Patents

Literature

94results about How to "Reduce IR emissivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

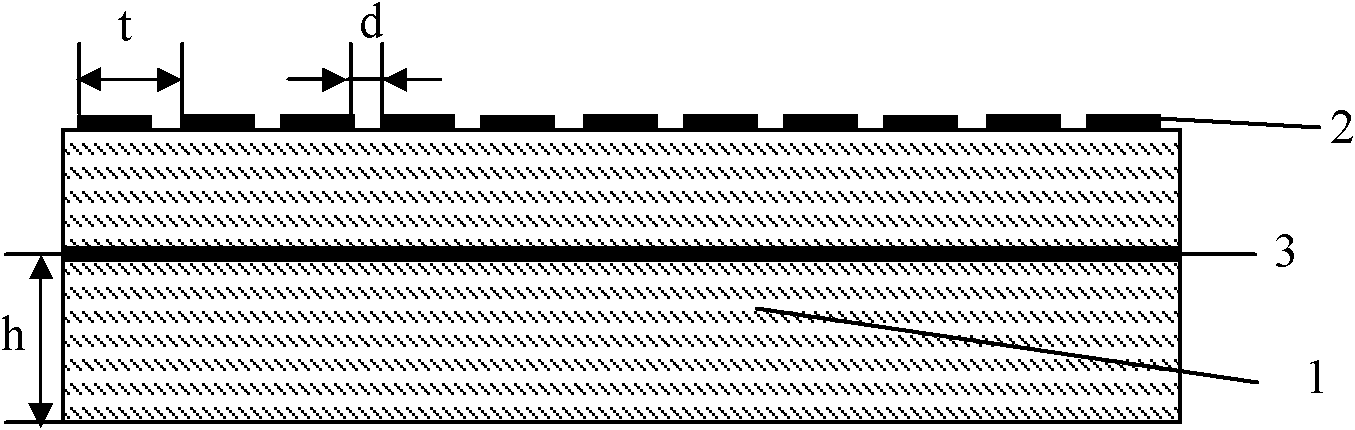

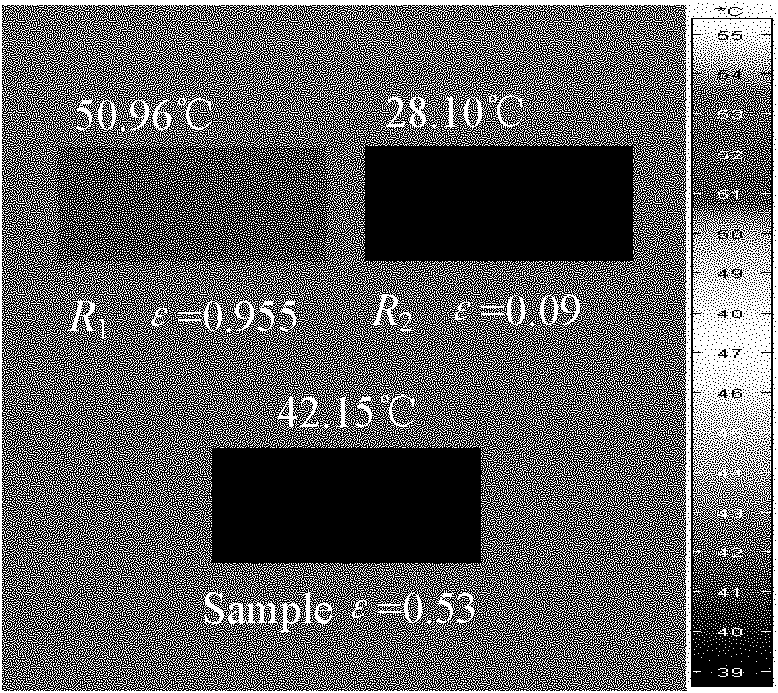

Radar and infrared compatible stealthy material and preparation method thereof

ActiveCN102179968AAchieve broadband absorbing performanceReduce IR emissivityLaminationLamination apparatusGlass fiberScreen printing

The invention discloses a radar and infrared compatible stealthy material and a preparation method thereof. The compatible stealthy material is mainly formed by compounding a radar wave absorbing structural layer and an infrared stealthy functional layer, wherein the radar wave absorbing structural layer is made of a glass fiber reinforced glass steel composite material; and the infrared stealthy functional layer is a capacitive frequency selective surface. The preparation method comprises the following steps of: preparing the capacitive frequency selective surface by a printed circuit board (PCB) process; preparing a layer of resistance sheet on glass fiber plain cloth by using conductive carbon slurry through a screen printing process; preparing the glass fiber reinforced glass steel composite material by using epoxy resin as a base material and the glass fiber plain cloth as a reinforcing material through a resin forming process; and curing to make the capacitive frequency selective surface compounded and superposed so as to obtain the radar and infrared compatible stealthy material. The compatible stealthy material has a simple structure and low cost, is convenient to prepare, and has the duplex characteristics of high reflection of an infrared wave band and high permeation of a radar wave band.

Owner:NAT UNIV OF DEFENSE TECH

Novel infrared and radar integrated stealth fabric and preparation method thereof

InactiveCN101995187AOvercome crackingOvercome sheddingSynthetic resin layered productsPersonal protection gearBursting strengthCoated surface

The invention discloses a novel infrared and radar integrated stealth fabric and a preparation method thereof. The stealth fabric comprises an infrared camouflage surface layer and an antistatic bottom layer in turn from outside to inside; the infrared camouflage surface layer comprises an infrared stealth layer, a fabric layer and a radar wave absorption attenuation layer in turn from outside toinside; the infrared stealth layer is compounded by using a coating coated by an infrared stealth coating and a magnetron sputtering ITO (indium tin oxide) film arranged on the surface of the coating; the radar wave absorption attenuation layer comprises a sponge body; and a wave absorption material is adsorbed on the sponge body. The stealth fabric can realize radar stealth function and infraredstealth function at the same time, has good integral wave absorption effect and low surface density of materials, and has good effects on the aspects of breaking strength, bursting strength and the like. Moreover, excessive complex processes are not adopted for manufacturing the stealth fabric, and the stealth fabric can be produced by using a conventional fabric production method, so the stealthfabric is convenient for production and easy for implementation.

Owner:WUYI UNIV

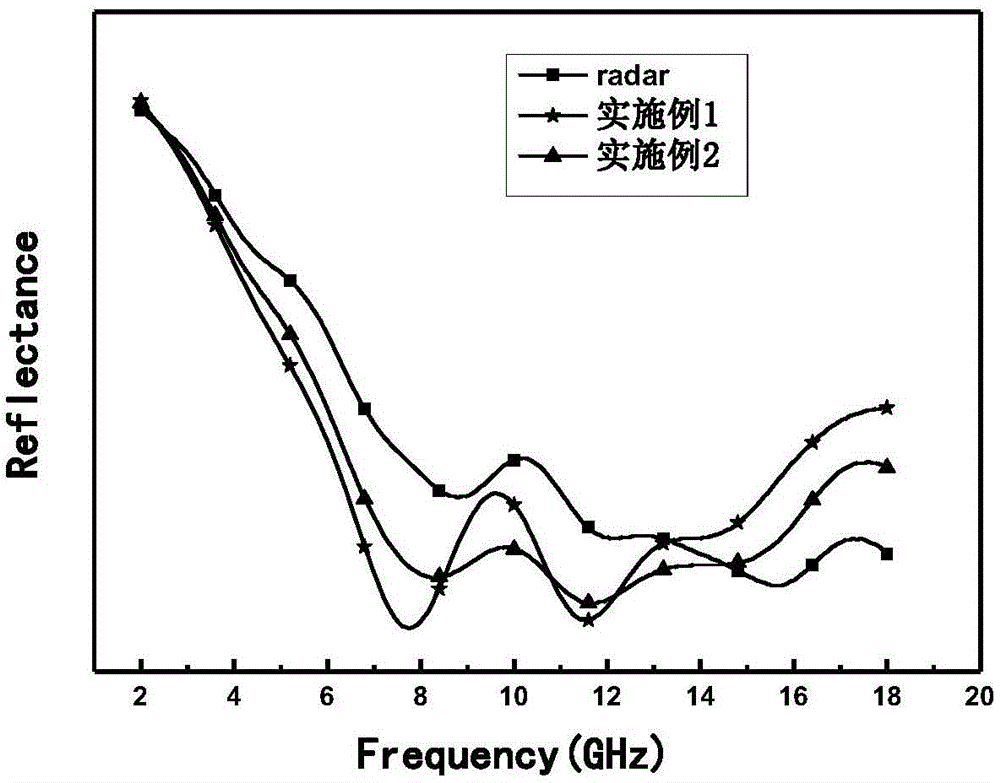

Method for coating infrared stealth coating on object surface coated with radar absorbing coating

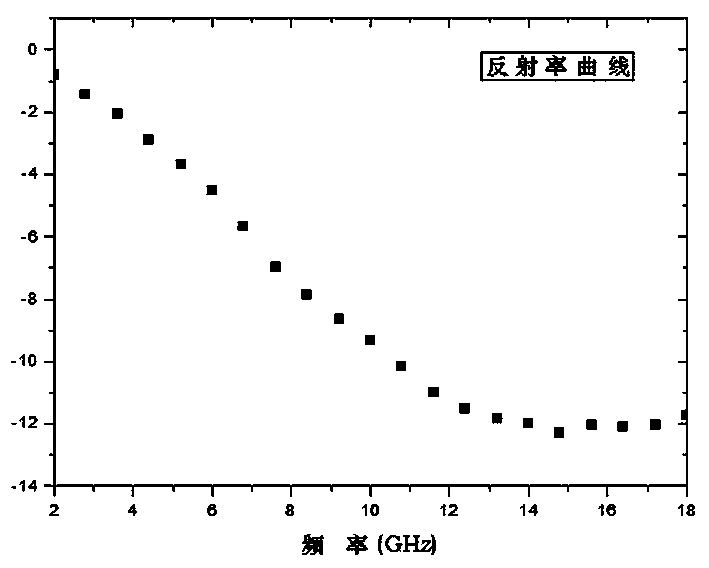

ActiveCN103980806AImprove radar absorbing performanceReduce IR emissivityPolyurea/polyurethane coatingsPaints with free metalsRadarMetallurgy

The invention discloses a method for coating an infrared stealth coating on an object surface coated with a radar absorbing coating, and belongs to the technical field of a functional material. The method comprises the following concrete processes: 1, preparing each coating carrier of a corresponding infrared stealth coating, a component A of the infrared stealth coating and a component B of the infrared stealth coating; 2, cleaning the object surface coated with the radar absorbing coating; 3, mixing and evenly agitating a to-be-used inner coating carrier with the component A and the component B, and spraying on the surface of the radar absorbing coating by adopting a compressed gas manner, and drying; 4, sequentially taking the to-be-used coating carrier to mix and evenly agitate with the component A and the component B in a manner same as spraying of the inner layer, spraying and drying by adopting the compressed gas manner to the outermost layer. The method has the advantages that the infrared emitting ability can be reduced to below 0.25, meanwhile, the radar absorbing performance of the coating can be significantly improved within the full-band range of 1-18GHz, and excellent infrared / radar and stealth performances are achieved.

Owner:成都佳驰电子科技股份有限公司

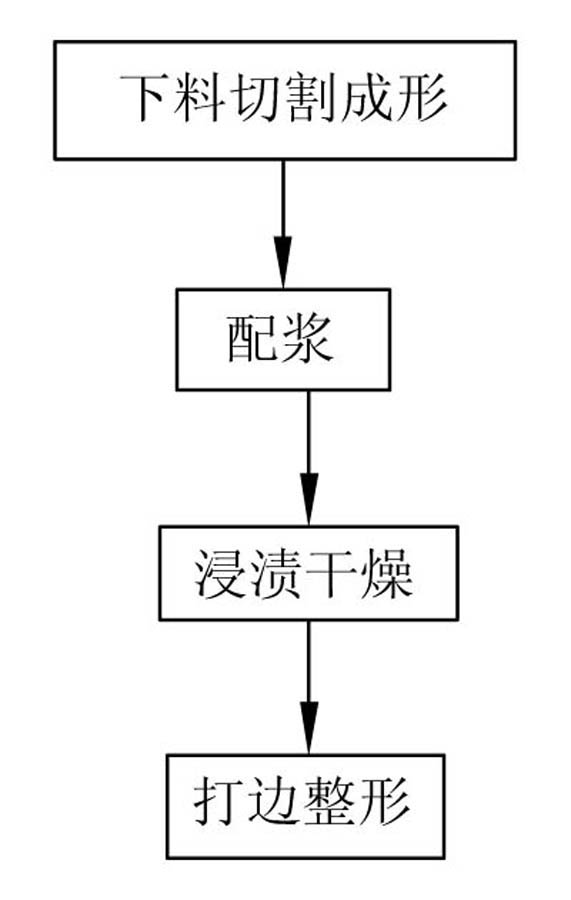

Infrared camouflage paint as well as preparation method and application thereof

ActiveCN103614058APacking is cheap and easy to getStrong adhesionPolyurea/polyurethane coatingsVegetal fibresLow emissivityRare earth

The invention relates to infrared camouflage paint as well as a preparation method and an application thereof. The paint comprises filler, a coating agent and an additive. The preparation method comprises the following steps: mixing and ball-milling 30-90 parts by weight of solvent, 1-30 parts by weight of wetting dispersant and 5-60 parts by weight of filler, so as to obtain lanthanum-based rare earth compound powder concentrated pulp, ball-milling the solvent and the coating agent so as to obtain the ball-milled coating agent, and ball-milling the solvent, the lanthanum-based rare earth compound powder concentrated pulp and the ball-milled coating agent so as to obtain the infrared camouflage paint. According to the application of the infrared camouflage agent, the infrared stealth coating is added to a substrate by using a dipping, coating or padding method. The invention provides a novel low-emissivity material, namely the infrared camouflage paint, not only are materials for the paint easy to obtain, but also the paint is simple to operate, relatively low in cost, capable of effectively pretending and shielding human bodies, glass, polymer films, military weapons and the like and reducing the possibility that the articles are detected by infrared detectors, and has a good application prospect.

Owner:DONGHUA UNIV

Medium-and-low-temperature solar selective absorption thin film and preparation method thereof

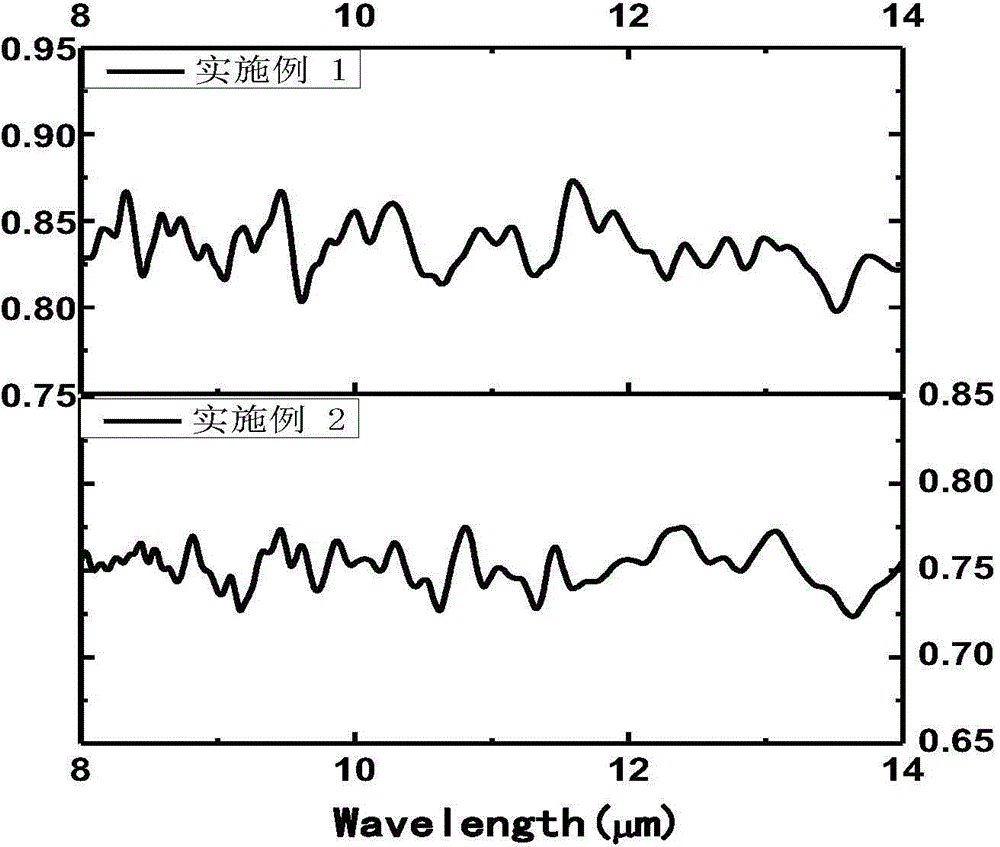

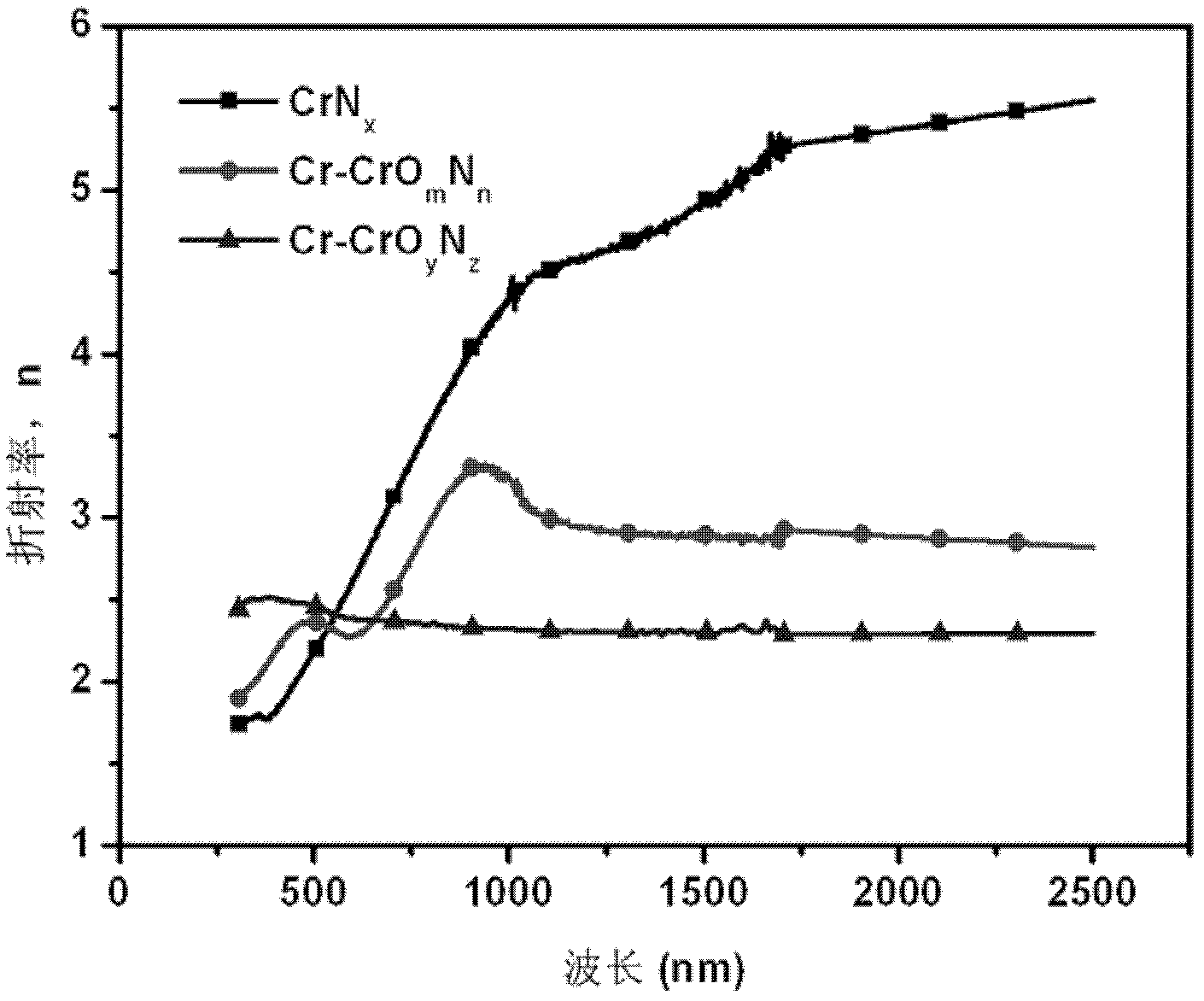

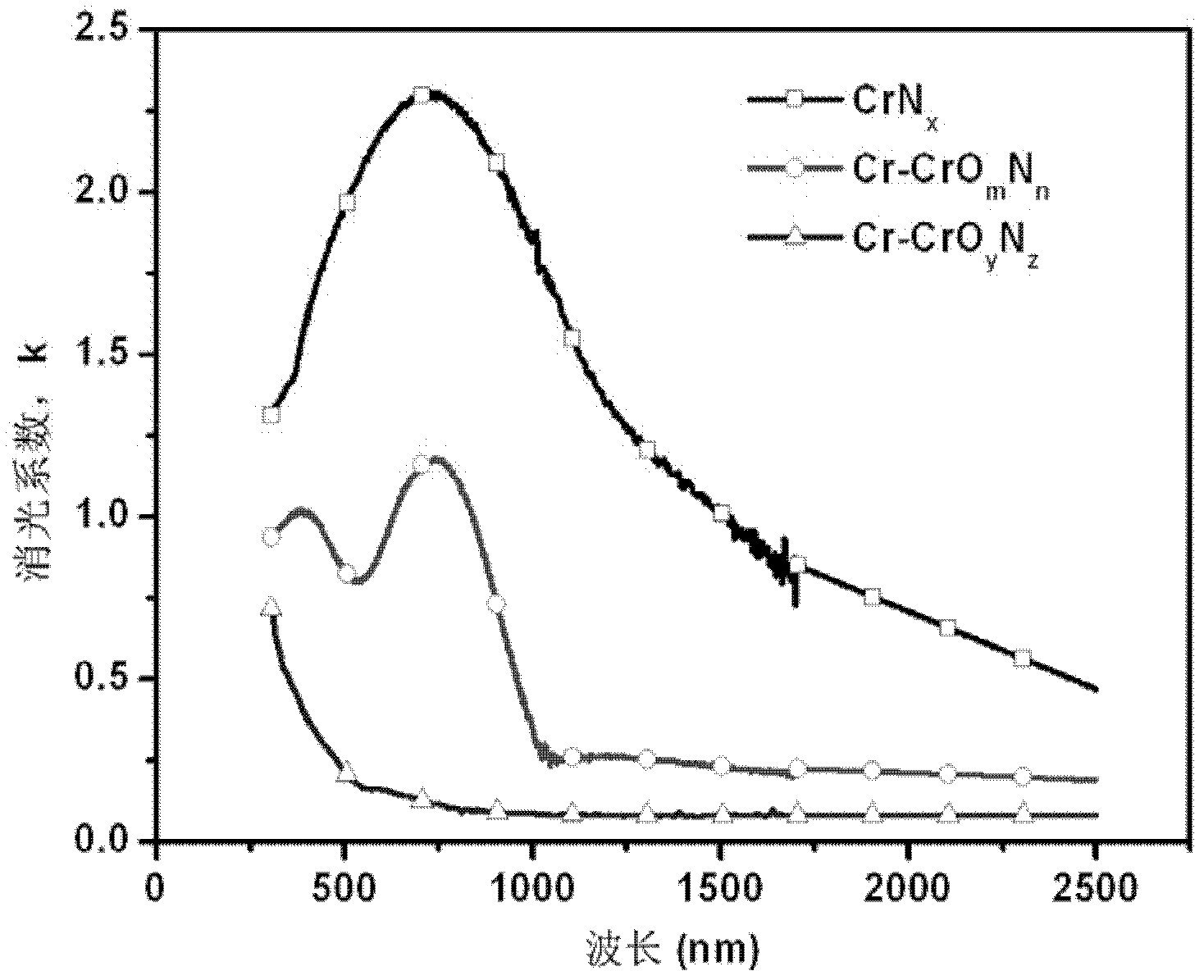

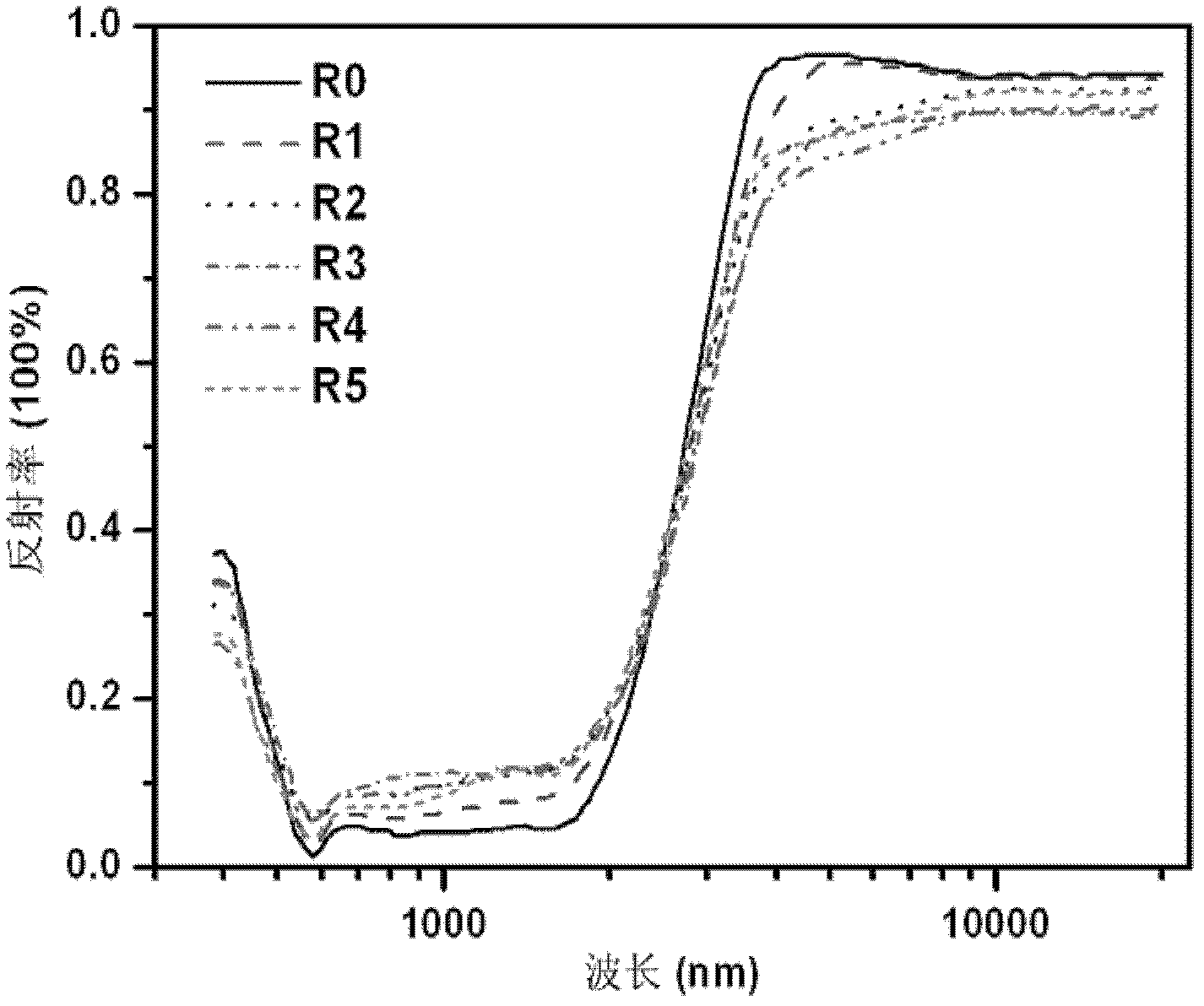

ActiveCN102620456ALow costSimple preparation processSolar heat devicesVacuum evaporation coatingHeat stabilitySilicon dioxide

The invention discloses a medium-and-low-temperature solar selective absorption thin film. The medium-and-low-temperature solar selective absorption thin film mainly comprises a diffusion blocking layer, an absorption layer and an anti-reflection layer, which are sequentially deposited on a substrate with an infrared reflection function, or the medium-and-low-temperature solar selective absorption thin film mainly comprises an infrared reflection layer, the diffusion blocking layer, the absorption layer and the anti-reflection layer, which are sequentially deposited on the substrate, wherein the infrared reflection layer comprises the components of copper (Cu), molybdenum (Mo) or silver (Ag); the diffusion blocking layer comprises the composite component of chromium and nitrogen; the absorption layer consists of one or two of chromium simple substance / chromium oxide multi-component phase and chromium simple substance / chromium oxynitride multi-component phase; and the anti-reflection layer is a silicon dioxide (SiO2) ceramic thin film. The medium-and-low-temperature solar selective absorption thin film is high in solar spectrum absorption rate, low in infrared emissivity, high in heat stability and high in weather resistance and can be used in medium-and-low-temperature atmospheric environment of below 278 DEG C for a long time. The invention also discloses a preparation method for the medium-and-low-temperature solar selective absorption thin film. The preparation method employs a magnetron sputtering method and is simple in process, low in cost, high in stability and applicable to industrial large-area preparation.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

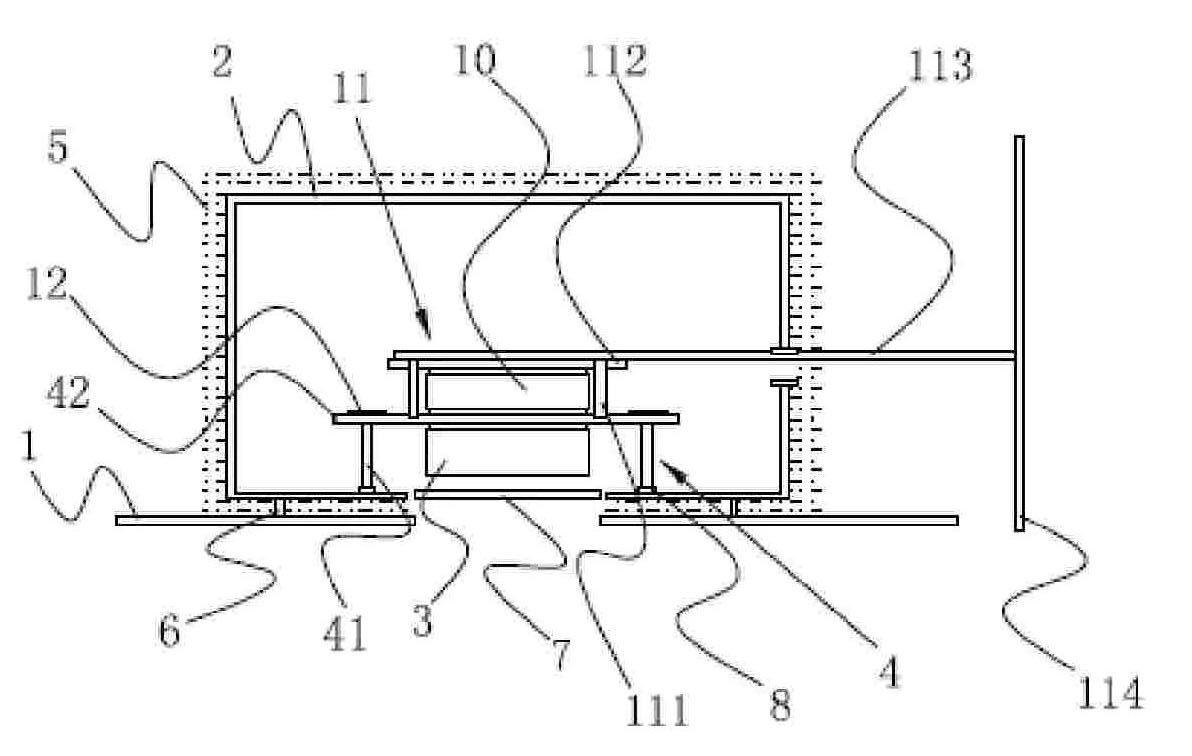

Temperature controlled focal plane detector mechanism

InactiveCN101813951ATo achieve different working temperature requirementsFulfill cooling needsTemperatue controlHeat conductingHeat leak

The invention discloses a temperature controlled focal plane detector mechanism, which mainly solves the problem that the conventional focal plane detector mechanism cannot work under different temperature conditions. The temperature controlled focal plane detector mechanism comprises a shell, a cabinet, a detector and a detector mounting base, wherein the detector mounting base comprises a detector support plate and a cold plate; the detector support plate is fixedly connected with the cabinet; the detector is arranged on one side of the cold plate, and is provided with a temperature test sensor; the other side of the cold plate is provided with a refrigerator of which the side far from the cold plate is provided with a heat conducting device; and the heat conducting device and the cold plate isolate and seal the refrigerator. The temperature controlled focal plane detector mechanism can meet the requirements of different working temperatures of the detector; and the detector is not influenced by frosting and pollution when working in various environments (laboratories or space environments), and the environmental heat leak is effectively reduced.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

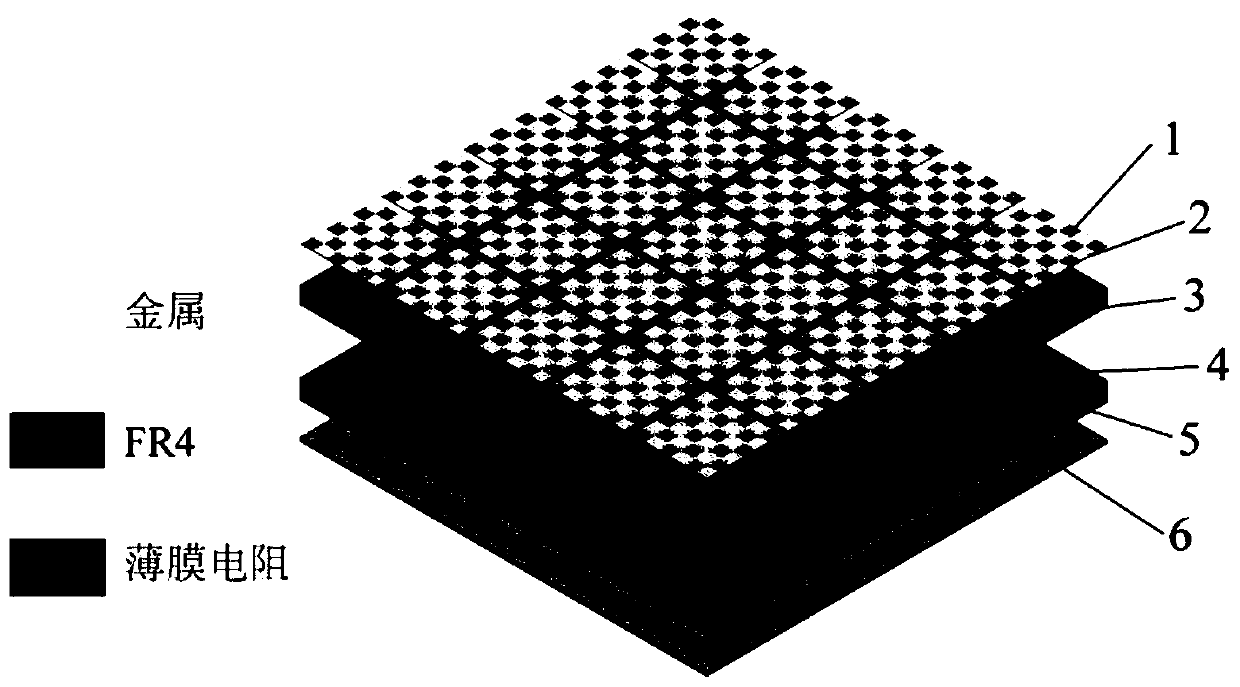

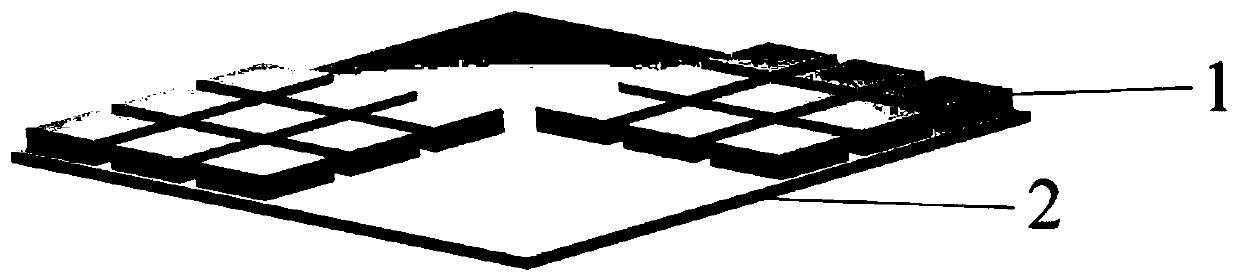

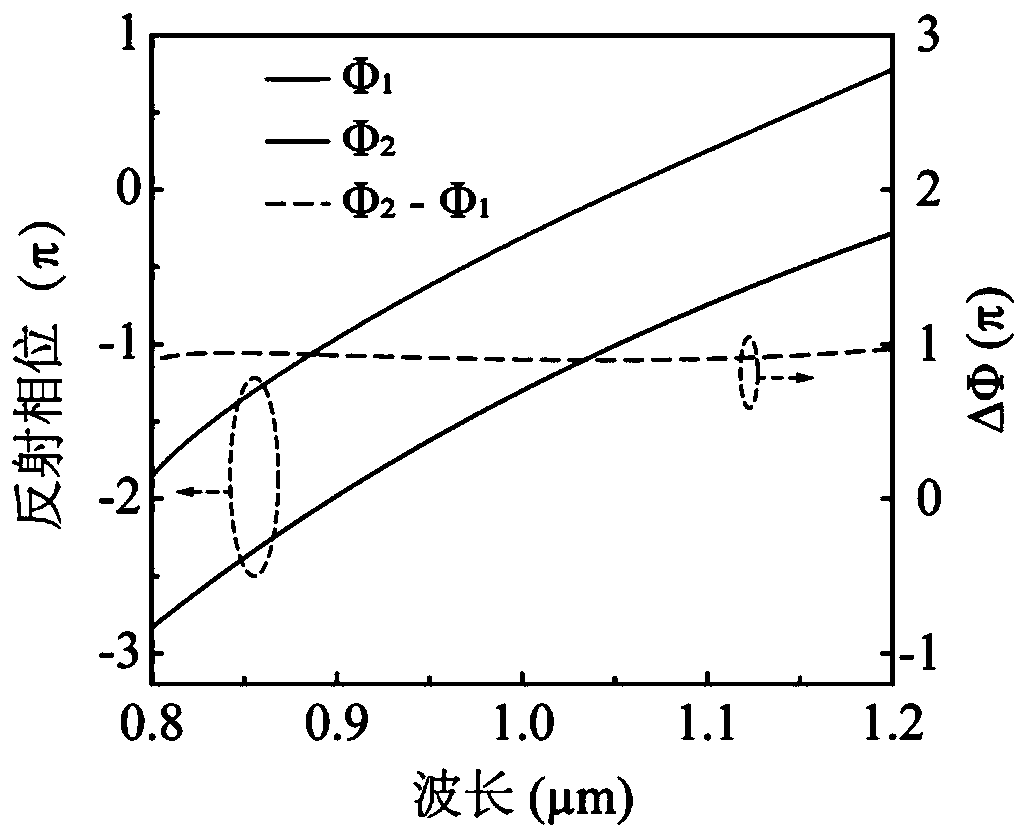

Layered structure capable of simultaneously realizing low laser reflection, low infrared radiation and high microwave absorption

The invention provides a layered structure capable of simultaneously realizing low laser reflection, low infrared radiation and high microwave absorption. The layered structure is formed by compounding an all-metal metasurface array and a metamaterial wave absorber. The all-metal metasurface array can effectively reduce specular reflectance by controlling the reflection direction of incident laser, and low laser reflection and low infrared radiation are achieved at the same time in combination with the inherent low infrared radiation characteristic of metal materials. The metamaterial wave absorber located below the all-metal metasurface array can achieve high absorption of broadband microwaves. According to the invention, the all-metal metasurface and the metamaterial wave absorber are ingeniously combined, the specular reflectance within the wave band of 0.8-1.2 microns can be effectively reduced, very low infrared emissivity is kept in infrared atmospheric windows (3-5 microns and 8-14 microns), high absorption of 6.5-13.4GHz microwaves is achieved at the same time, and multi-band electromagnetic characteristic regulation and control are achieved.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Antistatic artificial lawn and preparation method thereof

ActiveCN102535308AGood weather resistanceGood compatibilitySki bindingsElectroconductive/antistatic filament manufactureMasterbatchPolyresin

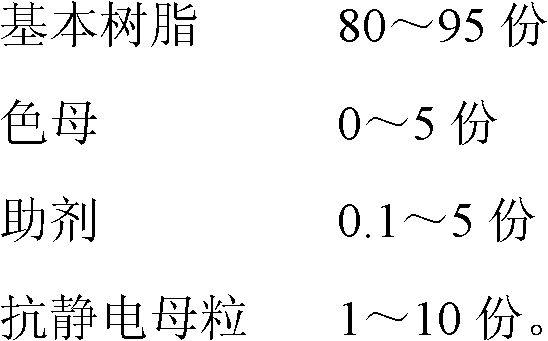

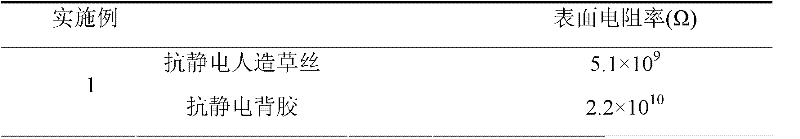

The invention discloses an antistatic artificial lawn which has long-term and effective antistatic performance and meets requirements of people on antistatic artificial lawns, and simultaneously, the invention also provides a preparation method of the antistatic artificial lawn. The antistatic artificial lawn comprises artificial grass, a bottom base fabric and stamp gum, wherein the artificial grass is antistatic artificial grass, and comprises the following components in parts by weight: 80-95 parts of base resin, 0-5 parts of color masterbatch, 0.1-5 parts of assistant and 1-10 parts of antistatic masterbatch.

Owner:COCREATION GRASS CO LTD

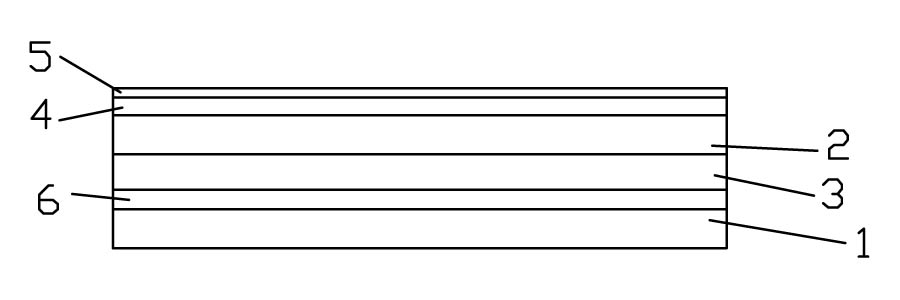

High-performance multilayer composite solar selective absorption coating and preparation method thereof

ActiveCN101598468AReduce IR emissivityImprove bindingSolar heat devicesVacuum evaporation coatingOxidation resistantFar infrared

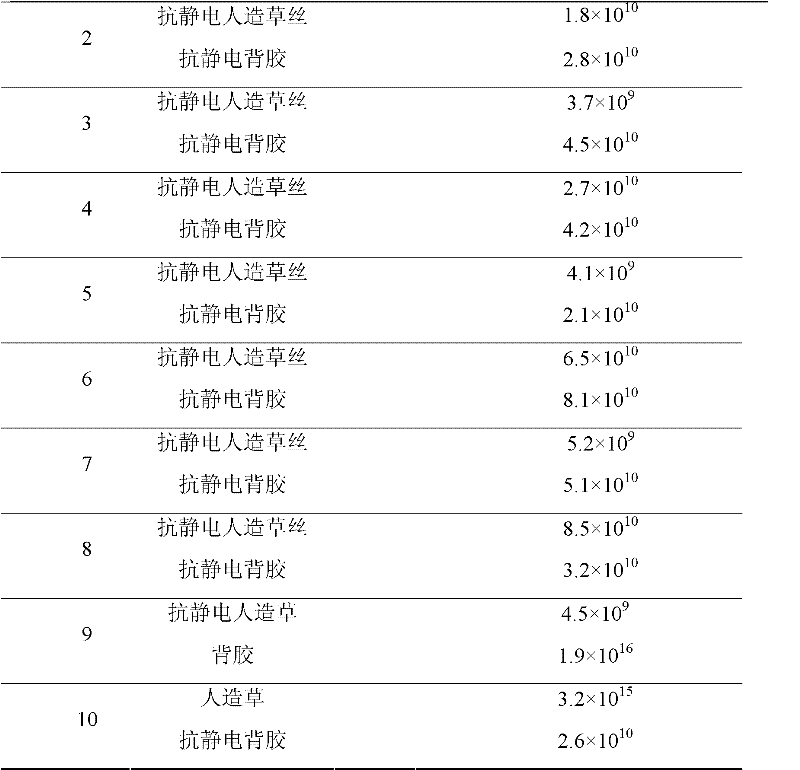

The invention relates to the technical field of solar collectors, in particular to a solar selective absorption coating and a preparation method thereof. The high-performance multilayer composite solar selective absorption coating comprises a far infrared reflecting layer (2), a composite heat absorption layer (4) and an anti-oxidation and anti-reflection layer (5) which are arranged on a matrix (1) in turn. The coating is mainly characterized in that the far infrared reflecting layer (2) is an Al layer which is sputter-deposited on the matrix (1); the composite heat absorption layer (4) is a TiNOX layer which is sputter-deposited on the far infrared reflecting layer (2); and the anti-oxidation and anti-reflection layer (5) is an SiO2 layer which is sputter-deposited on the composite heat absorption layer (4). The coating has the advantages that the solar absorption rate is as high as 90 to 95 percent, and the infrared emitting rate is 6 percent. A Ti+TiC stability layer is arranged between the reflecting layer and the absorption layer, and the stability layer can remarkably improve the binding force of the coating; and simultaneously, the TiC has high temperature resistance and oxidation resistance, thereby the corrosion resistance and high temperature resistance of the coating can be remarkably improved.

Owner:兰州大成科技股份有限公司 +2

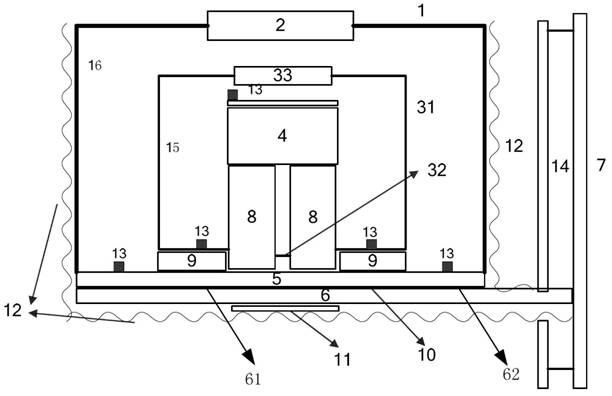

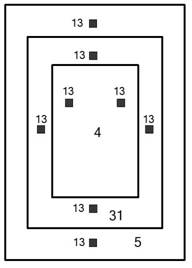

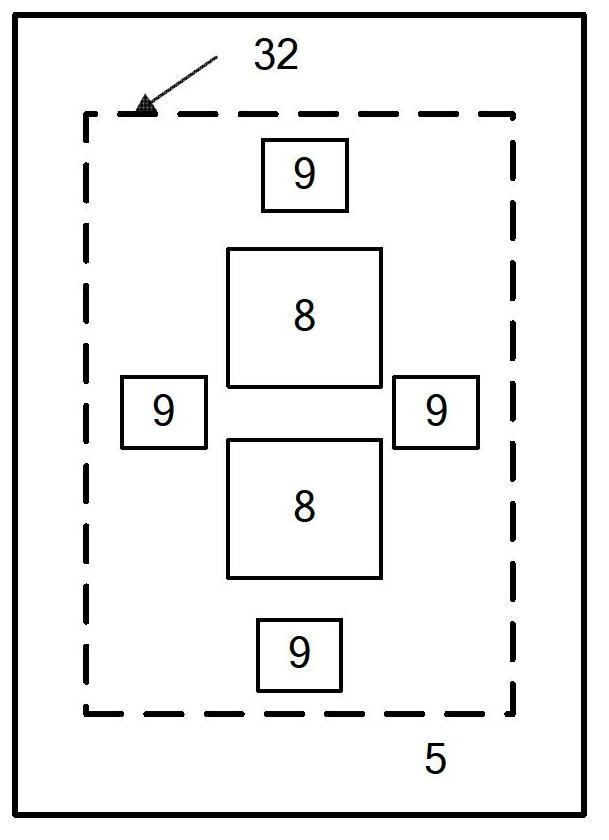

Precise thermal control mechanism of focal plane detector

InactiveCN102681568ATo achieve different working temperature requirementsFulfill heating needsTemperatue controlTemperature controlPhotovoltaic detectors

The invention relates to a precise thermal control mechanism of a focal plane detector, and the precise thermal control mechanism comprises a vacuum box body, a refrigerating assembly, a cold screen assembly, a heating assembly and a temperature collecting unit, and the precise thermal control mechanism also comprises a heat insulating layer which is arranged at the outer side of the vacuum box body and the outer side of the heating assembly, the refrigerating assembly comprises a refrigerator substrate, at least one detector refrigerator, at least one cold screen refrigerator, a heat tube assembly and a heat radiation plate. Due to the adoption of the precise thermal control mechanism, the technical problems that the quick variation of the temperature under the same working mode is difficult to realize because the temperature control of the traditional photoelectric detector thermal control mechanism mainly depends on the passive heat radiation way can be solved, a way combining the initiative refrigeration and the initiative heating is adopted, by the reasonable design of a thermal control system structure, not only is the quick variation of the temperature of the detector realized to meet the temperature requirement under different working modes, but also the temperature range can be precisely controlled, and the working reliability of the system is high.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

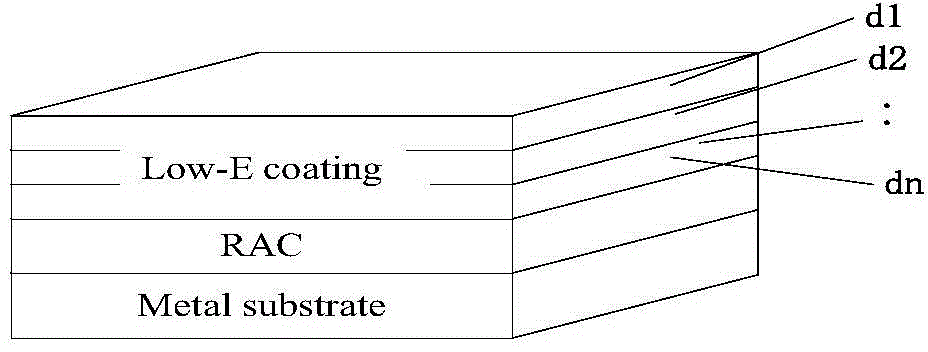

Radar-infrared compatible stealth material and preparation method thereof

InactiveCN103396692AReduce IR emissivityRetain absorbing performanceRadiation-absorbing paintsMicrowaveEmissivity

The invention discloses a radar-infrared compatible stealth material and also discloses a preparation method of the material. According to the preparation method, by adopting manners of primary ball milling and mixed ball milling, the required iron aluminum mixed material is finally obtained, the diameter of the platy material is 2-5mu m, and the thickness of the platy layer is 100-200nm. The preparation method is simple, and the prepared compatible stealth material also has very low infrared emissivity without changing the microwave absorbing property.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

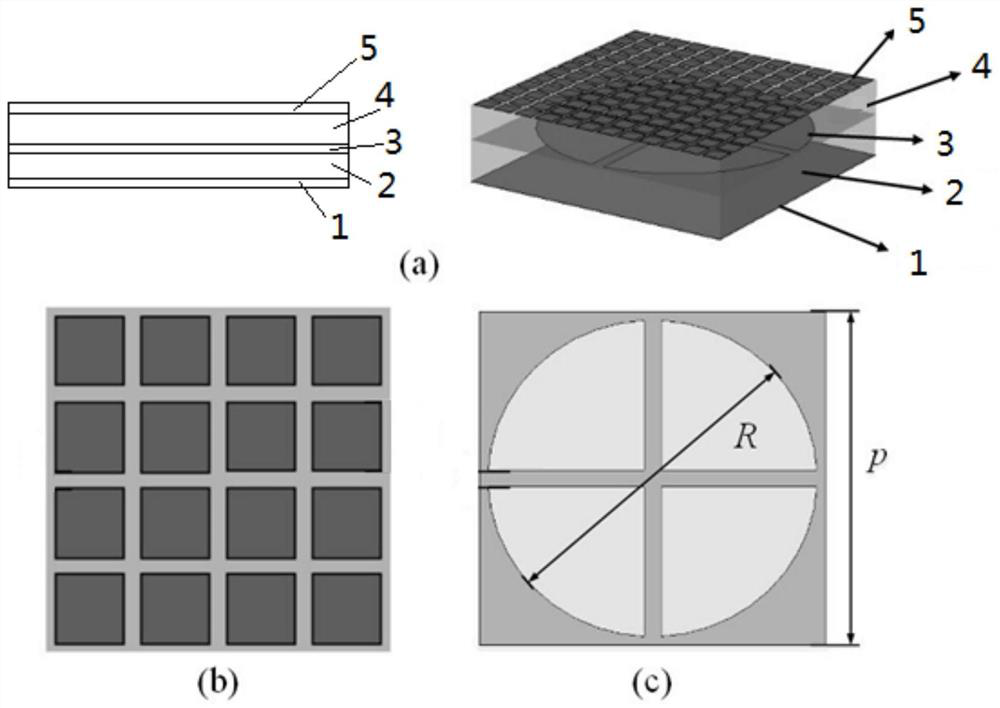

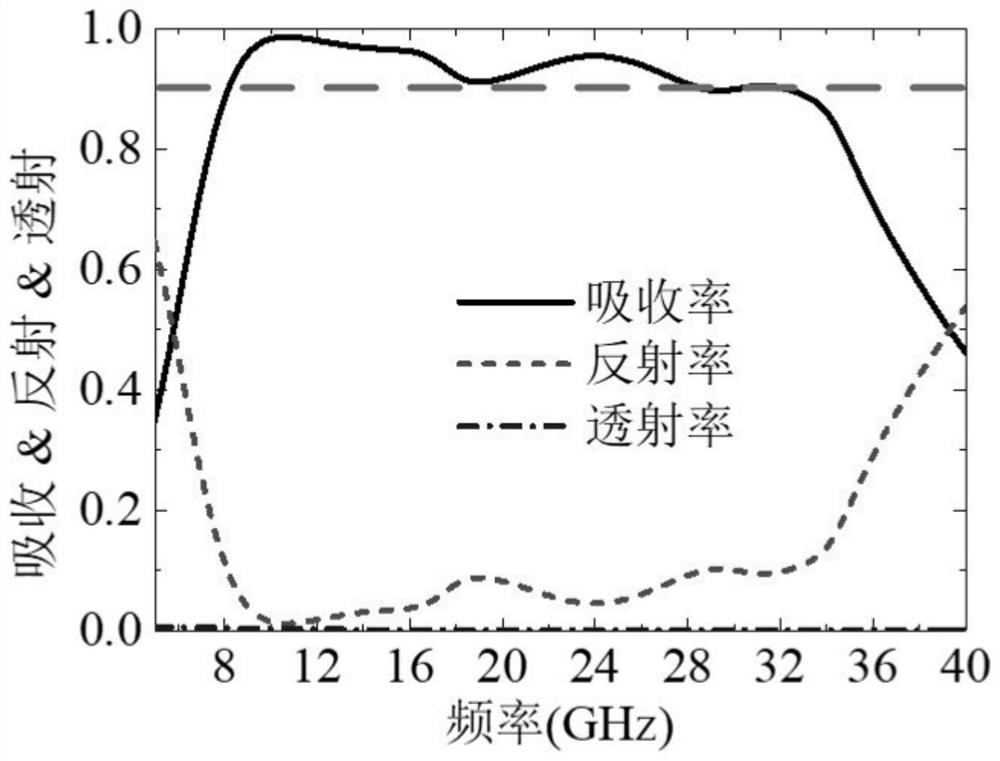

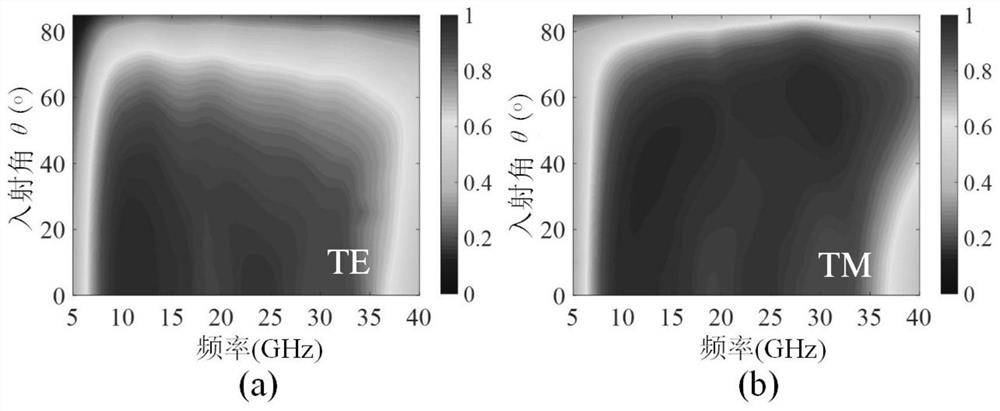

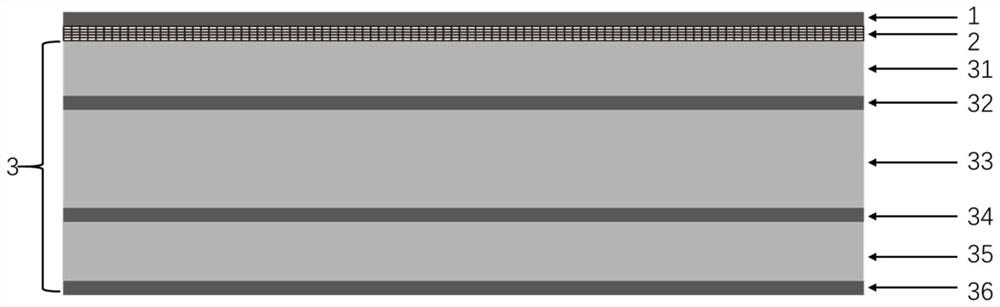

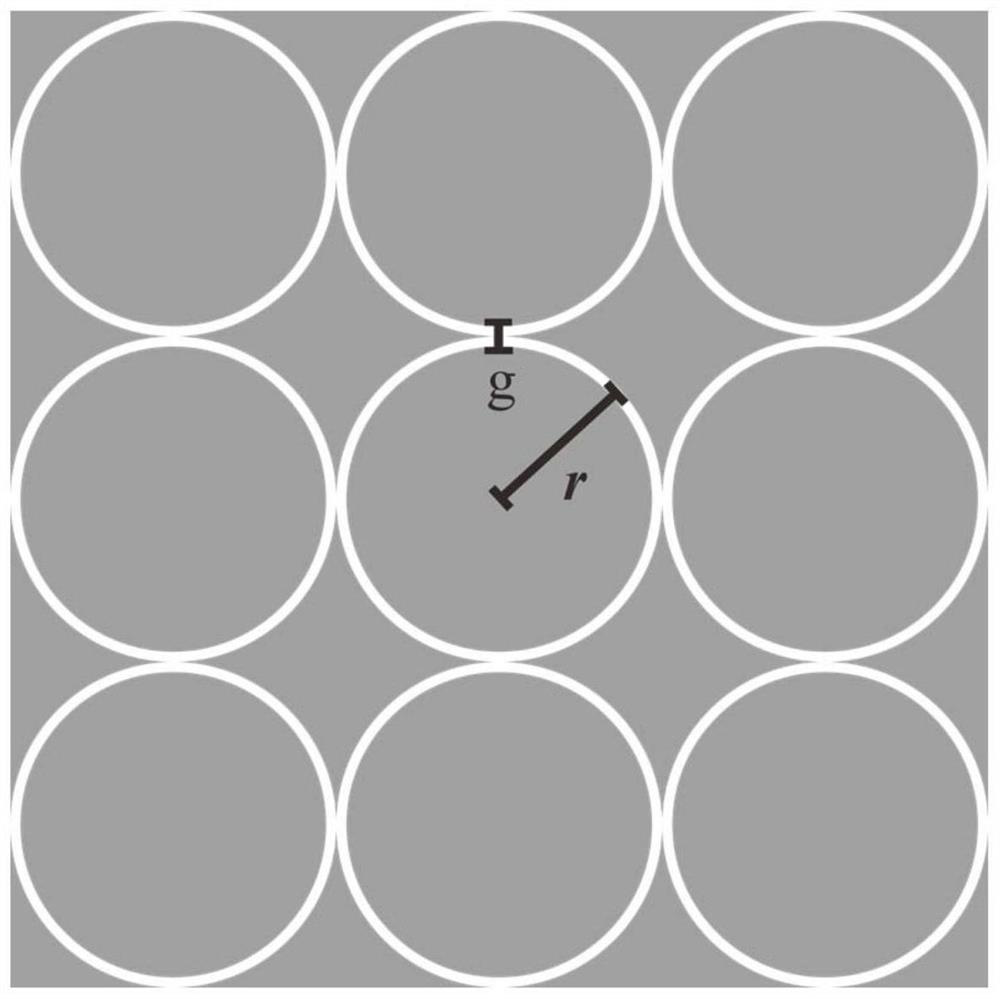

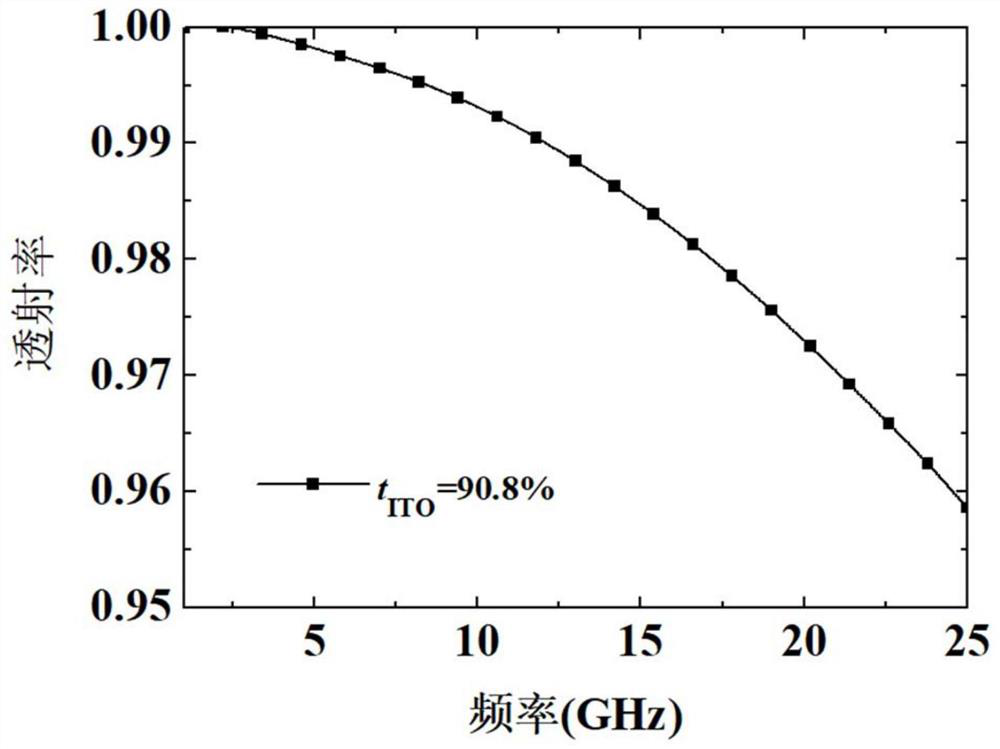

Optical transparent ultra-wideband radar and infrared double-stealth structure

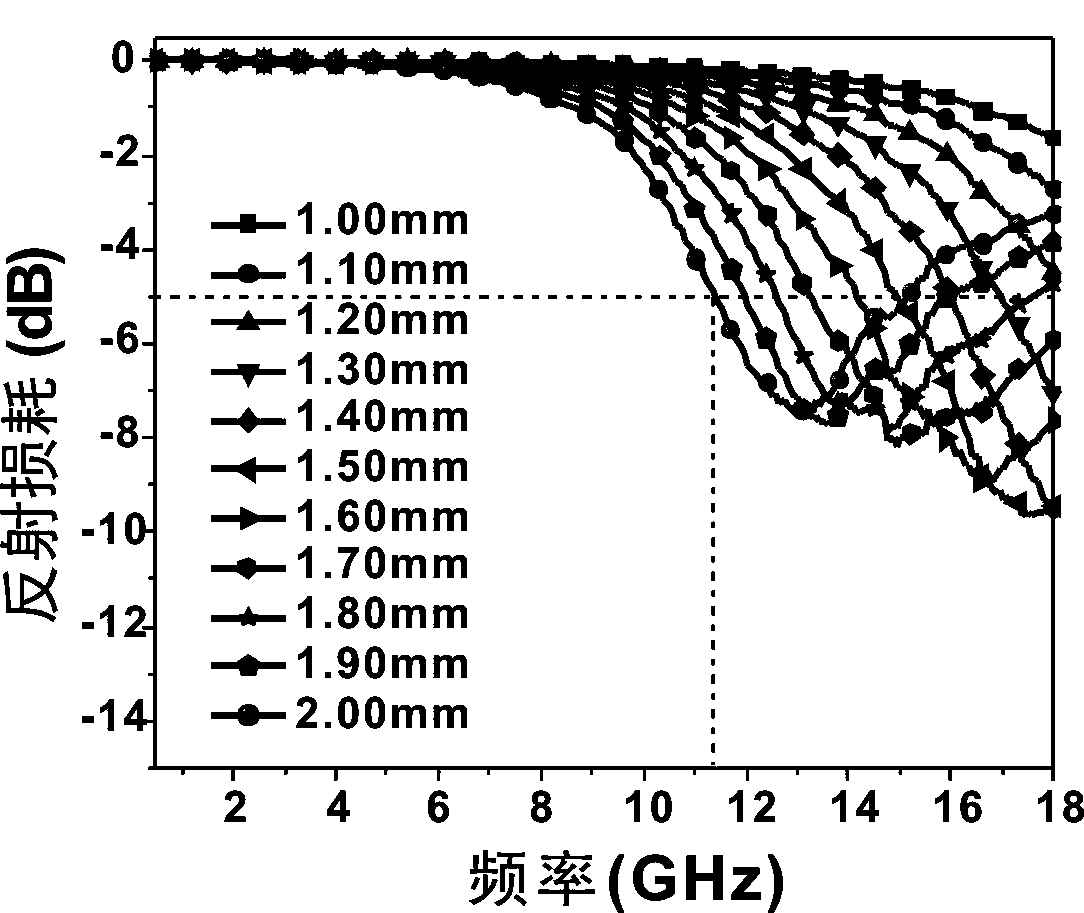

ActiveCN112622391AAddressing Optical TransparencySolving Radar StealthSynthetic resin layered productsCamouflage devicesUltra-widebandDielectric

The invention discloses an optical transparent ultra-wideband radar and infrared double-stealth structure, and relates to the technical field of multi-spectrum stealth, and the stealth structure mainly comprises a low-emissivity infrared stealth layer and an ultra-wideband radar wave-absorbing layer. In order to realize high transmittance of visible light, an optical transparent material transparent conductive film and a transparent dielectric are selected in the overall structural design; the radar wave-absorbing layer adopts a conductive film-medium-conductive film sandwich type wave-absorbing structure; the transparent conductive film is etched into a frequency selective surface by adopting a laser etching process to finish the preparation of the radar and infrared compatible stealth material; the optical transparent ultra-wideband radar and infrared compatible stealth material has high designability, the contradictory problem of optical transparency, radar stealth and infrared stealth can be well solved from the perspective of structural design by adopting a metamaterial technology, and the optical transparent ultra-wideband radar and infrared compatible stealth material has good ultra-wideband radar wave absorption performance, low infrared emissivity and optical transparency.

Owner:AIR FORCE UNIV PLA

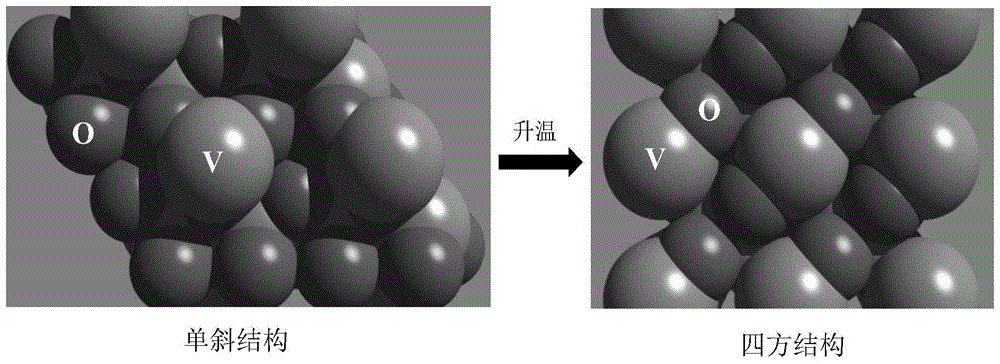

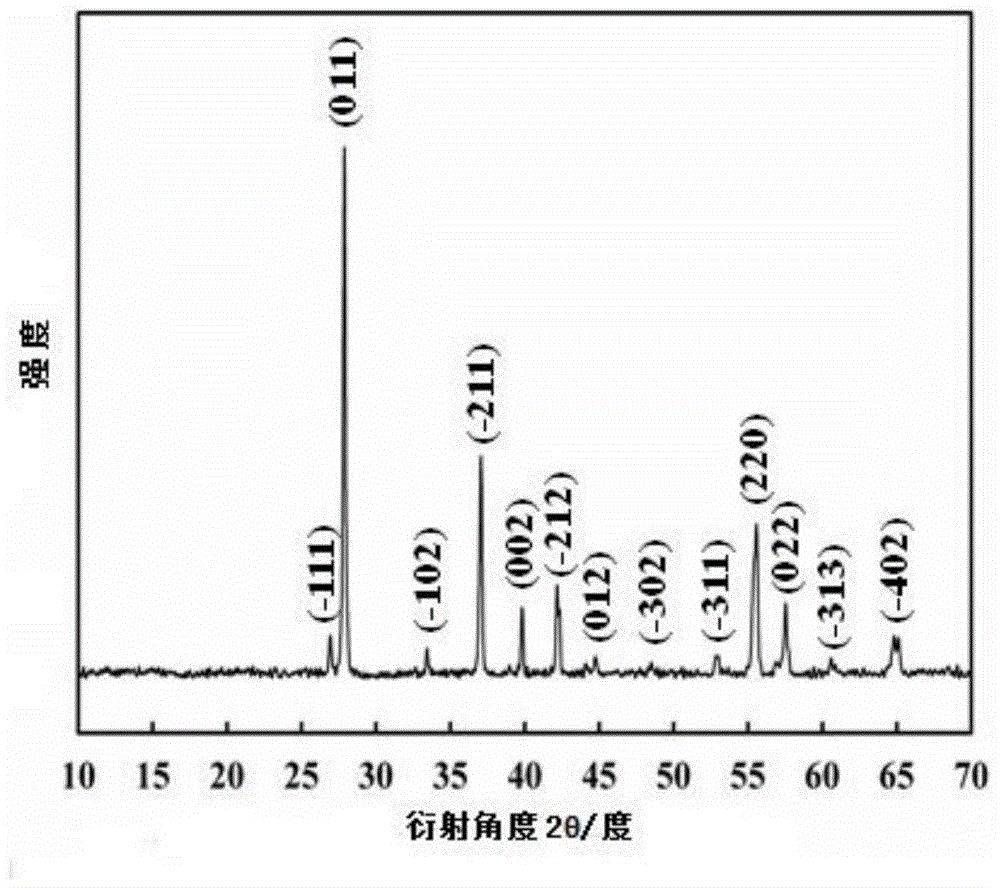

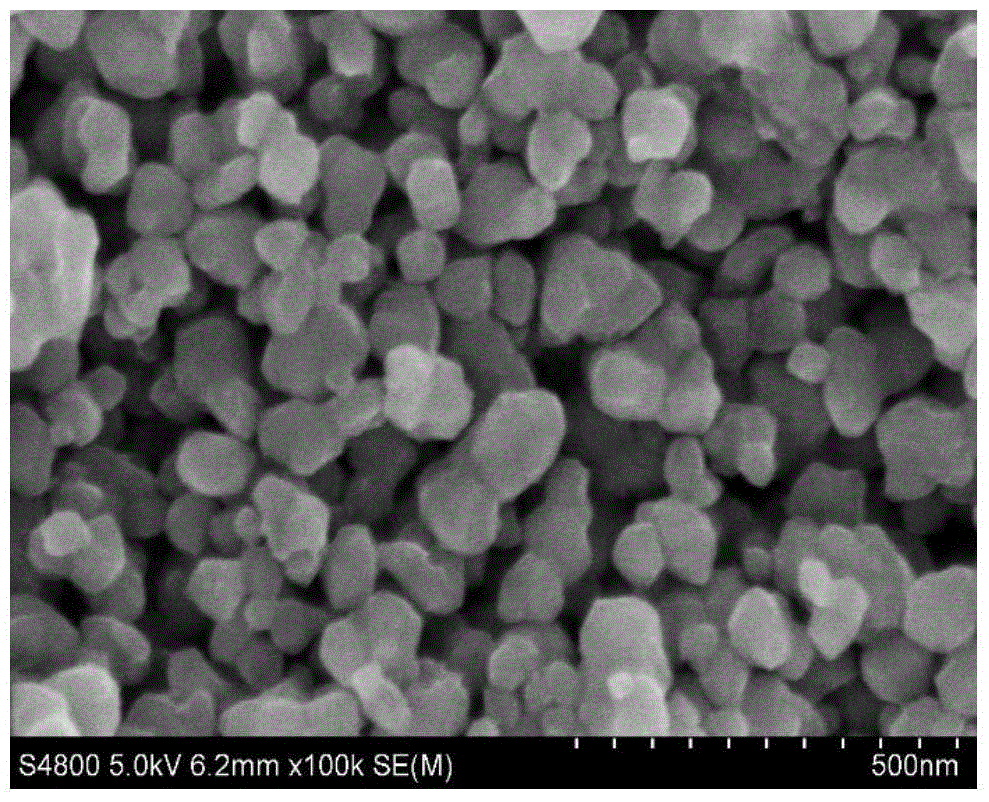

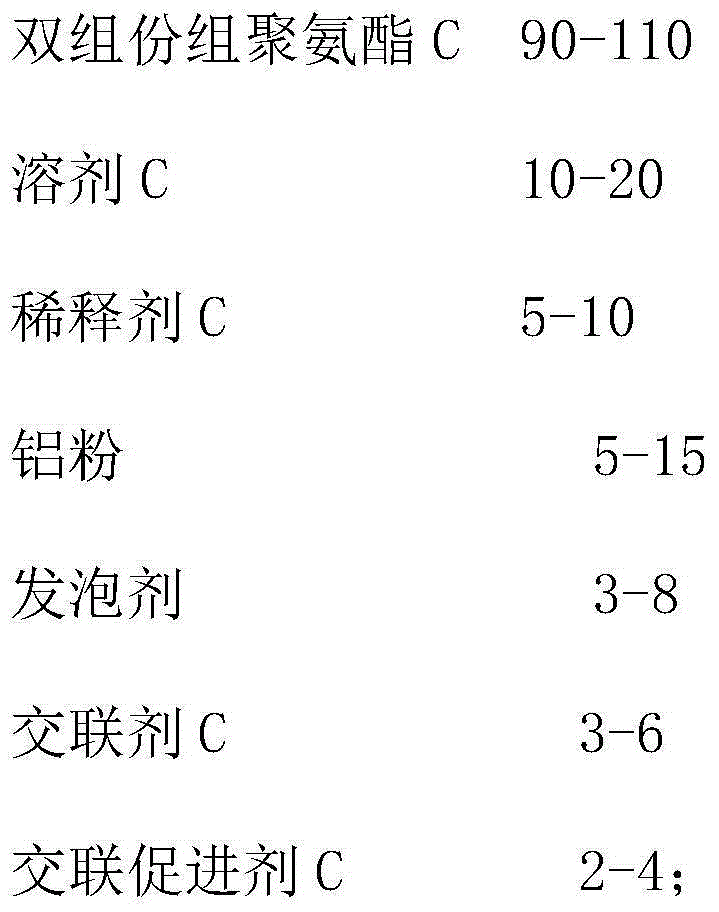

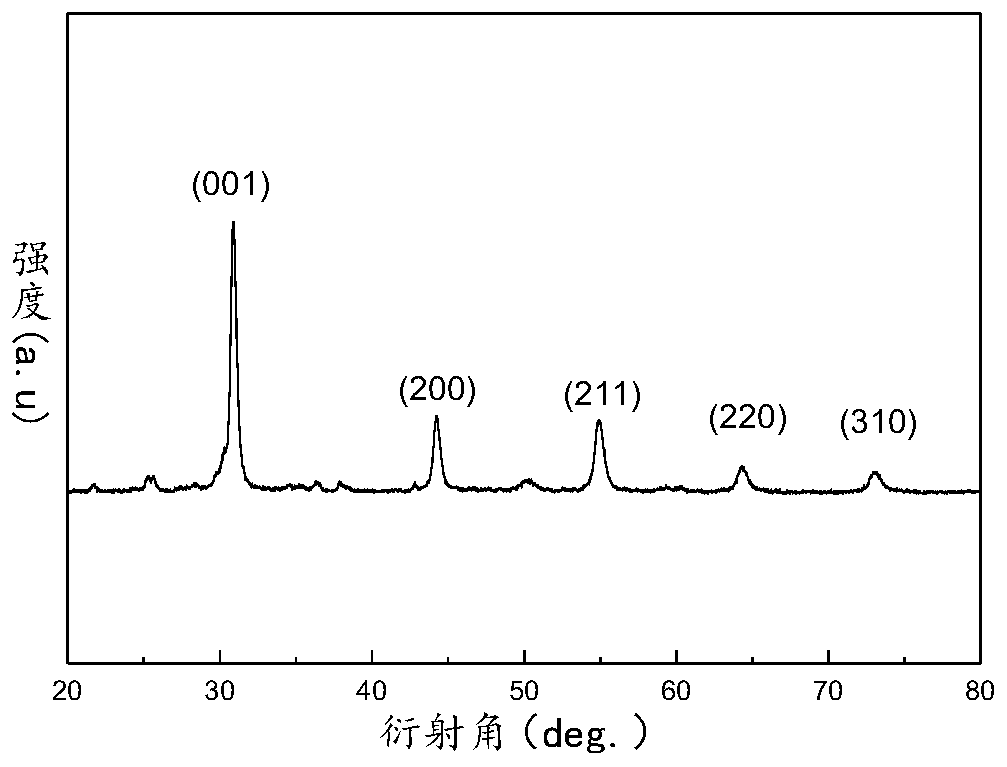

Preparation method for thermally-induced infrared-emission-rate-variable vanadium dioxide thin sheet

The invention discloses a preparation method for a thermally-induced infrared-emission-rate-variable vanadium dioxide thin sheet. The method includes the steps of: (A) with metavanadate, citric acid and deionized water as initial raw materials, stirring and mixing the raw materials uniformly according to certain ratio, and moving the mixture into a hydrothermal kettle to perform a hydrothermal reaction; and (B) when the reaction is finished, performing centrifugation, washing and vacuum drying to obtain nano vanadium dioxide powder, pressing the powder into thin sheets, and annealing the thin sheets to prepare the thermally-induced infrared-emission-rate-variable vanadium dioxide thin sheet. The preparation method is simple. The raw materials are toxic-free and low-cost. The product has good crystallinity. The vanadium dioxide thin sheet achieves intensive change in infrared emission rate at about room temperature with abrupt change value reaching 0.34. The thin sheet has high mechanical strength, is not liable to break, is convenient to mechanically process, can be processed into different sizes and pasted to required positions in practical utilization, is convenient to use and has wide application prospect in the fields of infrared stealth and military camouflage.

Owner:NAT UNIV OF DEFENSE TECH

Radar-infrared compatible stealth material with adjustable property and preparation method thereof

ActiveCN103497558AReduce IR emissivityRetain absorbing performanceRadiation-absorbing paintsChemical platingIron powder

The invention discloses a radar-infrared compatible stealth material with adjustable property and a preparation method thereof. The preparation method comprises the following steps of: placing 100 grams of steel balls, 10 grams of carbonyl iron powder, 0.01-0.1 gram of calcium stearate and 30-50 milliliters of acetone solutions into a ball milling jar together for ball milling; placing the carbonyl iron powder subjected to the ball milling into a degreasing fluid, and degreasing at the temperature of 50-70 DEG C for 8-10 minutes; placing the degreased carbonyl iron powder into a chemical plating solution, and plating the carbonyl iron powder at 30-75 DEG C under the pH value of 13-14 for 15-45 minutes; cleaning and drying a material subjected to chemical plating to obtain a needed composite material. The preparation method disclosed by the invention has the advantages of simpleness, easiness and convenience for process flow and low cost.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

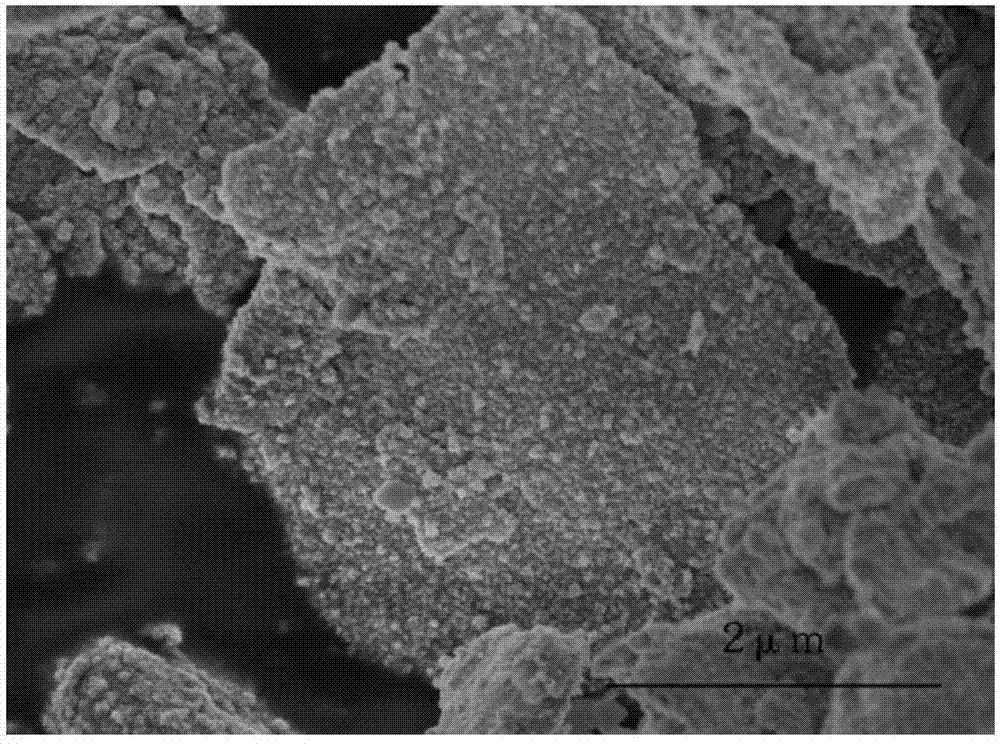

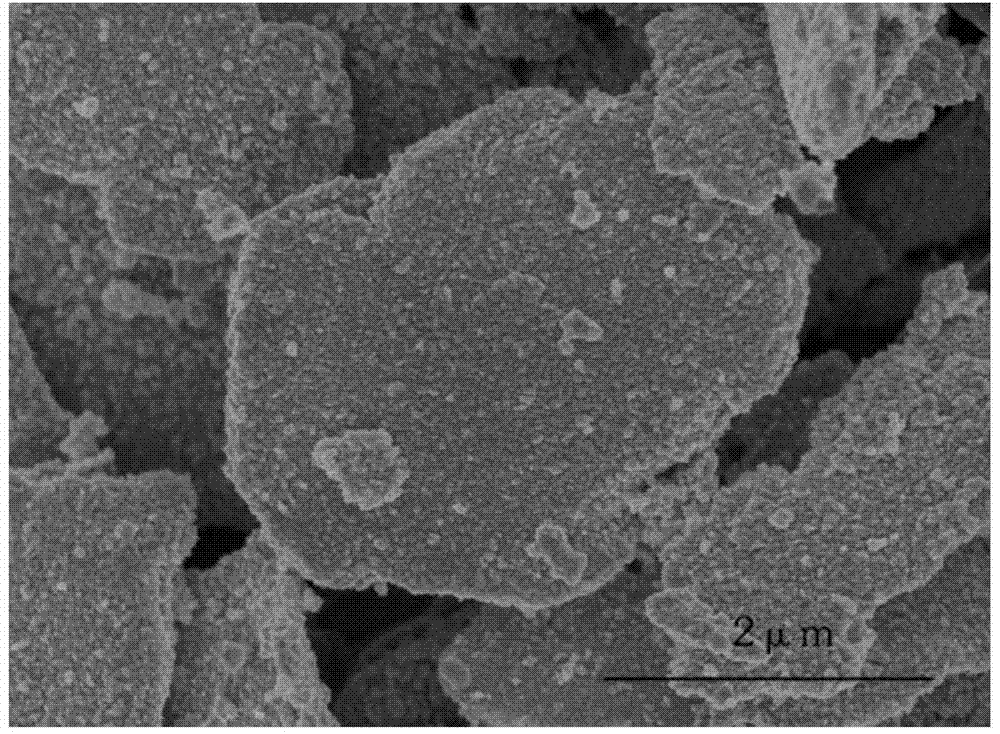

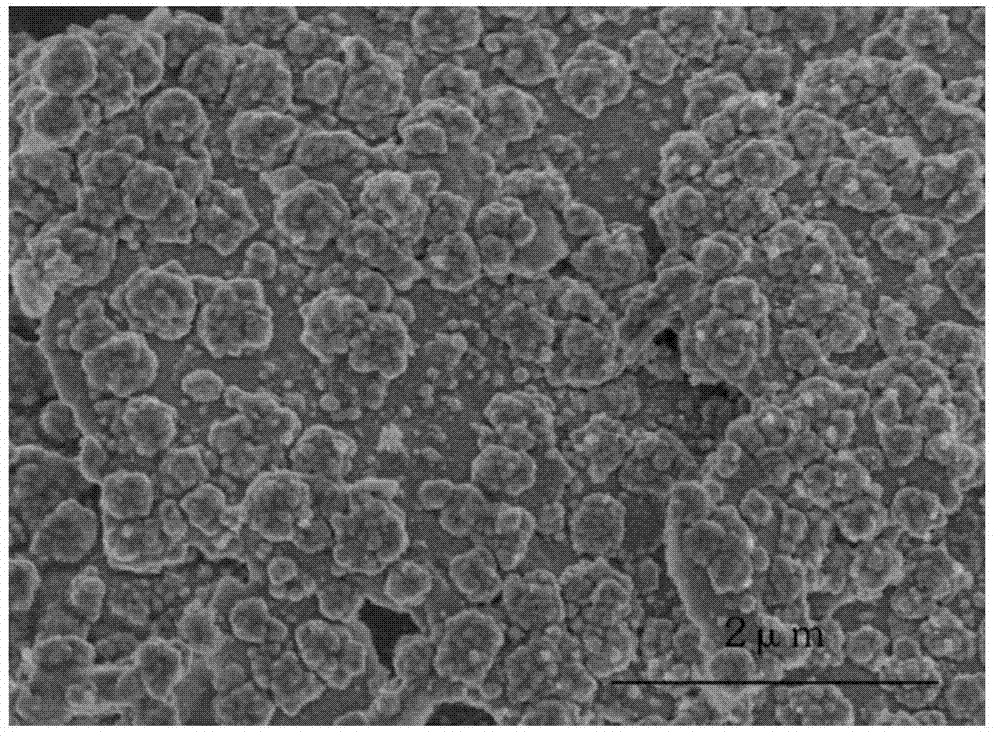

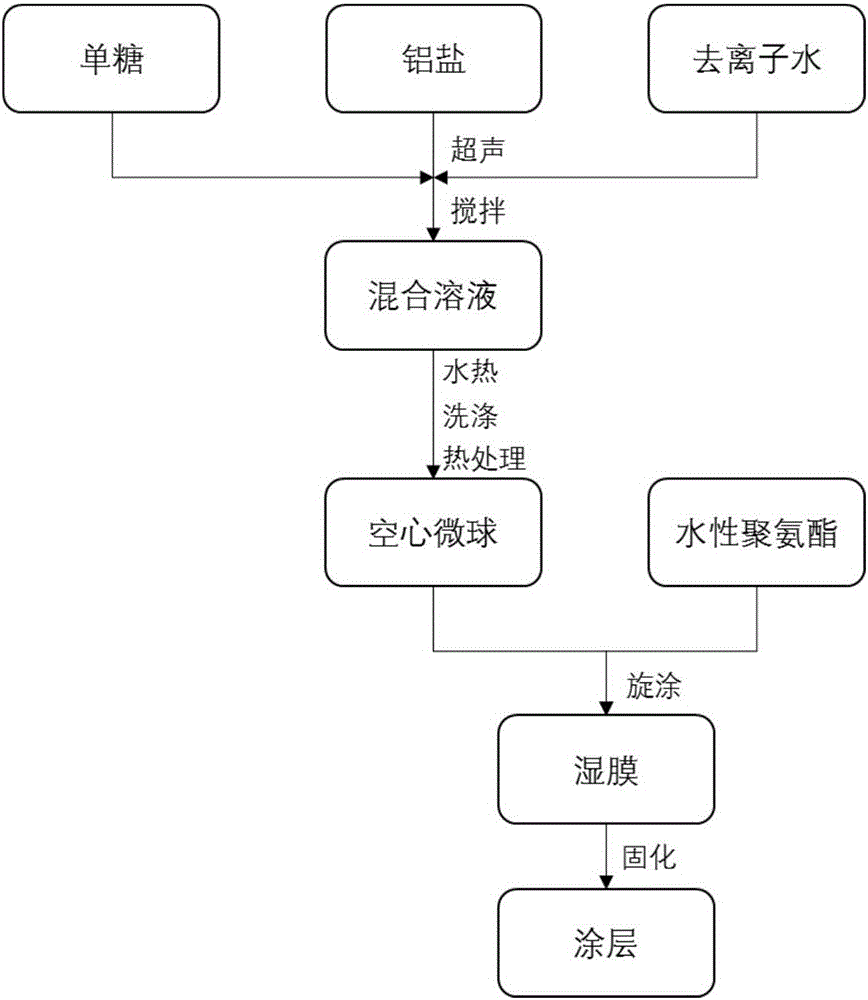

Preparation method of hollow aluminum oxide ceramic microsphere modified polyurethane coating

InactiveCN106634514AHigh strengthHigh hardnessAnti-corrosive paintsPolyurea/polyurethane coatingsMicrosphereMaterials science

The invention relates to a preparation method of a hollow aluminum oxide ceramic microsphere modified polyurethane coating. The preparation method comprises the following steps: preparing hollow aluminum oxide ceramic microspheres, namely treating aluminum nitrate and monosaccharide raw materials by virtue of steps of ultrasound, magnetic stirring, hydrothermal treatment, heat treatment and the like to obtain the hollow aluminum oxide ceramic microspheres with uniform particle size; and blending the obtained ceramic microspheres with waterborne polyurethane, and carrying out high-speed dispersion, ultrasound, spin coating and curing to obtain a composite coating. The preparation method provided by the invention has the advantages that nontoxic and easily available raw materials are adopted, a preparation process is simple, technology is controllable, cost is low, repeatability is good, and the hollow aluminum oxide ceramic microspheres are uniformly distributed. The prepared composite coating has the characteristics of environmental friendliness, light weight, high strength, high hardness, high wave transmission, low thermal conductivity, low infrared emissivity, excellent wear resistance, excellent weather resistance and the like and can be applied to the fields of heat insulation coatings, infrared stealth and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Collagen base nano infrared low emissivity colouring pigment and preparing method

InactiveCN1554713AReduce IR emissivityGood compatibilityPigment treatment with macromolecular organic compoundsOrganic solventLow emissivity

The collagen base nano coloring pigment with low infrared emissitivity is in core-shell structure with inner core of nano metal oxide coloring pigment and outer collagen grafting copolymer. Collagen molecule is first adsorbed onto the surface of nano pigment particle to modify and stabilize the nano particle, lipophilic grafting branch chain is then introduced to the collagen molecule via solution grafting copolymerization under the action of initiator and the collagen grafting copolymer coats the coloring pigment. The collagen base nano coloring pigment has relatively low infrared emissivity and good dispersivity in organic solvent or water, and it has pigment particle size smaller than 100 nm and outer shell thickness less than 20 nm. It is used in preparing stealth coating and stealth costume and can realize visible light stealth and infrared stealth without damaging radar stealth.

Owner:SOUTHEAST UNIV

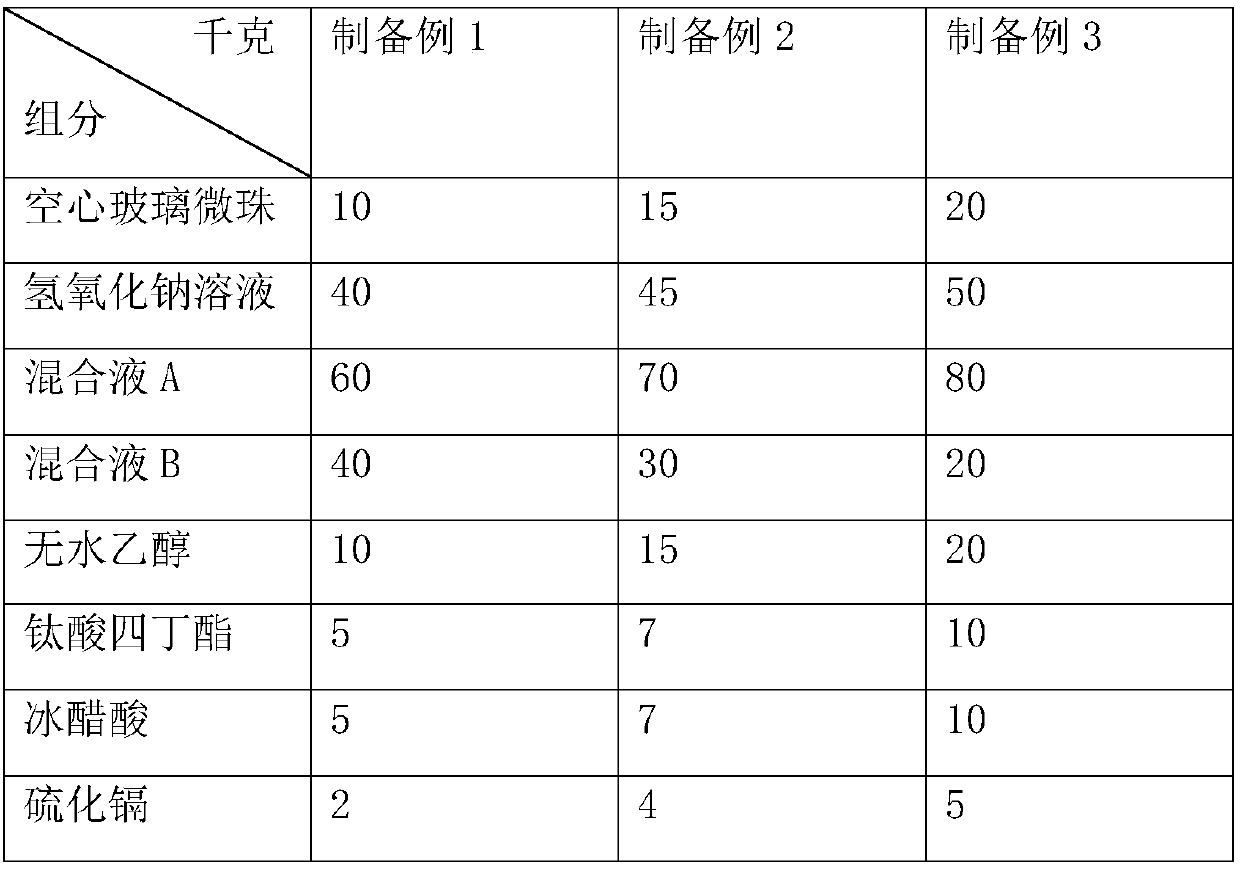

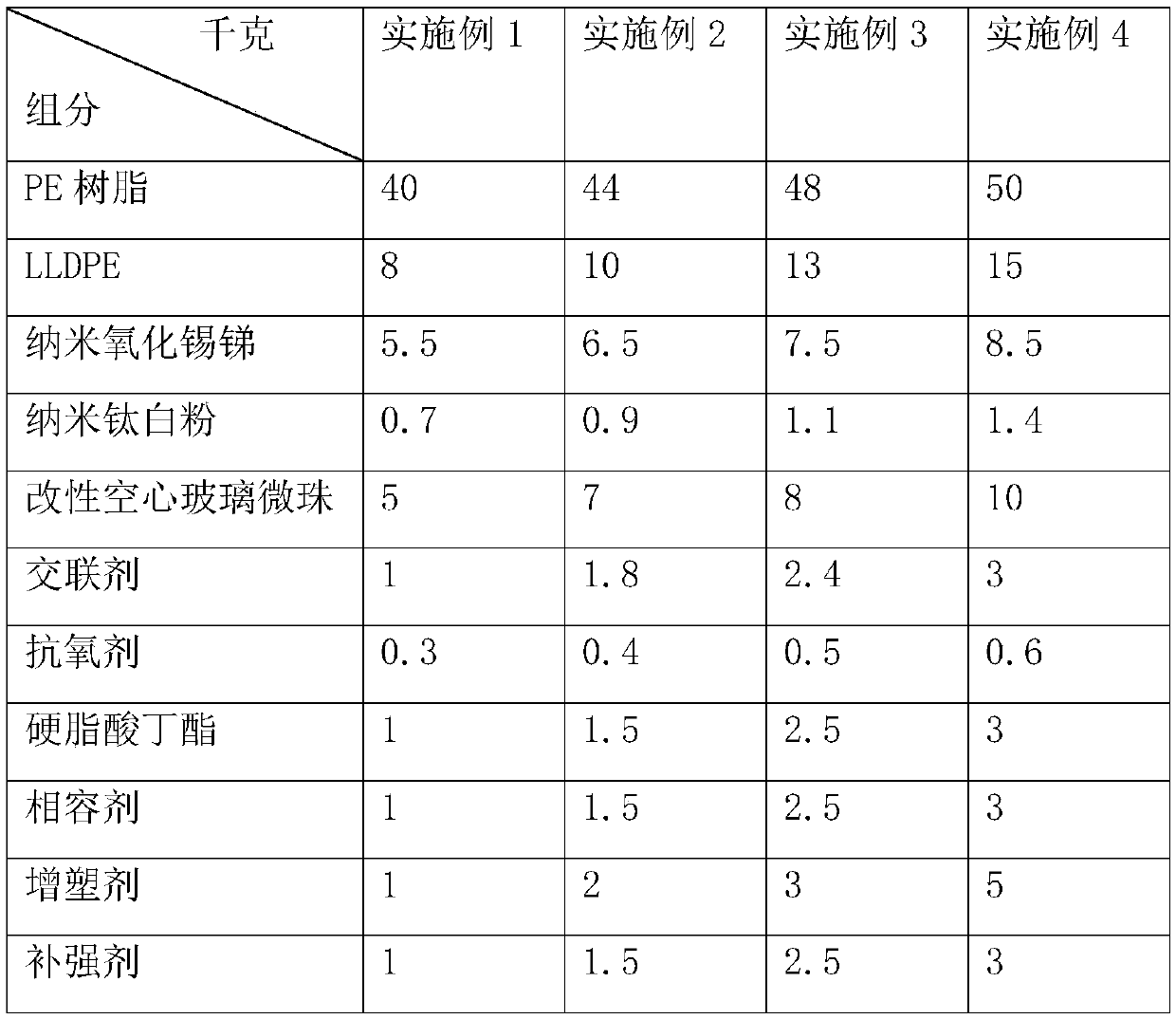

Pesticide packaging bottle and preparation method thereof

The invention discloses a pesticide packaging bottle and a preparation method thereof. The pesticide packaging bottle contains the following components (by weight): 40-50 parts of PE resin, 8-15 partsof LLDPE, 5.5-8.5 parts of nanometer tin antimony oxide, 0.7-1.4 parts of nano titanium dioxide, 5-10 parts of modified hollow glass beads, 1-3 parts of a cross-linking agent, 0.3-0.6 part of an antioxidant, 1-3 parts of butyl stearate, 1-3 parts of a compatilizer, 1-5 parts of a plasticizer, 1-3 parts of a reinforcing agent, and 5-10 parts of zinc borate. The preparation method comprises the following steps: S1: calcination; S2: melt blending extrusion; S3: vacuum reaction; and S4: blow molding. The pesticide packaging bottle of the invention has the advantages of good heat resistance and heat insulation, and high toughness and strength; in addition, the preparation method of the invention has the following advantages: the bottom of the prepared packaging bottle has no joint line, and the bottle body and the bottom are integrated as a whole.

Owner:杭州普信塑料包装有限公司

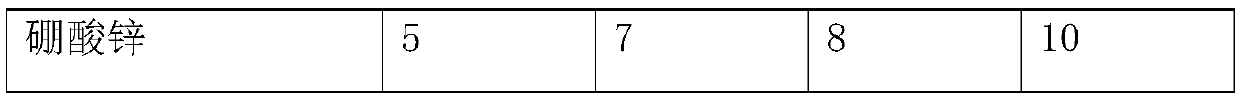

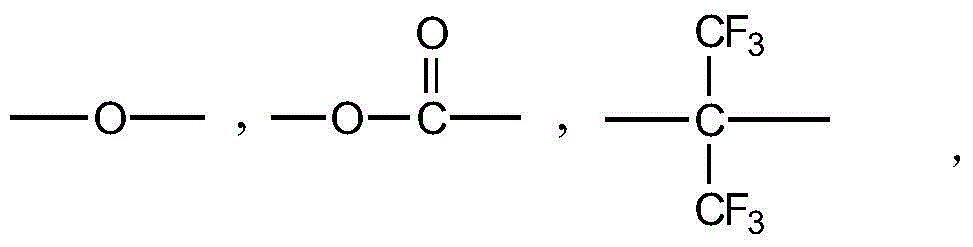

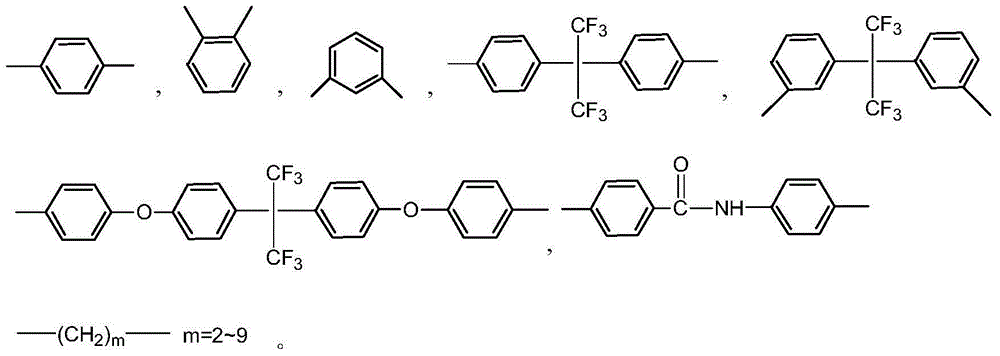

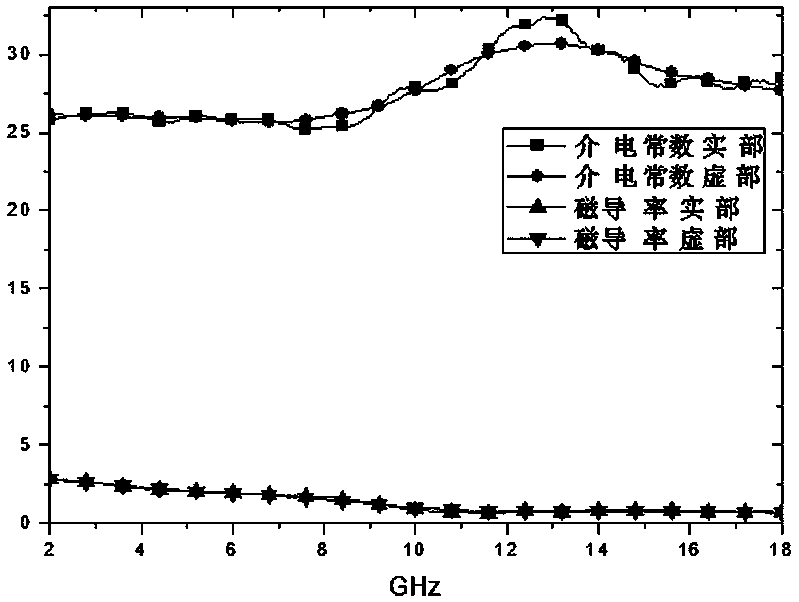

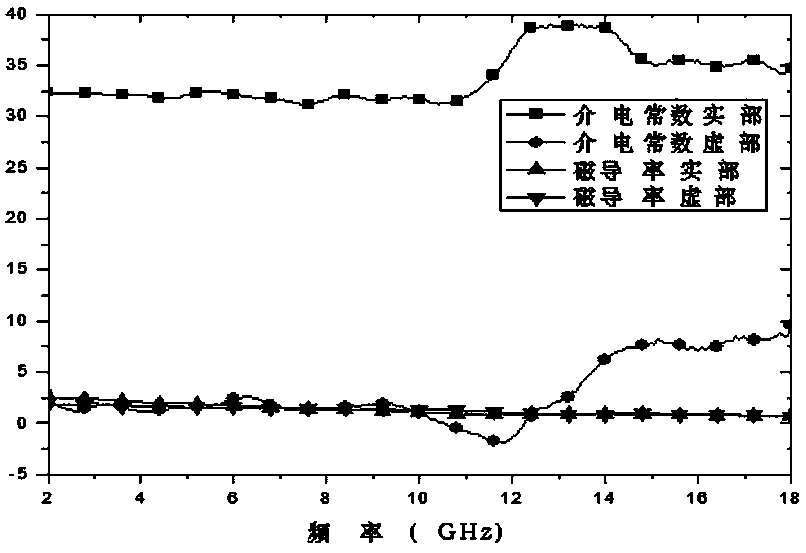

Fluorine-containing polyimide composite film material with low infrared emissivity and preparation method thereof

The invention provides a fluorine-containing polyimide composite film material with a low infrared emissivity and a preparation method thereof. The composite material is prepared by adding 1 to 10% of nano inorganic substances into a fluorine-containing polyimide material, and the nano inorganic substances are actually crystal particles dispersed in the fluorine-containing polyimide. The experiment results show that the thermal stability, environment resistant performance, and low infrared emissivity property of the composite material containing the inorganic substances are all improved, especially the infrared emissivity is greatly reduced, so the provided material can be used to prepare infrared stealth materials having a high requirement on stability and has a good application prospect in the military and civilian fields.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

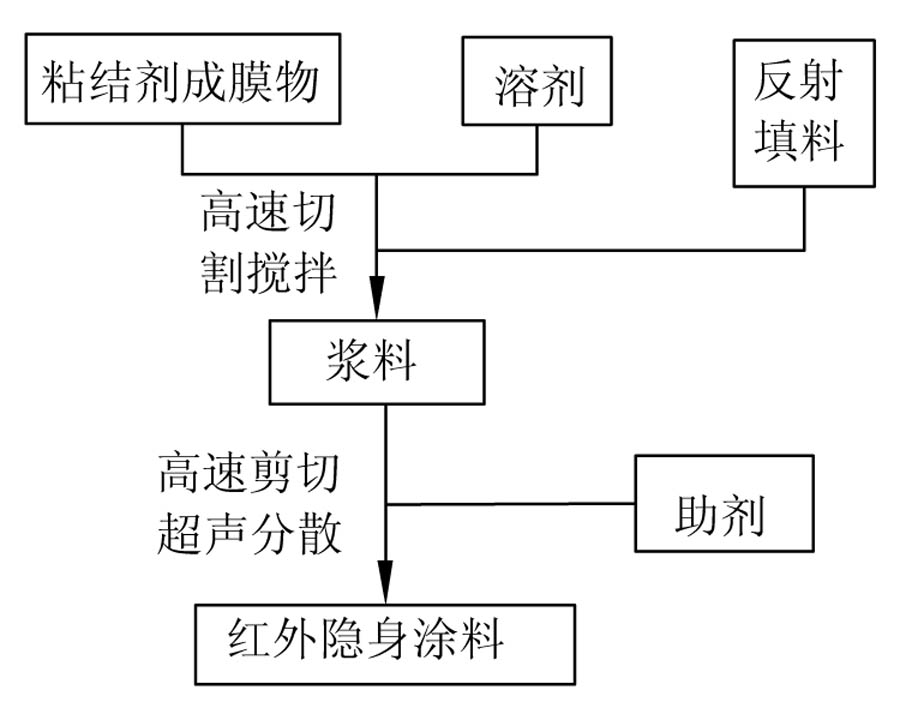

Graphene containing infrared radar compatible stealth coating and preparation method thereof

InactiveCN110054942AImprove reflective absorption performanceImprove conductivityRadiation-absorbing paintsElectrically-conductive paintsSlurrySolvent

The invention discloses a graphene containing infrared radar compatible stealth coating and a preparation method thereof. The graphene containing infrared radar compatible stealth coating comprises aresin system formed by mixing of resin, a solvent and an assistant, aluminum powder with conductivity and a radar wave reflection absorbent are dispersed in the resin system, and the radar wave reflection absorbent is composed of graphene with high dielectric constant and a magnetic absorbent. The dielectric properties of graphene are combined with electromagnetic properties of the magnetic absorbent to improve the reflection and absorption properties of the coating from two aspects of dielectric loss and electromagnetic loss, so as to achieve the effect of radar stealth' in addition, the graphene for radar absorption is dispersed among aluminum slurry particles in the resin system, the aluminum slurry particles are connected by the lamellar structure of the resin system to improve the conductivity of the coating, and low infrared emissivity is achieved; the coating can be used in high temperature radiation and radar bright spots of ships and warships, and can also be extended to ground equipment with high temperature position and radar stealth demand.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Fiber-reinforced ceramic matrix composite surface antioxidant/infrared stealth coating capable of resisting temperature of 1650 DEG C and preparation method thereof

ActiveCN111732457AGood compatibilityMinimizes differences in thermal expansion coefficientsLiquid surface applicatorsMolten spray coatingLayered structureOxidation resistant

The invention relates to the technical field of high-temperature infrared stealth materials and particularly discloses a fiber-reinforced ceramic matrix composite surface antioxidant / infrared stealthcoating capable of resisting the temperature of 1650 DEG C. The infrared stealth coating is of a layered structure and comprises a ceramic inner layer, a ceramic middle layer, a ceramic outer layer and a low-infrared-emissivity functional layer from bottom to top, wherein the ceramic inner layer is a mullite layer, the ceramic middle layer is a rare earth silicate layer, the ceramic outer layer isan 8YSZ layer, and the low-infrared-emissivity functional layer is a coating with Pt as a conductive phase and Bi2O3 as a binding phase. The invention further provides a preparation method of the fiber-reinforced ceramic matrix composite surface antioxidant / infrared stealth coating capable of resisting the temperature of 1650 DEG C. According to the infrared stealth coating, the oxidation resistance and the high-temperature stability of the composite material are improved, the infrared radiation intensity of a base material can be remarkably reduced, and the infrared stealth coating has excellent oxidation resistance and an infrared stealth function.

Owner:NAT UNIV OF DEFENSE TECH

Preparation method of radar wave absorption composite material with infrared stealth

InactiveCN111286079AAvoid reflectionsIncrease reflection lossSpecial leather manufactureChemical reactionRadar

The invention discloses a preparation method of a radar wave absorption composite material with an infrared stealth function. The preparation method comprises the following steps: preparing a metal particle complex (BM-M) having absorption performance and loaded on a base material by utilizing a chemical reaction between the base material and metal ions, and loading and storing a phase change material PCM by utilizing hydrophobicity and porous structure characteristics of the base material to prepare the product BM-M / PCM. The composite material prepared by the invention has the characteristicsof softness and high mechanical strength, so that the radar wave stealth and infrared stealth compatible leather prepared by taking the leather as the base material has the characteristics of being bendable and wearable.

Owner:SICHUAN UNIV

An infrared-radar compatible stealth material and its preparation method

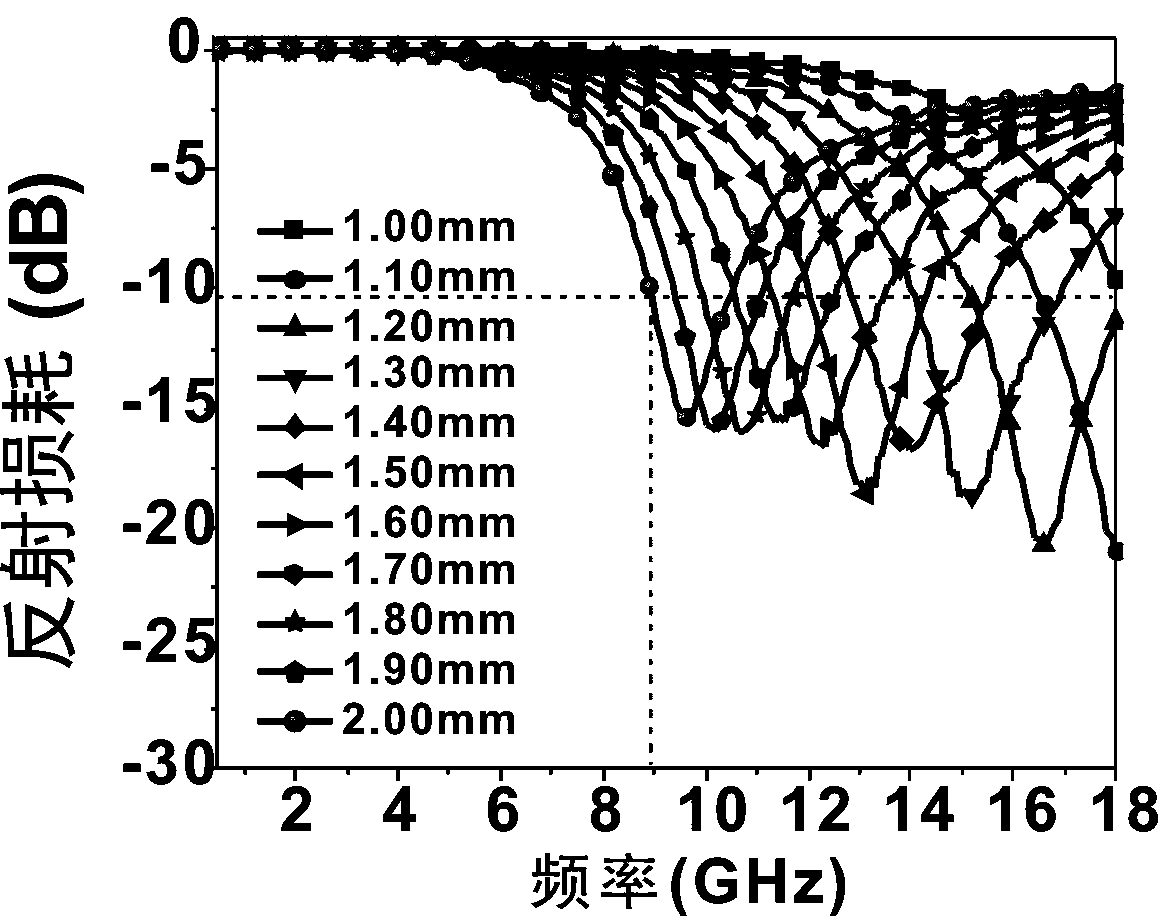

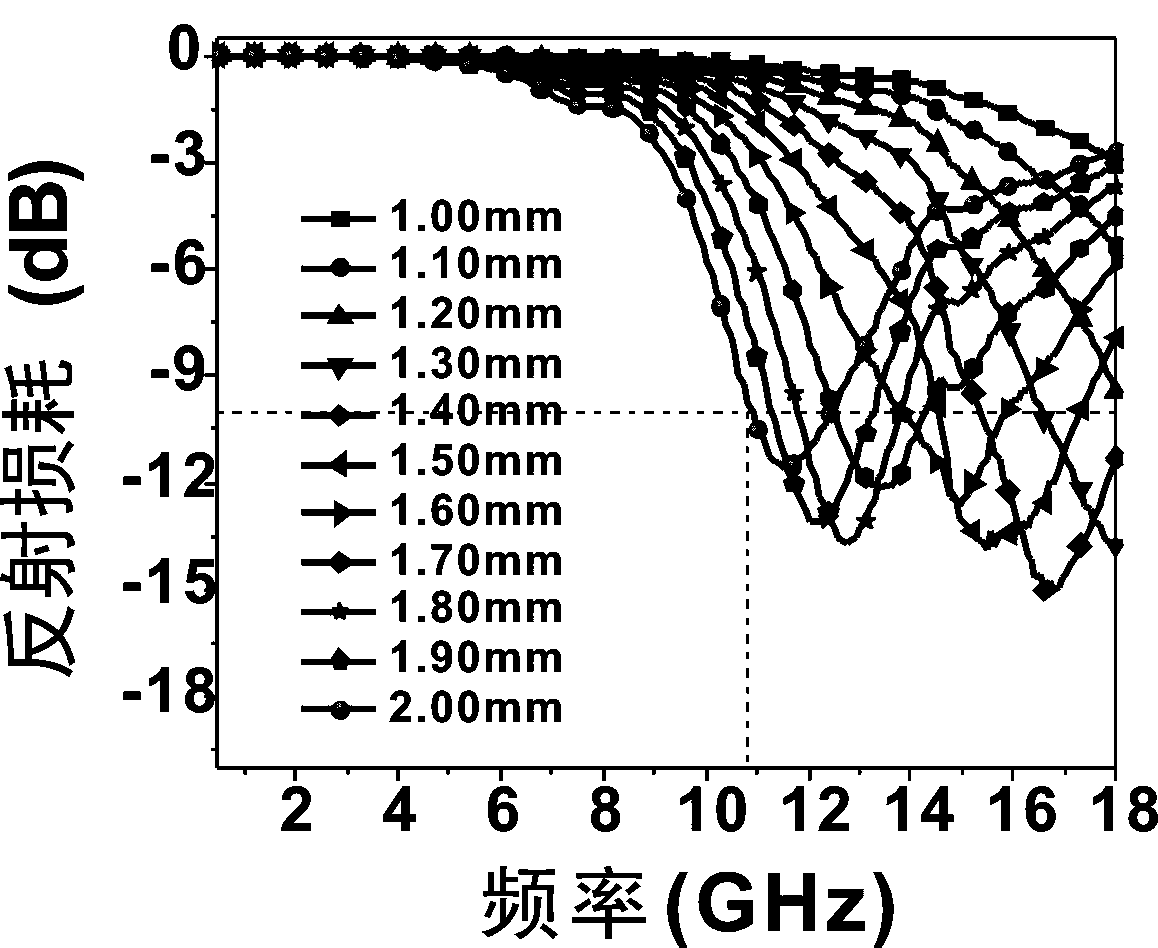

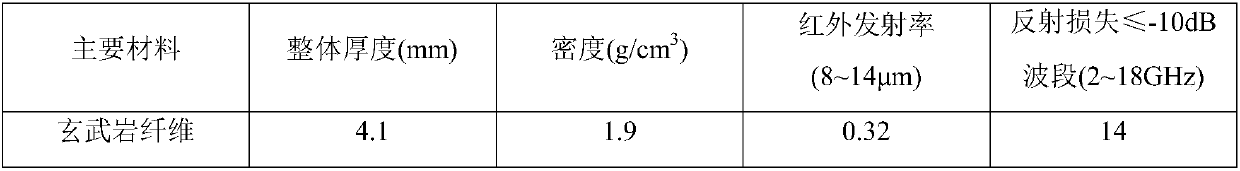

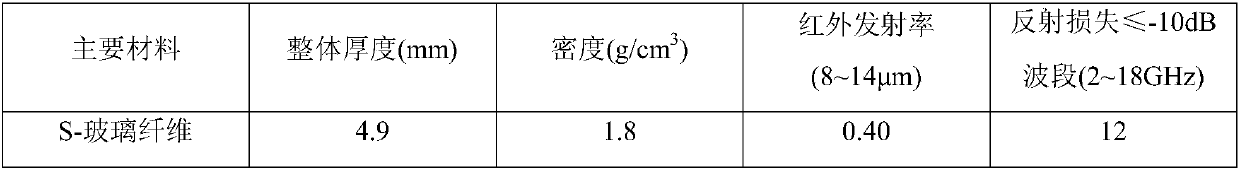

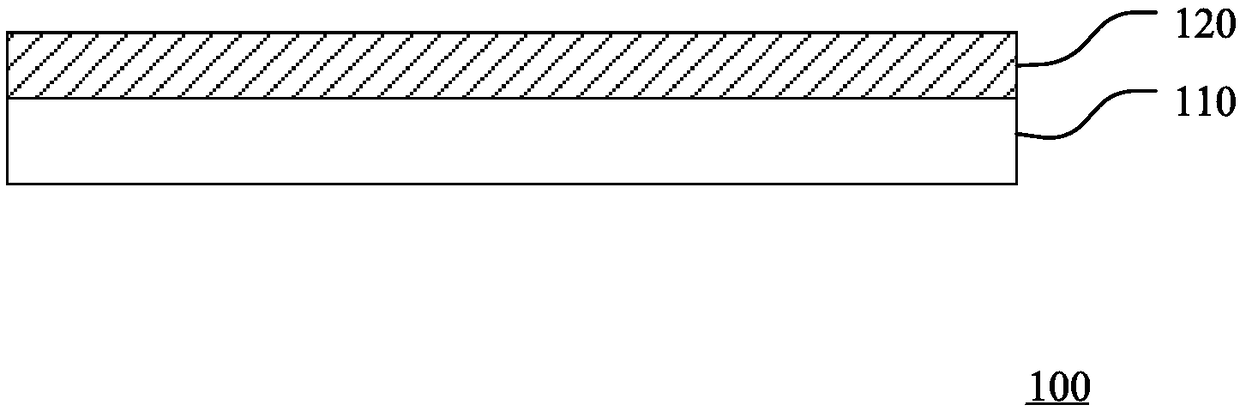

ActiveCN106183315BExcellent infrared stealth performanceImprove absorbing performanceSynthetic resin layered productsGlass/slag layered productsEmissivityCarbon fibers

The invention discloses an infrared-radar compatible stealthy material and a preparation method thereof. The material sequentially comprises a low infrared emissivity layer, a radar wave transmission layer, a radar wave absorbing layer and a radar reflecting layer from top to bottom, wherein the low infrared emissivity layer takes an inorganic adhesive capable of bearing high temperature of 1000K or above as a matrix material, takes fibers with infrared emissivity not higher than 0.8 at a wave band of 8 to 15mu m as a reinforcing material, and takes metal or a semiconductor as an auxiliary material; the radar wave transmission layer takes resin as a matrix material and takes continuous fibers with high transmissivity to radar wave of 2 to 18GHz, and high strength as a reinforcing material; the radar wave absorbing layer takes resin containing a nitrile functional group as a matrix material, takes basalt fibers as a reinforcing material and takes a ferrite radar wave absorber as an auxiliary material; the radar reflecting layer takes resin as a matrix material and takes carbon fibers as a reinforcing material. The stealthy material disclosed by the invention is excellent in infrared and radar stealthy performance and is simple in preparation process.

Owner:SICHUAN AEROSPACE TUOXIN BASALT IND +1

Self assembly laminated infrared film material and preparation method of self assembly laminated infrared film material

ActiveCN102876287BEffectively eliminate interferenceEliminate distractionsOxide/hydroxide preparationOther chemical processesEmissivityLayer by layer self assembly

The invention aims at providing a self assembly laminated infrared film material and a preparation method of the self assembly laminated infrared film material. The material is formed by using infrared absorption material LDHs (layered double hydroxides) nanometer sheets and single-layer oxidized graphene as basic elements through alternate layer-by-layer self assembly, the layer structure with the LDHs nanometer sheet / single-layer oxidized graphene sequence laminated layer is adopted, the layer number is 2 to 40, the material film thickness is 2 to 200nm, the wave band is 8 to 14mum at 25 DEG C, and the infrared emissivity of the material is 0.300 to 0.600. Layer plate metal ions of the LDHs nanometer sheets consist of metal ions M1 and metal ions M2, wherein the mol ratio of the metal ions M1 to the metal ions M2 is 2:1, the metal ions M1 are one kind of ions or the combination of many kinds of ions from Mg<2+>, Co<2+>, Mn<2+> and Zn<2+>, and the metal ions M2 are one kind of ions or the combination of two kinds of ions from Fe<3+> and Co<3+>.

Owner:SOUTHEAST UNIV

Invisible patch

PendingCN114179466AAchieving Compatible StealthEffective absorptionSynthetic resin layered productsCamouflage devicesEngineeringMechanical engineering

The invention relates to a stealth patch which comprises an infrared stealth layer (1) and a radar absorption layer (3) and further comprises a visible light camouflage layer (2), and the infrared stealth layer (1) and the radar absorption layer (3) are located on the two sides of the visible light camouflage layer (2). According to the invention, visible light, infrared and radar compatible stealth can be realized.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

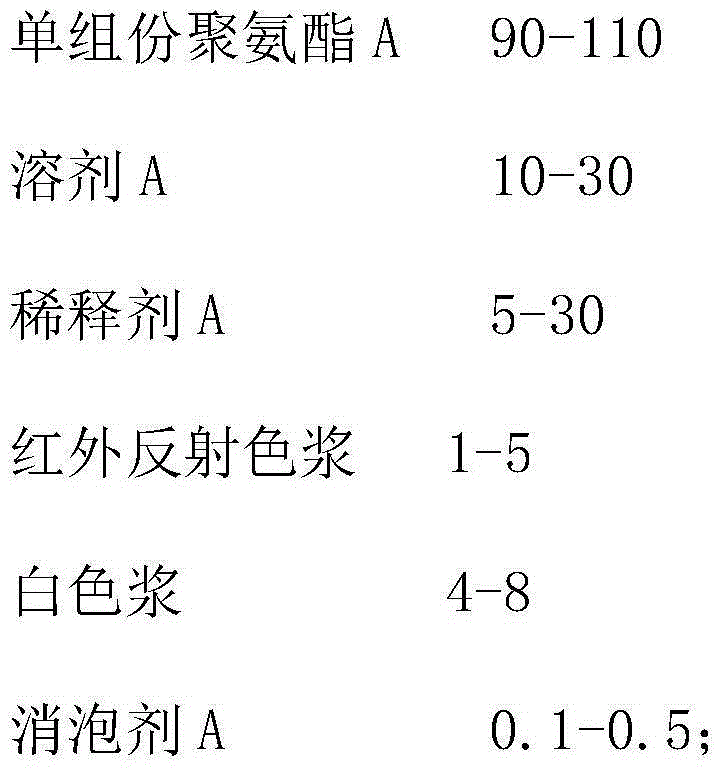

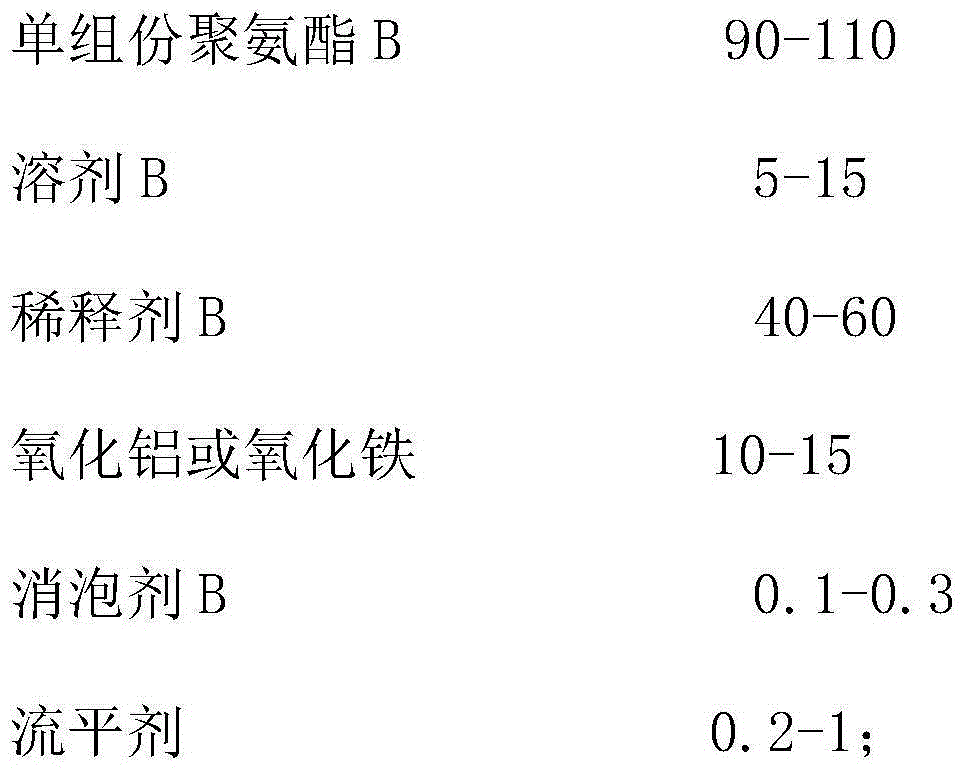

Preparation method of infrared stealth textile coating fabric

ActiveCN105040462ASimple methodIncrease productivityPolyureas/polyurethane adhesivesDyeing processSurface layerEngineering

The invention provides a preparation method of an infrared stealth textile coating fabric. According to the method, a printing layer, a surface layer, a thermal-insulating layer, a bonding layer and a base cloth layer are laminated together; the method specifically comprises the following steps: step one, scrape coating the surface layer on release paper by using the scraper of a coating machine, and drying in an oven; step two, scrape coating the thermal-insulating layer on the surface layer by using the scraper of the coating machine, foaming and curing in the oven, cooling to the temperature below 50 DEG C after drying; step three, scrape coating the binding layer on the thermal-insulating layer by using the scraper of the coating machine, drying in the oven and cooling to the temperature below 50 DEG C after the drying; step four, laminating the base cloth on the bonding layer, and stripping the release paper; step five, transferring the printing layer onto the surface layer by using the anilox roller of a printing machine, drying by using the oven, and cooling to the temperature below 50 DEG C after the drying. According to the preparation method provided by the invention, the preparation process is simple, the cost is low, and the prepared fabric has the softness of textiles, can prevent rain and corrosion, can be used both on sunny days and slushy days, and has stealth and warmth retention effects.

Owner:CTA HI TECH TEXTILES

Novel low-infrared-emissivity corrosion-resistant coating

ActiveCN102977726AReduce IR emissivityImprove corrosion resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsAl powderEmissivity

The invention discloses a novel low-infrared-emissivity corrosion-resistant coating comprising the components of, by weight, 80 parts of polyurethane, 120 parts of maleic-anhydride-modified ethylene propylene diene monomer (EPDM) rubber, 0-50 parts of floating flake-shaped Al powder, 0-50 parts of floating flake-shaped Cu powder, 10-20 parts of a silane coupling agent KH550, 10-20 parts of xylene, and 4-8 parts of cyclohexane. The prepared coating has low infrared emissivity, and the corrosion resistance of the modified coating is greatly improved. The method has good application prospect.

Owner:RUNTAI CHEM CO LTD

Rare earth doped nano indium tin oxide infrared stealth coating

ActiveCN109135531AImprove stabilityGood dispersionPolyurea/polyurethane coatingsRadiation-absorbing paintsRare earthIndium tin oxide

The invention relates to a rare earth doped nano indium tin oxide infrared stealth coating. SnCl4, InCl3 and ErCl3 are adopted at a molar ratio of 0.4-1.2:10:0.08-0.12, and rare earth doped nano indium tin oxide powder is prepared by a liquid phase chemical coprecipitation method. The rare earth doped nano indium tin oxide powder is modified by silane coupling agent KH570, and the amount of KH570is 4%-8% of the mass of the rare earth doped nano indium tin oxide powder; the modified rare earth doped indium tin oxide powder is dispersed in absolute ethanol at a ratio of 1 g / ml, mixed with polyurethane, and sprayed on an aluminum substrate to obtain the infrared stealth coating, and the mass ratio of the indium tin oxide to the polyurethane is 1-2:3. The preparation process is simple, and the infrared stealth coating has low density, low infrared reflectivity, high transparency and good physical, mechanical and chemical properties.

Owner:NANCHANG HANGKONG UNIVERSITY

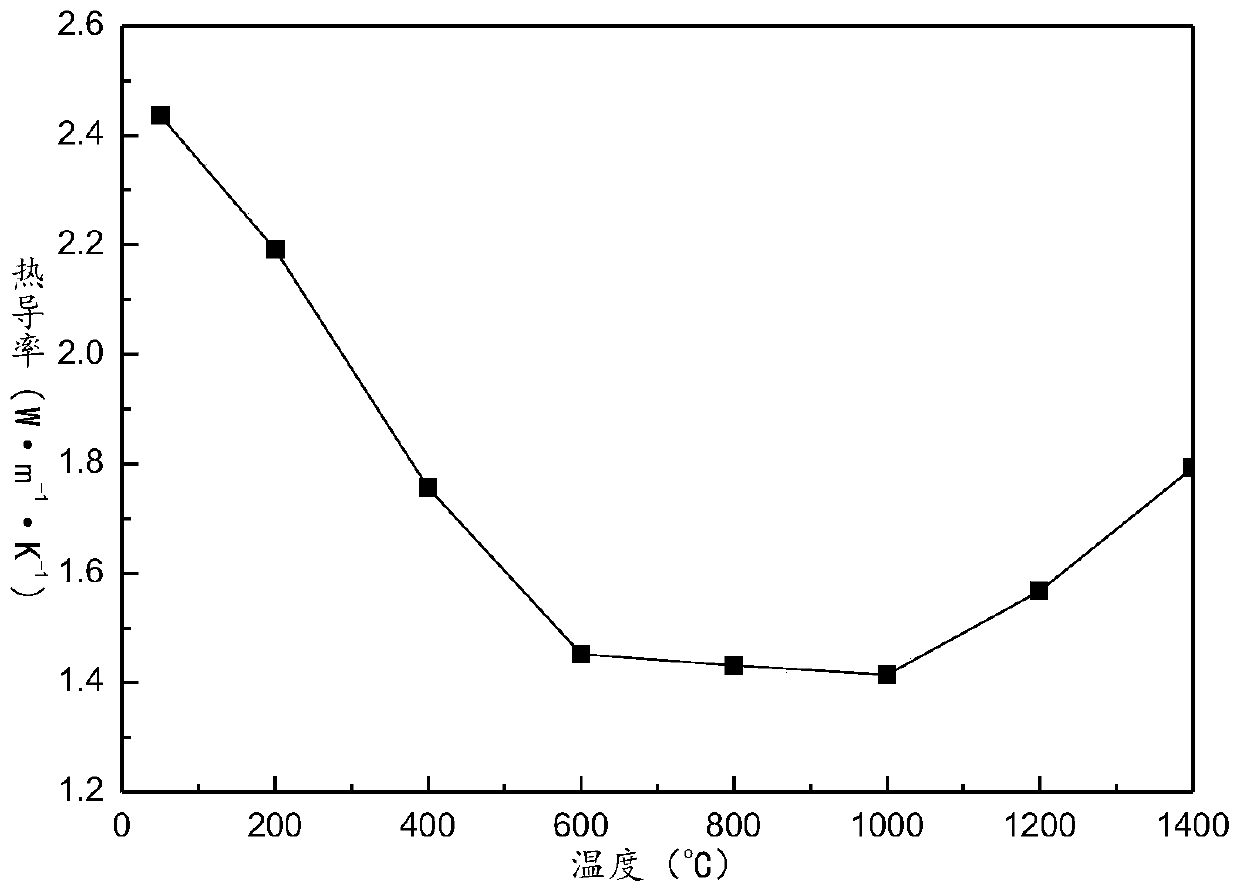

Al<3+> doped low-infrared and low-thermal-conductivity semiconductor ceramic material and preparation method thereof

The invention discloses an Al<3+> doped low-infrared and low-thermal-conductivity semiconductor ceramic material and a preparation method thereof; the semiconductor ceramic material has the molecularformula of SrZr(1-x)AlxO3, wherein x is the atom percentage of Al<3+> doped substituted Zr. According to the preparation method, strontium zirconate SrZrO3 is used as a matrix, Al<3+> with different proportions is doped to prepare the semiconductor ceramic material, and the preparation method specifically comprises the following steps: (1) preparation of strontium zirconate powder; (2) biscuit forming; and (3) ceramic firing. The infrared radiance of the prepared semiconductor ceramic material is less than 0.5 at the waveband of 3-5 [mu]m; the heat conductivity is lower than 2.5 W*m<-1>*K<-1>;the semiconductor ceramic material can be used at the environment temperature ranging from the room temperature to 1400 DEG C, the heat conductivity at the temperature of 600-1200 DEG C can be reduced to 1.5 W*m<-1>*K<-1> or below, and the semiconductor ceramic material can well serve in the high-temperature environment, and is stable in performance and high in corrosion and oxidation resistancein the long-term high-temperature environment.

Owner:INNER MONGOLIA UNIV OF TECH

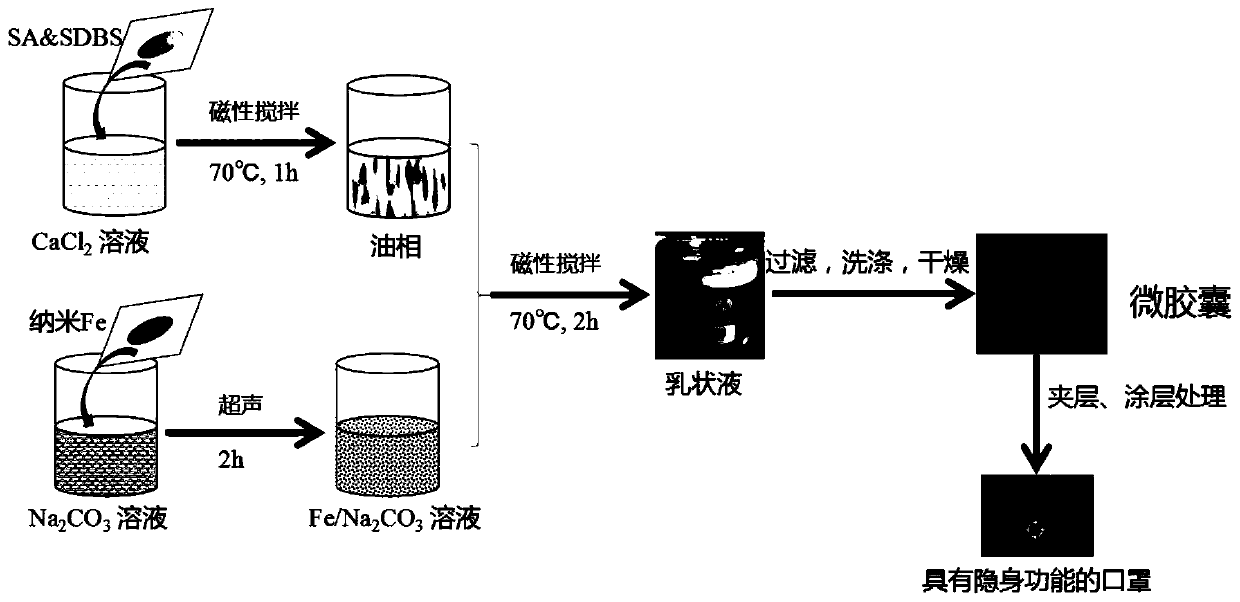

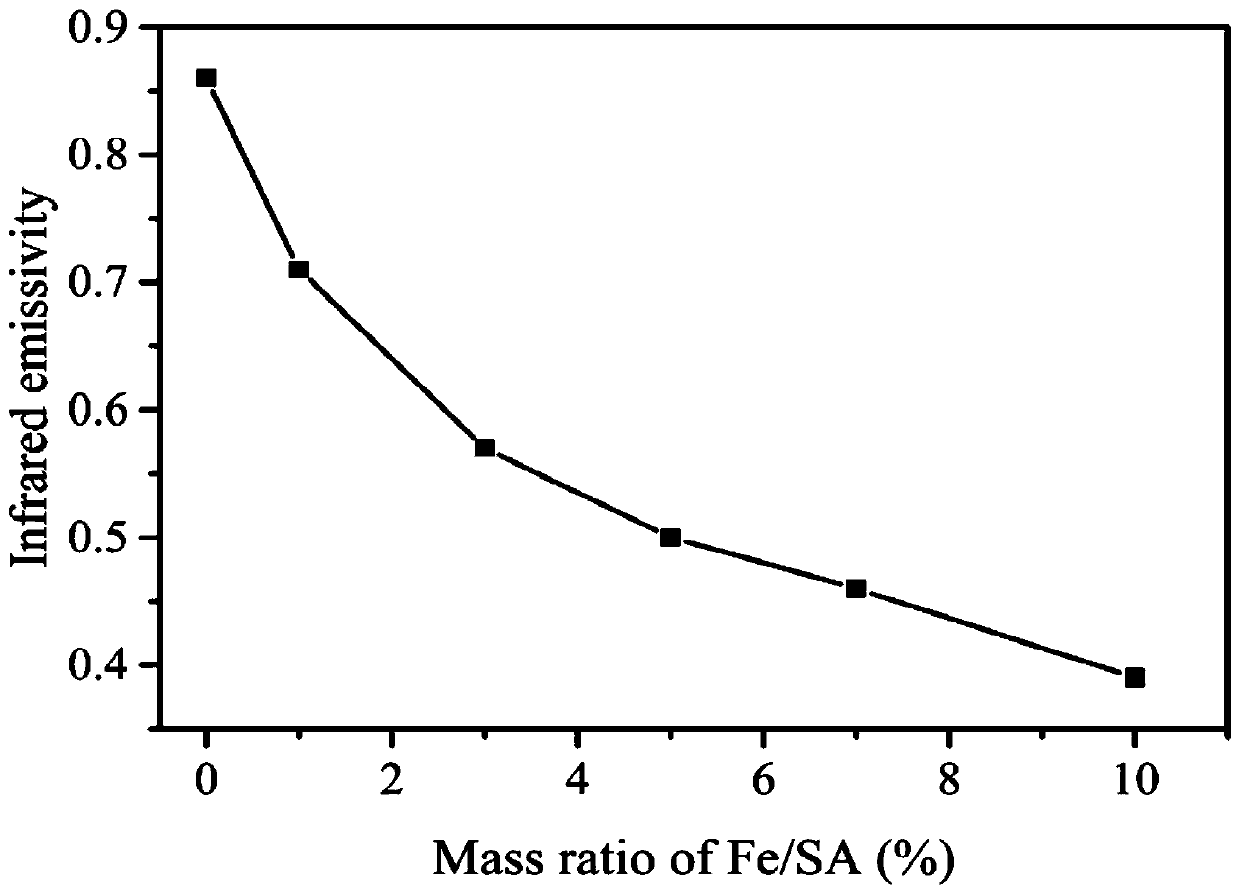

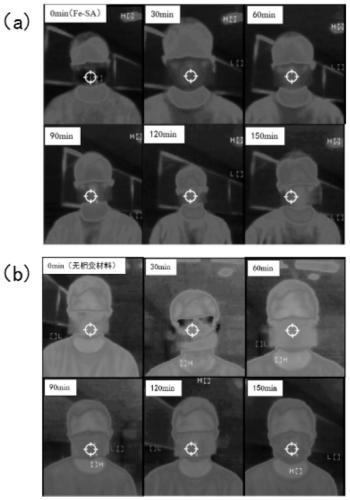

Preparation method and application of phase change-infrared stealth difunctional composite microcapsule

ActiveCN111205829AGood stealth effectStable performanceHeat-exchange elementsProtective garmentIn situ polymerizationCalcium carbonate

The invention discloses a preparation method and application of a composite microcapsule phase change material with double functions of heat storage, temperature control and infrared stealth. Stearicacid is mainly used as a core material, calcium carbonate is used as a wall material, a nano ferromagnetic material is doped at the same time, and the difunctional composite microcapsule phase changematerial with a core-shell structure is prepared by adopting an in-situ polymerization method, the difunctional composite microcapsule phase change material is processed into an interlayer, a hollow part of clothes is coated with the interlayer by adopting a coating treatment mode, and a heat storage and temperature control-infrared stealth nocturnal clothing. For more simply illustrating, the interior of a mask is coated with the composite microcapsule phase change material, and the infrared stealth performance of a mask person-wearing area and other areas is tested and compared.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Infrared stealth coating, preparation method thereof, infrared stealth fabric and preparation method of infrared stealth fabric

PendingCN109233410AReduce IR emissivityImprove fitPolyurea/polyurethane coatingsTextiles and paperEpoxyAdhesive

The invention discloses an infrared stealth coating, a preparation method thereof, infrared stealth fabric and a preparation method of the infrared stealth fabric. The infrared stealth coating is prepared from a composite pigment and an adhesive, wherein the composite pigment contains aluminium paste and a color pigment; the adhesive contains any one of aliphatic elastic polyurethane, one-component elastic polyurethane and epoxy resin; the infrared stealth fabric is obtained by spraying the infrared stealth coating to at least one surface of a substrate. Compared with the prior art, the infrared stealth coating and the infrared stealth fabric with low emissivity have the advantages that human bodies and military weapons can be camouflaged and shielded effectively, probability that the human bodies and the military weapons are detected by an infrared detector is reduced, the coating and the substrate are better bound, and probability of powder falling, cracking and even falling off of the coating from the substrate is reduced.

Owner:LUOYANG INST OF CUTTING EDGE TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com