Broadband wave-absorbing material and preparation method thereof

A wave-absorbing material and high-frequency wave-absorbing technology, which is applied in the field of broadband wave-absorbing materials and their preparation, can solve problems such as single product structure, poor designability, and insufficient manufacturing technology, and achieve low preparation costs, high molding efficiency, and good quality. Designable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0057] The preparation method of the low-scattering covering for field testing provided by the invention has the following steps:

[0058] 1. Design of broadband absorbing material

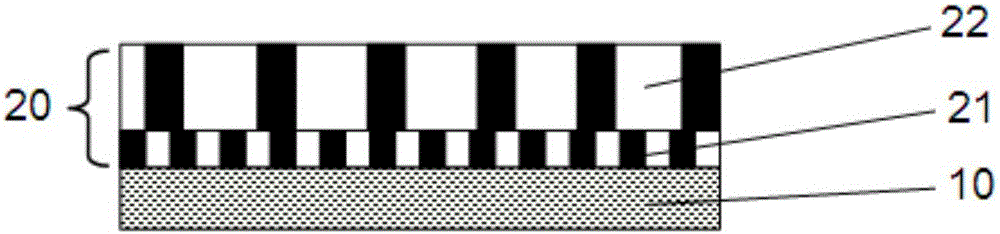

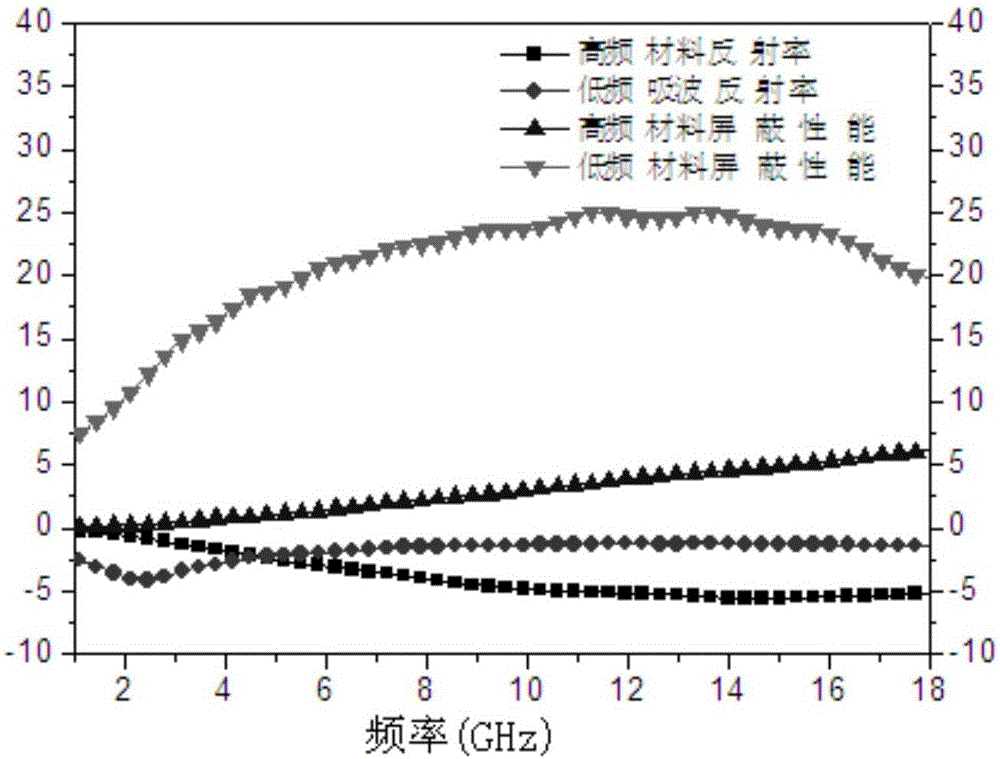

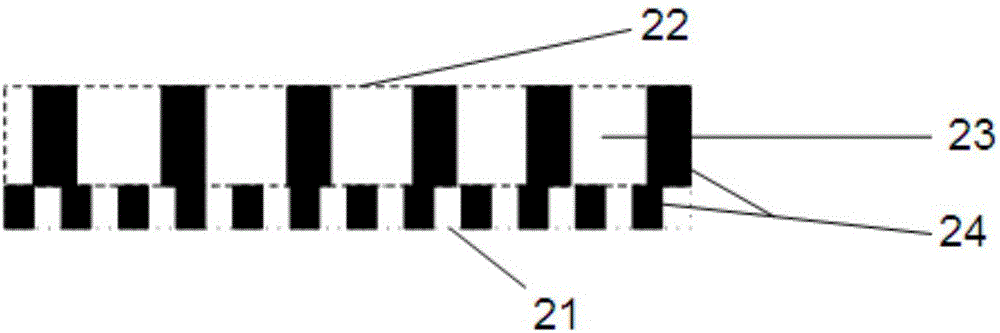

[0059] ① The absorbing materials in the high frequency range of 2-18GHz are mainly sheet-like carbonyl iron particles, and the absorbing materials in the low-frequency range of 1-2GHz are mainly sheet-type FeSi materials. The average particle size of carbonyl iron particles is generally 3-5μm. The flake FeSi particle size is close to 40-100 μm. The double-layer structure design is carried out according to the particles of two sizes, that is, the layered design of the two particle materials, the upper layer of carbonyl iron small particle absorbing material, and the lower layer of FeSi large particle absorbing material.

[0060] ②Using the multi-layer design principle to design the high-frequency wave-absorbing layer, the design frequency band is 8-18GHz. Firstly, the genetic algorithm is used to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com