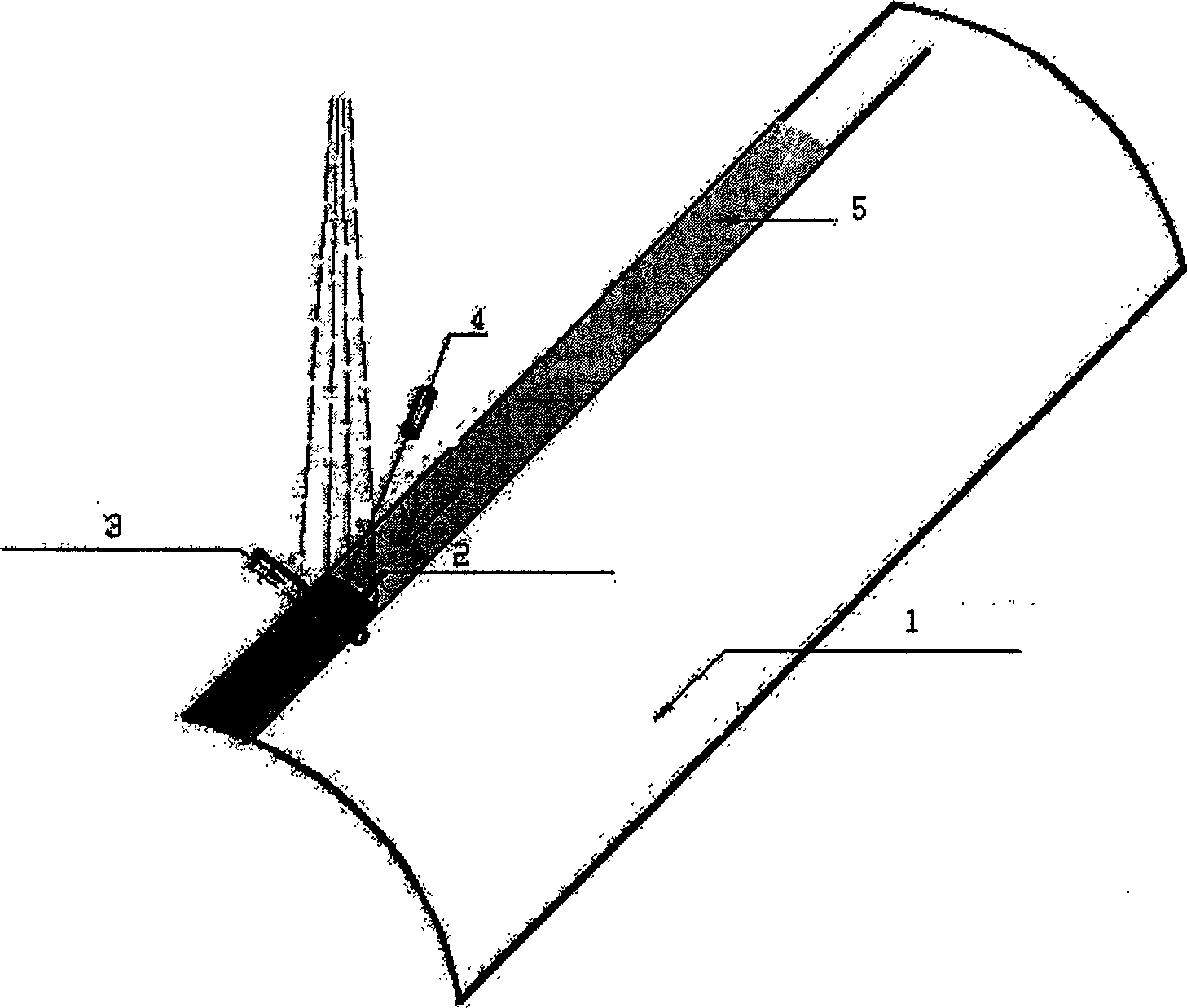

Laser reinforcing process of the intake side of turbine vane

A laser-strengthening, air-inlet technology, applied in manufacturing tools, heat treatment equipment, heat treatment process control, etc., can solve the problems of poor reliability, difficult operation, instability, etc., and achieve the best mechanical properties, easy operation, and good moisture resistance. effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: A light-absorbing material with a width of 20 mm is coated on a sample made of 0Cr17Ni4Cu4Nb (17-4PH), and the spot size is 18×12 (mm); the scanning speed is 120mm / min, and the power density is 800W / The laser beam of cm2 is used for solid solution treatment, and the cooling medium is water. The aging temperature is 460°C, and the holding time is 3.5 hours. Finally, a hardened layer with a hardness of HRC: 47, 47, 47, 48, 46 and a depth of 2 mm was obtained.

Embodiment 2

[0019] Embodiment 2: A light-absorbing material with a width of 20 mm is coated on the back arc side of the blade with a width of 0Cr17Ni4Cu4Nb (17-4PH), and the spot size is 18×12 (mm); the scanning speed is 80 mm / min , The laser beam with a power density of 755W / cm2 is used for solid solution treatment, and the cooling medium is water. The aging temperature is 480°C, and the holding time is 3.0 hours. Finally, a hardened layer with a hardness of HRC: 43, 40, 40, 44, 45 and a depth of 3 mm is obtained.

Embodiment 3

[0020] Embodiment three: a light-absorbing material with a width of about 16 millimeters is coated on the back arc side of the air inlet edge of the blade made of 0Cr17Ni4Cu4Nb (17-4PH), and the spot size is 14 × 12 (mm); the scanning speed is 180mm / min, the laser beam with a power density of 1100W / cm2 is used for solid solution treatment, and the cooling medium is argon. The aging temperature is 460°C, and the holding time is 2.0 hours. Finally, a hardened layer with a hardness of HRC: 48, 48, 47, 46, 46 and a depth of 1.5mm is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com