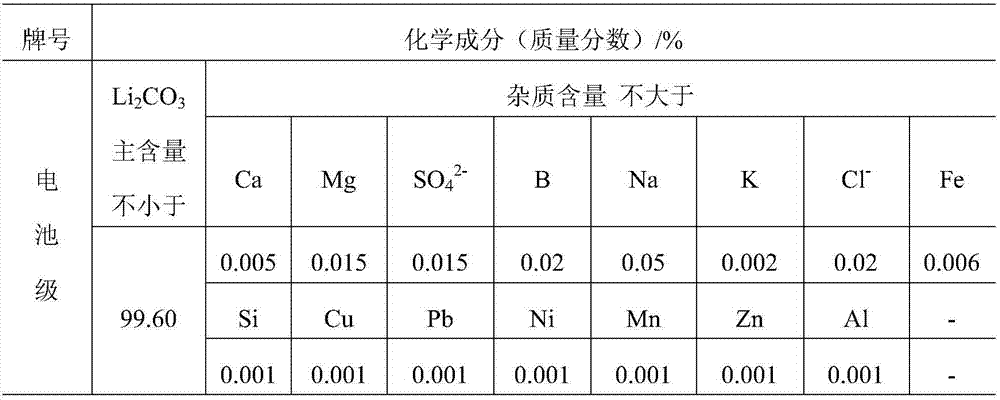

Method for extracting lithium from magnesium-removal bittern and preparing battery-grade lithium carbonate

A battery-grade, lithium carbonate technology, applied in the direction of lithium carbonate; Utilization rate and effect of small loss of lithium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

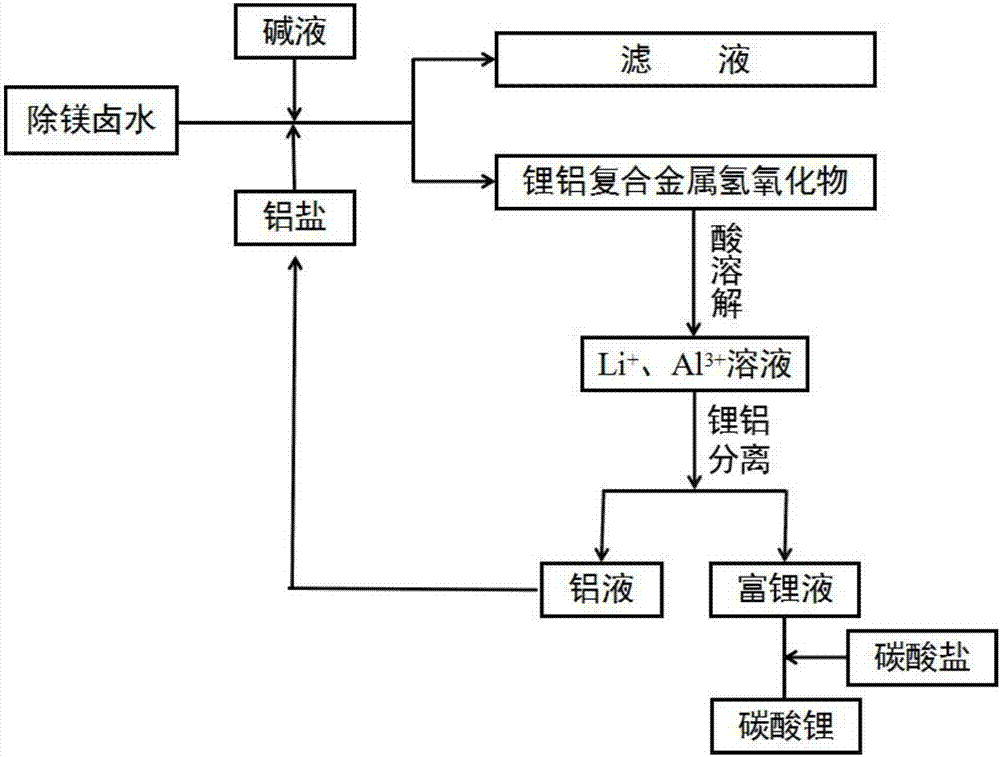

[0041] A. Take 250mL of high-sodium brine after removing magnesium, in which the mass ratio of sodium to lithium is about 48, and add AlCl 3 ·6H 2 O 11.741g obtains mixed salt solution A;

[0042] B. Weigh 4.3767g of NaOH, NaOH 2 CO 3 5.1548g was dissolved in deionized water, and the 250mL volumetric flask was constant volume to obtain mixed alkali solution B;

[0043] C. Pour the mixed salt solution A and the mixed alkali solution B into the colloid mill at the same time, and rotate at a speed of 3000r / min for 3 minutes to form a magnesium-doped lithium-aluminum composite hydroxide crystal nucleus; transfer the crystal nucleus solution to the reactor, Crystallize with dynamic stirring at 80°C for 12 hours to grow;

[0044] D. Solid-liquid separation, filtration to obtain lithium-aluminum composite hydroxide filter cake, lithium-aluminum composite hydroxide filter cake was dried at 70 ° C for 12 hours to obtain a white solid product, its chemical formula is [LiAl 2 (OH) ...

Embodiment 2

[0051] A. Take 250mL of high-sodium brine after magnesium removal, wherein the mass ratio of sodium to lithium is about 48, add Al(NO 3 ) 3 9H 2 O18.243g obtains mixed salt solution A;

[0052] B. Weigh 4.3766g of NaOH, NaOH 2 CO 3 5.1548g was dissolved in deionized water, and the 250mL volumetric flask was constant volume to obtain mixed alkali solution B;

[0053] C. Pour the mixed salt solution A and the mixed alkali solution B into the colloid mill at the same time, and rotate at a speed of 3000r / min for 3 minutes to form a magnesium-doped lithium-aluminum composite hydroxide crystal nucleus; transfer the crystal nucleus solution to the reactor, Crystallize with dynamic stirring at 80°C for 12 hours to grow;

[0054] D. Solid-liquid separation, filtration to obtain lithium-aluminum composite hydroxide filter cake, lithium-aluminum composite hydroxide filter cake was dried at 70 ° C for 12 hours to obtain a white solid product, its chemical formula is [LiAl 2 (OH) 6...

Embodiment 3

[0061] A. Take 250mL of high-sodium brine after removing magnesium, in which the mass ratio of sodium to lithium is about 48, and add Al 2 (SO 4 ) 3 18H 2 O32.396g obtains mixed salt solution A;

[0062] B. Weigh 4.3769g of NaOH, NaOH 2 CO 3 5.1548g was dissolved in deionized water, and the 250mL volumetric flask was constant volume to obtain mixed alkali solution B;

[0063] C. Pour the mixed salt solution A and the mixed alkali solution B into the colloid mill at the same time, and rotate at a speed of 3000r / min for 3 minutes to form a magnesium-doped lithium-aluminum composite hydroxide crystal nucleus; transfer the crystal nucleus solution to the reactor, Crystallize with dynamic stirring at 80°C for 12 hours to grow;

[0064] D. Solid-liquid separation, filtration to obtain lithium-aluminum composite hydroxide filter cake, lithium-aluminum composite hydroxide filter cake was dried at 70 ° C for 12 hours to obtain a white solid product, its chemical formula is [LiAl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com