Carbon coated thermal battery electrode material and preparation method thereof

An electrode material, thermal battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor air stability, difficult long-term storage, easy corrosion, etc., to improve electrical conductivity, good air stability, and reduce discharge electrodes. effect of chemical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Weigh 0.5g cetyltrimethylammonium bromide and disperse it in 100ml water, stir until solution A is formed;

[0033] 2. Weigh 0.5g fructose, 4g sodium sulfide, and 2g cobalt acetate into solution A in sequence, and stir until solution B is formed;

[0034] 3. Transfer the obtained solution B into a reaction kettle, heat to 180°C, react at a constant temperature for 12 hours, and separate the product C after cooling;

[0035] 4. Put product C in an oven, heat up to 100°C, and dry at constant temperature for 6 hours to obtain product D;

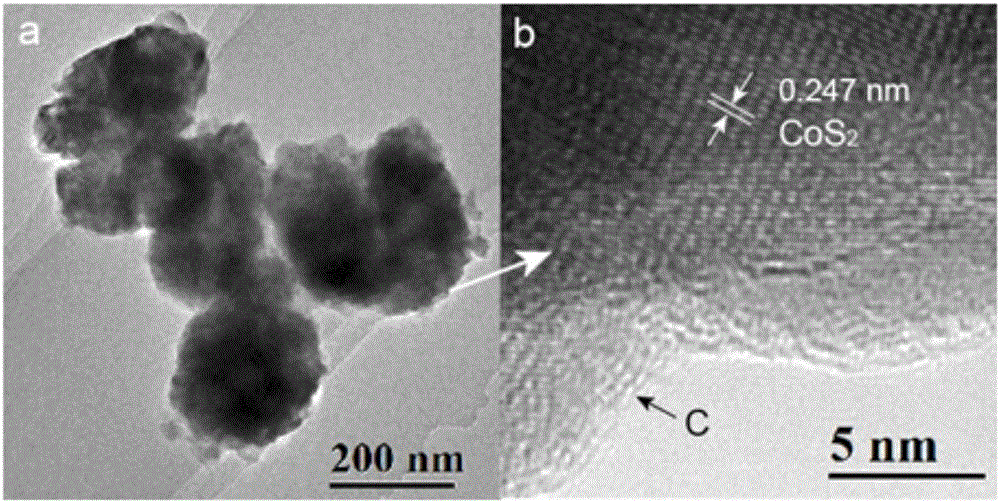

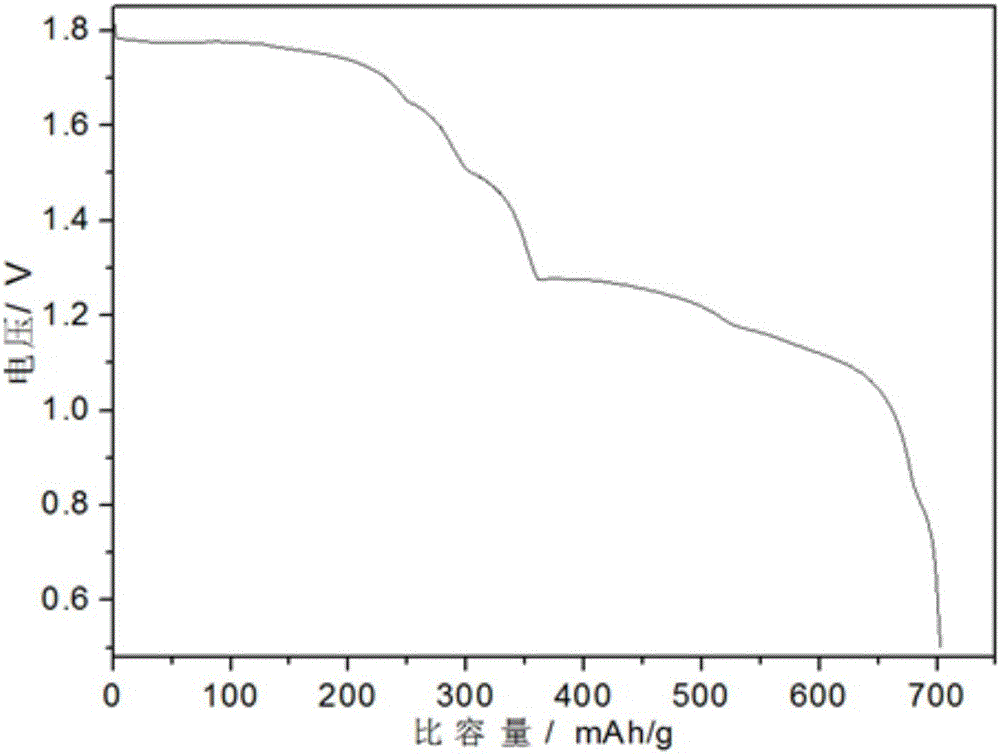

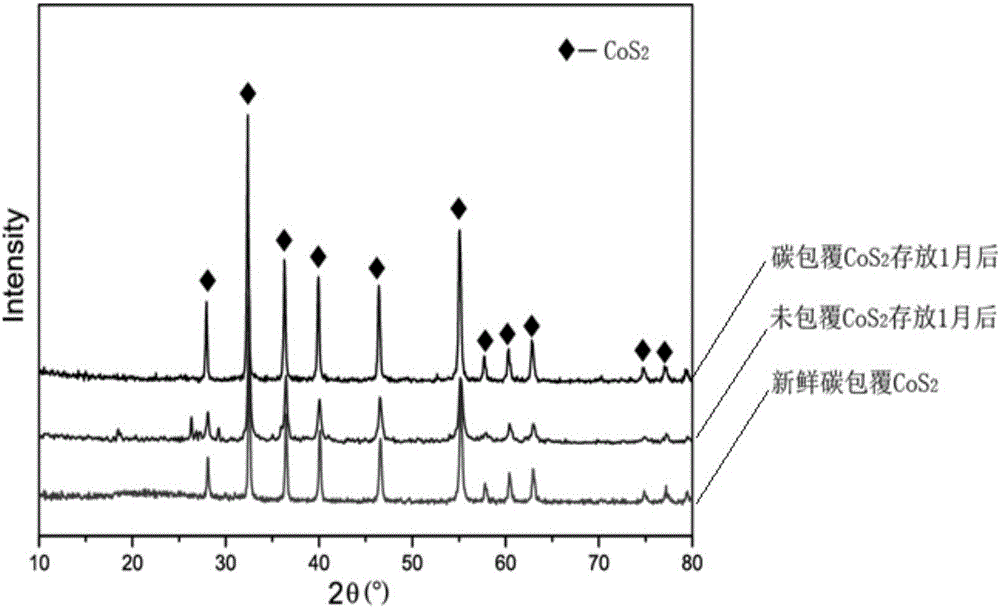

[0036] 5. Put the product D into a tube furnace, raise the temperature to 500°C under an argon atmosphere, keep the temperature for 3 hours, and collect the final product E after cooling, that is, cobalt disulfide with a carbon-coated structure containing 15% carbon Electrode material ( figure 1 It is the transmission electron micrograph of the obtained carbon-coated cobalt disulfide, from figure 1 It can be seen that carbon is ef...

Embodiment 2

[0039] 1. Weigh 0.01g of sodium dodecylsulfonate and disperse it in 100ml of water, stir until solution A is formed;

[0040] 2. Weigh 0.05g of glucose, 1g of sodium thiosulfate, and 0.5g of cobalt nitrate into solution A in sequence, and stir until solution B is formed;

[0041] 3. Transfer the obtained solution B into a reaction kettle, heat to 100°C, react at a constant temperature for 48 hours, and separate the product C after cooling;

[0042] 4. Put product C in an oven, raise the temperature to 60°C, and dry at constant temperature for 24 hours to obtain product D;

[0043] 5. Put the product D into a tube furnace, raise the temperature to 300°C in a helium atmosphere, keep the temperature for 8 hours, and collect the final product after cooling, that is, a cobalt disulfide electrode with a carbon-coated structure containing 1% carbon Material;

[0044] 6. The obtained electrode material is assembled into battery sheets according to the method shown in Example 1, and ...

Embodiment 3

[0046] 1. Weigh 0.1g sodium dodecylbenzenesulfonate and disperse it in 100ml water, stir to form solution A;

[0047] 2. Weigh 0.2g of sucrose, 2g of sulfur powder, and 1g of cobalt sulfate into solution A in sequence, and stir until solution B is formed;

[0048] 3. Transfer the obtained solution B into a reaction kettle, heat to 150°C, react at a constant temperature for 15 hours, and separate to obtain product C after cooling;

[0049] 4. Put product C in an oven, heat up to 80°C, and dry at constant temperature for 15 hours to obtain product D;

[0050] 5. Put the product D into a tube furnace, raise the temperature to 400°C under a neon gas atmosphere, keep the temperature for 5 hours, and collect the final product E after cooling, that is, cobalt disulfide with a carbon-coated structure containing 5% carbon electrode material;

[0051] 6. The obtained electrode material was assembled into a battery sheet according to the method in Example 1, and the 2 discharge at a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com