Integral forging method of variable-wall-thickness thick-wall end socket of high flange

A technology of integral forging and variable wall thickness, applied in the direction of metal processing equipment, etc., can solve the problems of unfavorable grain structure refinement and homogenization, lengthy process, damage and cracking, etc., to avoid excessive thinning of wall thickness, shortening of process, The effect of preventing forging cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] A method for integrally forging a thick-walled head with a high flange and variable wall thickness, comprising the following steps:

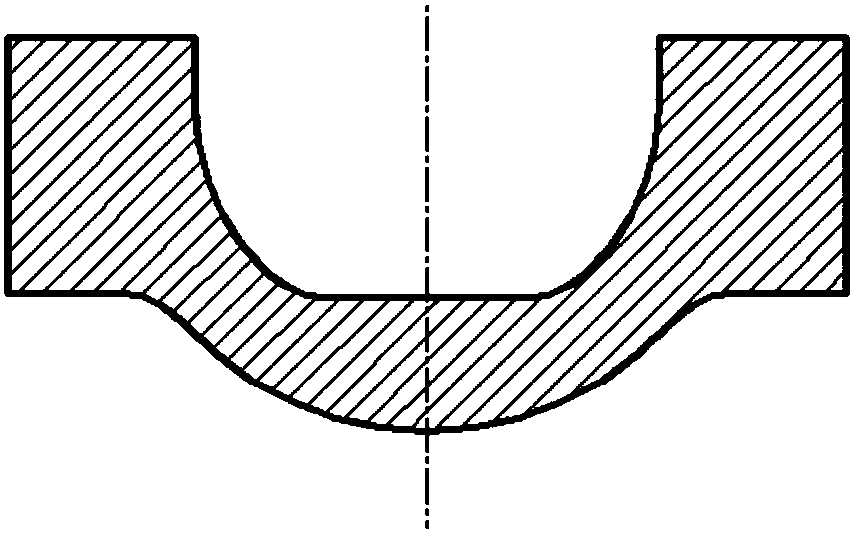

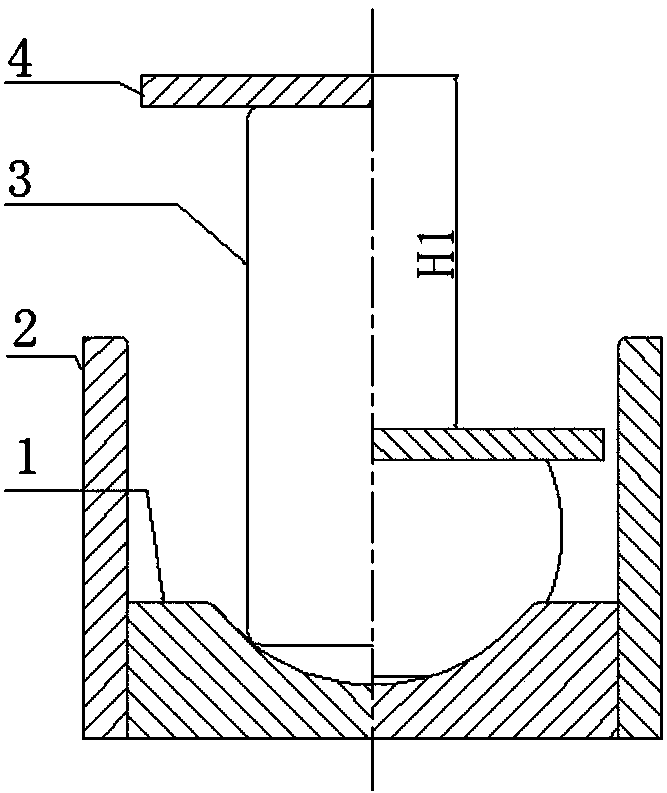

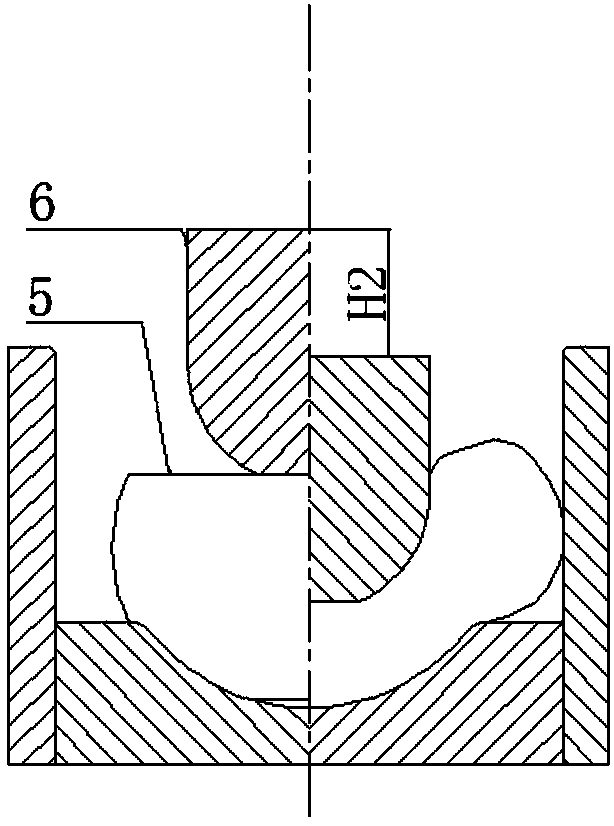

[0031] 1. According to figure 1 The relevant data of the target head shown is determined by calculation for the shape and size of the blank for forging and the shape and size of the mold, and the die 1, the barrel die 2, the rotary punch 6 for extrusion, the ring inner pressure ring 8, the ring outer pressure ring Circle 9.

[0032] 2. Heating the steel ingot to 1250±20°C, performing repeated upsetting and elongation forging to eliminate the internal casting defects of the steel ingot, and forging it into a cylindrical billet 3.

[0033] 3. Place the forming die 1 together with the cylinder mold 2 assembled with it on the press platform, put the cylindrical blank 3 hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com