Al<3+> doped low-infrared and low-thermal-conductivity semiconductor ceramic material and preparation method thereof

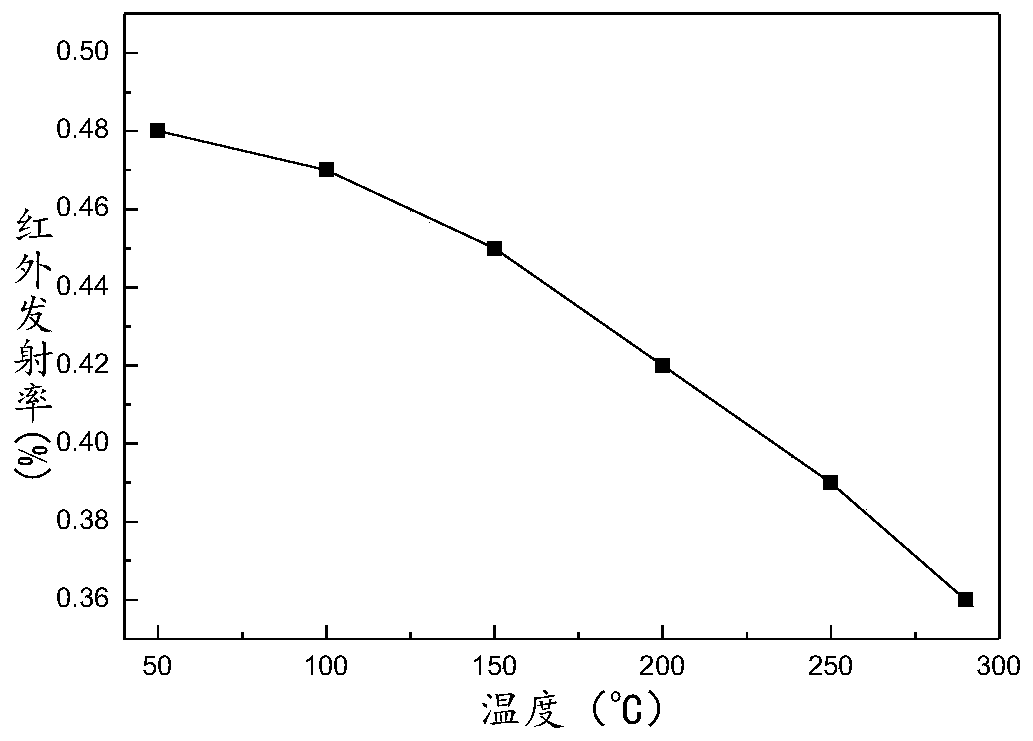

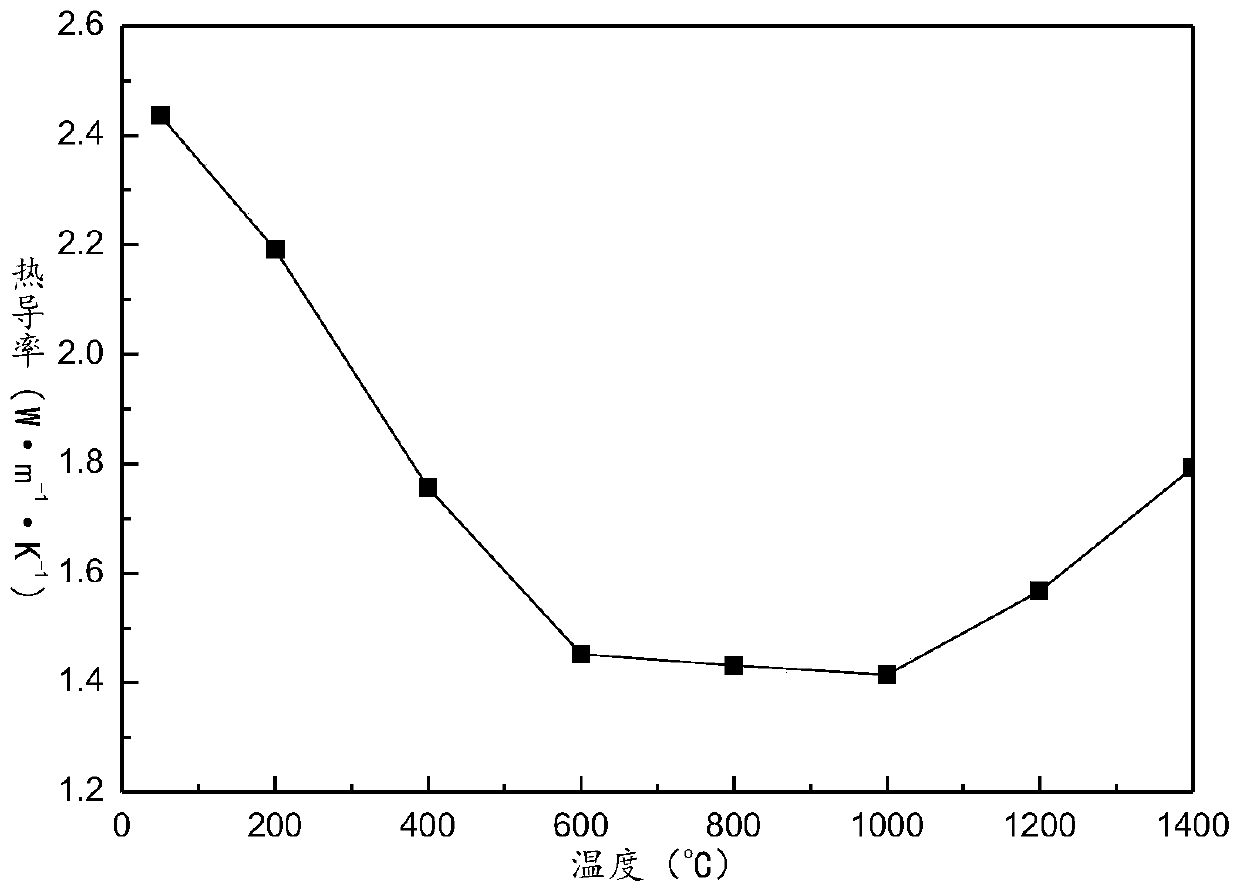

A ceramic material, low thermal conductivity technology, applied in low thermal conductivity semiconductor ceramic material and its preparation, Al3+ doped low infrared field, can solve the problems of increased infrared emissivity, low infrared emissivity and high emissivity, and achieves resistance to The effect of strong corrosion and oxidation ability, low infrared emissivity and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

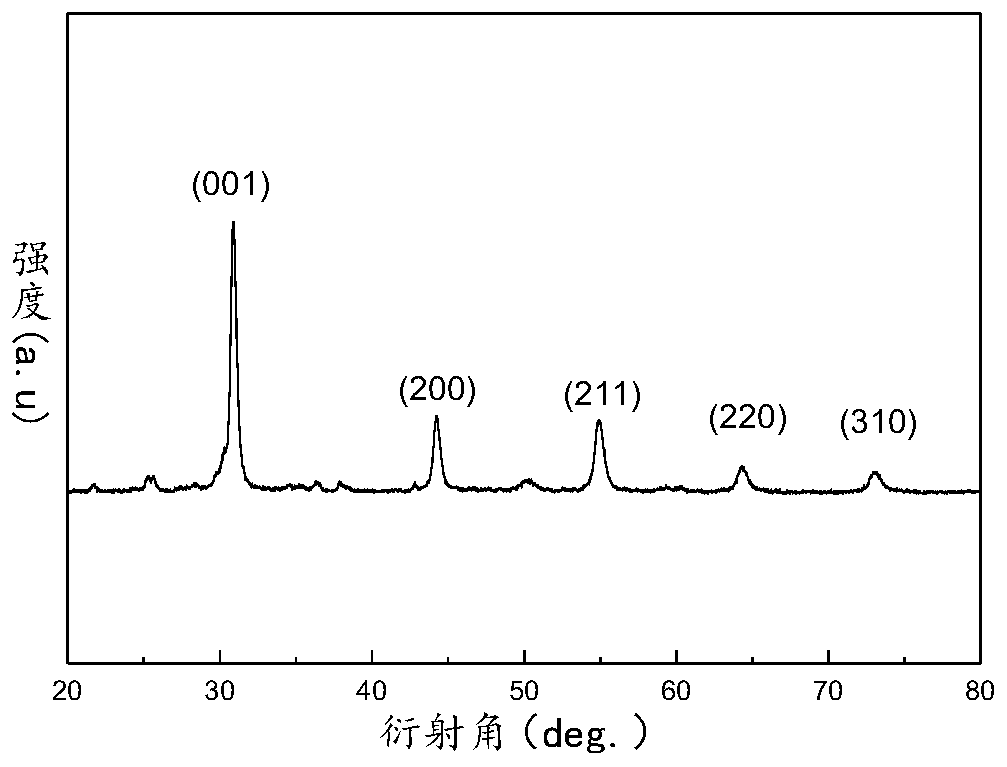

[0034] SrZr of this embodiment 0.875 Al 0.125 O 3 The citric acid preparation steps of ceramic materials are as follows:

[0035] 1. Preparation of strontium zirconate ceramic powder. In this example, strontium zirconate powder was prepared by the citric acid method

[0036] (A-1) According to the molecular formula SrZr 0.875 Al 0.125 O 3 Calculate the added amount of zirconium nitrate, strontium nitrate, and aluminum nitrate, and weigh zirconium nitrate, strontium nitrate, and aluminum nitrate as raw materials;

[0037] (A-2) Add 10 times the total mass of the reactant raw materials and stir in deionized water. After all the reactants are dissolved, add citric acid. The addition amount of the citric acid is zirconium source raw material, strontium source raw material and aluminum source raw material 2 times the total moles of metal ions, adjust the pH of the solution to 8 with ammonia water, then stir and heat in a water bath at 80°C until the solution is viscous, and stand still fo...

Embodiment 2

[0043] SrZr of this embodiment 0.875 Al 0.125 O 3 The steps of the ceramic material solid-phase reaction method preparation method are as follows:

[0044] 1. Preparation of strontium zirconate powder. In this example, solid phase reaction method was used to prepare strontium zirconate powder.

[0045] (B-1) According to the molecular formula SrZr 0.875 Al 0.125 O 3 Calculate the added amount of zirconium nitrate, strontium nitrate, and aluminum nitrate, and weigh zirconium nitrate, strontium nitrate, and aluminum nitrate as raw materials;

[0046] (B-2) High-speed ball milling for 24 hours to fully mix the reactants;

[0047] (B-3) Put the mixed powder in a high-temperature furnace and keep it at 1600°C for 6 hours to obtain strontium zirconate ceramic powder material.

[0048] 2. Green molding: mix the obtained strontium zirconate ceramic powder material with polyvinyl alcohol (PVA) uniformly, grind and dry, then place the mixture in a mold, dry powder tablet, molding pressure 20MPa, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com