Method for 3D printing of monolithic catalyst

A monolithic catalyst and 3D printing technology, which is applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve problems such as high cost, inability to realize catalyst integrated molding, complex process, etc., and achieve low cost , Improve the effect of catalytic reaction, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

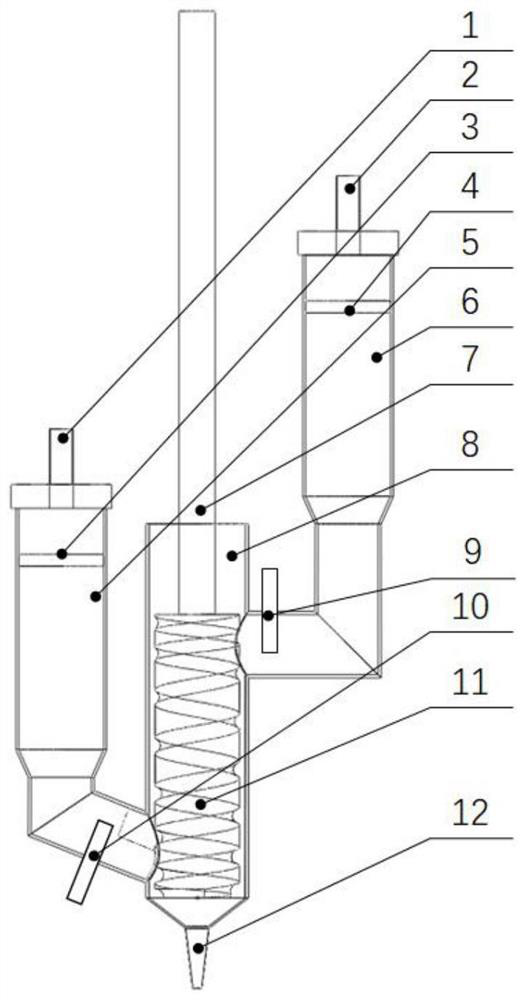

[0033] Embodiment 1, a kind of method of 3D printing monolithic catalyst, comprises the following steps:

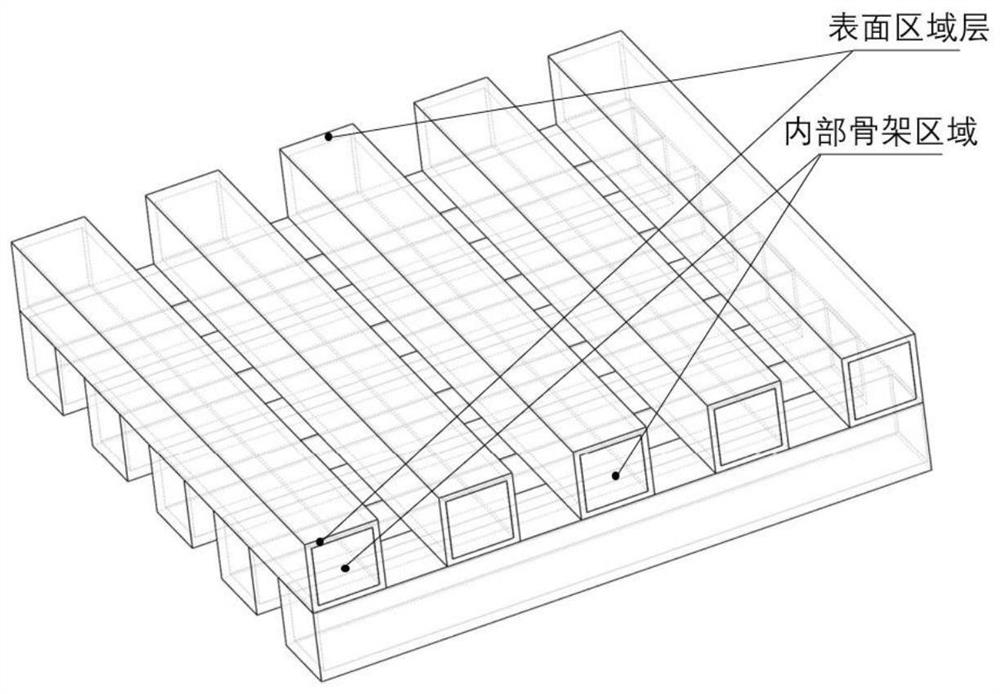

[0034] 1) Design the 3D model of the monolithic catalyst, and simulate the 3D model with different wall thickness and porosity in the COMSOL software for the catalytic experiment of methane dry reforming, and obtain the 3D model structure under the optimal mass transfer, heat transfer and conversion efficiency ,like figure 2 shown;

[0035] 2) Take 5.27g nickel nitrate hexahydrate, 1.03g ammonium dihydrogen phosphate, 0.1g turnip powder, 2.4g methylcellulose, 5g distilled water, and mechanically stir at a speed of 100r / min for 30min to obtain the catalytically active component slurry , into the first barrel 5; get 20g pseudo-boehmite, 2.4g10% dilute acetic acid, 18g distilled water, 0.075g scallop powder, mechanically stir at a speed of 100r / min for 30min to obtain alumina ceramic slurry, load into the second barrel 6;

[0036]Print on a printing base plate covered wi...

Embodiment 2

[0039] Example 2, the difference between Example 2 and Example 1 is that in step 4), the monolithic catalyst blank after constant temperature and humidity drying was kept at 400 ° C for 3 hours, and then cooled to room temperature with the furnace to prepare the monolithic catalyst 2.

Embodiment 3

[0047] Embodiment 3, a kind of method of 3D printing monolithic catalyst, comprises the following steps:

[0048] 1) Design the three-dimensional model of the monolithic catalyst, and simulate the catalytic experiment of the one-step preparation of ethylene glycol by using COMSOL software for the models with different wall thicknesses and porosities, and obtain the optimal mass transfer, heat transfer and conversion efficiency. 3D model structure;

[0049] 2) Take 5 g of titanium-silicon molecular sieve TS-1, 0.18 g of scallop powder, 2 g of silica sol, and 4 g of distilled water, mechanically stir at a speed of 100 r / min for 30 min to obtain a slurry of catalytically active components, and load it into the first cylinder 5; Take 20g of silicon dioxide, 5g of silica sol, 5g of distilled water, and 0.5g of scallop powder, mechanically stir at a speed of 100r / min for 30min to obtain a silicon oxide ceramic slurry, and put it into the second barrel 6;

[0050] Print on a printin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com