Nitrogen-doped carbon/titanium dioxide composite nanofibers carrier preparation method

A technology of composite nanofibers and titanium dioxide, which is applied in catalyst carriers, chemical instruments and methods, chemical characteristics of fibers, etc., can solve the problems of reducing catalyst activity, electrical conductivity, uneven distribution, weak interaction, etc., and achieves good application prospects. The effect of improving corrosion resistance and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

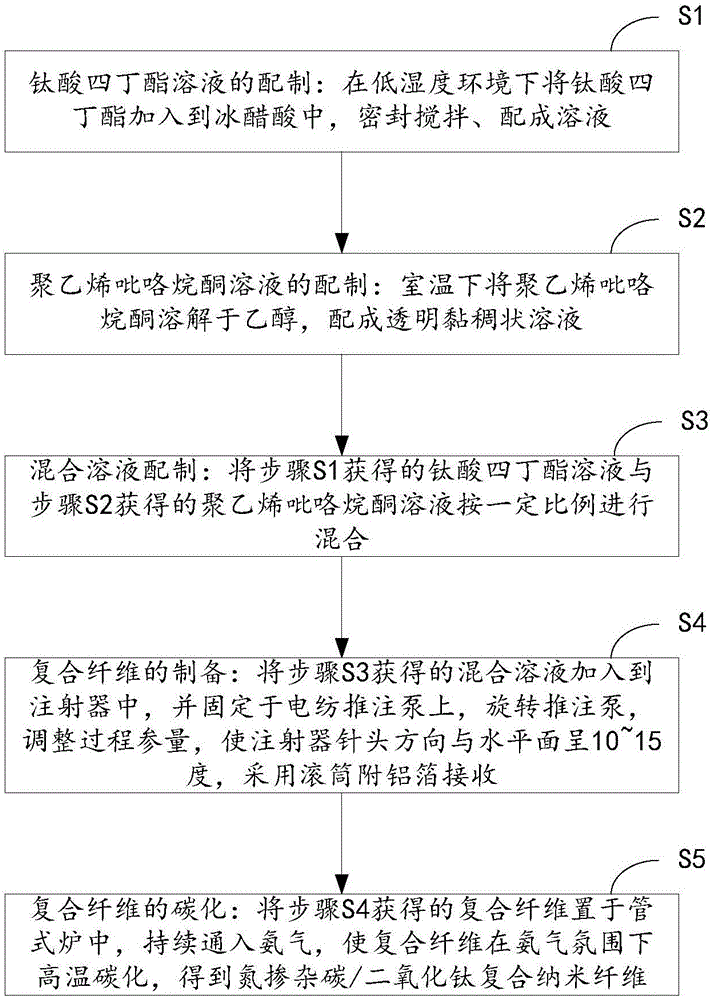

[0034] seefigure 1 , the present invention discloses a method for preparing a nitrogen-doped carbon / titania composite nanofiber carrier, the preparation method comprising:

[0035] Step S1. Preparation of tetrabutyl titanate solution: add tetrabutyl titanate to glacial acetic acid in a low-humidity environment, seal and stir to form a solution; wherein, the concentration of tetrabutyl titanate ranges from 0.01 to 0.5 g / ml, sealed and stirred for 15-60 minutes;

[0036] Step S2. Preparation of polyvinylpyrrolidone solution: dissolve polyvinylpyrrolidone in ethanol at room temperature to form a transparent viscous solution; wherein the concentration of polyvinylpyrrolidone ethanol solution is 10-20 wt.%, magnetically stirred for 6-8 hours, polyvinylpyrrolidone The average molecular weight ranges from 40,000 to 1,500,000 (K30 to K90), and the concentration of the prepared solution depends on the molecular weight of the selected polyvinylpyrrolidone. The higher the molecular weig...

Embodiment 2

[0041] A preparation method of nitrogen-doped carbon / titanium dioxide composite nanofiber carrier, the preparation method comprising:

[0042] Mix the glacial acetic acid solution of tetrabutyl titanate and the ethanol solution of polyvinylpyrrolidone in an appropriate proportion, prepare a composite fiber material by electrospinning technology, and then carbonize the material at high temperature in an ammonia atmosphere to obtain nitrogen-doped carbon / Titanium dioxide composite fibers.

Embodiment 3

[0044] A preparation method of nitrogen-doped carbon / titanium dioxide composite nanofiber carrier, said preparation method comprising the steps of:

[0045] (1) Preparation of tetrabutyl titanate solution: take 0.1 g of tetrabutyl titanate and add it to 2 ml of glacial acetic acid, prepare a solution with a volume mass fraction of 0.05 g / ml, and stir magnetically for 15 min;

[0046] (2) Preparation of polyvinylpyrrolidone solution: Dissolve 1g of polyvinylpyrrolidone K90 in 8ml of ethanol to prepare a solution with a volume mass fraction of 13.5wt.%, and magnetically stir for 6 hours to obtain a transparent solution;

[0047] (3) Preparation of the composite solution: mix the tetrabutyl titanate solution obtained in step (1) and the polyvinylpyrrolidone solution obtained in step (2), and magnetically stir for 20 minutes at room temperature to obtain a light yellow transparent viscous liquid;

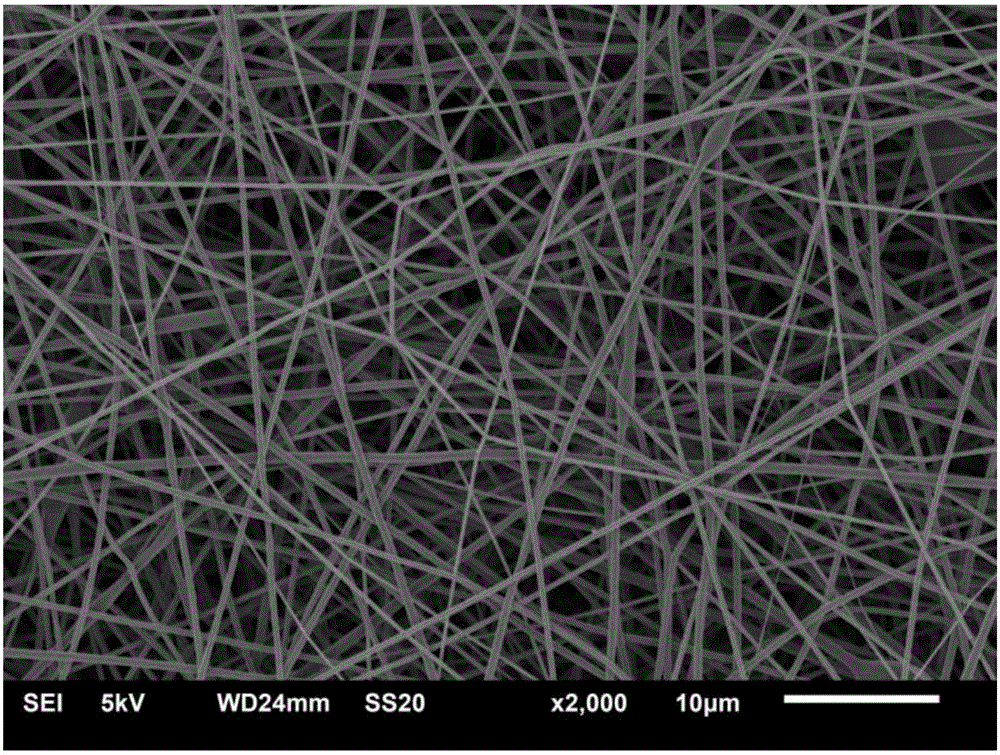

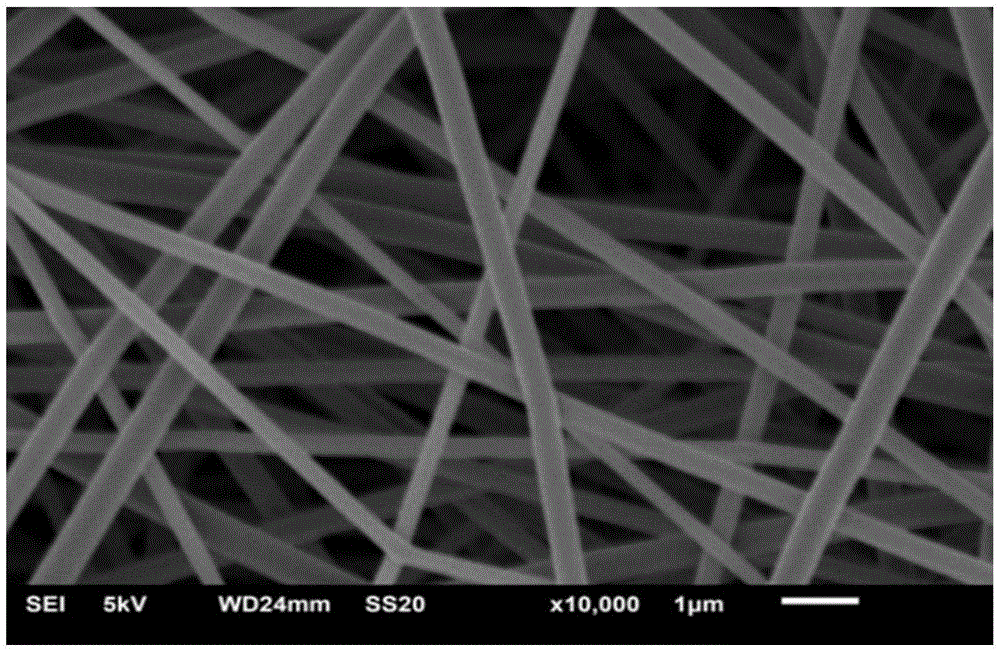

[0048] (4) Preparation of composite nanofiber membrane: Add the composite solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com