Patents

Literature

159results about How to "Suitable for scale" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

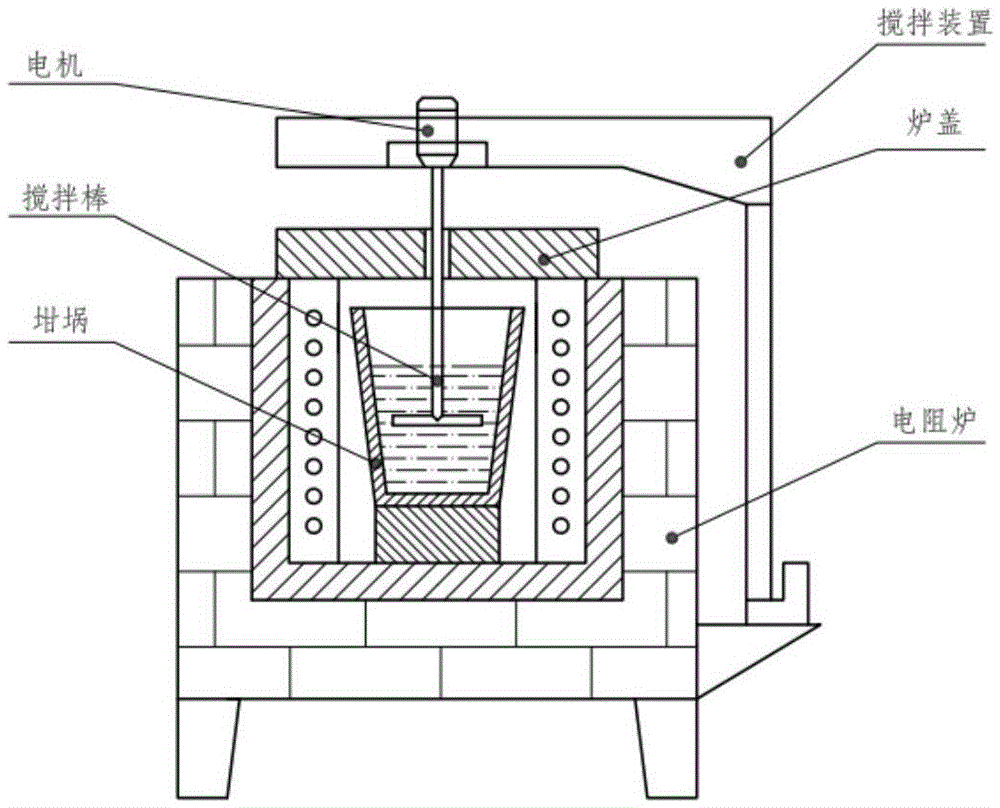

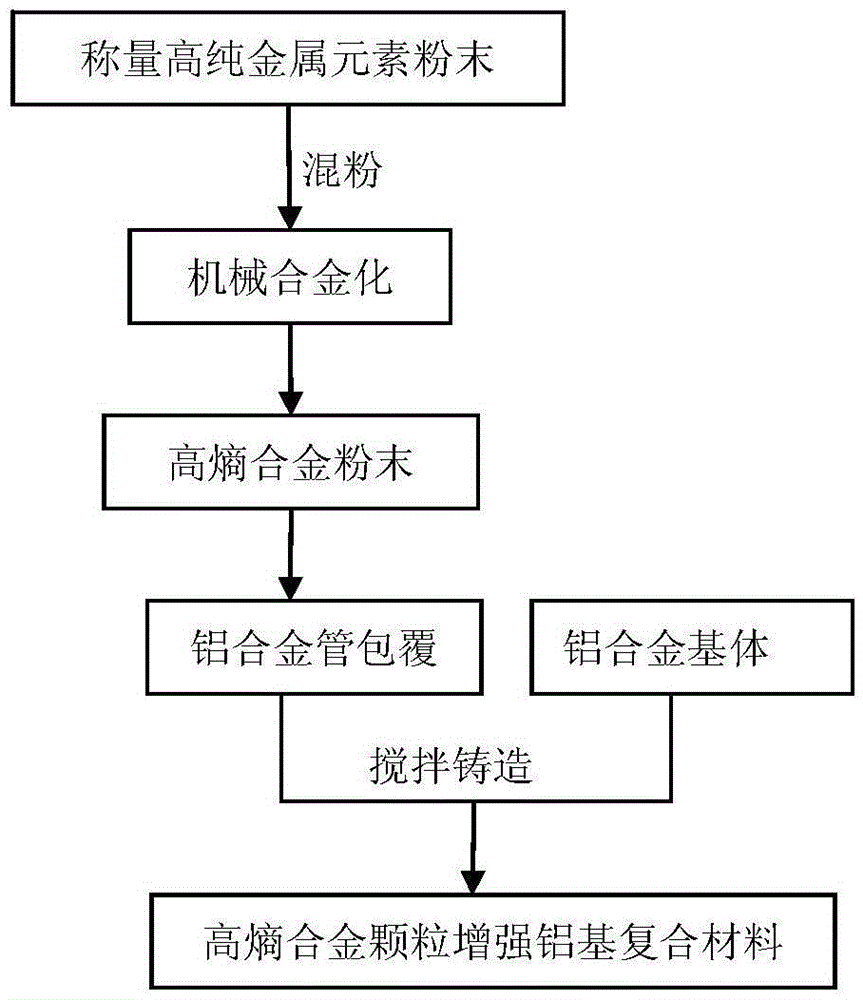

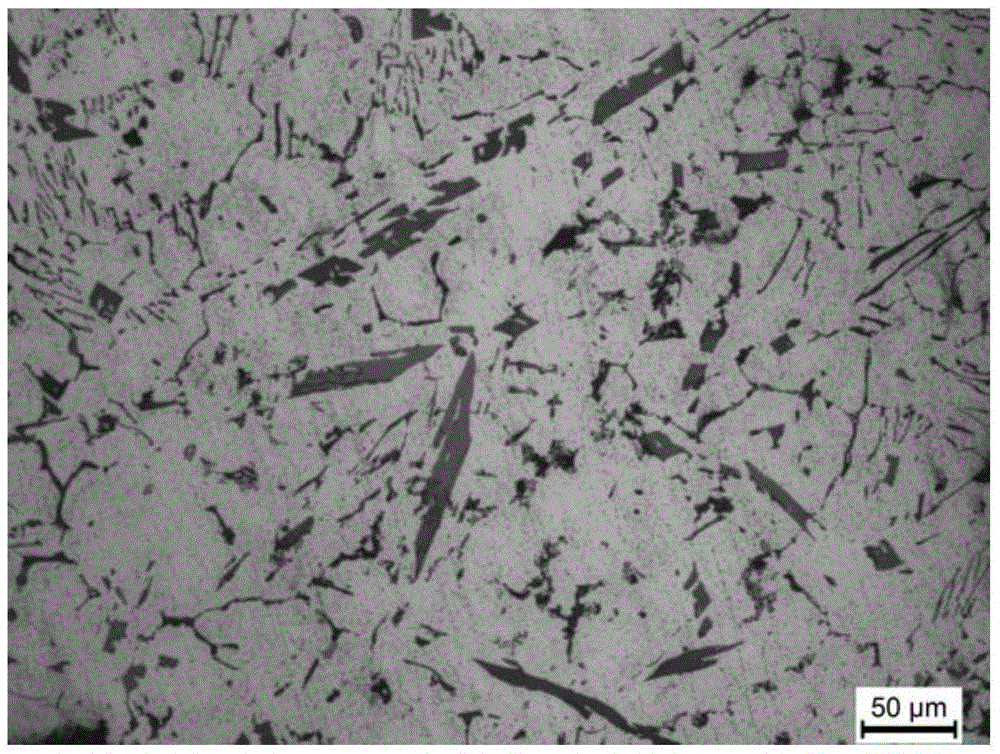

High-entropy alloy particle reinforced aluminum base composite material and stirring casting preparation process thereof

The invention discloses a high-entropy alloy particle reinforced aluminum base composite material and a stirring casting preparation process thereof. The preparation process adopts mechanical alloying to prepare high-entropy alloy powder and screen to obtain high-entropy alloy particles; the high-entropy alloy particles are sealed by adopting an aluminum alloy pipe having the same material with a basal body; the aluminum alloy pipe weighed in a segmented manner is added in the molten basal body; the high-entropy alloy particles are dispersed by a stirring mode; and the high-entropy alloy particle reinforced aluminum base composite material is prepared by a casting process. The high-entropy alloy particles are 0.1-35%; aluminum alloys are 65-99.9%; and the sum of the two is 1. The high-entropy alloy particles in the structure of the prepared composite material are uniformly dispersed; the high-entropy alloy and aluminum alloy interface bonding compatibility is excellent; the strength and the toughness are excellent; the preparation process is simple; the powder has no need to be treated; the cost is low; the stability is good; and the composite material is suitable for large-batch production and standard production, and is excellent in promotion and application prospect.

Owner:GUANGDONG XINGFA ALUMINUM +1

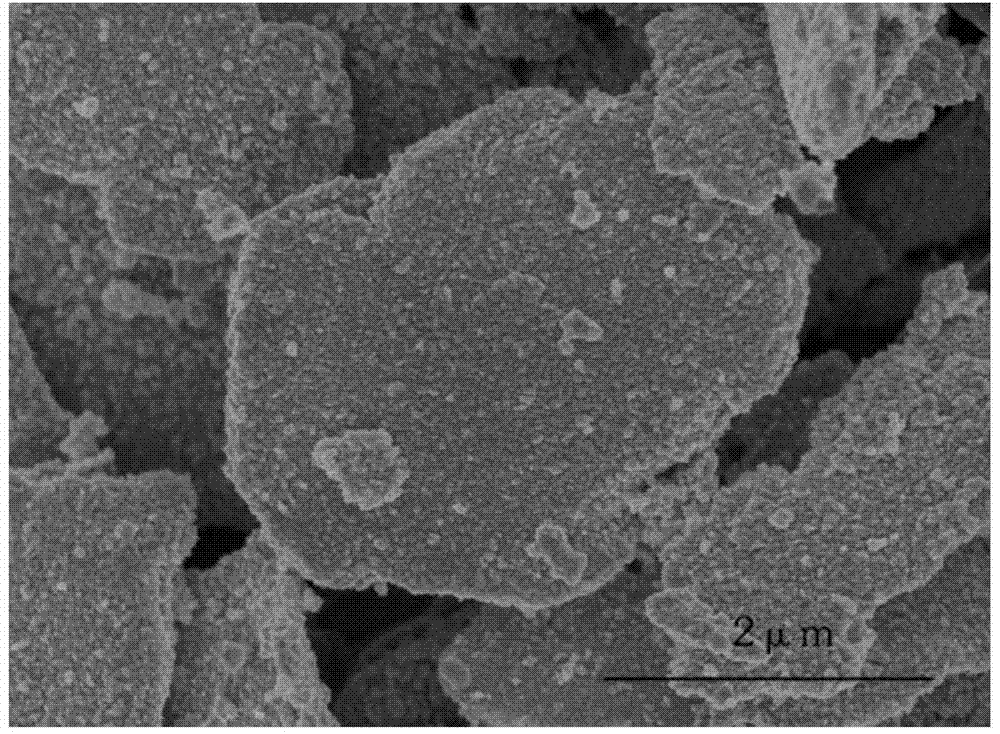

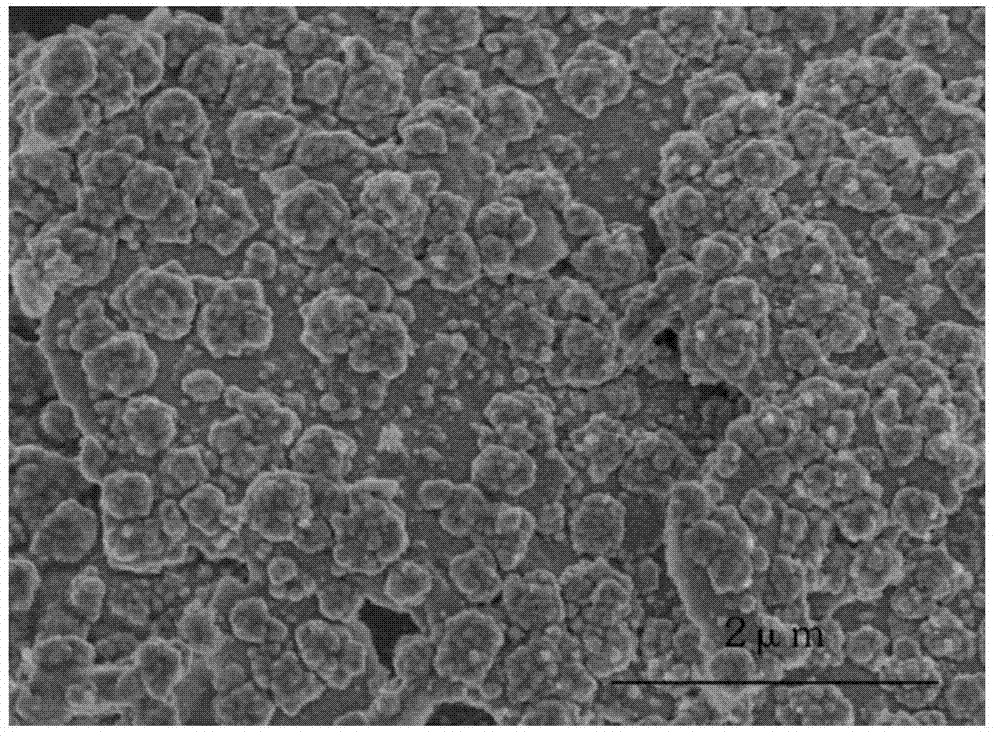

Battery-grade anhydrous iron phosphate and preparation method thereof

The invention relates to a battery grade anhydrous iron phosphate and a preparation method thereof. The battery grade anhydrous iron phosphate is in an orthorhombic type. The preparation method of the battery grade anhydrous iron phosphate is an oxidation precipitation method using air as oxidant and includes steps: adding pH value modifier solution into aqueous solution of mixture of ferrous salt with phosphoric acid or phosphate, feeding air and stirring for reaction to generate a crystalline-state composite containing ammonium, hydroxyl and water of crystallization; and obtaining the battery grade anhydrous iron phosphate after solid-liquid separating, washing, drying and roasting. The battery grade anhydrous iron phosphate is an ideal material for preparation of lithium iron phosphate which is the material of anodes of lithium ion batteries. The preparation method is suitable for large-scale, economical, stable and reliable production of high-quality battery grade anhydrous iron phosphate, and has evident advantages and practical value.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

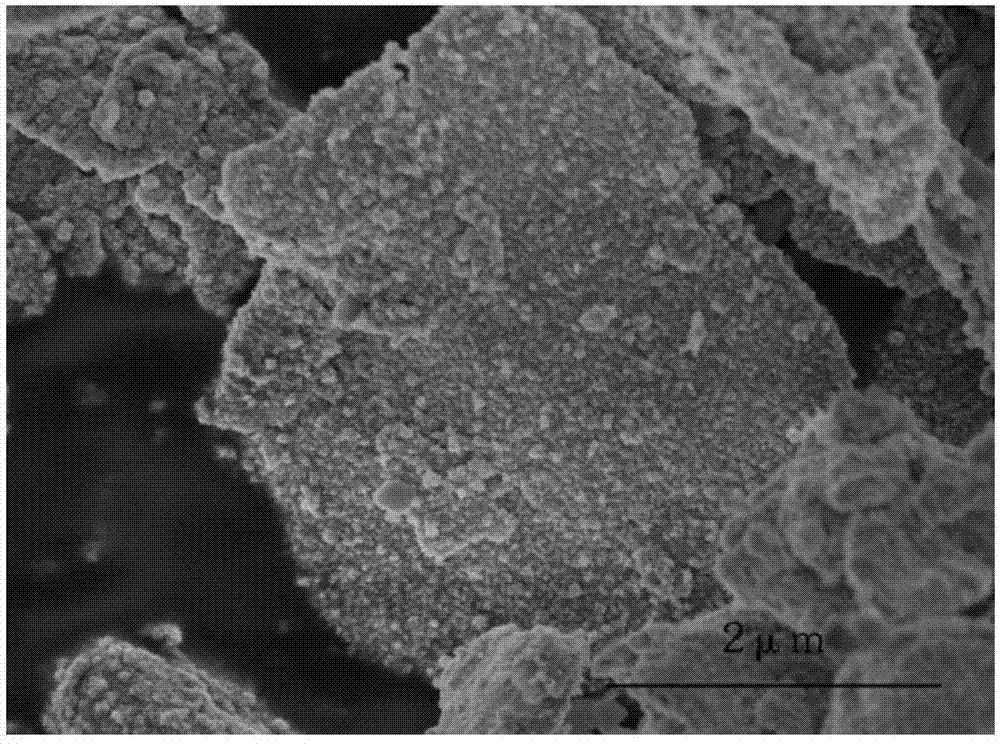

Preparing method of refractory high-entropy alloy spherical powder

InactiveCN108145170AHigh sphericityGood surface finishAdditive manufacturing apparatusMolten spray coatingHigh entropy alloysThermal spraying

Owner:CENT SOUTH UNIV

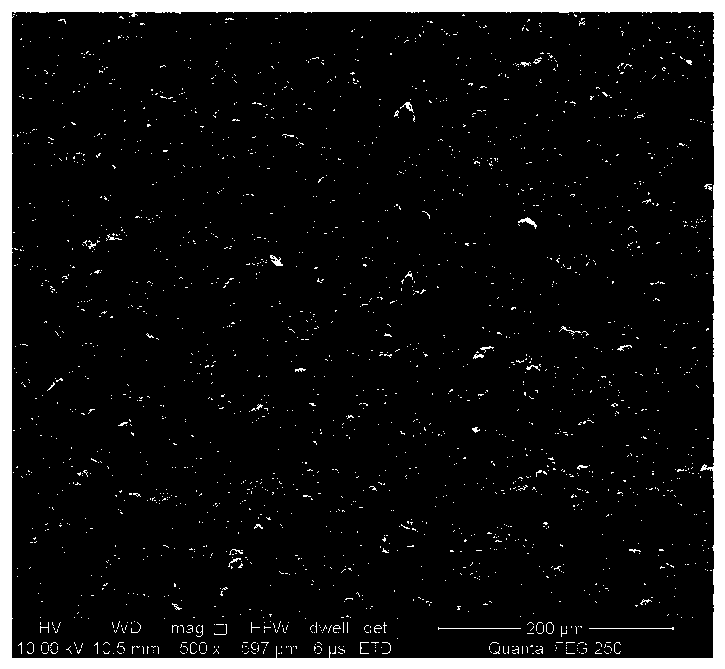

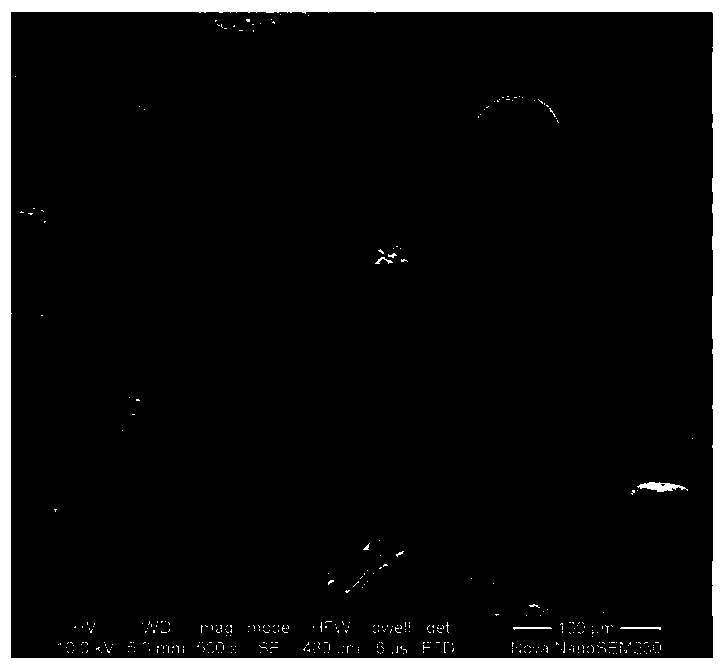

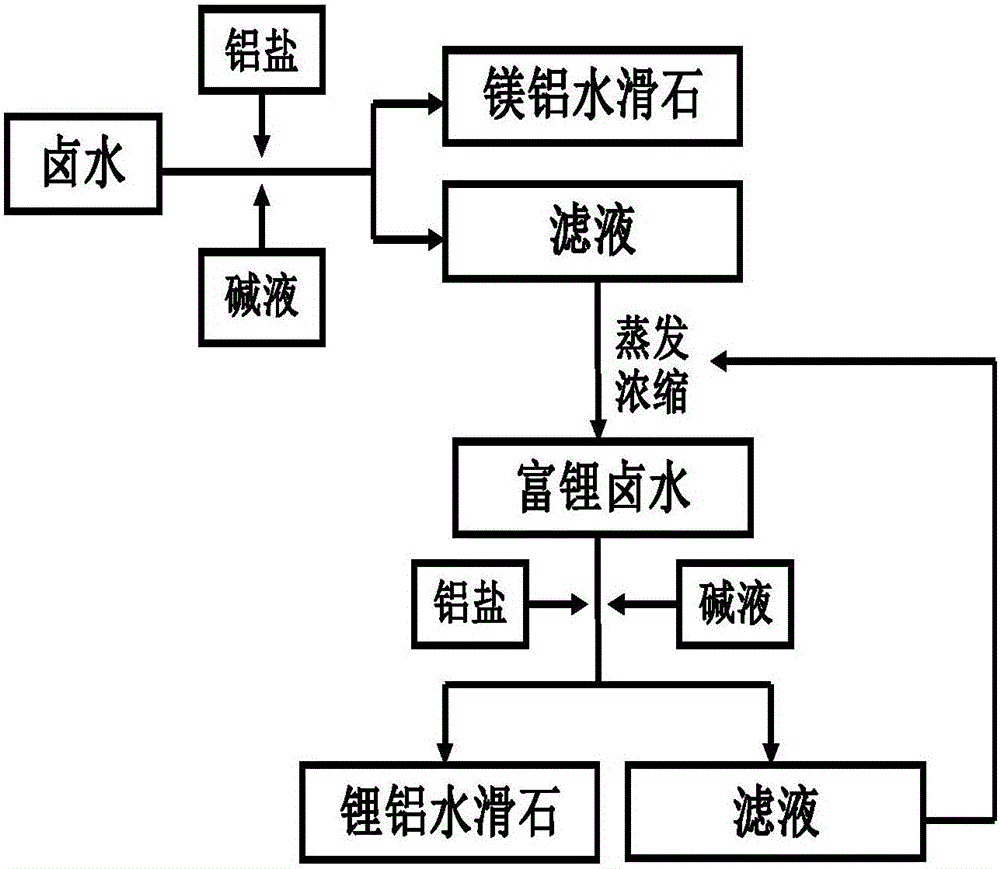

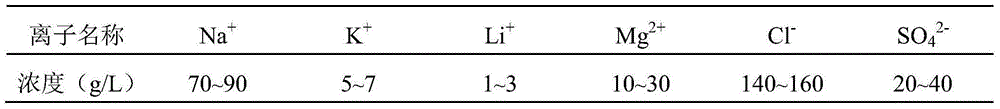

Process method for extracting Mg and Li from bittern and simultaneously producing hydrotalcite

ActiveCN105152193ARealize resource separationAchieve productionSemi-permeable membranesHydrotalciteLithiumEvaporation

The invention provides a process method for separating Mg and Li from salt lake bittern and simultaneously producing magnesium-aluminum layered double hydroxide (MgAl-LDH) and lithium-aluminum layered double hydroxide (LiAl-LDH) by a reaction-separation combined technology. The process method comprises adding an Al salt in bittern, carrying out coprecipitation and crystallization on the bittern and alkali lye for coprecipitation to obtain an MgAl-LDH solid product and a filtrate, carrying out evaporation concentration on the filtrate to obtain Li-rich bittern, adding an Al salt into the Li-rich bittern, carrying out coprecipitation on the mixed Li-rich bittern and alkali lye, carrying out separation to obtain a LiAl-LDH solid product and a filtrate, carrying out evaporation concentration on the filtrate and recycling the concentrate. Mg in bittern can form MgAl-LDH and the MgAl-LDH is separated at first so that the traditional method for separating Mg and Li from a high Mg / Li ratio solution has high difficulty. Through the reaction-separation combined technology, Mg and Li resources in salt lake bittern are separated and simultaneously, MgAl-LDH and LiAl-LDH functional material production is realized. The process method realizes salt lake resource separation and produces a high added value functional material.

Owner:QINGHAI WESTERN MAGNESIUM NEW MATERIAL CO LTD

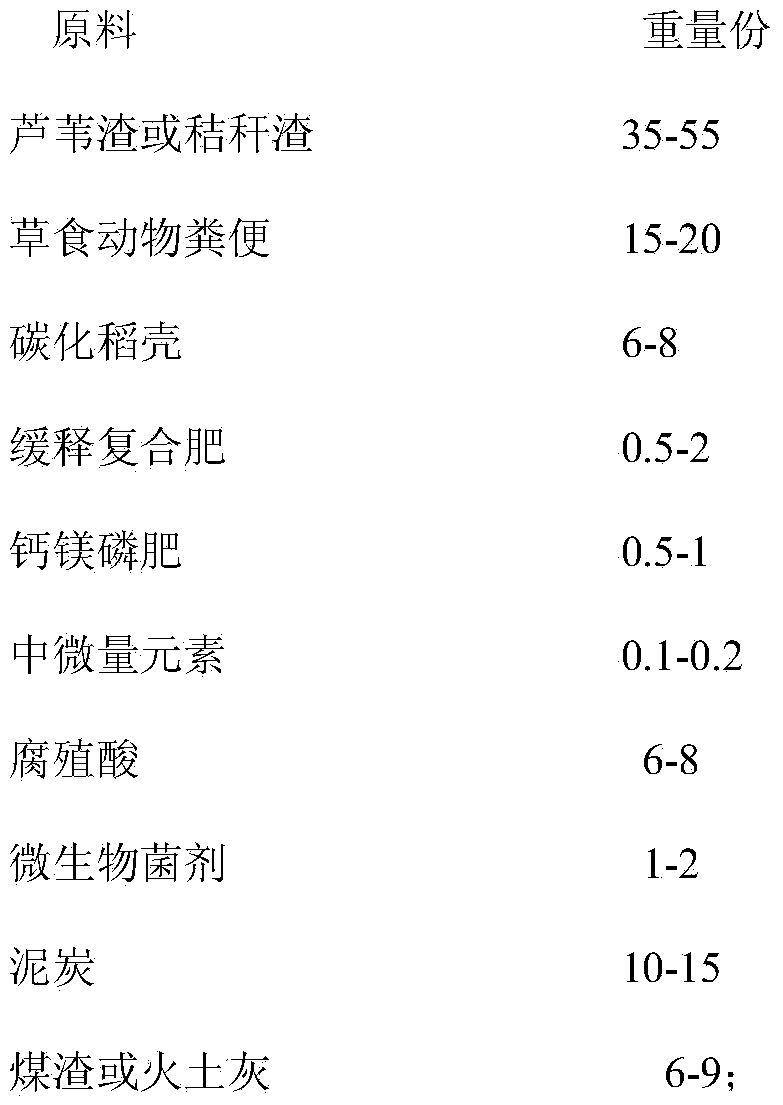

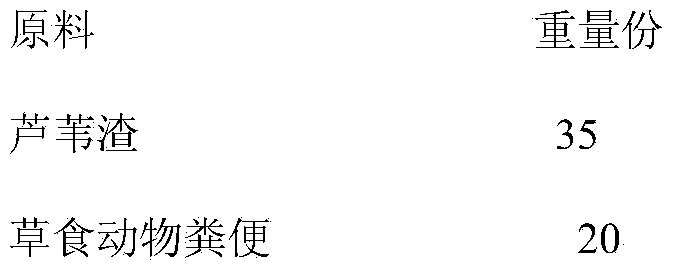

Vegetable and fruit biological activity seedling culture matrix as well as preparation method and application thereof

ActiveCN103626586ASufficient quantityThe source is stable and controllableFertilizer mixturesRoot systemDisease

The invention discloses a vegetable and fruit biological activity seedling culture matrix as well as a preparation method and application of the vegetable and fruit biological activity seedling culture matrix. The vegetable and fruit biological activity seedling culture matrix is prepared by adding auxiliary ingredients such as excrements of plant-eating animals, soil ash or coal slag, peat, a slow-release fertilizer, a calcium-magnesium phosphate fertilizer, medium trace elements and a microbial agent into papermaking wastewater serving as a main ingredient. The matrix is soft, loose, ventilating, water-saving and drought-resisting. The matrix for culturing vegetable and fruit seedlings can achieve the effects of high seedling emerge speed, short seedling age, seedling strengthening, quality improvement, root activity enhancement, disease resistance and improvement on seedling emerge rate and seedling rate; furthermore, the vegetable and fruit biological activity seedling culture matrix is convenient to transplant; the slow seedling period is short; stable yield and high yield of vegetables and fruits are guaranteed.

Owner:长沙浩博生物技术有限公司

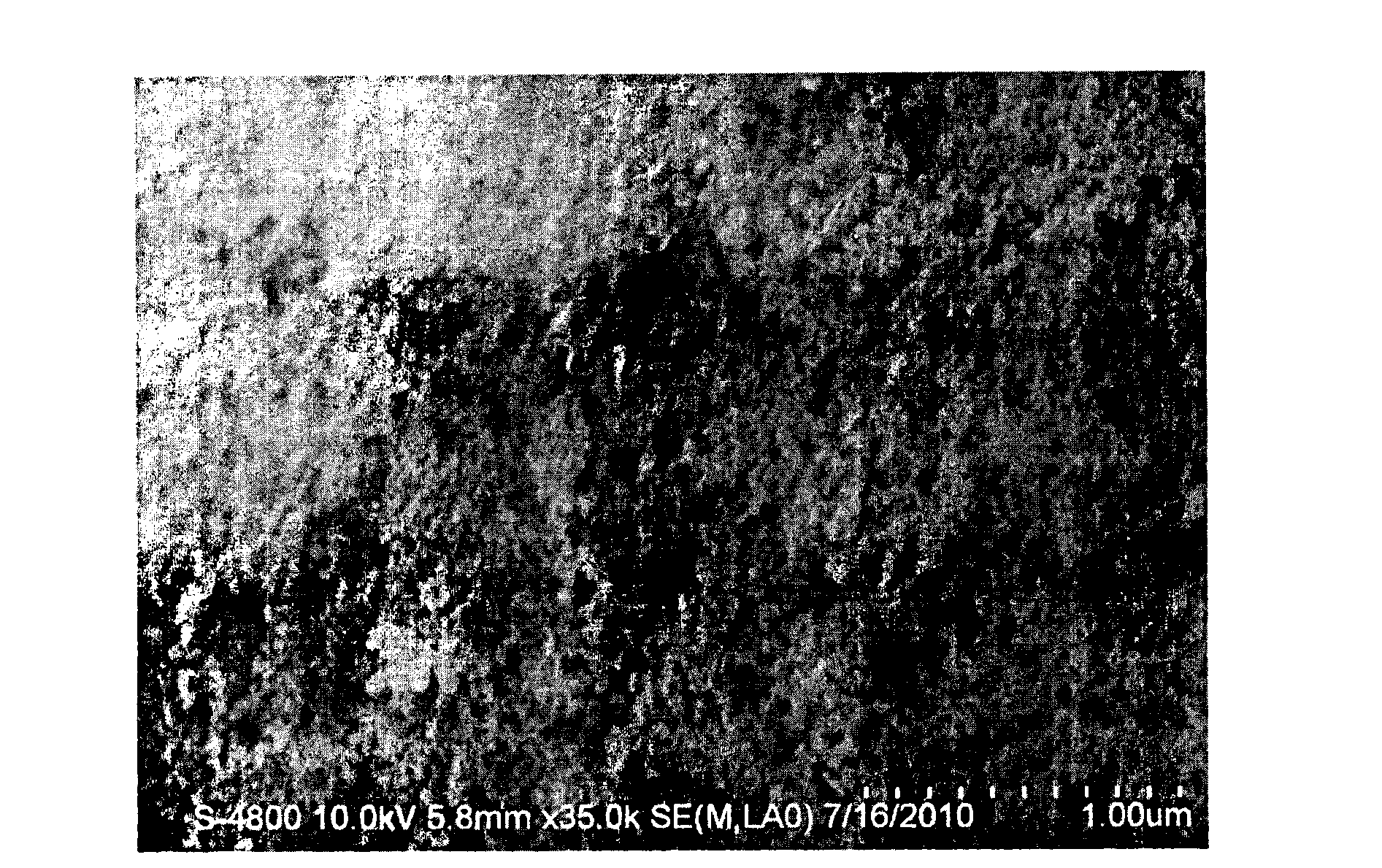

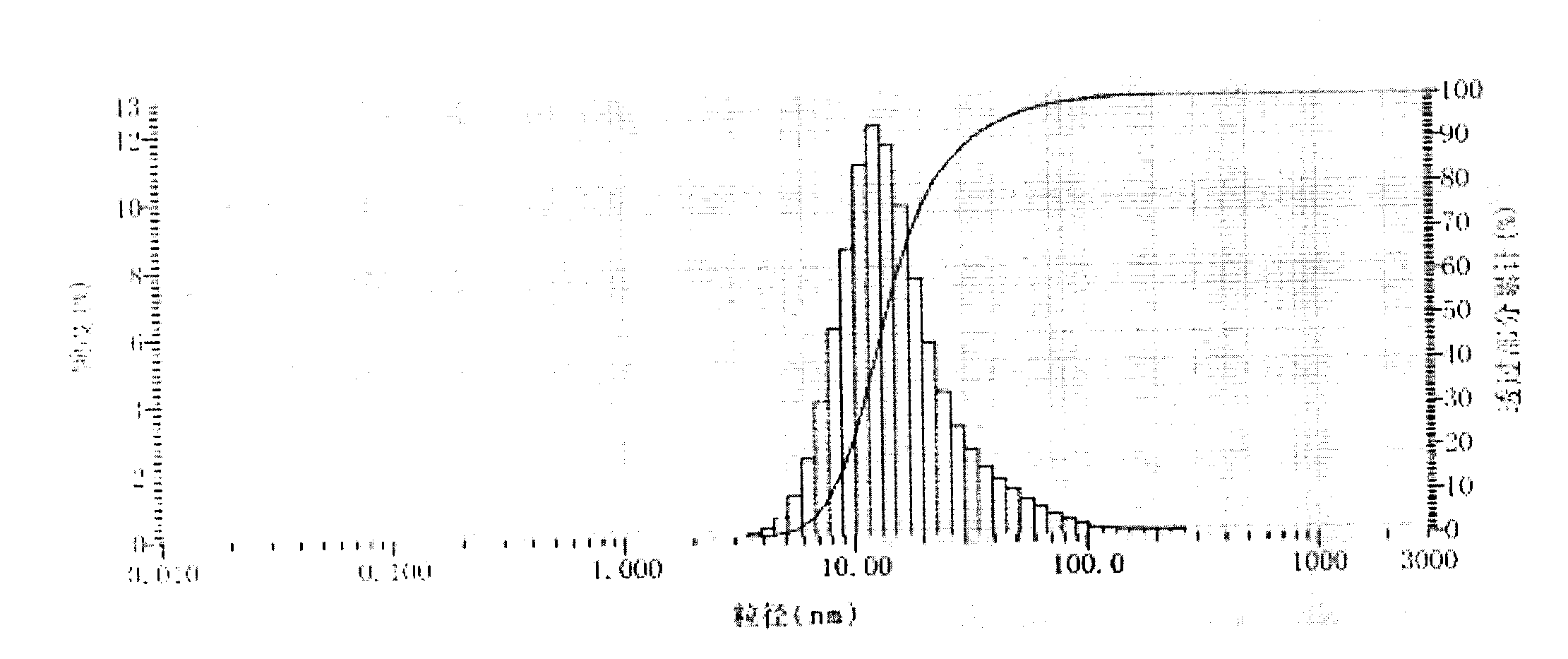

Method for preparing magnetic nano microparticles with biological compatibility

InactiveCN1461020AUniform and controllable particle sizeAdjustable crystallinityNanomagnetismNanostructure manufactureBoiling pointChemical compound

The preparation method of magnetic nano particle with bio-compatibility includes the following steps: heating and decomposing metal organic iron compound in high boiling point polar solvent in the presence of bio-compatibility molecule, precipitating and separating so as to obtain said magnetic nano particles with bio-compatibility. By adopting bio-compatibity molecules containing double-functional group (for example double-functional group polyglycol and its derivative, etc.) to make modification the magnetic nano particles whose surface has different functional groups can be obtained. By adopting different iron materials the nano particles with different types of Fe, gamma-Fe2O3 and Fe3O4 can be obtained.

Owner:苏州欣影生物医药技术有限公司

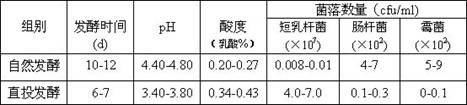

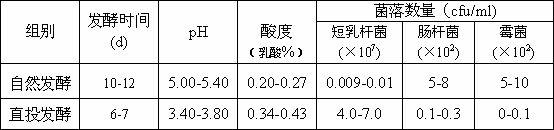

Jerusalem artichoke pickle produced by direct-vat-set lactobacillus brevis leavening agent, and process of same

ActiveCN102613518AIncrease productivityShort fermentation cycleFood preparationNutritionFermentation starter

The utility model relates to jerusalem artichoke pickle produced by direct-vat-set lactobacillus brevis leavening agent and a process of same, and belongs to the technical field of deep processing of vegetable and food bioscience. Lactobacillus brevis is adopted to be developed into high-density lactobacillus brevis leavening agent (the total number of bacterial colonies reaches 109 / ml); and the jerusalem artichoke pickle is produced by utilizing a direct-vat-set leavening process, so that a modern bioprocess technology of producing high-quality jerusalem artichoke pickle quickly is formed and achieved. The invention has a simple technological process and is easy to operate; compared with a conventional leavening process, the direct-vat-set leavening process has the advantages that the operation procedure is simplified, the production cost is reduced, and the nutritional ingredient and flavor substance of the jerusalem artichoke can be kept furthest at the same time; the jerusalem artichoke pickle is crispy, tasty, refreshing, and nourishing, and is a probiotic health product applicable to all ages. The invention is a green natural, safe and healthful production process and technology.

Owner:东台海滨科技创业园管理有限公司

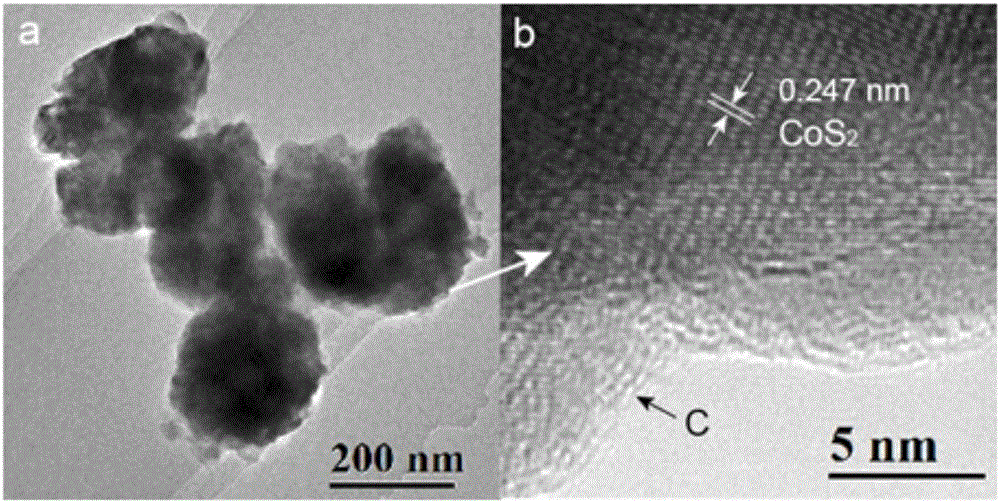

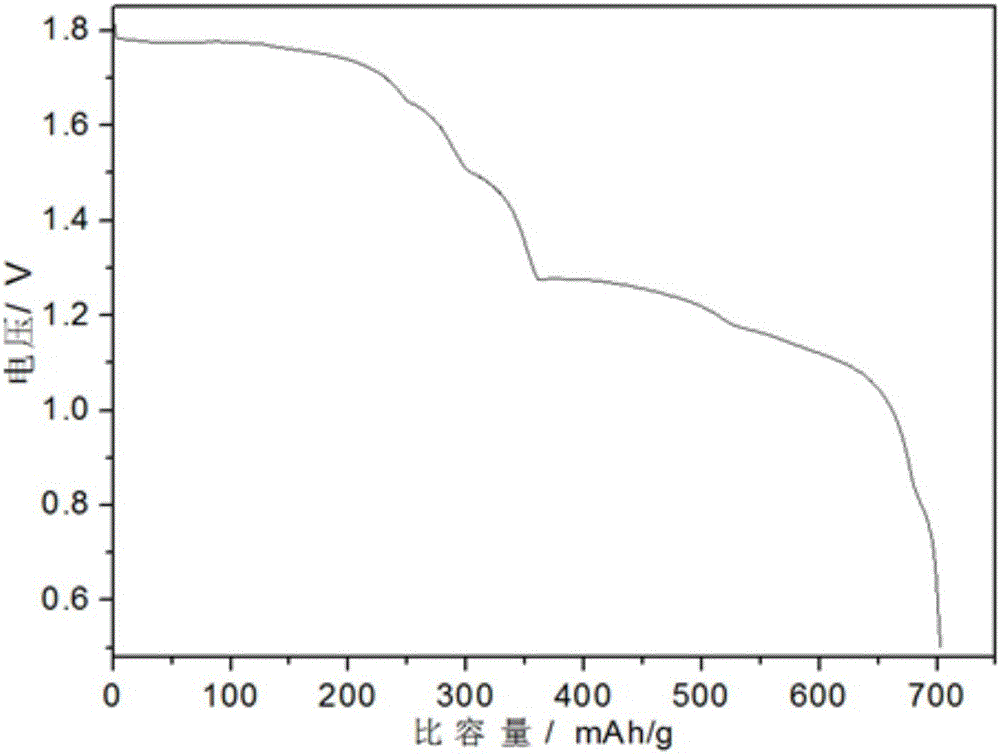

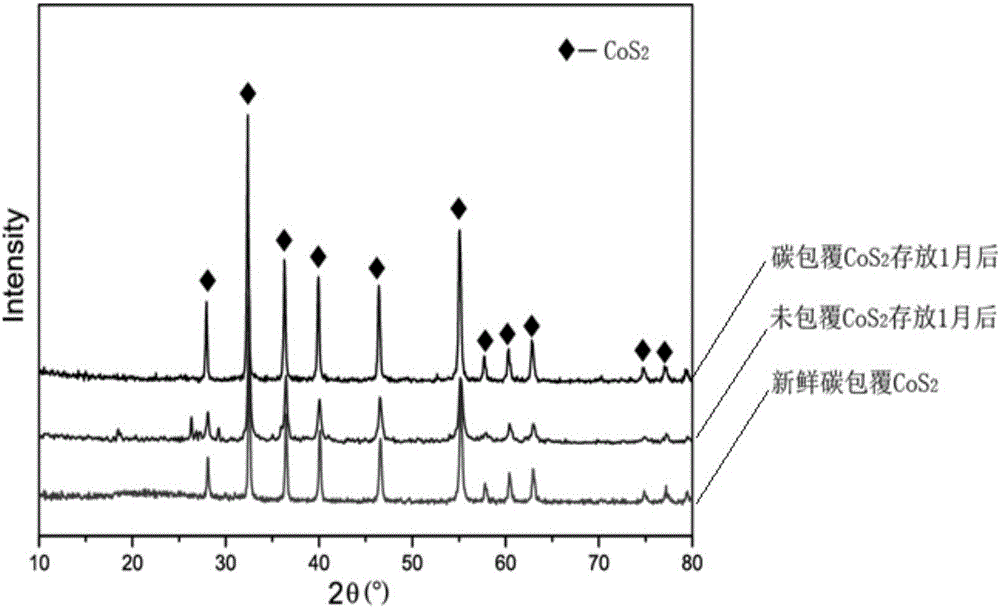

Carbon coated thermal battery electrode material and preparation method thereof

ActiveCN105870429ACorrosion resistantImprove air stabilityCell electrodesElectrical batteryThermal Battery

The invention belongs to the field of thermal batteries, and relate to a carbon coated thermal battery electrode material and a preparation method thereof. Glucose and other carbon sources are added in the process of preparing cobalt disulfide through a hydrothermal method, and the cobalt disulfide electrode material with a carbon coated structure is prepared in situ; the mass content of carbon in the obtained material relative to cobalt disulfide ranges from 1% to 25%. The electrode material has the advantages of being high in specific capacity, good in air stability, simple in preparation process, easy to prepare in a large scale and the like.

Owner:CHENGDU SCI & TECH DEV CENT CHINA ACAD OF ENG PHYSICS

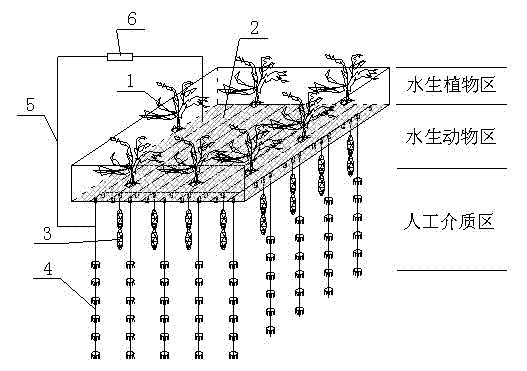

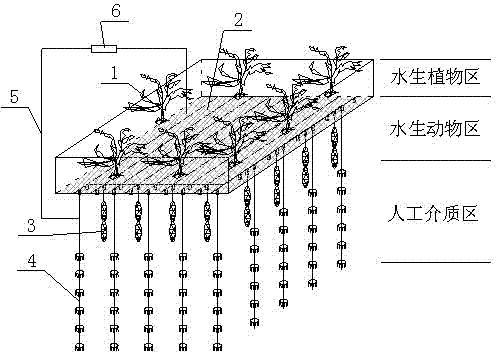

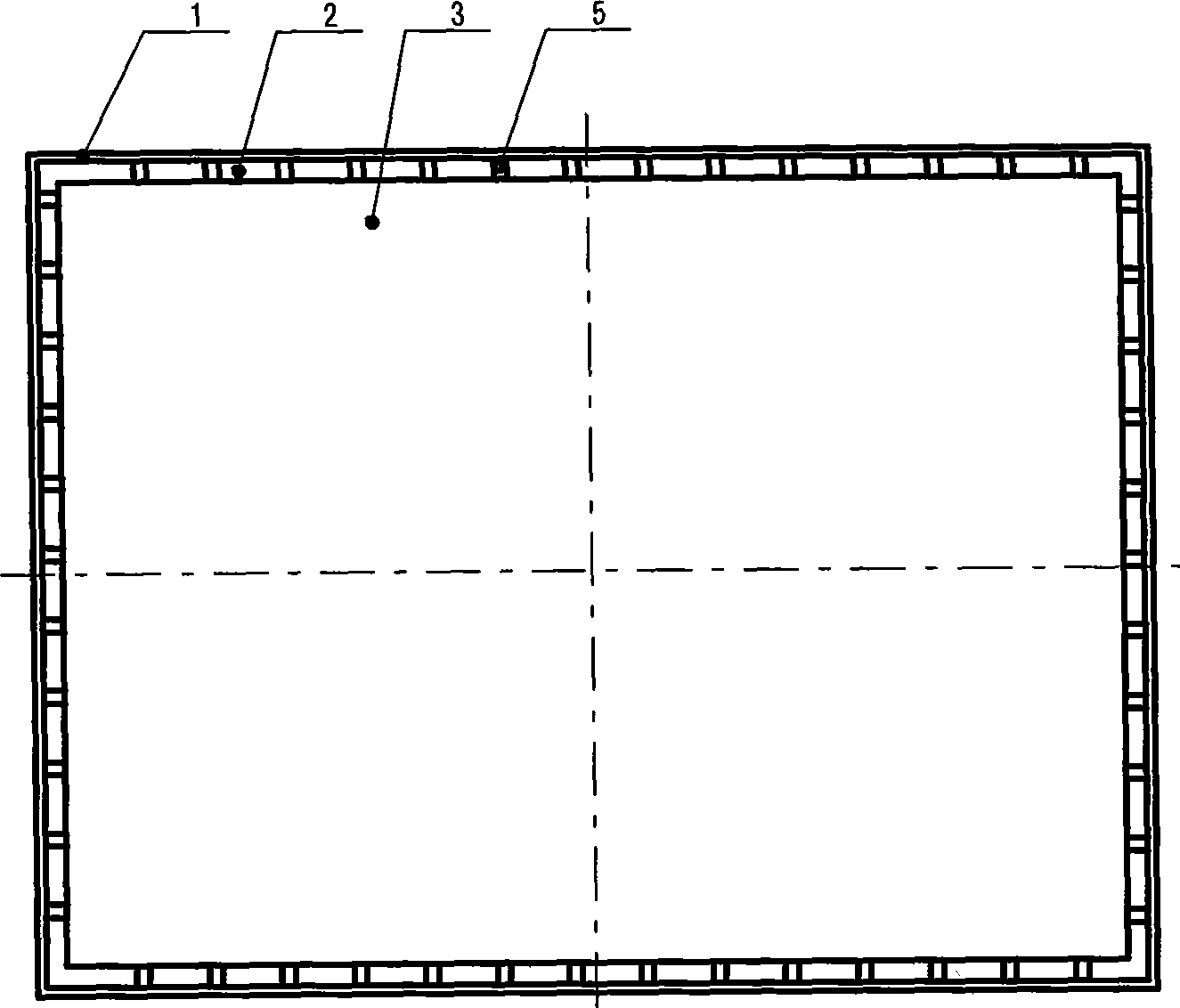

Combined ecological floating bed device for using microbial fuel cell to purify lake water

InactiveCN102531181APromote performance activationPromote degradationBiochemical fuel cellsBiological water/sewage treatmentAquatic animalConductive materials

The invention relates to a combined ecological floating bed device for using a microbial fuel cell to purify lake water. The combined ecological floating bed device for using the microbial fuel cell to purify the lake water comprises a combined ecological floating bed and the microbial fuel cell, wherein the combined ecological floating bed comprises a surface aquatic plant unit, a middle aquatic animal unit and a lower artificial medium unit from the top to the bottom; the aquatic plant unit consists of aquatic economic plants (1) and a conductive material (2) for fixing the aquatic plants; the aquatic animal unit is used for aquaculturing predatory aquatic animal shellfish (3); in the artificial medium unit, an active carbon nanoparticle artificial medium (4) is enriched with a great number of microbes to form a high-efficiency biomembrane purifying area; the combined ecological floating bed device for using the microbial fuel cell to purify the lake water is characterized in that the conductive material (2) is led out of the device through a conductive wire (5) to form an air cathode electrode of the microbial fuel cell. The combined ecological floating bed device for using the microbial fuel cell to purify the lake water can improve the water quality fundamentally and can recycle energy, and is applicable to large-scale, modeled and mechanical work.

Owner:SOUTHEAST UNIV

Method for preparing porous alumina ceramic

InactiveCN103342544ALow thermal conductivityHigh porosityCeramicwareAir atmosphereManufacturing technology

The invention relates to a manufacturing technology of heat insulation ceramic materials and particularly relates to a method for preparing porous alumina ceramic. The method comprises the following steps of: (a), with alumina powder as a raw material, adding a proper amount of pore-forming agent and molding by adopting a gel casting process; (b), naturally drying a molded biscuit for 12-24 hours at room temperature, and then drying for 5-10 hours at 40-80 DEG C; and (c), putting the dried sample into a high-temperature furnace, raising the temperature to 600 DEG C in an air atmosphere at a speed of 1-3 DEG C / minute, preserving the heat for 2-4 hours so as to remove the pore-forming agent, raising the temperature to 1350-1550 DEG C at the speed of 2-25 DEG C / minute, preserving the heat for 30-180 minutes, and carrying out high-temperature sintering to obtain the porous alumina ceramic. The method can be used for preparing the porous alumina ceramic material with complicated appearance; in addition, the prepared alumina ceramic has the excellent performances such as low heat conductivity and high porosity.

Owner:JIANGSU MAGNET VALLEY TECH +1

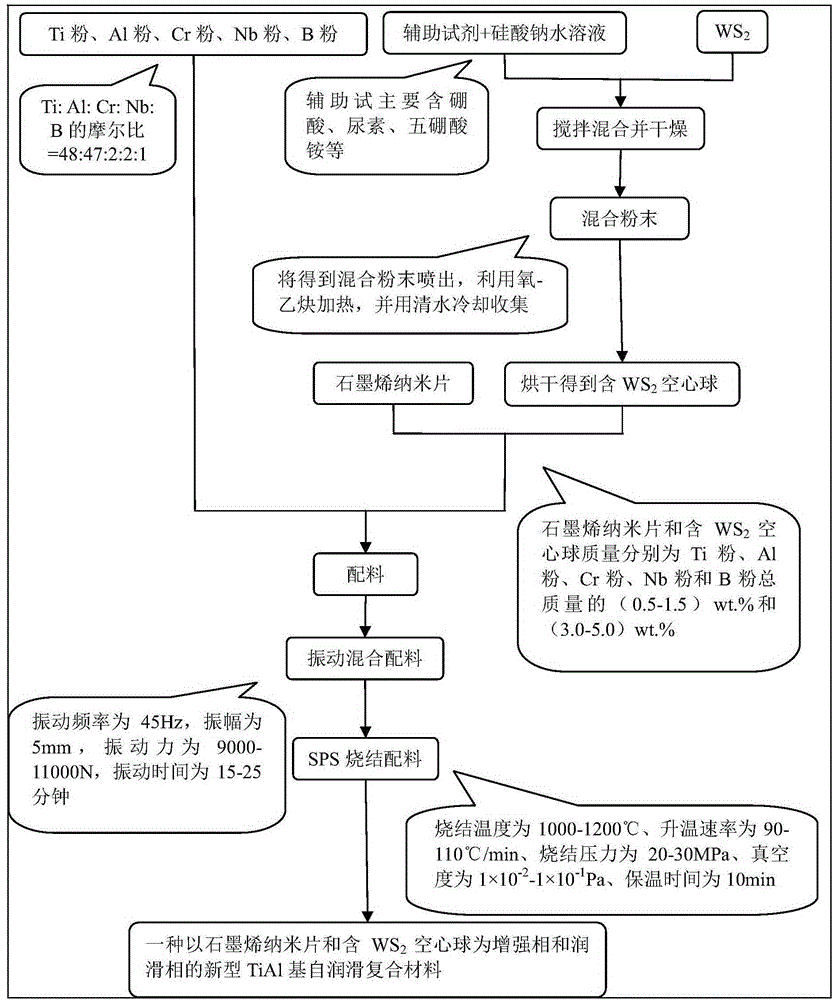

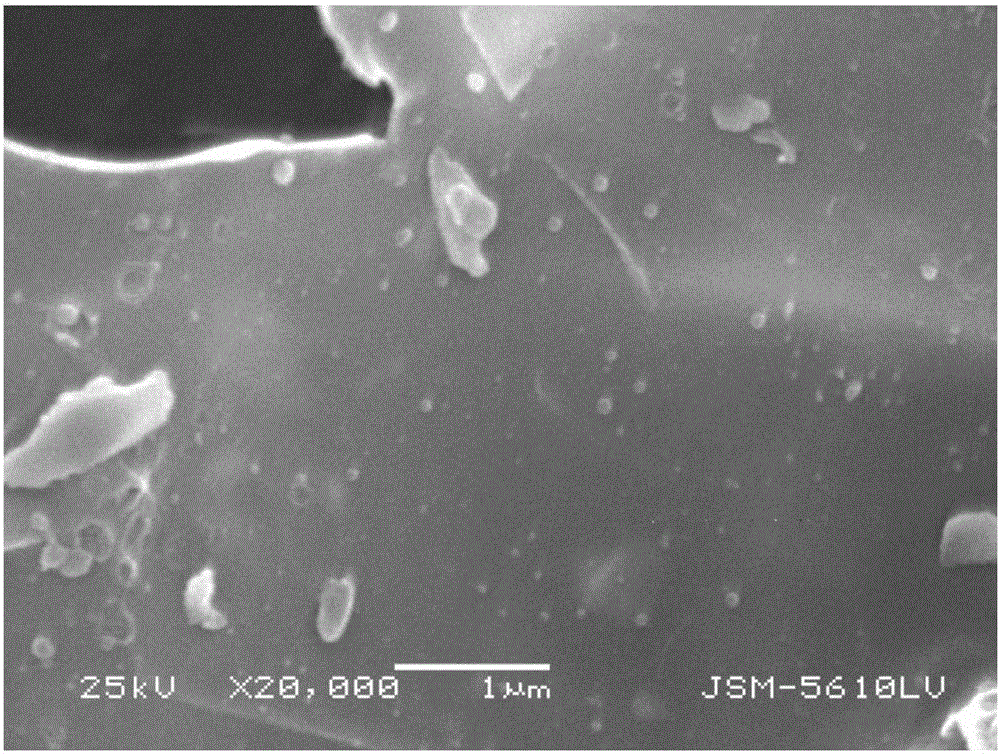

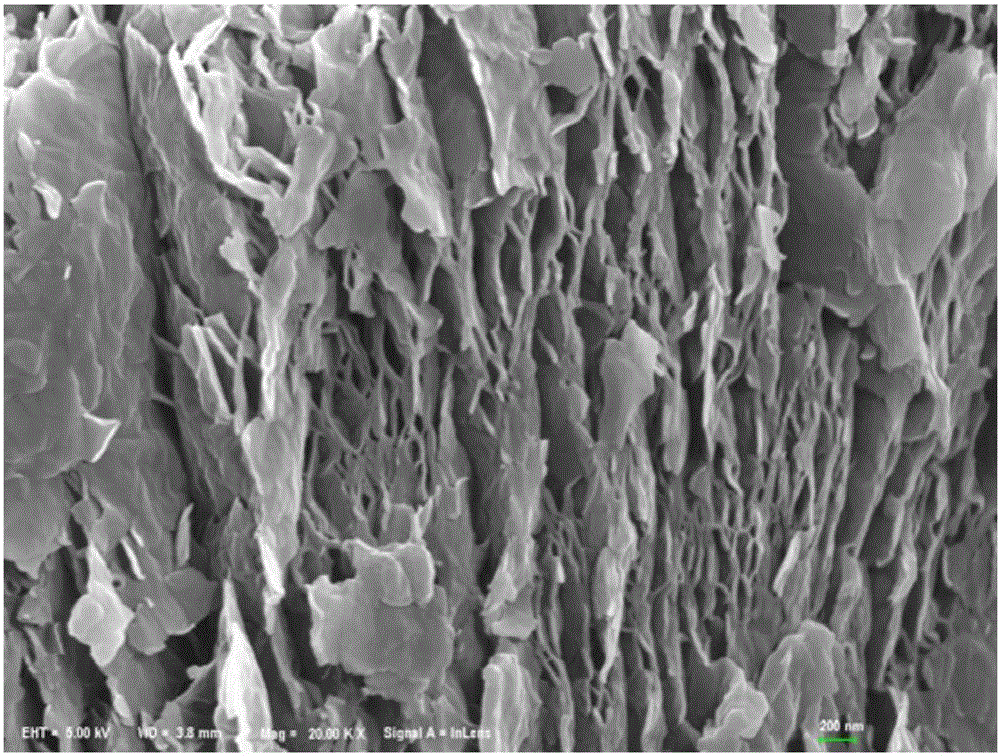

Novel TiAl base self-lubricating composite and preparing method

InactiveCN105861876AImprove mechanical propertiesGood wear reductionGraphene nanoplateletMechanical property

The invention relates to a novel TiAl base self-lubricating composite. The novel TiAl base self-lubricating composite is characterized in that a TiAl base serves as a matrix, and graphene nanosheets and hollow spheres containing WS2 serve as an enhancing phase and a lubricating phase. The graphene nanosheets account for 0.5-1.5 wt.% of the matrix by mass, and hollow spheres containing WS2 account for 3.0-5.0 wt.% of the matrix by mass. A preparing method of the novel TiAl base self-lubricating composite comprises the following steps that elementary substance powder is weighed according to the mole ratio of elements contained in the TiAl base to serve as matrix materials, the graphene nanosheets and the hollow spheres containing WS2 are weighed according to the proportion, the materials are evenly mixed and then subjected to spark plasma sintering, and the novel TiAl base self-lubricating composite is obtained. With the graphene nanosheets and the hollow spheres containing WS2 as the enhancing phase and the lubricating phase, the TiAl base self-lubricating composite is high in compactness, good in mechanical property and high in abrasion relieving and resisting performance.

Owner:WUHAN UNIV OF TECH

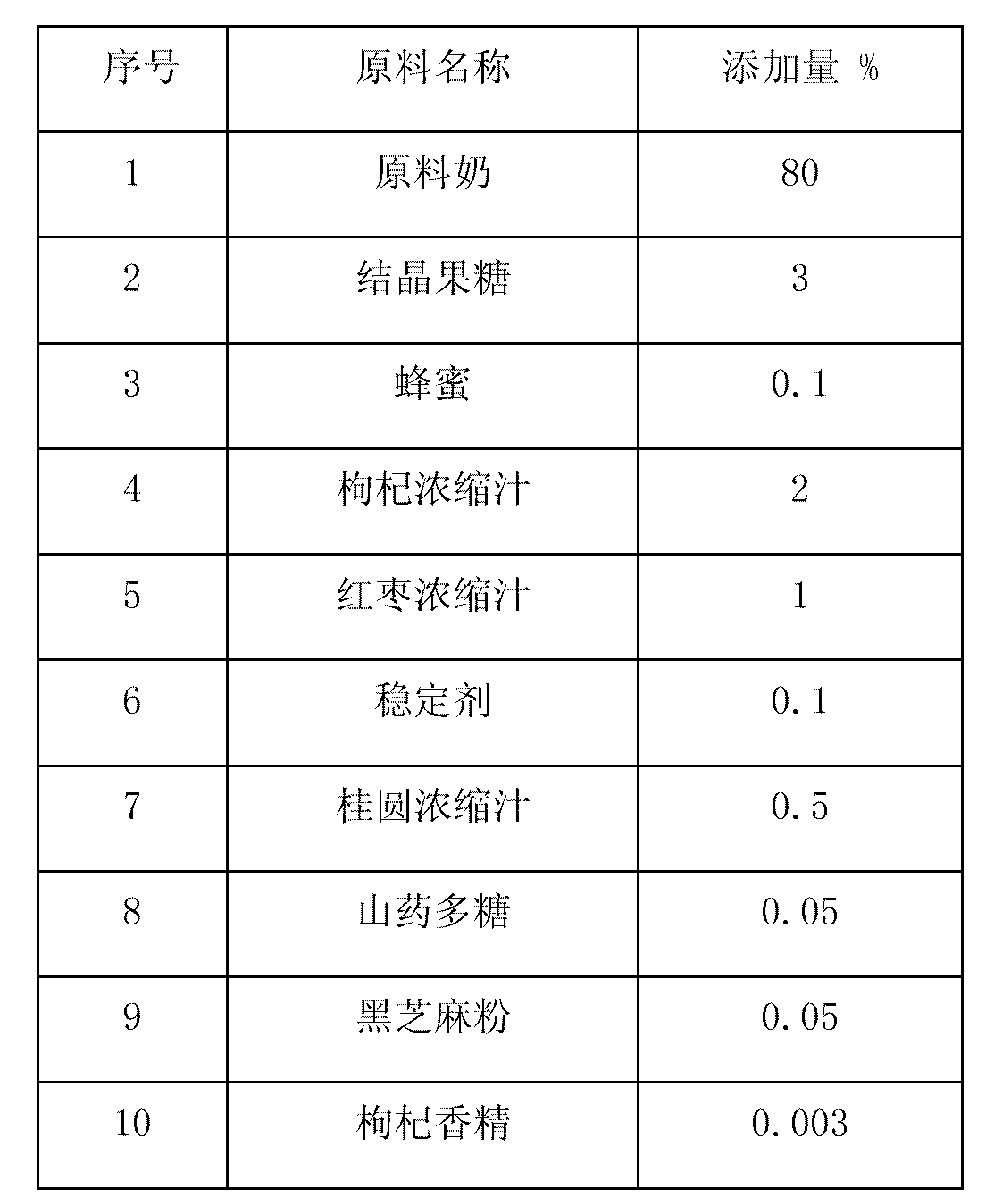

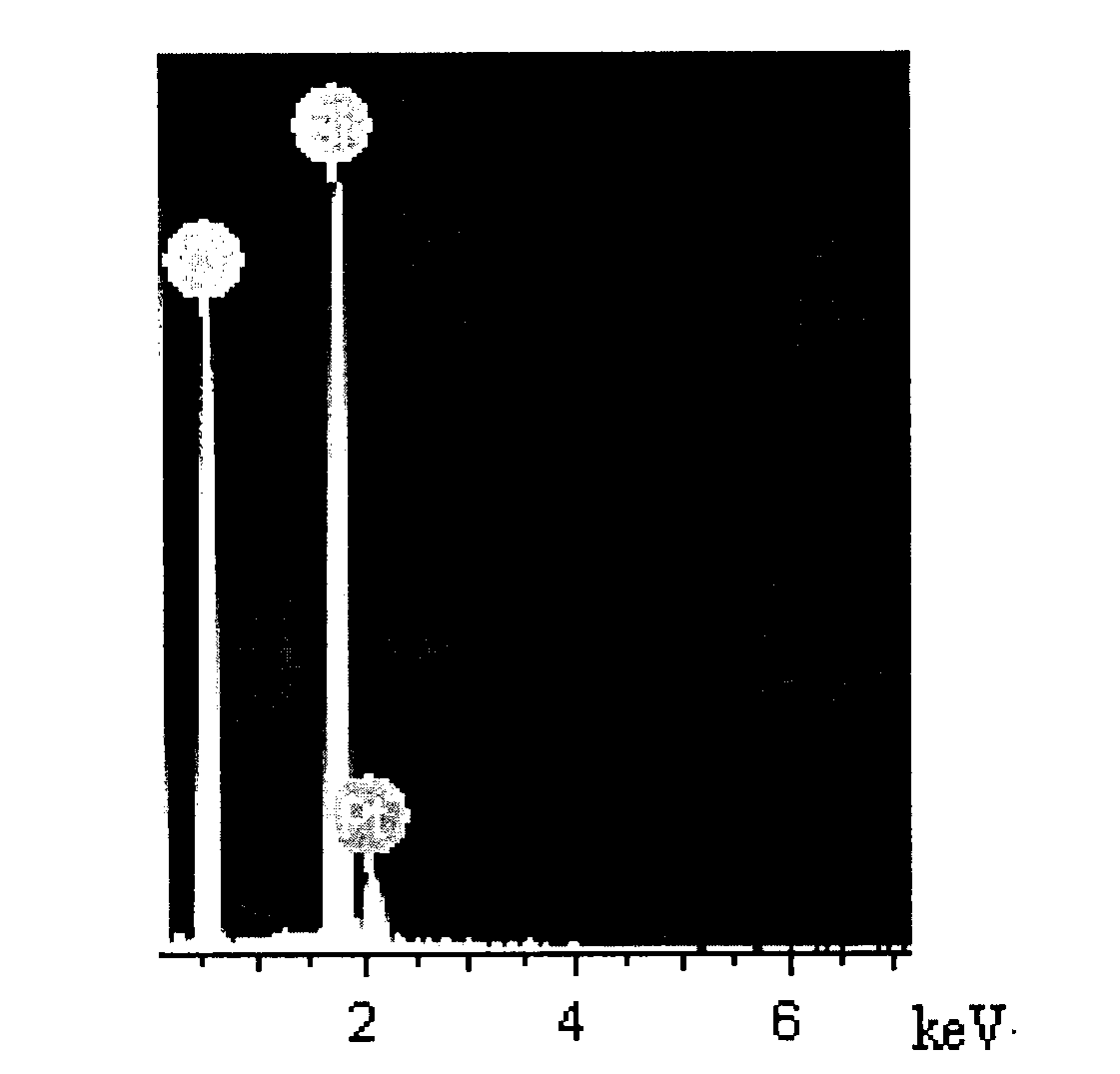

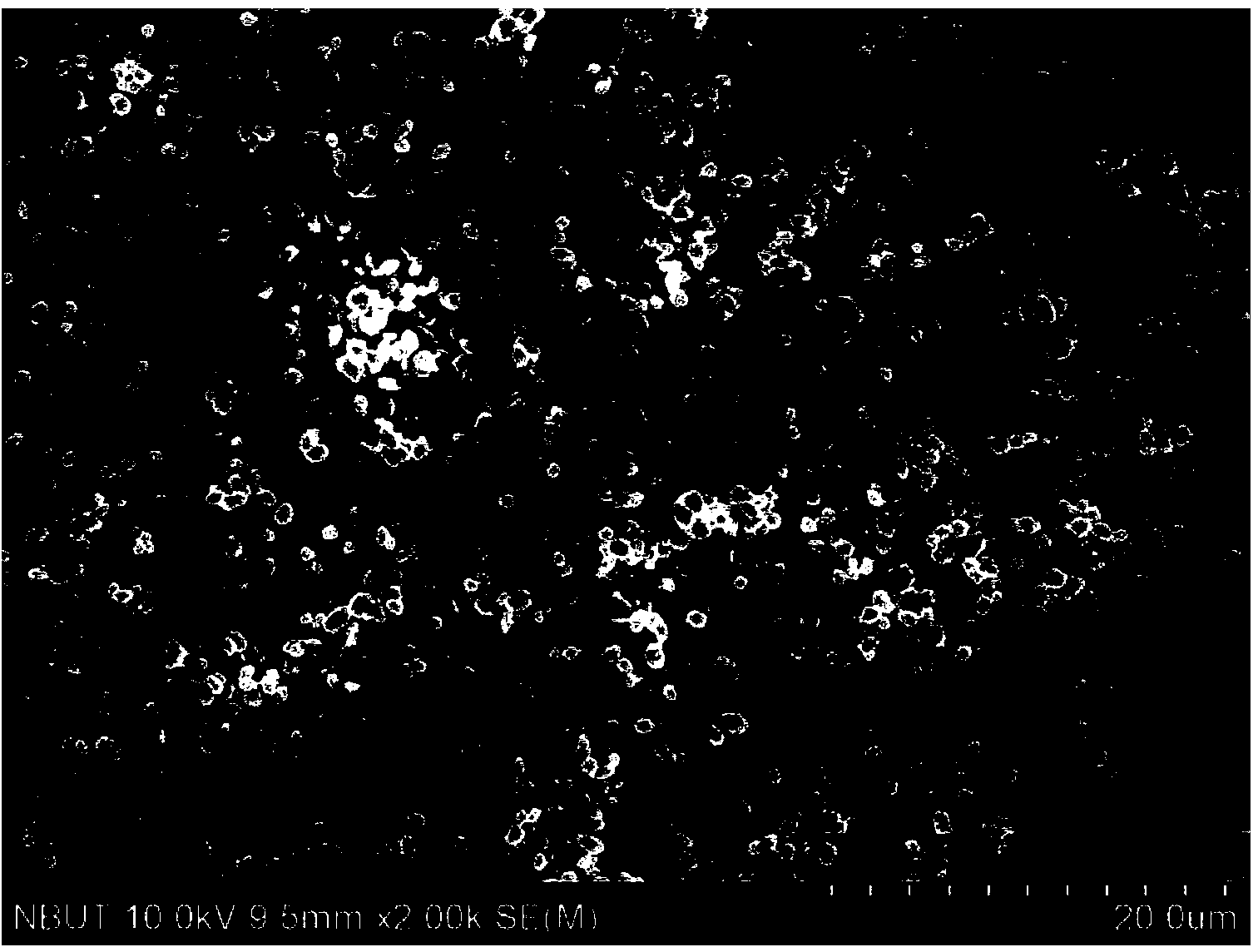

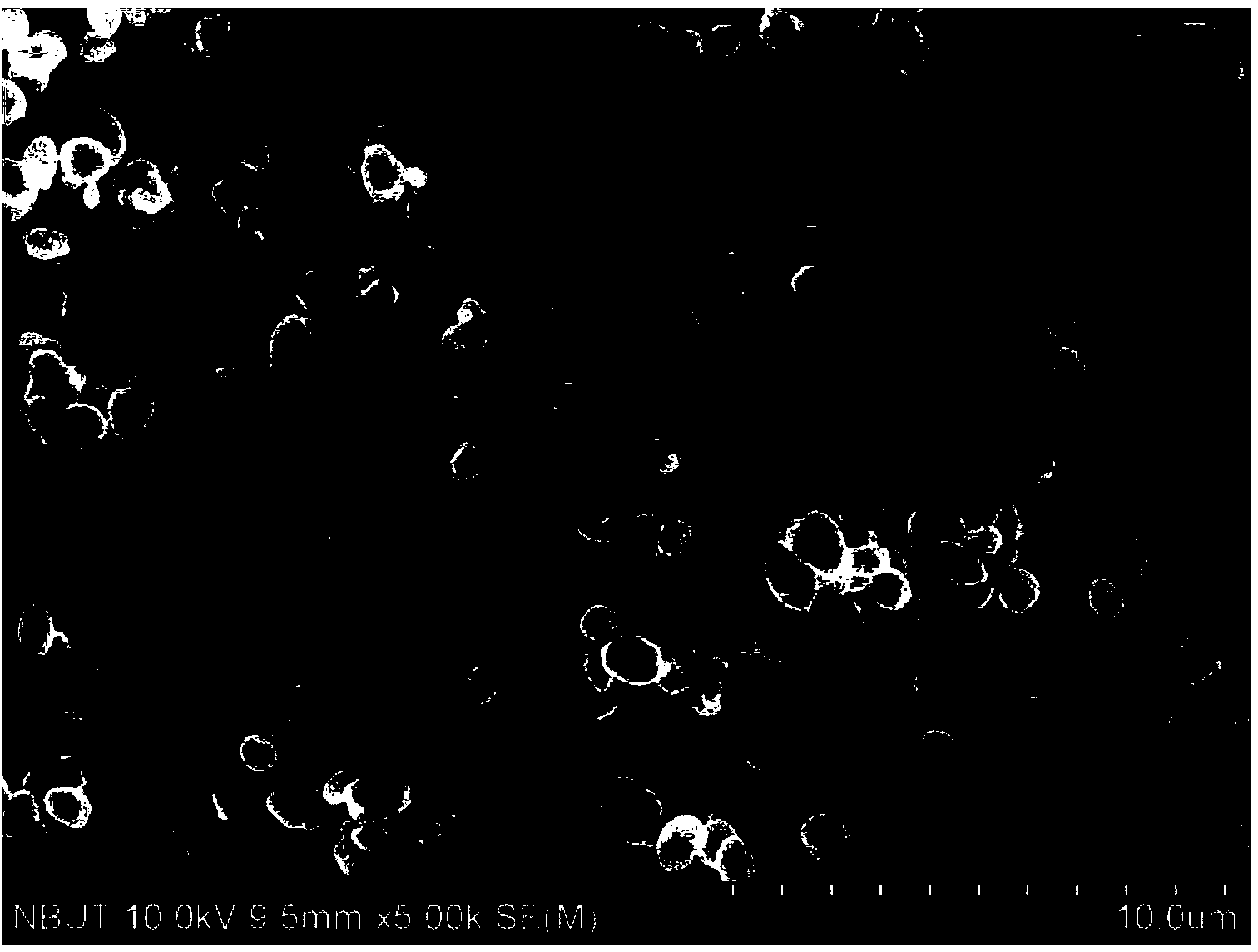

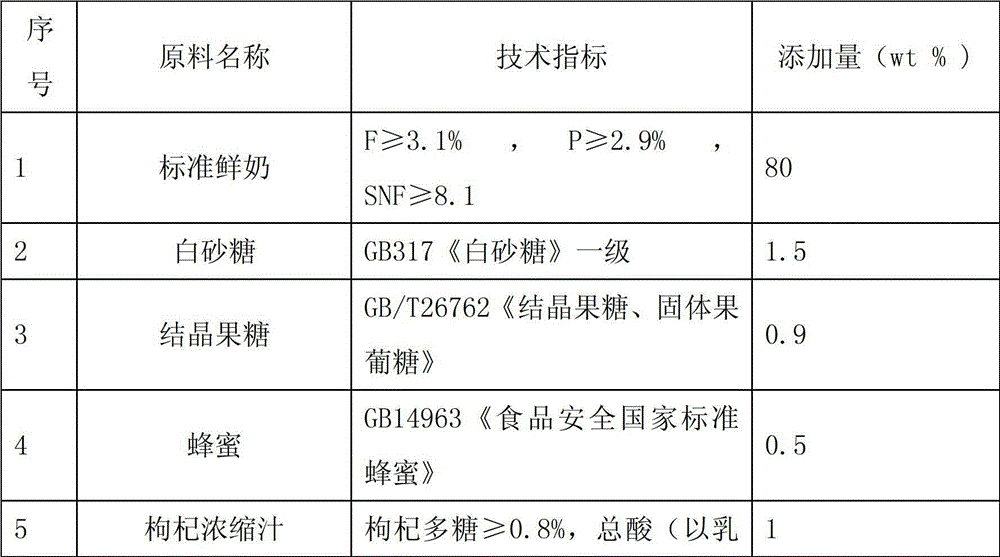

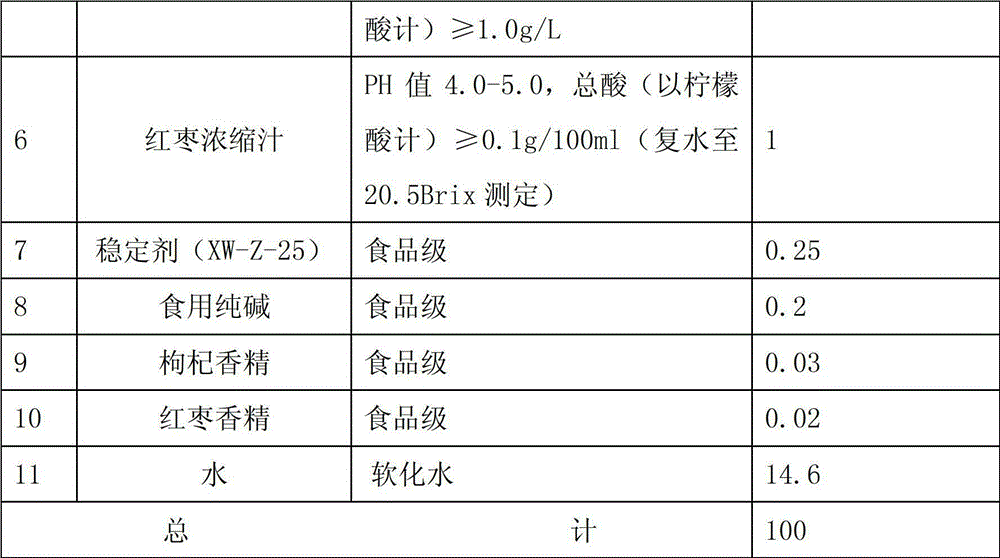

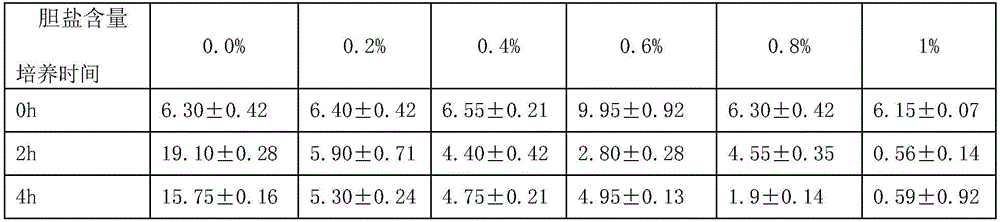

Wolfberry and jujube health promotion milk and preparation method of health promotion milk

ActiveCN103229835ANatural tasteReduce dosageMilk preparationFood scienceAdditive ingredientBULK ACTIVE INGREDIENT

The invention relates to wolfberry and jujube health promotion milk and a preparation method of the health promotion milk, belonging to the technical field of modulated milk. The wolfberry and jujube health promotion milk consists of the following raw materials by weight percent: 80-90% of raw milk, 2-3% of wolfberry concentrated juice, 1-2% of jujube concentrated juice, 0.5-10% of crystal line fructose, 0.1-0.3% of a stabilizer, 0.005-0.1% of edible essence, 0.5-3% of longan concentrated juice, 0.05-0.1% of Chinese yam polysaccharide, 0.05-0.5% of black sesame powder, 0.1-0.5% of honey and the balance of soft water. By being scientifically proportioned according to the health promotion principle of traditional Chinese medicines and prepared through an advanced processing process, the wolfberry and jujube health promotion milk is natural and pure in taste and rich in nutrition and remains nutritional ingredients and active ingredients of natural health products such as milk, wolfberry, jujube, longan and Chinese yam up to the hilt, so that the beneficial ingredients of each raw material are brought out the best in each other and the health function is strong.

Owner:NINGXIA XIAJIN DAIRY GRP

Method for preparing silicon dioxide aerogel

The invention provides a method for preparing silicon dioxide aerogel. The method comprises the following steps of: preparing silicon dioxide sol by solid-solid reaction, preparing silicon dioxide gel, replacing a solution, performing surface modification treatment and drying under normal pressure. According to the method, the silicon dioxide aerogel which is few in impurities, high in purity and narrow in particle size distribution is prepared by taking superfine mineral powder of silicon micro powder, micro silicon powder, kieselguhr, vermiculite powder, sepiolite, a perlite filter aid and the like which are high in content of silicon dioxide, readily available, low in cost and light in mass as a raw material; and according to the preparation method, the production cost is low, and a production process is simple.

Owner:中亨新型材料科技有限公司

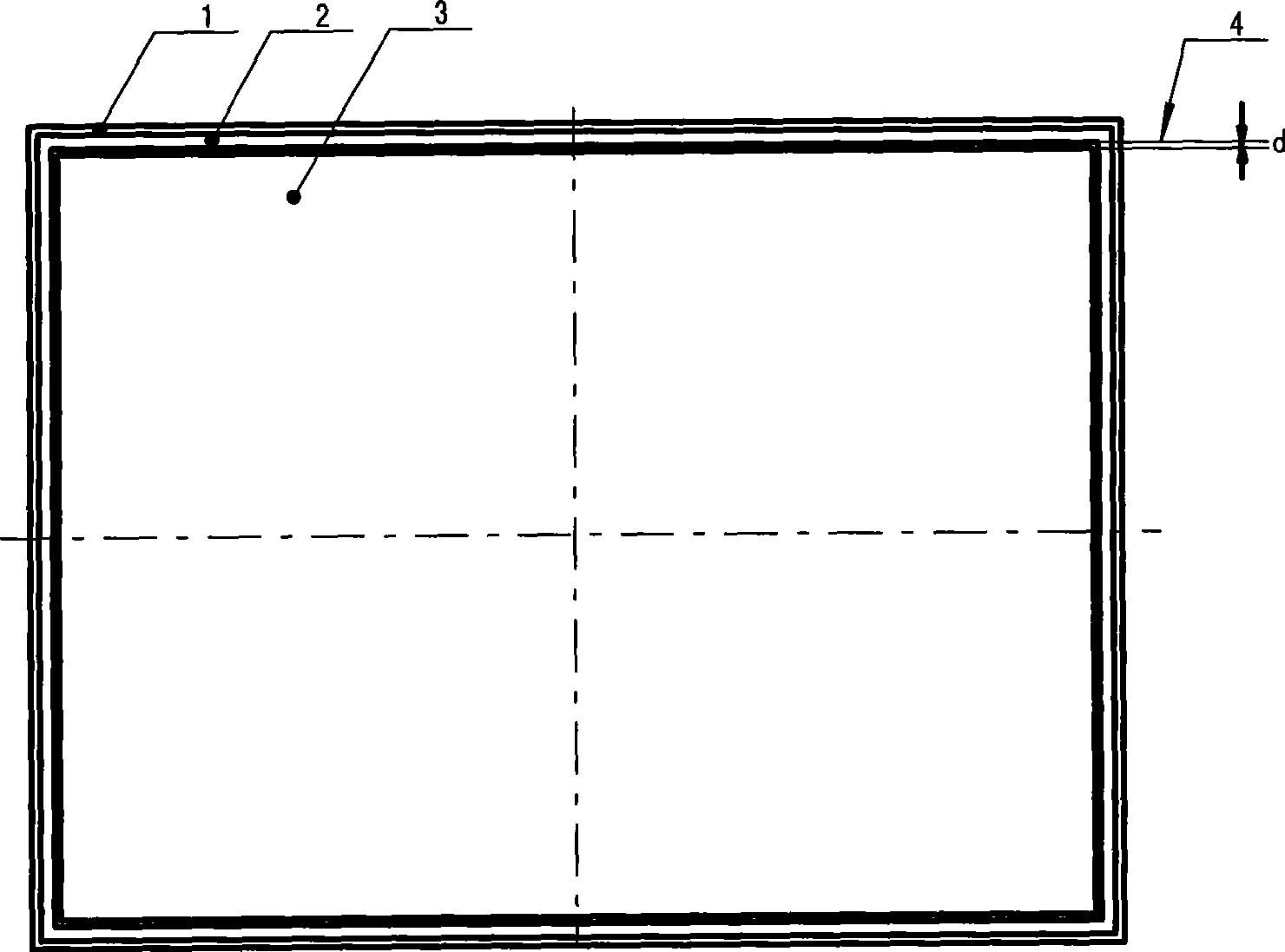

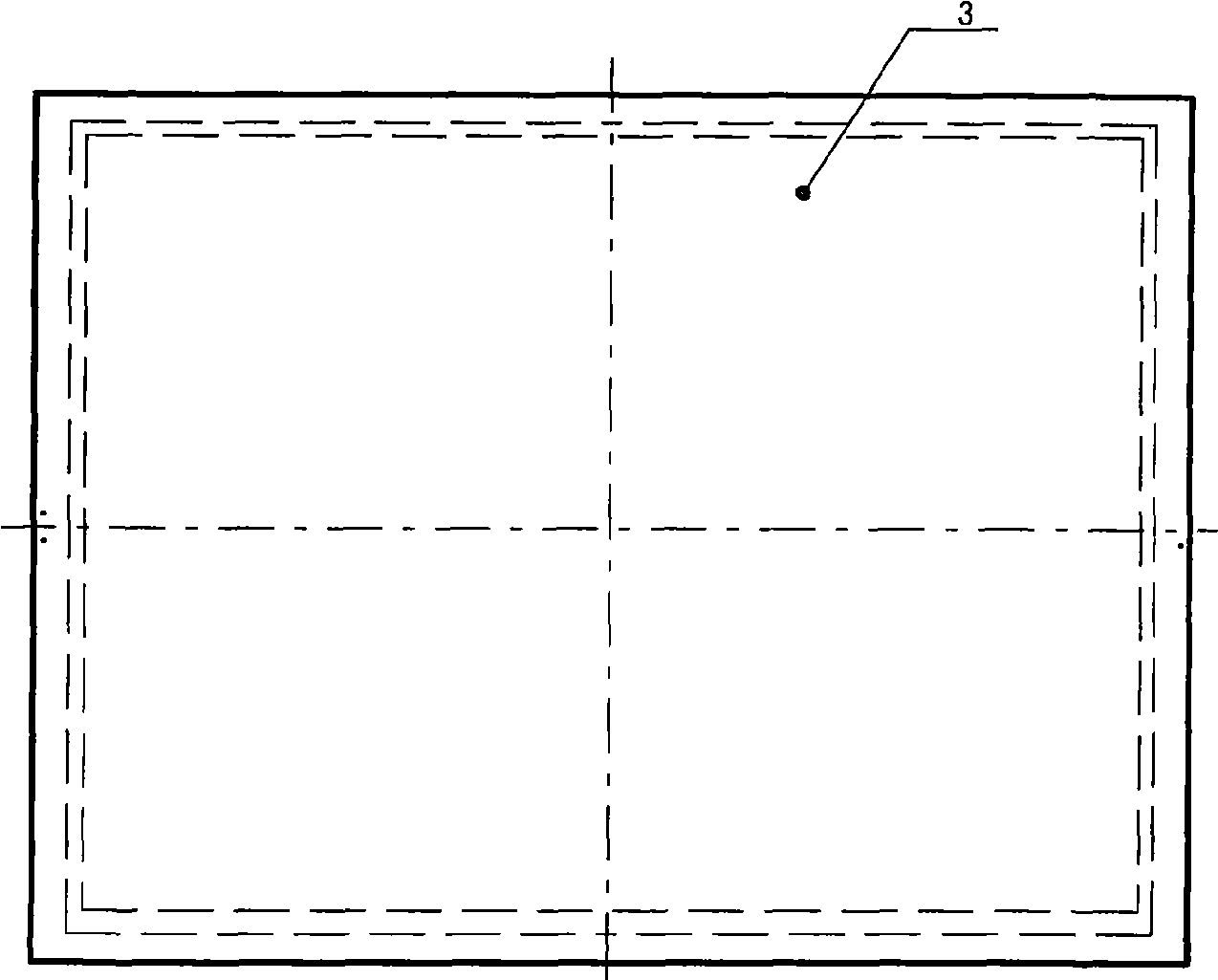

Automatic edge sealing process for vacuum glass

InactiveCN101481205AImprove the effect of edge bandingBeautiful edge bandingGlass reforming apparatusHeating furnaceAir tightness

The invention relates to an automatic edge sealing technology for vacuum glass, which comprises the following steps of arranging supporters on basal board glass, arranging upper plate glass on the basal board glass, using low melting-point glass powder between the upper plate glass and the basal board glass for sealing edges, placing the upper plate glass and the basal board glass into a vacuum heating furnace to be heated and taking out upper plate glass and the basal board glass to get a finished vacuum glass, wherein in the step of using the low melting-point glass powder for sealing the edge, a section bar of low melting-point glass powder or the low melting-point glass powder is arranged on the basal board glass, and a gap of air escaping in the evacuation in the heating furnace is left in a chamber formed between the basal board glass and the upper plate glass. The invention has simple integrated structure, greatly shortens the evacuation time, increases the work efficiency, has reliable automatic evacuation and sealed package, good air tightness, little air leakage hazard, attractive appearance and production technology simplification, greatly promotes the development of the vacuum glass industry, and is particularly suitable for the industrialized, the scale and the standardized production of the vacuum glass.

Owner:左树森

Battery-grade ferric phosphate and preparation method

Owner:NINGBO UNIVERSITY OF TECHNOLOGY +1

Chinese wolfberry milk and preparation method thereof

The invention discloses a proportion of raw materials of Chinese wolfberry milk, and relates to a method for preparing the Chinese wolfberry milk. The method comprises the following steps of: (1), mixing a sweetening agent, a stabilizing agent and crystalline fructose; (2), mixing Chinese wolfberry condensed juice, red date condensed juice, honey and edible pure alkali and performing polyethylene (PEF) treatment, wherein the optimal parameters comprise 20-40kV / cm of electric field intensity, the pulse time of 150-200 mu S, and the pulse frequency of 200-300Hz; (3), pre-treating the raw material milk and performing the PEF treatment, wherein the optimal parameters comprise 20-40kV / cm of electric field intensity, the pulse time of 400-600 mu S, and the pulse frequency of 200-300Hz; (4), mixing a material liquid; (5), performing the PEF treatment on the mixed liquid to mix; (6), mixing the mixed liquid with essence; (7), performing secondary homogeneity on the mixed liquid; and (8) performing ultra-high temperature sterilization (UHT) on the mixed liquid to obtain the Chinese wolfberry milk.

Owner:NINGXIA XIAJIN DAIRY GRP

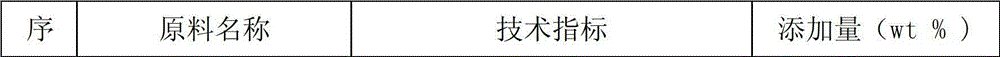

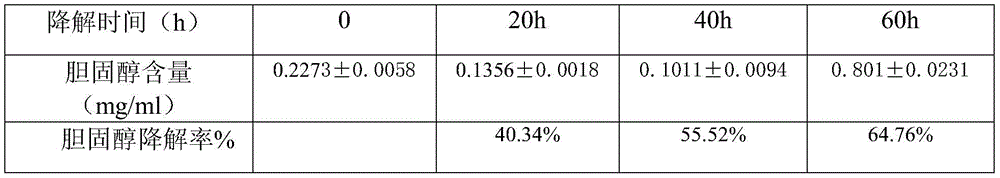

Probiotic dry red wine and preparation method thereof

InactiveCN105647721AFunction increaseEliminate sournessMicroorganism based processesWine preparationMetaboliteAdditive ingredient

The invention discloses probiotic dry red wine and a preparation method thereof. The preparation method includes that dry red wine and rose flowers are used as raw materials, and low-temperature extraction technologies like high-voltage pulse electric field, microwave, ultrasound and biological enzymolysis are organically combined, so that functional substances and fragrant ingredients of the rose flowers can be retained to maximum extent; probiotics like functional Lactobacillus plantarum are used as fermentation agents, and temperature-variable fermentation and graded inoculation are adopted, probiotic multiplication and accumulation of functional metabolite can be realized to maximum extent, malic acid in the dry red wine can be further converted into lactic acid, acor of the dry red wine can be eliminated, and taste, healthcare function and wine stability of the dry red wine can be improved; the high-voltage pulse electric field, ultrasonic technology and peracetic acid are combined to accelerate aging, so that the probiotic dry red wine obtained has quality equivalent to that of existing fermented common dry red wine after aging for 8-10 years, and is good in aging effect, short in period and high in efficiency.

Owner:TIANJIN ZHONGTIAN JINGKE SCI & TECH

Method for extracting lithium from magnesium-removal bittern and preparing battery-grade lithium carbonate

ActiveCN107043116AMild reaction conditionsSimple equipmentLithium carbonates/bicarbonatesSolid phasesHigh sodium

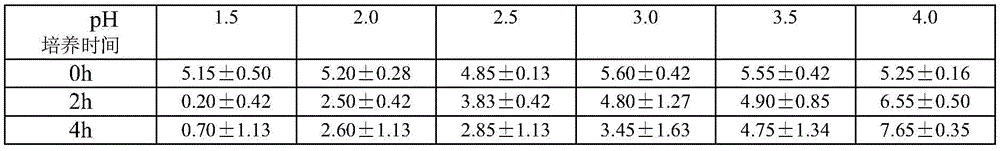

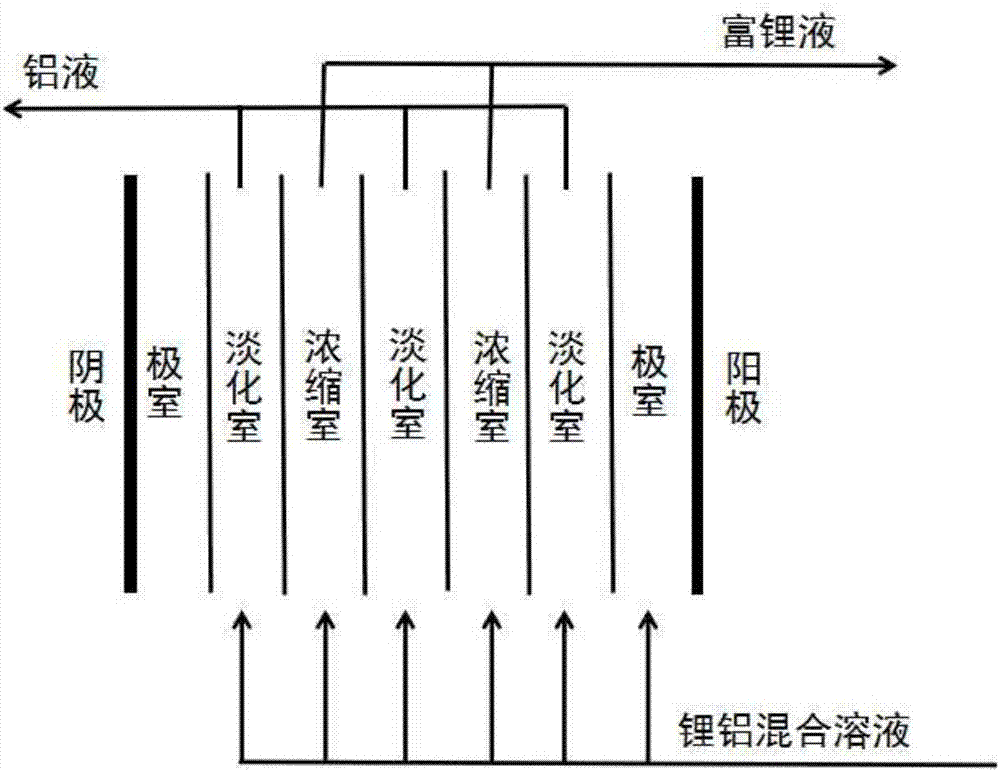

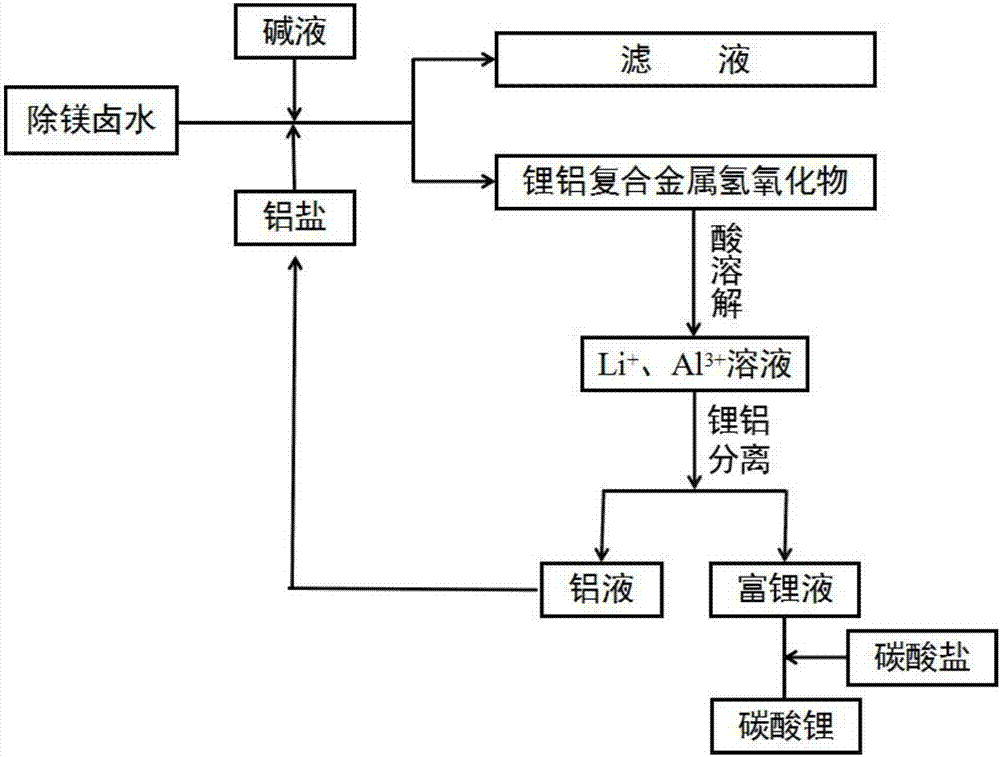

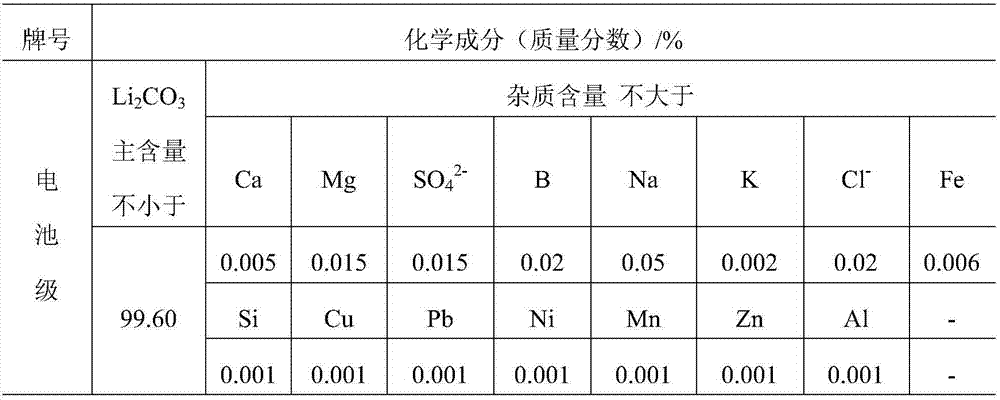

The invention discloses a method for extracting lithium from magnesium-removal bittern and preparing battery-grade lithium carbonate. The method uses a reaction-separating coupling technology for separating, extracting a lithium resource from magnesium-removal bittern and generating the battery-grade lithium carbonate, a technology comprises the following steps: aluminium salt is added in high sodium bittern after magnesium removal, and steps of nucleation and crystallization are carried out with alkali lye in a colloid grinder to obtain a lithium-aluminium composite metal hydroxide solid, lithium ions are introduced into a solid phase, the sodions stay in a solution, so that lithium ions and sodions are effectively separated. The lithium-aluminium composite metal hydroxide is dissolved by acid to obtain a solution containing lithium ions and aluminum ions, then lithium and aluminium are separated by an electrodialysis apparatus, the separated solution containing aluminium can be recycled, a lithium-rich solution is subjected to a precipitation reaction, and the battery-grade lithium carbonate is obtained. A reaction-separation coupling technology is used, while lithium and sodium are separated, the battery-grade lithium carbonate is prepared, so that high efficiency and high value utilization of the salt lake lithium resource can be realized.

Owner:青海西部镁业新材料有限公司

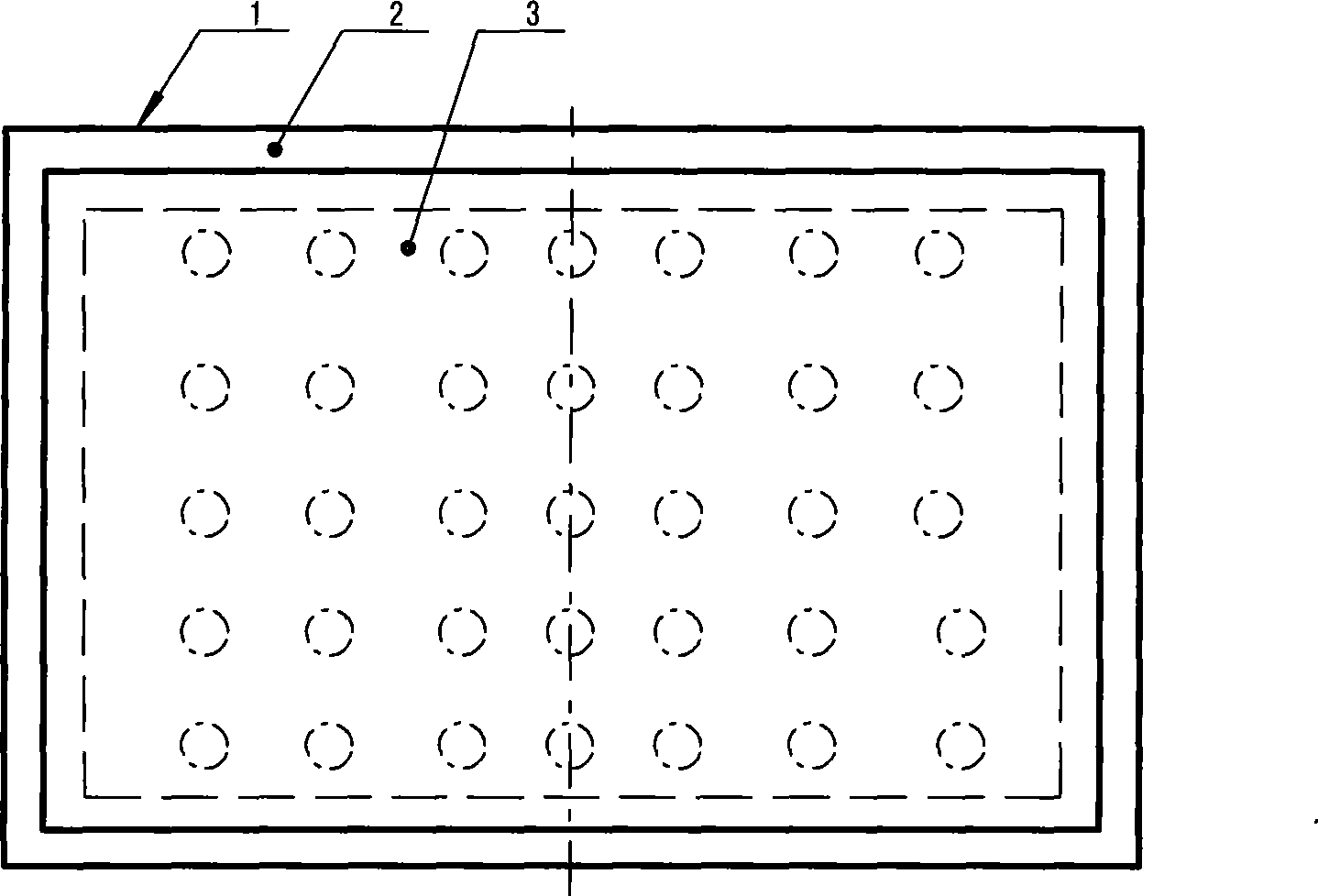

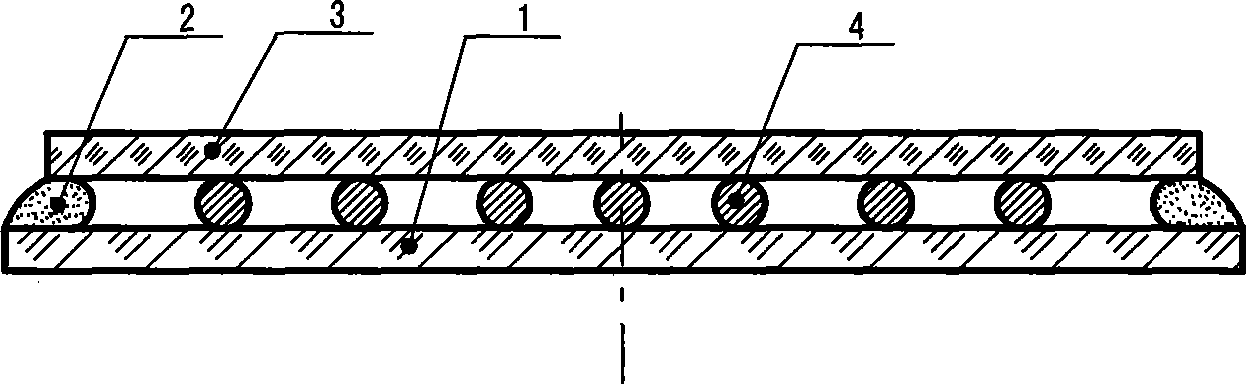

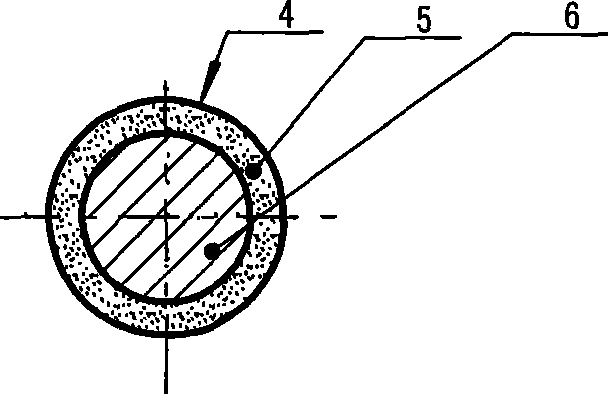

Vacuum glass with self-regulating flatness and manufacturing method thereof

InactiveCN101481206AEnhance firmness and rigidityOvercoming local stress problemsGlass reforming apparatusStress ProblemMetal

The invention relates to vacuum glass of automatic flatness adjustment and a preparation method thereof, which comprises upper plate glass, basal board glass, supporters and a low melting-point glass powder sealed edge, wherein supporters are uniformly arranged between the upper plate glass and the basal board glass at intervals and are rigid supporters, and a layer of low melting-point glass powder is uniformly wrapped on the outer edge of every rigid supporter. The rigid supporters of the invention combine soft support and rigid support into a whole, the partial stress problem and the supporter sliding problem of metal fixing supporters are overcome, the technical steps of the vacuum glass are reduced, and the low melting-point glass powder wrapped on the rigid supporters can be used for automatically adjusting the flatness of the vacuum glass, the quality of the vacuum glass is guaranteed, the production cost is lowered, and the development of the vacuum glass industry is promoted. The invention is particularly suitable for the industrialized, the scale and the standardized production of the vacuum glass.

Owner:左树森

Radar-infrared compatible stealth material with adjustable property and preparation method thereof

ActiveCN103497558AReduce IR emissivityRetain absorbing performanceRadiation-absorbing paintsChemical platingIron powder

The invention discloses a radar-infrared compatible stealth material with adjustable property and a preparation method thereof. The preparation method comprises the following steps of: placing 100 grams of steel balls, 10 grams of carbonyl iron powder, 0.01-0.1 gram of calcium stearate and 30-50 milliliters of acetone solutions into a ball milling jar together for ball milling; placing the carbonyl iron powder subjected to the ball milling into a degreasing fluid, and degreasing at the temperature of 50-70 DEG C for 8-10 minutes; placing the degreased carbonyl iron powder into a chemical plating solution, and plating the carbonyl iron powder at 30-75 DEG C under the pH value of 13-14 for 15-45 minutes; cleaning and drying a material subjected to chemical plating to obtain a needed composite material. The preparation method disclosed by the invention has the advantages of simpleness, easiness and convenience for process flow and low cost.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

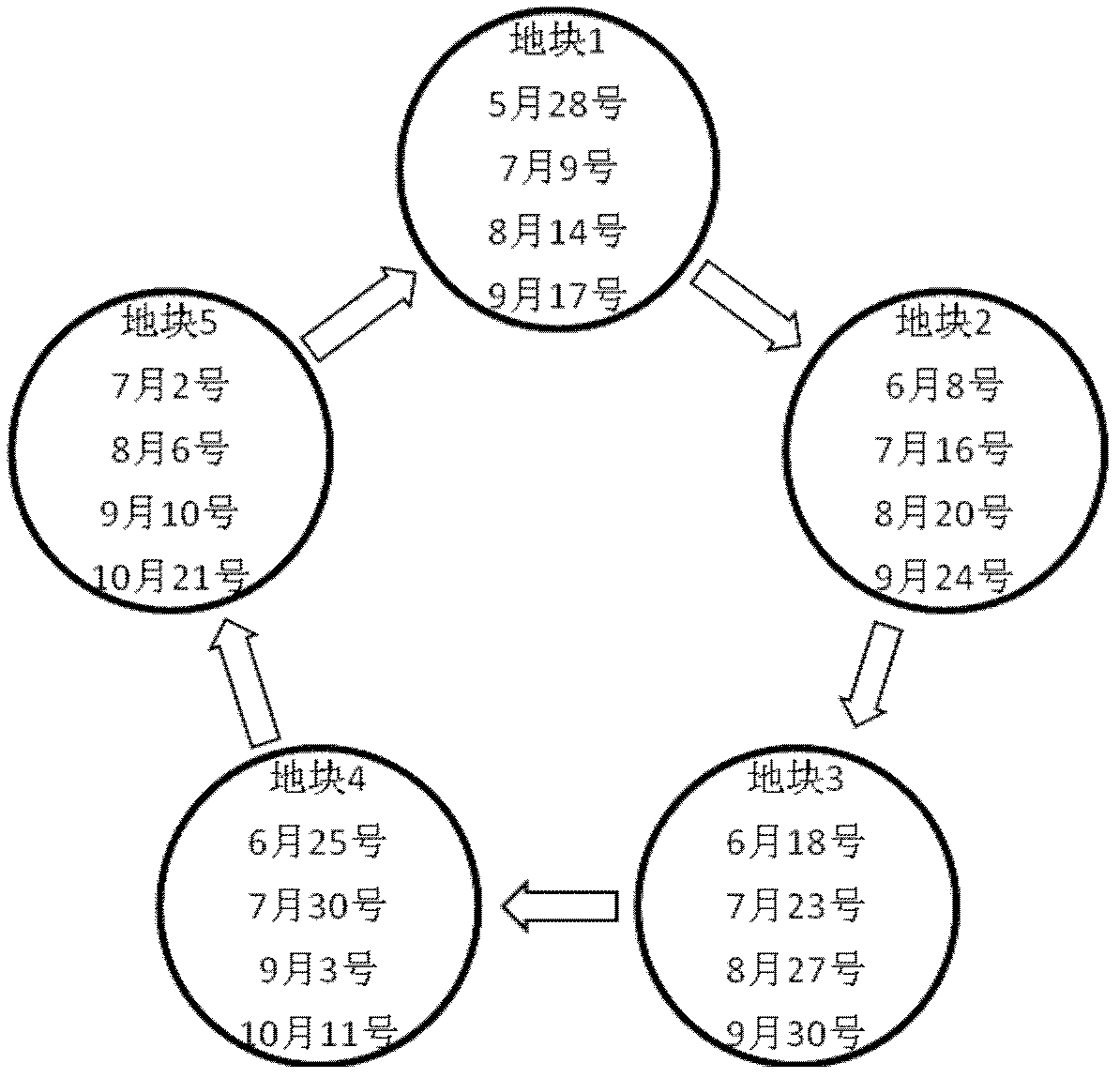

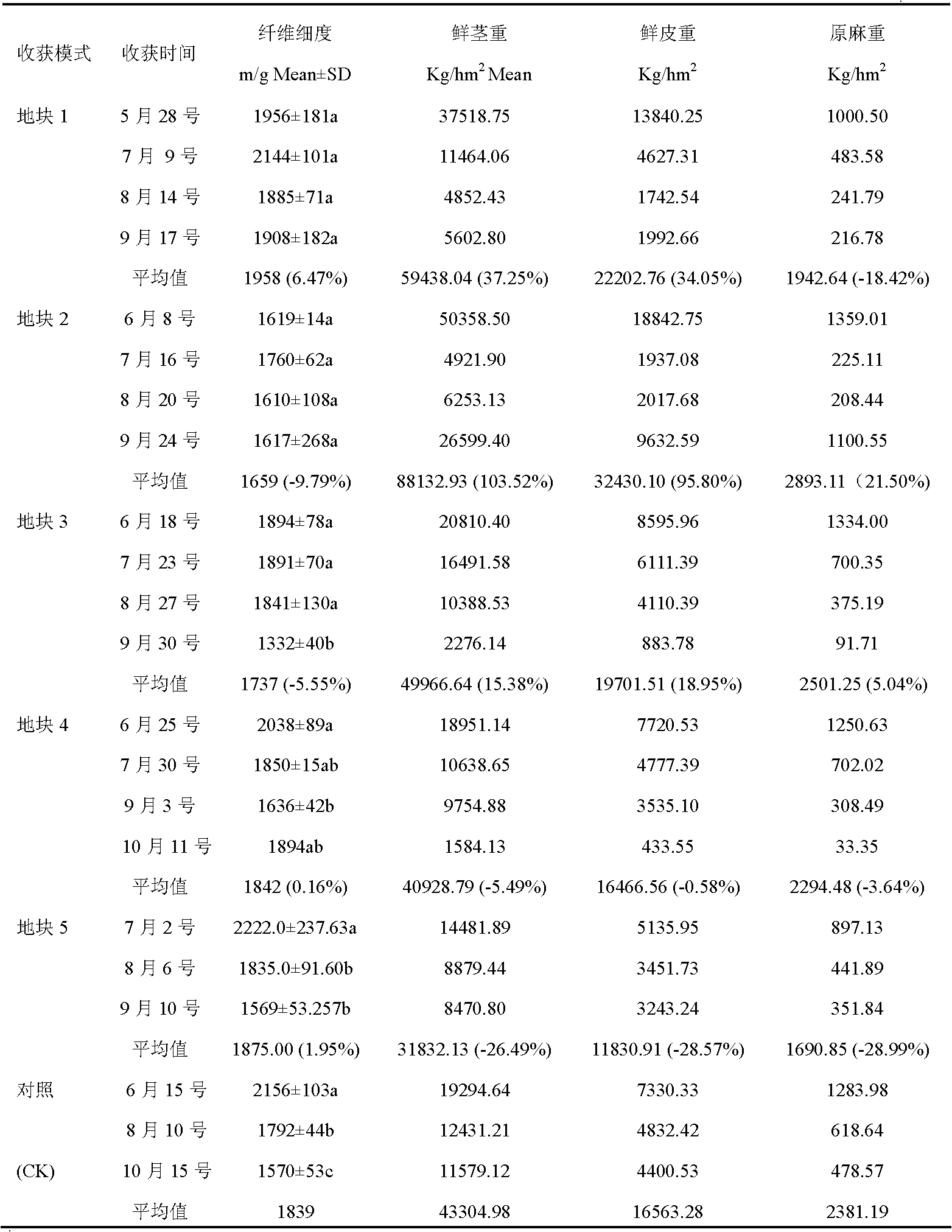

Method for continuously harvesting ramie fibers

The invention discloses a method for continuously harvesting ramie fibers, which comprises the following steps of: A. ramie plantation segmentation: the planted ramie is harvested in different areas in different time periods, the area of a ramie plantation is divided into blocks according to the standard of harvesting 1-10 days / block, and by utilizing the natural condition with sufficient rainfall and sunlight in June-September, the continuous harvest in May-October in each year can be realized; B. early harvesting: the time is five-twenty days earlier than the normal harvesting time; C. additionally fertilizing: after the ramie fibers are harvested, a nitrogenous fertilizer is applied according to a N60-80kg / hm2 standard; and D. culturing and managing in winter: the culture and the management are strengthened in winter, and a cake fertilizer (1,000-1,500kg / hm2) and NPK compound-fertilizers (600-80kg / hm2) are applied again.

Owner:HUAZHONG AGRI UNIV

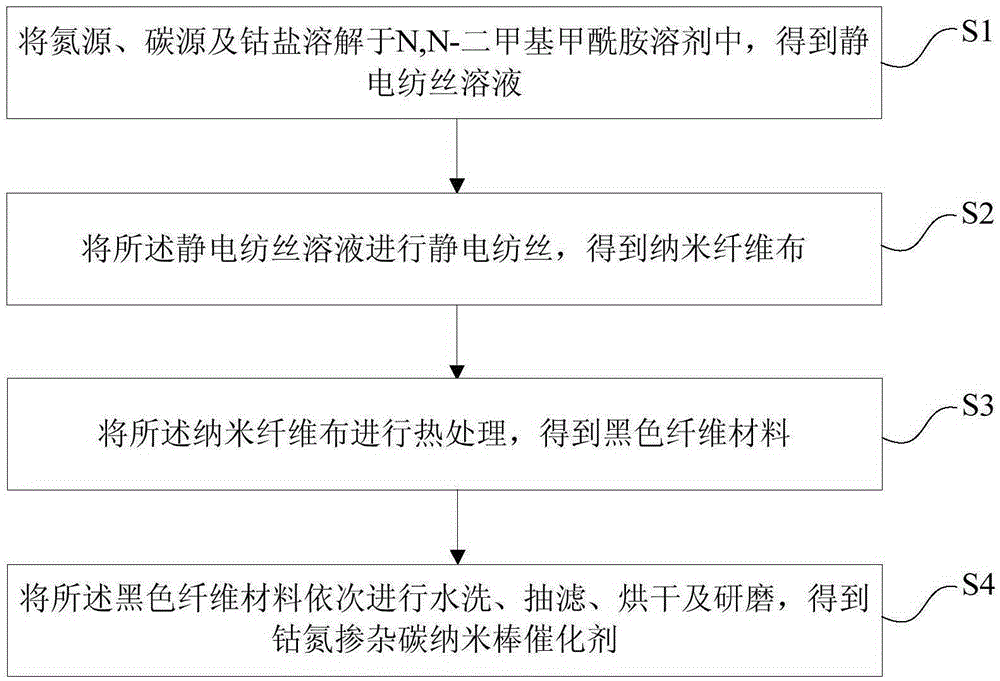

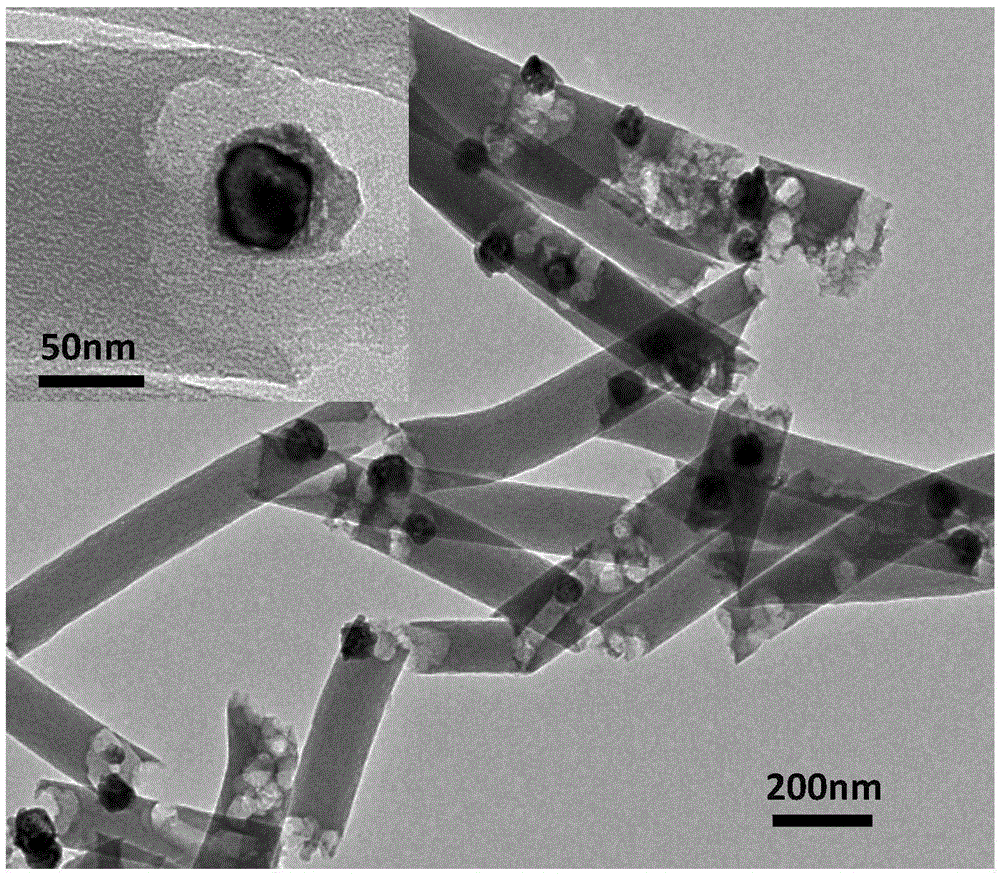

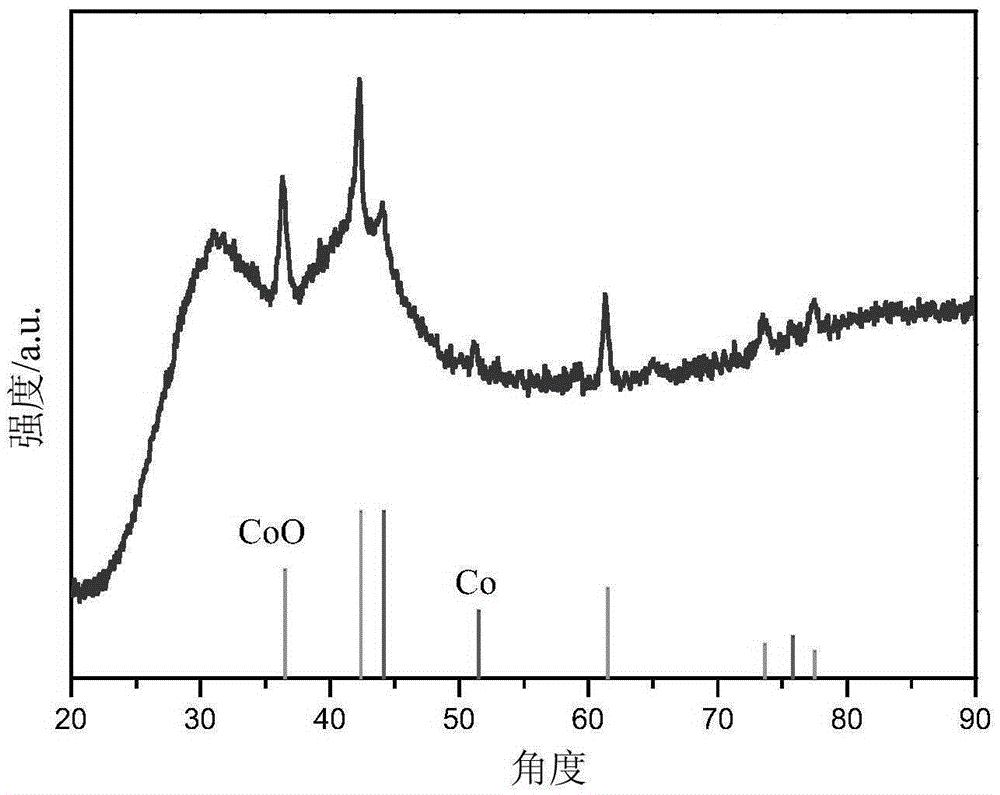

Cobalt and nitrogen doped carbon nanorod catalyst as well as preparation method and application thereof

ActiveCN106887620ALow costUniform structureFuel and primary cellsCell electrodesFiberN dimethylformamide

The invention provides a cobalt and nitrogen doped carbon nanorod catalyst as well as a preparation method and an application thereof. The preparation method comprises the following steps: 1) a nitrogen source, a carbon source and cobalt salt are dissolved in a N,N-dimethylformamide solvent in order to obtain a static spinning solution; 2) static spinning is carried out for the static spinning solution in order to obtain nanofiber cloth; 3) heat treatment is carried out for the nanofiber cloth in order to obtain a black fibrous material; 4) washing, pumping filtration, drying and grinding are carried out for the black fibrous material in order, and the cobalt and nitrogen doped carbon nanorod catalyst is obtained. The method which combines static spinning and heat treatment technology is employed for preparing the cobalt and nitrogen doped carbon nanorod catalyst, the catalyst has the advantages of low cost, uniform structure and excellent performance, and excellent oxygen reduction reaction (ORR) electrocatalytic activity is shown in acidic and alkaline mediums; the whole preparation technology is simple and reliable, and is suitable for scale expansion; in the future, the catalyst can replace platinum based noble metal catalyst, and can be applied to the fields of proton exchange membrane fuel cell, metal-air fuel cell, and the like.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Light food composition for weight-loss meal replacement and preparation method thereof

PendingCN111053190APromote innovationSimple designFood shapingNatural extract food ingredientsMeal replacementGynostemma

The invention discloses a light food composition for weight-loss meal replacement and a preparation method thereof. The light food composition for weight-loss meal replacement comprises 10-15 parts ofcereal powder, 8-14 parts of composite grease microcapsules,3-6 parts of fiveleaf gynostemma herb microcapsules, 6-13 parts of resistant dextrin, 6-13 parts of xylitol, 7-14 parts of soy isolate protein, 5-13 parts of medium-chain triglyceride powder, 5-10 parts of inulin, 2-5 parts of stachyose, 1-5 parts of chia seeds, 1-5 parts of konjaku flour, 0.7-3 parts of wheat oligopeptide, 0.2-2 parts of xylooligosaccharide powder, 0.1-2 parts of white kidney bean extract and 10-15 parts of composite fruit powder.

Owner:NINGBO YUFANGTANG BIOTECH

Cultivation method of flammulina velutipes

The invention relates to the novel technical field of edible fungi cultivation, and particularly relates to a cultivation method of flammulina velutipes. The method concretely comprises the following steps: selecting a flammulina velutipes variety which is free of infectious microbes, robust in mycelial growth, and adapted to local climate, and grows out hypha all over without aging as a seed source; selecting corncob, saw dust, bran and the like as raw materials; then mixing raw materials, bagging, sterilizing, inoculating and cultivating to obtain a fungi bag for production; finally carrying out open fruiting, fruiting management, recovery and final-period management, thus finishing the overall cultivation process. By implementing the method, the yield and the quality of the flammulina velutipes are further improved and the production cycle is shortened by selecting high-quality bacteria, grasping the optimal cultivation season and adopting high-quality raw materials, optimal formula, culture method improvement and the like, and the production cost and the economic benefits are greatly reduced. The cultivation method is applicable to factorial, large-scale and intensive production of the flammulina velutipes.

Owner:黄秀英

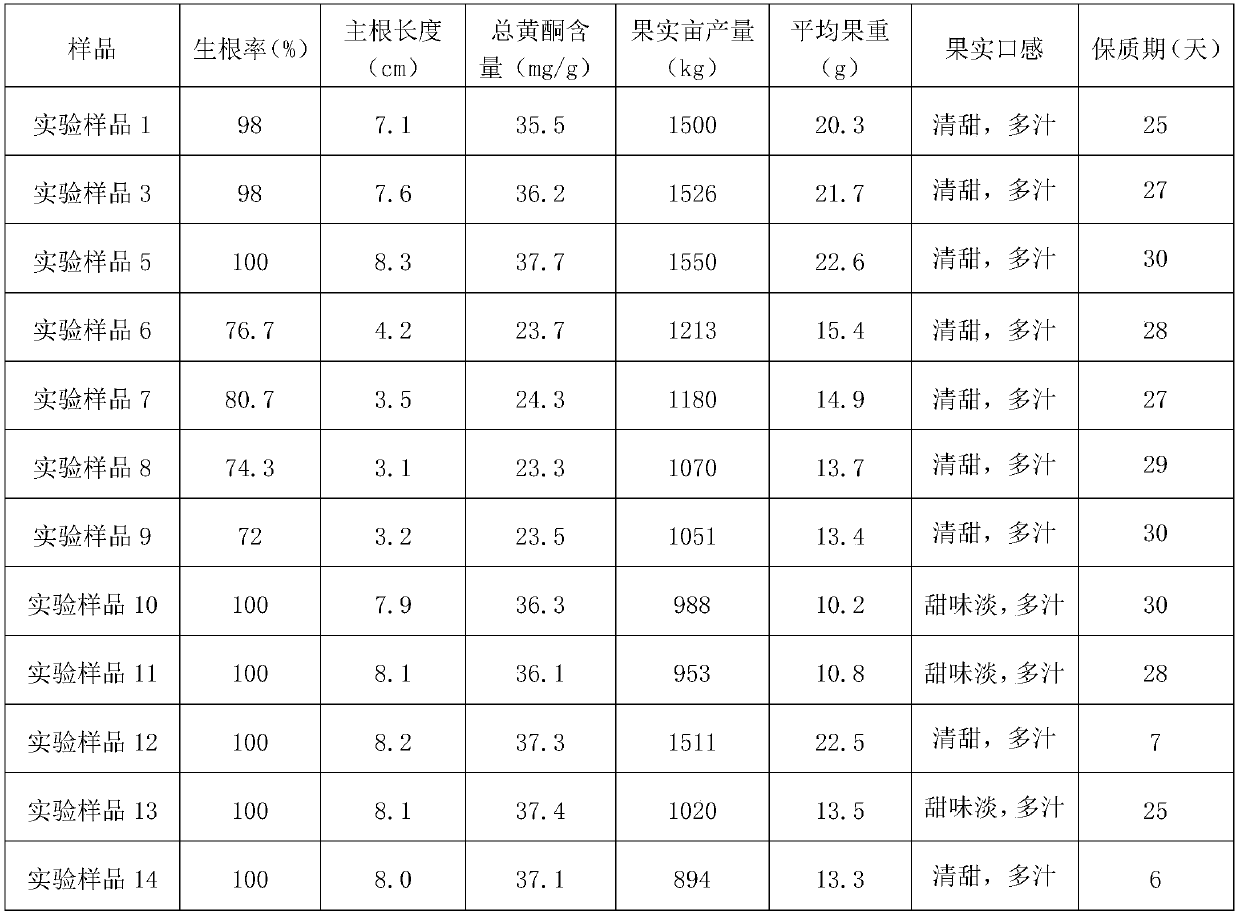

Melastoma dodecandrum lour planting method

InactiveCN109819834AHeavy qualitySweetness enoughPlant growth regulatorsBiocideSweetnessPlant cultivation

The invention provides a melastoma dodecandrum lour planting method, and particularly relates to the technical field of plant cultivation. The method adopts a mode for planting melastoma dodecandrum by using a seedling solution for rooting culture of cutting strips. Firstly, the cutting strips are placed and soaked in rooting water, cultivating and rooting are conducted with the seedling solution,field planting is conducted in a planting field, when water and fertilizer management is carried out, a vine enhancing agent and a fruit promoting agent are sprayed at the right time, the rooting rate of the cutting strips is over 98%, the total flavonoid content of active ingredients of a plant is above 35mg / g, which makes fruits have a heavy weight, enough sweetness and high yield, the shelf life of fresh fruits is prolonged to more than 20 days, so that the fresh fruits keep the original taste and freshness and do not easily rot, and the planting method is green, environmentally friendly,easy to operate, convenient to manage and suitable for scale and industrialization popularization.

Owner:三江县丰农农业科技有限公司

Method for preparing magnesia-stabilized zirconia crucible through casting molding

The invention discloses a method for preparing a magnesia-stabilized zirconia crucible through casting molding, and relates to the technical field of refractory materials. The preparation method comprises the steps that: in commercial magnesia-stabilized zirconia powder (MgO 3.5%, ZrO2 96.5%), a binding agent, deionized water and a dispersing agent with a certain ratio are added, such that a slurry with good fluidity is obtained, wherein a weight ratio of the above materials is 100:(5-15):(15-30):(0.5-5). Mixing is carried out in a drum, such that a slurry is obtained; the slurry is added into a plaster mold; the plaster mold is placed in air with an inclined position; demolding is carried out after 0.5-1.5h, and a blank is fetched; a final firing temperature is 1600-1700 DEG C, and the temperature is maintained for 3-10h; and a cooling speed is controlled, such that the magnesia-stabilized zirconia crucible is obtained. The method has the advantages of simple process equipment and uniform crucible wall thickness. The prepared magnesia-stabilized zirconia crucible has relatively high strength, relatively high refractoriness, high density, good thermal stability, good erosion resistance, and cracking resistance during a sintering process.

Owner:SHANGHAI UNIV

Wall type stereoscopic cultivation method for needle mushrooms

InactiveCN103518536AMeasures uniqueSimple production processHorticultureEdible mushroomNutrient solution

The invention relates to the novel technical field of edible mushroom cultivation, in particular to a wall type stereoscopic cultivation method for needle mushrooms. The method comprises the steps that raw material organizing, material mixing, material filling, sterilizing, inoculating and cultivating are conducted according to a conventional method; positions 5-6cm away from the material surfaces of the two ends of each mushroom bag where spawn running is completed are annularly cut for a circle by a sharp knife respectively, the middle section of each bag is scraped and taken away, and each 15cm mushroom stick is exposed for standby application; the mushroom sticks are stacked into a mushroom wall with 5-6 layers, the mushroom wall is coated with mud with the thickness being 1cm, then a film covers the fruiting face of the wall, fruiting management is conducted according to the conventional method finally, and the fresh mushrooms are collected by 3-4 crops generally. The wall type stereoscopic efficient cultivation method is adopted, space is fully used, the occupied area is saved, later-period nutrient solution is complemented easily, management is simplified, and output and quality of the needle mushrooms can be improved. The wall type stereoscopic cultivation method is very suitable for factory-like, large-scale and intensification production of the needle mushrooms.

Owner:黄秀英

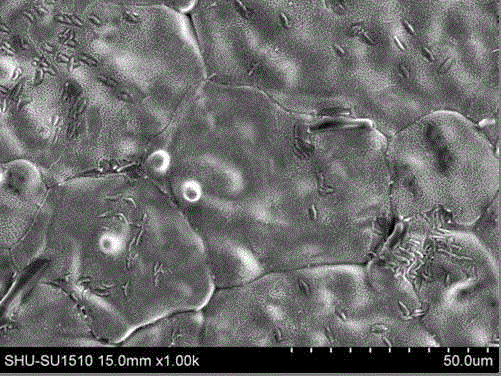

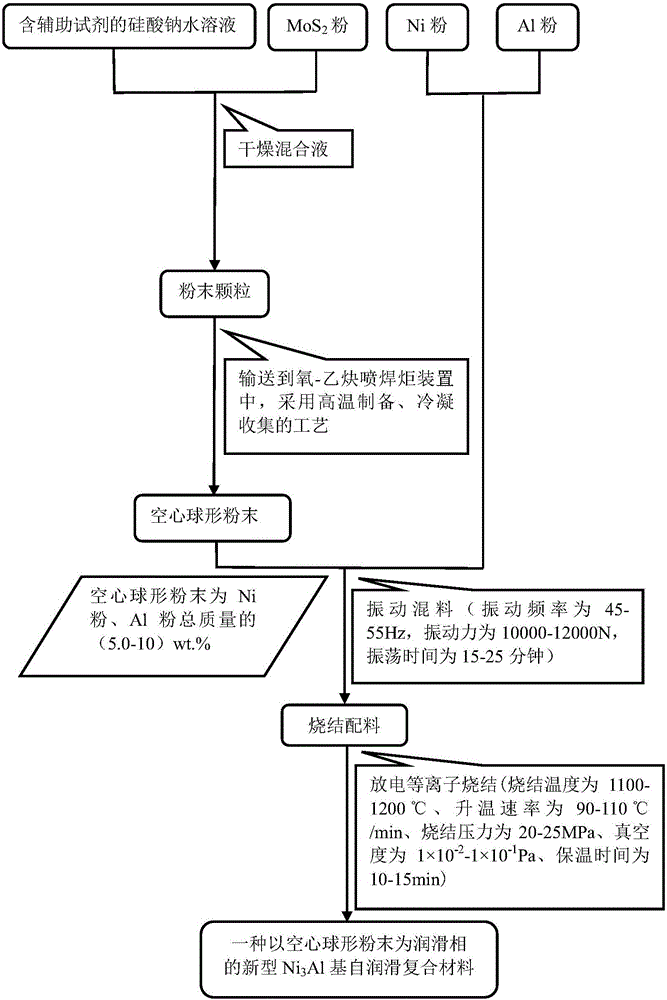

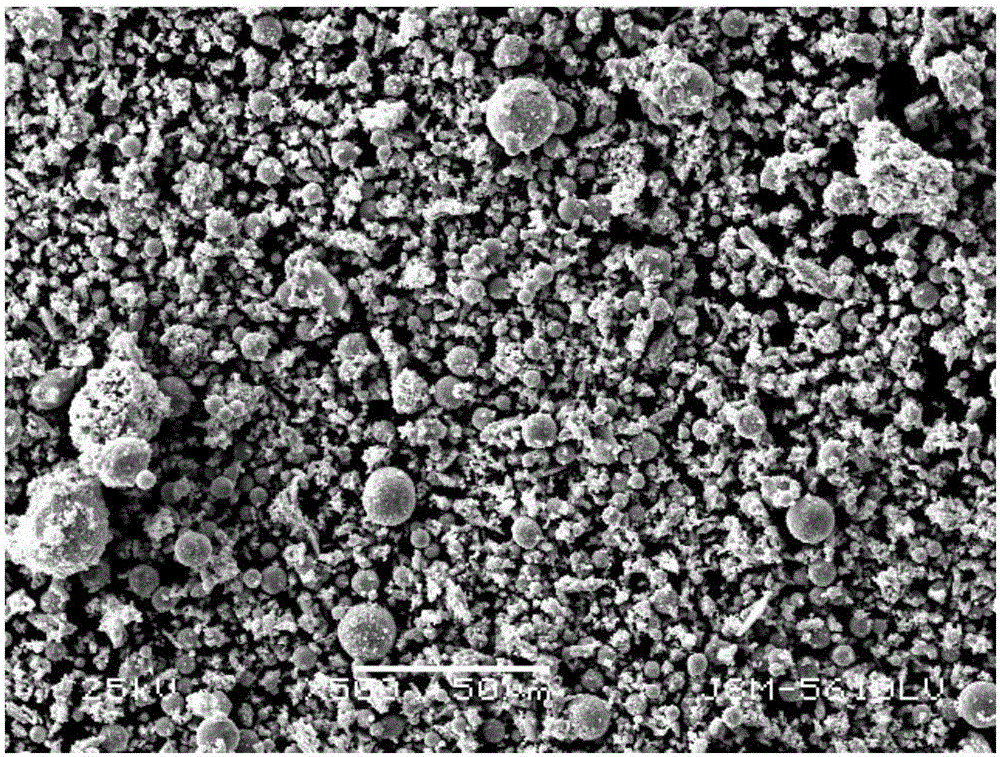

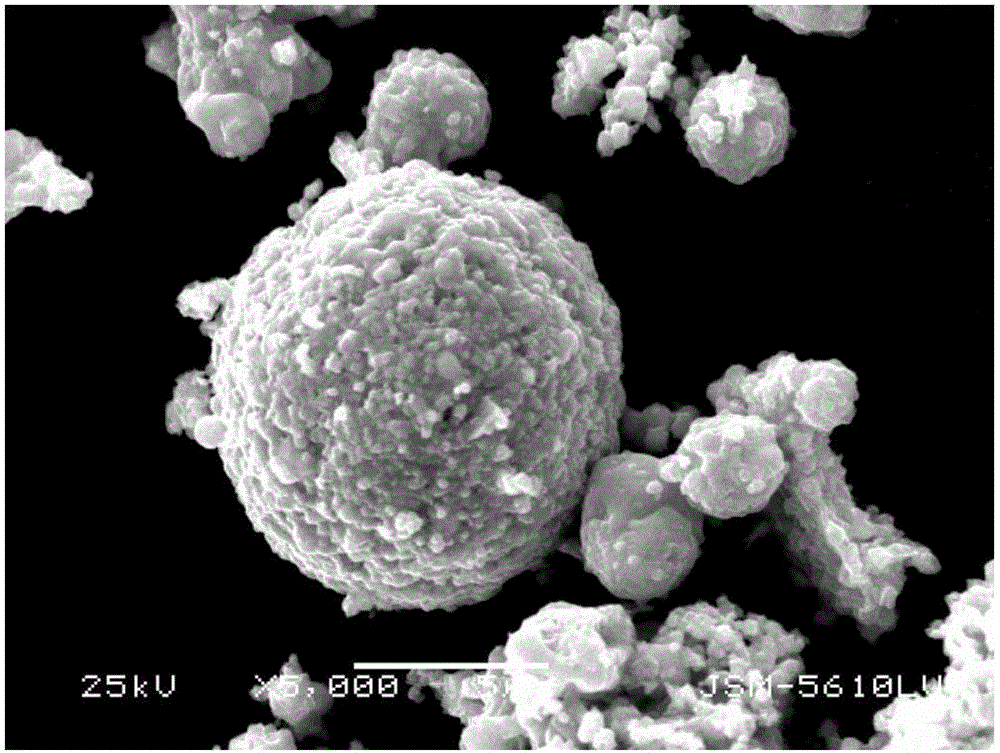

Novel Ni3Al based self-lubricating material with hollow spherical powder as lubricating phase and preparation method

The invention relates to a novel Ni3Al based self-lubricating material with hollow spherical powder as a lubricating phase. The novel Ni3Al based self-lubricating material is prepared from Ni powder, Al powder and the hollow spherical powder. The lubricating phase MoS2 and a glass phase serve as main chemical components of the hollow spherical powder, wherein the molar ratio of Ni to Al is 3:1, and the mass of the hollow spherical powder is (1.0-2.0)wt.% of the total mass of the Ni powder and the Al powder. According to the self-lubricating material, the hollow spherical powder is compounded in a Ni3Al matrix in situ; the obtained self-lubricating material is low in friction coefficient and wear rate in the friction wear process and has excellent tribology performance; and a preparation method is simple and novel, and technological parameters are easy to control in the preparation process.

Owner:WUHAN UNIV OF TECH

Method for preparing fruiting fungus bag for oyster mushroom with cornstalk as principal raw material

InactiveCN103404369AMeasures uniqueThe implementation process is simpleHorticultureFertilizer mixturesOysterHusk

The invention belongs to the novel technical field of cultivation of edible mushrooms, and particularly relates to a method for preparing a fruiting fungus bag for oyster mushroom with a cornstalk as a principal raw material. The method comprises the steps as follows: the pure elongated cornstalk which is not required to be smashed is taken as the principal raw material and cut into segments of 25-30 cm, and the segments are soaked in lime water and fermented; and corncobs, corn husks, corn flour and quick lime are taken as auxiliary materials, the fermented cornstalk segments and the auxiliary materials are bagged, and the fruiting fungus bag for production is prepared through sterilization, inoculation and fungus cultivation. According to the method, the used principal raw material, namely, the cornstalk is not required to be smashed or ground during application and is used integrally, investment for special facilities, and labor and the like which are required when the cornstalk is smashed or ground at ordinary times is reduced; besides, the speed of the hypha is slow when the hypha is transformed into the cornstalk, the transformation period is long, the biotransformation rate is high, and the produced economic benefits are remarkable.

Owner:何寒

Method for recovering ganoderma lucidum solid strain into liquid strain

InactiveCN104782384AUnique methodSimple processCultivating equipmentsMushroom cultivationCorn flourSterile water

A method for recovering a ganoderma lucidum solid strain into a liquid strain particularly includes the following steps that the raw materials of a culture medium are composed of corn flour and saw dust, and the culture medium is subpackaged into a triangular bottle and then sterilized according to a common method; the ganoderma lucidum solid strain is put in the triangular bottle according to a common method, and the ganoderma lucidum mycelia is cultured to grow full of the culture medium; sterilized water is poured into the triangular bottle, the strain the bottle is smashed, and then the ganoderma lucidum solid strain is recovered into the liquid strain. A traditional ganoderma lucidum liquid strain needs a professional fermentation tank. According to the method, only the common triangular bottle is needed, investment is small, and risks are low. The safety coefficient of the method is improved by N times compared with the traditional liquid strain. In the implementation process of the method, the culture medium does not contain sugar, thereby being not prone to being polluted, and the culture medium is easy to store and convenient to convey. By means of the method, the prepared ganoderma lucidum liquid strain has the same effect as the traditional ganoderma lucidum liquid strain, but the investment is reduced by nearly 50 times.

Owner:黄秀英

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com