Semi-conductor oxidate gas sensor preparation method

A gas sensor and oxide technology, applied in electrical components, electrical solid devices, material resistance, etc., can solve problems such as hindering the popularization and use of gas sensors, difficult to effectively control the microstructure, and increasing the cost of component manufacturing, and achieve excellent consistency. The effect of stability and stability, uniform shape, and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

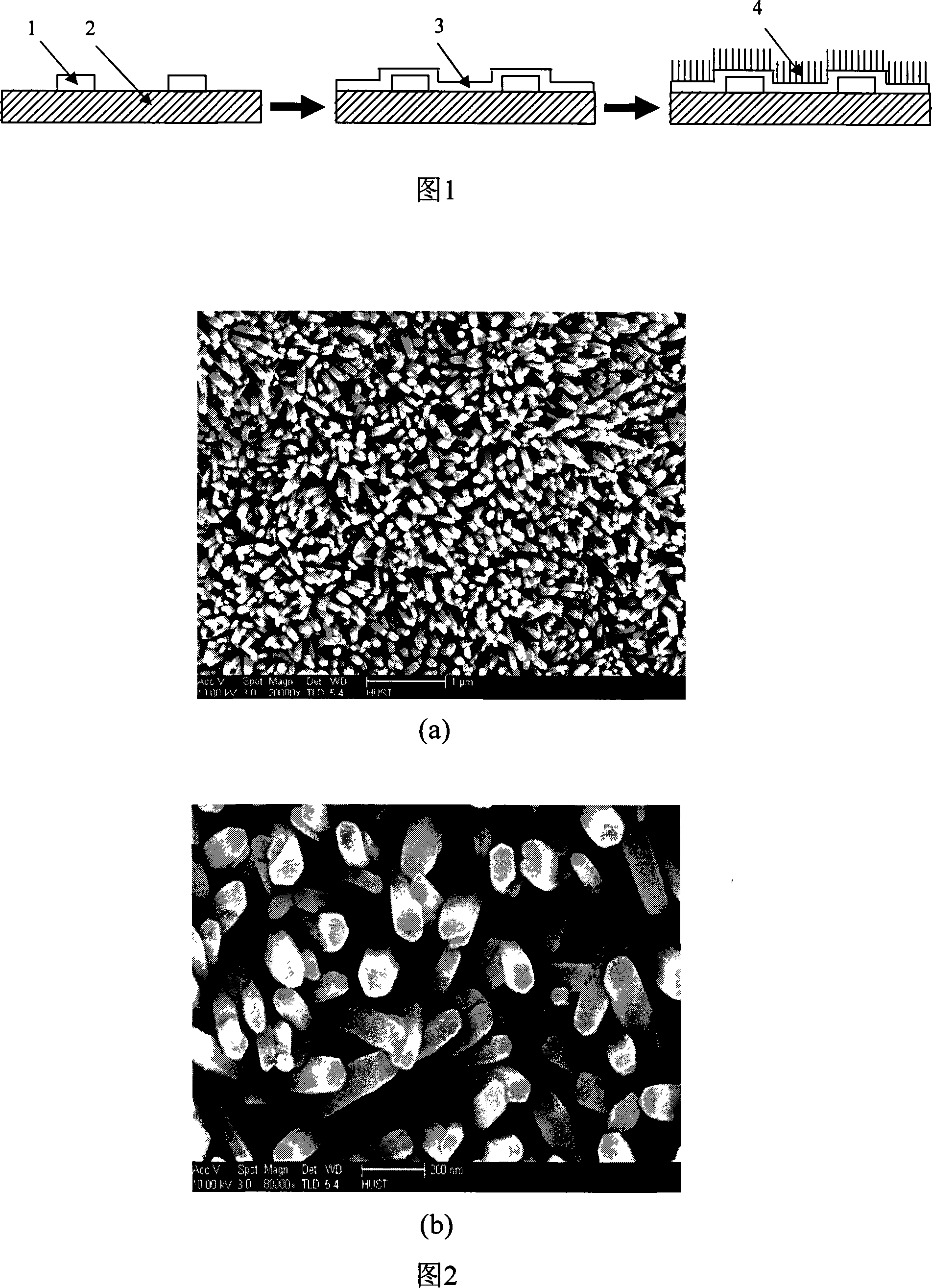

[0032] Pretreatment: Place the flat silicon substrate with heating and measuring electrodes in the alcohol solution of 0.5 mol / L zinc acetate and soak for 10 minutes, take it out and dry it at 80°C, and heat it at 350°C for decomposition. Repeat the above operation steps 5 times to form a layer of nano ZnO seed crystals on the substrate;

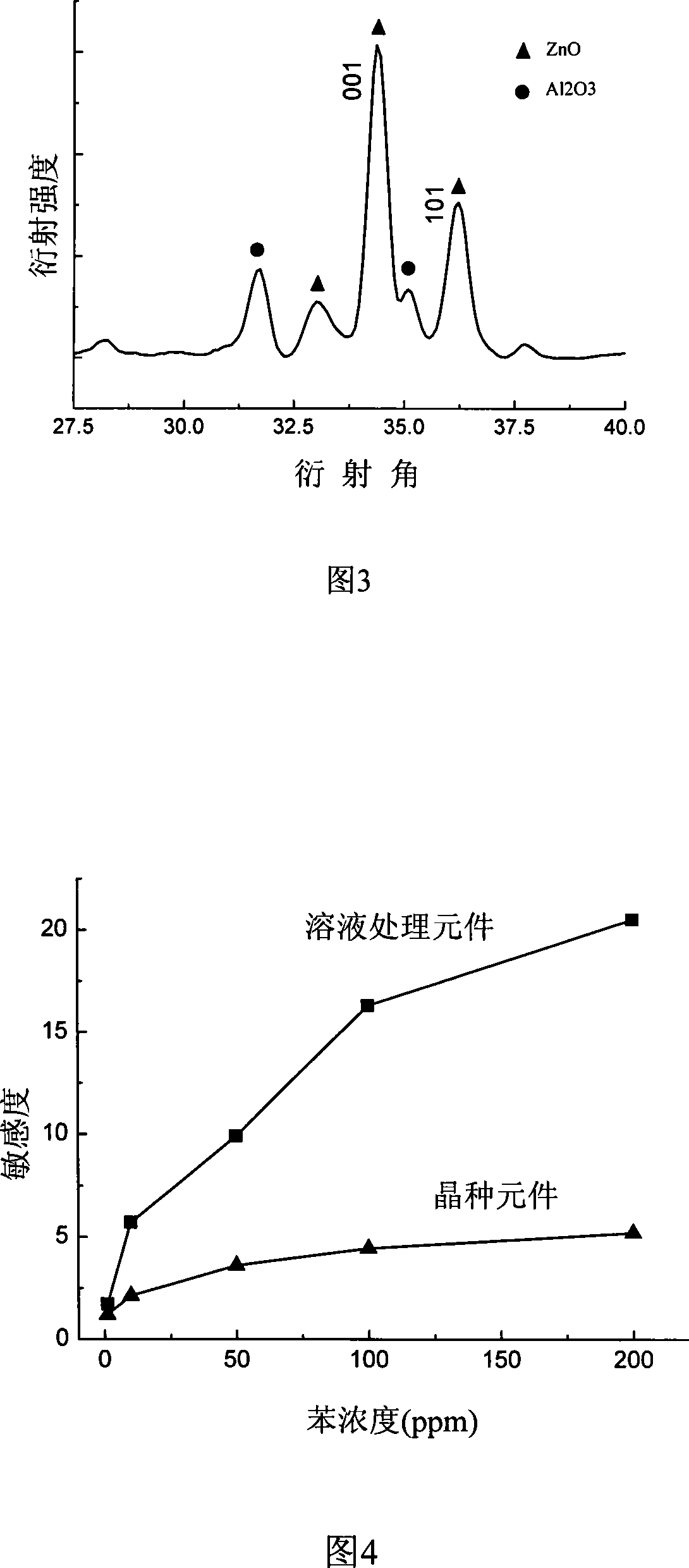

[0033] Solution treatment: add 0.6584 g of zinc acetate to 120 ml of deionized water, oscillate ultrasonically to form a uniform solution, drop into 320 μl of ethylenediamine, and transfer it to a sealable container. Suspend the flat substrate deposited with the ZnO seed crystal film in the solution, seal it with a cover, and place it in a water bath box at 80° C. for one and a half hours to keep warm. Take it out and cool it down to room temperature, wash it with deionized water for 15 minutes, put it in a drying oven for drying at 40°C, and then transfer it to a horse boiling furnace for sintering at 350°C to form a flat gas sensor (see Fi...

example 2

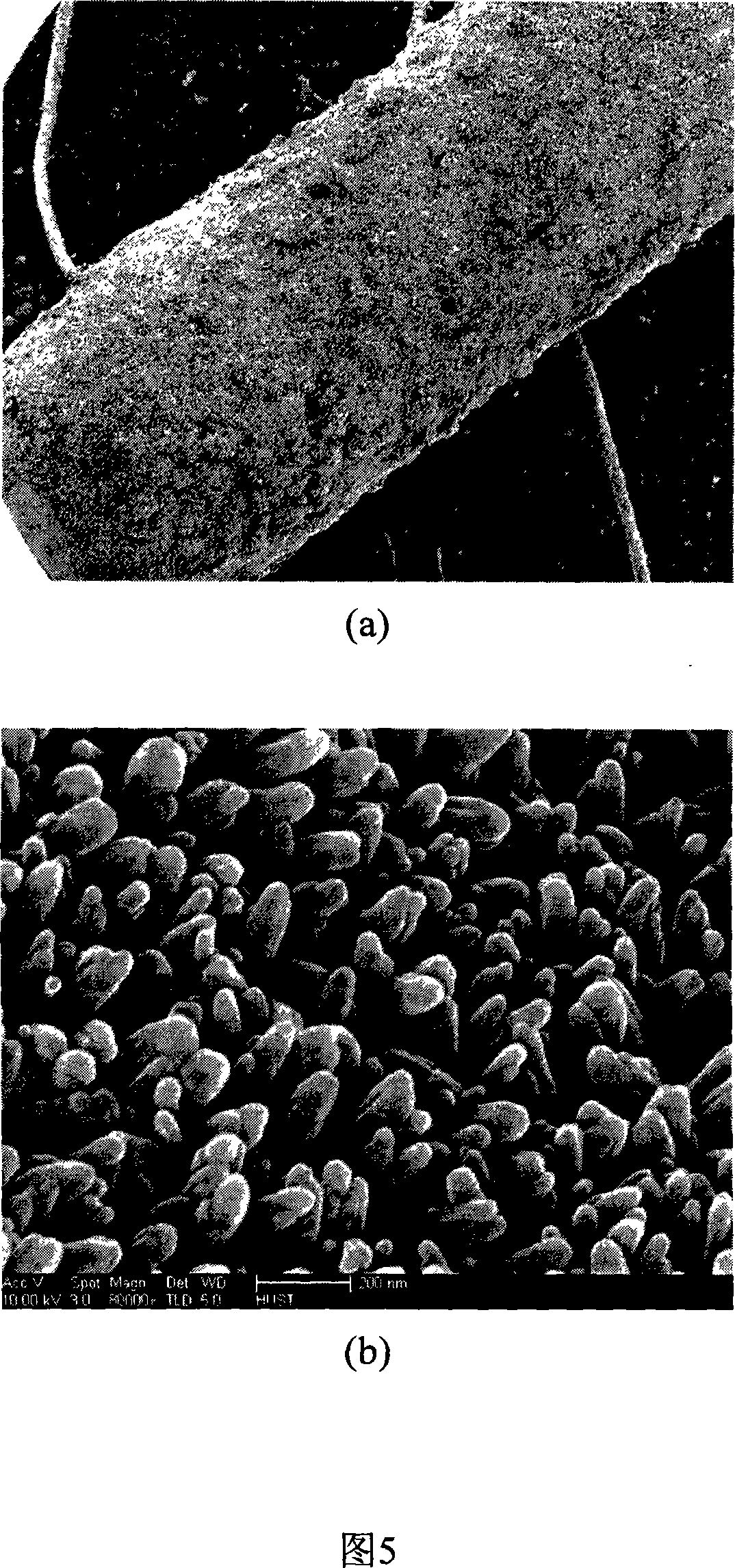

[0047] Pretreatment: Place the flat ceramic substrate with heating and measuring electrodes in the alcohol solution of 0.5 mol / L stannous sulfate and soak for 10 minutes, take it out and dry it at 80°C, and heat it to decompose at 400°C.

[0048] Repeat the above operation steps 5 times to form a layer of nano SnO on the substrate 2 Seed;

[0049] Solution treatment: Add 0.3187 g of stannous sulfate to 120 ml of dehydrated ethanol, oscillate with ultrasonic waves to form a uniform solution, drop into 320 μl of ethylenediamine, and transfer it into a sealable container. will deposit the SnO 2 The flat substrate of the seed crystal film is suspended in the solution, sealed with a cover, and kept in a water bath at 95°C for 24 hours. Take it out and cool it down to room temperature, wash it with deionized water for 15 minutes, put it in a drying oven for drying at 40°C, and then transfer it to a horse boiling furnace for sintering at 350°C to form a flat-plate gas sensor.

[0...

example 3

[0056] Pretreatment: Place the flat ceramic substrate with heating and measuring electrodes in the alcohol solution of 0.5 mol / L ferric nitrate and soak for 10 minutes, take it out and dry it at 80°C, and heat it to decompose at 350°C. Repeat the above steps 5 times to form a layer of nano-Fe on the substrate 2 o 3 Seed;

[0057] Solution treatment: Add 1.105g of ferric nitrate into 60ml of deionized water, and ultrasonically oscillate to form a uniform solution; at the same time, add 0.3g of sodium hydroxide to 60ml of deionized water and ultrasonically oscillate to form a uniform solution; in an airtight container. will deposit Fe 2 o 3 The flat substrate of the seed crystal film is suspended in the solution, covered and sealed, and kept in an 80° C. water bath for one and a half hours. Take it out and cool it down to room temperature, wash it with deionized water for 15 minutes, put it in a drying oven for drying at 40°C, and then transfer it to a horse boiling furnace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com