Vacuum glass with self-regulating flatness and manufacturing method thereof

A vacuum glass and flatness technology, which is applied in glass manufacturing equipment, glass forming, glass reshaping, etc., can solve the problems of sliding and shifting metal supports, reducing the yield of vacuum glass, and affecting vacuum quality, etc., to achieve enhanced firmness and rigidity, overcome local stress problems, and reduce the effect of process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0022] It should be noted that in the embodiment of the present invention, illustrations such as the exhaust pipe are omitted to highlight the innovations of the present invention.

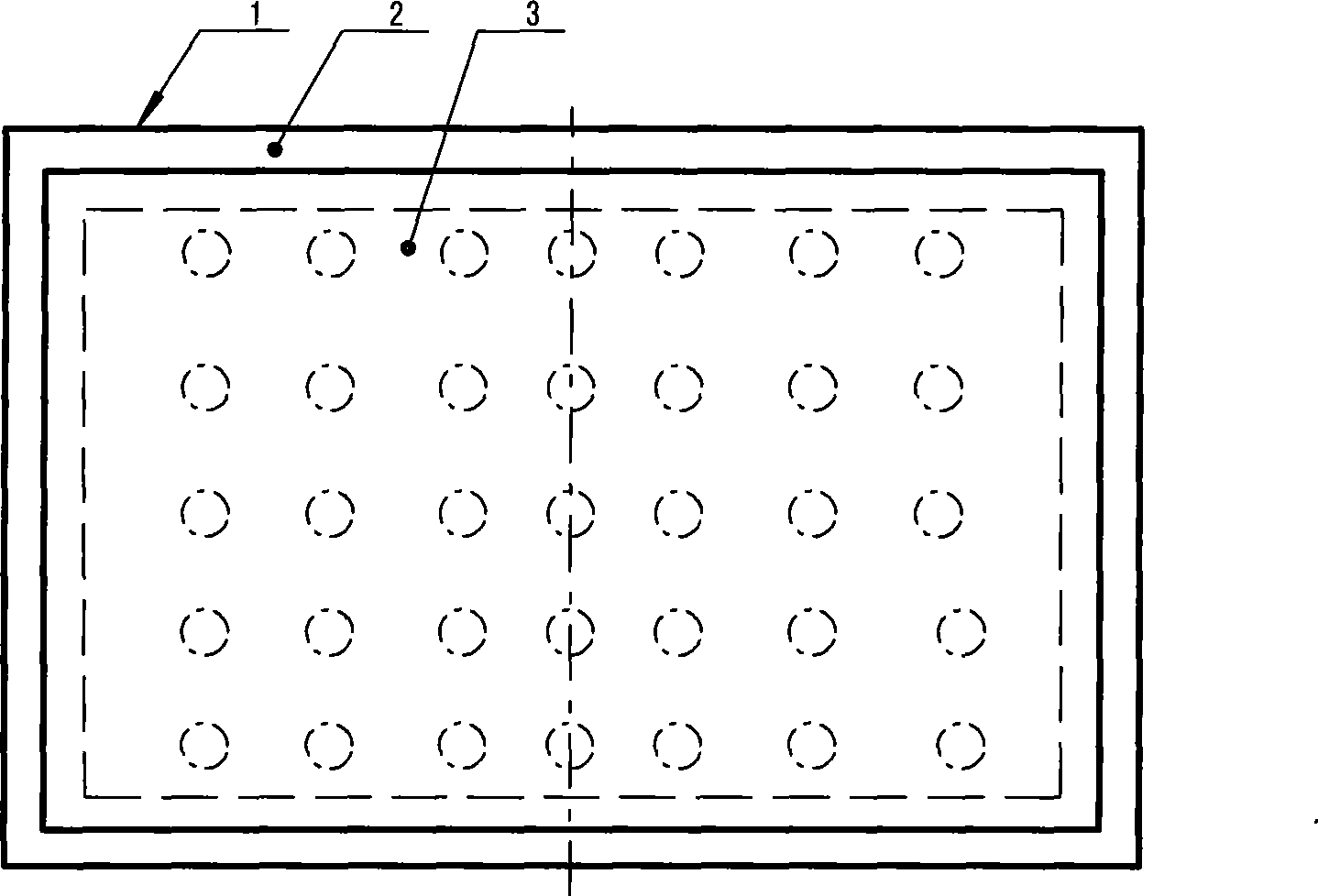

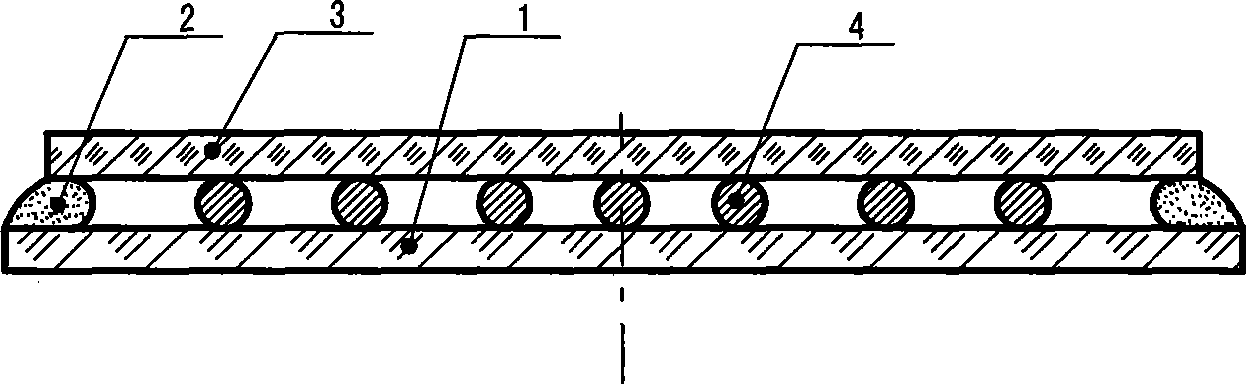

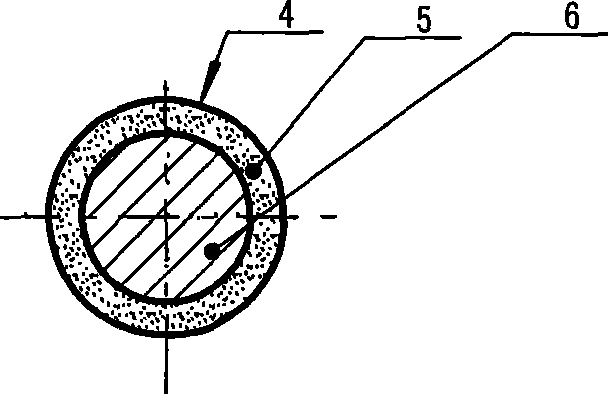

[0023] A self-adjusting flatness vacuum glass is composed of an upper glass 3, a substrate glass 1, a support 4, and a low-melting point glass powder 2 for sealing the edges of the upper glass and the substrate glass. Supports are evenly spaced between the upper piece of glass and the substrate glass. The support is a rigid support. , high-temperature plastic, quartz, ceramic, glass made of beads, blocks, strips flat sheet support. In the heating furnace, the flatness between the upper glass and the substrate glass can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com