Radar-infrared compatible stealth material with adjustable property and preparation method thereof

A stealth material and radar technology, applied to radiation-absorbing coatings, coatings, etc., can solve the problems of fixed performance and complicated preparation methods, and achieve the effects of low cost, simple process flow, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

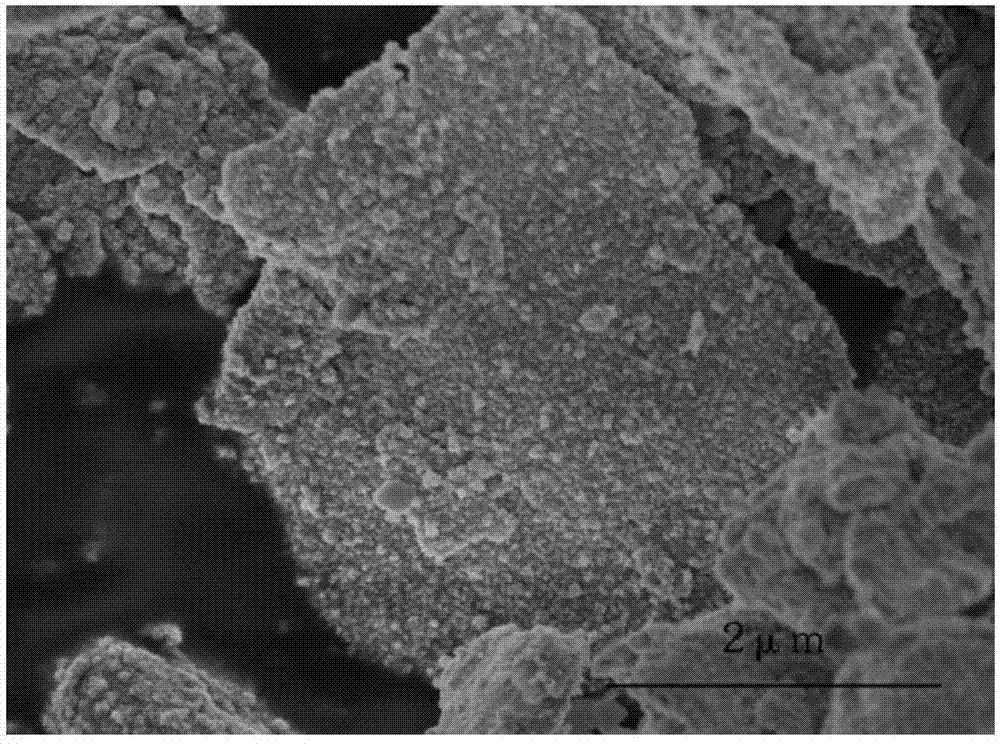

Embodiment 1

[0034] A method for preparing a radar-infrared compatible stealth material with adjustable performance, comprising the following steps:

[0035] Step 1, at room temperature, take 100g of steel balls with a diameter of 4mm, 10g of carbonyl iron powder, and 0.01g of calcium stearate, measure 30ml of acetone solution, add them to a 100ml ball mill jar, and mill at a speed of 500 rpm for 8 hours;

[0036] Step 2, put the carbonyl iron powder after ball milling into 100ml degreasing liquid, and degrease at 50°C for 8 minutes; wherein, in the degreasing liquid, the mass concentration of NaOH is 40g / L, NaCO 3 The mass concentration is 20g / L, Na 4 P 2 o 7 The mass concentration is 20g / L;

[0037] Step 3, put the degreased carbonyl iron powder into 200ml of electroless plating solution, adjust the pH value of the chemical plating solution to 13 with NaOH, and then perform plating at 30°C for 45 minutes; among them, in the chemical plating solution, potassium citrate The mass concen...

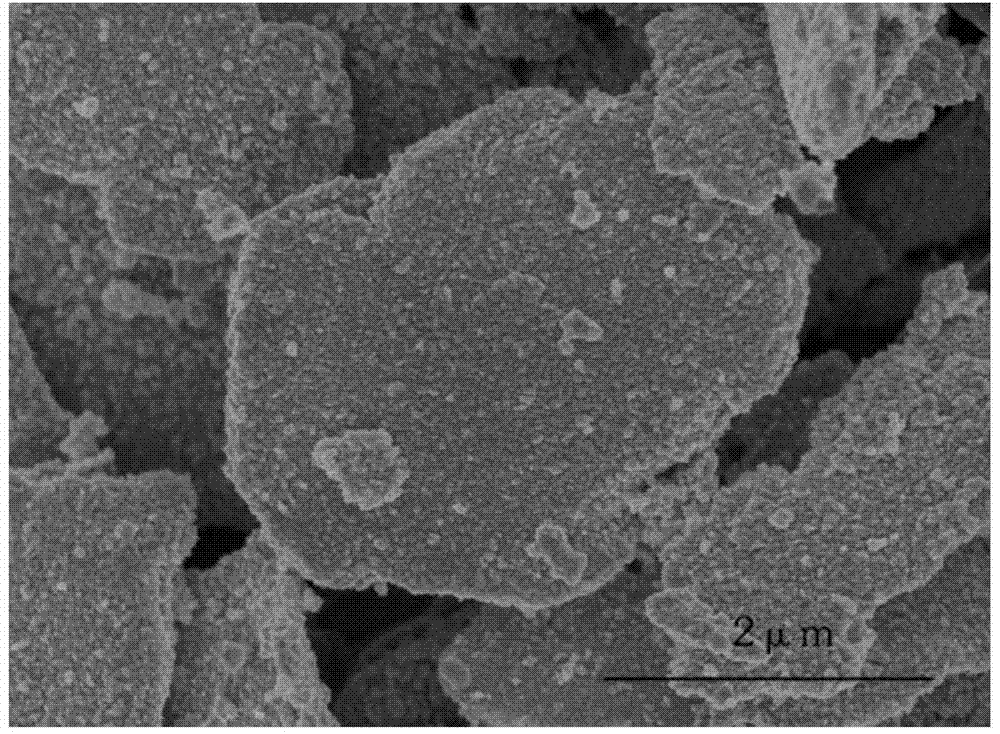

Embodiment 2

[0040] A method for preparing a radar-infrared compatible stealth material with adjustable performance, comprising the following steps:

[0041] Step 1, at room temperature, take 100g of steel balls with a diameter of 4mm, 10g of carbonyl iron powder, and 0.1g of calcium stearate, measure 40ml of acetone solution, add them to a 100ml ball mill jar, and mill at a speed of 500 rpm for 10 hours;

[0042] Step 2, put the carbonyl iron powder after ball milling into 100ml degreasing liquid, and degrease at 60°C for 9 minutes; wherein, in the degreasing liquid, the mass concentration of NaOH is 40g / L, NaCO 3 The mass concentration is 20g / L, Na 4 P 2 o 7 The mass concentration is 20g / L;

[0043]Step 3, put the degreased carbonyl iron powder into 200ml of electroless plating solution, adjust the pH value of the chemical plating solution to 14 with NaOH, and then perform plating at 60°C for 30 minutes; among them, in the chemical plating solution, potassium citrate The mass concent...

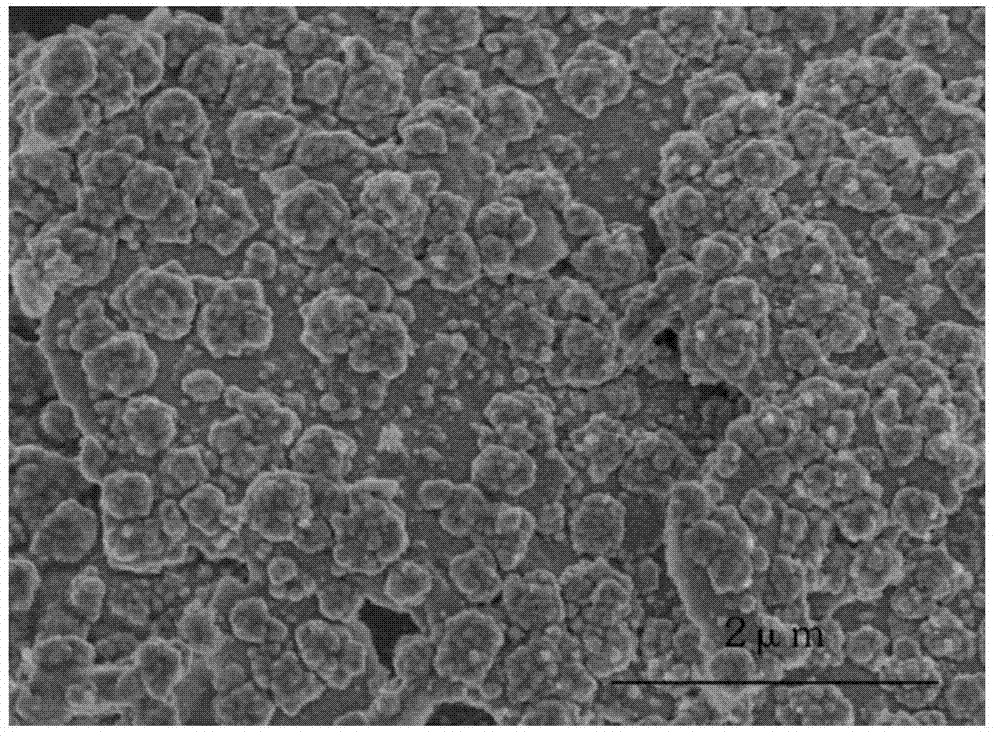

Embodiment 3

[0046] A method for preparing a radar-infrared compatible stealth material with adjustable performance, comprising the following steps:

[0047] Step 1, at room temperature, take 100g of steel balls with a diameter of 4mm, 10g of carbonyl iron powder, and 0.1g of calcium stearate, measure 40ml of acetone solution, add them to a 100ml ball mill jar, and mill at a speed of 500 rpm for 12 hours;

[0048] Step 2, put the carbonyl iron powder after ball milling into 100ml of degreasing liquid, and degrease at 70°C for 10 minutes; wherein, in the degreasing liquid, the mass concentration of NaOH is 50g / L, NaCO 3 The mass concentration is 25g / L, Na 4 P 2 o 7 The mass concentration is 25g / L;

[0049] Step 3, put the degreased carbonyl iron powder into 200ml electroless plating solution, adjust the pH value of the electroless plating solution to 14 with NaOH, and then perform plating at 75°C for 15 minutes; among them, in the electroless plating solution, potassium citrate The mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com