High temperature resistant radar wave absorption material based on double-layer metamaterials and preparation method thereof

A technology of radar absorbing materials and metamaterials, applied in printing devices, electrical components, printing, etc., can solve problems such as poor designability, narrow absorbing frequency band, and difficult implementation, and achieve simple structure, stable performance, and easy The effect obtained

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

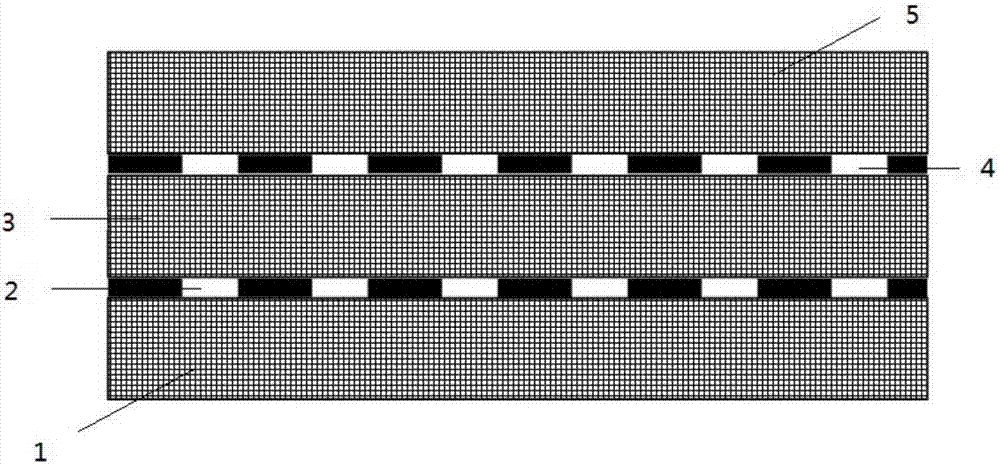

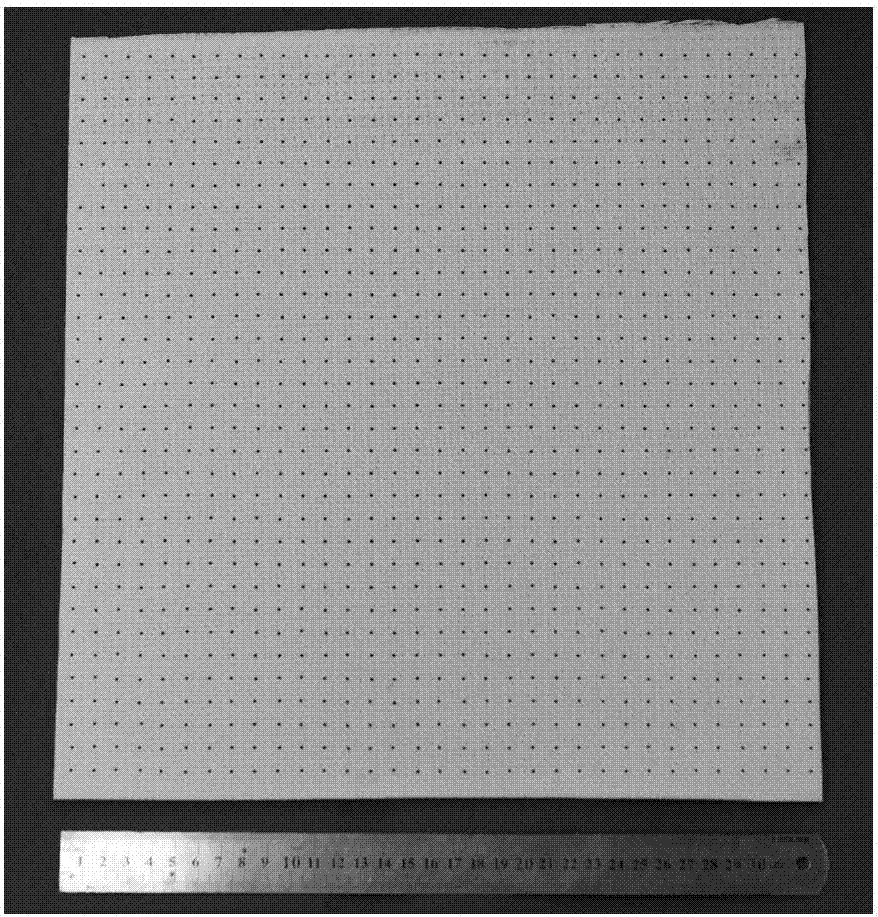

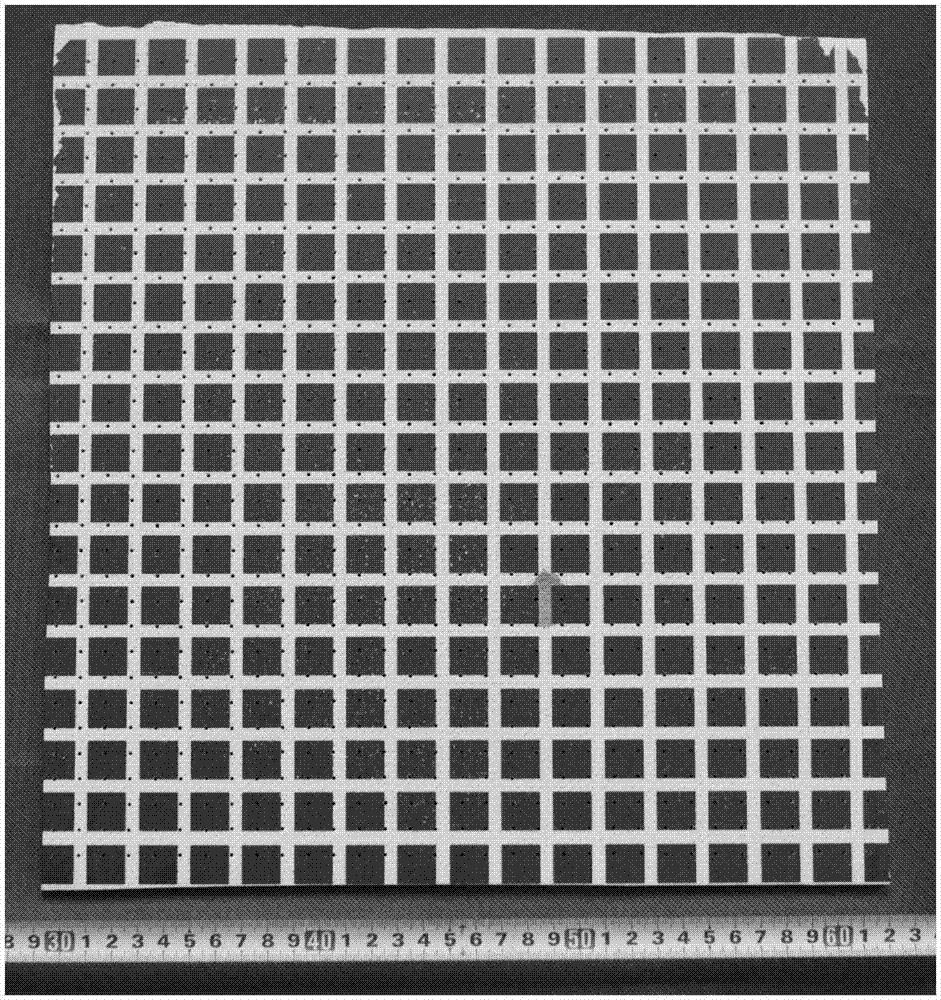

[0048] Such as figure 1 As mentioned above, the high-temperature-resistant radar absorbing material of this embodiment sequentially includes an inner dielectric layer 1, an inner resistive high-temperature metamaterial layer 2, an intermediate dielectric layer 3, an outer resistive high-temperature metamaterial layer 4, Outer dielectric layer 5.

[0049] Among them, the three dielectric layers are all made of continuous aluminosilicate fiber-reinforced mullite composite materials; the inner resistive high-temperature metamaterial layer 2 and the outer resistive high-temperature metamaterial layer 4 both include the electric phase substance RuO 2 Powder, glass powder, and organic carrier are prepared, wherein, in the inner resistance type high-temperature metamaterial layer 2, glass powder and RuO 2 The mass ratio of powder is 48:52, according to the mass of organic carrier, it is glass powder and RuO 2 25% of the sum of the powder mass is prepared, and the organic vehicle in...

Embodiment 2

[0062] Such as figure 1 As mentioned above, the high-temperature-resistant radar absorbing material of this embodiment includes an inner dielectric layer 1, an inner resistive high-temperature metamaterial layer 2, an intermediate dielectric layer 3, an outer resistive high-temperature metamaterial layer 4, and an outer resistive high-temperature metamaterial layer from the inside to the outside. Layer Dielectric Layer 5.

[0063] Among them, the three dielectric layers are all made of continuous aluminosilicate fiber reinforced mullite composite materials; the inner resistive high-temperature metamaterial layer 2 and the outer resistive high-temperature metamaterial layer 4 are composed of conductive phase materials lead ruthenate, Glass powder and organic carrier are prepared, wherein, in the inner resistance type high-temperature metamaterial layer 2, the mass ratio of glass powder and lead ruthenate powder is 49:51, and the mass ratio of glass powder and lead ruthenate pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com