Three-dimensional molding based microwave absorbing body preparing method and corresponding microwave absorbing body

A three-dimensional molding and system technology, which is used in processing and manufacturing, devices that apply liquid to surfaces, electrical components, etc., can solve the problems of single powder addition ratio for molding, limited to flat materials, and difficulty in ensuring accuracy, and achieve molding. The effect of high efficiency, low preparation cost and good designability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

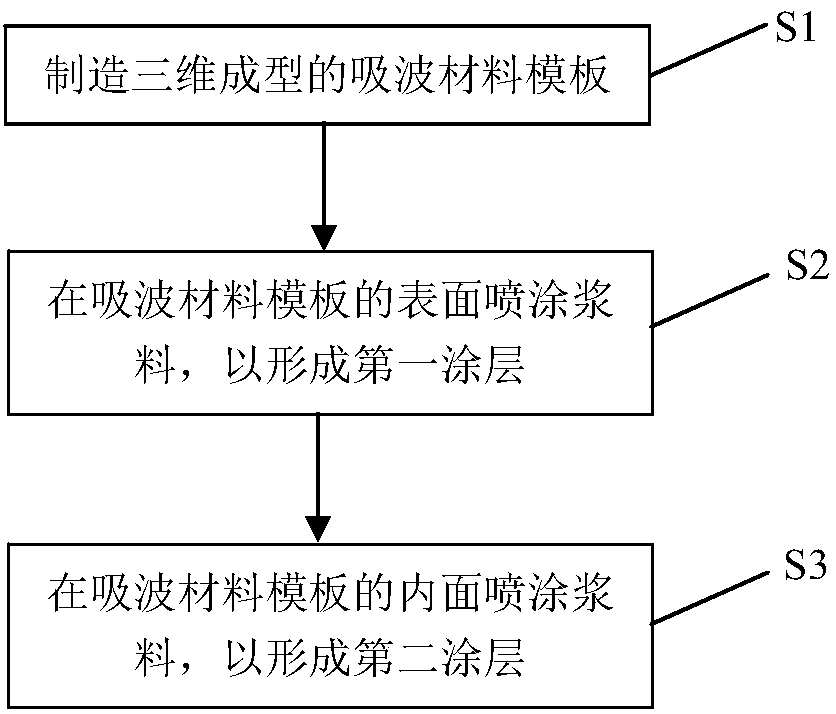

[0040] like figure 1 As shown, the present invention provides a method for preparing a wave absorber based on three-dimensional molding, which comprises the following steps:

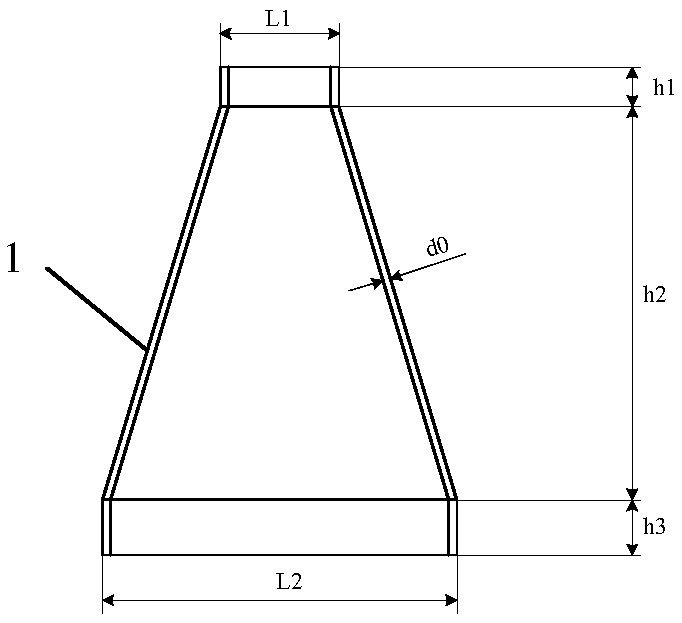

[0041] S1. Manufacture a three-dimensionally formed wave-absorbing material template 1;

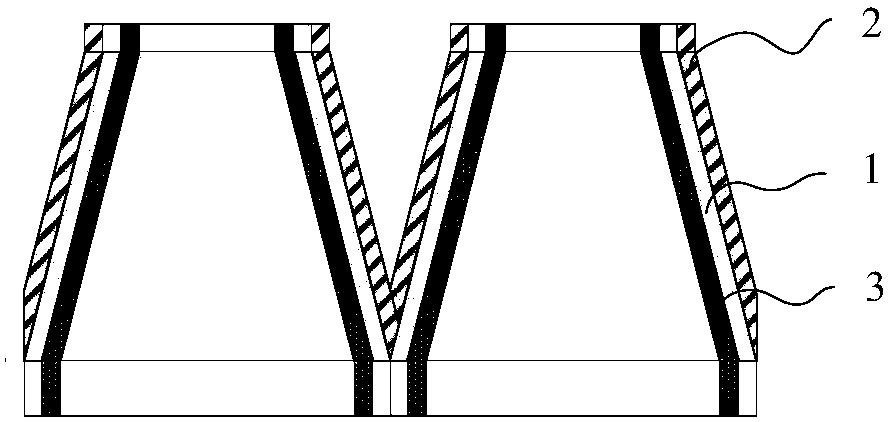

[0042] S2. Spraying slurry on the surface of the wave-absorbing material template to form the first coating 2;

[0043] S3. Spraying slurry on the inner surface of the wave-absorbing material template to form the second coating 3 .

[0044] Different from the spraying and molding mechanism of other conventional wave-absorbing materials, the forming method is a combination of spraying and three-dimensional forming to prepare gradient wave-absorbing materials, which can meet the expected requirements of electromagnetic characteristics and realize the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com