Leakage-free synchronous long-telescopic steam ash blower

A long-stretching, leak-synchronized technology used in steam soot blowing. , In the field of leak-free synchronous long telescopic steam sootblowers, it can solve the problems of long man-hours, low soot blowing efficiency, and large resource consumption, and achieve the effect of reducing material usage, equipment usage, and steam consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

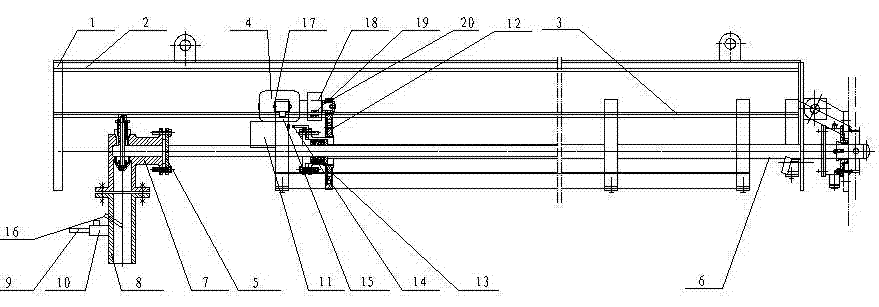

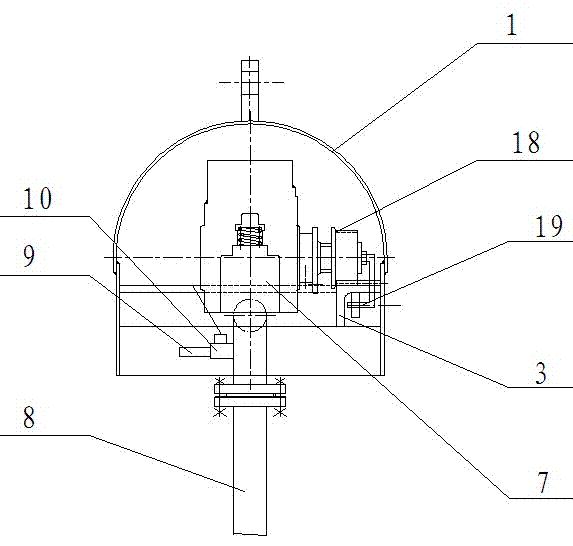

[0011] Such as figure 1 , 2 As shown, the present invention mainly consists of a soot blower including a cover 1, a structural beam 2, a support rail 3, a synchronous drive device 4, an inner tube 5 of a soot blowing pipe, a soot blowing pipe 6, a soot blowing steam solenoid valve 7, and an external steam pipe 8 , heating pipe waste takeover 9, heating pipe solenoid valve 10 and electric control device 11 are formed.

[0012] The cover 1 covers the structural beam 2 , the upper surface of the structural beam 2 is provided with a supporting track 3 , and the synchronous driving device 4 is supported on the supporting track 3 .

[0013] A driven gear 12 is installed on the soot blowing pipe 6, and one end of the inner pipe 5 of the soot blowing pipe is inserted into the soot blowing pipe 6, and a packing gland is provided at the connection between the inlet end of the soot blowing pipe 6 and the inner pipe 5 of the soot blowing pipe type sealing device 13, a rotation angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com