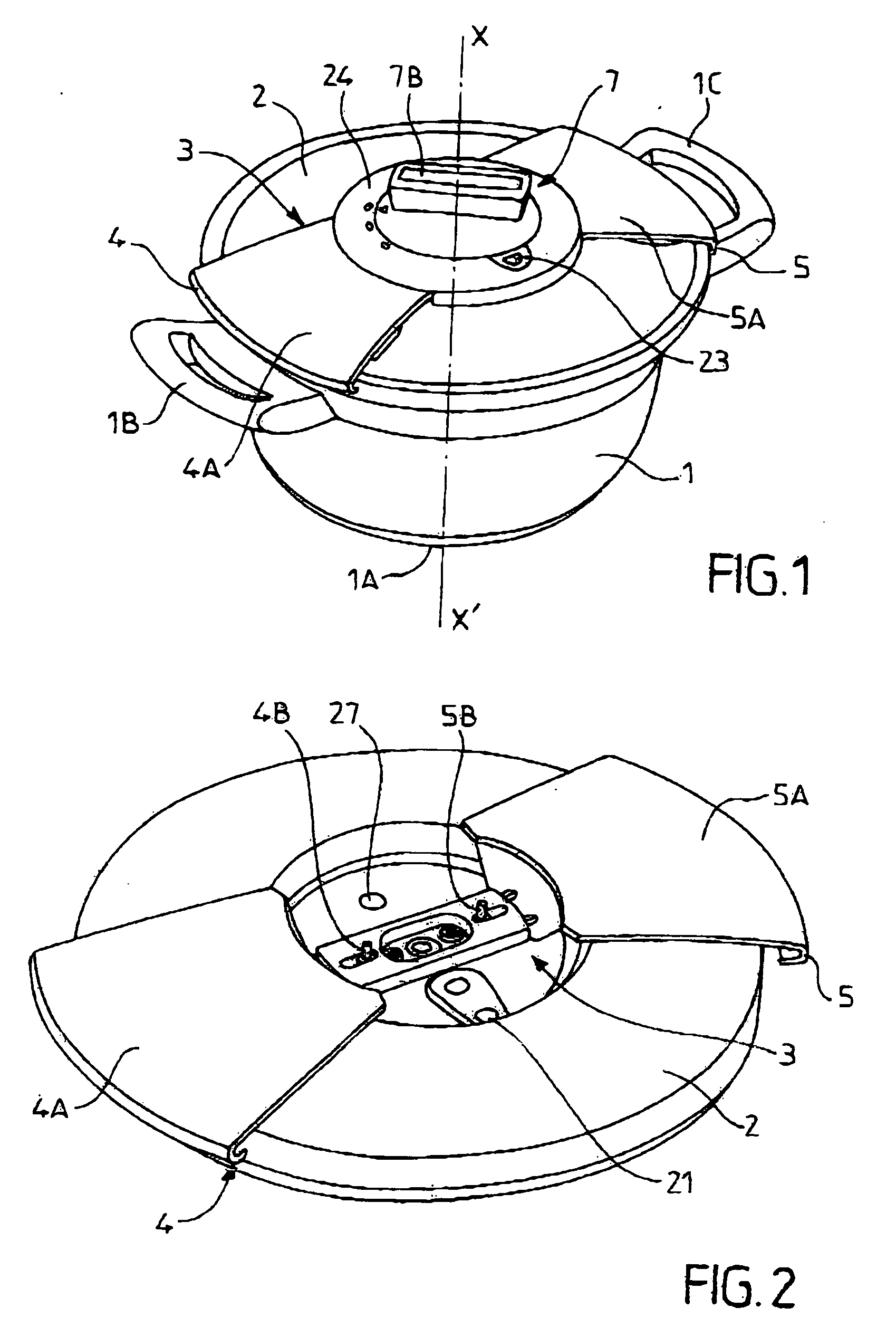

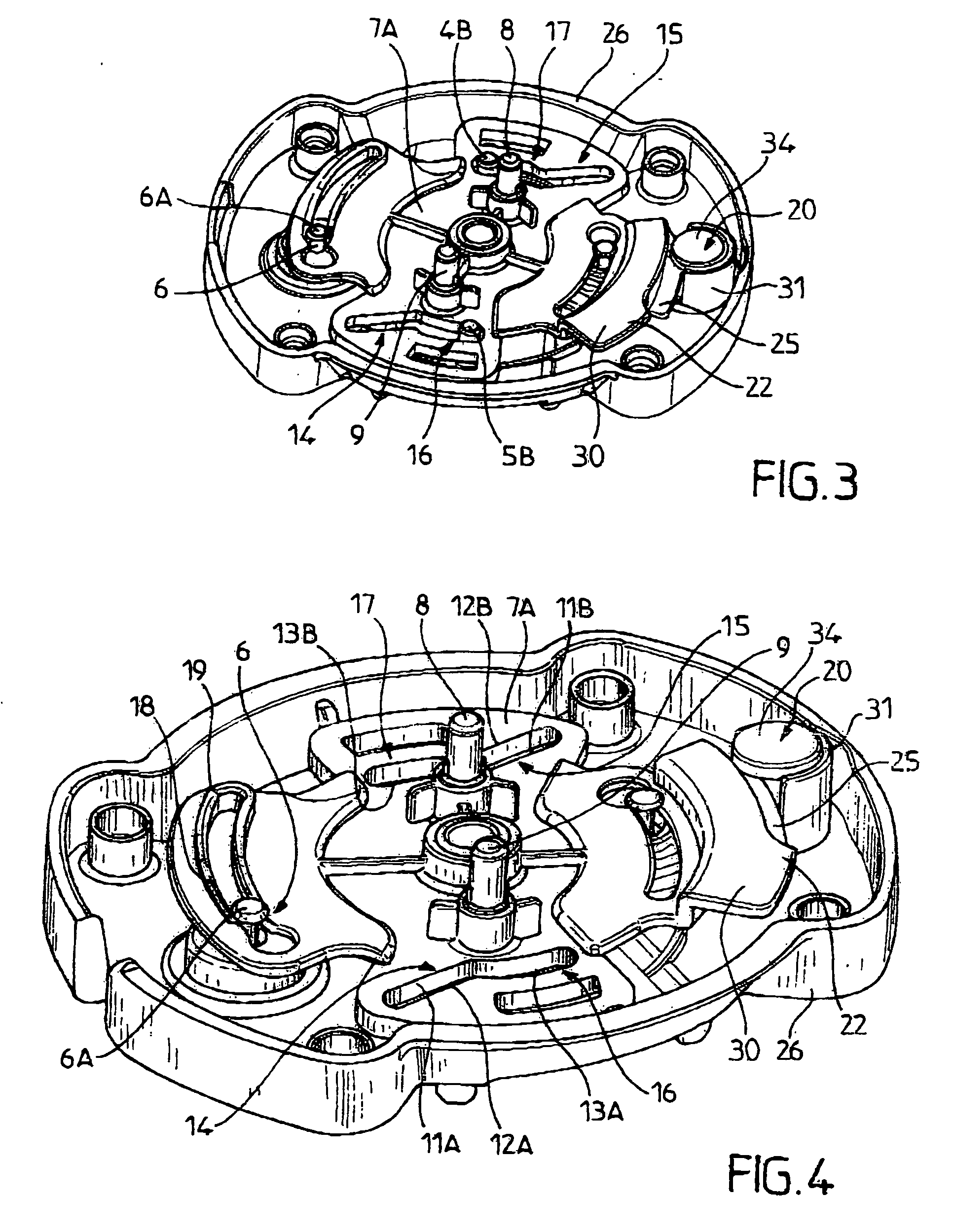

Pressure-cooking appliance including opening safety means

ActiveUS7523696B2Easy to useHigh speedWater heating stoves/rangesStove/ranges for heating waterHome applianceNeutral position

The invention relates to an appliance for cooking under pressure, the appliance comprising:a bowl and a lid; andopening safety means suitable for going between a neutral position, in which they allow the lid to be unlocked, and a blocking position, in which they prevent the lid from being unlocked, said safety means being designed to find themselves in the blocking position when the pressure prevailing inside the vessel is greater than or equal to a predetermined value or “rise pressure”, and / or when the temperature prevailing inside the vessel is greater than or equal to a predetermined value or “rise temperature”;said appliance being further comprising actuating means for actuating the safety means, which actuating means are arranged to make it possible to place the safety means in the blocking position. The invention is applicable to household appliances for cooking under pressure.

Owner:SEB SA

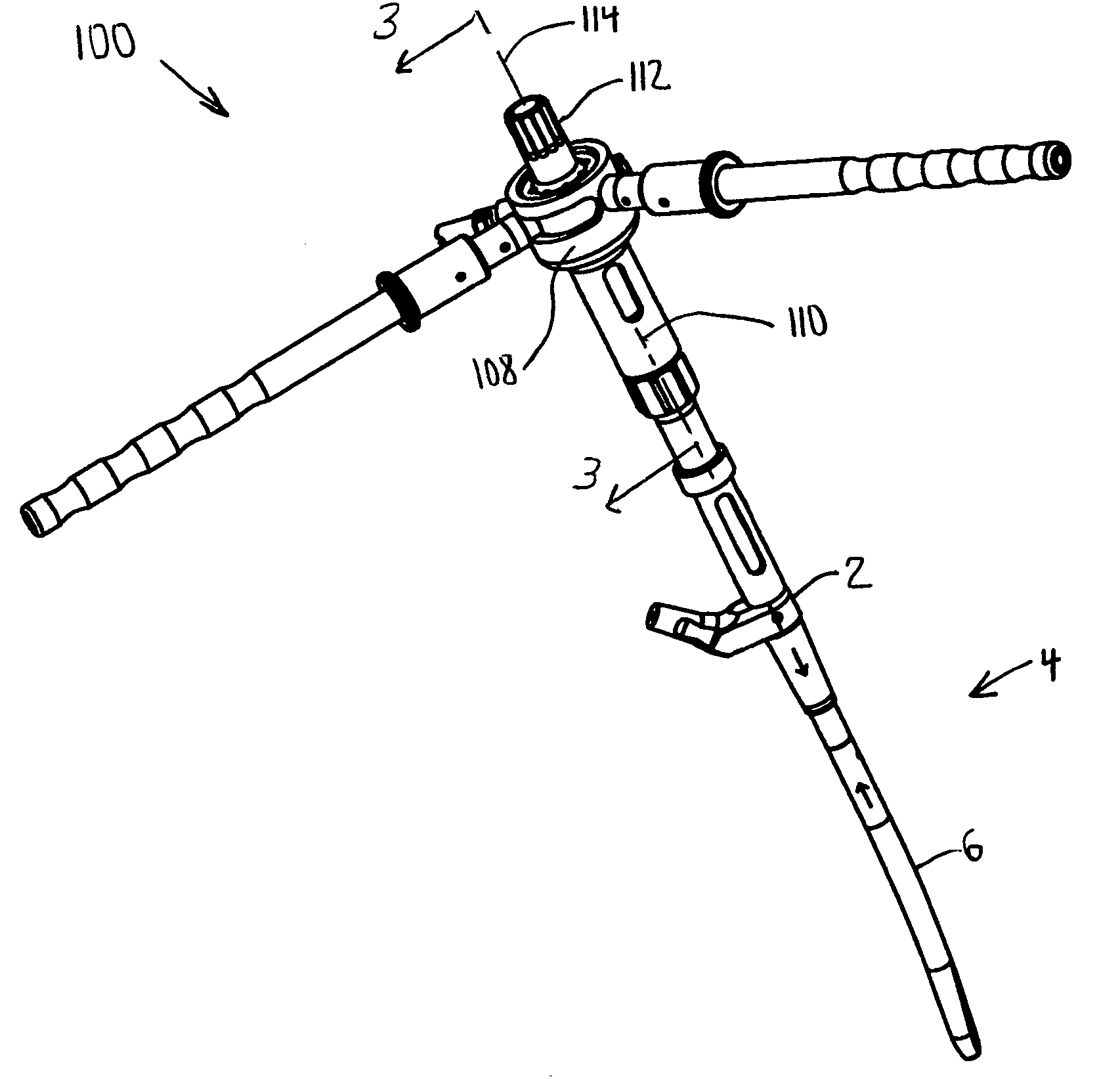

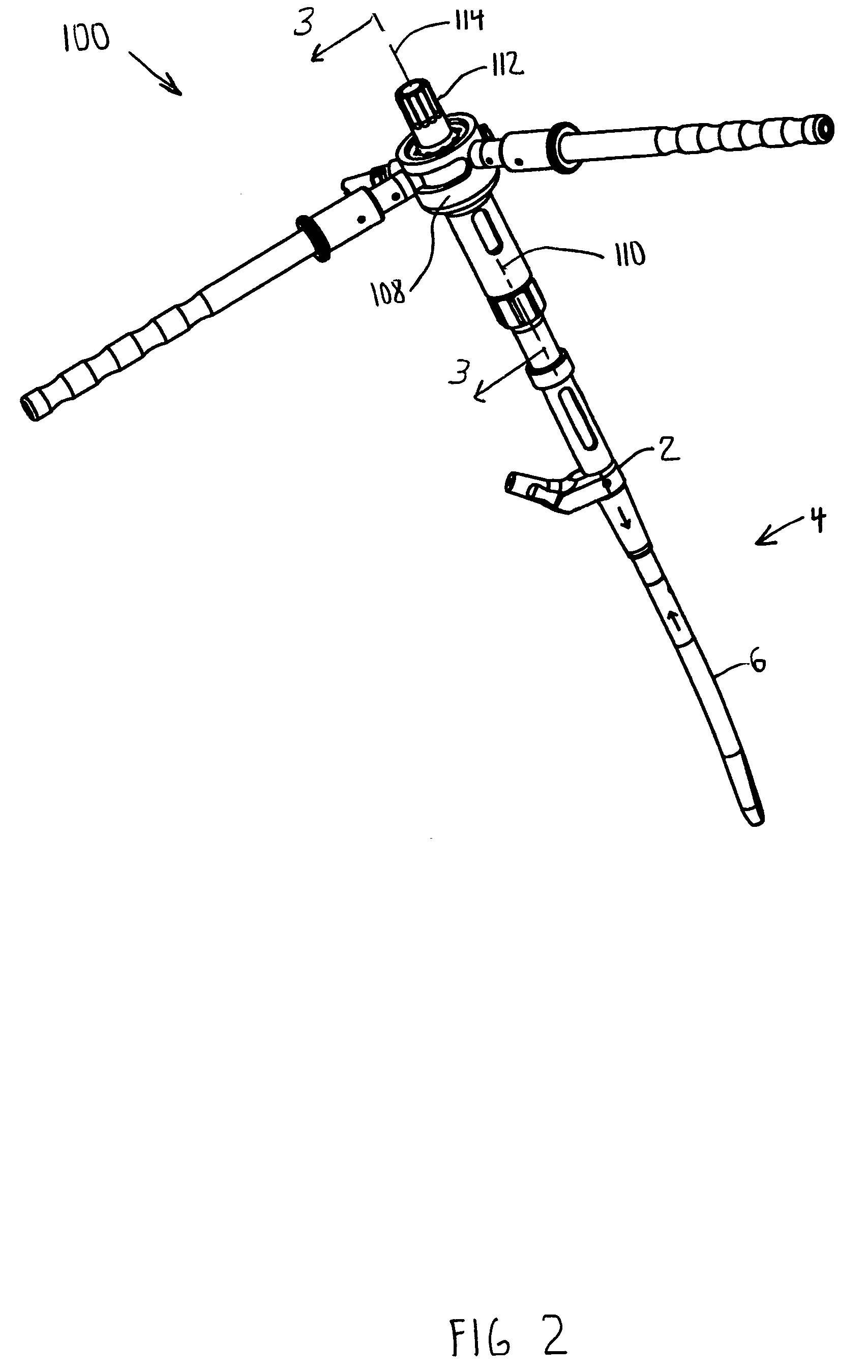

Assembly tool for modular implants and associated method

InactiveUS7297166B2Easy to holdSimple optimum ergonomicsJoint implantsFemoral headsJoint arthroplastyProsthesis

An assembly tool (1) for assembly of a first component (2) of a prosthesis (4) to a second component (6) of the prosthesis (4) for use in joint arthroplasty is provided. The tool (1) includes a first member (8) operably associated with the first component (2). The first member (8) defines a first member longitudinal axis (10) of the first member (8). The tool also includes a second member (12) operably associated with the second component (6). The second member (12) defines a second member longitudinal axis (14) of the second member (12). The second member (12) is adapted to provide relative motion of the second member (12) with respect to the first member (8) when the second member (12) is rotated relative to the first member (8) about the second member longitudinal axis (14).

Owner:DEPUY PROD INC

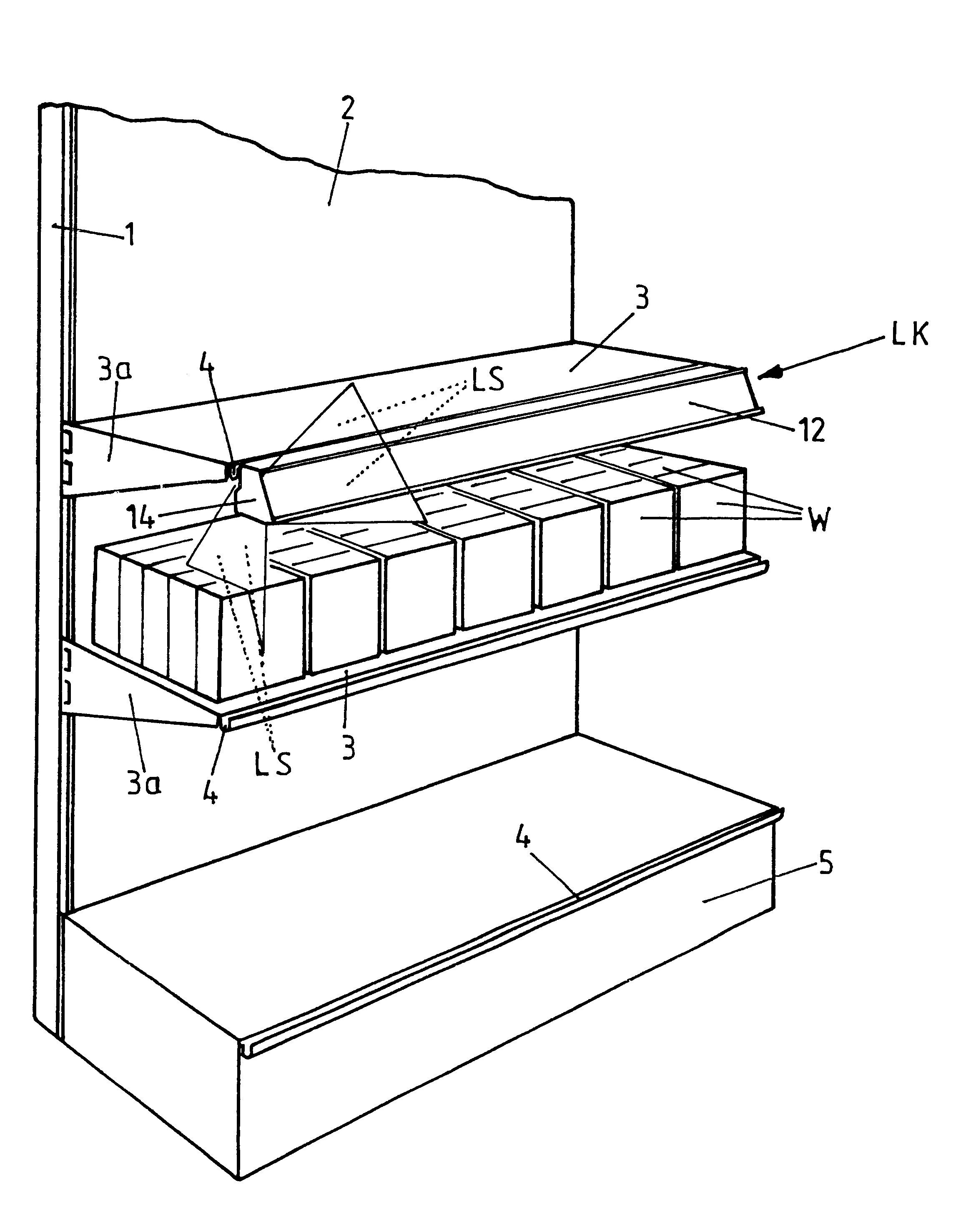

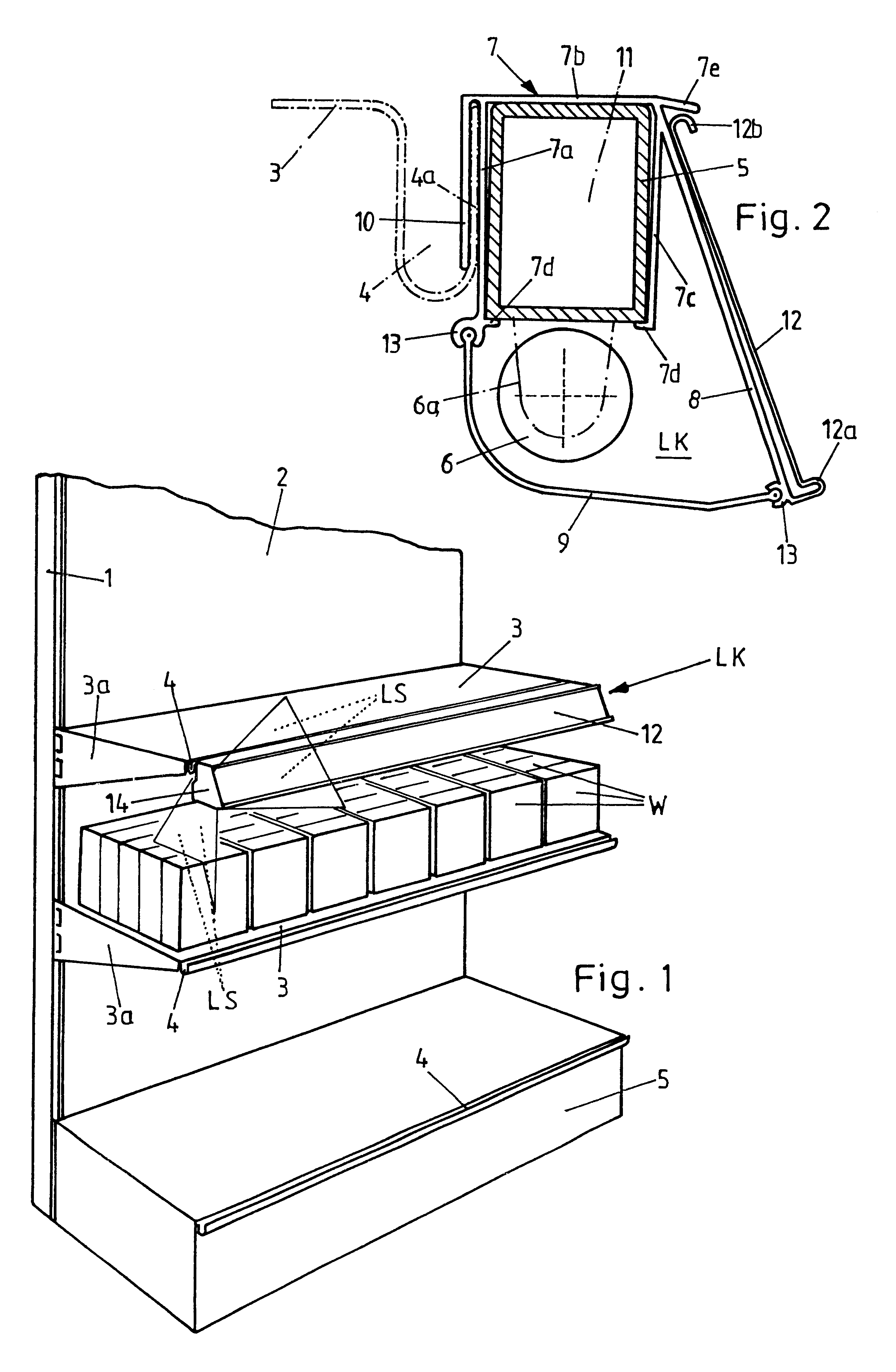

Rack lamp

InactiveUS6276810B1Simple and inexpensive designEasily and securely and removably fastenedShow cabinetsLighting applicationsLight beamEngineering

Disclosed is a lamp for a display stand or a rack, to be secured to a shelf and designed as an adaptable lamp to be removably hung at the shelving edge (3) and to project light beams (LS) on the shelf front face and the lower part of the display rack (3). The inventive adaptable lamp resembles a light channel to be fitted into a U-shaped moulding in the rack front face (3) in such a way that it occupies the whole width of the light channel, in which both the lamp casing and the lamp itself, preferably a set of fluorescent lamps, are incorporated. The light channel (LK) profile (7) is designed so that the channel can house the lamp casing in a fixed position (5), and that the front and lower profile area (8, 9) can let the light beams (LS) through.

Owner:DECOR METALL KARL BECKER

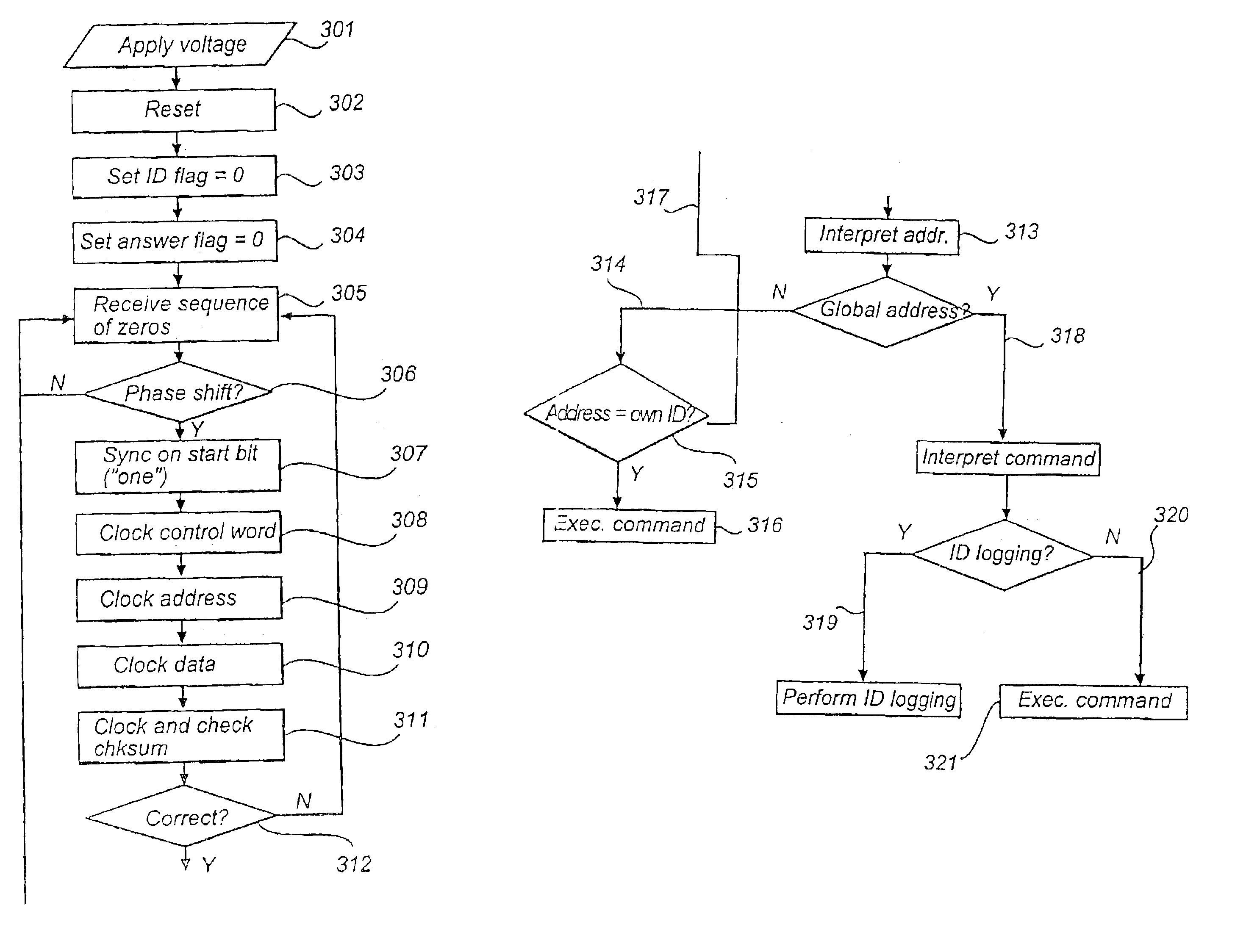

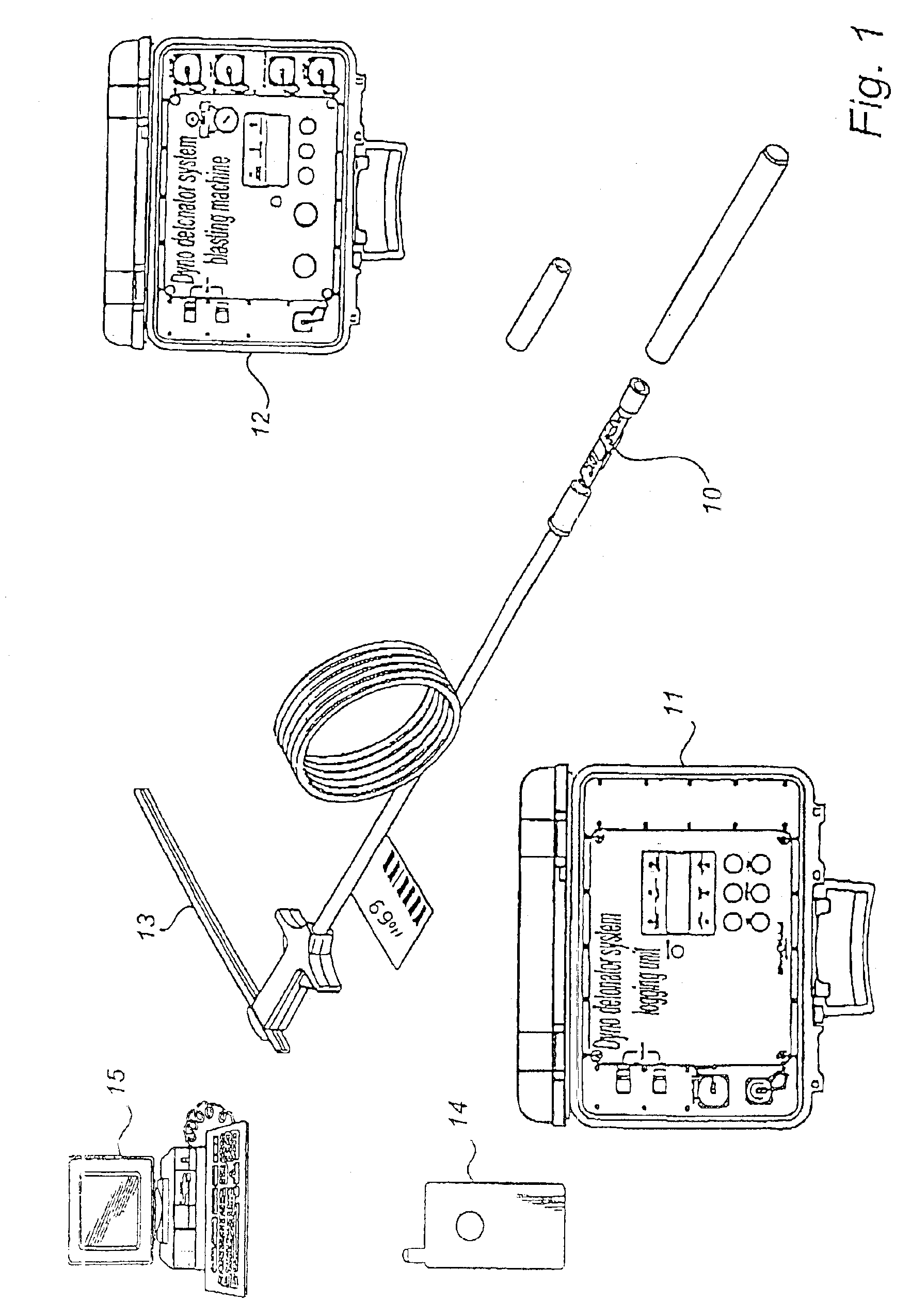

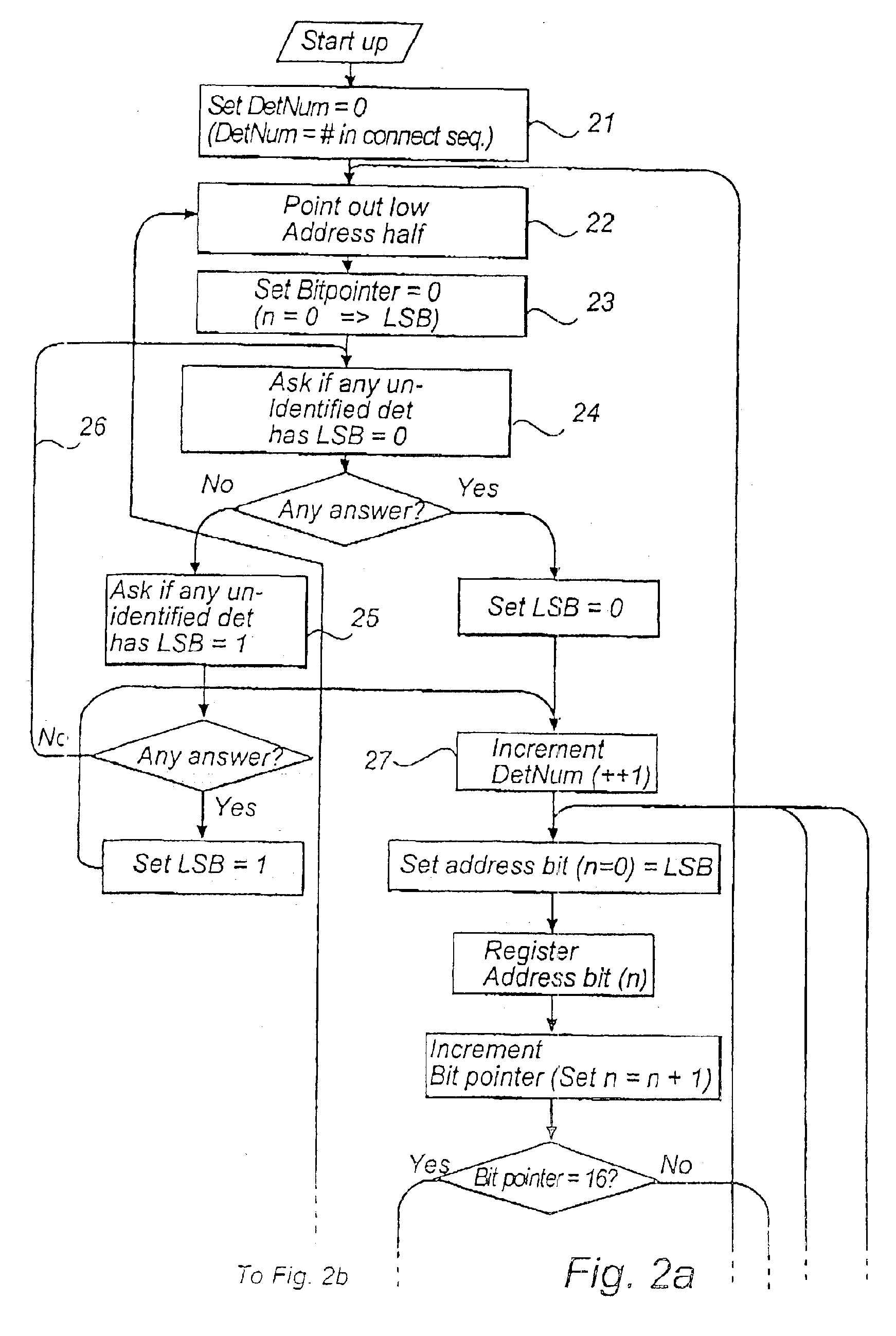

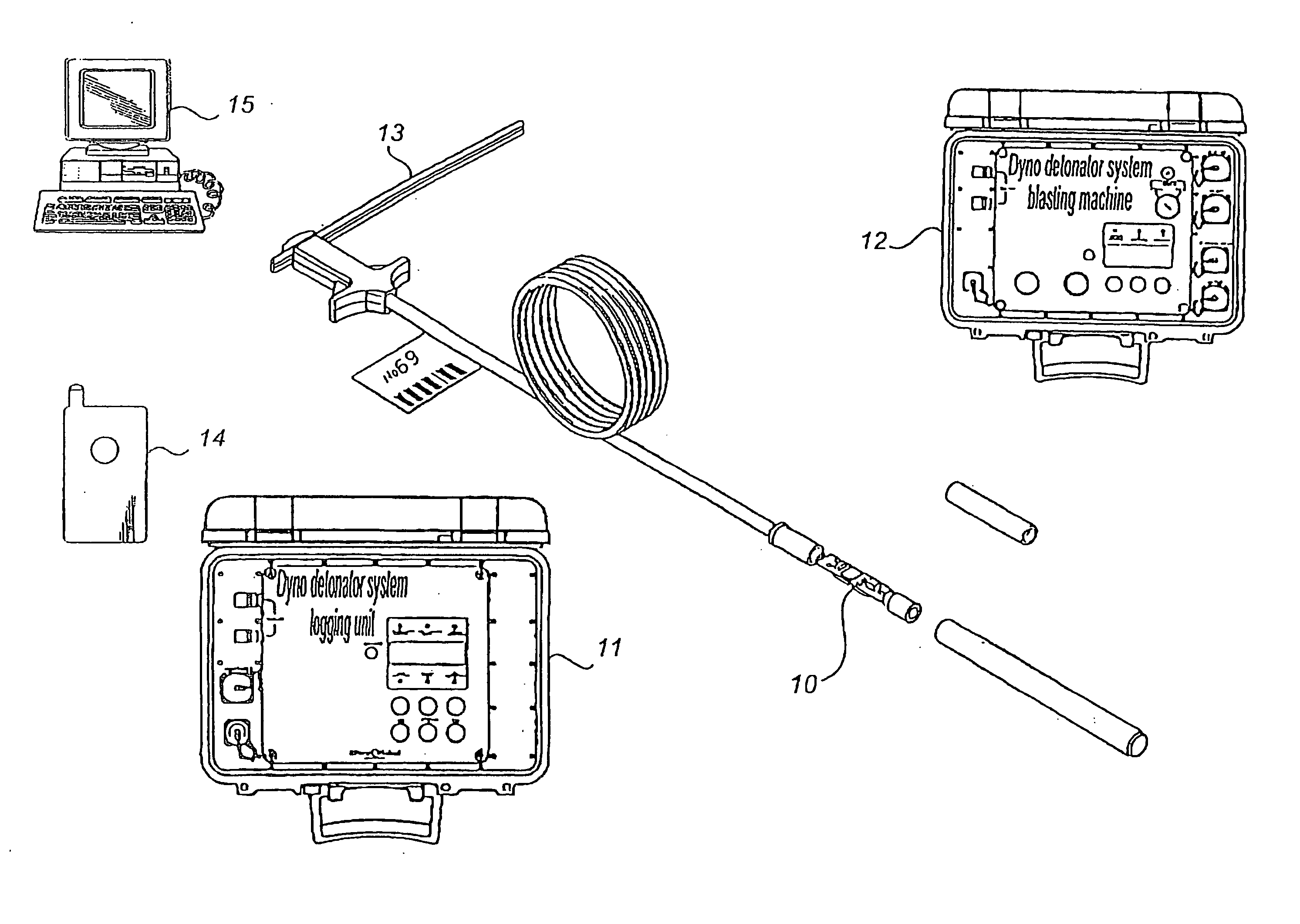

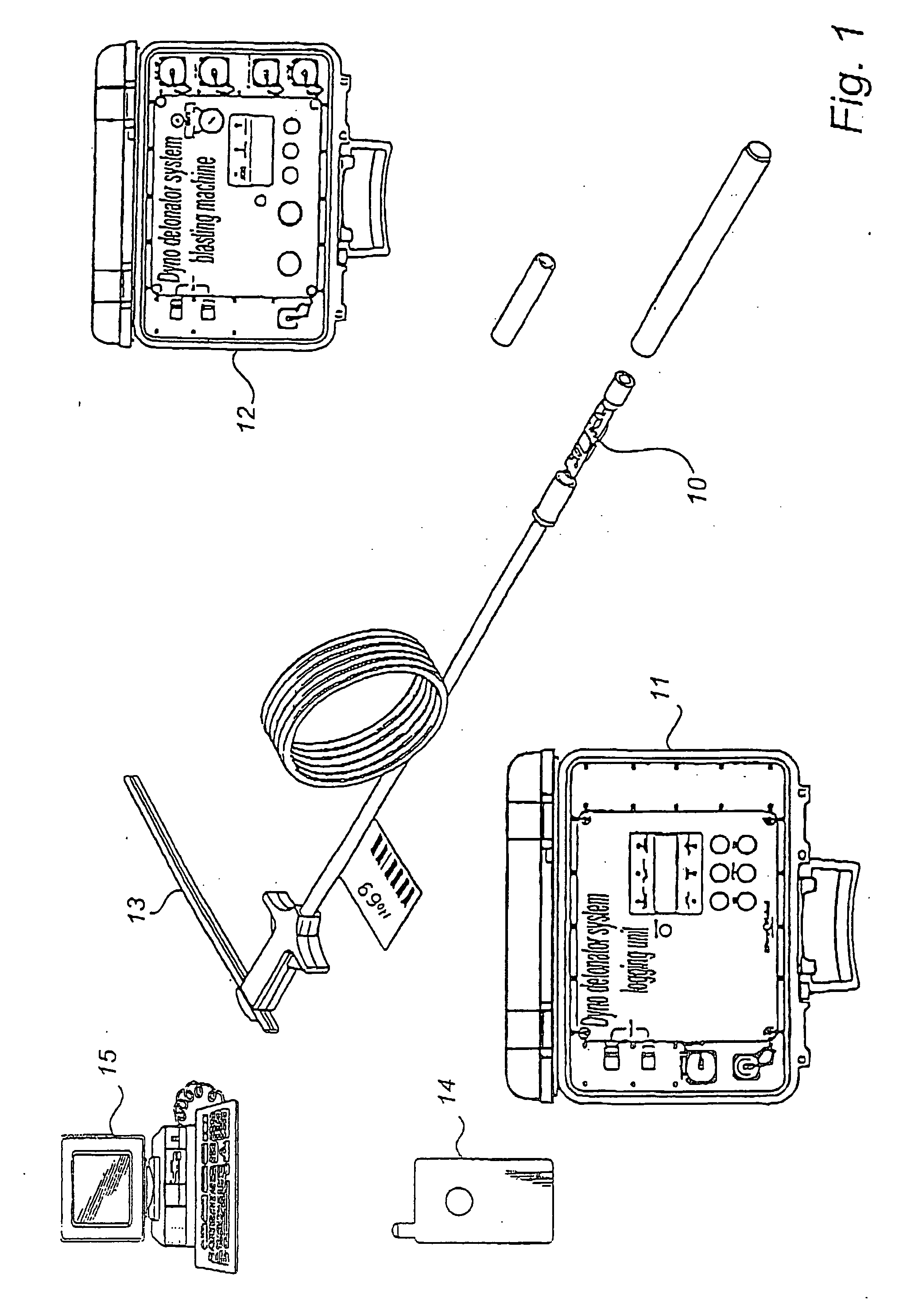

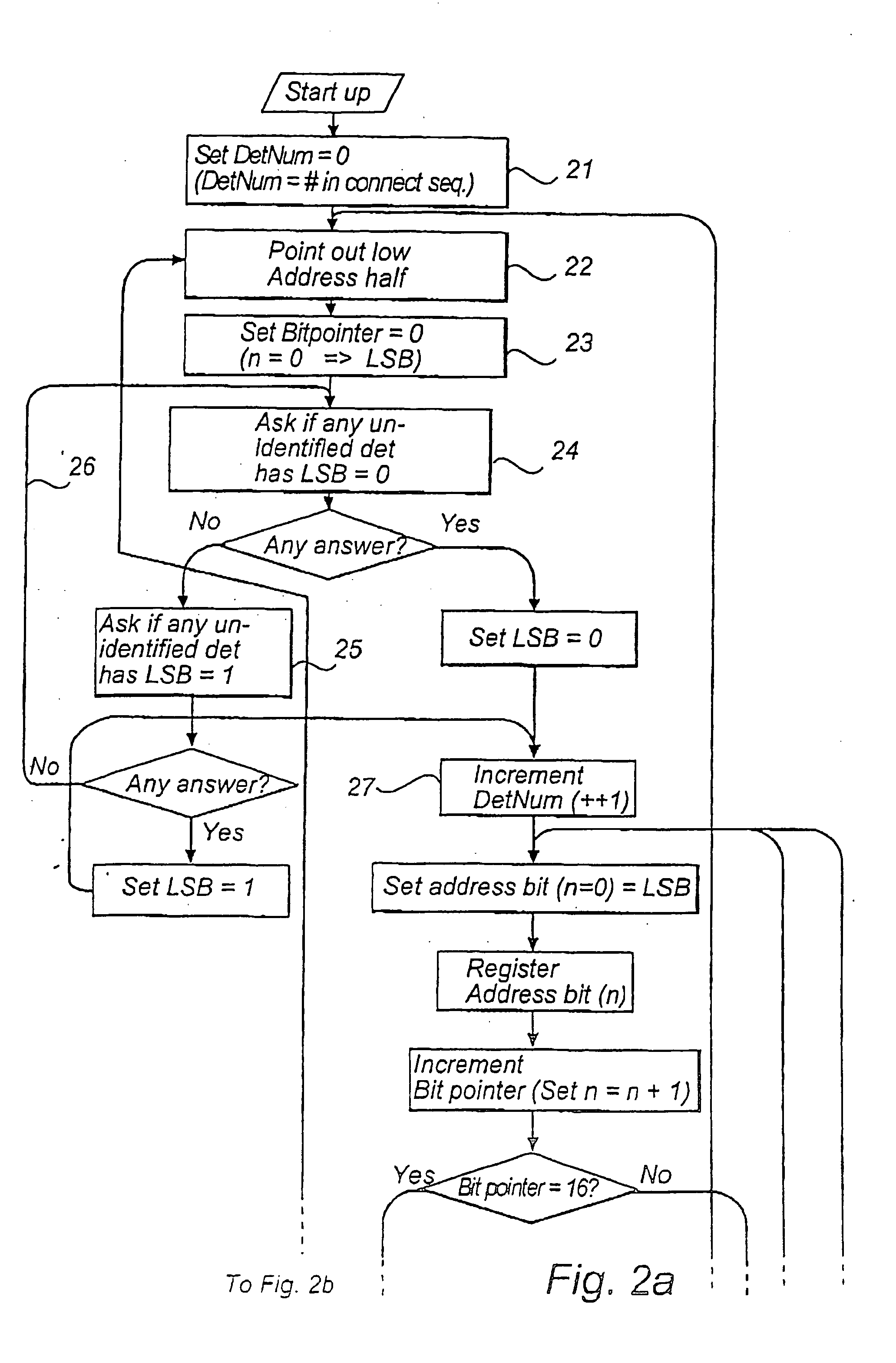

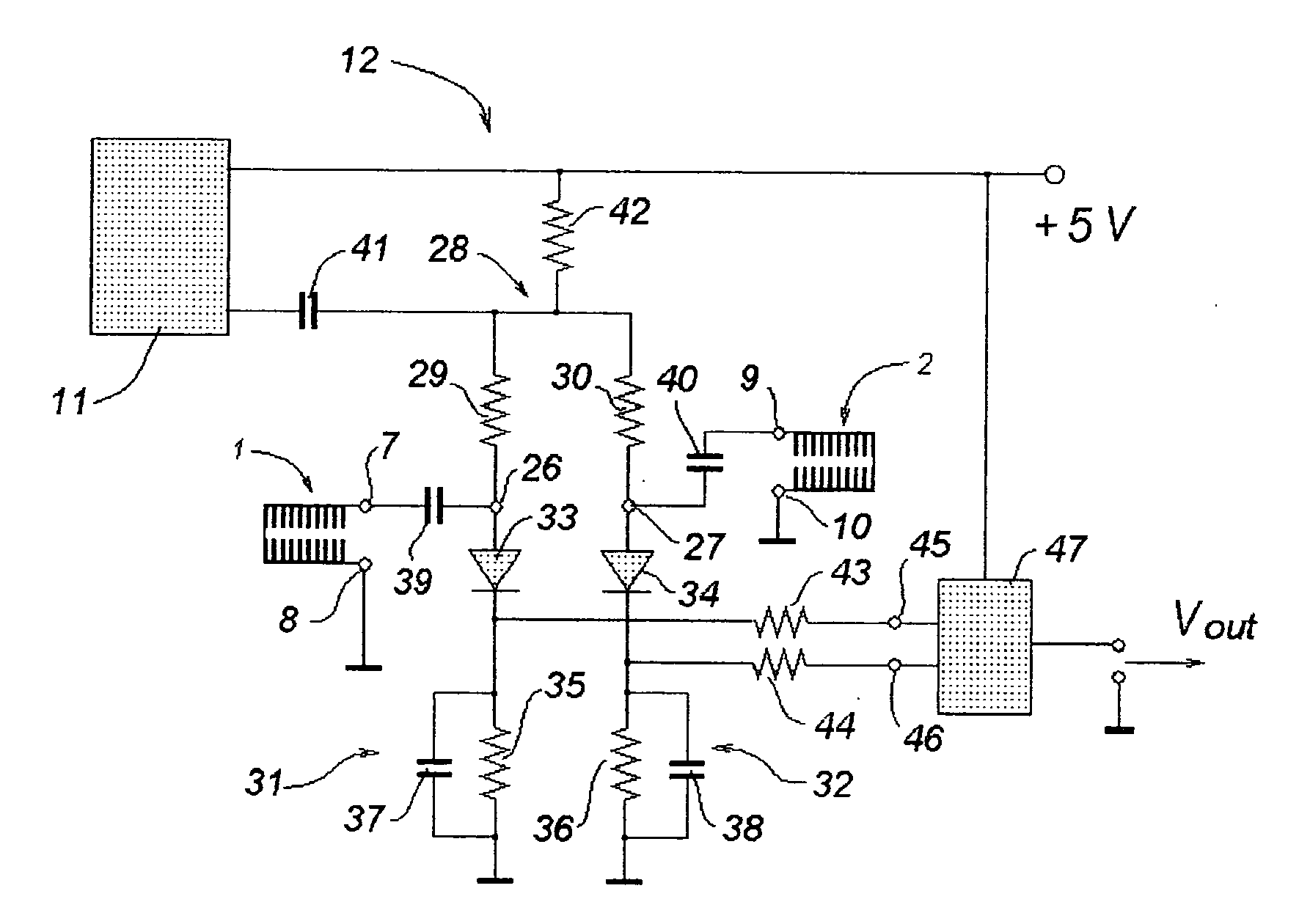

Flexible detonator system

InactiveUS6837163B2Simple and inexpensive designSimple designIncandescent ignitionBlastingDigital dataDetonator

An electronic detonator system includes a control unit, a plurality of electronic detonators and a bus which connects the detonators to the control unit. Each electronic detonator includes a number of flags which may assume either of two possible values, each flag indicating a substate of the respective detonators. The flags are readable from the control unit by means of digital data packets and the control unit is adapted, by means of these flags, to check the state of the electronic detonator and control the operation of the electronic detonator. When reading the flags, the electronic detonators give responses in the form of analog response pulses on the bus. The detonator system also includes a portable message receiver which on the basis of the flags obtains messages regarding the connecting status of a detonator.

Owner:DETNET SOUTH AFRICA (PTY) LTD

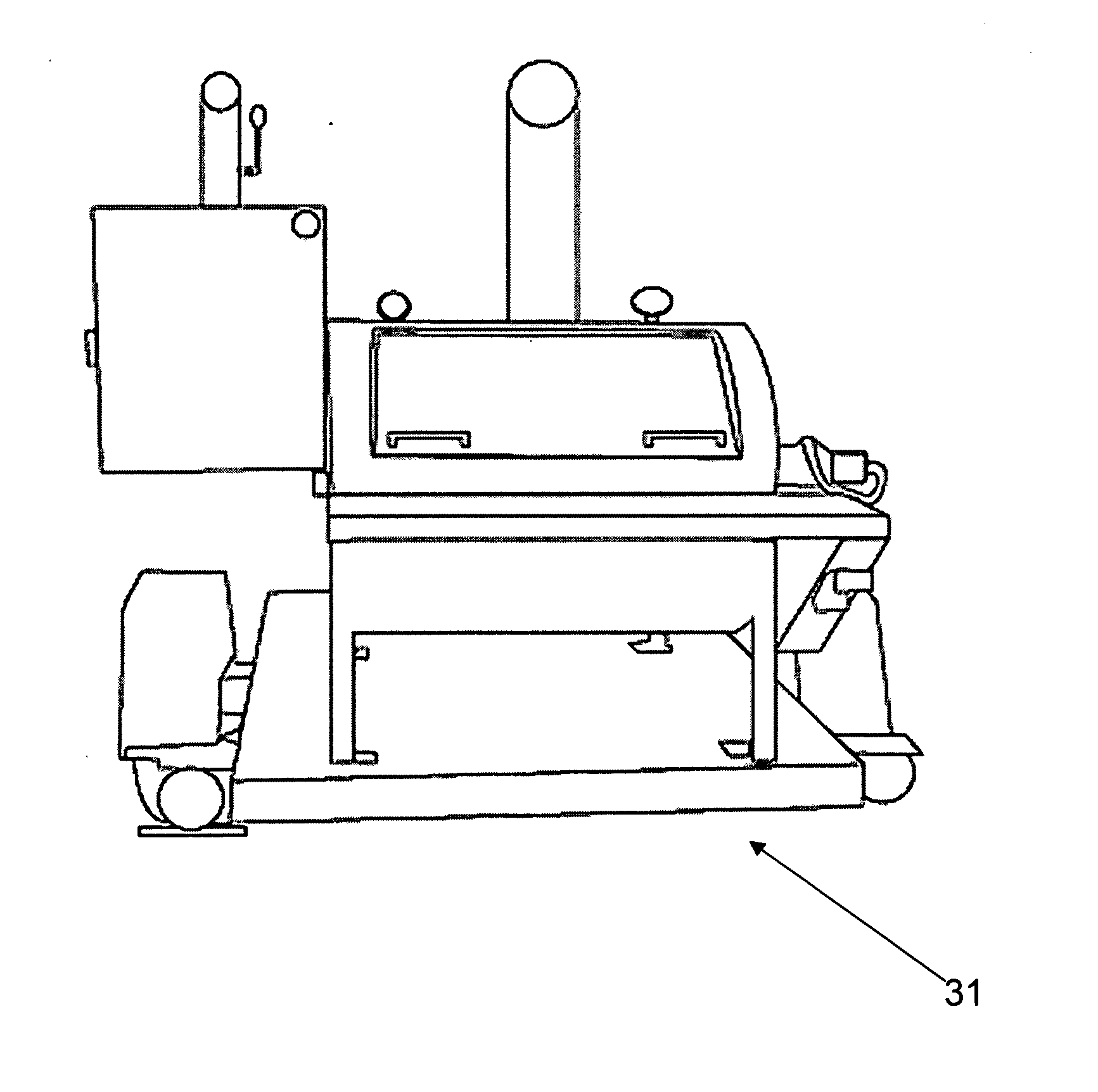

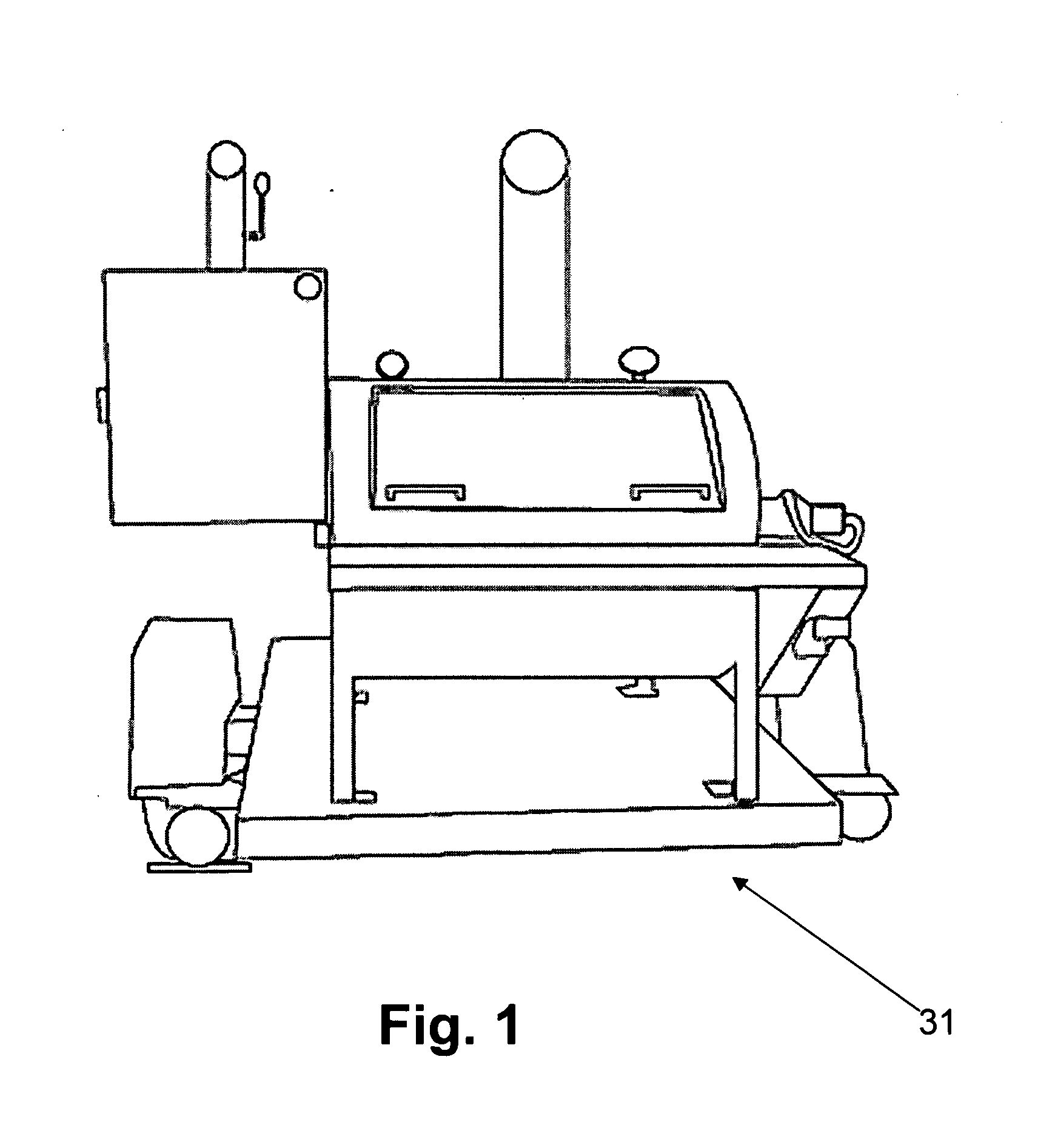

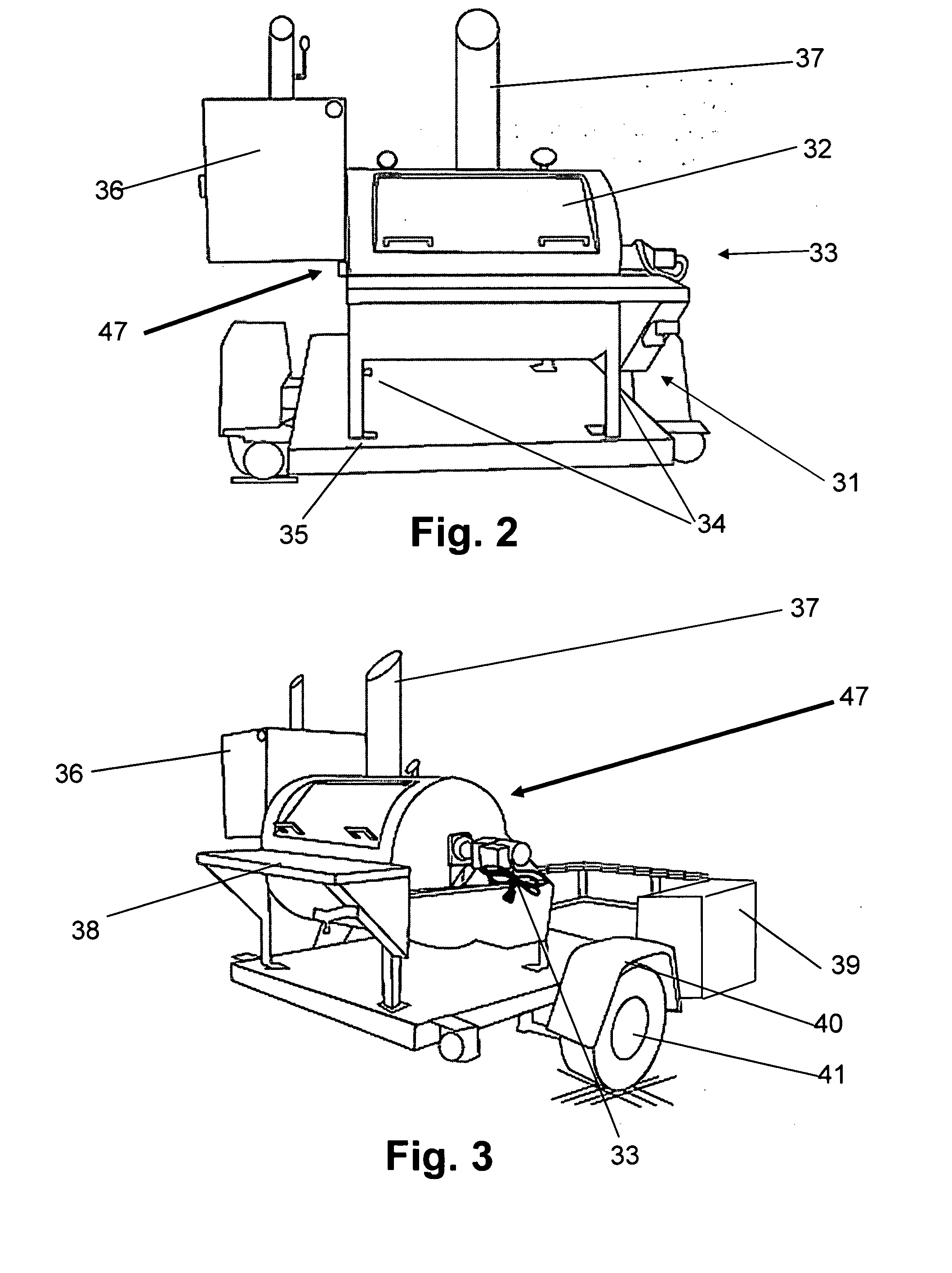

Transportable cooking and smoking barbeque

InactiveUS20050155498A1Improve majoritySuperior fireboxAir-treating devicesFood preparationStart up timeEngineering

The IMPROVED and TRANSPORTABLE COOKING AND SMOKING BARBEQUE APPARATUS is an apparatus that is often called a Smoker. The device may be utilized as a stand alone Smoker to cook and smoke various foods such as meat and fish, fruits and vegetables. The device may be freestanding or on a portable set of wheels or trailer. The main components of this invention are comprised of a cooking chamber with a food rotisserie, a firebox, a draft system for controlling the air, and various options to enhance the convenience of the device. These main components have additional features to improve the start-up time to attain the temperature desired and sealing features which permit the smoke and heat to be well controlled.

Owner:KILLION RONALD B

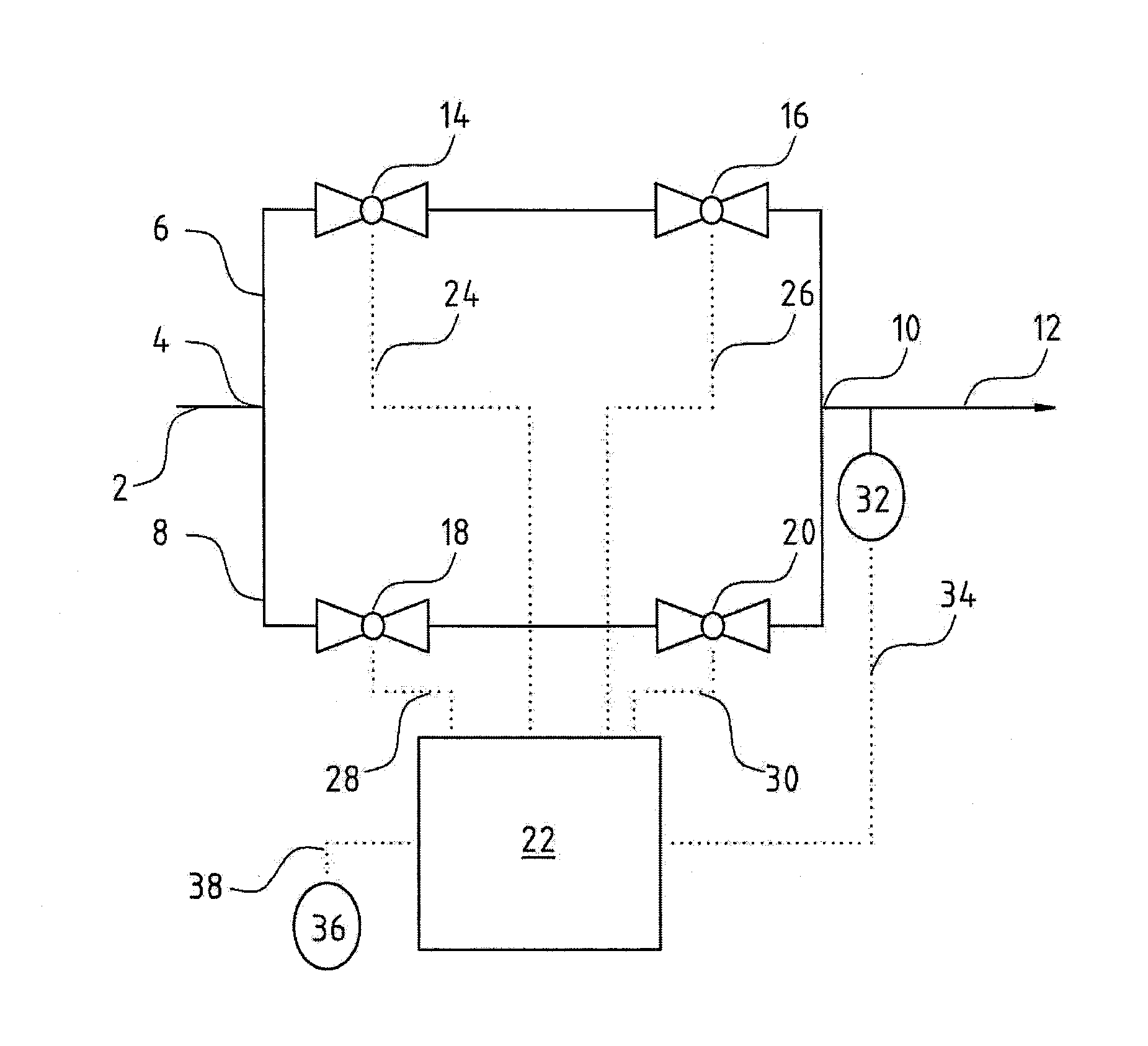

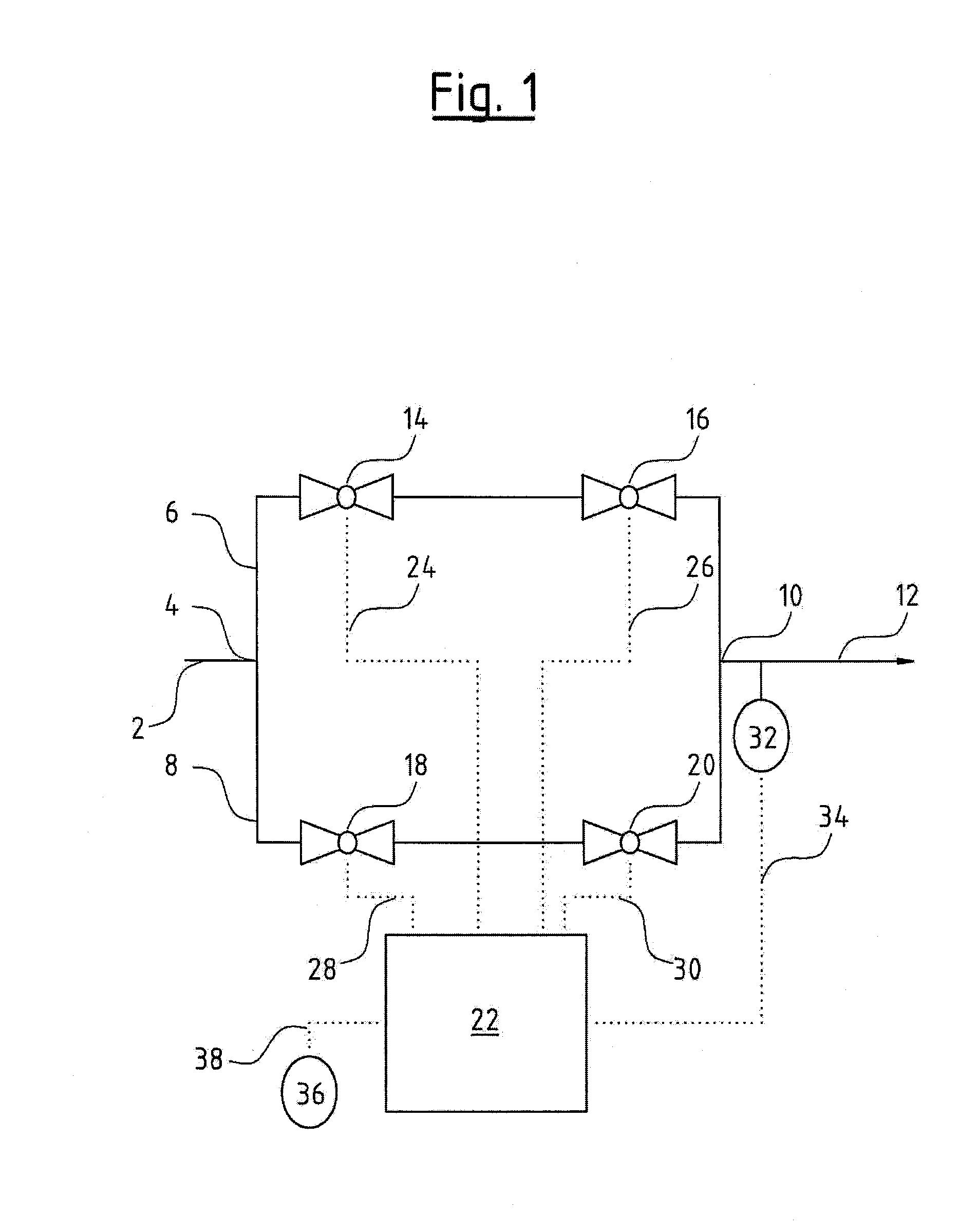

Pressure regulation device, in particular for an oxygen emergency supply system in an aircraft

InactiveUS20080053541A1Simple and inexpensive designImprove reliabilityOperating means/releasing devices for valvesFlying suitsEmergency SupplyEngineering

A pressure regulation device is provided, in particular for an oxygen emergency supply system in an aircraft. The device includes at least two parallel conduits in each of which at least two controllable valves are arranged in series. Further, a pressure sensor is arranged on the exit side of the valve arrangement, for the detection of the actual pressure value, and a controller is provided, which is signal-connected to the pressure sensor and controls the valves.

Owner:DAE SYST

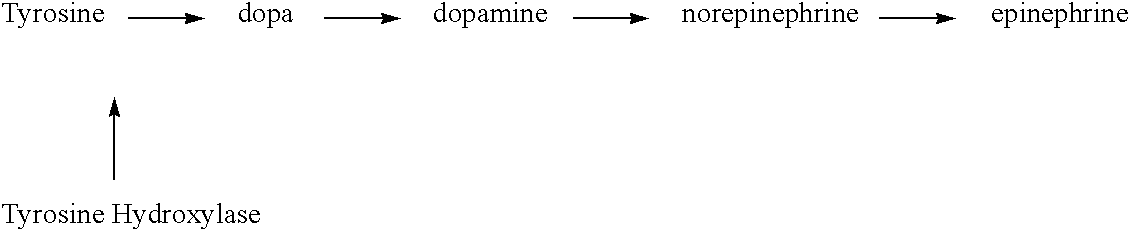

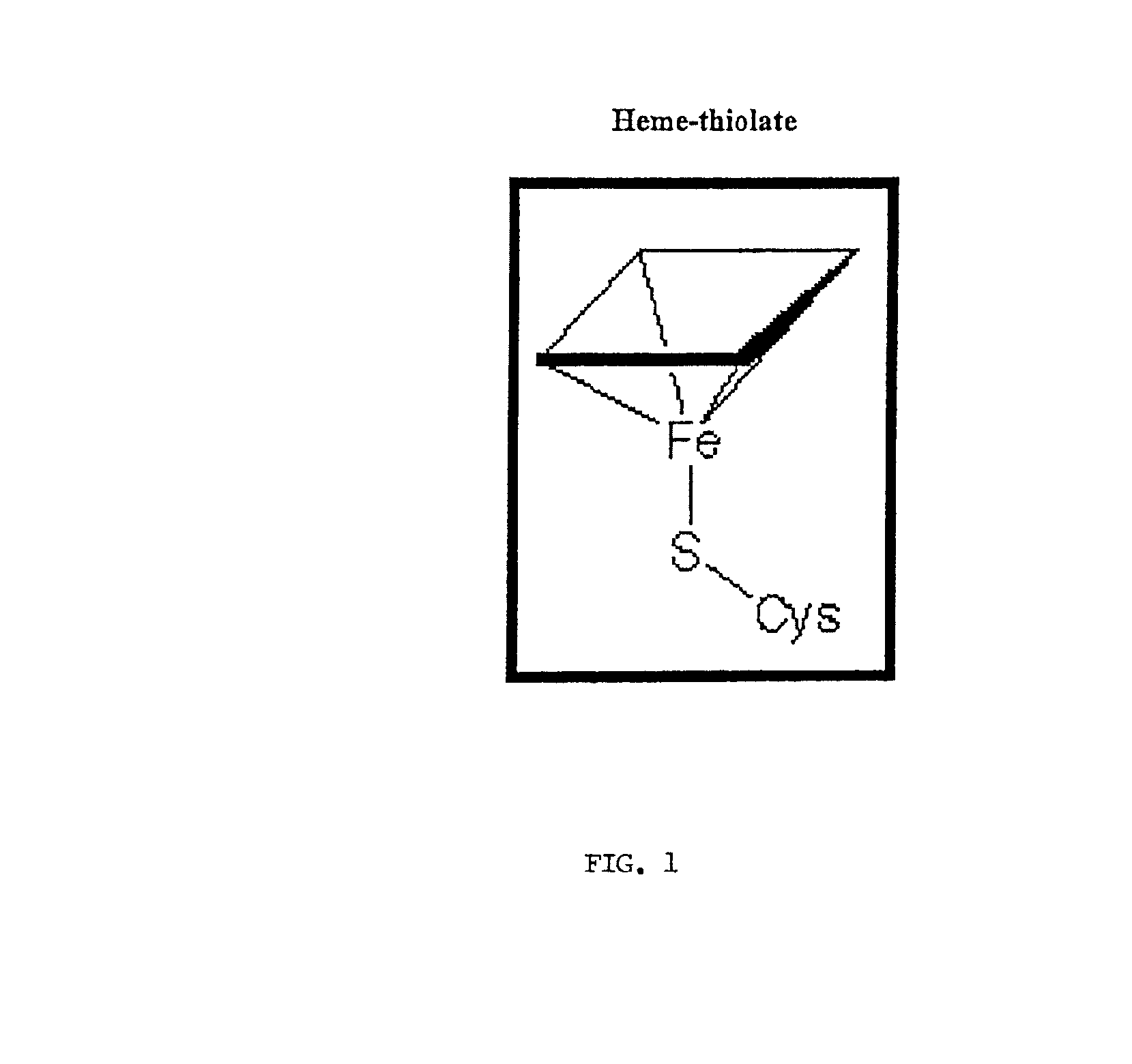

Comprehensive pharmacologic therapy for treatment of obesity including cysteine

InactiveUS20050065190A1Simple and inexpensive designWithout fear of injury to personsBiocidePeptide/protein ingredientsDiethylpropionVitamin C

The comprehensive pharmacologic therapy for treatment of obesity including Cysteine is a procedure which involves the administration of a desired therapeutic range of Diethylpropion and / or Phentermine in combination with a SSRI medication and nutritional supplementation for brief and long durations which may be 12 months or more. The preferred procedure involves the administration of drugs in combination which are identified as: Citalopram (Celexa) and Phentermine; Citalopram (Celexa) and Diethylpropion; Citalopram (Celexa), Phentermine, and Diethylpropion. In addition nutritional supplementation such as a multivitamin, 5-Hydroxytryptophan, Cysteine, vitamin B6, vitamin C, Tyrosine, Calcium, and Lysine may be used to enhance the performance of the weight loss treatment program.

Owner:FEDERAL LAW ENFORCEMENT DEV SERVICES

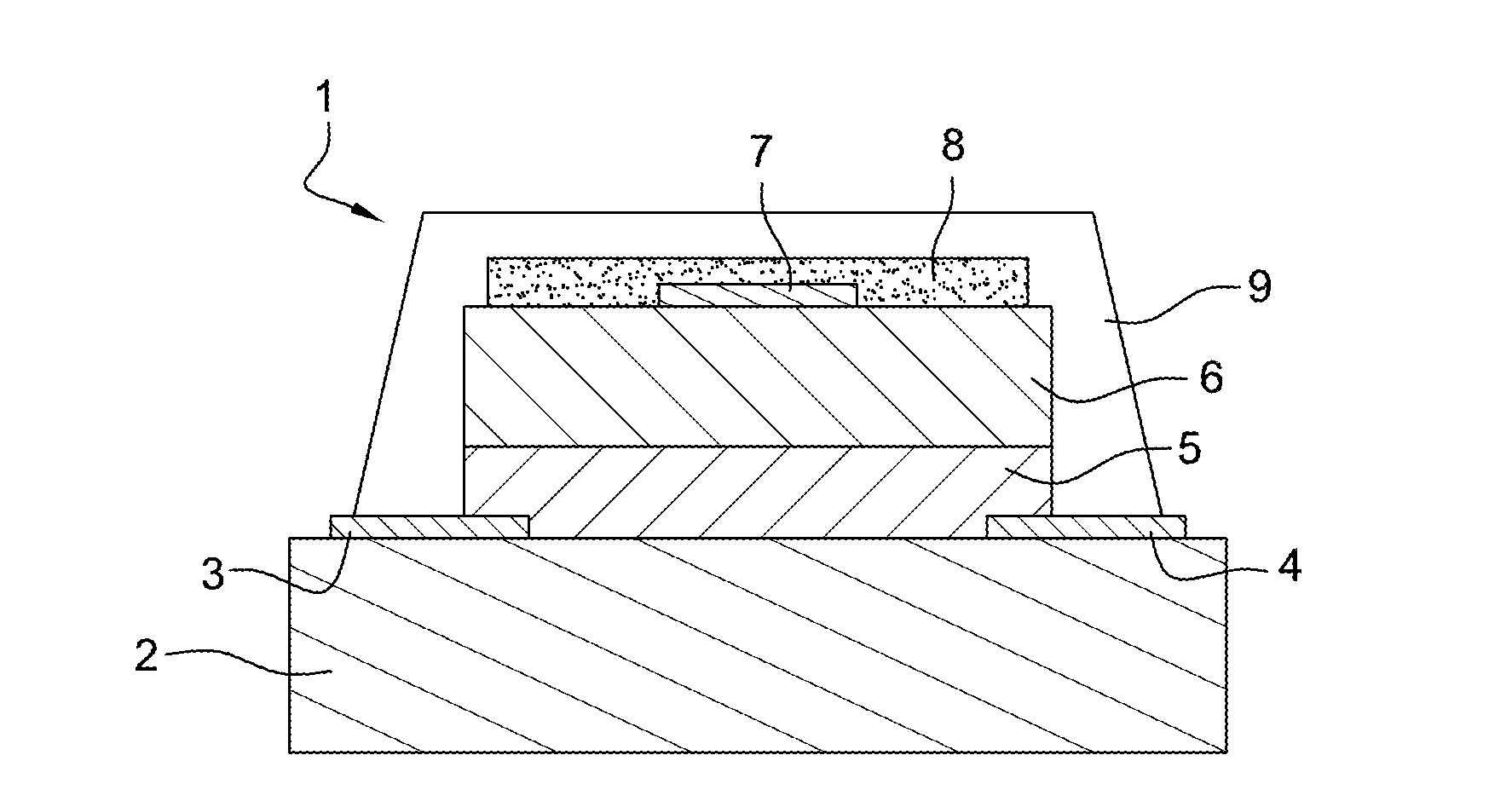

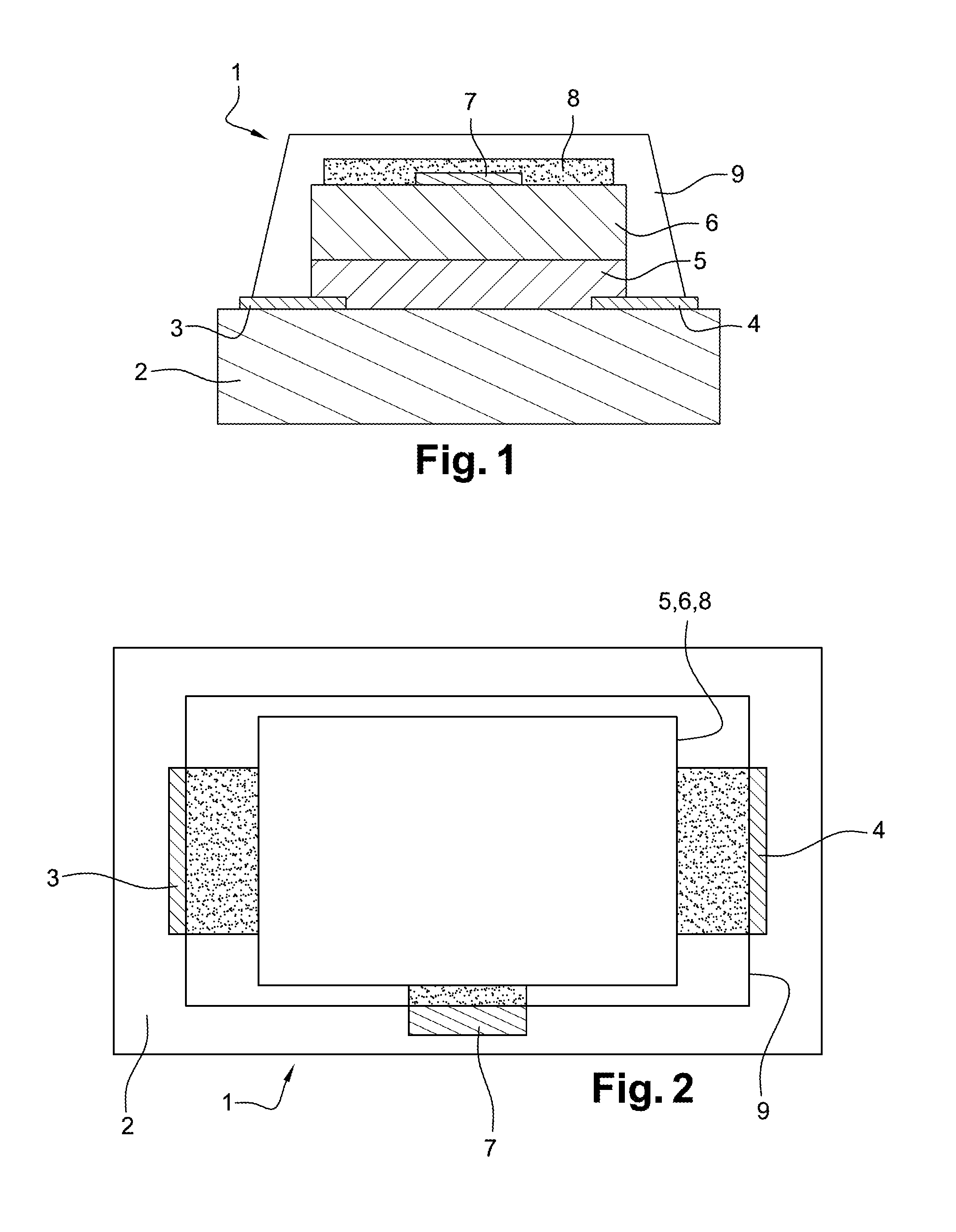

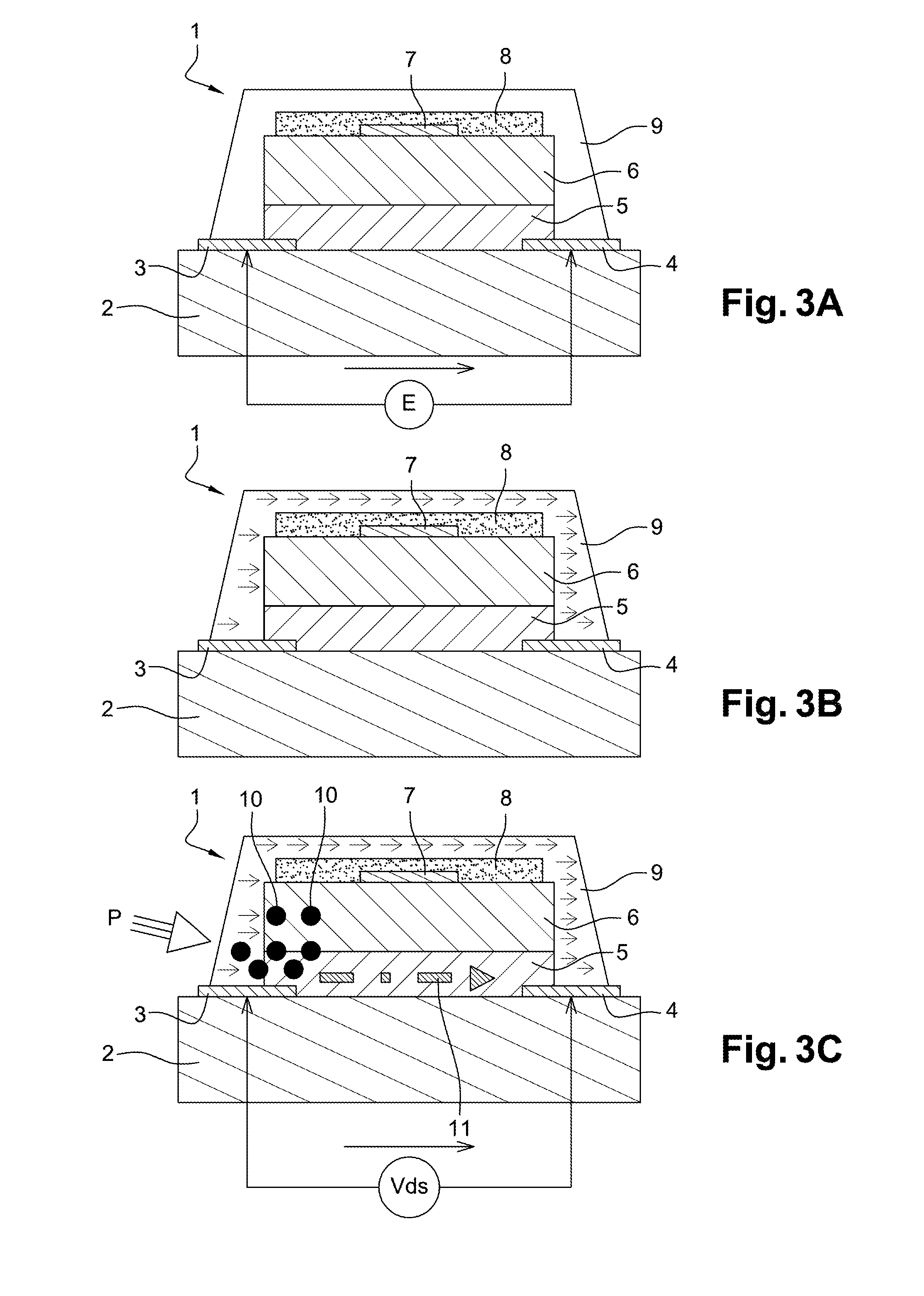

Piezoelectric pressure sensor

ActiveUS20140191221A1Simple and inexpensive designHigh measurement sensitivityFluid pressure measurement using piezo-electric devicesAcceleration measurement using interia forcesPhysicsPressure sensor

A pressure sensor including a lower substrate having two electrodes partially covered with a semiconductor layer and a piezoelectric layer made of a piezoelectric material, and in contact with the semiconductor layer in such a way that semiconductor material is in contact with the piezoelectric material and with the two electrodes, deposited thereon. The electrodes are intended to be connected to a voltage source or to a device for measuring the intensity of a current generated by the displacement of the electric charges in the semiconductor layer between the electrodes, said electric charges being created when a pressure is exerted on the piezoelectric layer.REPLACEMENT SHEET

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

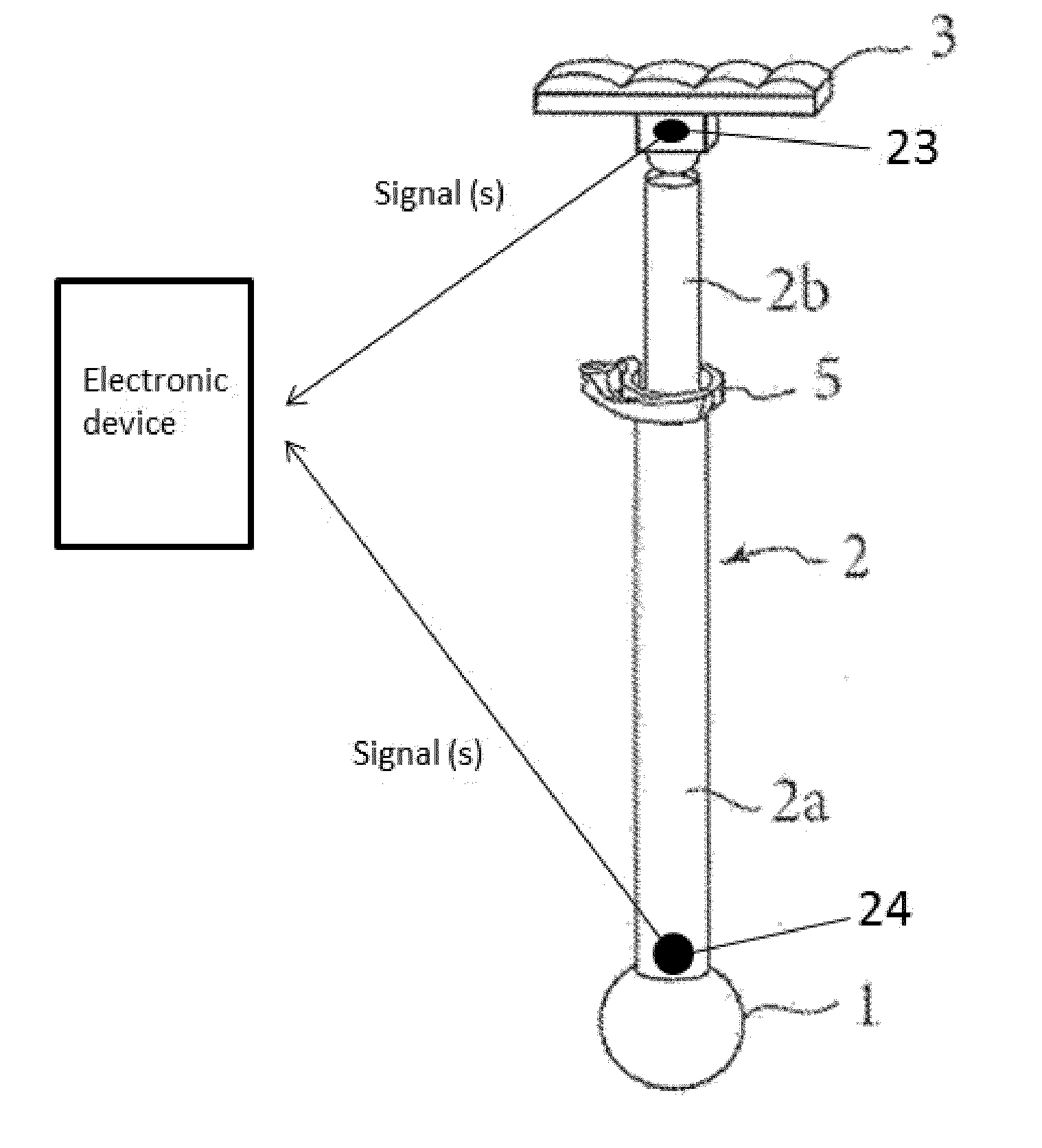

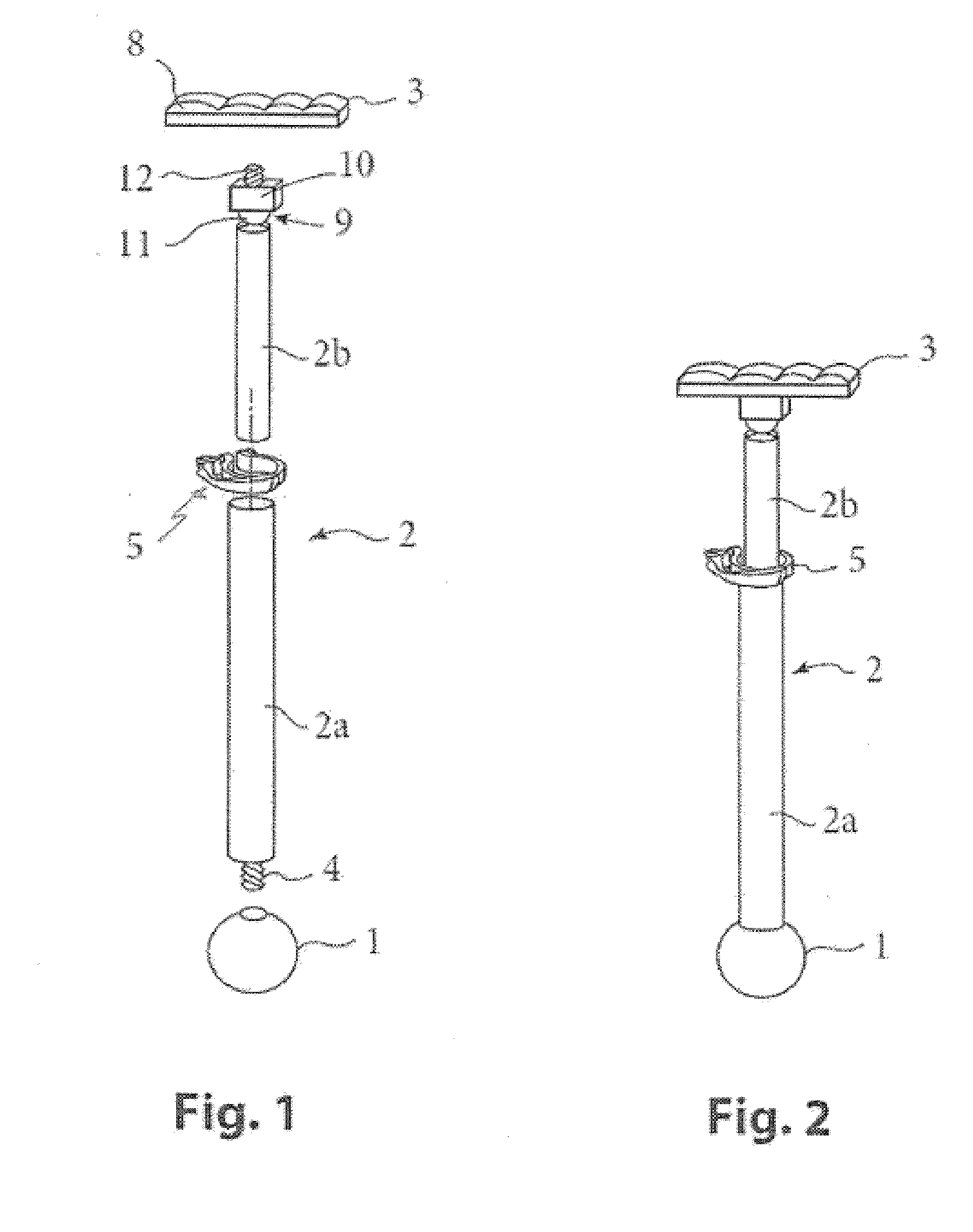

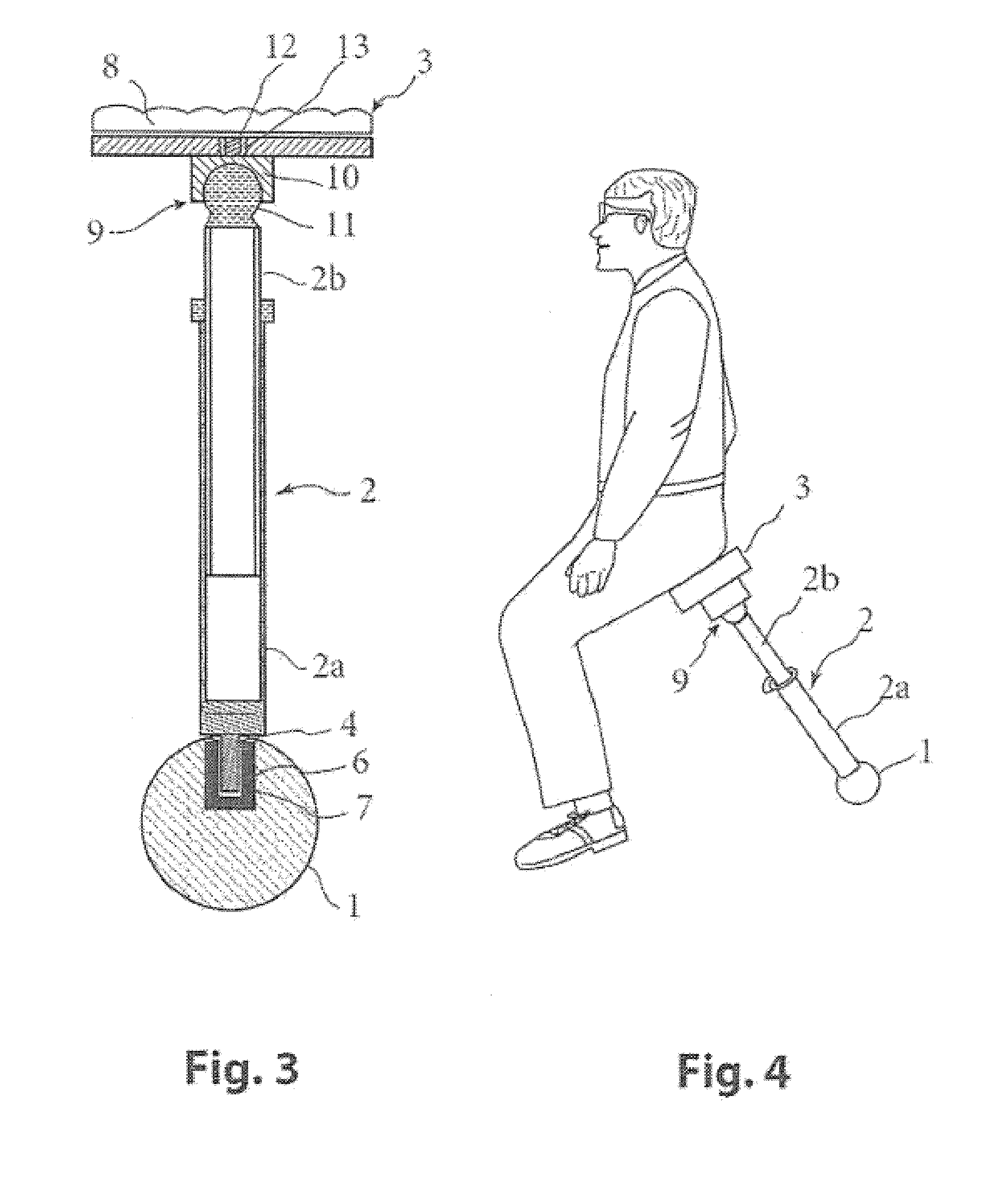

Dynamic pendula stool

ActiveUS20160038780A1Simple and inexpensive designOffice stoolsResilient force resistorsMuscle groupThree degrees of freedom

Disclosed herein is a dynamic pendula stool possessing a foot, a leg secured to the foot, and a seat secured to the top end of the leg. The leg has a telescopic column that includes a lower part secured to a spherical foot with a diameter of 20-cm or less and an upper part with a free end having an articulation. The articulation has three degrees of freedom and is secured to the underside of the seat so that when a user rests against the seat, the leg forms an angle between 30 and 90 degrees with respect to the horizontal, thereby allowing an isometric contraction of the muscle groups of the lower limbs and of the abdominal girdle in the seated position. The stool is further provided with one or more sensors configured to send data signals to a remote electronic device.

Owner:ACTIVE BASE

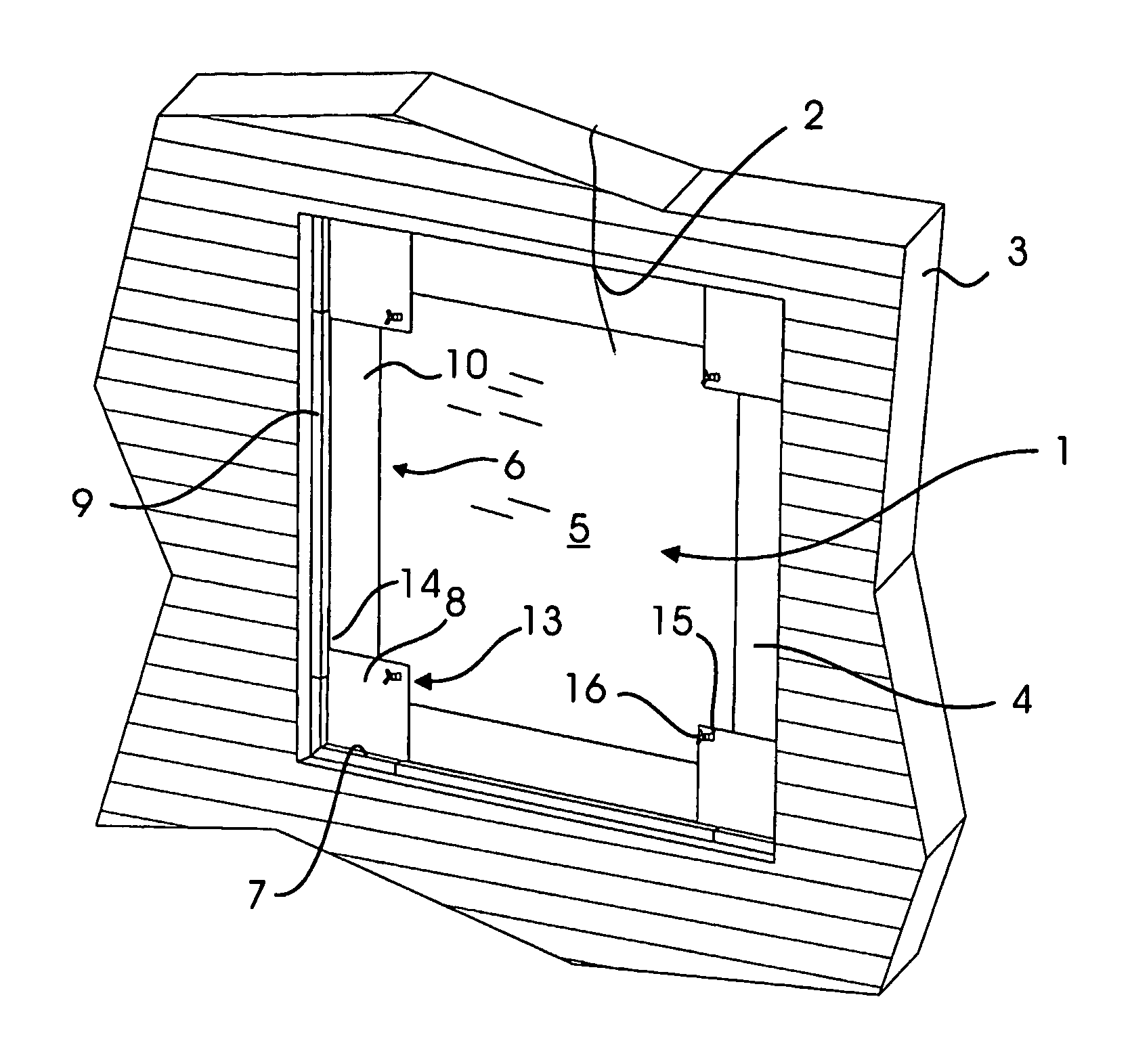

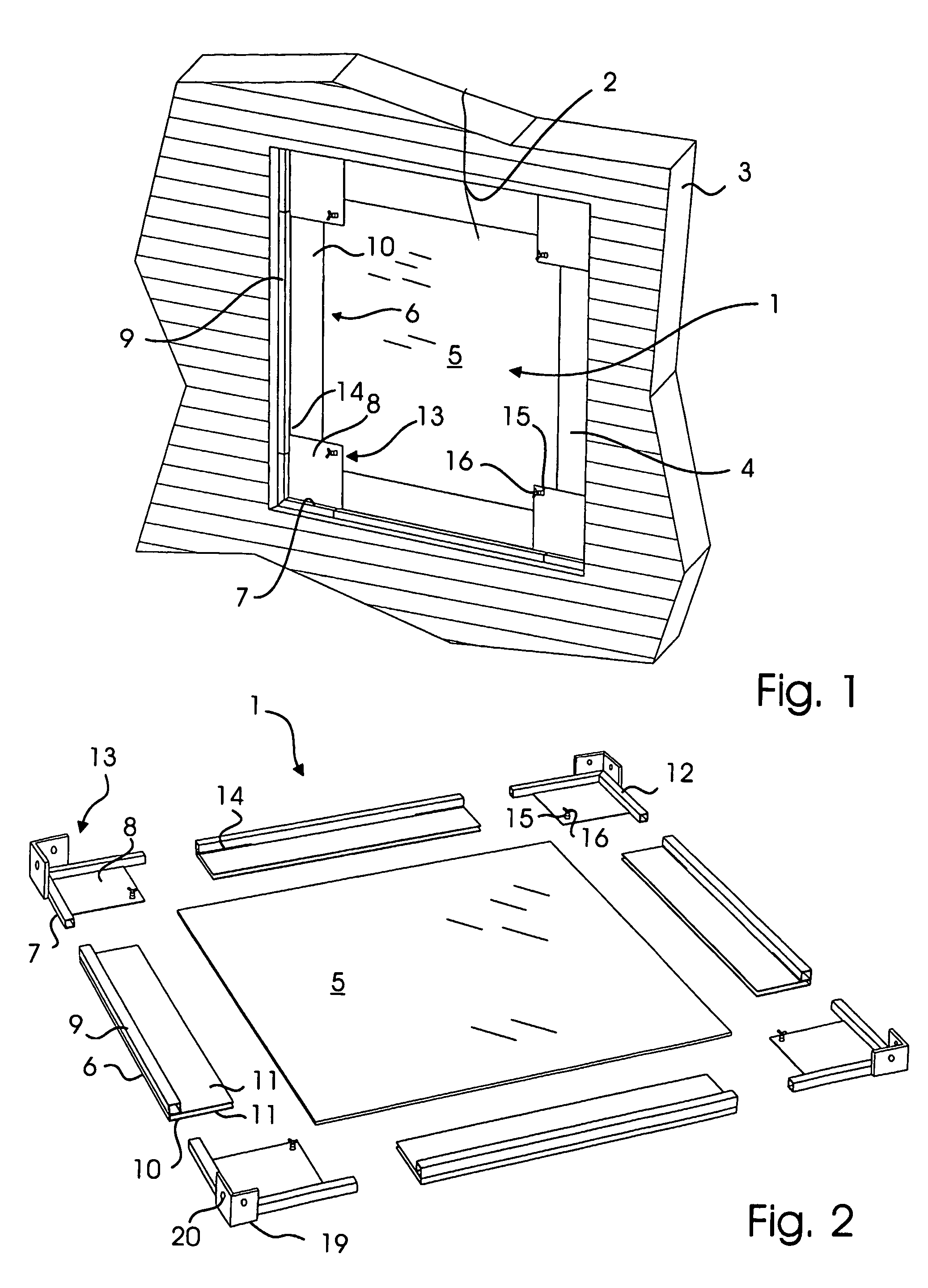

Temporary closure

ActiveUS7624548B2Simple and inexpensive designEasy to changeExtensible doors/windowsCorner/edge jointsPlastic filmFastener

Owner:LASSE RAMSKOV HLDG

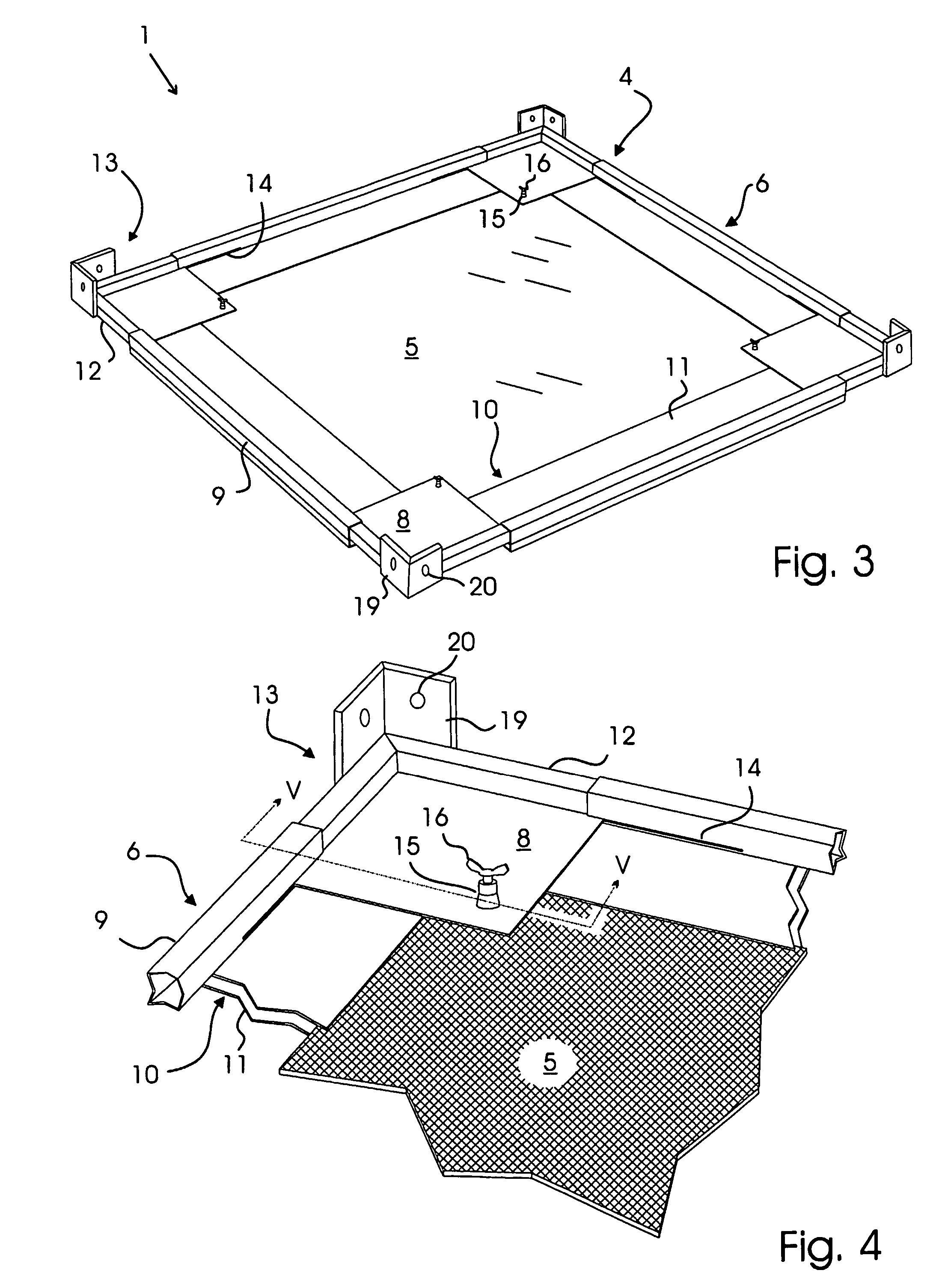

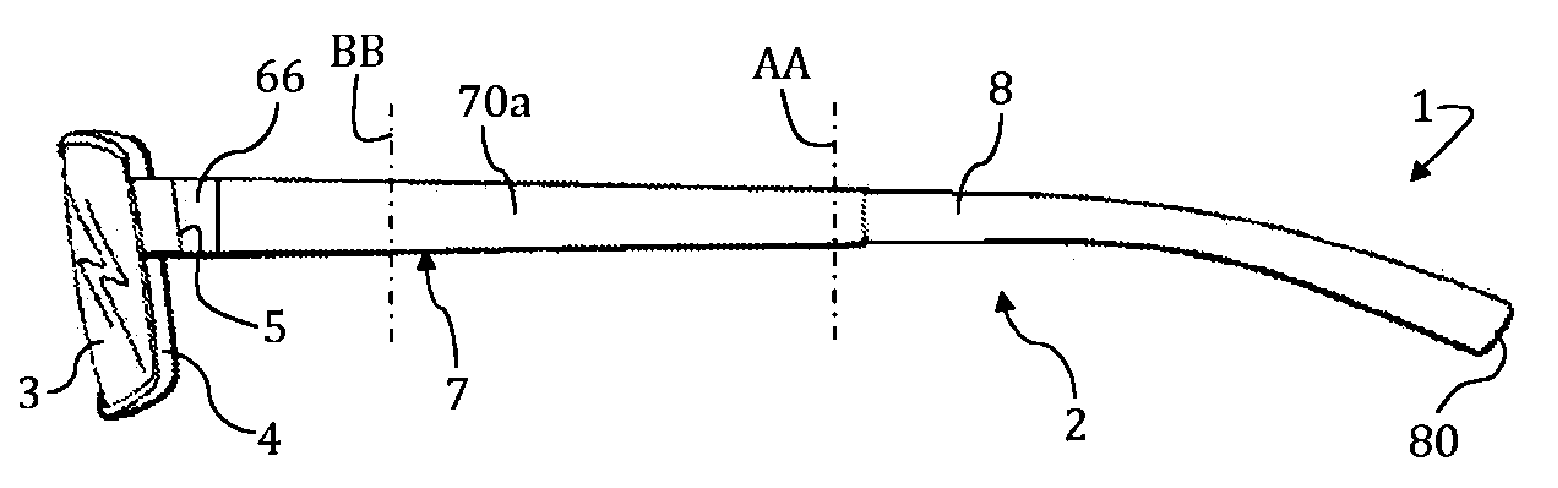

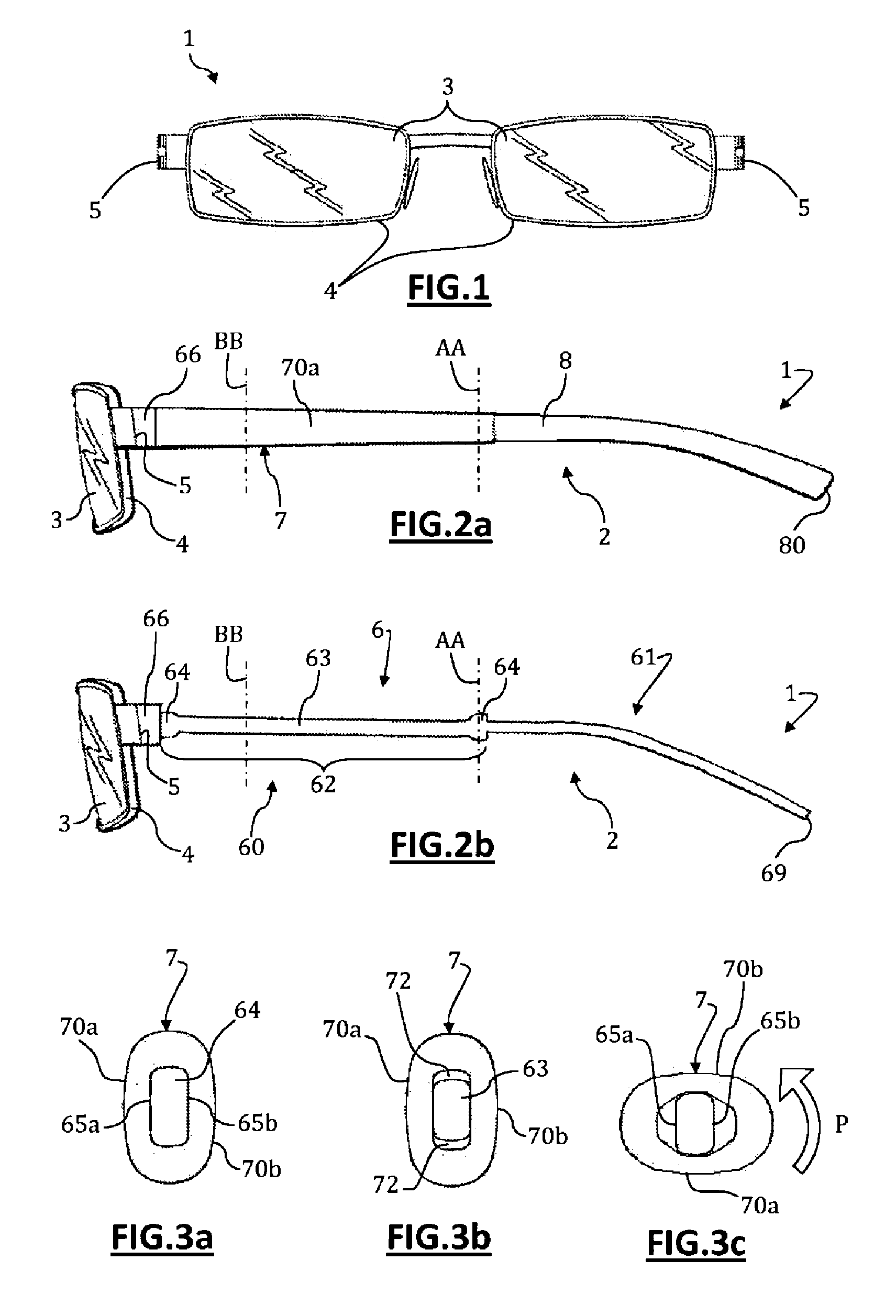

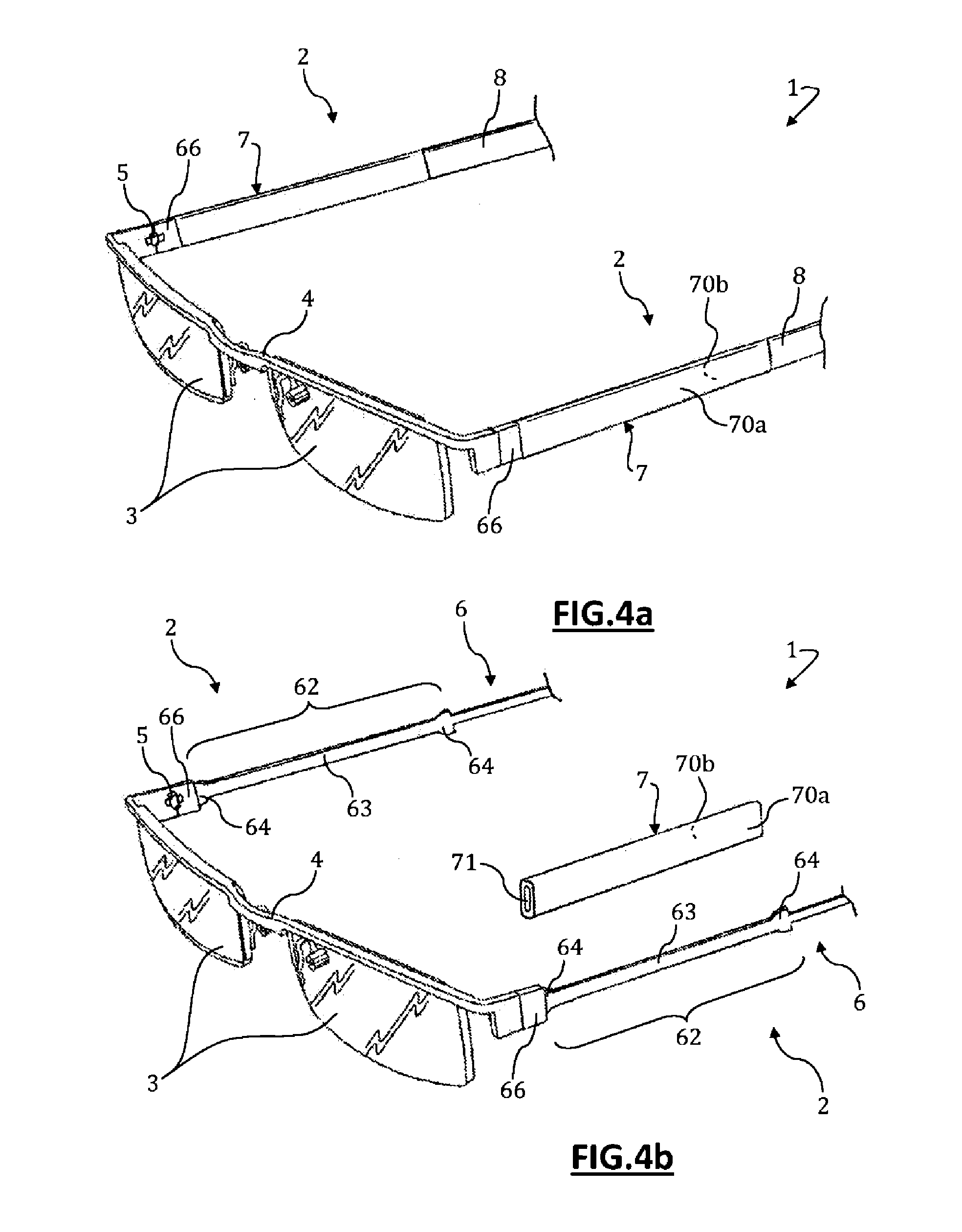

Arm for spectacles and associated spectacles

InactiveUS20120113381A1Simple and inexpensive designEasy to operateNon-optical adjunctsNon-optical partsBiomedical engineering

Owner:KILLINE OPTICAL

Pressure-cooking appliance including opening safety means

ActiveUS20050132896A1Easy to useHigh speedWater heating stoves/rangesStove/ranges for heating waterEngineeringNeutral position

The invention relates to an appliance for cooking under pressure, the appliance comprising: a bowl and a lid; and opening safety means suitable for going between a neutral position, in which they allow the lid to be unlocked, and a blocking position, in which they prevent the lid from being unlocked, said safety means being designed to find themselves in the blocking position when the pressure prevailing inside the vessel is greater than or equal to a predetermined value or “rise pressure”, and / or when the temperature prevailing inside the vessel is greater than or equal to a predetermined value or “rise temperature”; said appliance being further comprising actuating means for actuating the safety means, which actuating means are arranged to make it possible to place the safety means in the blocking position The invention is applicable to household appliances for cooking under pressure.

Owner:SEB SA

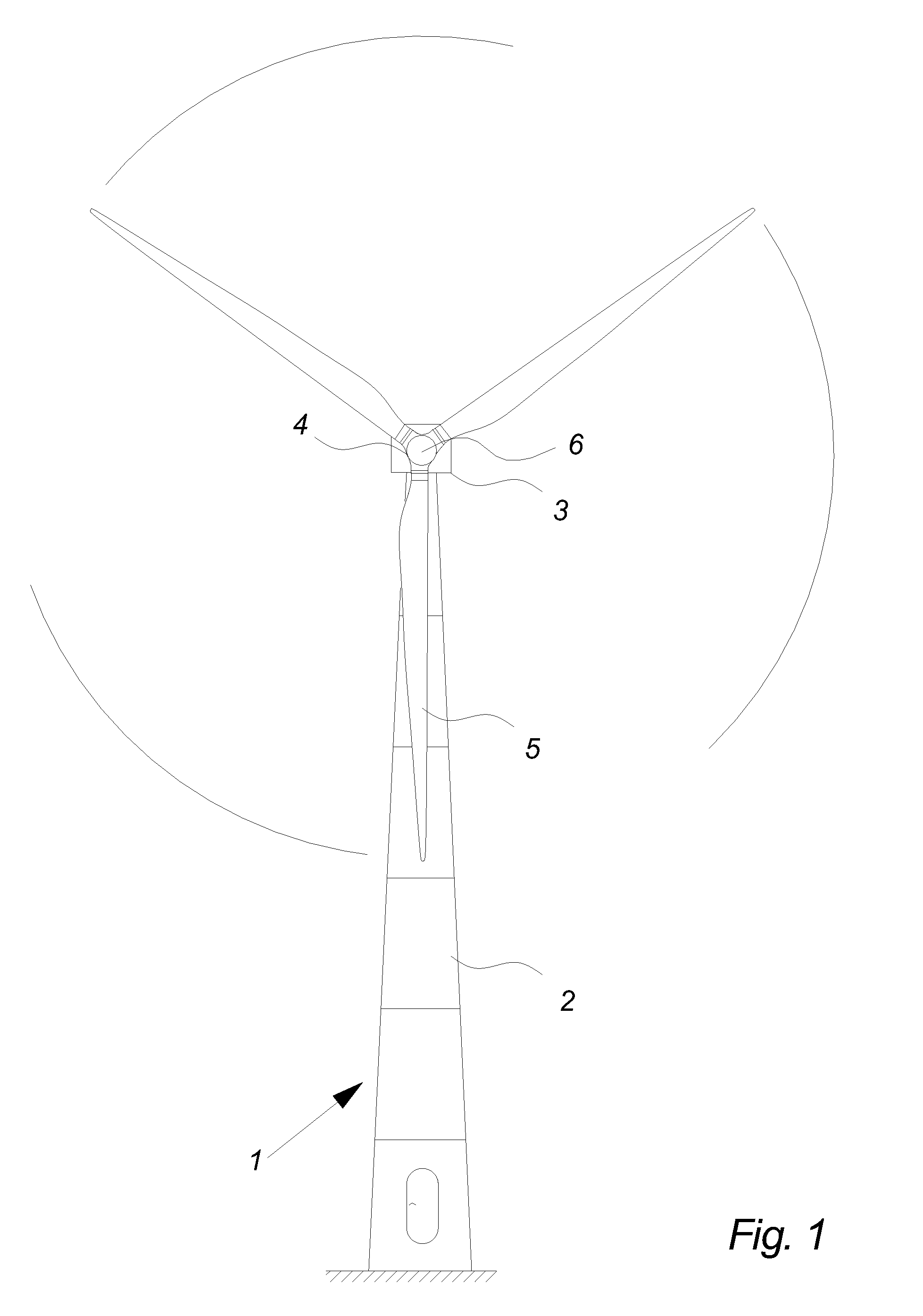

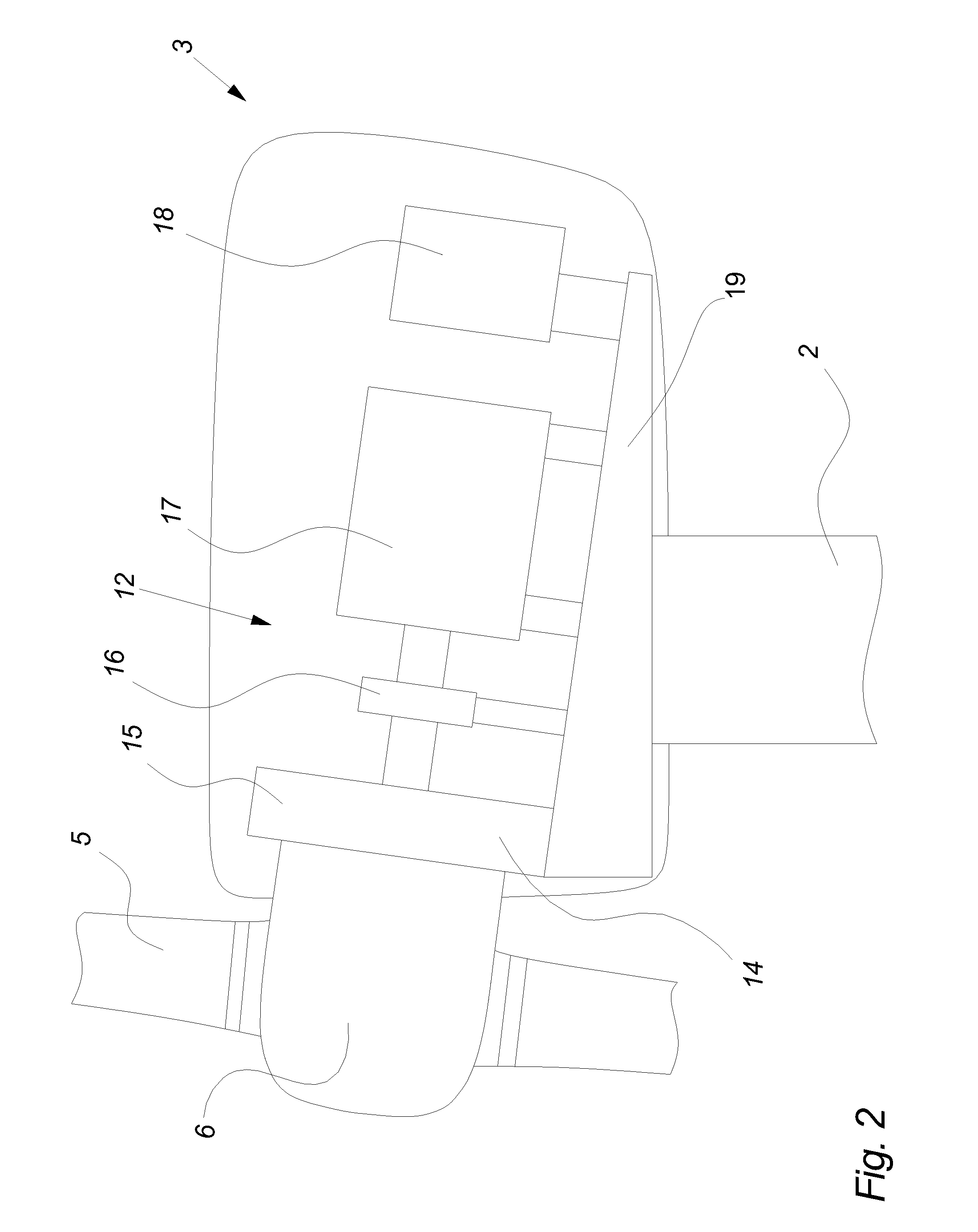

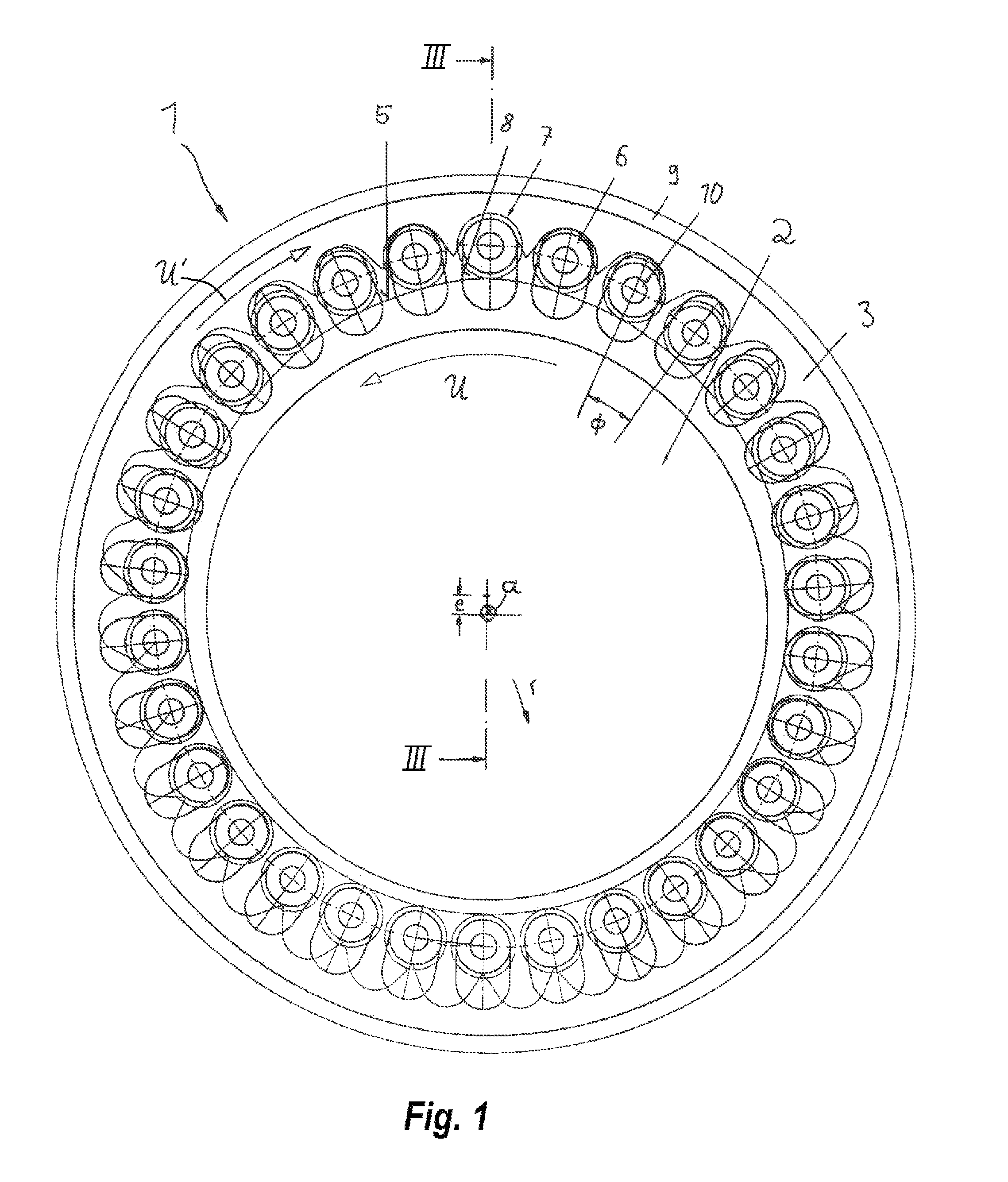

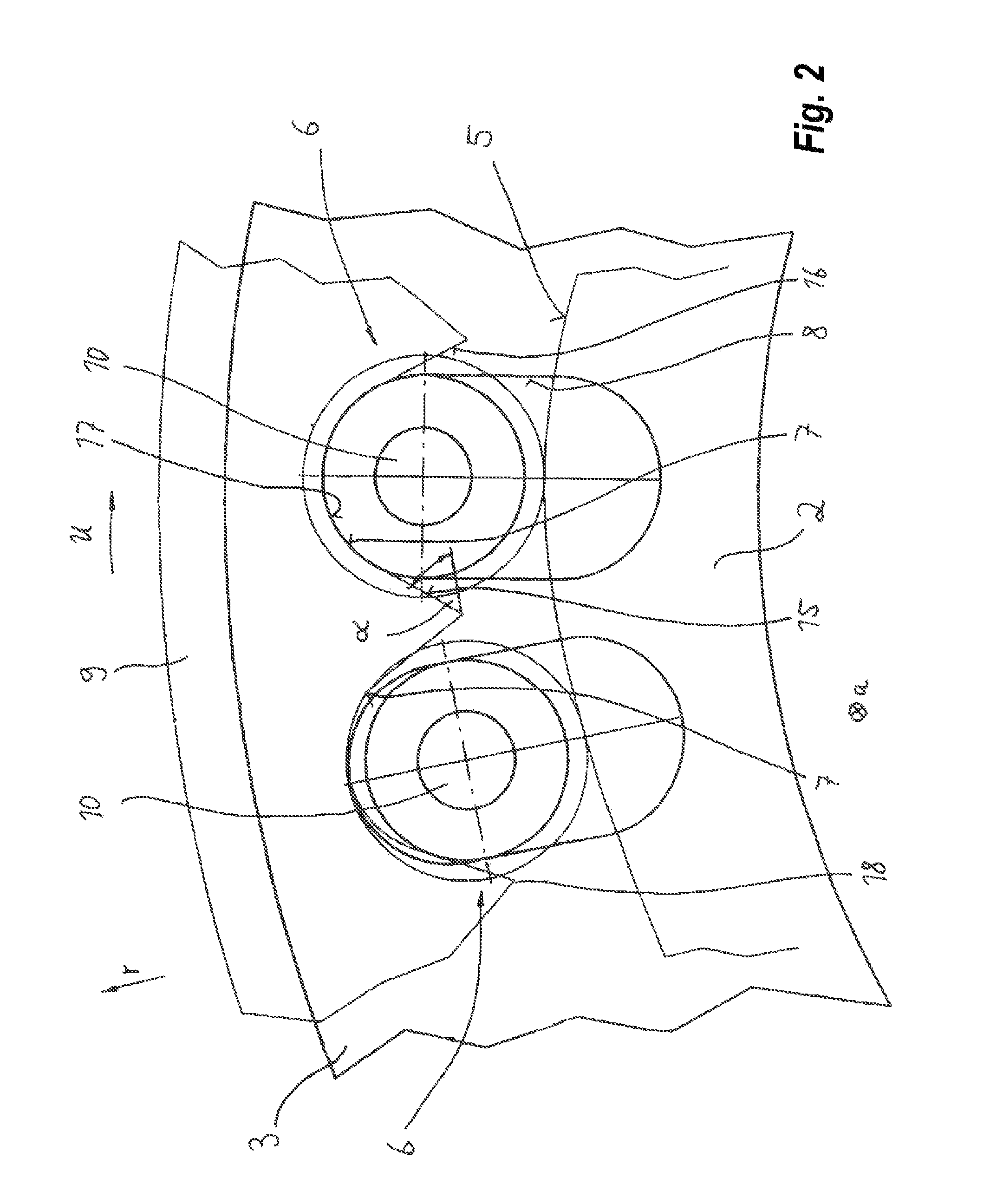

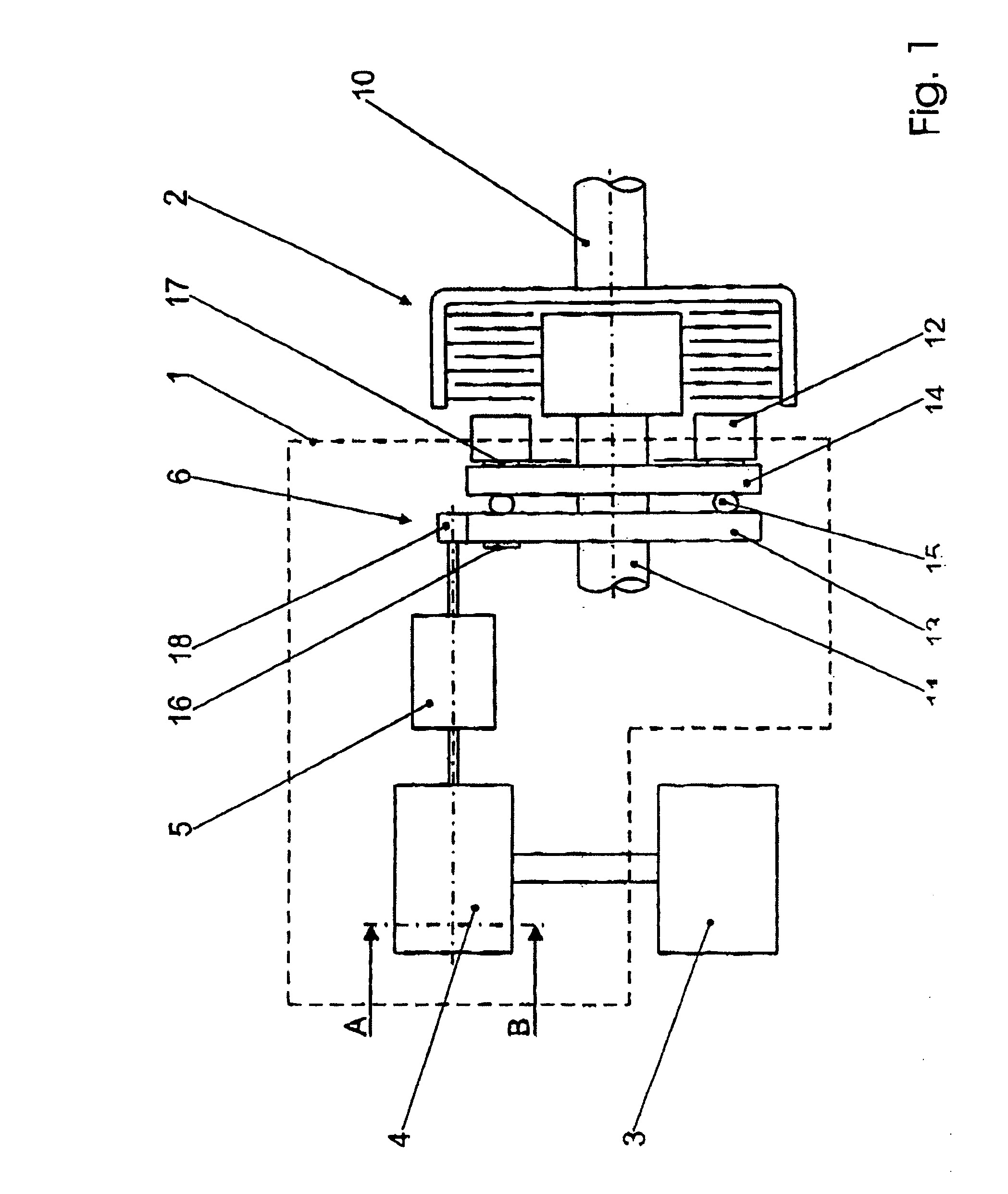

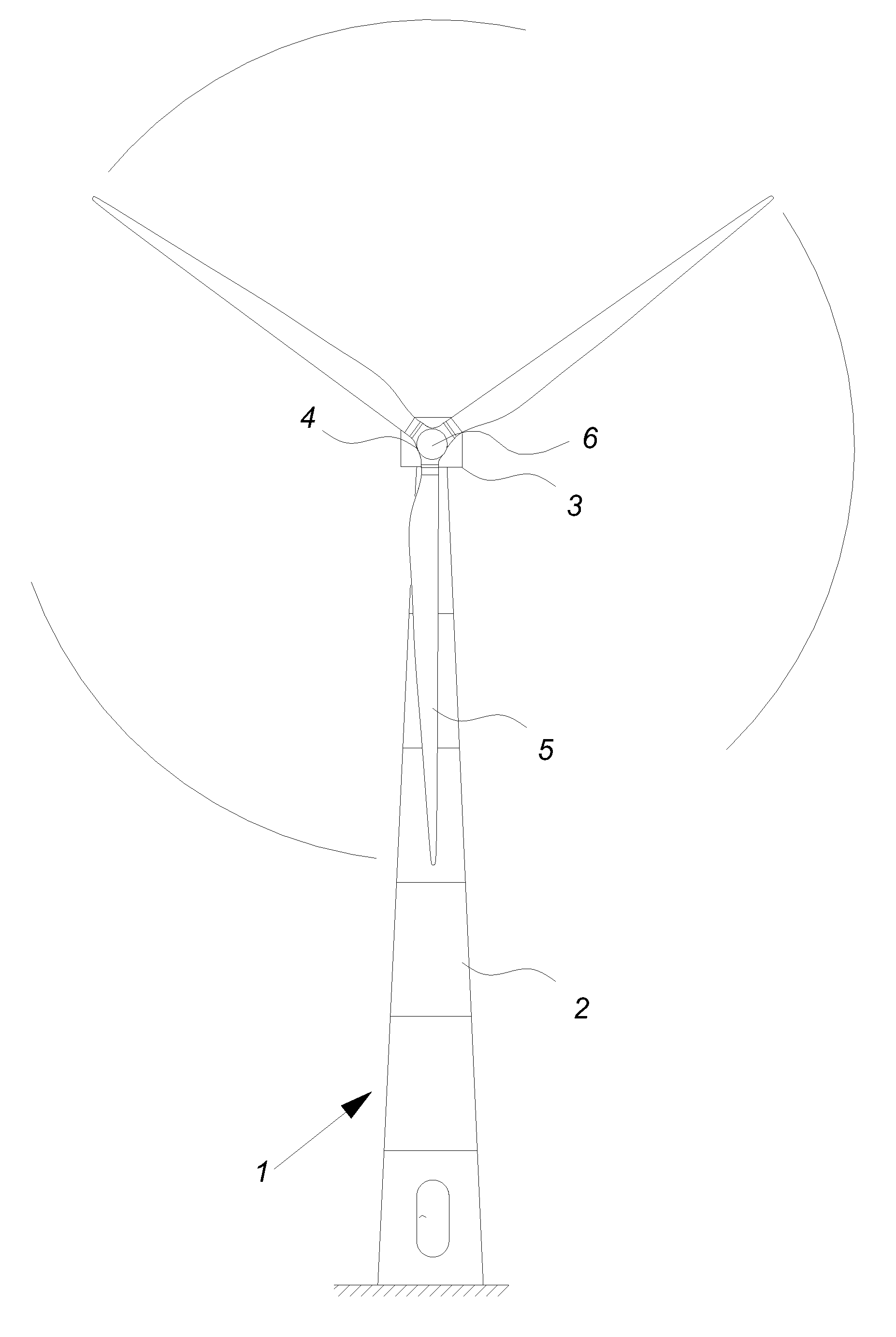

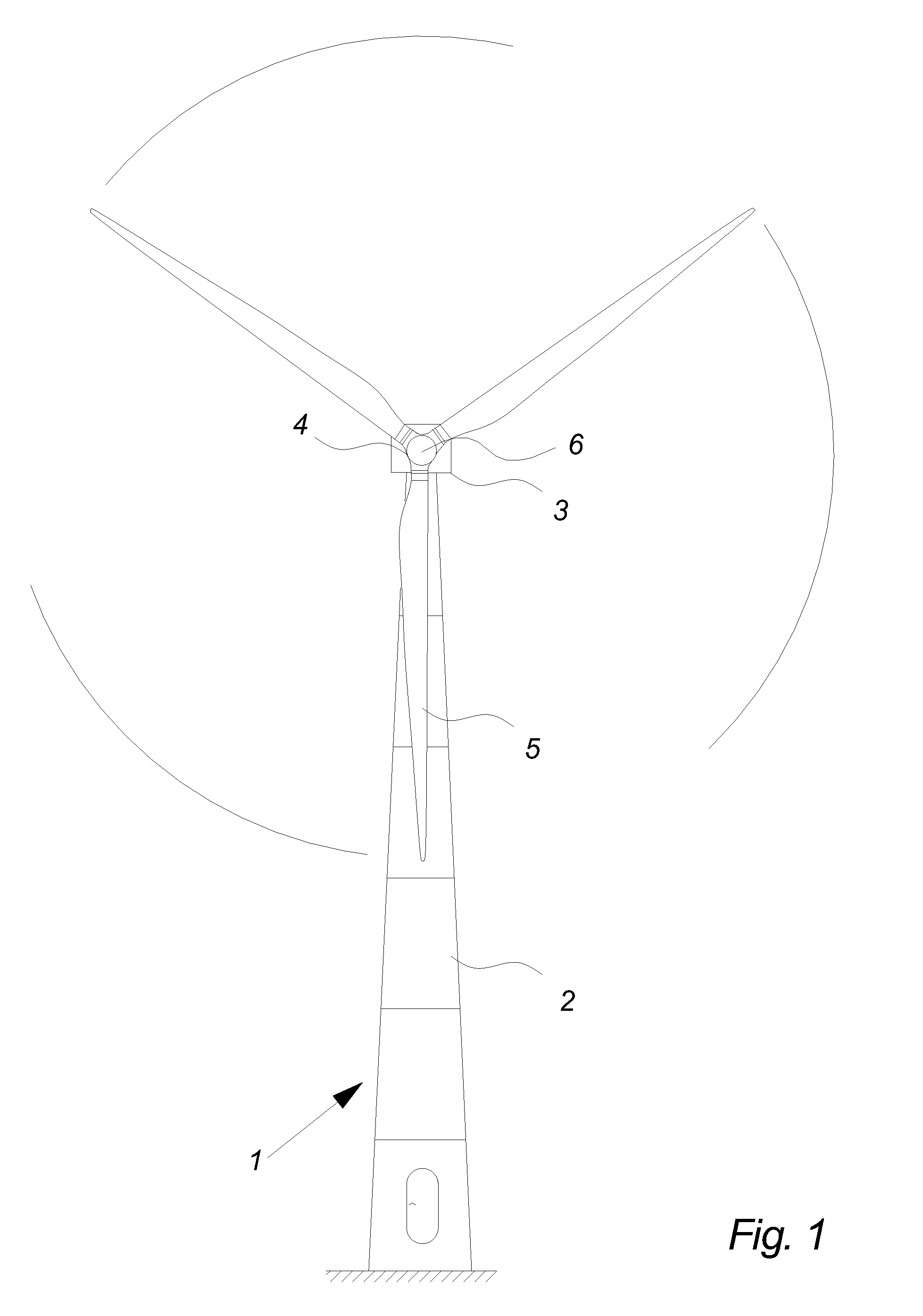

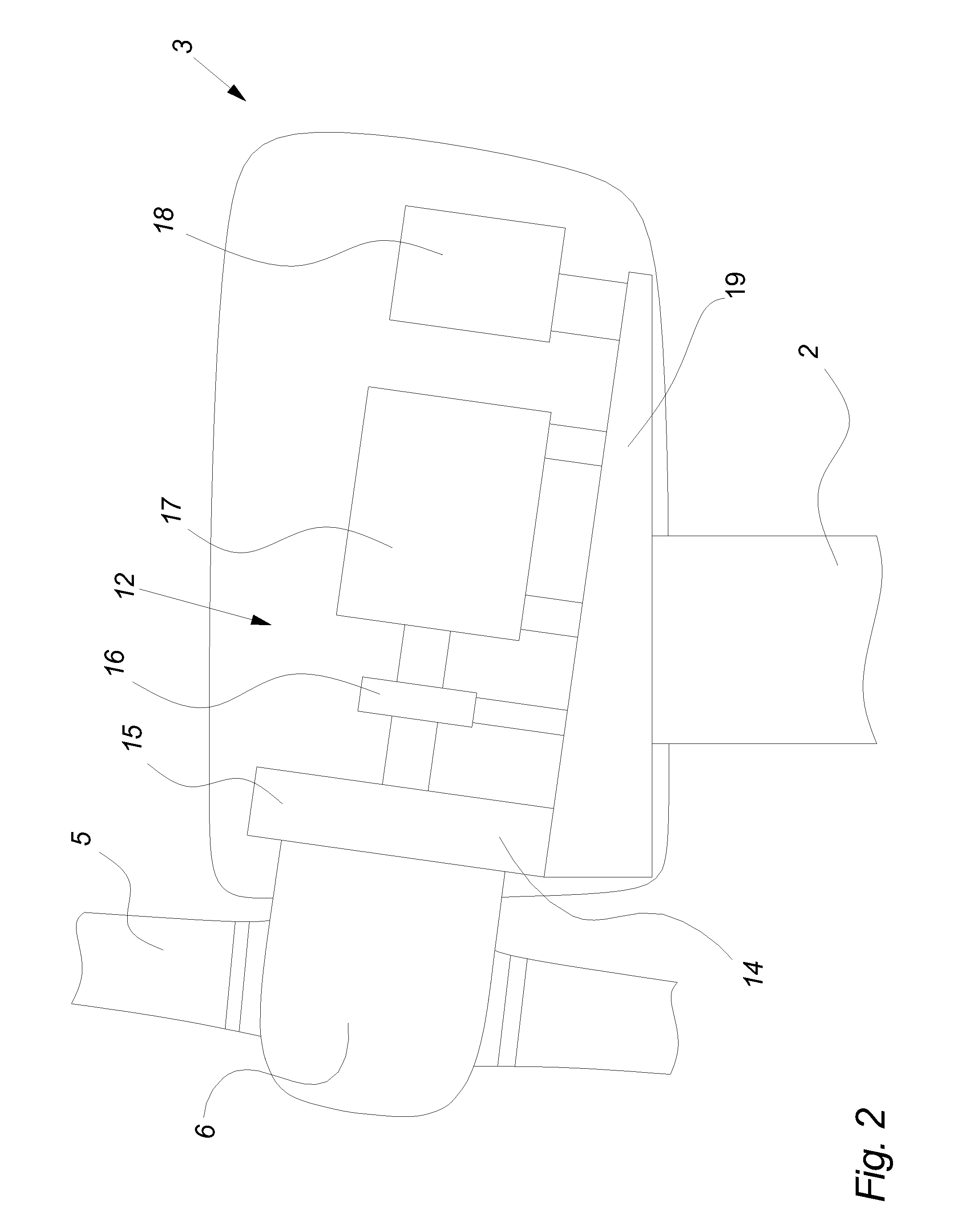

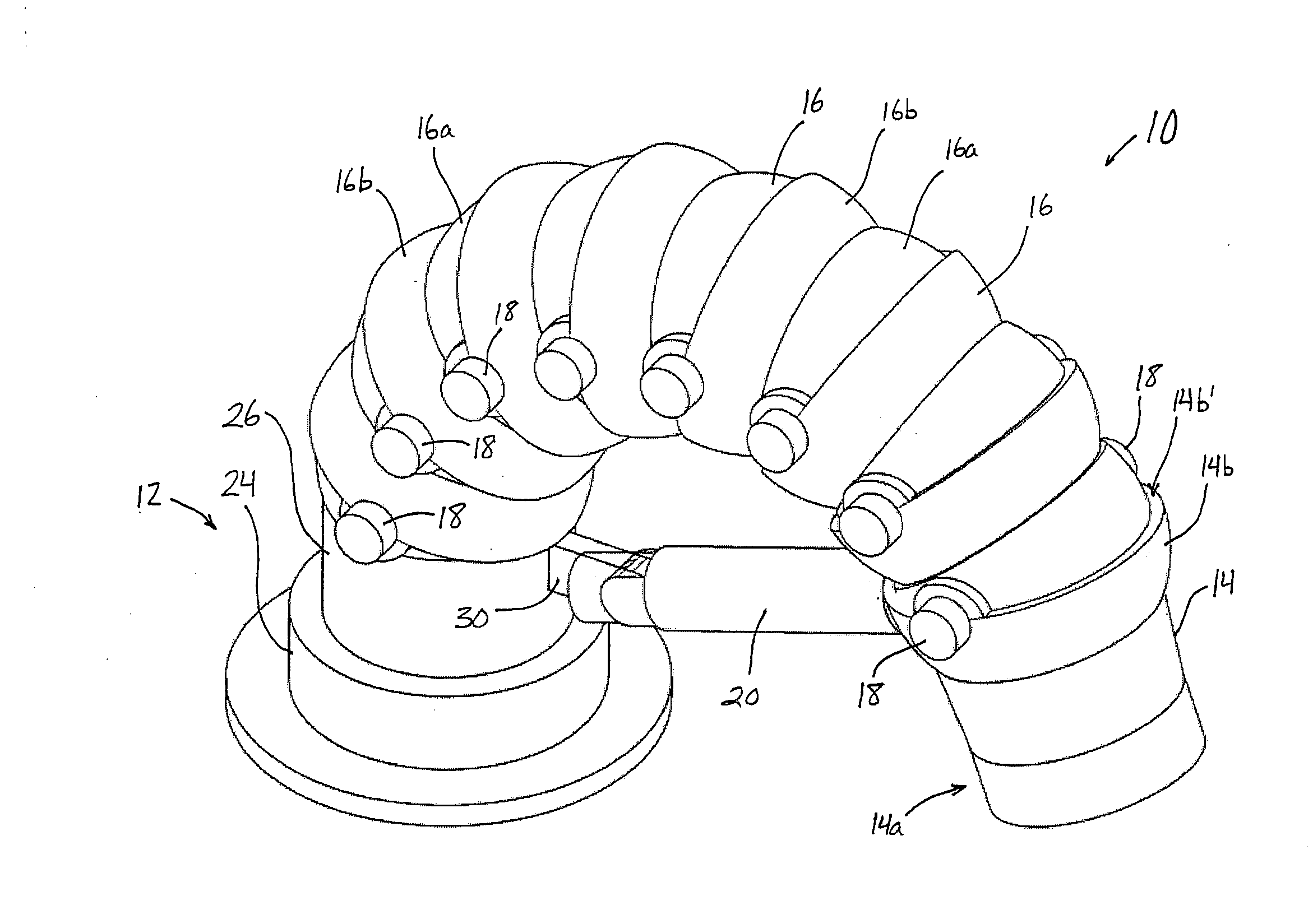

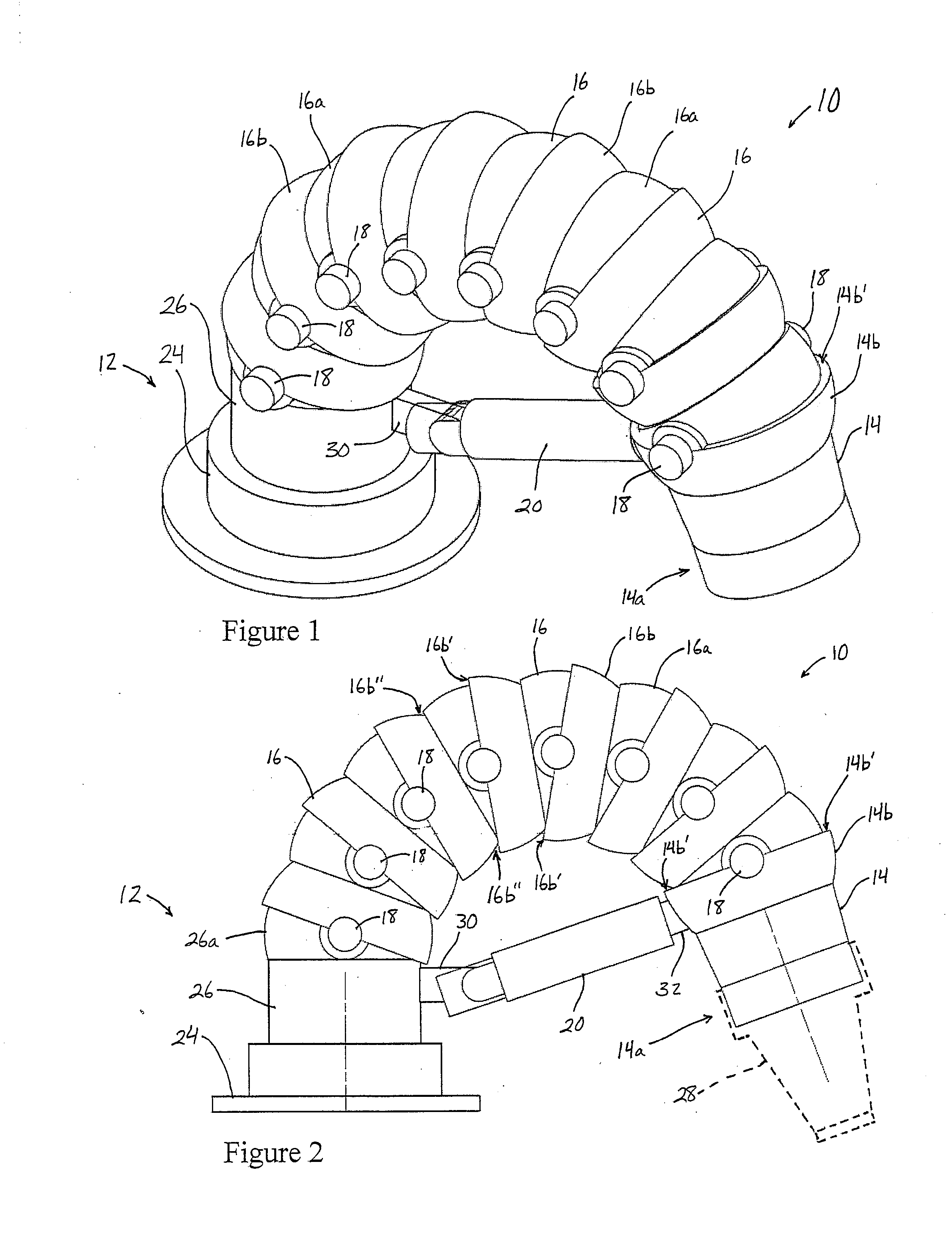

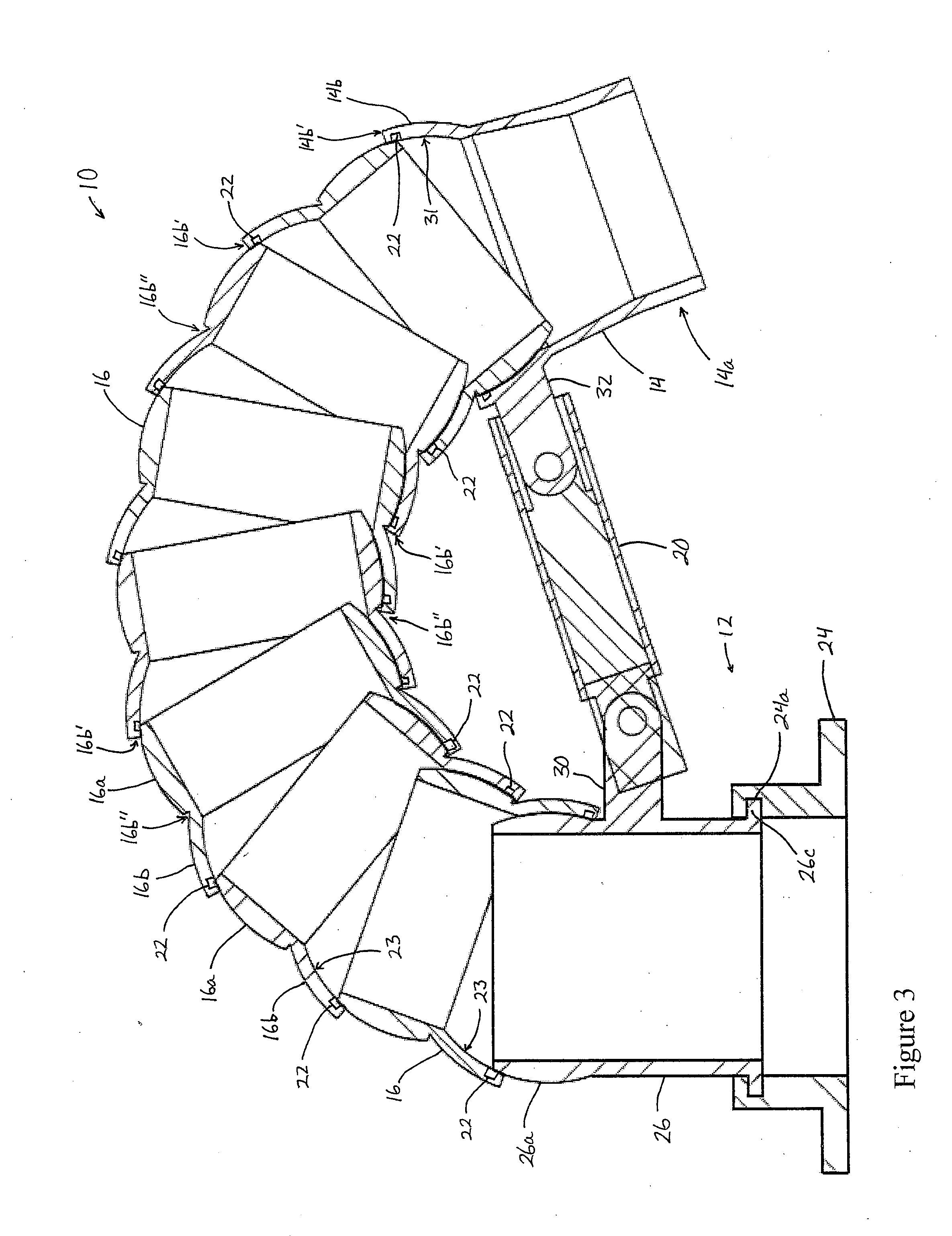

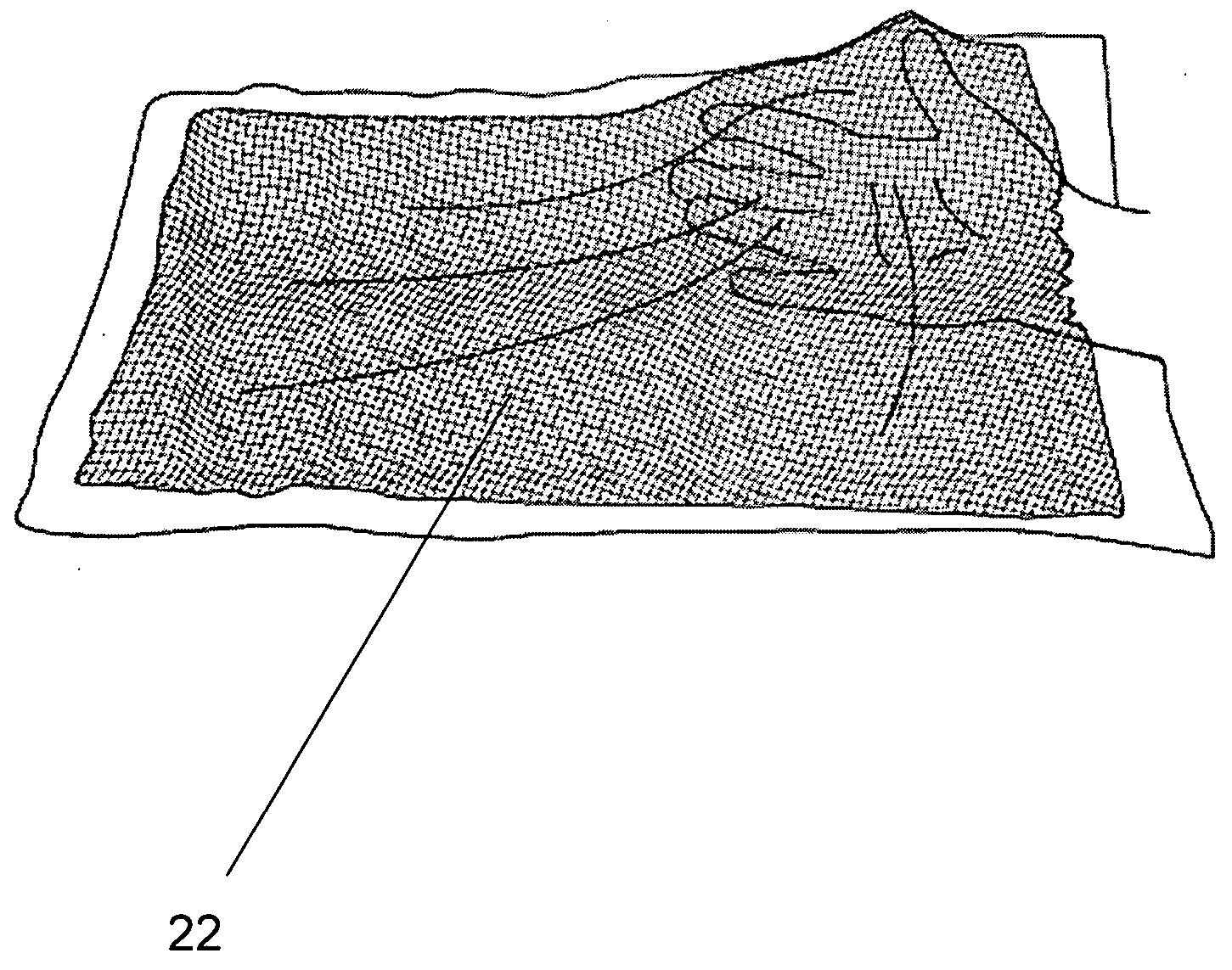

Wind Turbine With A Drive Train

InactiveUS20090289460A1Flexible designSimple and inexpensive designEngine manufactureFinal product manufactureNacelleEngineering

A wind turbine with a drive train placed partly or entirely in a nacelle of the wind turbine is provided. The drive train includes an epicyclical gearbox including at least one gear stage having a plurality of planet gears meshing with a sun gear and / or an annulus gear. The gearbox partly or completely speed-up the rotation speed of a rotor of the wind turbine to at least one generator of the wind turbine. The wind turbine is characterized in that the drive train further includes at least one locally radial self tracking bearing for enabling the rotation of the rotor in relation to a nacelle structure of the nacelle.

Owner:VESTAS WIND SYST AS

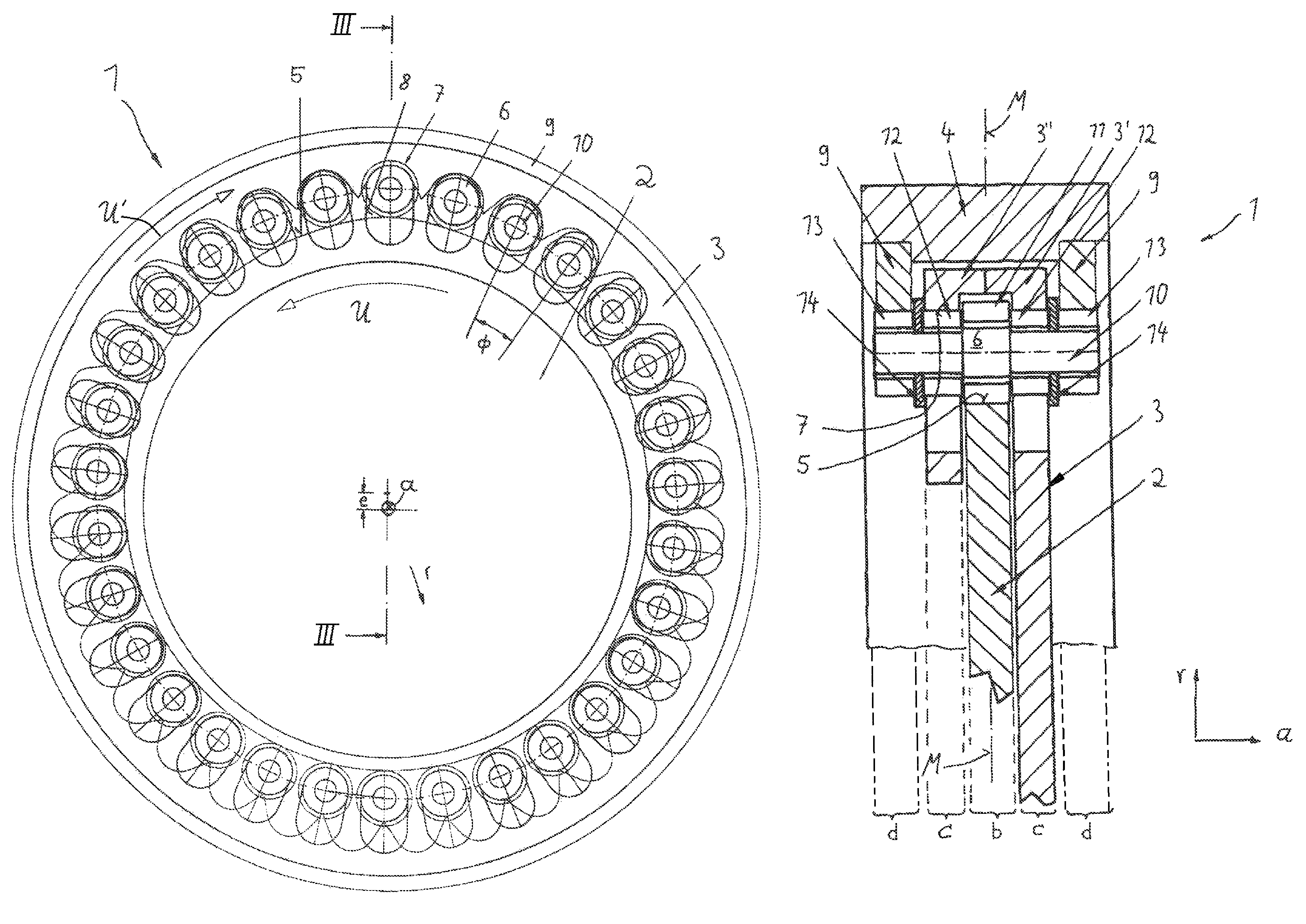

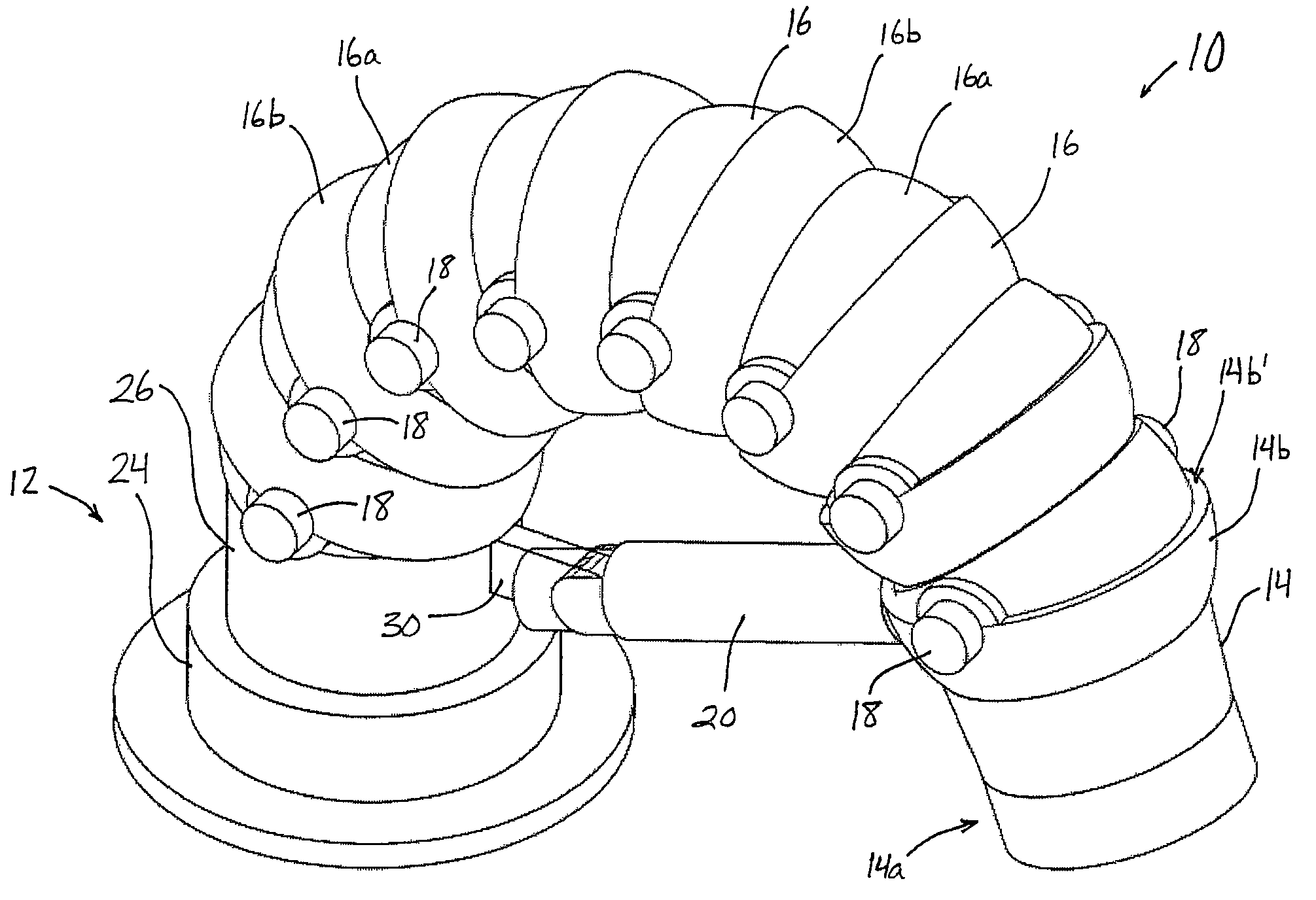

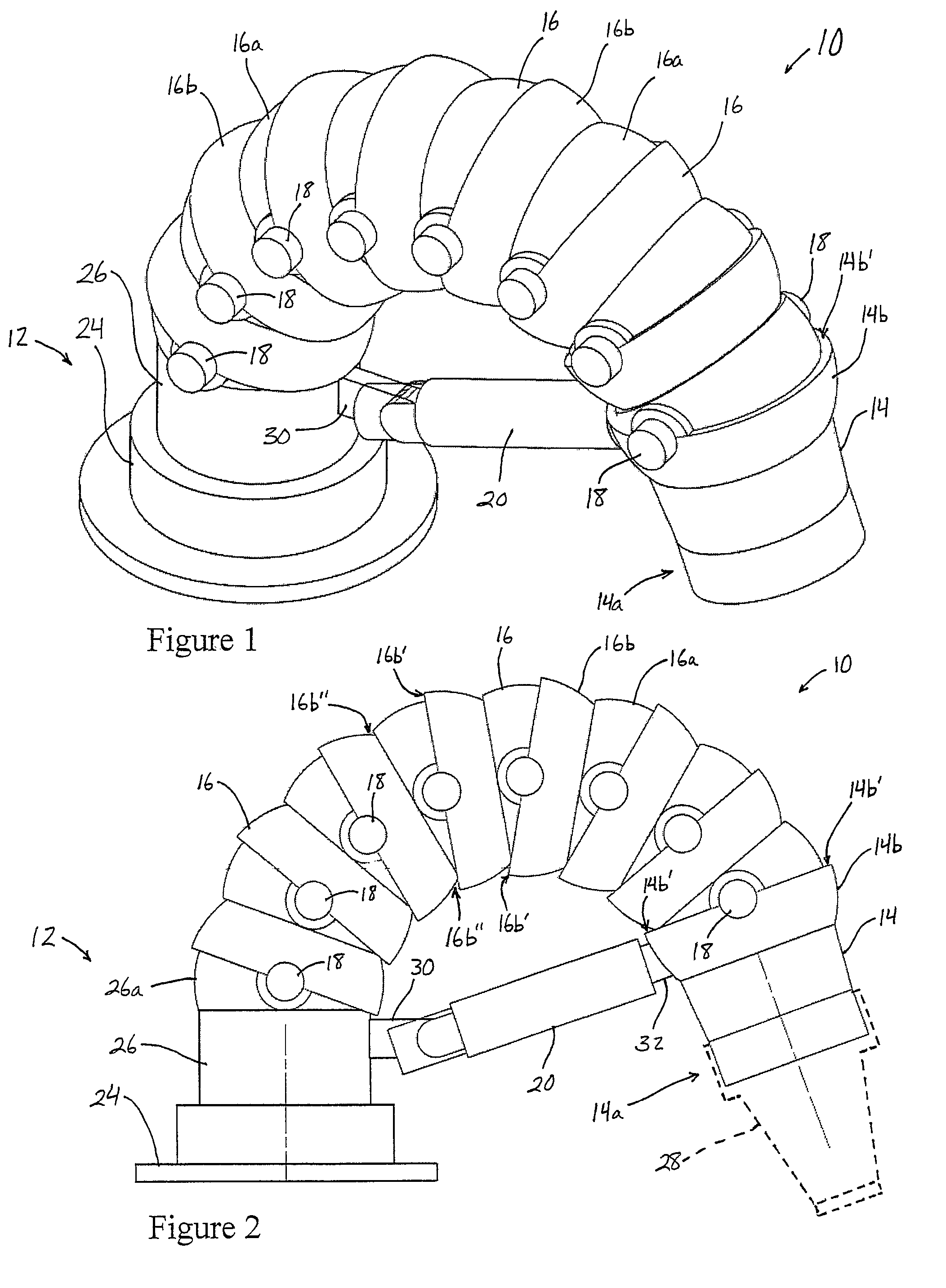

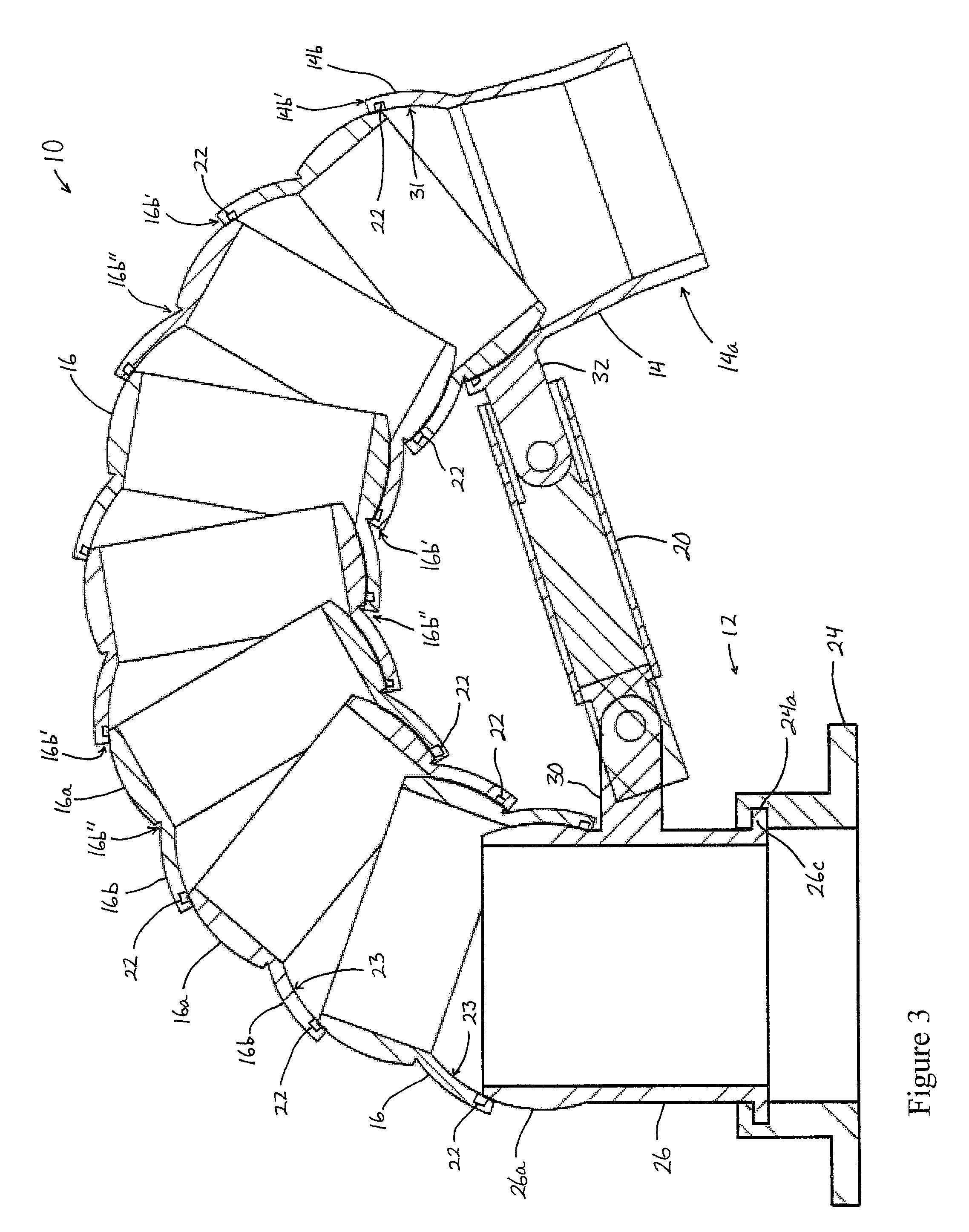

Rotary speed-change transmission

InactiveUS8998763B2Spread the wordTransmit high torquesToothed gearingsEngineeringMechanical engineering

A transmission has a housing having a main axis with a retaining element fixed in the housing and forming a set having a predetermined number of radially extending and angularly equispaced guides. An output element rotatable in the housing about the axis is formed with an array having a number smaller than the predetermined number of radially inwardly open recesses axially adjacent the guides. An input element rotatable in the housing about the axis has a radial outer and generally circular peripheral surface centered on an axis radially offset from the main axis. Respective transmission elements radially displaceable in the guide grooves between inner and outer positions each have a shaft extending substantially parallel to the axis with a guide section engaged and radially shiftable in the respective guide groove, a driven section engageable in the recesses, and a drive section radially engageable with the input-element surface.

Owner:SMS MEER

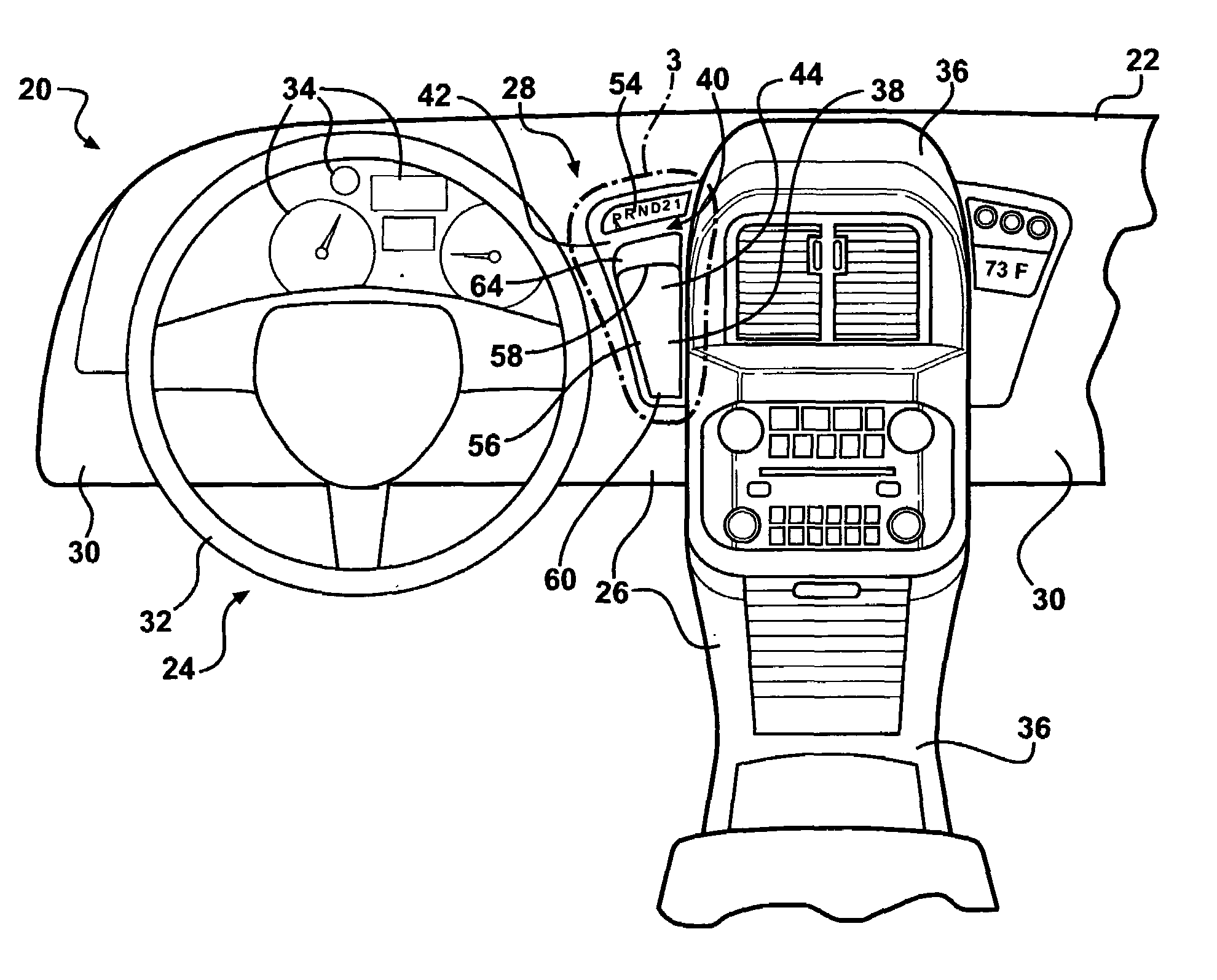

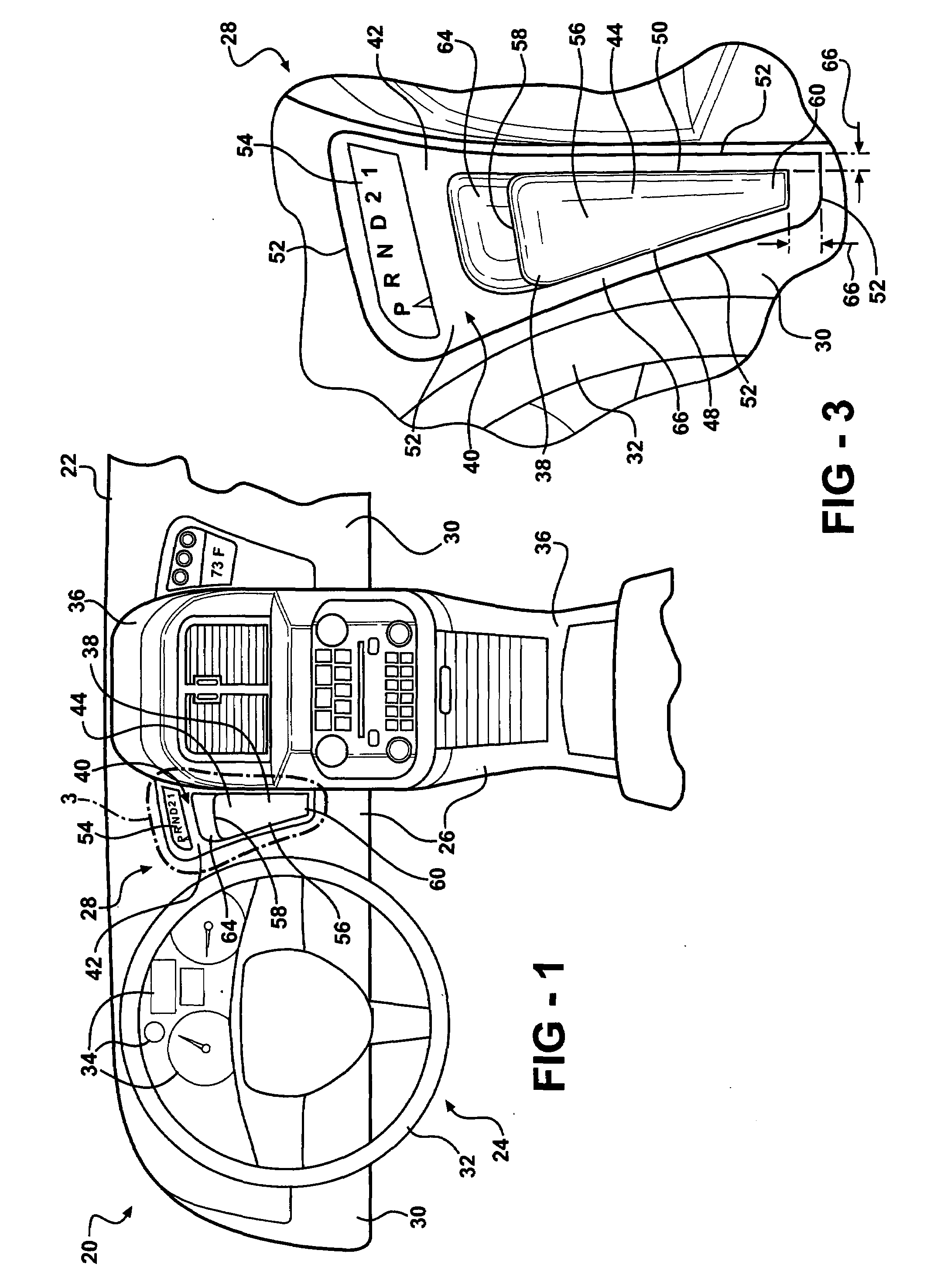

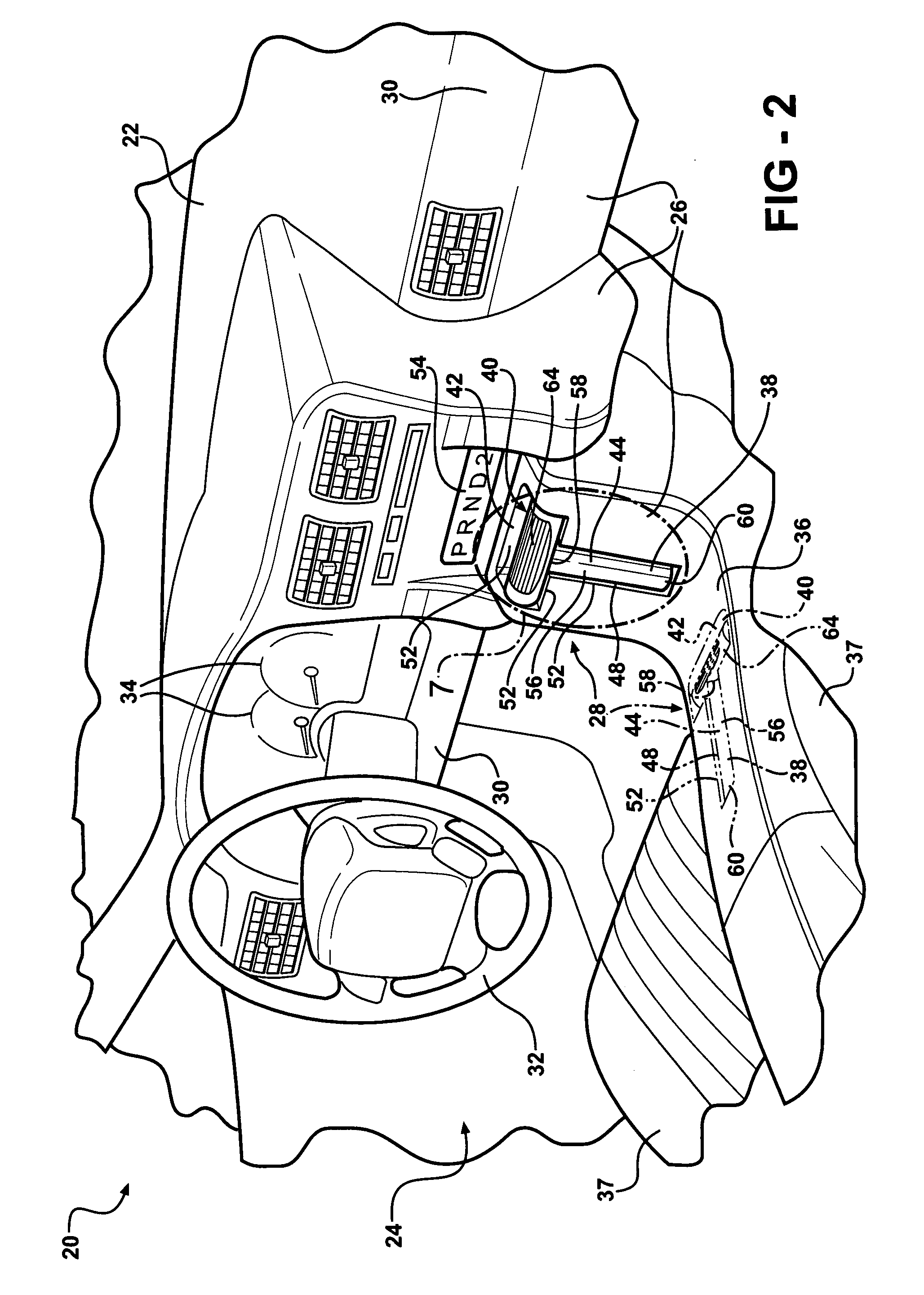

Instrument panel assembly for a vehicle

InactiveUS20080100086A1Simple and inexpensive designLess componentsControlling membersGearing controlDashboardElectrical and Electronics engineering

The present invention provides for an instrument panel assembly for a vehicle. The instrument panel assembly includes a dashboard with an interior panel disposed proximal to the dashboard. A shift lever is pivotally attached to the interior panel and movable between a drive position for allowing movement of the vehicle and a park position for preventing movement of the vehicle. At least one wall extends inwardly from the interior panel to define a pocket complementary in configuration to a portion of the shift lever for receiving the shift lever when in the parked position and the shift lever spaced from the pocket when in the drive position.

Owner:GM GLOBAL TECH OPERATIONS LLC

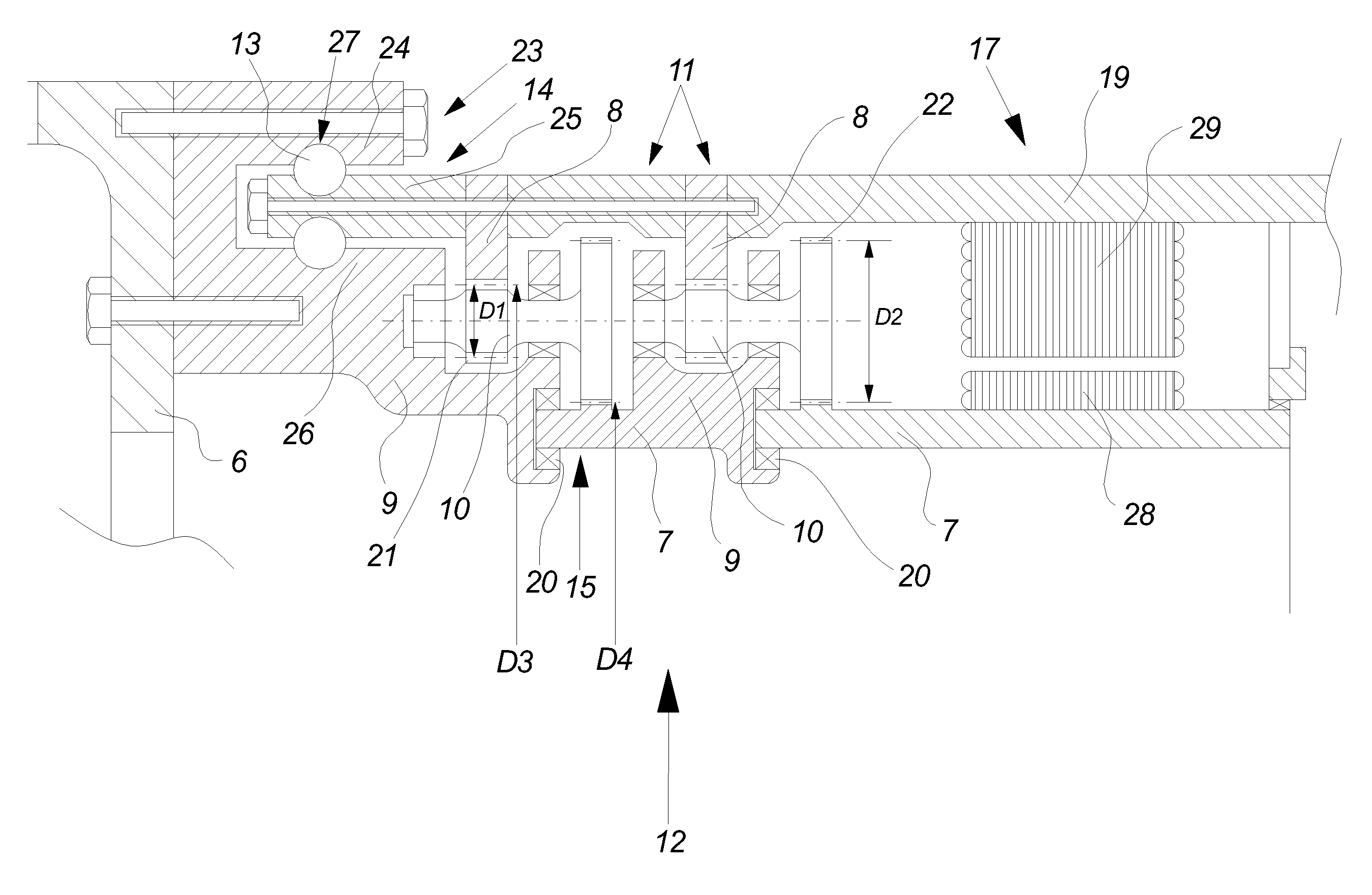

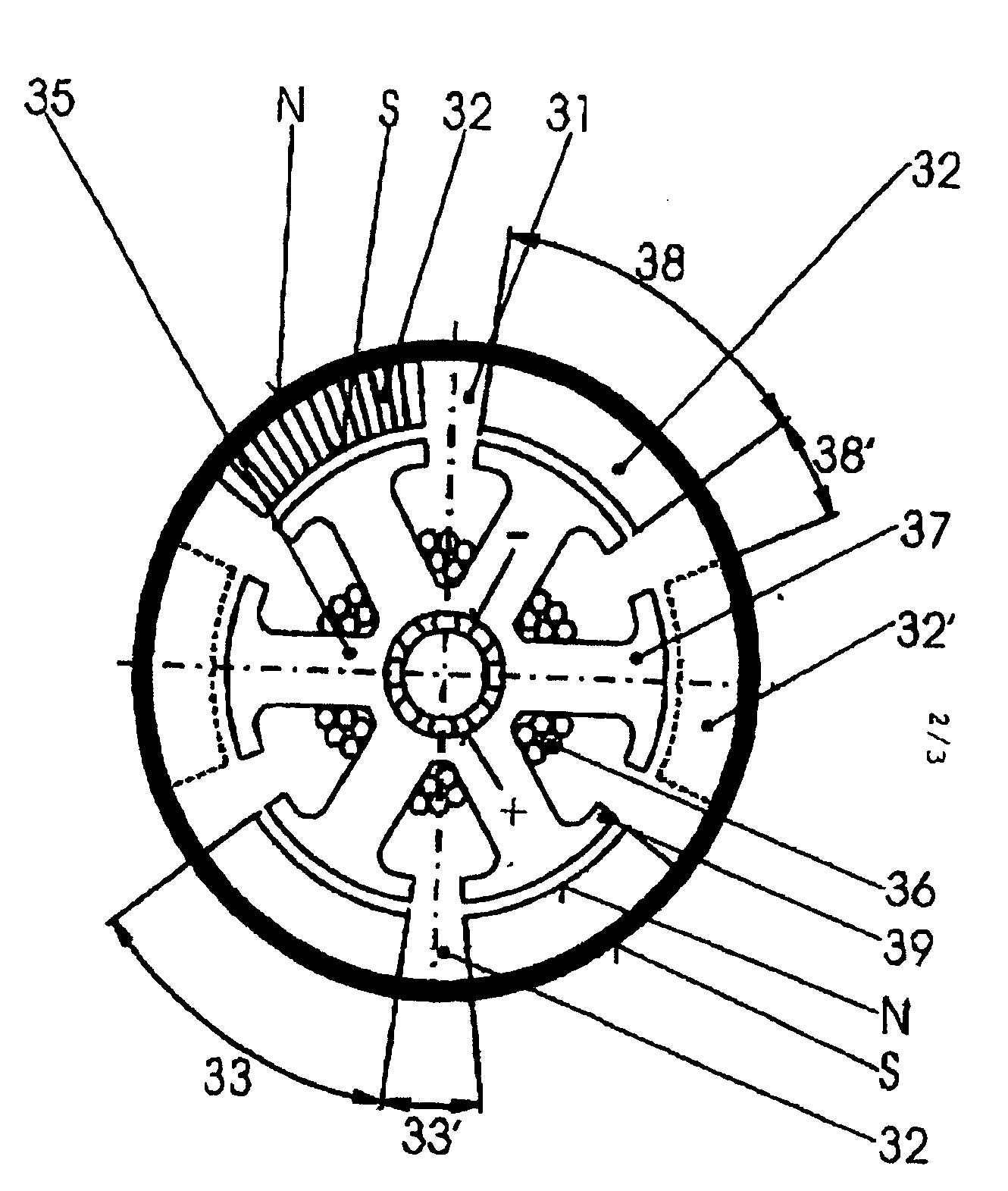

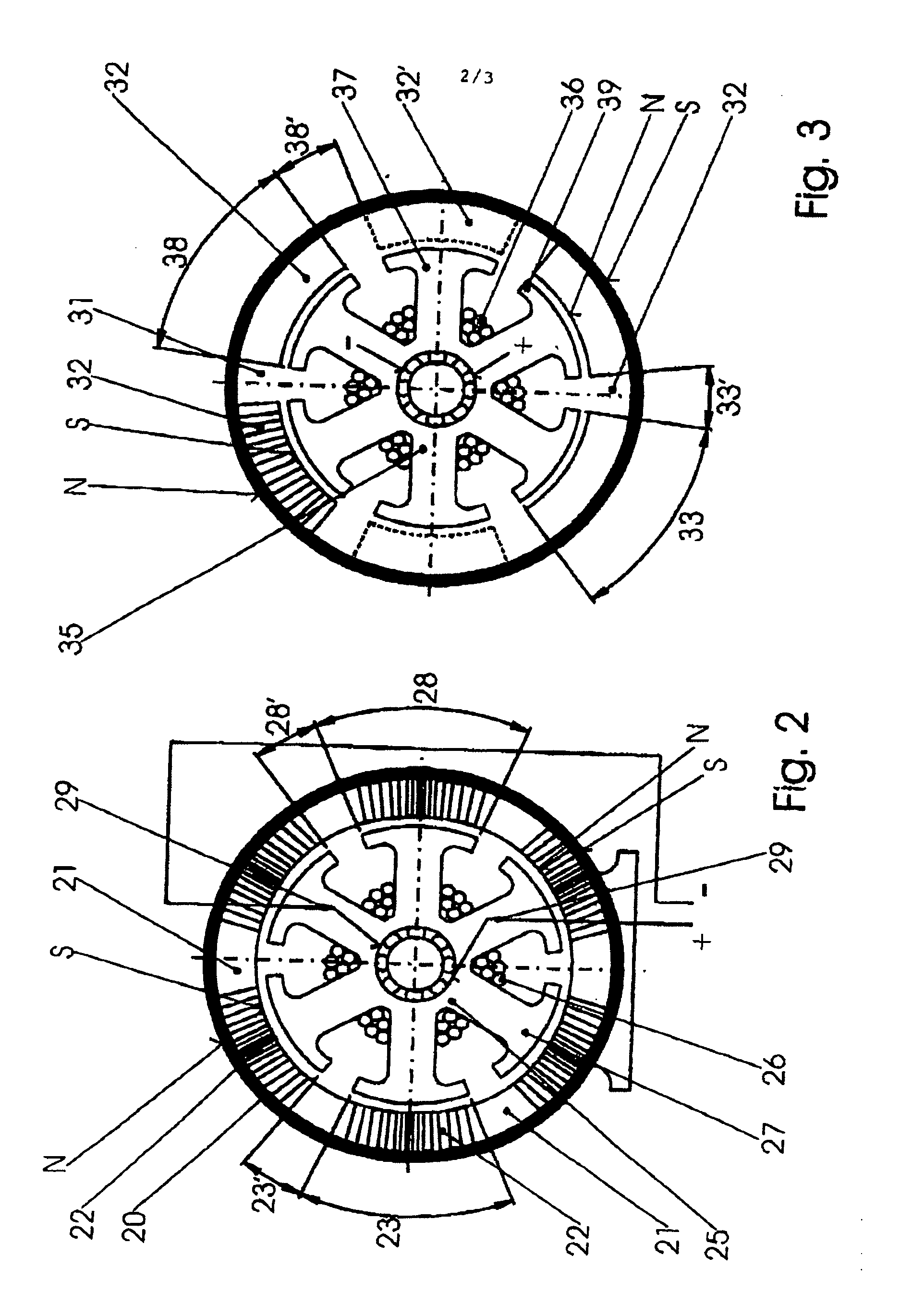

Actuator Having An Electric Actuating Motor And Controllable Friction Clutch Having Such An Actuator

InactiveUS20080278015A1Reduce magnetic field strengthIncrease the magnetic field strengthMechanical actuated clutchesMagnetic circuitActuatorConductor Coil

An actuator comprises an electric actuating motor, a transmission mechanism and an actuating element, the actuating motor being a DC motor which comprises a first part having permanent magnets and a second part having windings and pole teeth. In order to be able to hold the actuator in any desired, adopted position without any additional apparatuses, the first part (30) has alternately first zones having a low magnetic field strength (31) and second zones having a high field strength (32) over its circumference, the circumferential angle (33) of the second zones (32) being equal to the circumferential angle (38) of the pole teeth (37) of the second part (35), the number of pole teeth (37) being selected such that all of the second zones (32) are always passed at the same time by a pole tooth (37), with the result that, in the event of a rotation in the state in which there is no current flowing, a pulsating torque is exerted between the first part (30) and the second part (35).

Owner:MAGNA STEYR FAHRZEUGTECHN

Comprehensive pharmacologic therapy for treatment of a dysfunction

InactiveUS20050233008A1Promote resultsHigh expectation of weight lossBiocidePeptide/protein ingredientsDiethylpropionVitamin C

The comprehensive pharmacologic therapy for treatment of obesity is a procedure which involves the administration of a desired therapeutic range of Diethylpropion and / or Phentermine in combination with a SSRI medication and nutritional supplementation for brief and long durations which may be 12 months or more. The preferred procedure involves the administration of drugs in combination which are identified as: Citalopram (Celexa) and Phentermine; Citalopram (Celexa) and Diethylpropion; Citalopram (Celexa), Phentermine, and Diethylpropion. In addition nutritional supplementation such as a multivitamin, 5-Hydroxytryptophan, vitamin B6, vitamin C, Tyrosine, Calcium, and Lysine may be used to enhance the performance of the weight loss treatment program.

Owner:FEDERAL LAW ENFORCEMENT DEV SERVICES

Fire-fighting monitor

ActiveUS7802630B2Simple and inexpensive designSmall spacingSpraying apparatusAdjustable jointsEngineeringMechanical engineering

Owner:ELKHART BRASS MFG

Wind turbine with a drive train

InactiveUS8403786B2Flexible designSimple and inexpensive designEngine manufactureEngine fuctionsNacelleGear wheel

A wind turbine with a drive train placed partly or entirely in a nacelle of the wind turbine is provided. The drive train includes an epicyclical gearbox including at least one gear stage having a plurality of planet gears meshing with a sun gear and an annulus gear. The gearbox is used to transfer and speed-up the rotation of a rotor of the wind turbine, as applied to at least one generator of the wind turbine. The drive train further includes at least one locally radial self tracking bearing for enabling the rotation of the rotor in relation to a nacelle structure of the nacelle. The self tracking bearing includes bearing elements for locally transferring loads in both radial directions between one or more bearing rings.

Owner:VESTAS WIND SYST AS

Comprehensive pharmacologic therapy for treatment of obesity including cysteine

InactiveUS7268161B2Simple and inexpensive designEffective therapyBiocidePeptide/protein ingredientsDiethylpropionVitamin C

The comprehensive pharmacologic therapy for treatment of obesity including Cysteine is a procedure which involves the administration of a desired therapeutic range of Diethylpropion and / or Phentermine in combination with a SSRI medication and nutritional supplementation for brief and long durations which may be 12 months or more. The preferred procedure involves the administration of drugs in combination which are identified as: Citalopram (Celexa) and Phentermine; Citalopram (Celexa) and Diethylpropion; Citalopram (Celexa), Phentermine, and Diethylpropion. In addition nutritional supplementation such as a multivitamin, 5-Hydroxytryptophan, Cysteine, vitamin B6, vitamin C, Tyrosine, Calcium, and Lysine may be used to enhance the performance of the weight loss treatment program.

Owner:FEDERAL LAW ENFORCEMENT DEV SERVICES

Flexible detonator system

InactiveUS20050183608A1Simple and inexpensive designSimple designIncandescent ignitionBlastingDetonatorDigital data

An electronic detonator system includes a control unit, a plurality of electronic detonators and a bus which connects the detonators to the control unit. Each electronic detonator includes a number of flags which may assume either of two possible values, each flag indicating a substrate of the respective detonators. The flags are readable from the control unit by means of digital data packets and the control unit is adapted, by means of these flags, to check the state of the electronic detonator and control the operation of the electronic detonator. When reading the flags, the electronic detonators give responses in the form of analog response pulses on the bus. The detonator system also includes a portable message receiver which on the basis of the flags obtains messages regarding the connecting status of a detonator.

Owner:DETNET SOUTH AFRICA (PTY) LTD

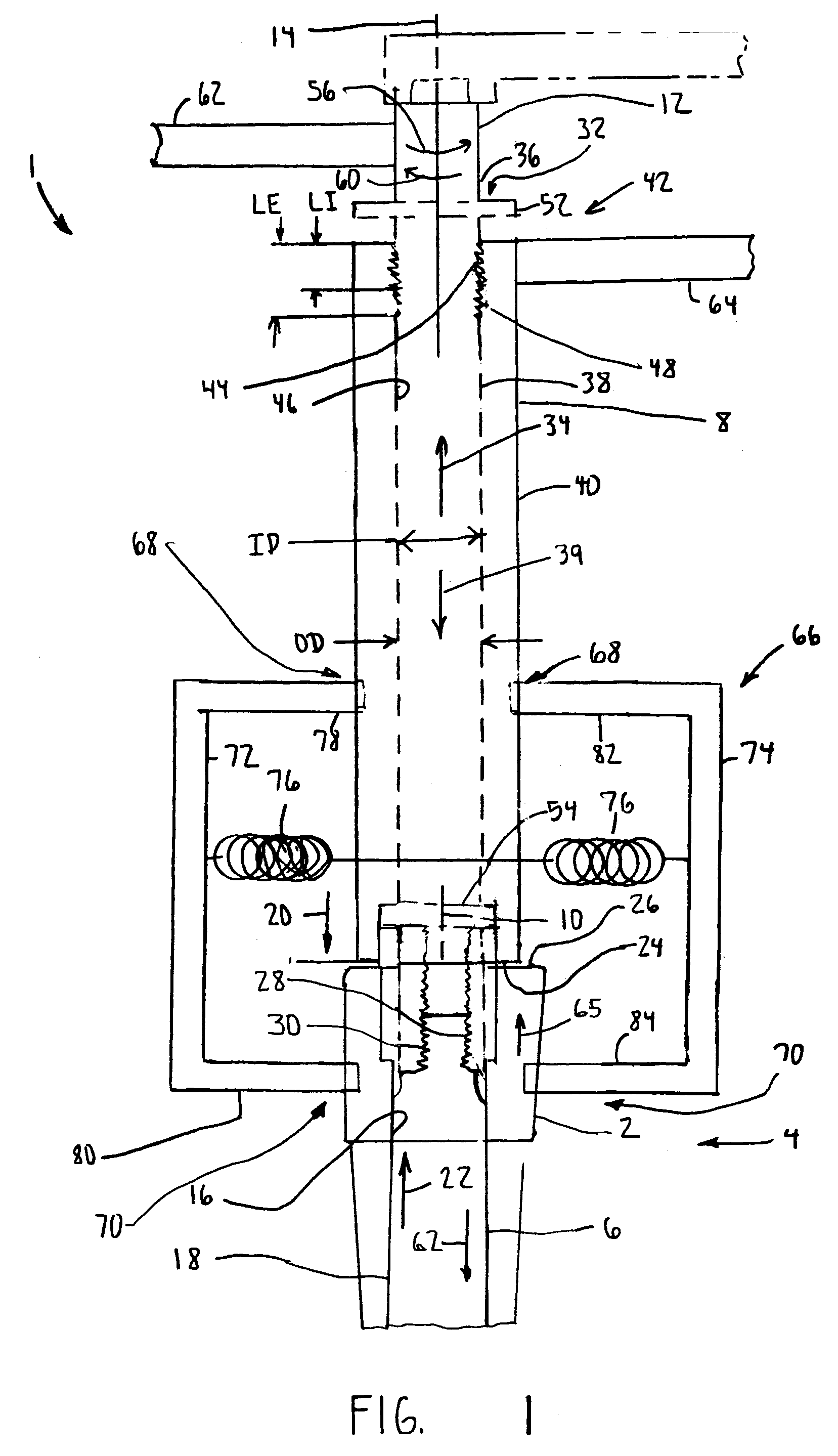

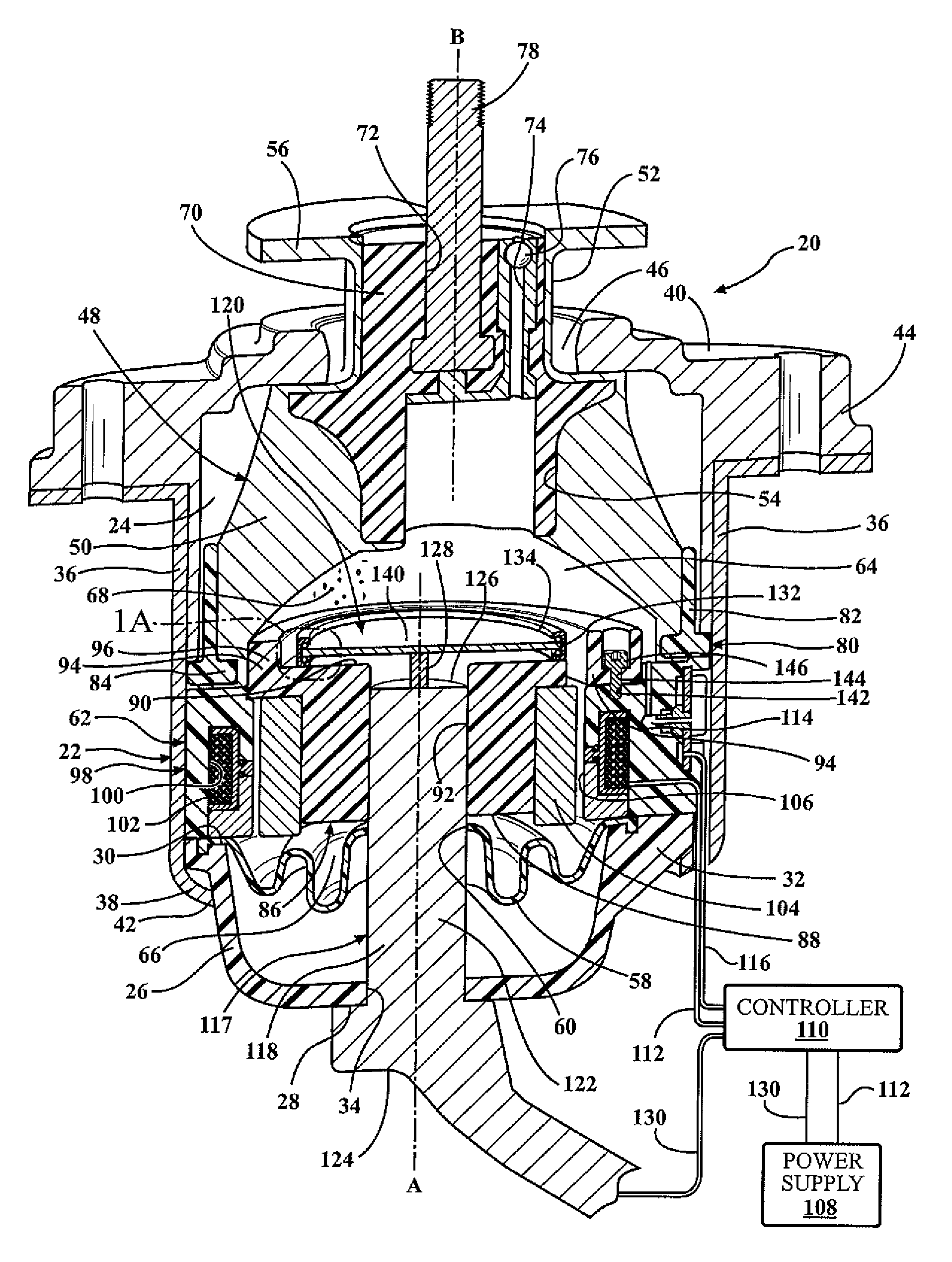

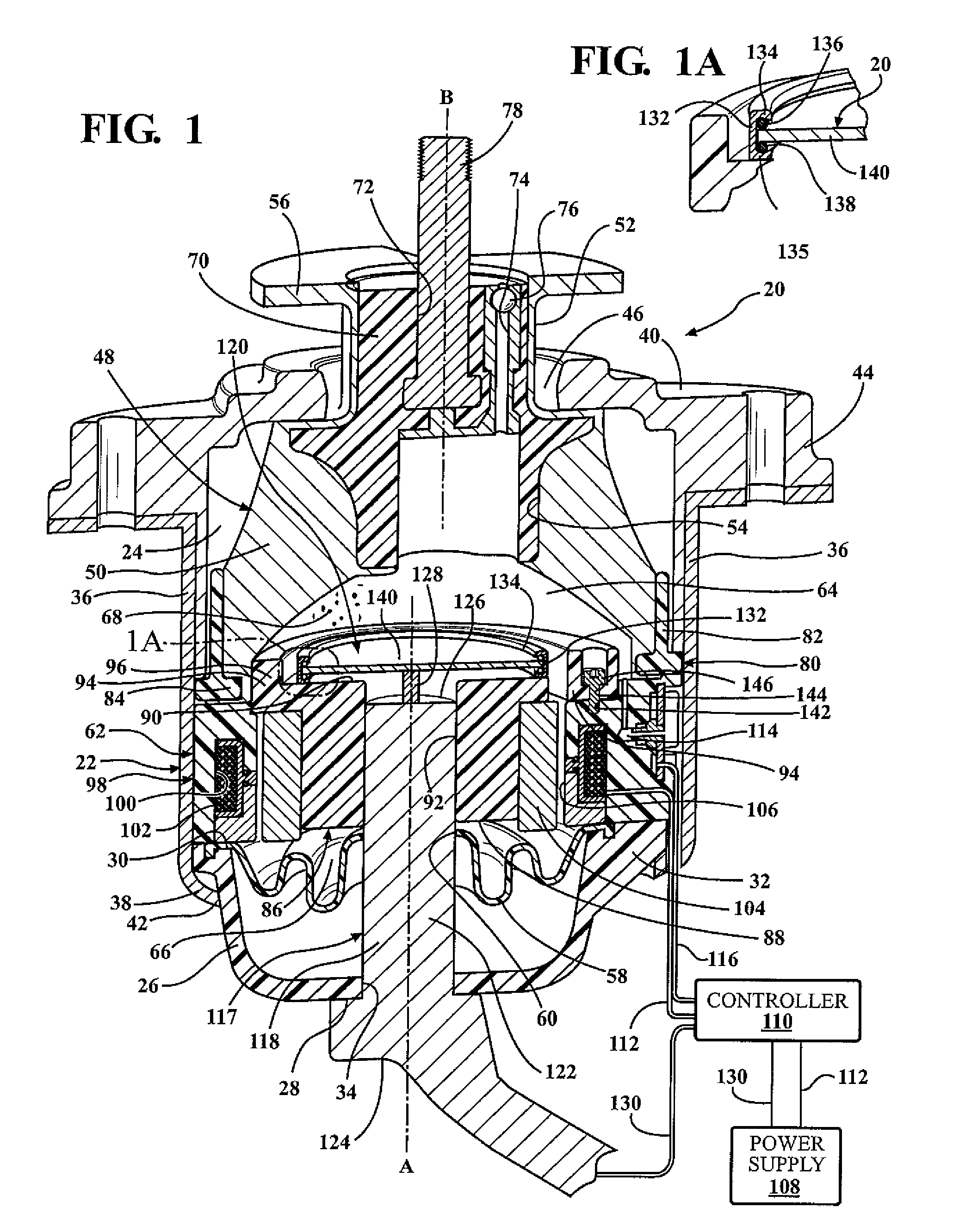

Hydraulic mount apparatus for supporting vibration source

ActiveUS9322451B2Overall light weightSimple and inexpensive designSpringsSprings/dampers design characteristicsPump chamberMagnetorheological fluid

A hydraulic mount apparatus (20) for supporting a vibration source is disclosed. The mount apparatus (20) includes a housing (22) that defines a housing chamber (24) separated by a partition assembly (62) into a pumping chamber (64) and a receiving chamber (66), each containing a magnetorheological fluid (68). A flexible body (48) is partially disposed in the pumping chamber (64) for deforming elastically in response to vibrations caused by an external excitation. A fluid passage (106) extends between the pumping chamber (64) and the receiving chamber (66) for passing the fluid therebetween during low frequency vibrations. A piezostack actuator (118) partially extends into the pumping chamber (64) for moving within the pumping chamber (64) for varying the volume of the pumping chamber (64) to prevent a pressure increase in the pressure chamber to substantially cancel relatively high frequency vibrations.

Owner:BEIJING WEST IND CO LTD

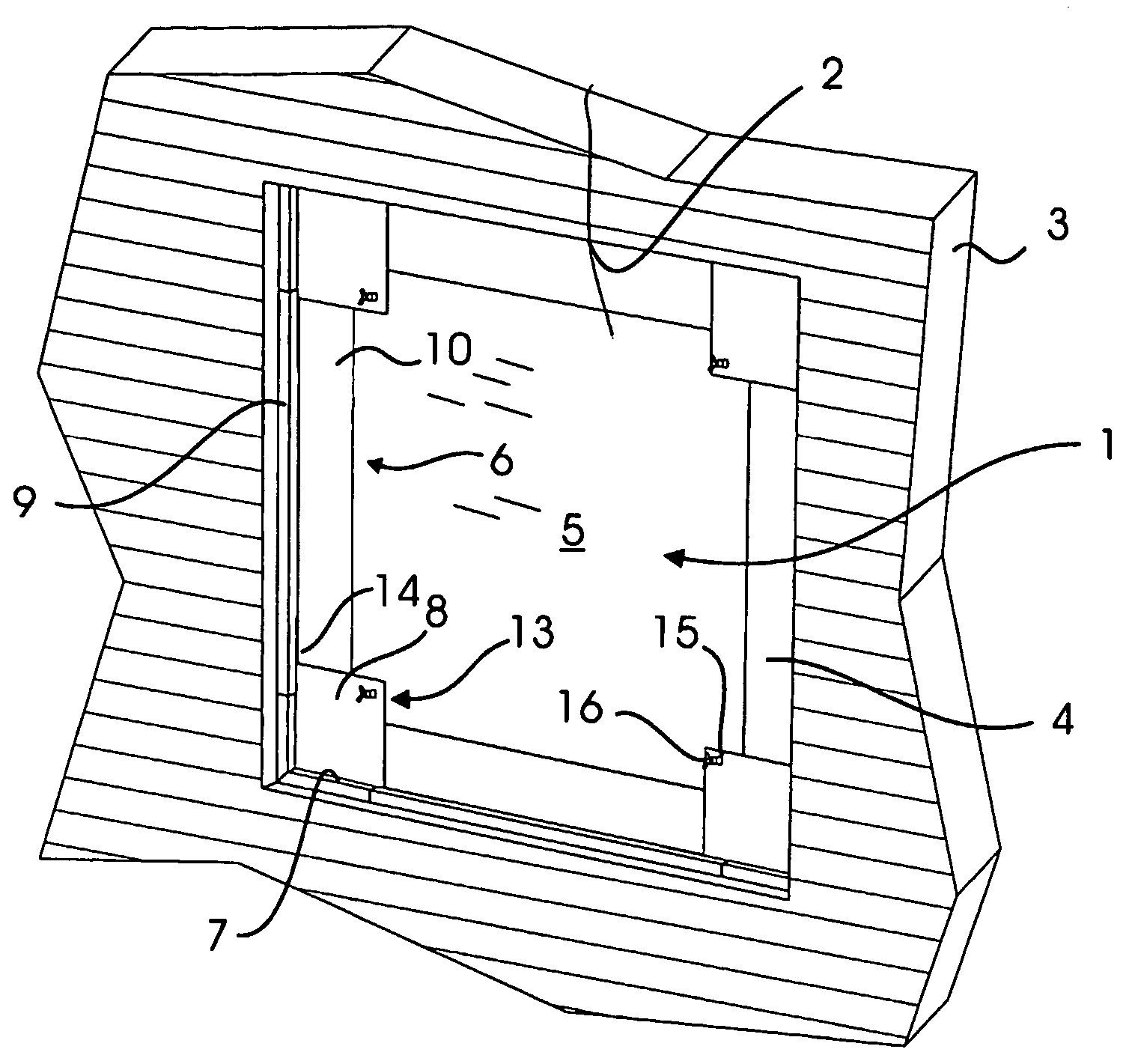

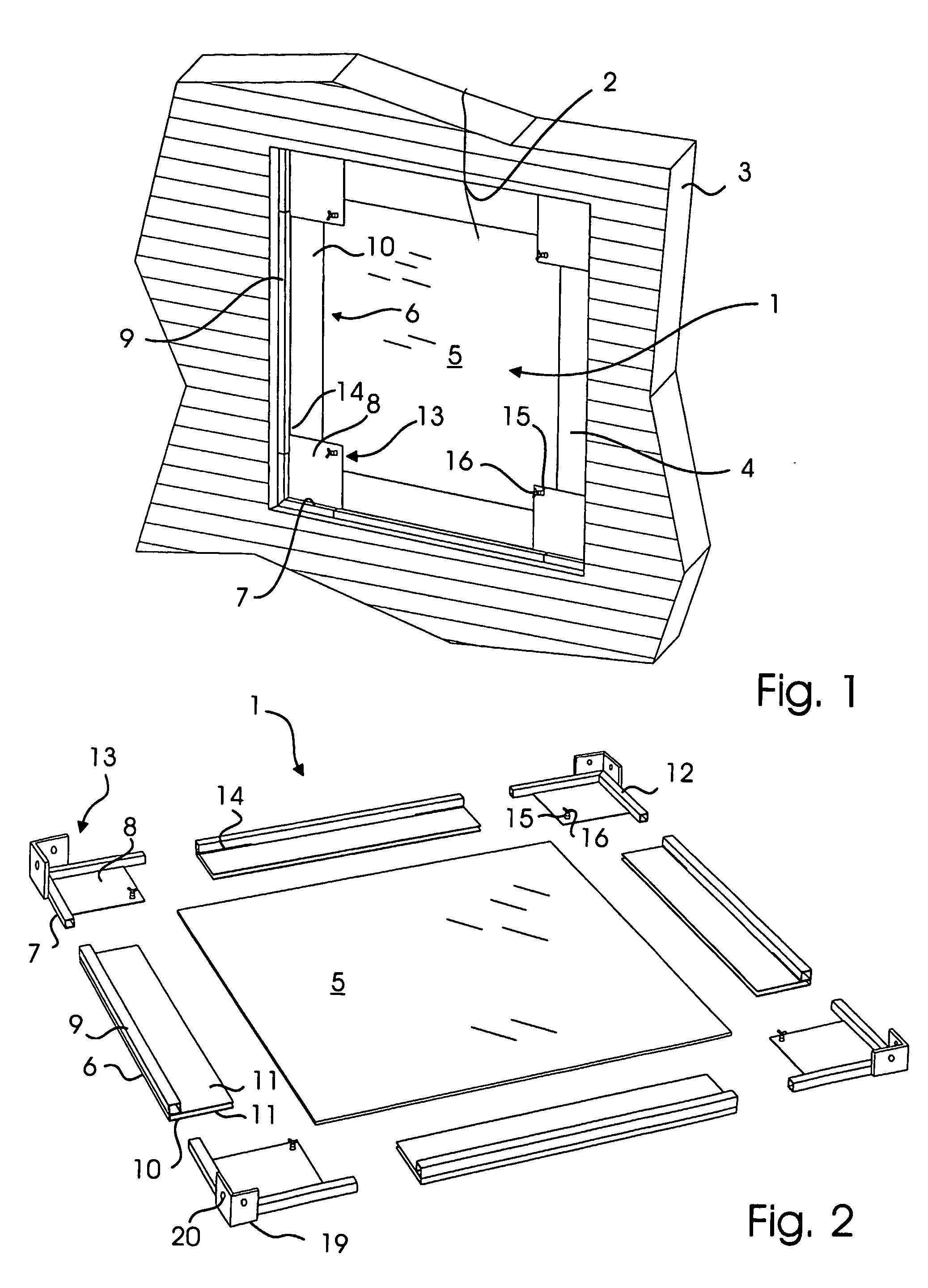

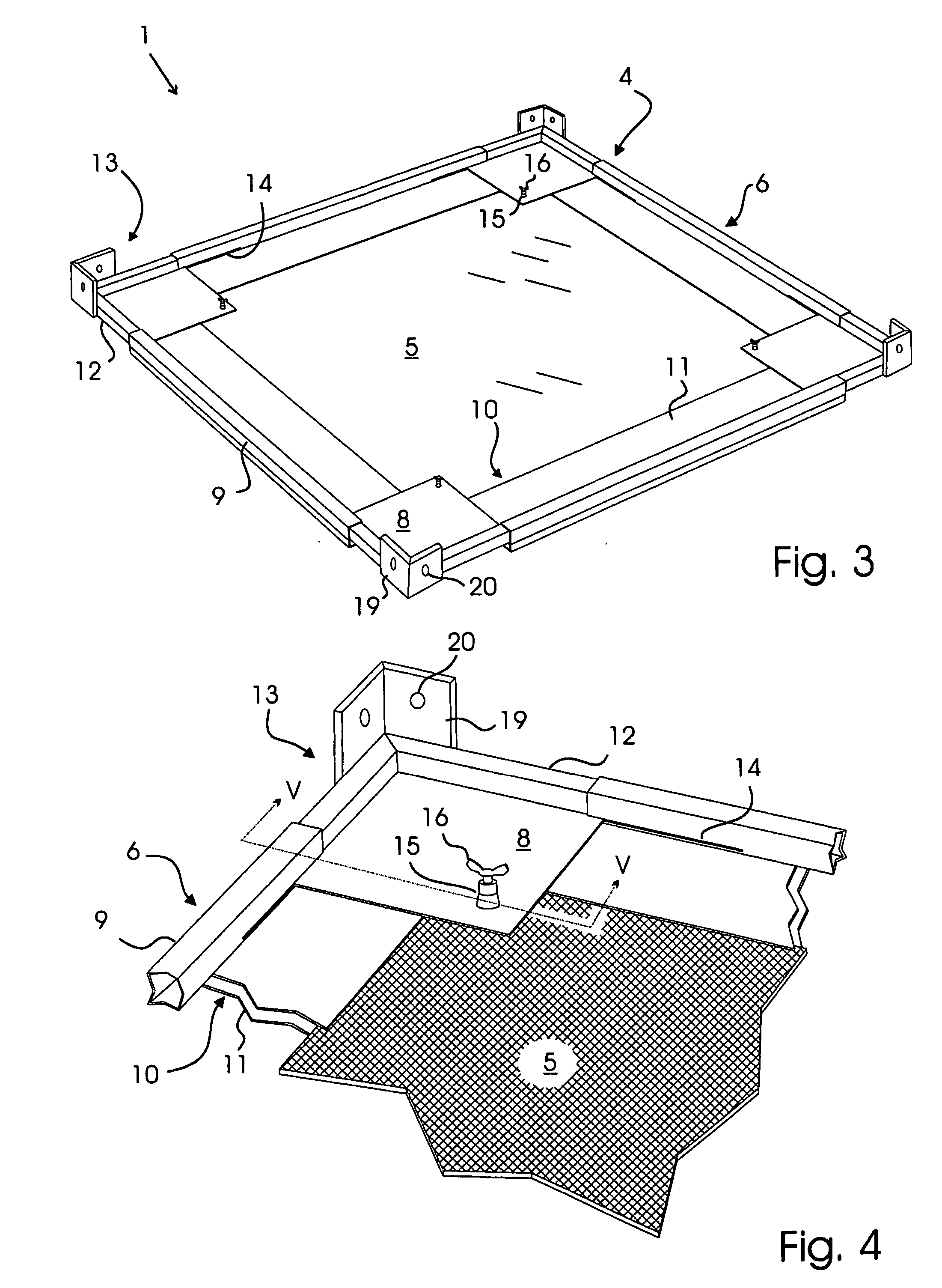

Temporary closure

ActiveUS20060174561A1Simple and inexpensive designEasy to changeExtensible doors/windowsCorner/edge jointsEngineeringFastener

A temporary closure with a solid pane of for example glass framed in a quadrangular frame that includes four side members forming at least a part of each their side of the frame sides; eight corner members each telescopically connected to a side member and in pairs forming the four corners of the frame; four longitudinal mountings fastened on each their side member and each arranged to displaceably receive an area of the pane, and a fastener for fixing the pane in a wanted position in the frame. The frame includes at least one corner plate fastened on each of the corners of the frame and having sides that are longer than the extent of the adjacent mounting in the transverse direction. The temporary closure can be mounted and demounted quickly and easily, and its size can be changed to adapt to an opening. The temporary closure gives good security against the intrusion of unauthorized persons, as the solid pane cannot easily be broken through or cut open in the same way as panes consisting of a flexible plastic sheet.

Owner:LASSE RAMSKOV HLDG

Fire-fighting monitor

ActiveUS20090000795A1Little stowage spaceSimple and inexpensive designSpraying apparatusAdjustable jointsEngineeringMechanical engineering

Owner:ELKHART BRASS MFG

Cat litter pods

An apparatus for animal litter called a Cat Litter Pod. This apparatus features a bottom built-in liner, impervious to liquids; a top gauze-like, cheesecloth material to cover the litter granules; a way to join the top and bottom to provide an encasement space; and absorbent granules of various litter material inside the encasement. This litter pod provides convenience and portability to necessary sanitation devices for cats that are kept inside. Configured as a low profile and disposable this apparatus is particularly important to older or infirm cats that have problems with limited mobility.

Owner:KINCAID VIRGINIA E

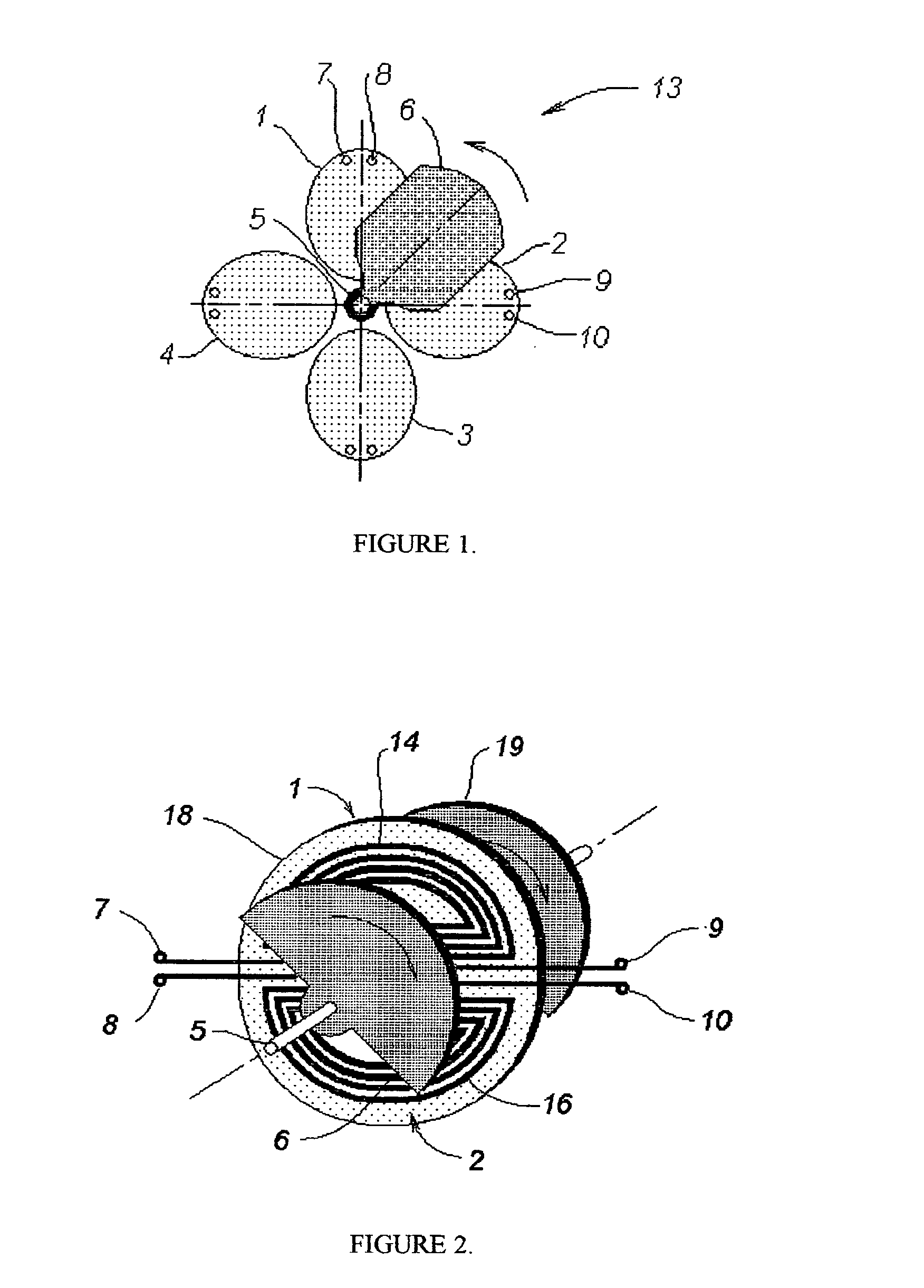

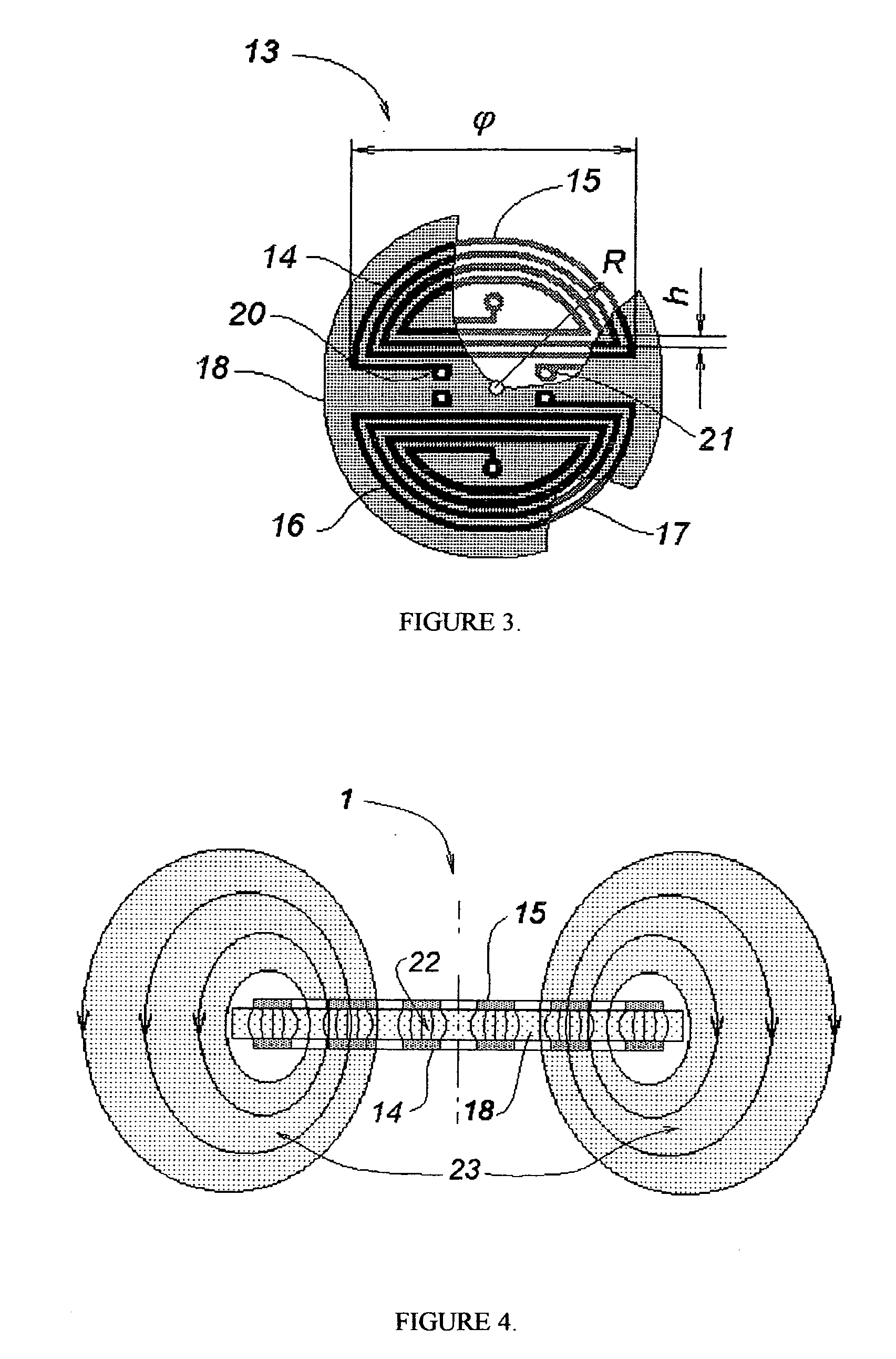

Electromagnetic apparatus for measuring angular position

InactiveUS20080054911A1Maximum sensitivityPromote conversionResistance/reactance/impedenceDevices using electric/magnetic meansWave structureClassical mechanics

An apparatus is disclosed for measuring the angular position of a movable part. The method and apparatus comprise at least two resonators formed by coupled slow-wave structures, e.g. coupled spirals, and a movable target. The angular position of the target is representative of the angular position of the movable part. A change in the angular position of the target causes a change in electrodynamic parameters of the resonators. The change in the electrodynamic parameters is converted to a reading of angular position of the target with respect to the resonators. An electromagnetic field is excited in the resonators at a frequency at which electromagnetic parameters of the resonators depend upon the position of the target.

Owner:NYCE DAVID S +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com