Method for fast preparing high-temperature service total IMC microscale solder joint through multi-layer micron and submicron film

A high-temperature service and multi-layer film technology, applied in the field of micro-connection, can solve problems such as low production efficiency, inability to achieve precise control of joint components, and difficulty in large-scale industrial application, so as to achieve stable performance and promote large-scale industrial applications. The effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

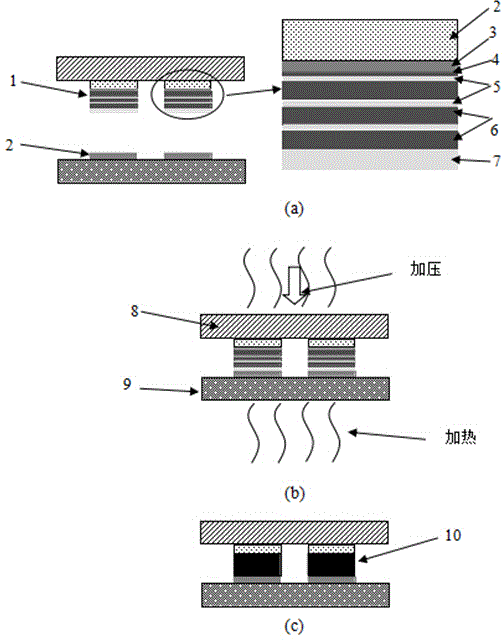

[0031] Such as figure 1 As shown, Cu 3 The Sn full IMC micro-soldering method comprises the steps:

[0032] Step 1: Prepare corresponding openings on the photoresist film by photolithography in the area of the bonding pad on the chip surface. The area of the pad and the size of the photoresist opening are 300 microns × 300 microns, and the height of the photoresist is 12.0 Microns.

[0033] Step 2: A Cu film is prepared on the bonding pad area of the chip by an evaporation method, and the thickness of the film layer is 2.0 microns.

[0034] Step 3: An electroplating method is used to prepare a Sn film on the surface of the Cu film in the previous step, and the thickness of the film layer is 0.8 microns.

[0035] Step 4: Deposit Cu on the surface of the Sn film in the previous step by vapor deposition. The thickness of the deposited film is prepared according to the atomic molar ratio of the Cu film to the previous layer of Sn film slightly less than 3:1, and the thick...

Embodiment 2

[0042] Such as figure 1 As shown, the rapid preparation of Ag by multilayer micron and submicron films 3 The Sn full IMC micro-soldering method comprises the steps:

[0043] Step 1: Prepare a mask plate by laser etching. The opening area of the mask corresponds to and aligns with the pad area to be bonded to the wafer. The area of the pad and the size of the mask opening are 200 microns × 200 microns. The mask The thickness is 15.0 microns.

[0044] Step 2: A sputtering method is used to prepare an Ag film on the pad area of the wafer, and the thickness of the film layer is 3.0 microns.

[0045] Step 3: Preparing a Sn film on the surface of the Ag film in the previous step by evaporation method, the thickness of the film layer is 0.5 micron.

[0046] Step 4: Depositing Ag on the surface of the Sn film in the previous step by sputtering, the thickness of the deposited film layer is prepared according to the atomic molar ratio of the Ag film to the previous Sn film bein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com