Patents

Literature

311results about How to "Suitable for commercial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

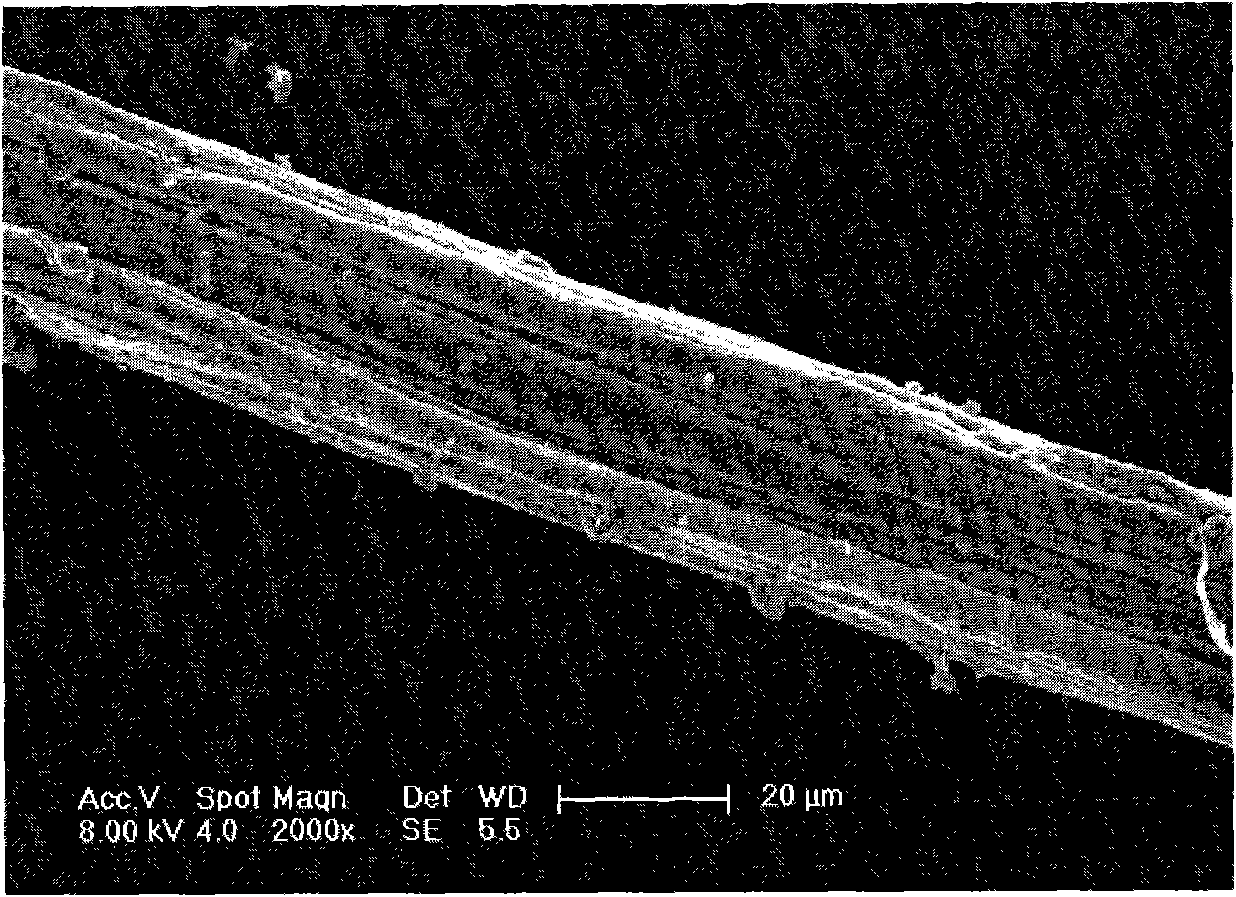

Surface processing technology for dental implant

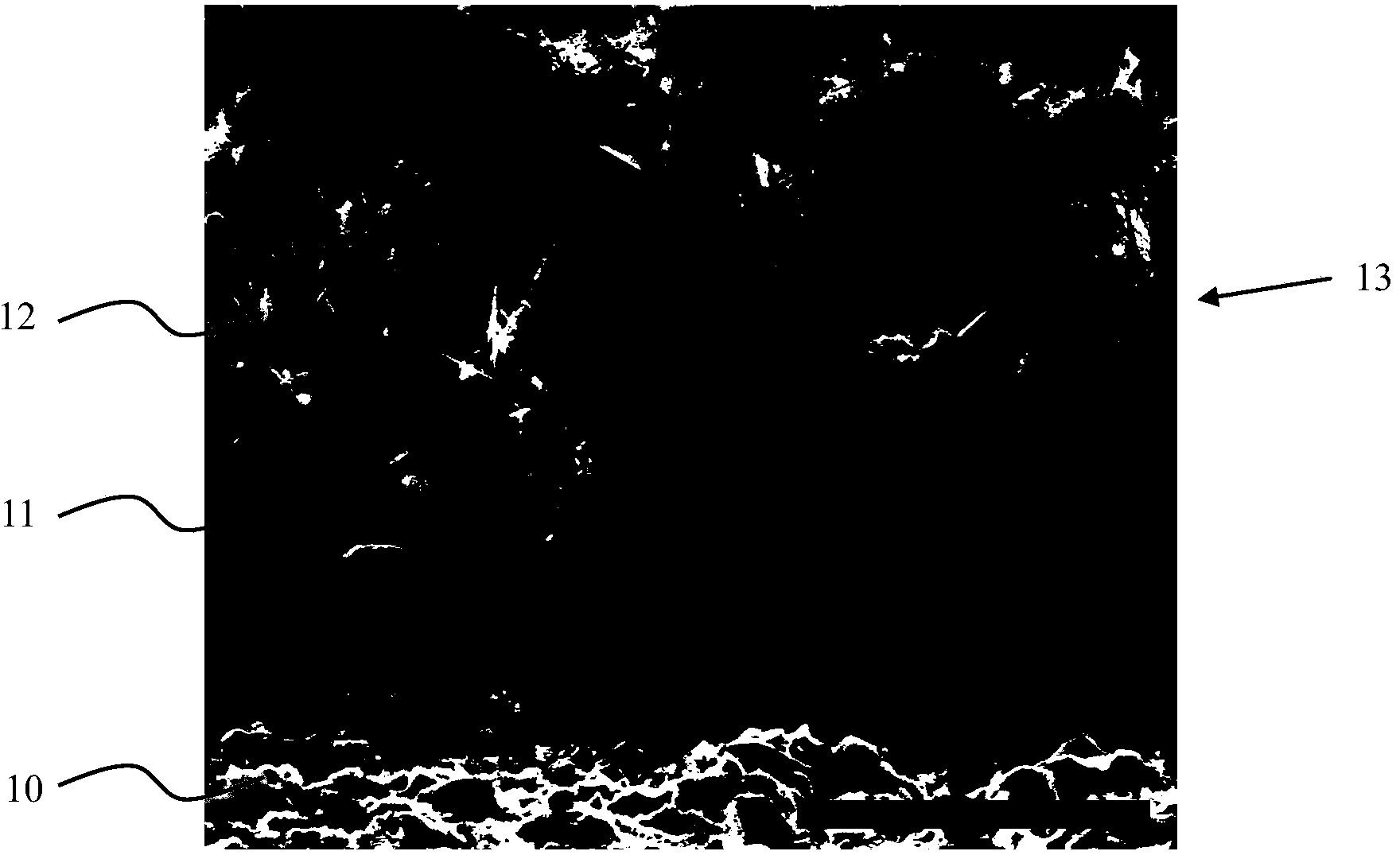

InactiveCN102232876AGood surface morphologyGood rough surfaceArtificial teethCleaning using liquidsAcid etchingTitanium

The invention discloses a surface processing technology for a pure-titanium dental implant. The technology comprises the following steps: A, removing oil from the dental implant by ultrasonic cleaning; B, sandblasting the dental implant by white corundum to make the surface of the implant to be uniform gray in color and allow a three-dimensional porous structure to be formed on the surface of the dental implant; C, carrying out acid etching on the surface of the sandblasted dental implant with a mixed liquid with a certain concentration and a certain ratio of sulfuric acid to hydrochloric acid to allow gradually decreased multilevel scallops to be formed on the surface of the dental implant; and D, flushing and neutralizing the acid etched dental implant, and removing oil. According to the surface processing technology for the dental implant designed by the invention, the multilevel porous structure with biological activity is formed on the surface of the pure-titanium implant, so the biological activity of the pure-titanium implant is improved, the stability of the implant is improved, the bone combination speed of the dental implant is accelerated, the bone interfacial combination strength of the implant is enhanced, thereby the technology has the advantages of simple and high efficient technology, and low cost.

Owner:JIANGSU TRAUSIM MEDICAL INSTR

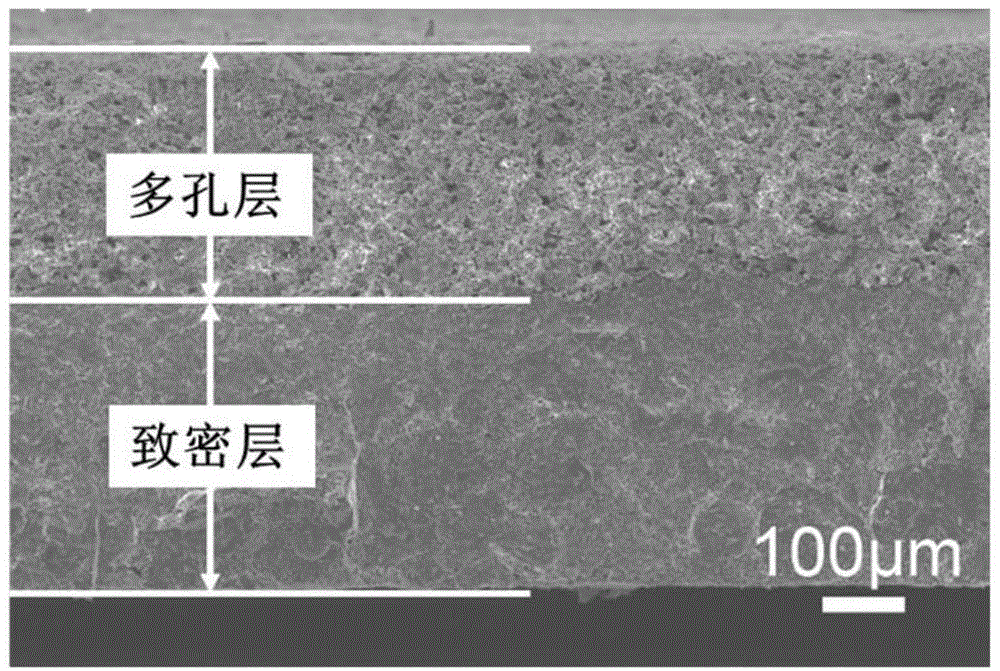

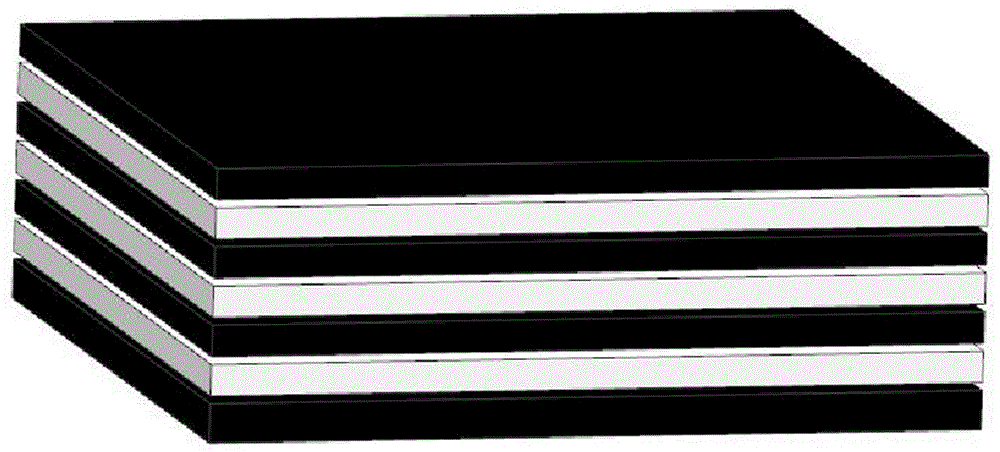

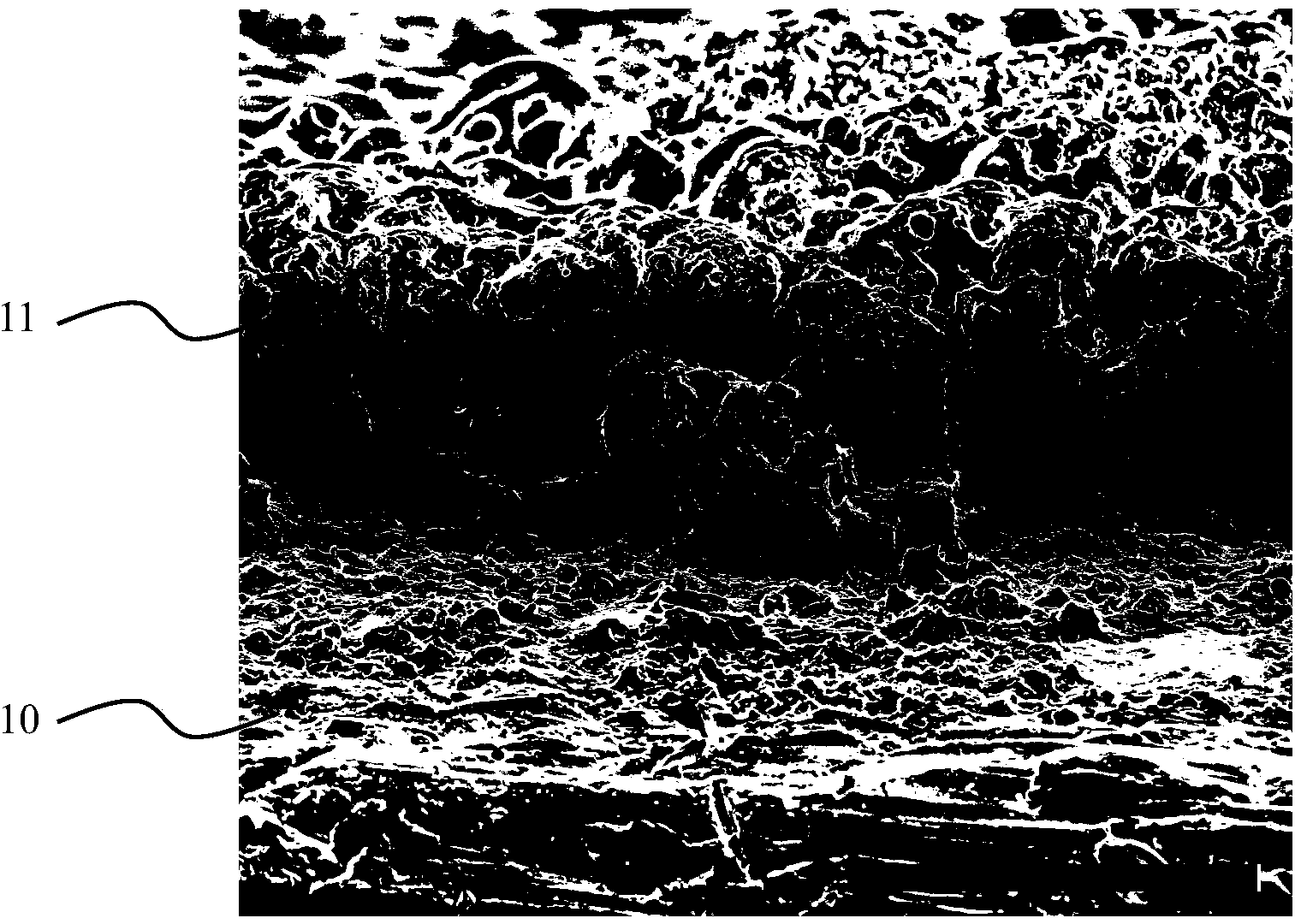

Porous-compact double-layer electrolyte ceramic sintered body, lithium ion battery and lithium-air battery

ActiveCN104916869ASolve the leakFix security issuesFuel and secondary cellsFinal product manufactureCeramic sinteringAll solid state

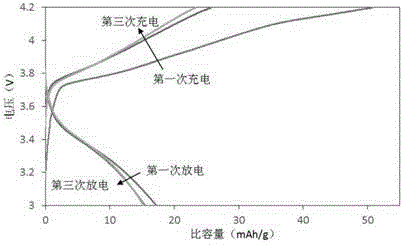

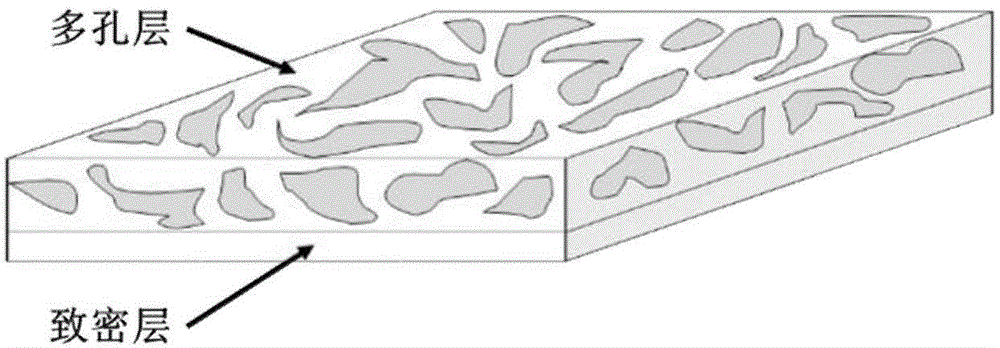

The invention discloses a porous-compact double-layer electrolyte ceramic sintered body based on inorganic solid state lithium ion electrolyte materials, an all-solid-state secondary lithium ion battery, an all-solid-state secondary lithium-air battery, and preparation methods. The preparation method for the sintered body comprises the following steps: first, powder of inorganic solid state lithium ion electrolyte materials is provided; second, part of the powder and pore forming agents are mixed, and mixed powder is obtained; third, the other part of the powder and the mixed powder form a green body, the green body comprises a first green body layer and a second green body layer which are stacked mutually, the other part of the powder forms the first green body layer and the mixed powder forms the second green body layer; fourth, the green body is subjected to sintering, the pore forming agents are burnt off, the porous-compact double-layer electrolyte ceramic sintered body is obtained, the first green body layer forms a compact layer and the second green body forms a porous layer.

Owner:TSINGHUA UNIV

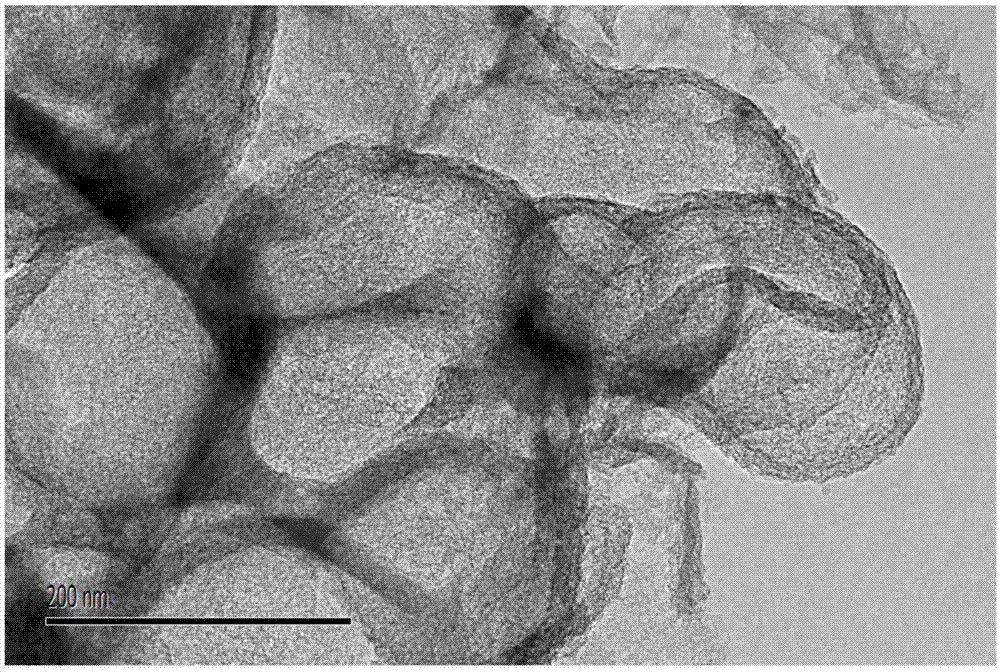

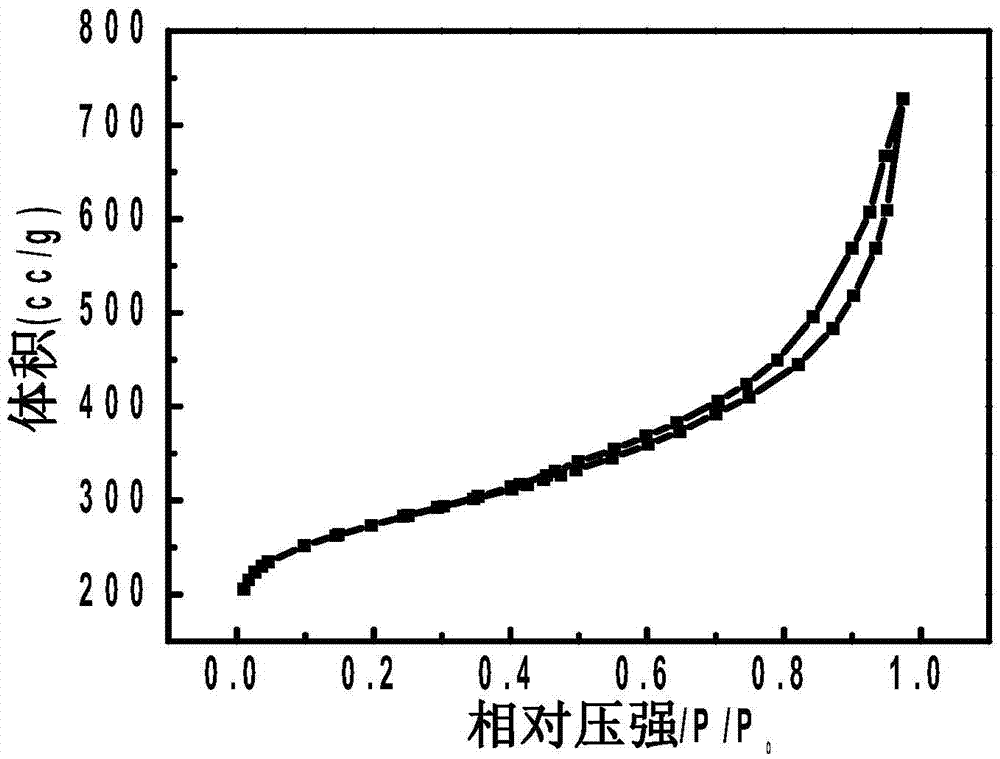

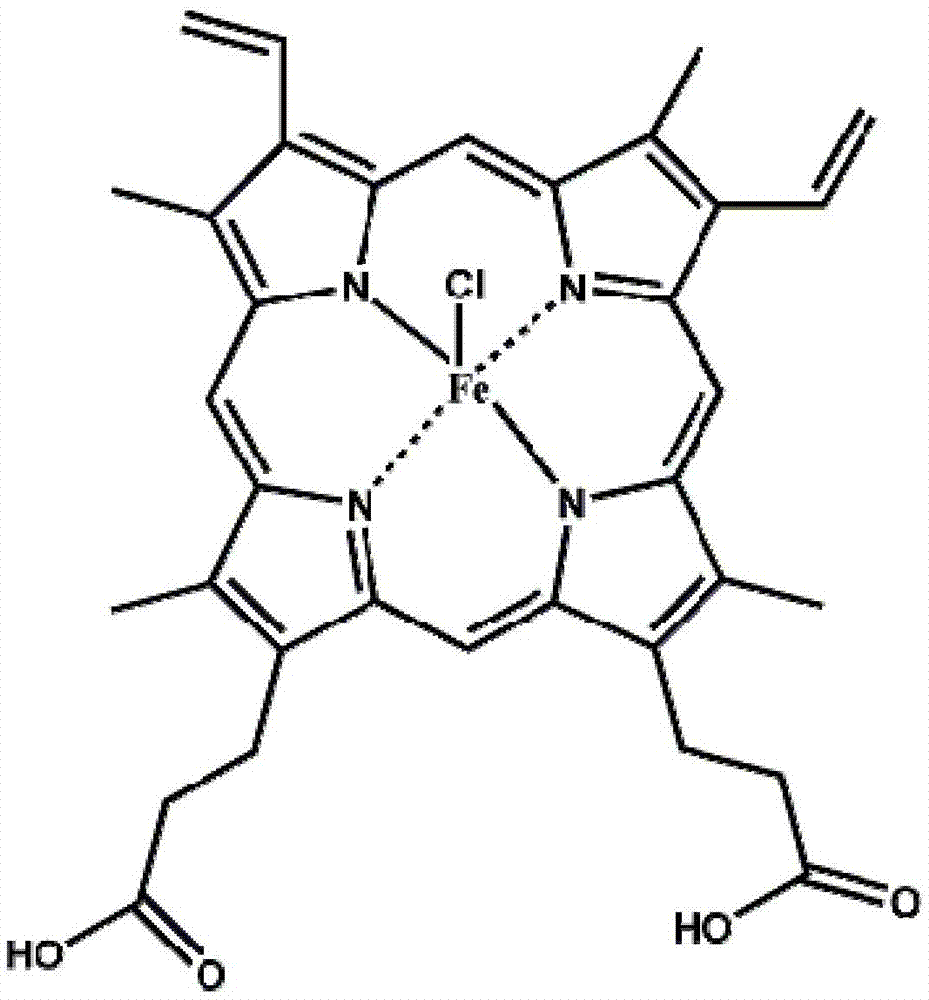

Preparation method for nitrogen-doped porous carbon supported non-noble metal electrocatalyst and electrocatalyst application

InactiveCN106876730AHigh activityLarge specific surface areaCell electrodesPorous carbonAcid washing

The invention discloses preparation method for nitrogen-doped porous carbon supported non-noble metal electrocatalyst. According to the method, magnesium oxide is taken as a hard template; mixture containing nitrogen ligands and polyacid is taken as a nitrogen source and a carbon source; mixture dispersion is carried out through an ultrasonic rotary evaporation method; carbonization is carried out through high temperature roasting; the template is removed through utilization of acid solution, thereby obtaining a porous carbon material; a non-noble metal macrocyclic compound and the porous carbon material are mixed through the rotary evaporation method; and the supported non-noble metal electrocatalyst is prepared through heat treatment and acid-washing. According to the method, the nitrogen-doped porous carbon material with a high specific surface area is taken as a carrier, thereby facilitating the dispersion of the metal-nitrogen / carbon in the non-noble metal macrocyclic compound and the mutual coordination effect between the carrier and the metal-nitrogen / carbon active site, so the oxygen reduction activity of the catalyst is greatly improved. The material has relatively high electrocatalytic activity for the oxygen reduction of a cathode of a fuel cell, the material has a potential application prospect and the commercial application process of the fuel cell is promoted.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

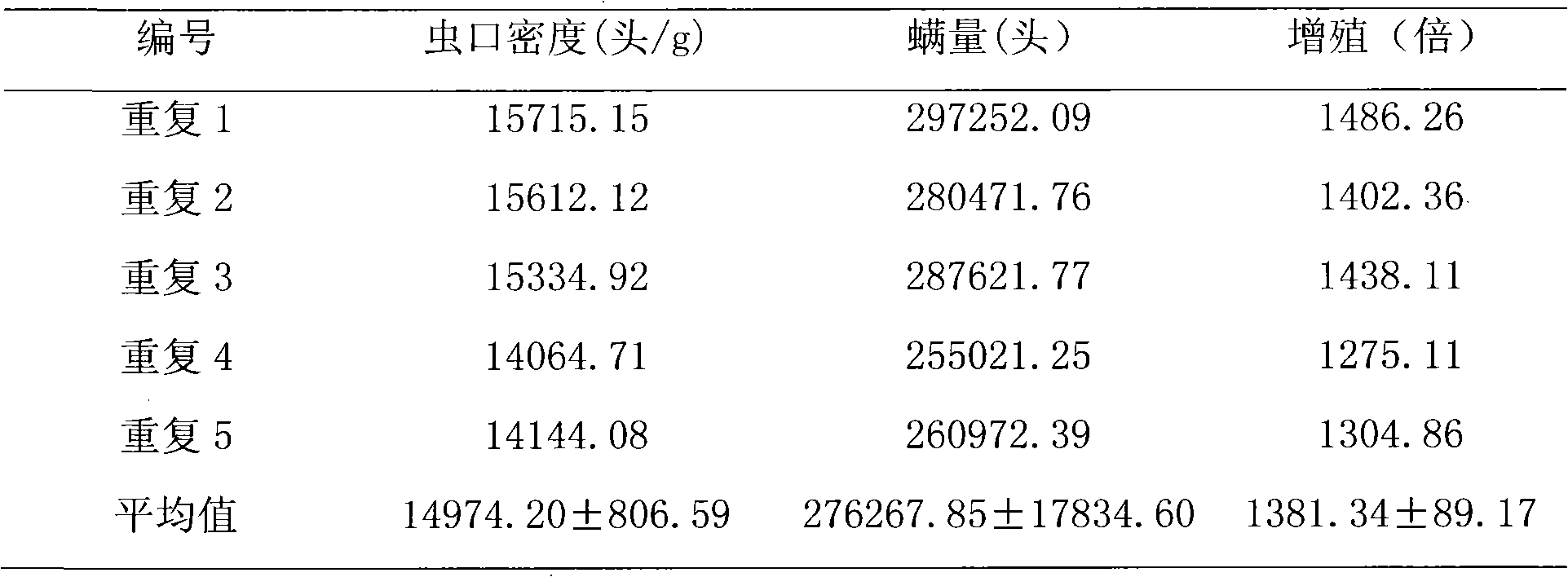

Method for artificially breeding mass Carpoglyphus lactis

ActiveCN101965822AEfficient feedingImprove nutritional statusAnimal husbandryYeastNutritional status

The invention relates to a method for artificially breeding mass Carpoglyphus lactis. In the method, the Carpoglyphus lactis is bred by 1 to 50 percent of sugar, 1 to 50 percent of yeast, 0 to 50 percent of breeding medium and 0 to 35 percent of water in an environment with the temperature of between 15 and 35 DEG C and the relative humidity of 65 to 95 percent. The method comprises the following steps of: after combining breeding materials, throwing the combined breeding materials into a breeding container; inoculating the Carpoglyphus lactis, wherein the Carpoglyphus lactis is inoculated in an amount of more than or equal to one Carpoglyphus lactis per milliliter; and breeding the Carpoglyphus lactis for 10 to 40 days to realize mass breeding. The Carpoglyphus lactis is bred by the sugar, the yeast, the breeding medium and the water, so the Carpoglyphus lactis can be efficiently bred, the method is easy to operate and has low cost, the bred Carpoglyphus lactis has the characteristics of good nutritional status, low death rate, high egg laying amount, high population density and the like, and the method is more suitable for low-cost commercial production of predatory mites.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI +2

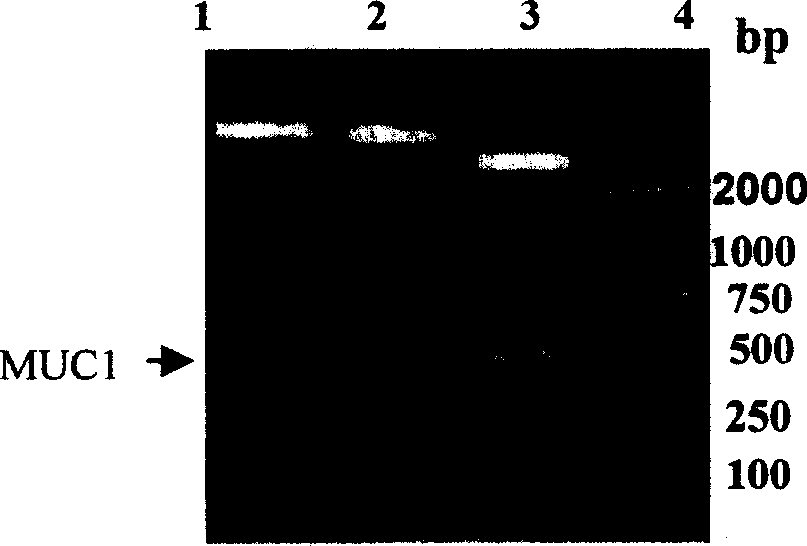

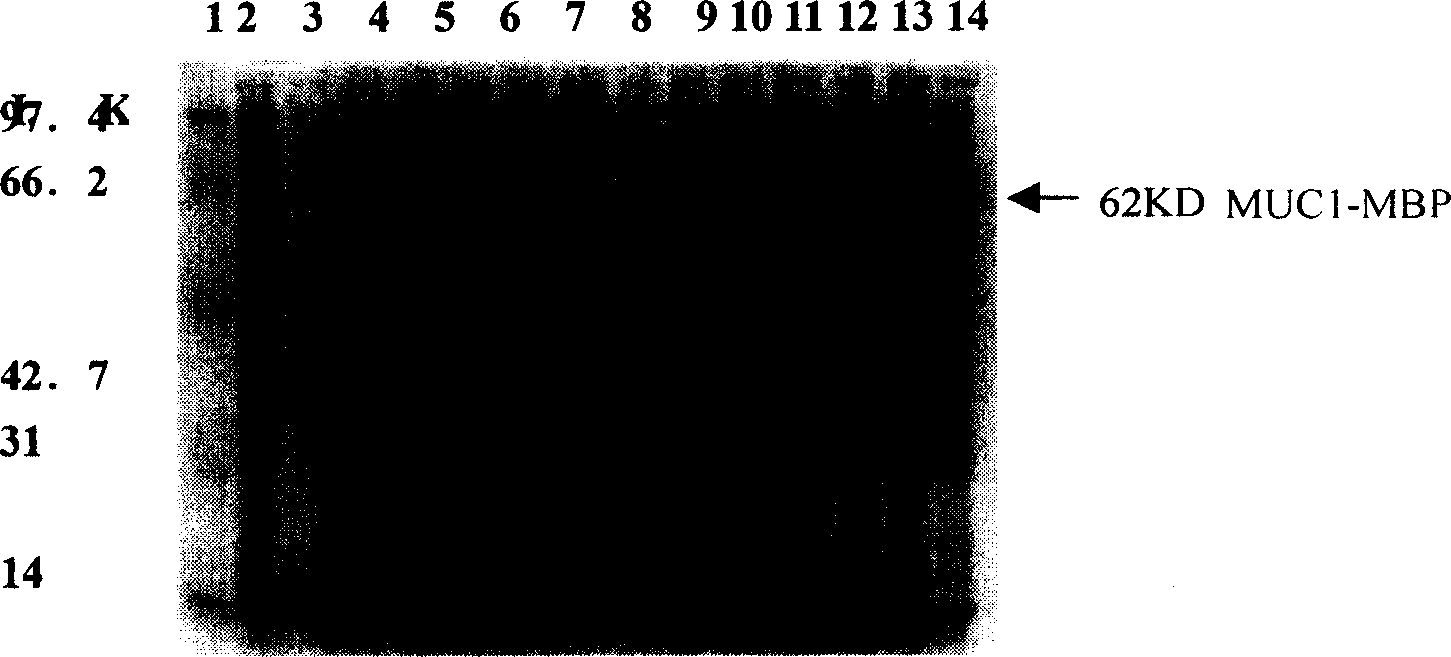

Recombination human Mucl-MBP fusion protein antitumour vaccine and production technology

InactiveCN1513556ATo achieve the purpose of anti-tumorLow costPeptide/protein ingredientsAntibody medical ingredientsEscherichia coliChemical synthesis

An anticancer vaccine of recombinant human MOC1-MBP fusion protein is disclosed, in which MBP is used as its adjuvant. The MBP gene and MUC1 gene are fused together. The MBP substituted for other fusion protein to induce CTL reaction. The pMAL-P2 is the carrier for effectively expressing maltose fusion protein. The serial repetitive sequence of MUC1 is inserted to downstream of malE gene.

Owner:台桂香

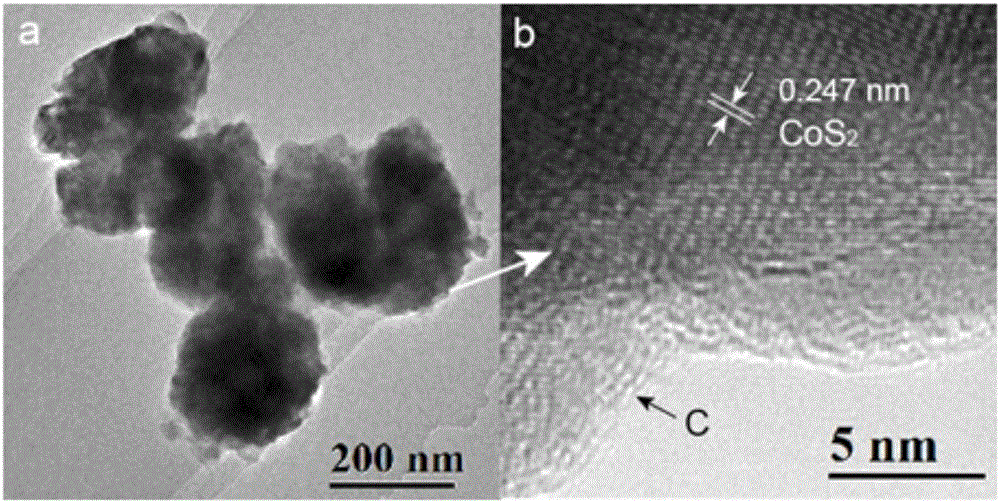

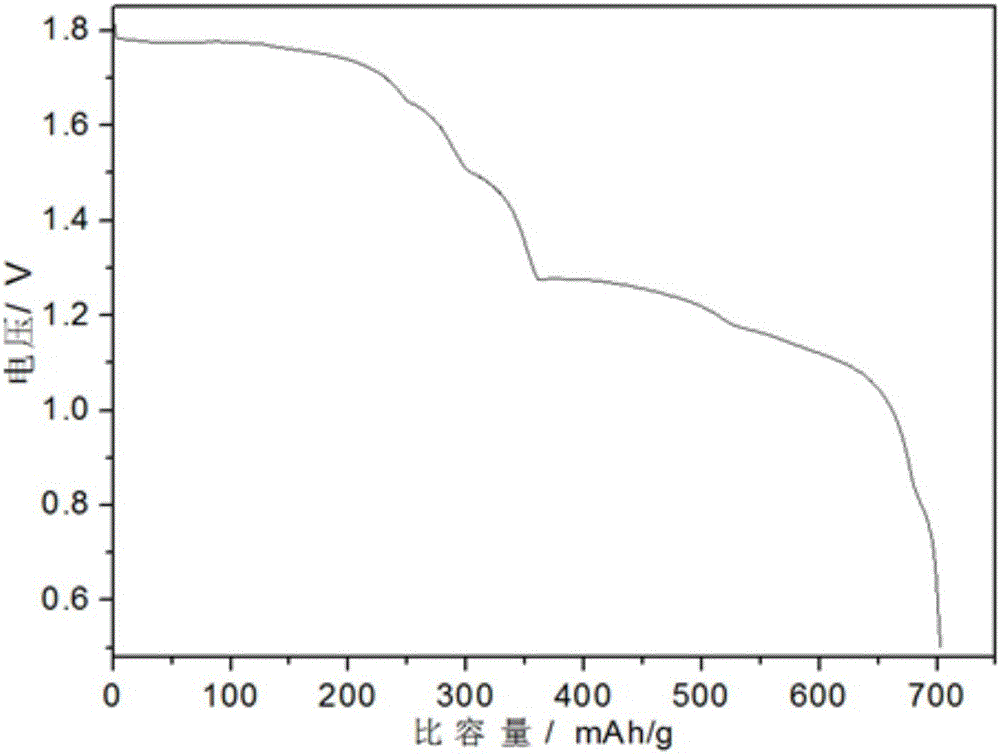

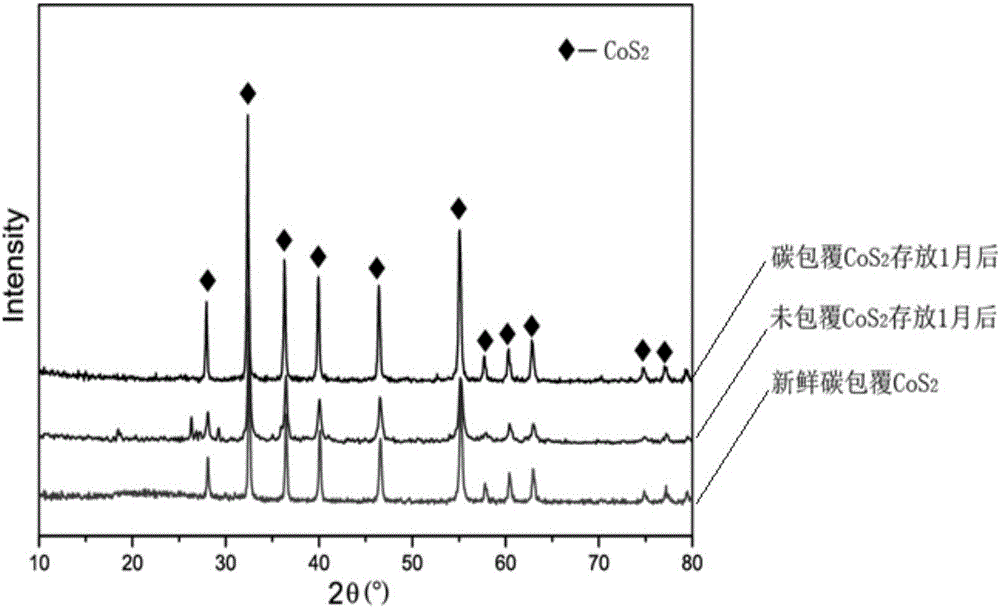

Carbon coated thermal battery electrode material and preparation method thereof

ActiveCN105870429ACorrosion resistantImprove air stabilityCell electrodesElectrical batteryThermal Battery

The invention belongs to the field of thermal batteries, and relate to a carbon coated thermal battery electrode material and a preparation method thereof. Glucose and other carbon sources are added in the process of preparing cobalt disulfide through a hydrothermal method, and the cobalt disulfide electrode material with a carbon coated structure is prepared in situ; the mass content of carbon in the obtained material relative to cobalt disulfide ranges from 1% to 25%. The electrode material has the advantages of being high in specific capacity, good in air stability, simple in preparation process, easy to prepare in a large scale and the like.

Owner:CHENGDU SCI & TECH DEV CENT CHINA ACAD OF ENG PHYSICS

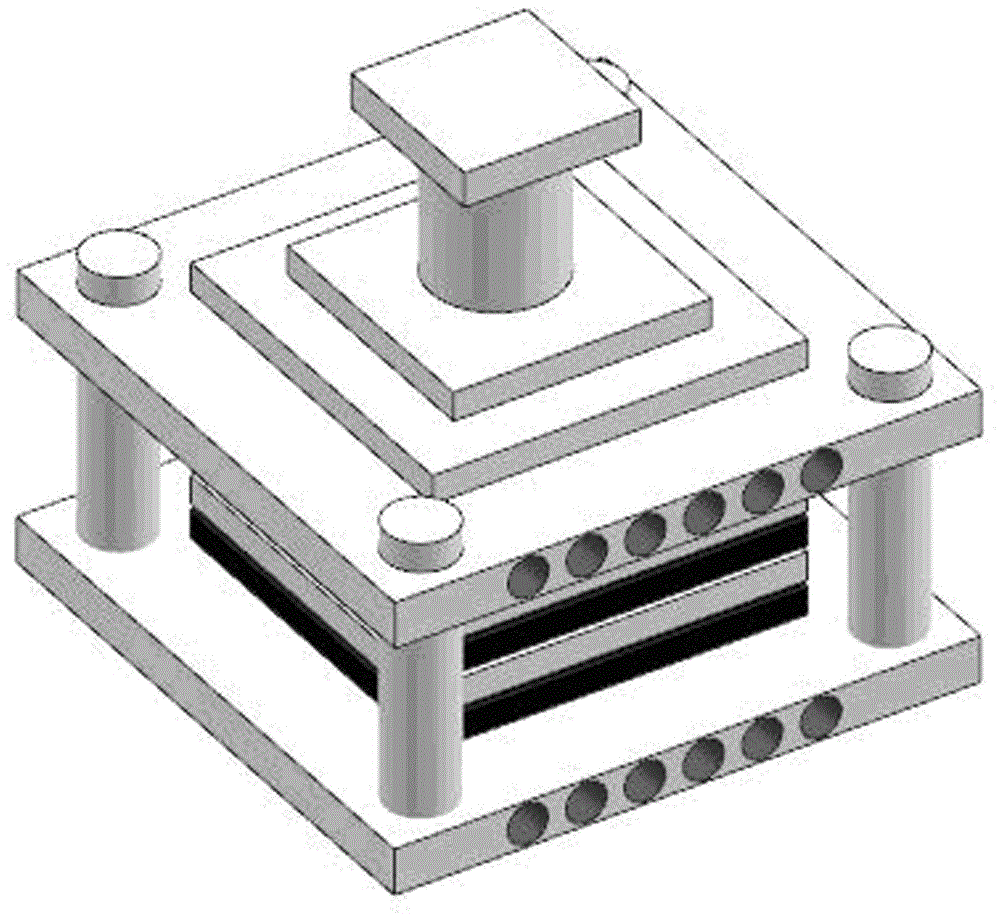

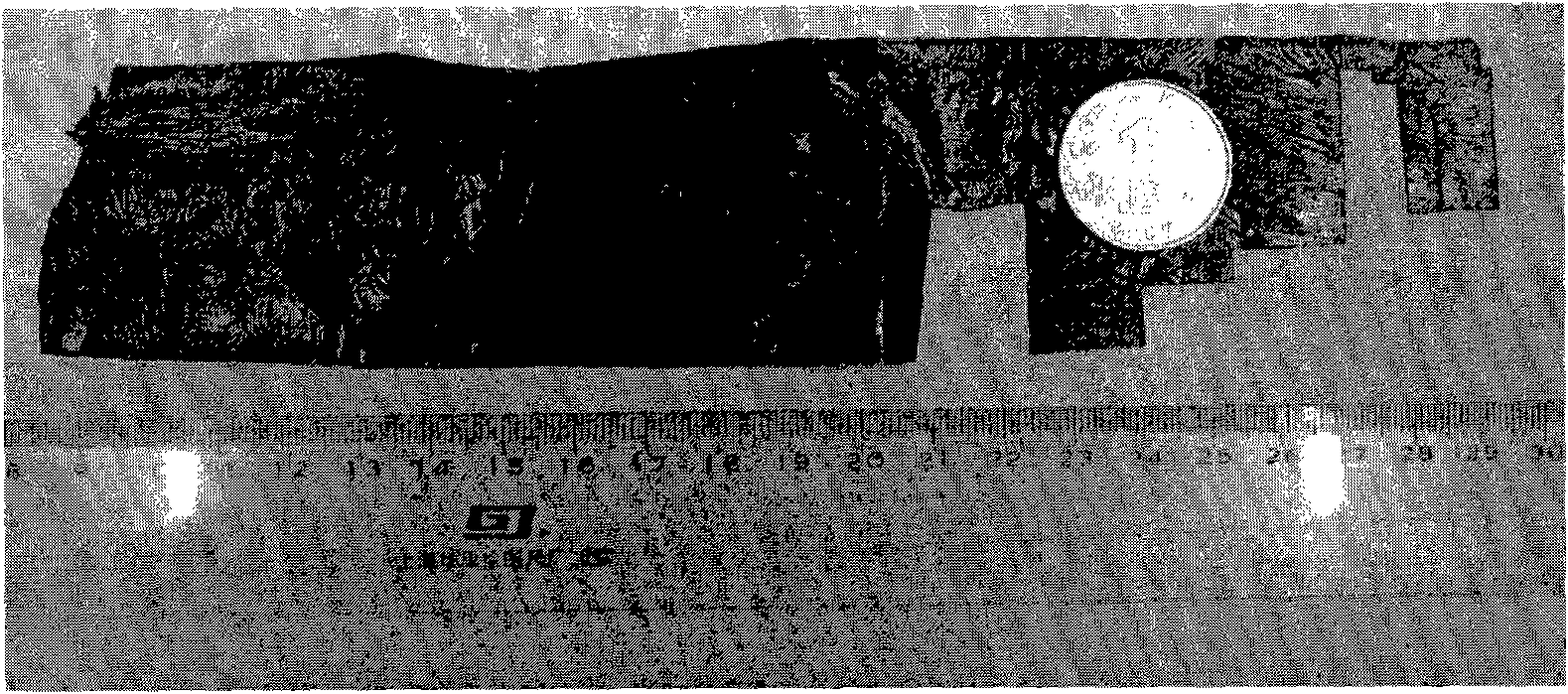

Method for preparing metal sealed intermetallic compound base lamination composite amour

The invention discloses a method for preparing a metal sealed intermetallic compound base lamination composite amour. The method comprises the following steps: (1) abrasive paper grinding and acetone ultrasonic cleaning surface treatment: a Ti foil and an Al foil are polished by an abrasive paper to remove surface impurities and oxide layers; and acetone is used for ultrasonically cleaning the Ti foil and the Al foil by 20 minutes for drying; (2) alternate lamination and rolling: a gap between rollers is adjusted, so that a sample alternately laminated by the Ti foil and the Al foil is rolled by two times for compaction, and is molded; (3) sealing and vacuumizing: the cold-rolled Ti foil and the Al foil are sealed by metal foils of 0.01 mm, and are vacuumized; and (4) sintering: the Ti foil and the Al foil are put in a hot pressing furnace for sintering after metal sealing, and are cooled along with a furnace. The method combines cold rolling, vacuum sealing and hot-pressed sintering to prepare the novel metal sealed intermetallic compound base lamination composite amour, and is unique in process circuit, simple, low in production cost and suitable for commercial production.

Owner:ZHONGBEI UNIV

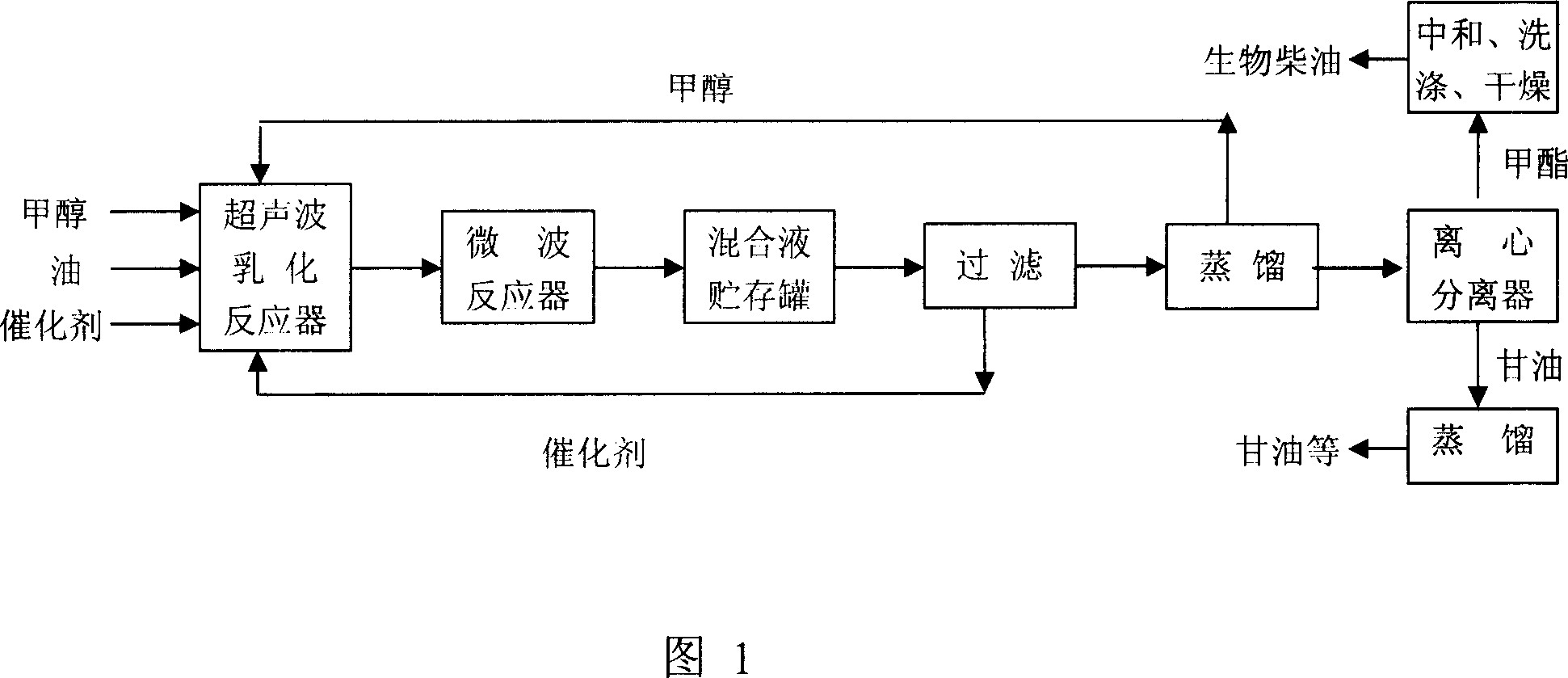

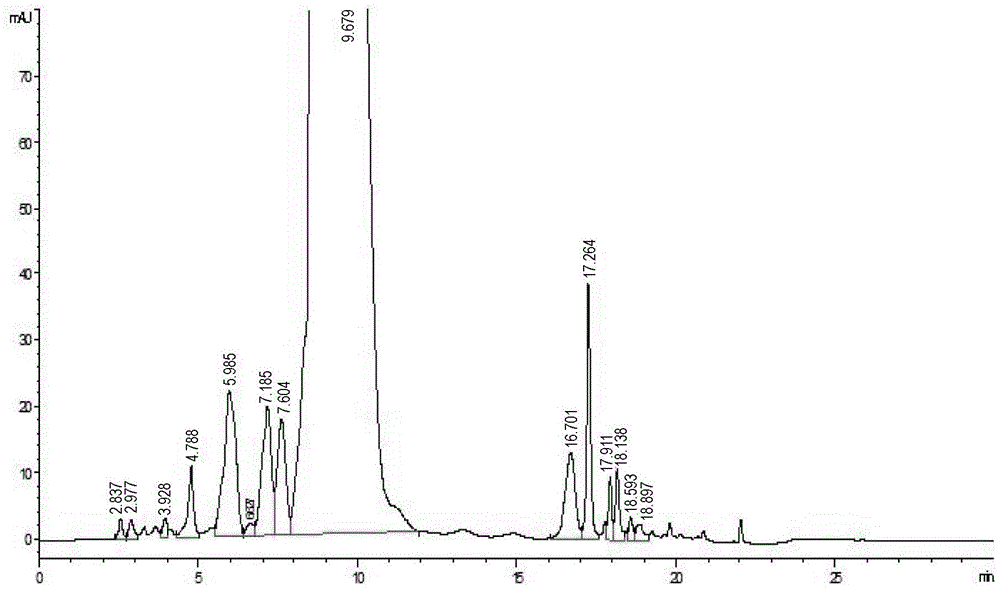

Method for preparing biodiesel by ultrasonic and microwave combination

InactiveCN1935947AImprove qualityNovel production processBiofuelsLiquid hydrocarbon mixture productionOil and greaseMicrowave

The invention relates to the method used ultrasonic wave and micro wave to prepare biological diesel oil. It includes the following steps: mixing the raw oil processed by depickling and dehydrating, methanol, and solid Lewis base catalyst; sending the mixture into ultrasonic wave emulsification reactor to process emulsification dispersion; then sending the mixture into micro wave reactor to process ester exchange; filtering the mixed liquor; processing centrifugal separation to divide the biological diesel oil from the glycerol; processing neutralizing, washing by water, drying, continuous vacuum distillation to gain high qualitative biological diesel oil. The invention is the method which uses animal and vegetable oils as raw material, adopts ultrasonic wave intensifying emulsifying dispersing technique and micro wave auxiliary energy providing to fast fit for commercialization product, reduce product cost and environment pollution.

Owner:NORTHWEST A & F UNIV

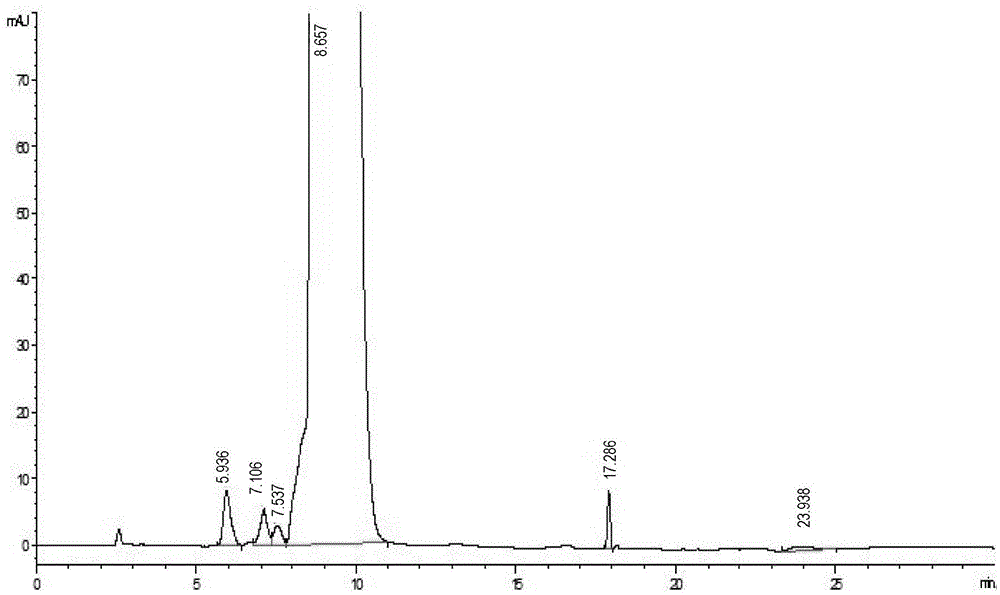

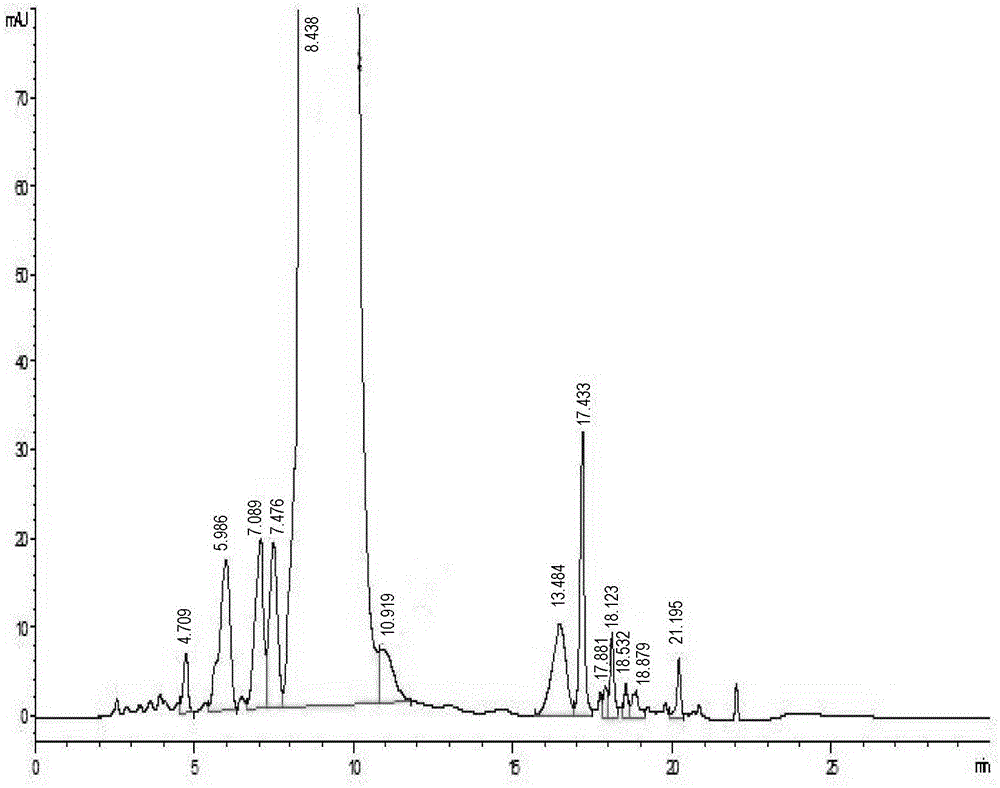

Separation and purification method of high-purity vancomycin hydrochloride

ActiveCN104610434AEasy to recycleColor Appearance EnhancementAntibacterial agentsSaccharide peptide ingredientsPurification methodsIon exchange

Provided is a separation and purification method for vancomycin hydrochloride of a high purity. The method comprises the following steps: (1) obtaining a vancomycin hydrochloride solution from a crude vancomycin product by ion exchange chromatography and obtaining a concentrate by nanofiltration desalination and concentration; (2) adjusting the concentrate with a hydrochloric acid solution and then performing a column chromatography using a reverse chromatography column for the adjusted concentrate; (3) collecting the chromatographic solution of vancomycin to obtain a mixed chromatographic solution; (4) adjusting the mixed chromatographic solution, and separating the solution and the salts by nanofiltration desalination and concentration to obtain a concentrate; and (5) obtaining a vancomycin dry powder with a chromatographic purity of up to 99% and a pure white appearance by dehydrating and drying the concentrate of step (4), or by solvent crystallization or salting-out crystallization.

Owner:ZHE JIANG MEDICINE CO LTD XINCHANG PHARMA FAB

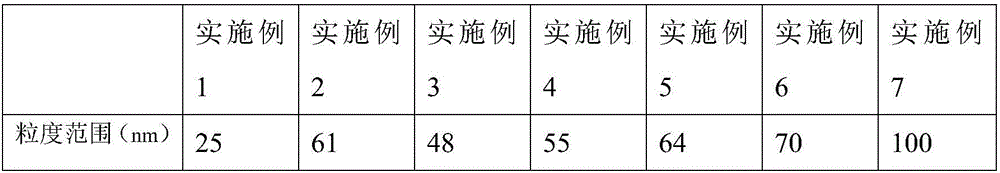

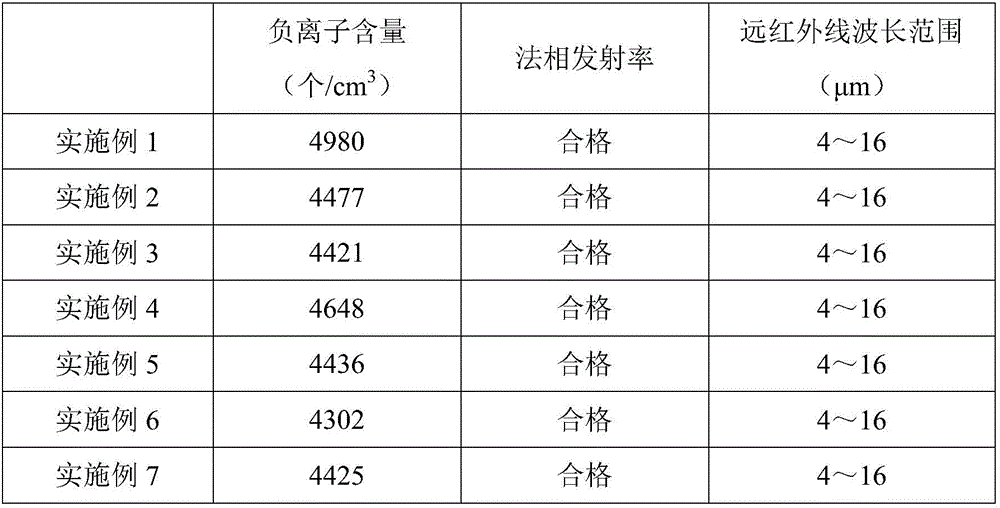

Negative ion far infrared nanometer multifunctional material

ActiveCN106726628AImprove the ability of ionized air to generate negative ionsImprove the ability to generate negative ionsCosmetic preparationsToilet preparationsInfraredAir Ionization

The invention provides a negative ion far infrared nanometer multifunctional material, which comprises the following ingredients in parts by weight: 1 to 86 parts of ore powder, 1 to 115 parts of rare earth powder and 1 to 200 parts of silica gel. The functional material provided by the invention has the advantages that on the basis of the prior art, the functional material capable of obviously improving the capability of generating negative ions of ore and rare-earth salts through air ionization is provided; on the other hand, the infrared ray releasing capability of the ore and the rare-earth salts can be obviously improved.

Owner:惠州市申天地生物科技有限公司

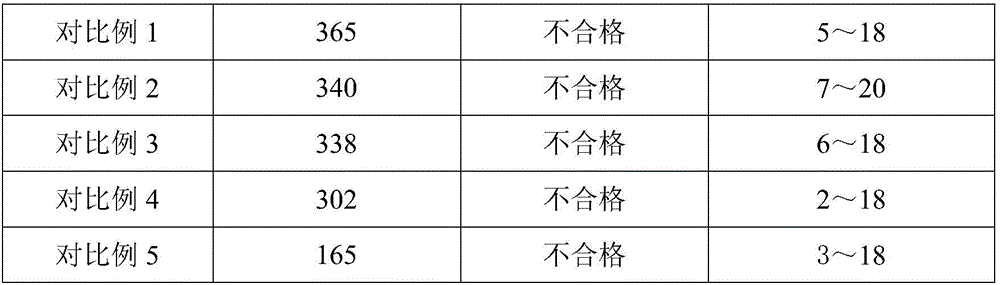

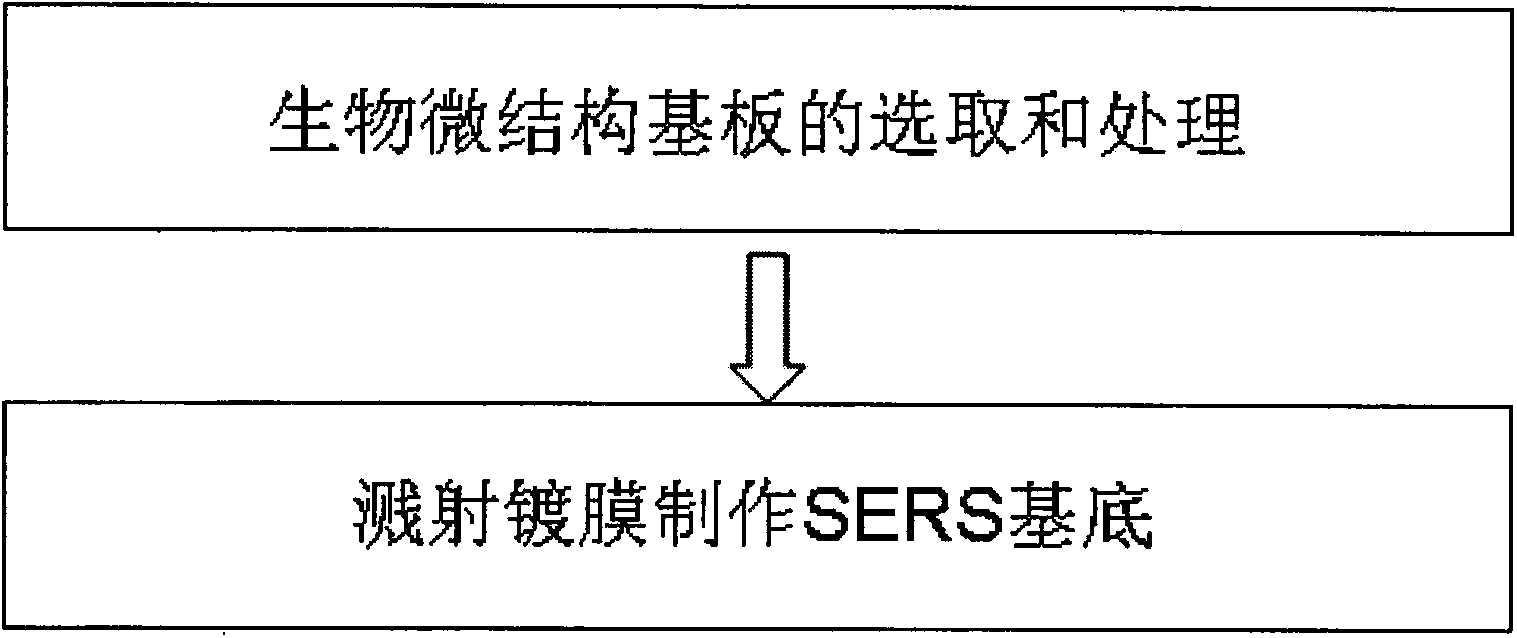

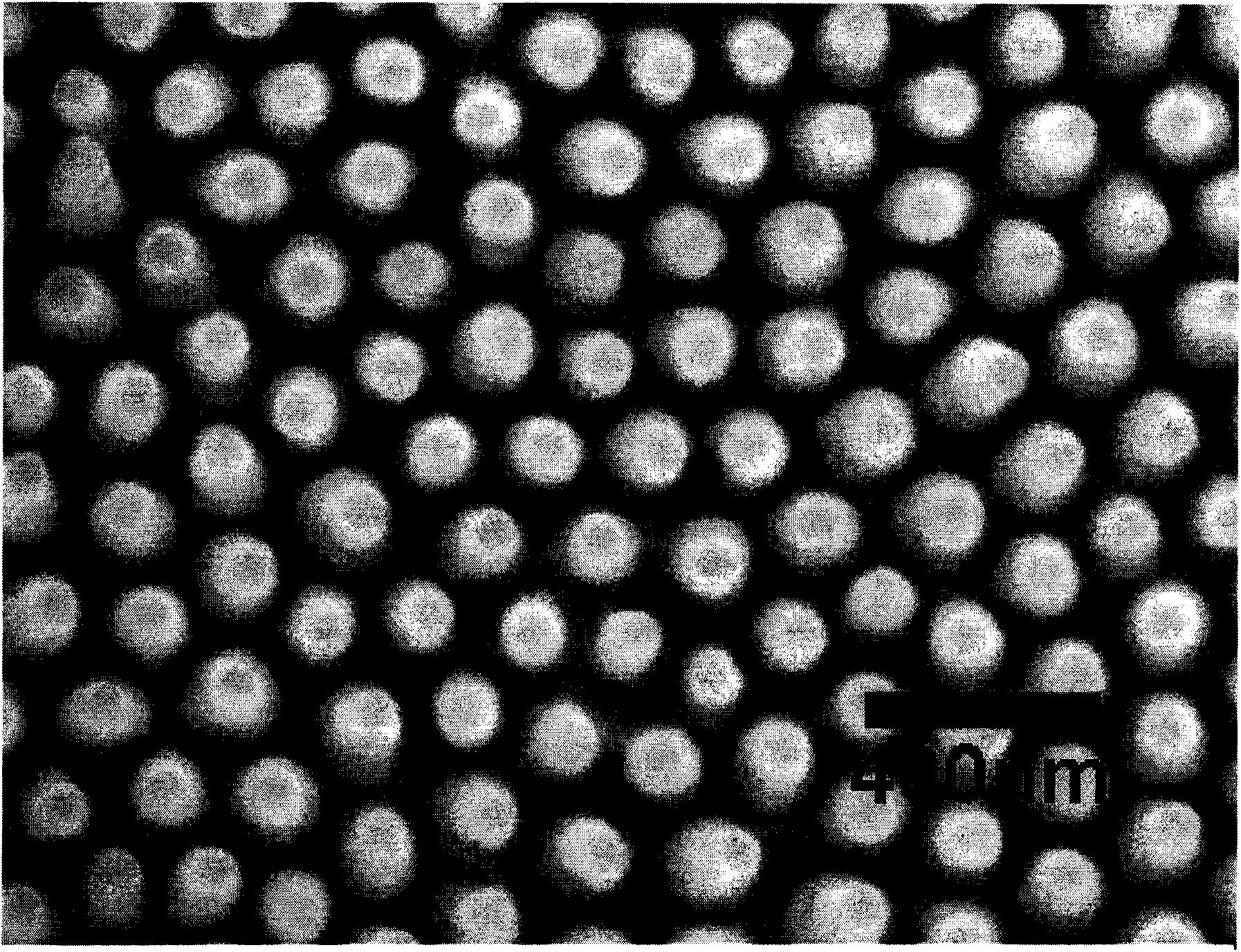

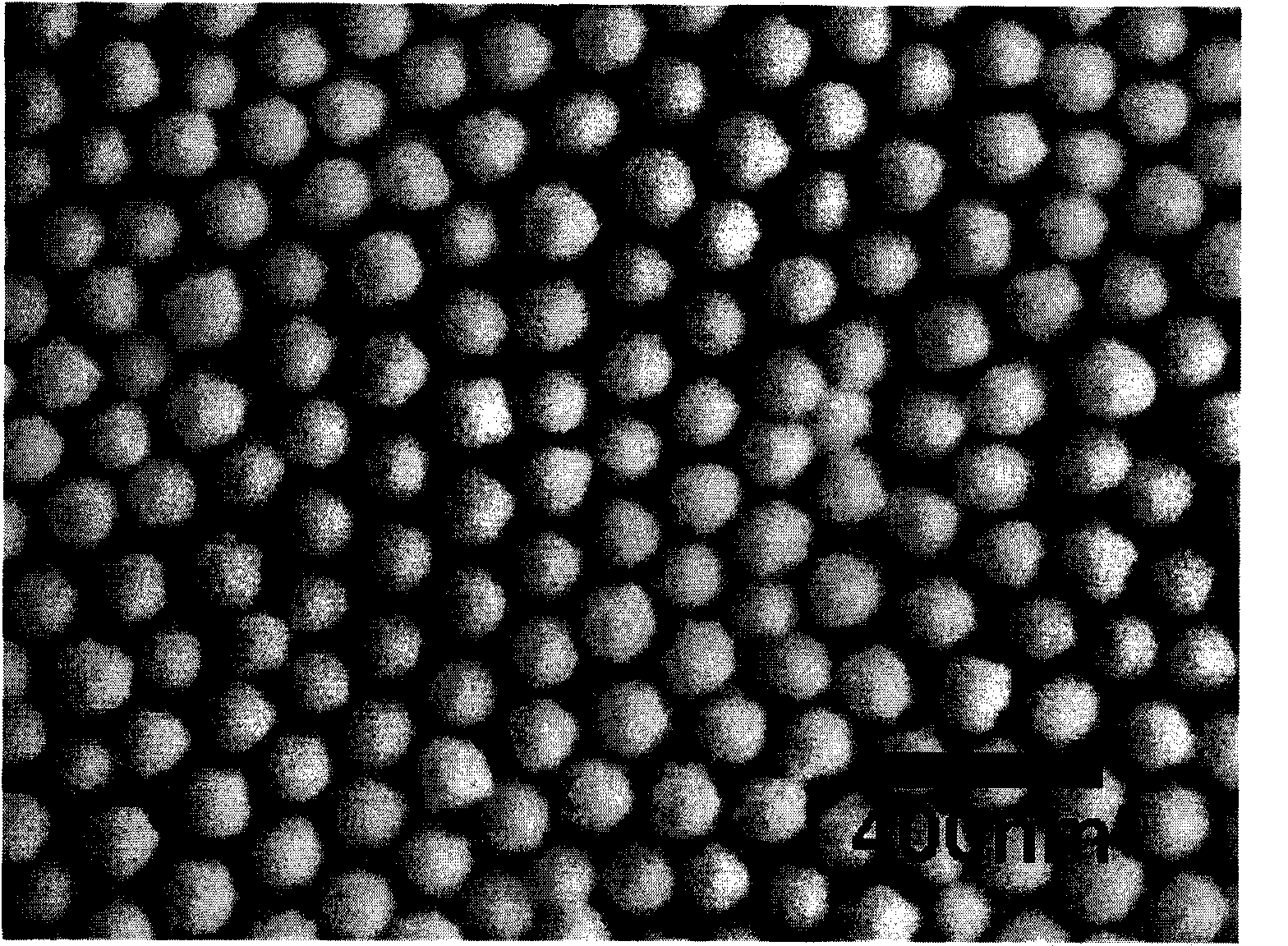

Method for manufacturing surface enhancement Raman scatting substrate

InactiveCN103361601ALow costSimple methodVacuum evaporation coatingSputtering coatingEnvironmental resistanceMicro nano

The invention discloses a method for manufacturing a surface enhancement Raman scatting (SERS) substrate having ultra high performance. The method comprises the steps: firstly, selecting a cicada wing, a butterfly wing, a scarlet macaw feather or other biological micro structures as a basal plate, and simply cleaning, drying and shaping the biological micro structure basal plate; and then plating gold, silver or other precious metals on the biological micro structure basal plate by magnetron sputtering or ion beam sputtering or other precise film plating methods to produce the SERS substrate. The gap size of a micro-nano structure is precisely controlled by controlling the thickness of the plating film, and the micro-nano gap size can be controlled to be less than 10 nm. The manufactured SERS substrate has the outstanding advantages of large area, low cost, uniformity, environmental protection, ultra sensitivity, precisely controllable gap and the like. The environmental protection material is selected as the basal plate, the quite simple, mature and low-cost method is used for manufacturing the high performance SERS substrate which meets the needs of practical applications and theoretical researches, so that a powerful tool and a solid foundation are provided for the theoretical researches and the practical applications of an SERS effect.

Owner:NANKAI UNIV

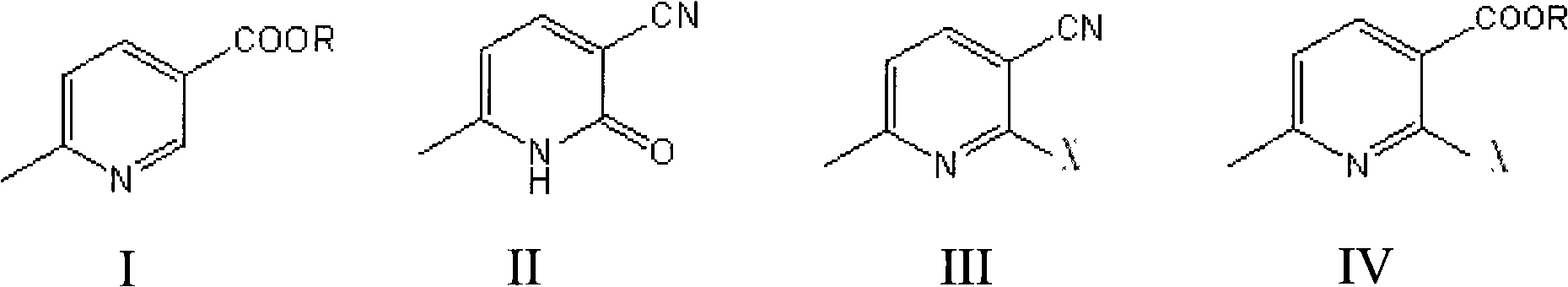

Method for preparing 6-methylnicotinic acid etoricoxib intermediate and ester thereof

The invention relates to a method for preparing 6-methylnicotinic acid etoricoxib intermediate and an ester thereof. The preparation method comprises halogenations, hydrolysis reaction and reducing dehalogenation. The method of the invention is simple in production process and mild in reaction conditions and is suitable for commercial production.

Owner:SHANGHAI HISOAR PHARMA TECH & DEV CO LTD +1

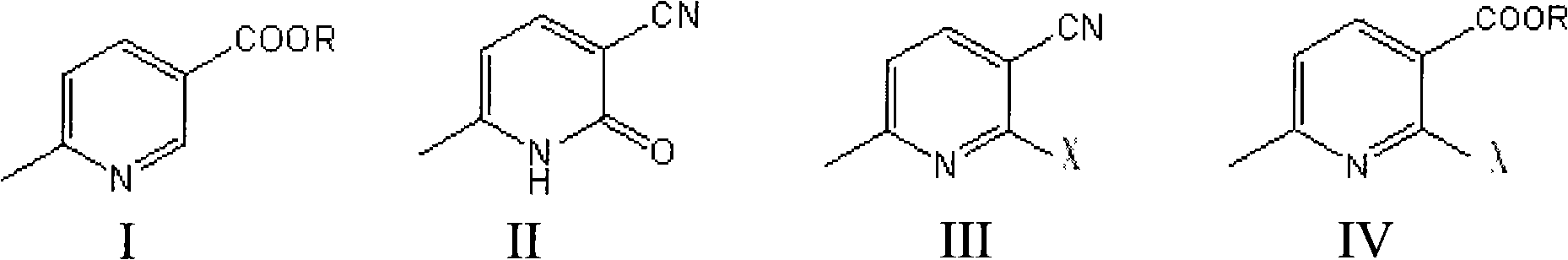

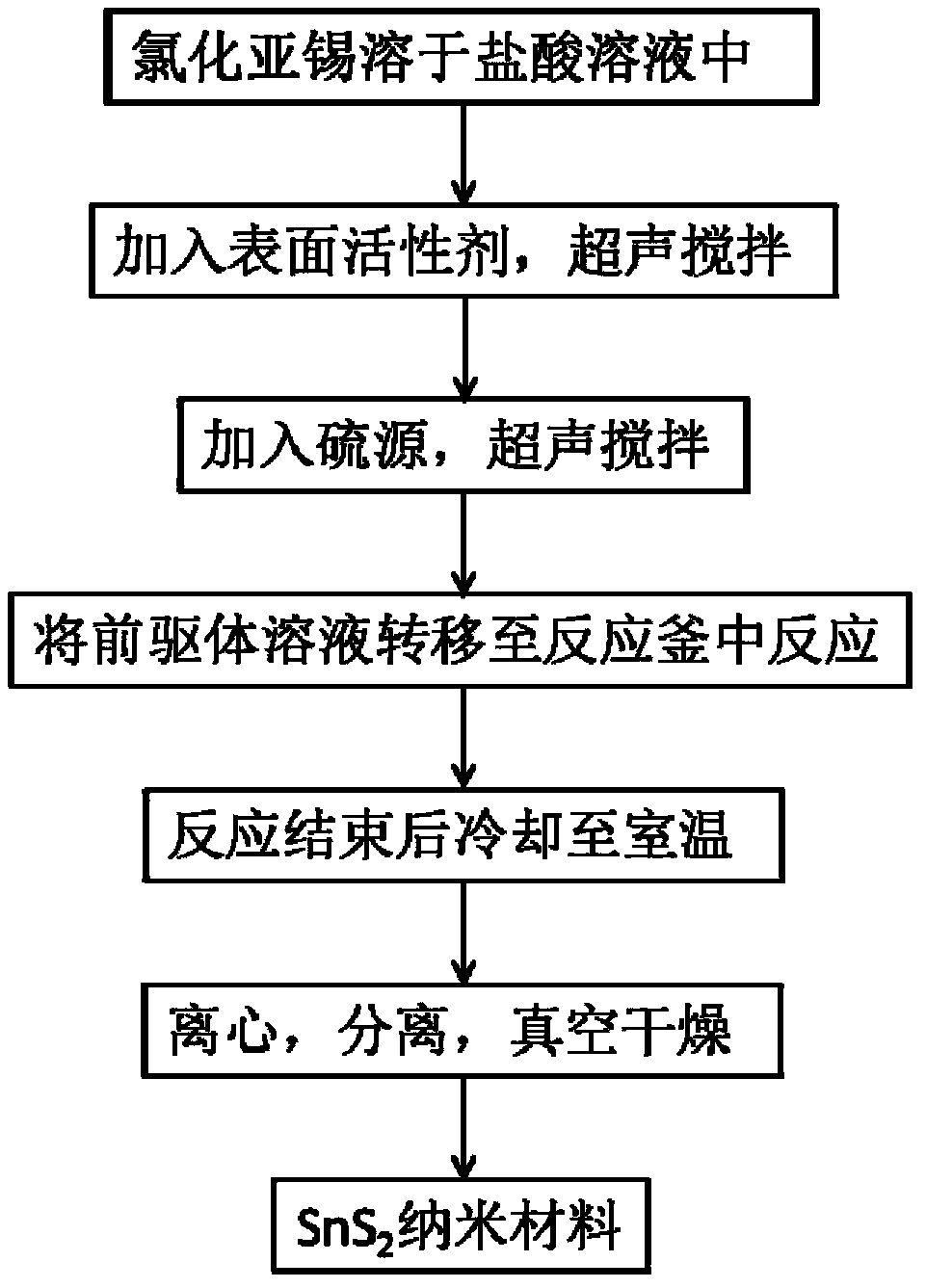

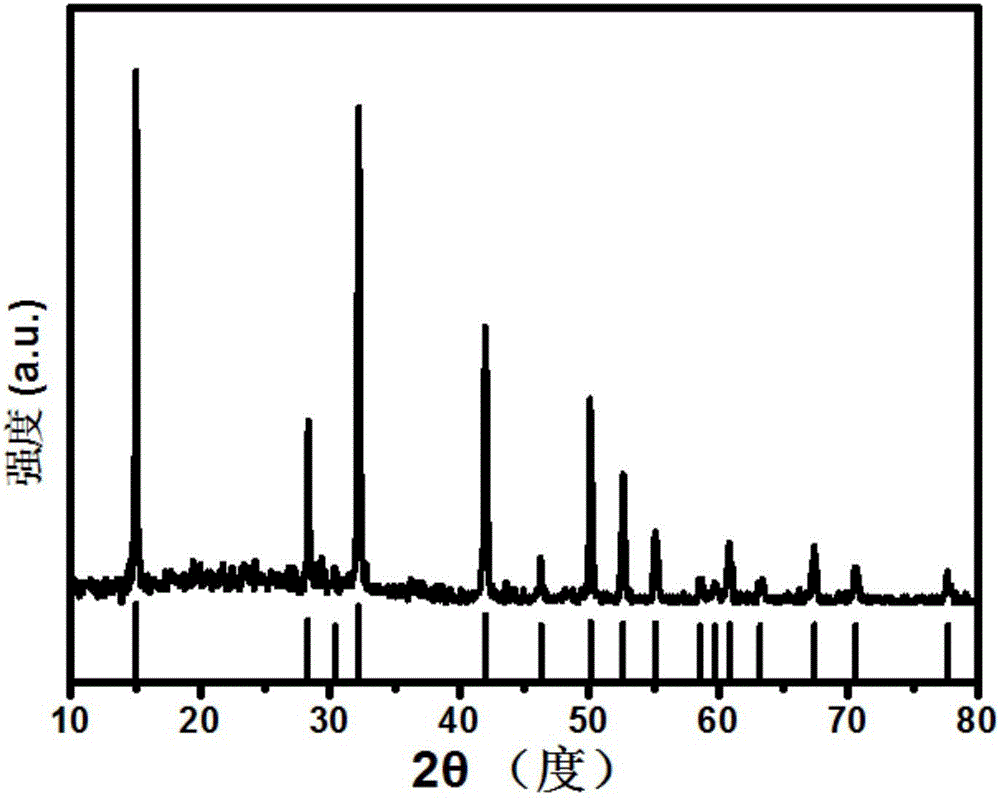

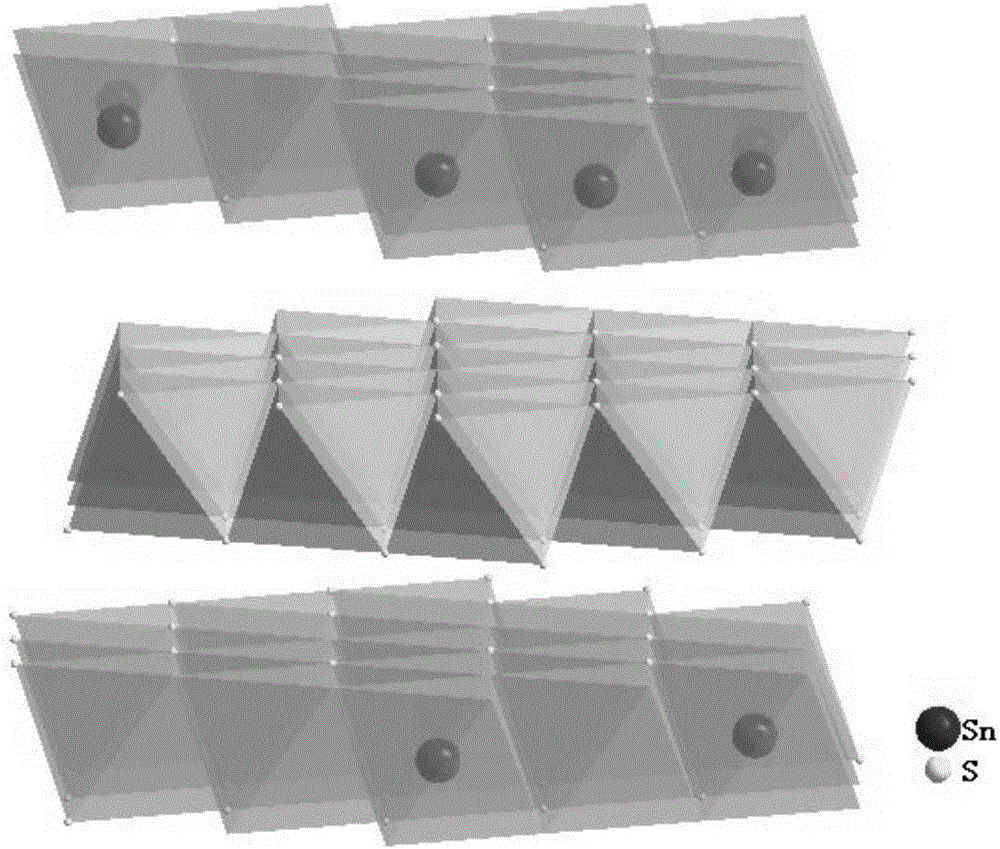

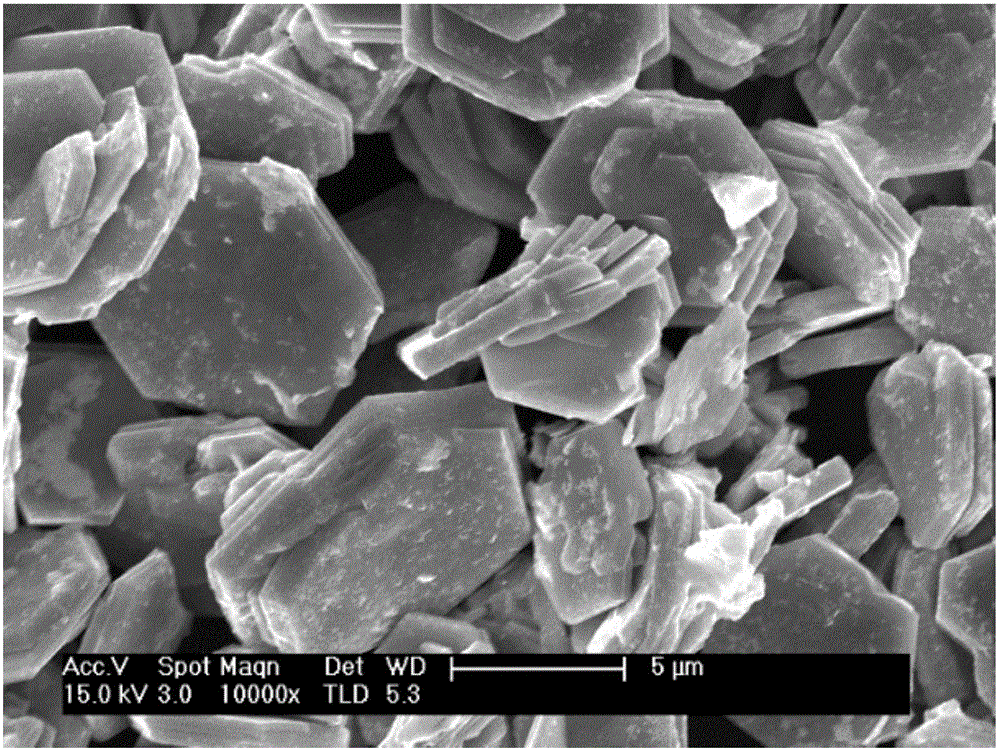

Method for hydrothermal synthesis of SnS2 nano-materials

ActiveCN103373742AGood size controlSmall sizeMaterial nanotechnologyTin compoundsSulfurHydrothermal synthesis

The invention discloses a method for hydrothermal synthesis of SnS2 nano-materials. The method comprises the following steps of: taking SnCl2.2H2O as a Sn source, performing hydrothermal synthesis reaction with a sulfur source under the auxiliary function of a surfactant, and regulating and controlling the type and using quantity of the surfactant as well as the time and temperature of the hydrothermal synthesis reaction to obtain the SnS2 nano-materials with different appearances and sizes. Compared with the prior art, the method disclosed by the invention adopts a hydrothermal method to synthesize the SnS2 nano-materials, the process is simple, and the SnS2 nano-materials with different appearances and sizes can be obtained by regulating and controlling the type and using quantity of the surfactant, the reaction time, the temperature and other conditions; and furthermore, the cost is low, and the method is suitable for commercial production.

Owner:SHANGHAI JIAO TONG UNIV

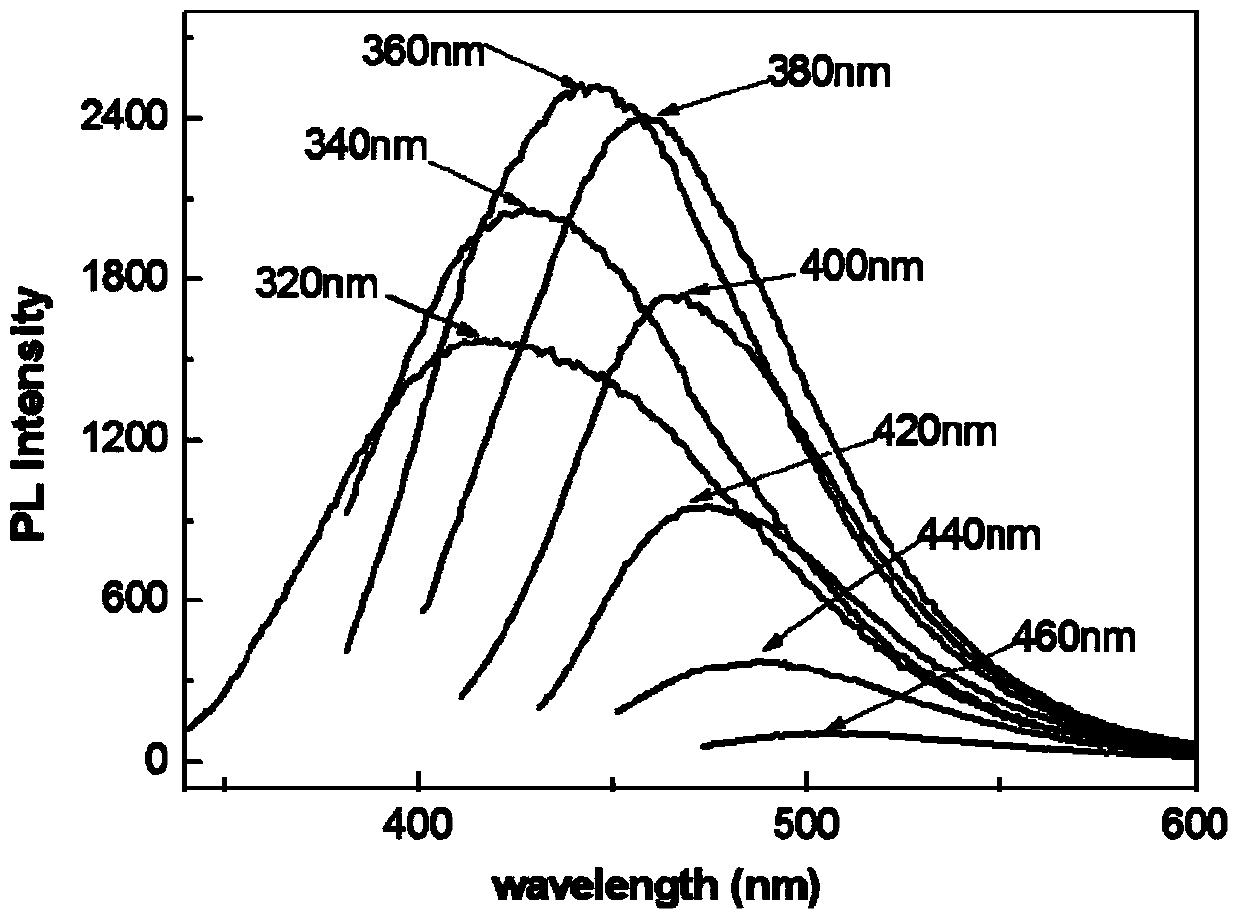

Simple and quick preparation method of nitrogen-doped carbon quantum dots

ActiveCN104059644AReduce processing costsMethod conditions are easy to meetLuminescent compositionsAlcoholOrganic matter

The invention provides a simple and quick preparation method of nitrogen-doped carbon quantum dots. The method comprises the following step: performing high-temperature treatment on an alcohol amine organic matter or a mixture of the alcohol amine organic matter and an oxidant. According to the method, raw materials are conventional materials, that is to say, the process cost is low and the method conditions are easily met; the alcohol amine organic matter is directly pyrolyzed to obtain the nitrogen-doped carbon quantum dots, and the process is very simple and quick; the method is short in process time, high in yield, very simple to operate, low in cost, capable of producing the nitrogen-doped carbon quantum dots on a large scale and obtaining the size-controllable nitrogen-doped carbon quantum dots, and suitable for commercialized production.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing SnS2 hexagonal nanosheets by hydrothermal process

The invention discloses a method for preparing SnS2 hexagonal nanosheets by a hydrothermal process. The method comprises the following steps: sequentially adding a reactant precursor sulfur compound, soluble tin salt, strong alkali and deionized water into a reaction kettle, stirring at room temperature until the reactants are dissolved, sealing the reaction kettle, putting the sealed reaction kettle into a vacuum drying oven, reacting at 180-240 DEG C for 12 hours-10 days, and naturally cooling to room temperature; and finally, washing the separated precipitate to obtain the SnS2 hexagonal nanosheets. The method is simple to operate, and has no requirements for equipment. Various solvents are environment-friendly, so no high-toxicity substance is generated; and the method is low in cost, and is suitable for commercial production.

Owner:SHANGHAI INST OF TECH

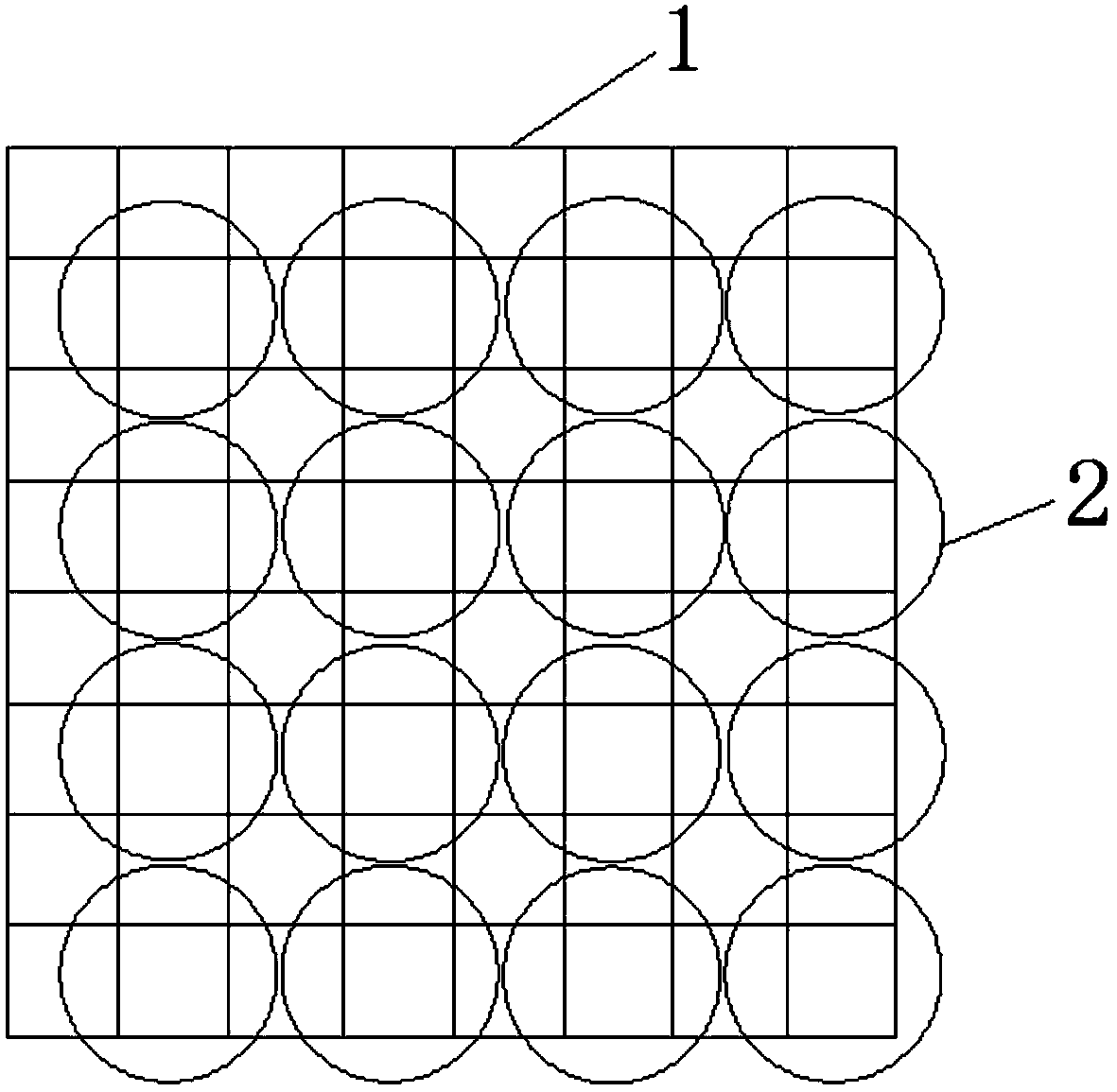

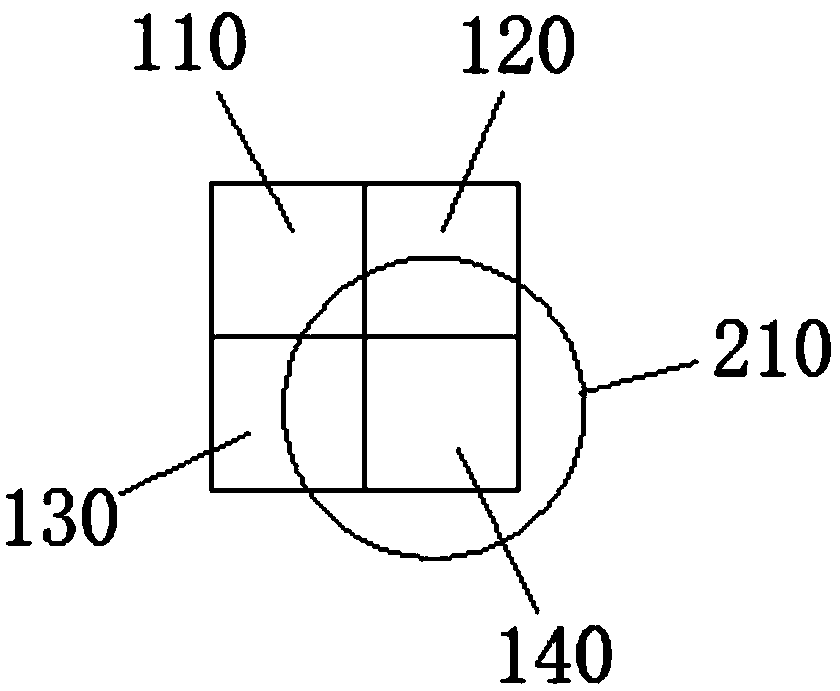

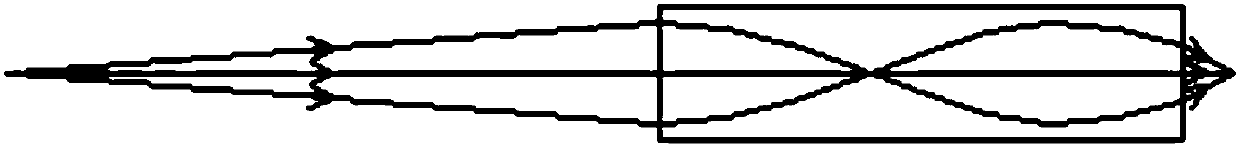

Self-focusing lens array for fingerprint identification and mobile terminal

InactiveCN107728240AReduce manufacturing costSmall conjugate distanceCharacter and pattern recognitionLensComputer scienceSelf-focusing

The invention discloses a self-focusing lens array for fingerprint identification and a mobile terminal. The self-focusing lens array is disposed below a pixel layer, and is formed by a plurality of self-focusing lenses which have erected real images and whose magnifying power is 1. Each self-focusing lens adopts the gap between pixel elements of the pixel layer as a clear aperture. The inventionis advantageous in that with the self-focusing lens array, the conjugate distance of the object image can be smaller than 7mm, system length can be greatly reduced, and the appearance of the mobile terminal and other functions will not be affected; the imaging process of the whole system can be completed only through the array, no other lens assistance is required, and mounting and adjusting process can be saved; the array area can meet the demand of the size of the mobile terminal screen, which means that imaging can be conducted on every part of the screen; the integral producing cost of thearray is not high, and the array is suitable for commercial production.

Owner:苏州端景光电仪器有限公司

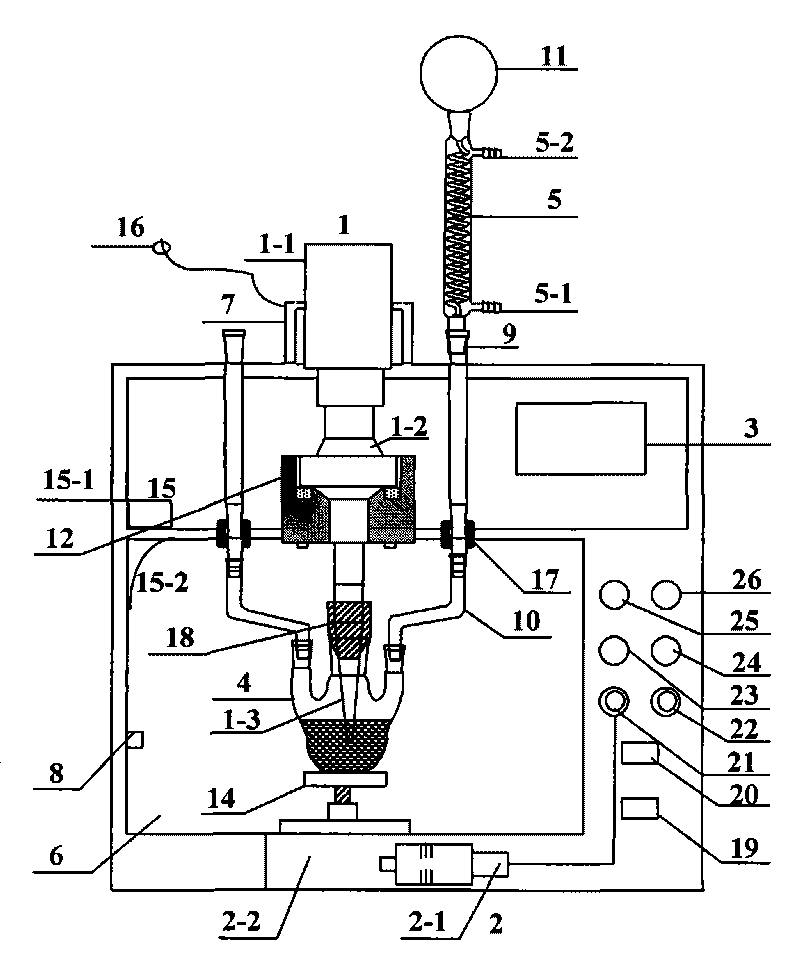

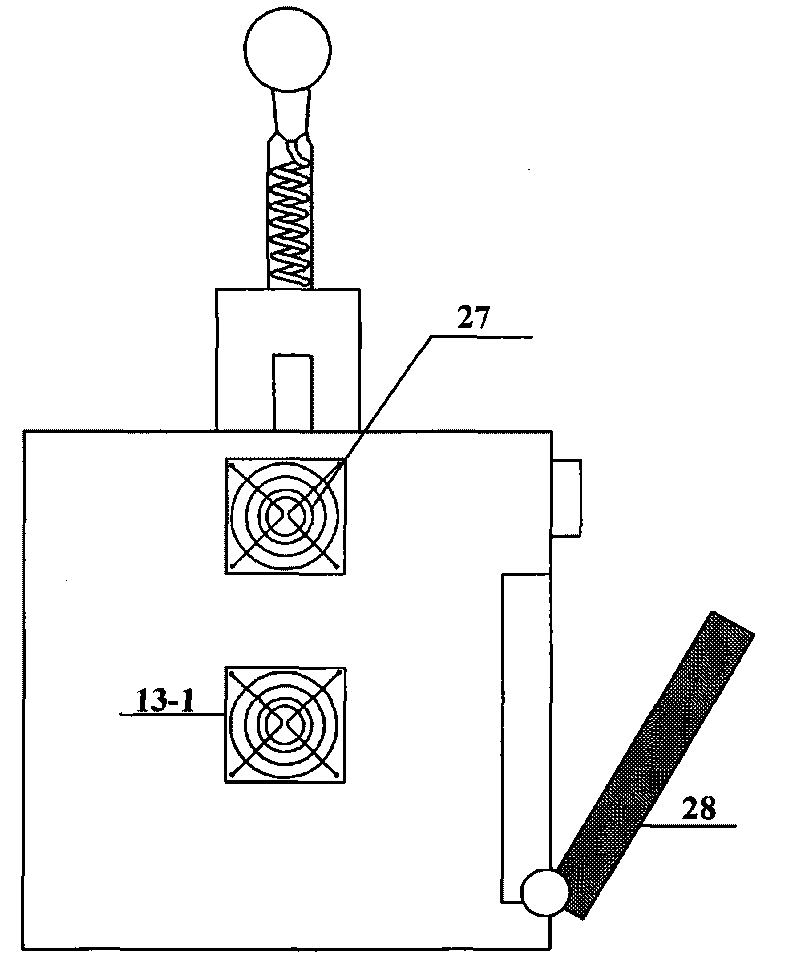

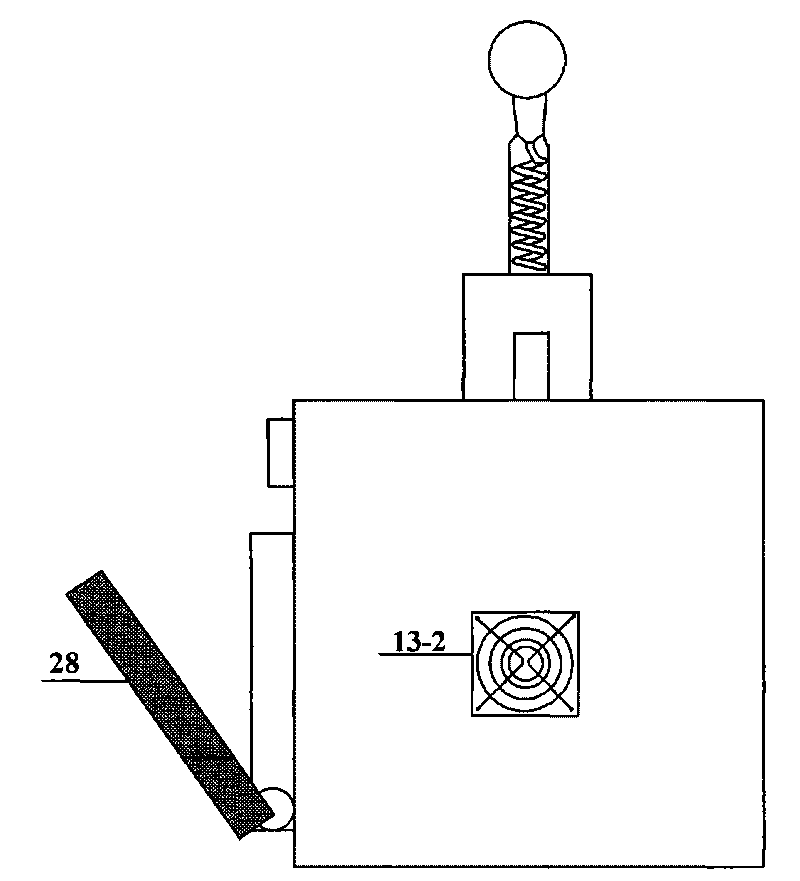

Multifunctional ultrasonic microwave collaborative chemical reactor and method for preparing nano semiconductor chalcogenide by using same

InactiveCN101711970AImprove sealingQuality improvementSulfide/polysulfide preparationEnergy based chemical/physical/physico-chemical processesChemical industryMicrowave shielding

The invention discloses a multifunctional ultrasonic microwave collaborative chemical reactor and a method for preparing a nano semiconductor chalcogenide by using the same. The multifunctional ultrasonic microwave collaborative chemical reactor comprises an ultrasonic generator, a microwave generator, a temperature / time / power display control device, a reaction vessel, a condensing device, a microwave resonator, a microwave shielding device, an air exhausting and air feeding device, and a reaction vessel supporting and lifting device. The chemical reactor has the advantages of uniform vibration, consistent action stressed by all the points in a sample medium, many varieties of selectable extraction solvents, wide range of targets, reduction of the binding force of the targets and sample substrates; accelerated process of the targets from solid phase to solvent phase, large processed sample amount and the like. The chemical reactor can overcome the phenomenon of overheat charring, and can obtain more uniform and better-quality products than single microwave reaction. The chemical reactor has wide application prospect in the fields of chemistry and chemical industry, pharmacy, materials, energy sources, food processing and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

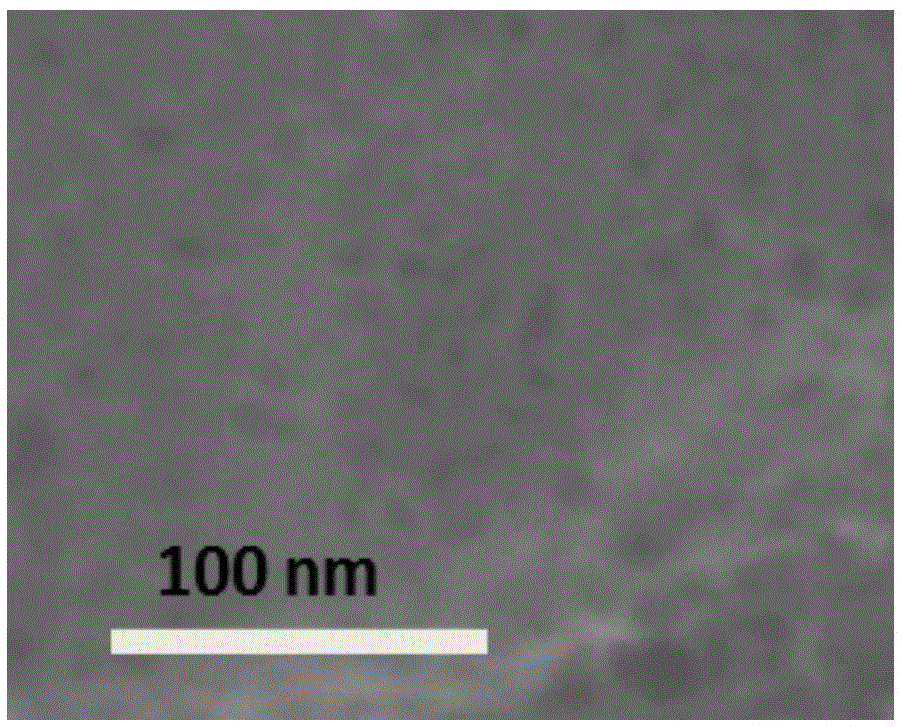

Nitrogen-doped porous graphite and preparation method thereof

InactiveCN105621406AReduce processing costsMethod conditions are easy to meetCarbon layerPorous graphene

The invention discloses nitrogen-doped porous graphite and a preparation method thereof. The preparation method comprises the following steps of conducting low temperature heat treatment on a mixed aqueous solution of nitrate and a carbon source, so that a metal oxide hard template-thin carbon layer precursor is formed; conducting graphitization on the obtained metal oxide hard template-thin carbon layer precursor, so that the nitrogen-doped porous graphite is obtained. According to the method, raw materials are conventional materials, process cost is low, and conditions of the method are easy to meet; the novel template method is adopted for directly pyrolyzing saccharides organic matter, so that the nitrogen-doped porous graphite is obtained, and the process is quite simple and fast; the nitrogen-doped porous graphite is quite simple in operation, low in cost, high in yield and capable of being produced on a large scale, the less-layer porous graphite which has abundant surface pores, narrow in pore size distribution and high in specific surface area can be obtained, and the nitrogen-doped porous graphite and the preparation method thereof are applicable to such fields as supercapacitors, fuel-cell catalysts, electrocatalysis, lithium batteries, adsorption and gas separation.

Owner:SHANGHAI JIAO TONG UNIV

Electrochemical catalyst for oxygen evolution reaction and preparation and application of electrochemical catalyst

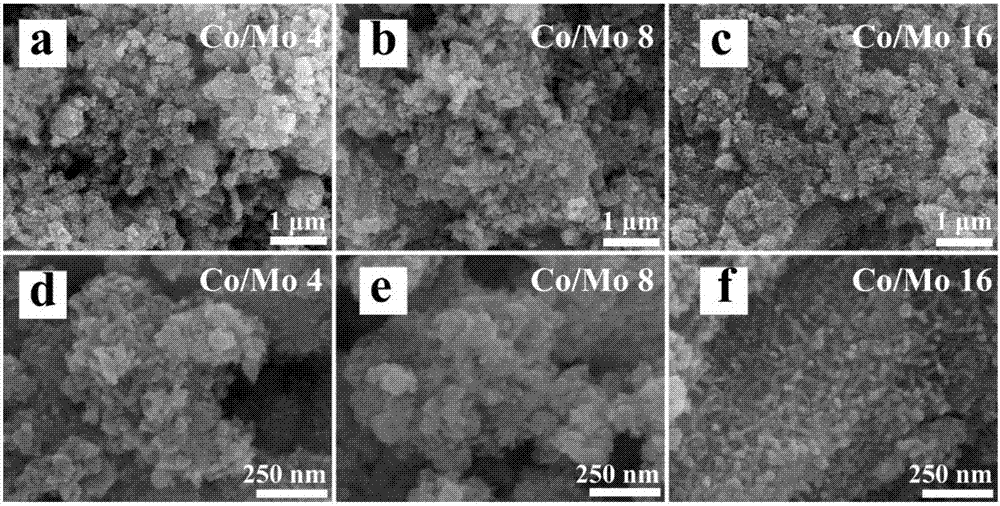

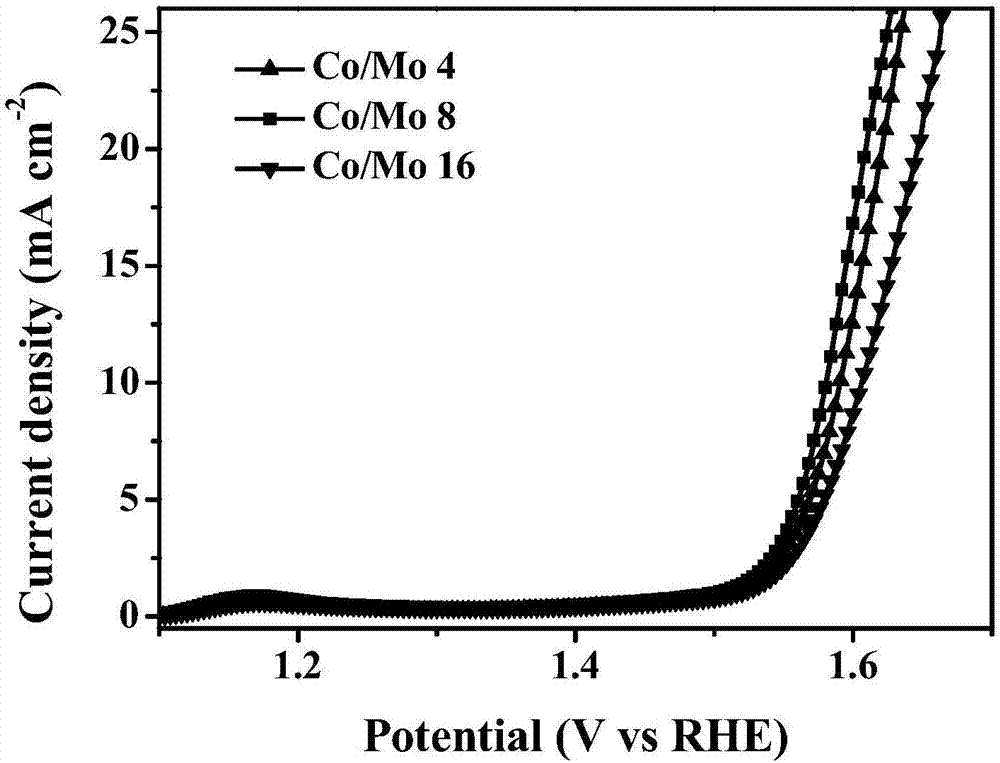

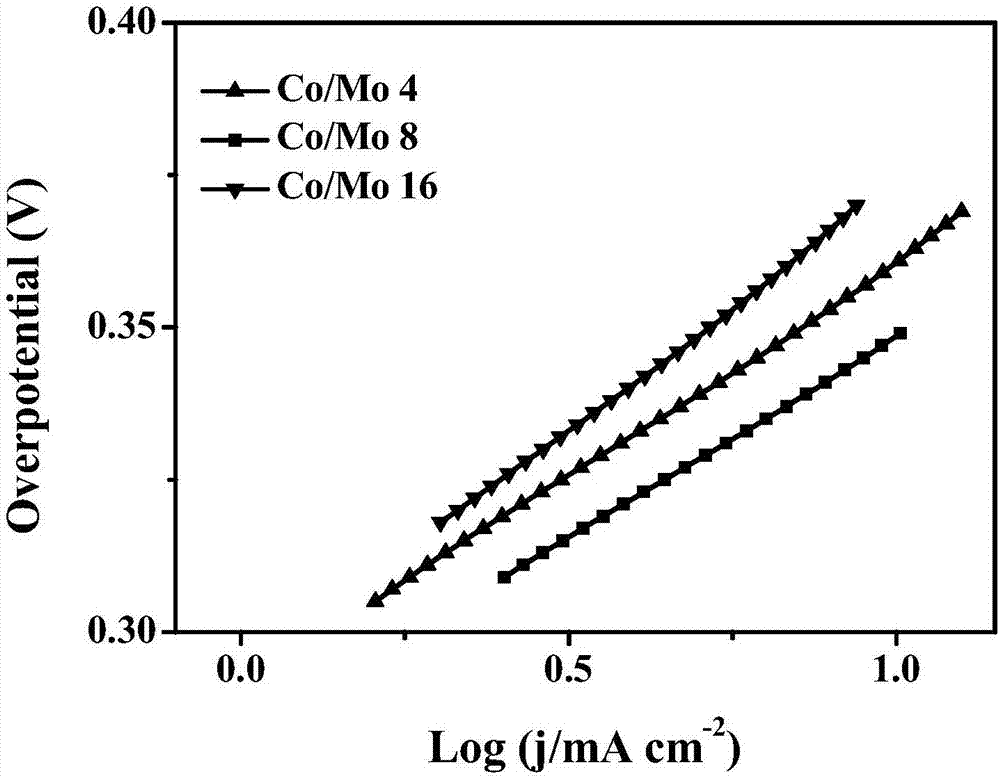

InactiveCN107308958AExcellent catalytic electrochemical oxygen evolution reaction effectImprove the efficiency of electrochemical water splittingPhysical/chemical process catalystsElectrodesHydrazine compoundPotassium hydroxide

The invention provides a preparation method of an electrochemical catalyst for oxygen evolution reaction. The preparation method includes: 1) adding cobalt salt and a nonionic surfactant polymer into water, mixing with stirring uniformly, adding a hydrazine hydrate, and incubating under a hydrothermal condition to obtain lamellar cobalt hydroxide, 2) adding the obtained lamellar cobalt hydroxide and thiomolybdate into N,N-dimethyl formamide, mixing by ultrasonic dispersion, and pyrolyzing the thiomolybdate under a solvothermal condition to obtain a non-amorphous-phase molybdenum sulfide layer on the surface of a lamellar base. The invention further provides the electrochemical catalyst for oxygen evolution reaction and application of the electrochemical catalyst. The preparation method has the advantages that the prepared cobalt-molybdenum compound material in an alkaline solution of potassium hydroxide has an excellent effect in catalyzing electrochemical oxygen evolution reaction, electrochemical water splitting efficiency can be improved effectively, and by adopting a hydrothermal method and a solvothermal method to prepare the catalysts, the preparation method is simple and easy to implement and high in controllability.

Owner:CAPITAL NORMAL UNIVERSITY

HA/TiO2 layer on surface of titanium alloy and preparation method thereof

InactiveCN103908699AMaintain biological activityHigh bonding strengthElectrolytic inorganic material coatingSurface reaction electrolytic coatingMicro arc oxidationPlasma electrolytic oxidation

The invention provides an HA / TiO2 layer on the surface of a titanium alloy. The binding strength of the HA / TiO2 layer and a titanium alloy substrate is 15-28MPa. The HA / TiO2 layer is characterized by comprising a porous TiO2 layer wrapped on the surface of the titanium alloy and an HA layer growing on the TiO2 layer. The invention further provides a method of preparing the HA / TiO2 layer on the surface of the titanium alloy. The method is characterized by comprising the following steps: S1, preparing a micro-arc oxidation treatment solution; S2, carrying out micro-arc oxidation treatment; S3, preparing an electrochemical deposition solution; S4, carrying out electrochemical deposition. The HA / TiO2 layer on the surface of the titanium alloy and the titanium alloy substrate have high binding strength which satisfies the demand on medical application. The preparation method of the HA / TiO2 layer comprises the following steps: firstly, forming a calcium and phosphorus-containing porous TiO2 layer on the surface of the titanium alloy by virtue of the micro-arc oxidation method; then, preparing the HA layer on the surface of the TiO2 layer by the electrochemical deposition method. The HA biological active coating is high in binding strength with the substrate, fast in growing speed and suitable for commercial production.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

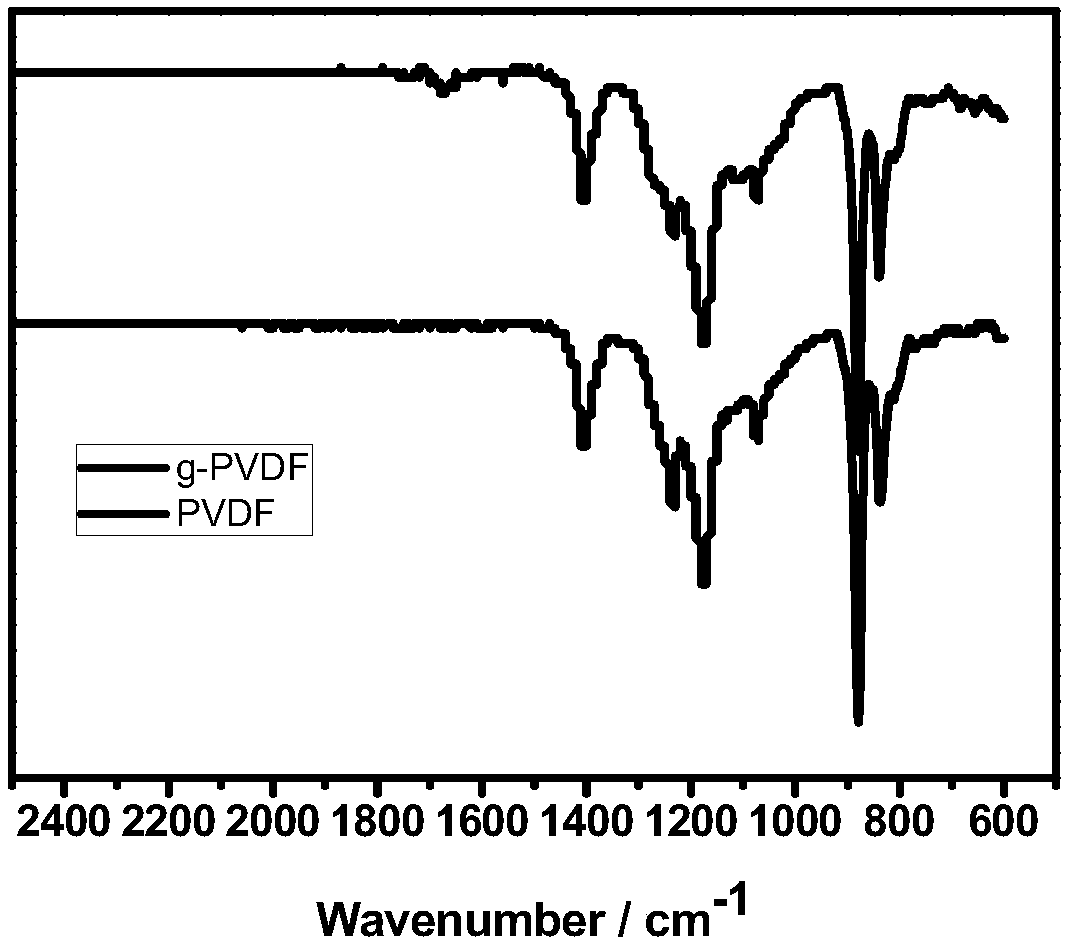

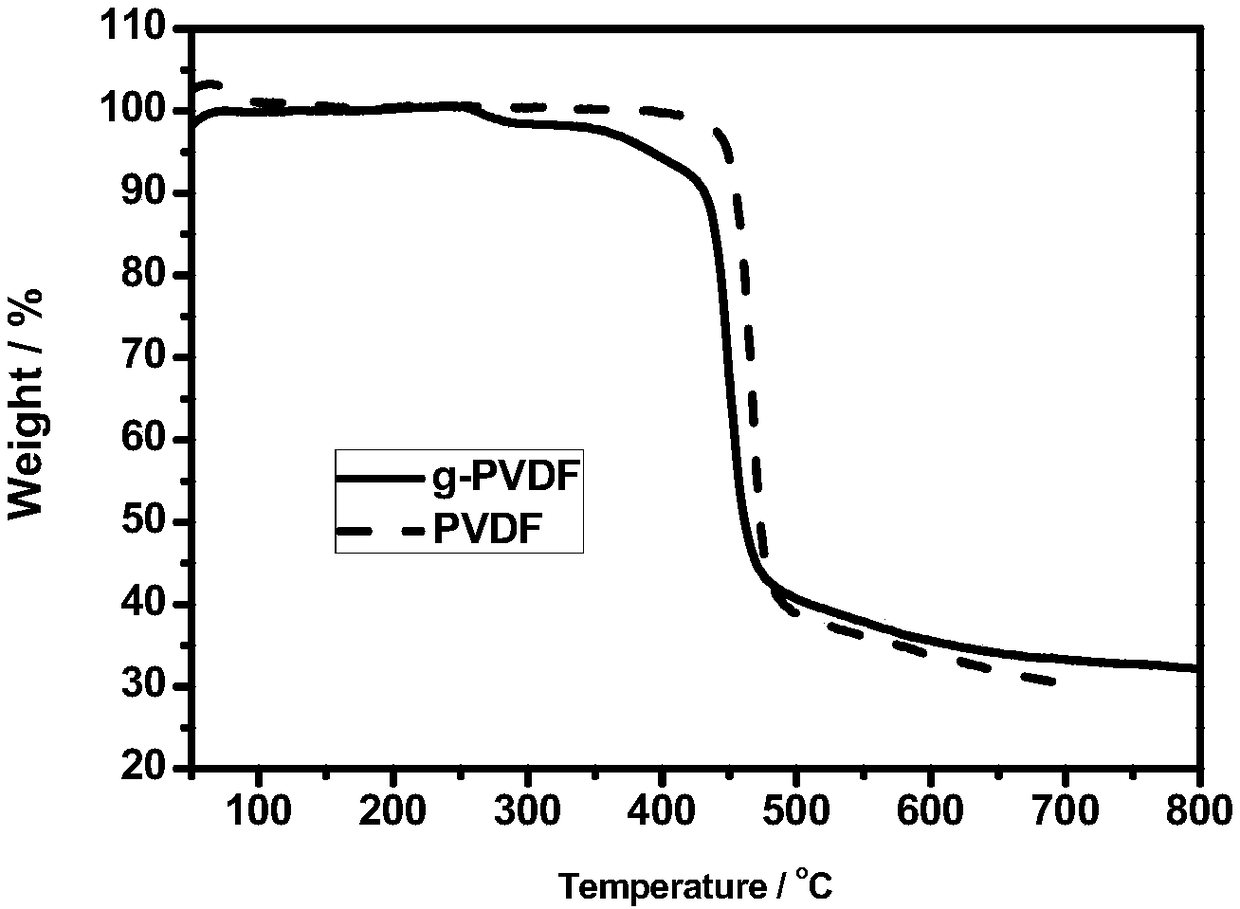

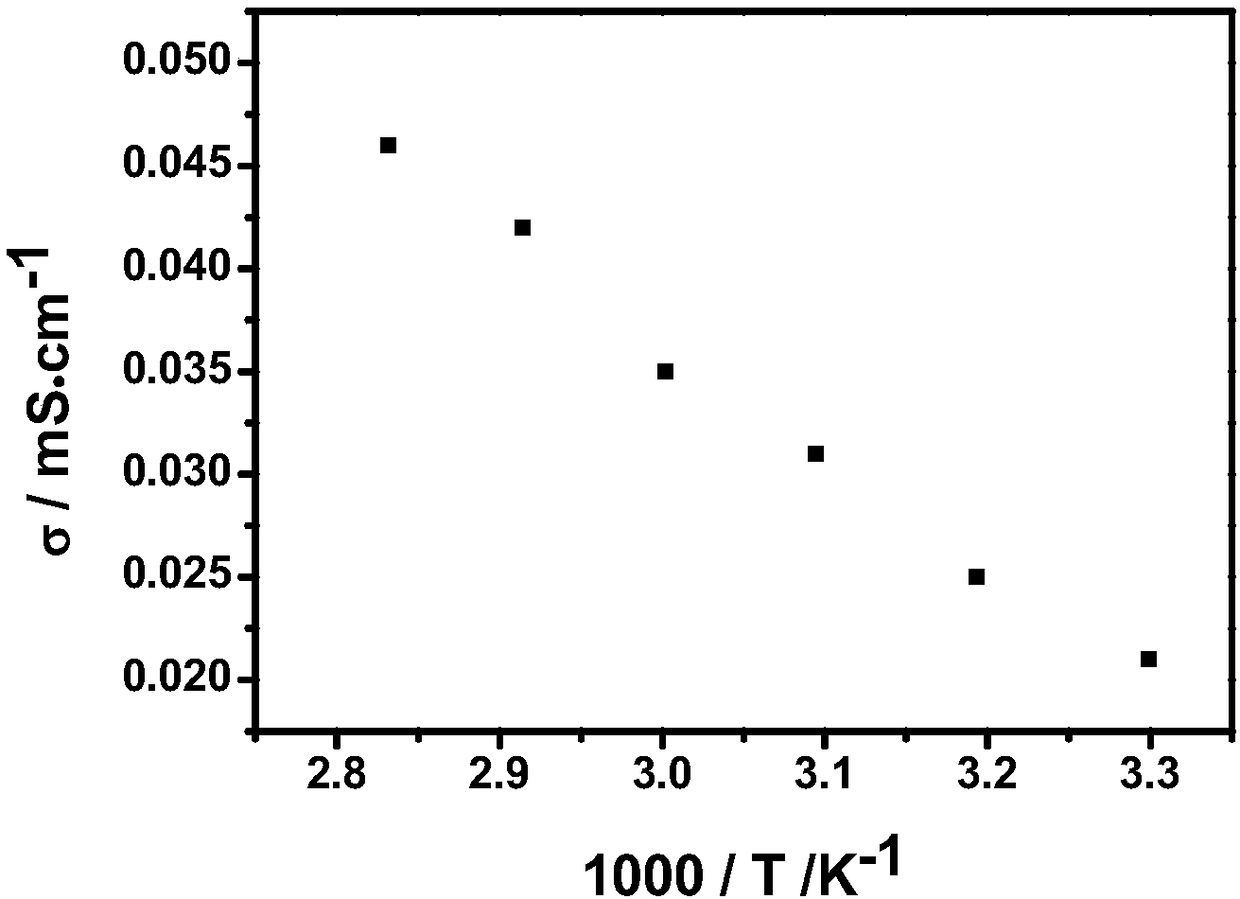

Novel single ion polymer electrolyte and preparation method and application thereof

The invention discloses a novel single ion polymer electrolyte and a preparation method and an application of the novel single ion polymer electrolyte. A radiation grafting method is used to synchronously graft two functional monomers on a powder substrate, wherein one monomer is a fluorine-containing monomer, and the other grafted monomer is a monomer comprising a lithium salt ion pair. The powder substrate is selected, the proportion of the monomers is regulated through the radiation grafting method without adding an initiator or a catalyst, and an evenly grafted pure double-monomer graftingmembrane is conveniently obtained. The grafting membrane is applied to a lithium ion battery, the lithium salt is not additionally added, only a small quantity of plasticizer is needed, and the grafting membrane has a prominent electrochemical performance. Meanwhile, the grafting membrane has the advantages of heat stability, size stability and mechanical property. The method is novel and effective, is simple, is low in cost and strong in operability, and is quite suitable for commercial production.

Owner:XIAMEN UNIV

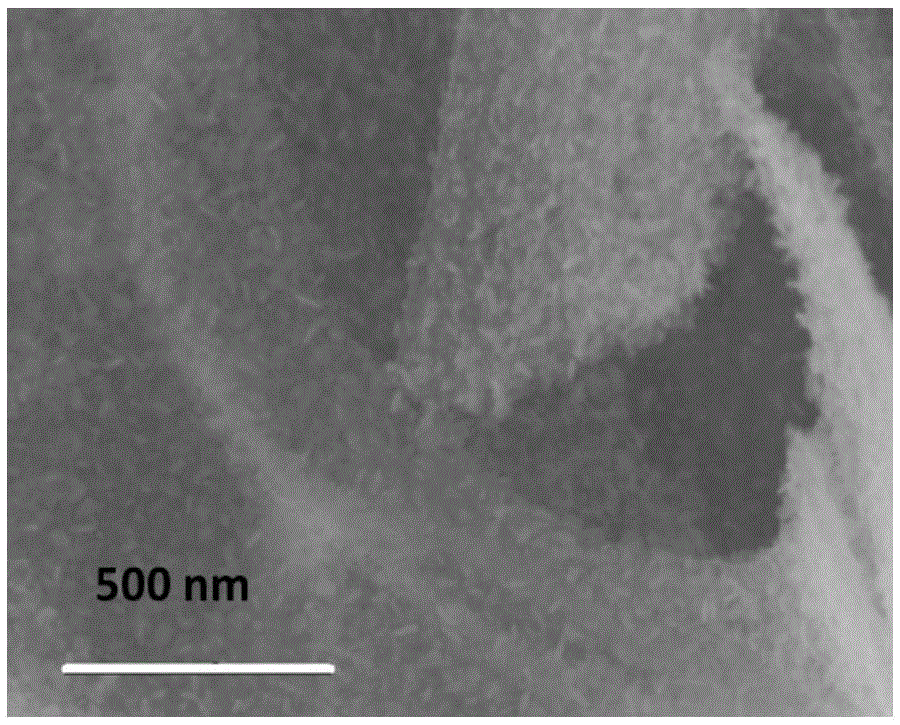

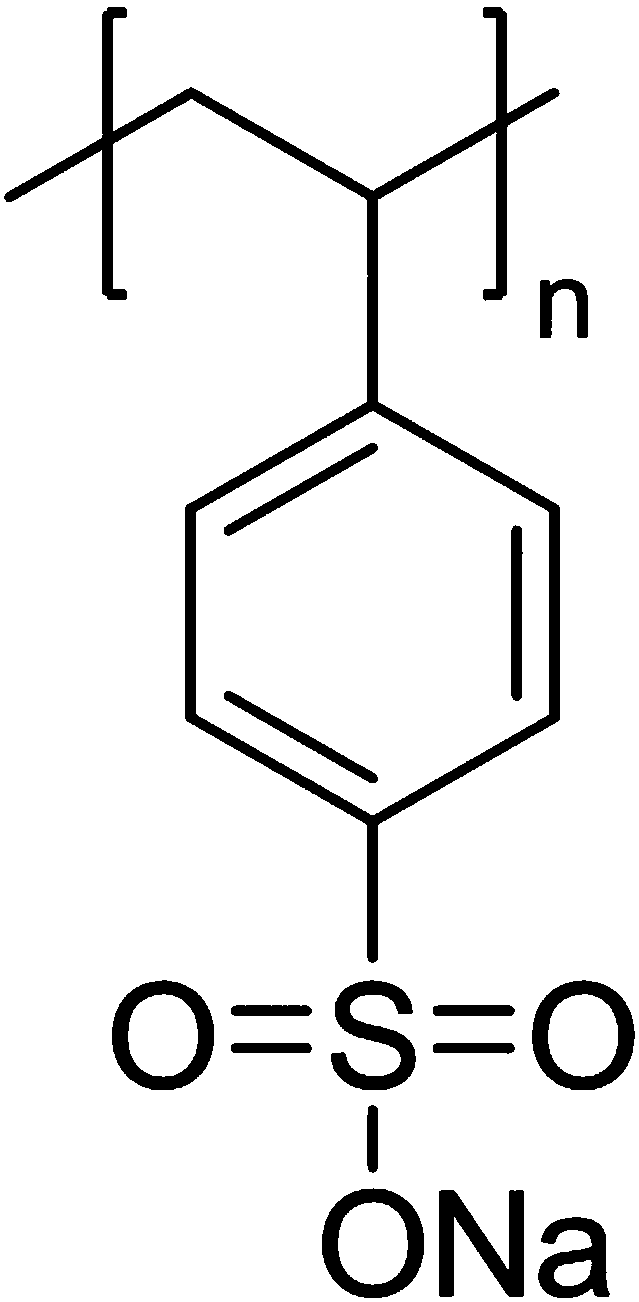

Method for improving dispersibility of single-walled carbon nanotube in aqueous solution

InactiveCN101941690AChange electrical propertiesChange mechanical propertiesNanostructure manufactureSolubilityCarbon nanotube

The invention belongs to the field of materials chemistry and in particular relates to a method for improving the dispersibility of a single-walled carbon nanotube in aqueous solution. The method comprises the following detailed steps of: dispersing a single-walled carbon nanotube purification sample in the aqueous solution of ethanol, and performing ultrasonic dispersion on the sample to uniformly suspense the sample in the solution; quickly cooling the obtained solution by using liquid nitrogen as a cooling medium and continuously supplying the cooling medium to guarantee that the cooling temperature of the sample reaches -50 to -190 DEG C; at normal temperature and under normal pressure, placing the solid sample in a closed device in which a high-speed blade rotates, wherein the rotation speed is 22,500rpm, the rotation time is 1 minute and the crushing process is repeated for 1 to 7 times; and filtering and drying the obtained sample to obtain the single-walled carbon nanotube aqueous solution with relatively good water solubility finally. In the invention, a physical method is adopted at normal temperature and under normal pressure, so that the structure of the single-walled carbon nanotube in aqueous solution is not damaged in a treatment process; the ethanol serving as a raw material is simple and available and causes no pollution to environment; and the method has the advantages of simple process and easy processing, so that the method is suitable for commercial production.

Owner:TONGJI UNIV

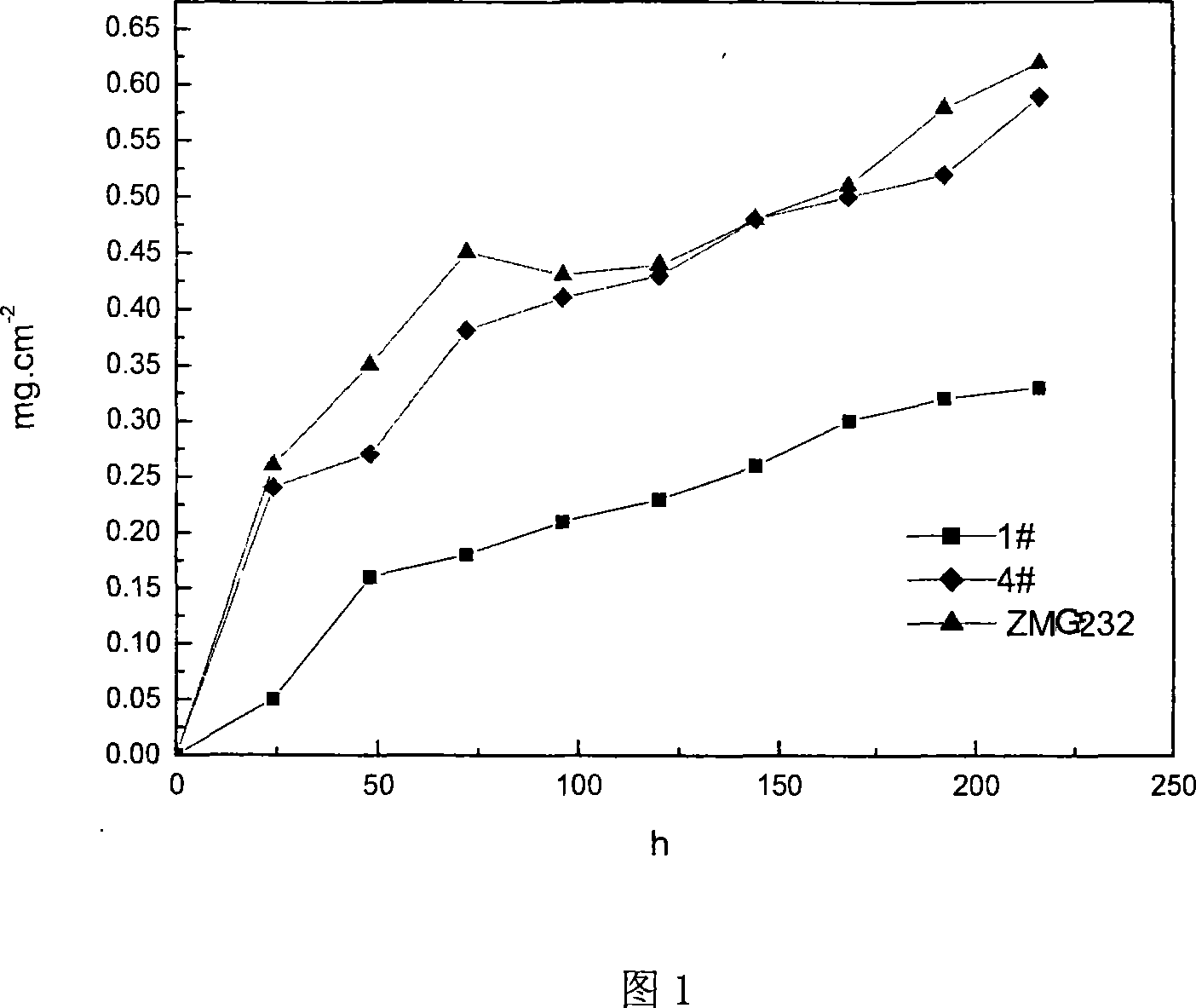

Ferritic stainless steel containing rare earth element yttrium for solid-oxide fuel battery

InactiveCN101195894AImprove high temperature resistanceImprove conductivityFinal product manufactureFuel cellsRare-earth elementYttrium

The invention relates to ferrite stainless steel which includes rare earth element yttrium and is used for a solid oxide fuel cell. The invention is characterized in that the invention comprises the following elements according to the mass percent: Y is 0.01 to 0.10 percent, C is lower than 0.03, Mn is 0.40 to 1.20 percent, Ni is 0.20 to 0.26 percent, Cr is 14.00 to 26.00 percent, Mo is 0.02 to 2.00 percent, W is 0.01 to 0.10 percent, P is lower than 0.04 percent, S is lower than 0.03 percent, Si is 0.01 to 0.05 percent, the residual is Fe; the thermal expansion coefficient is in the range of (11.8 to 13.0) is multiplied by 10 <-6> K at 25-1000 DEG C, and preferred in the range of (12.0 to 12.5) is multiplied by 10 <-6> K, and ferrite stainless steel alloy material is the alloy material which is particularly suitable for connecting and encapsulating the negative electrode and the positive electrode of the moderate temperature type solid oxide fuel cell, or can be used as the lighter of a vehicle engine, or can be used for high temperature boiler heating parts. The alloy is easy for the domestic industrial smelting and the processing formation, the manufacture cost is low, the alloy is suitable for the commercialization production, and has very high promotion and application value.

Owner:JILIN INST OF CHEM TECH

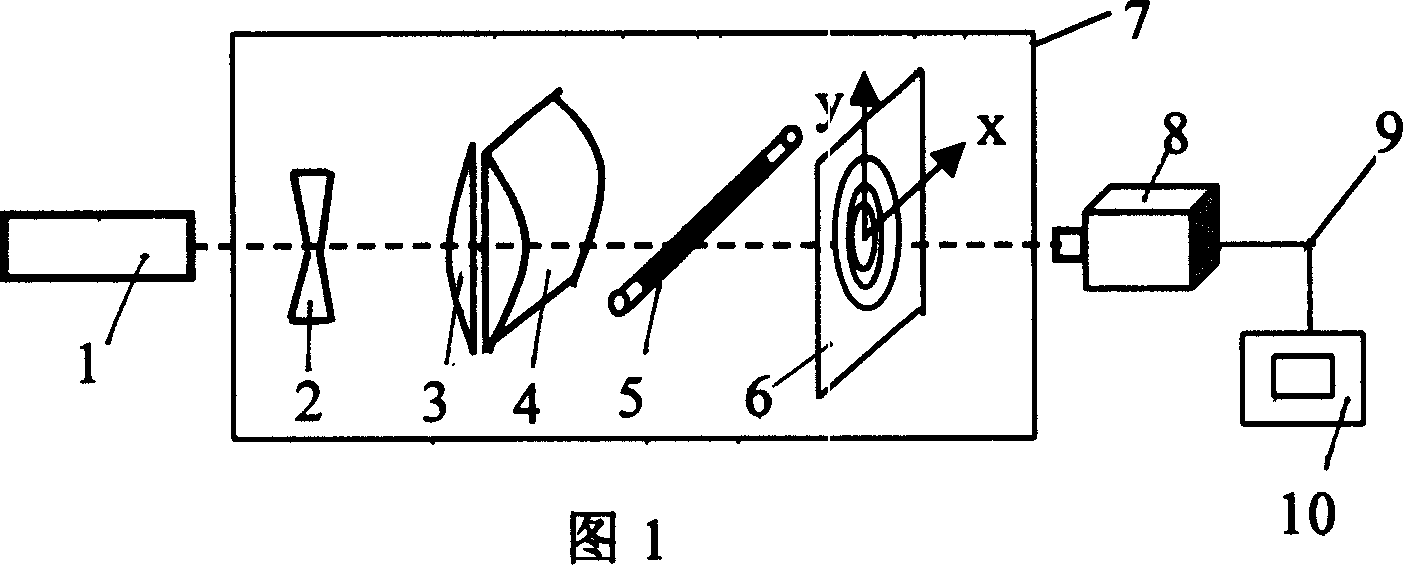

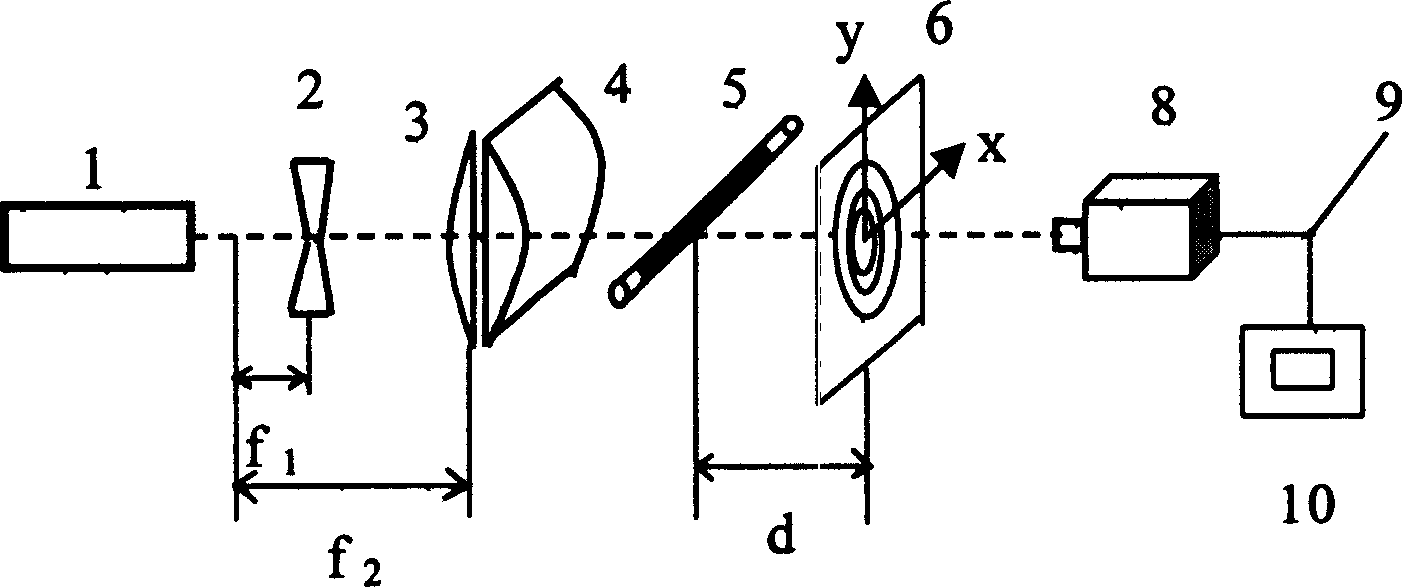

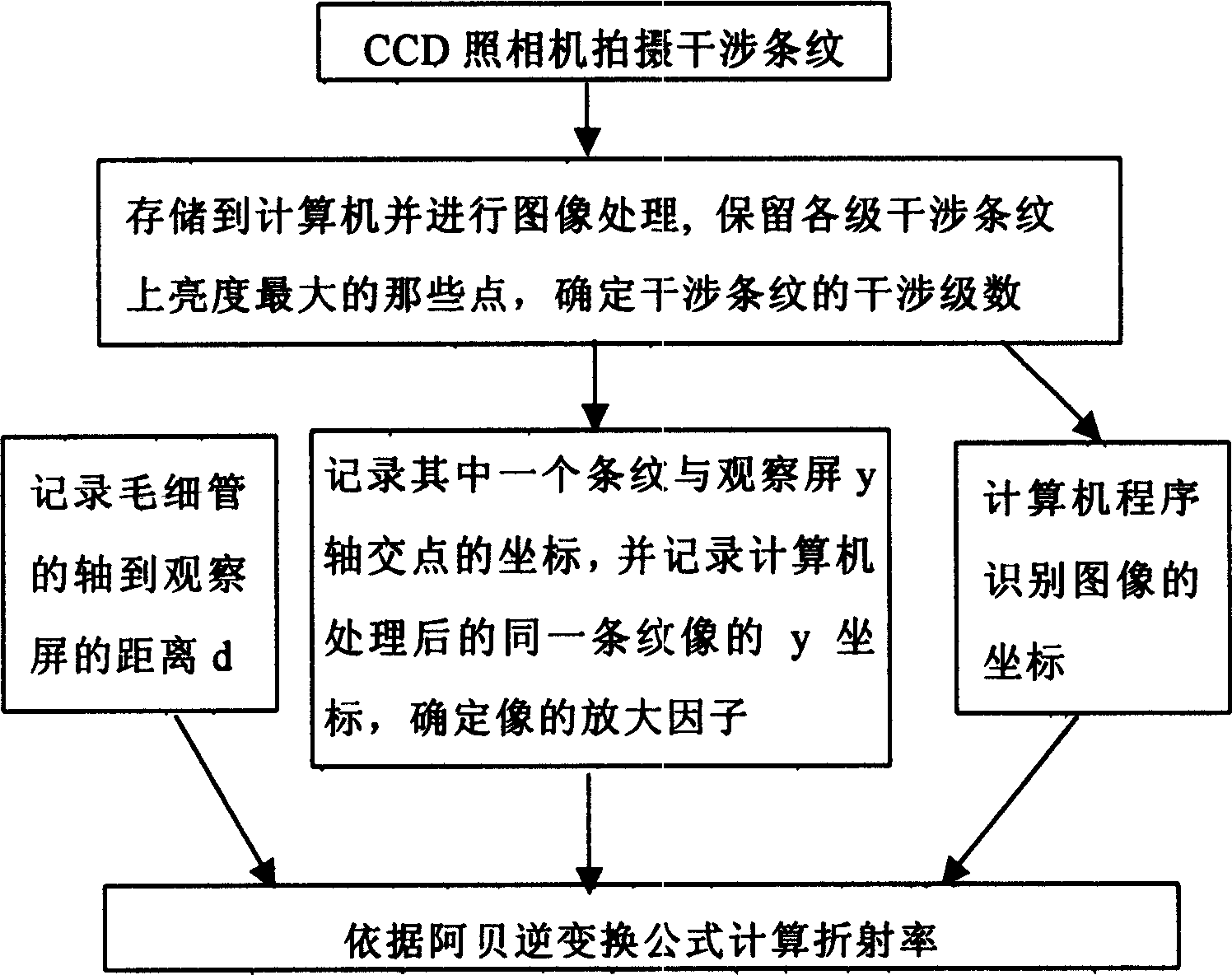

Device and method for measuring grade of maturity of oil occurrence rock

InactiveCN1598541ASimple preparation processLow costPhase-affecting property measurementsRefractive indexCcd camera

The invention is a device and method for measuring source rock maturity. It is made up of optical system forming stripe beam, capillary and observing screen behind it, CCD camera and computer, the capillary is placed horizontally, and its axis is parallel to the axis of the cylinder lens, and maintains the optical system and laser beam coaxial. The method uses parallel sample of source rock with known maturity, and uses CCD camera to record the interference stripe of source rock extract liquid, and differentiates the light and shade stripe and interference grades through image process, and uses the computer to program and forms a program, works out the reflection rate with Abelian reverse transition, creates a standard curve of source rock maturity and its extract liquid. To the source rock sample with unknown maturity, measures its reflection rate of its extract liquid, then it is compared with standard curve and acquires its maturity. The device is simple, the cost is low, and the precision is high.

Owner:OCEAN UNIV OF CHINA

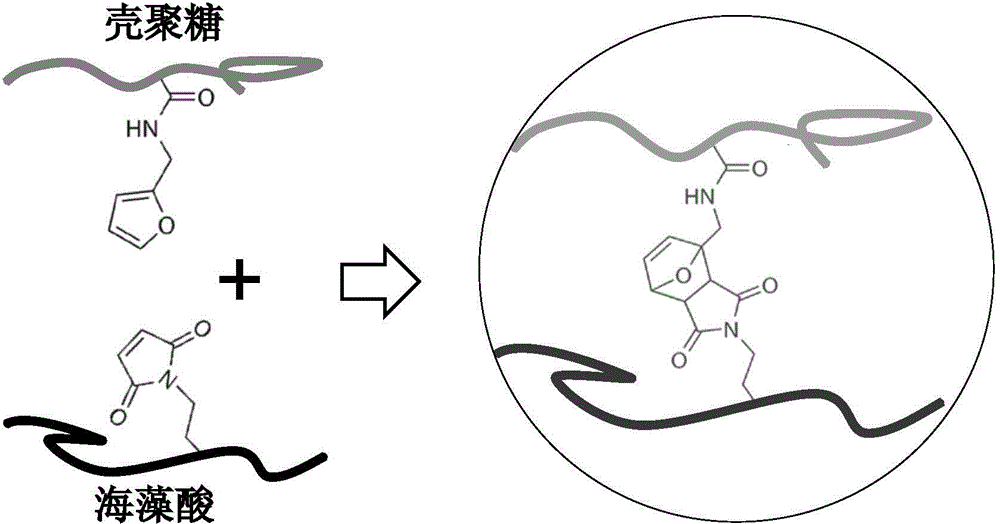

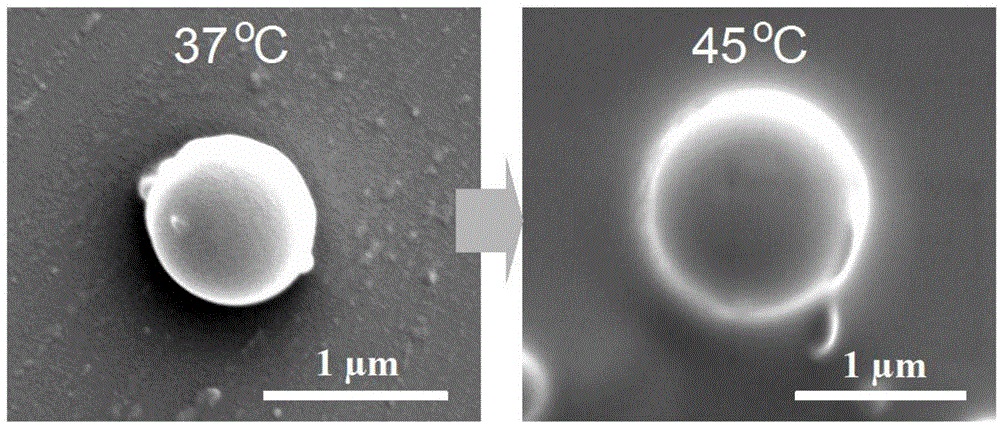

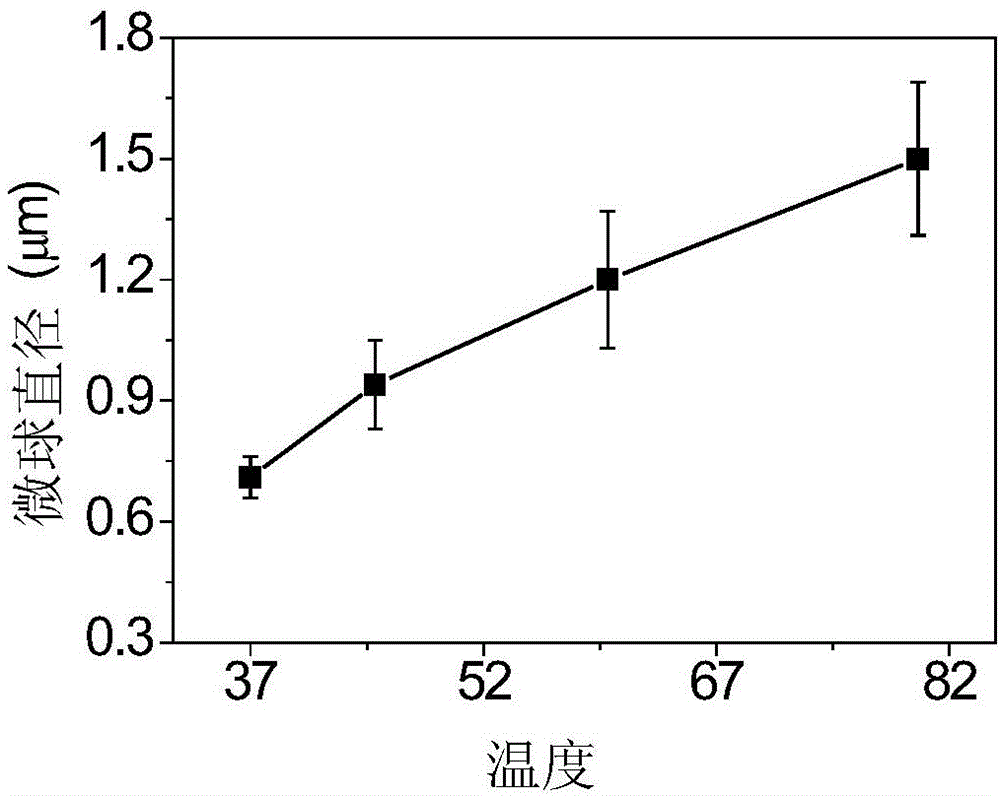

Preparation method of temperature controlled drug release polymer microsphere material

InactiveCN105770903AImprove biological activityRetain natural activityPeptide/protein ingredientsPharmaceutical non-active ingredientsFuranUltrasonic emulsification

The invention discloses a preparation method of a temperature controlled drug release polymer microsphere material. The steps consist of: dissolving chitosan in a lactic acid solution, adding succinic anhydride to carry out reaction so as to obtain water-soluble succinyl chitosan; dissolving the product in a buffer solution, and adding furfurylamine-2-furanomethylamine dropwise, then adding carbodiimide to carry out reaction so as to obtain furan chitosan; dissolving sodium alginate in water, and adding a sodium periodate solution dropwise to carry out reaction so as to obtain aldehyde sodium alginate; dissolving aldehyde sodium alginate in water, and adding 4-(4-N-maleimide phenyl)butyrate to carry out reaction so as to obtain maleimide sodium alginate; mixing a furan chitosan aqueous solution with a maleimide sodium alginate aqueous solution according to an equivoluminal ratio, then adding the mixture into paraffin oil containing an emulsifier span 80 to perform ultrasonic emulsification; subjecting the emulsion to stirring volatilization, then pouring the emulsion into isopropanol to precipitate polymer microspheres, and performing cleaning and freeze drying, thus obtaining the product. The invention significantly improves the use safety of the microsphere material, and the polymer microsphere material has important application value in the aspects of drug controlled release and gene therapy.

Owner:NANJING UNIV OF SCI & TECH

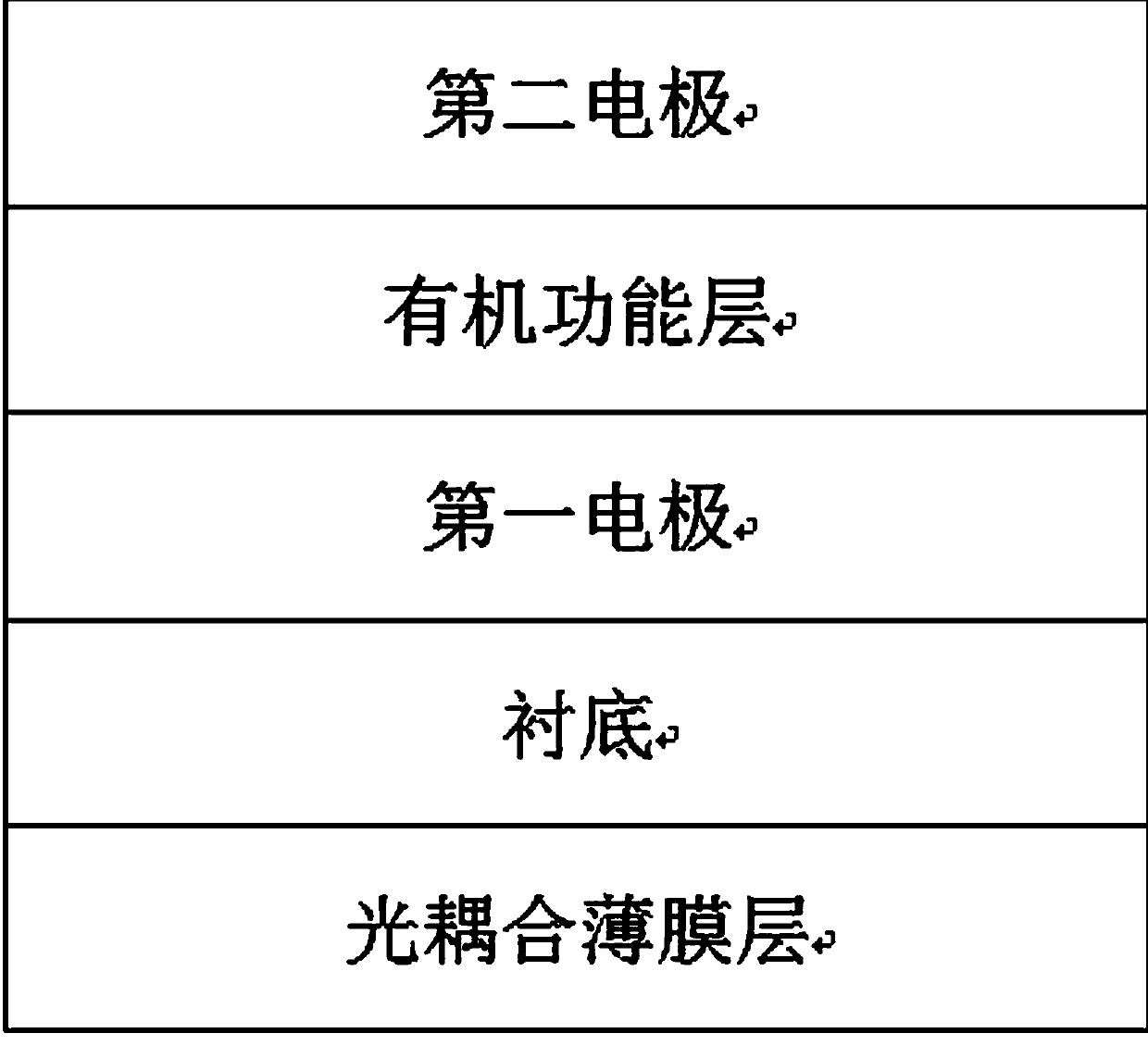

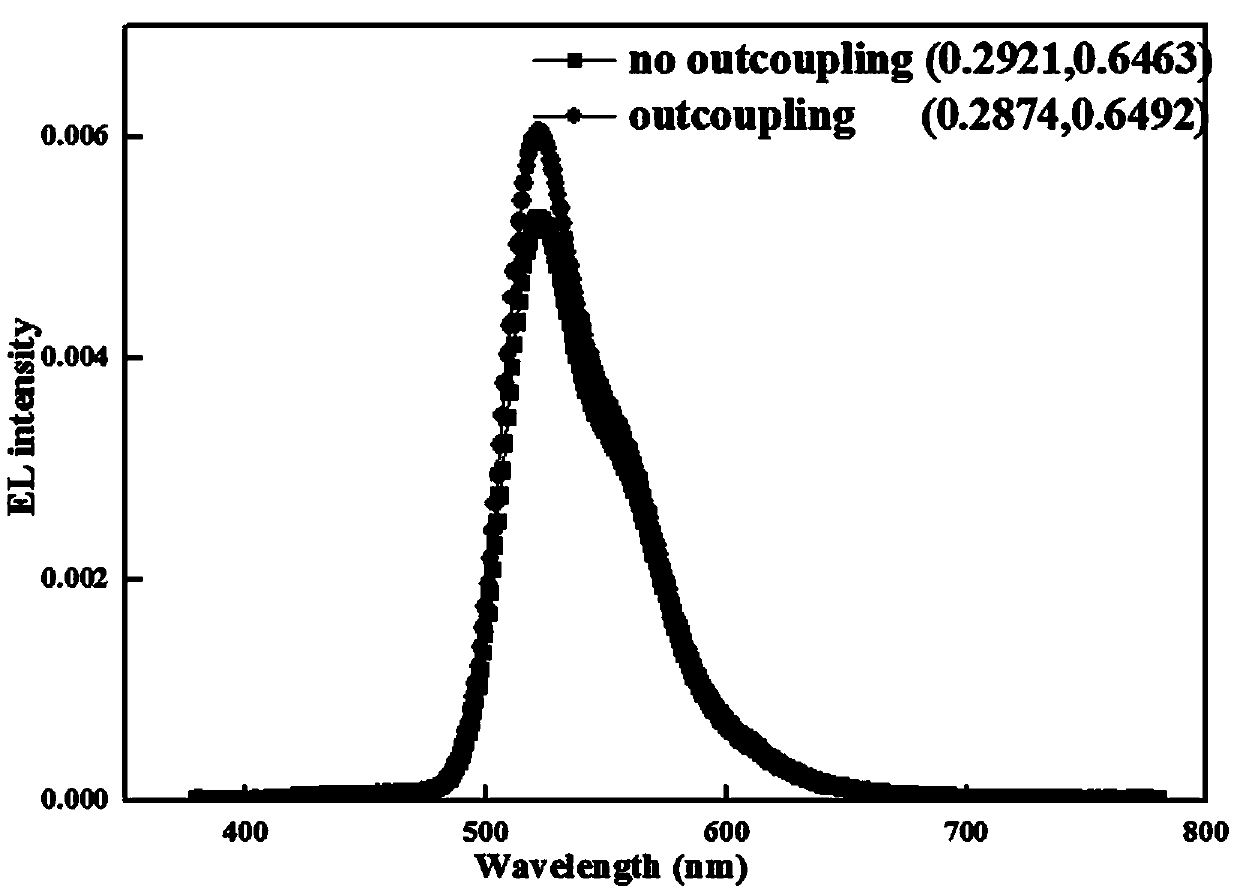

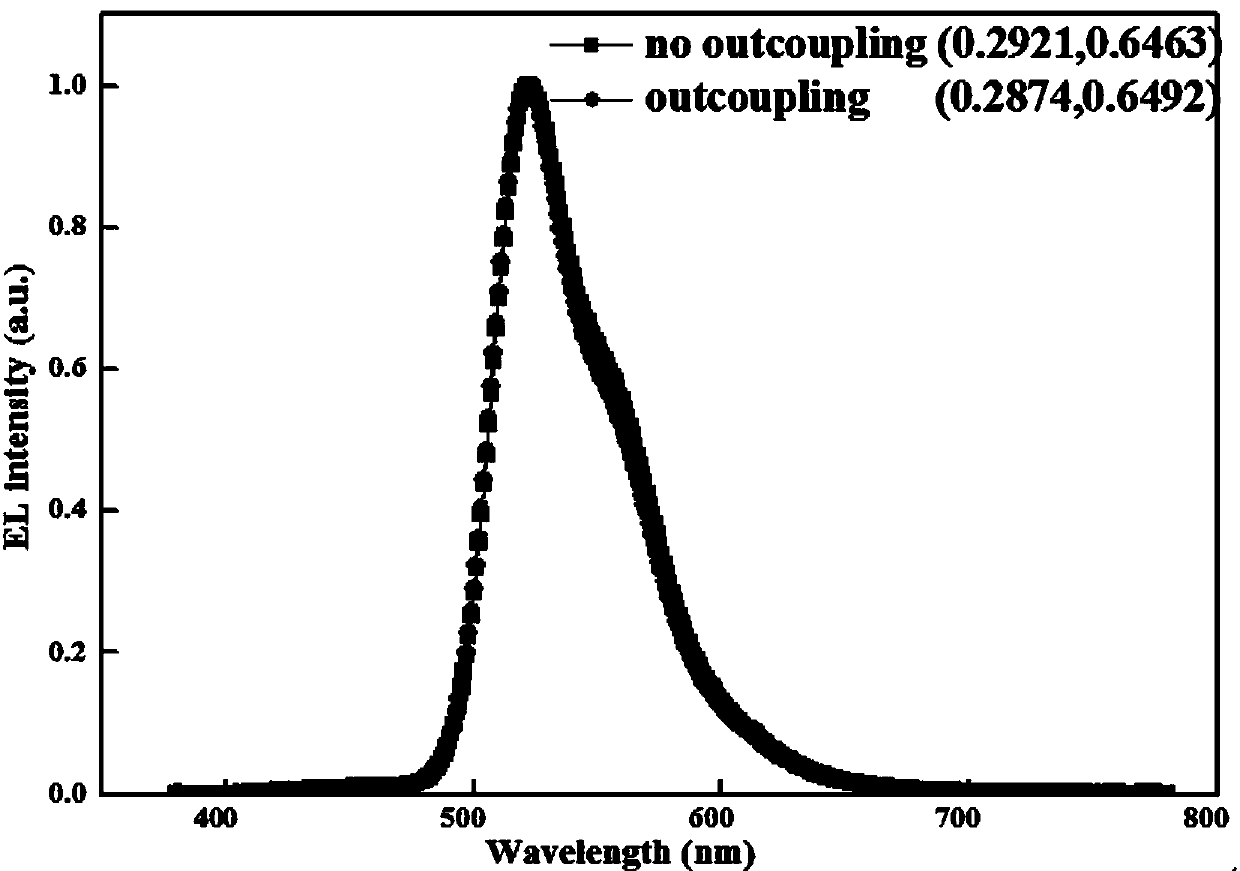

Organic light emitting device and manufacturing method thereof

InactiveCN103996797AReduce reflectionHigh outputSolid-state devicesSemiconductor/solid-state device manufacturingOrganic light emitting deviceThin membrane

The invention discloses an organic light emitting device which is provided with a transparent substrate, a first electrode, an organic function layer, a second electrode and an optical coupling film layer. The first electrode, the organic function layer and the second electrode are arranged on one face of the transparent substrate and sequentially stacked, and the optical coupling film layer is arranged on the other face of the transparent substrate. The optical coupling film layer is provided with a layer body and a patterned layer arranged on the surface of the layer body; or the optical coupling film layer is provided with a layer body and micro holes distributed in the layer body or distributed in the surface of the layer body; or the optical coupling film layer is provided with a layer body, micro holes distributed in the layer body or distributed in the surface of the layer body, and a patterned layer arranged on the surface of the layer body. A manufacturing method of the organic light emitting device comprises the steps of (a) manufacturing the first electrode, the organic function layer and the second electrode on one face of the substrate in sequence, and (b) manufacturing the optical coupling film layer on the other face of the substrate. The organic light emitting device has the advantages of being easy to process, and good in light taking-out effect.

Owner:GUANG ZHOU NEW VISION OPTO ELECTRONICS TECH

Preparation method of hydrogenation catalyst for nitrobenzene and derivatives thereof

InactiveCN109647517AIncrease load capacityEvenly distributedOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsNitrobenzeneChemistry

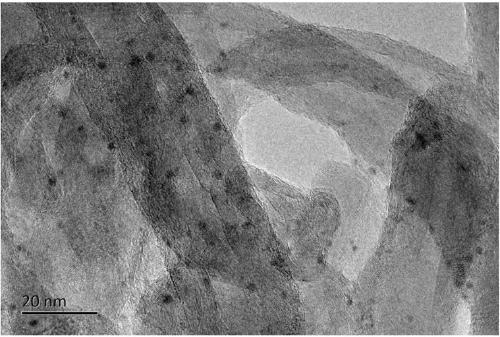

The invention relates to a preparation method of a hydrogenation catalyst for nitrobenzene and its derivatives. A carbon material is functionally modified with a high-molecular polymer and then loadedwith noble metal. The preparation method of the catalyst comprises the following steps: (1) the carbon material and the high-molecular polymer undergo ultrasonic treatment on in a certain concentration of a salt solution at a certain temperature for 0.5 to 6 hour to obtain a functionalized carbon material; (2) noble metal particles with a certain size distribution are prepared from the salt solution of the noble metal under the action of a protective agent and a reducing agent; (3) the aqueous solution or the organic solution of the obtained noble metal particles undergoes ultrasonic treatment for 10 min and is stirred for 2-12 h and then loaded on the functional group modified carbon material so as to obtain a noble metal-loaded catalyst. The preparation method of the catalyst is simple,effective and green and environmentally-friendly. After reduction by the reducing agent, the uniformly-dispersed noble metal-loaded catalyst with a certain size distribution is obtained. In addition,the catalyst has a broad application prospect in the field of catalysis of nitrobenzene and its derivatives.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

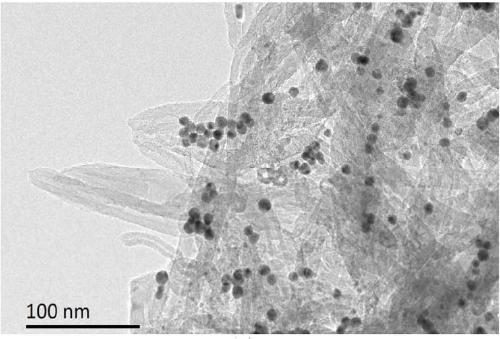

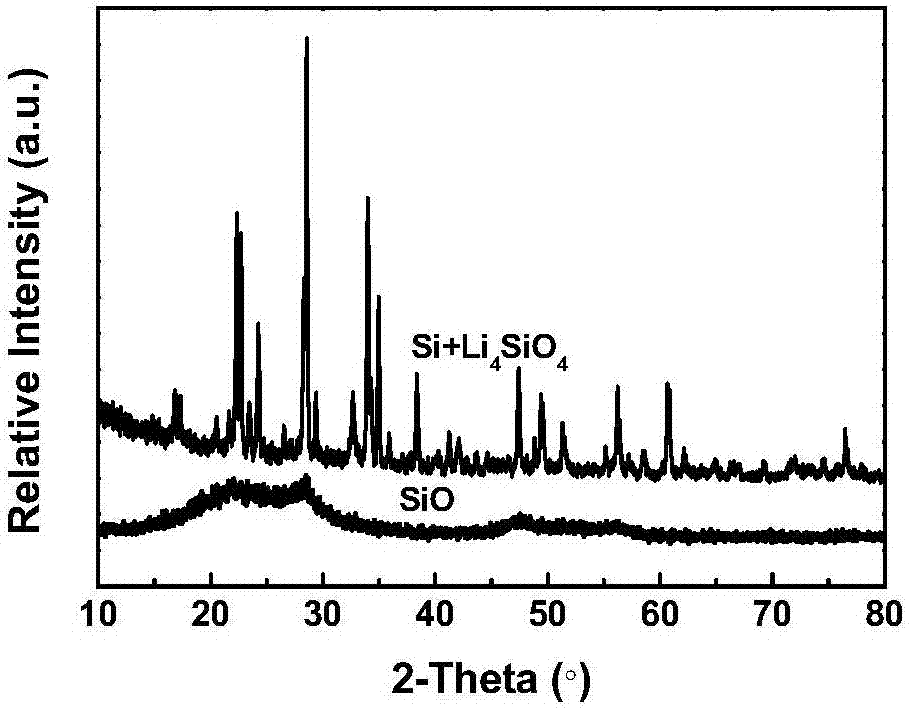

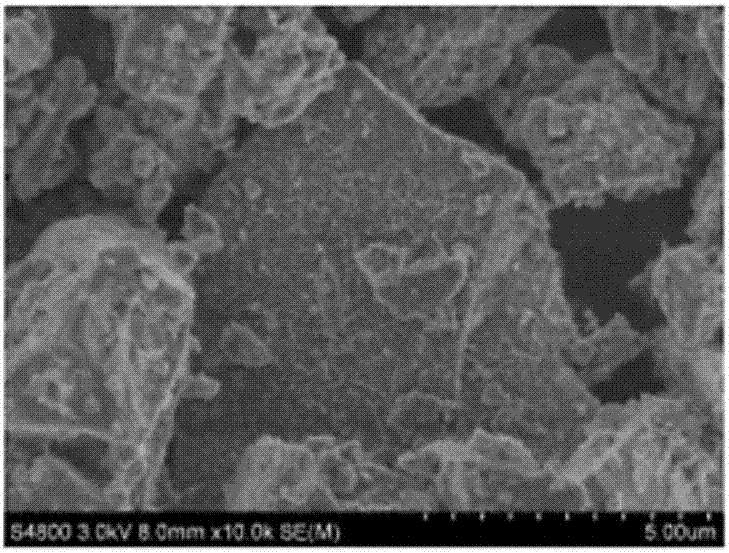

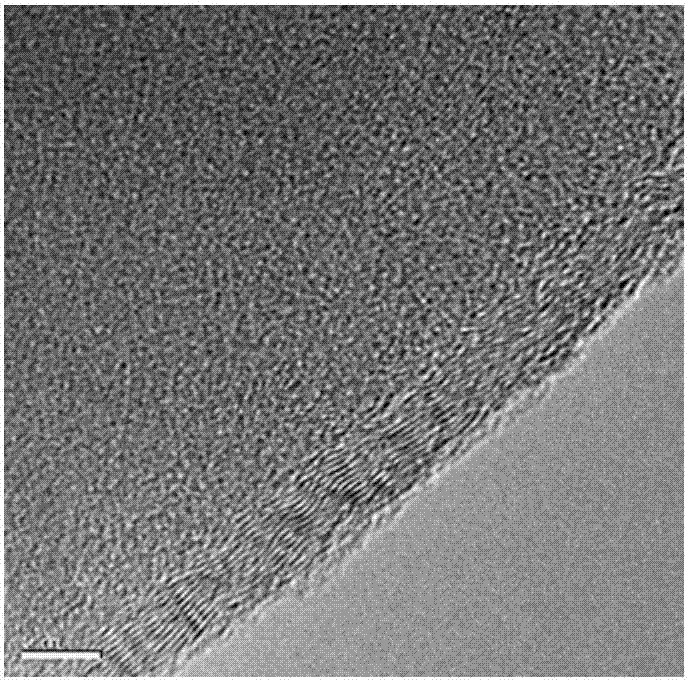

Composite silicon based electrode material, preparation method and application thereof

InactiveCN107394161AImprove stabilitySmall volume change rateCell electrodesSecondary cellsWater basedSolvent

Relating to the field of electrode materials, the invention in particular provides a composite silicon based electrode material, a preparation method and application thereof. The composite silicon based electrode material is mainly composed of a pre-lithiated silicon based core and a graphene layer coating the pre-lithiated silicon based core. The composite silicon based electrode material has the advantages of high environmental stability, good inertness to solvent, high initial coulomb efficiency and good cyclic stability, has no change after storage in the air for 24h or more, has initial coulomb efficiency up to 90% or more, shows good inertness to water based solvents and oil based solvents, and has a capacity retention ratio up to92% or more after 20 cycles.

Owner:PEKING UNIV

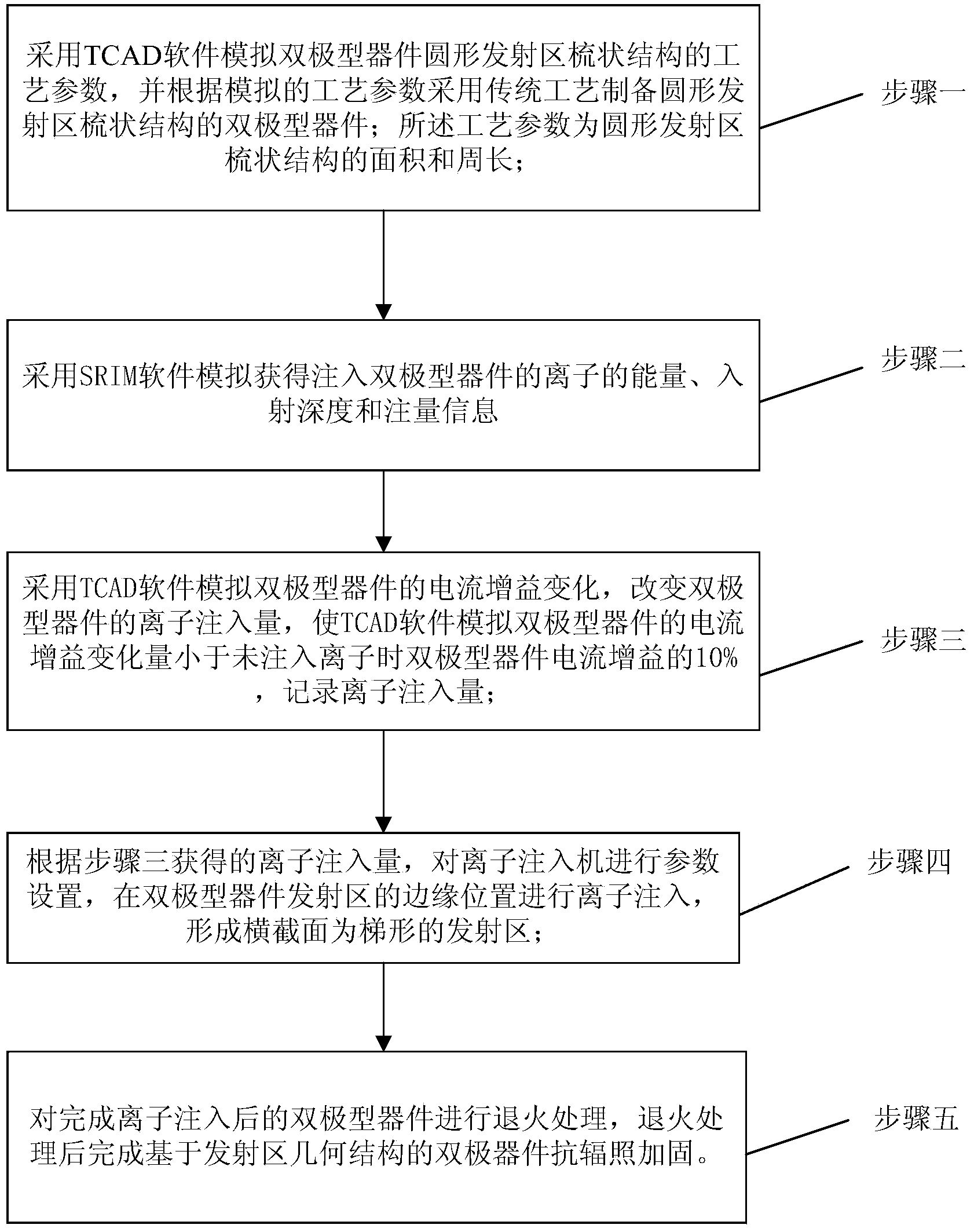

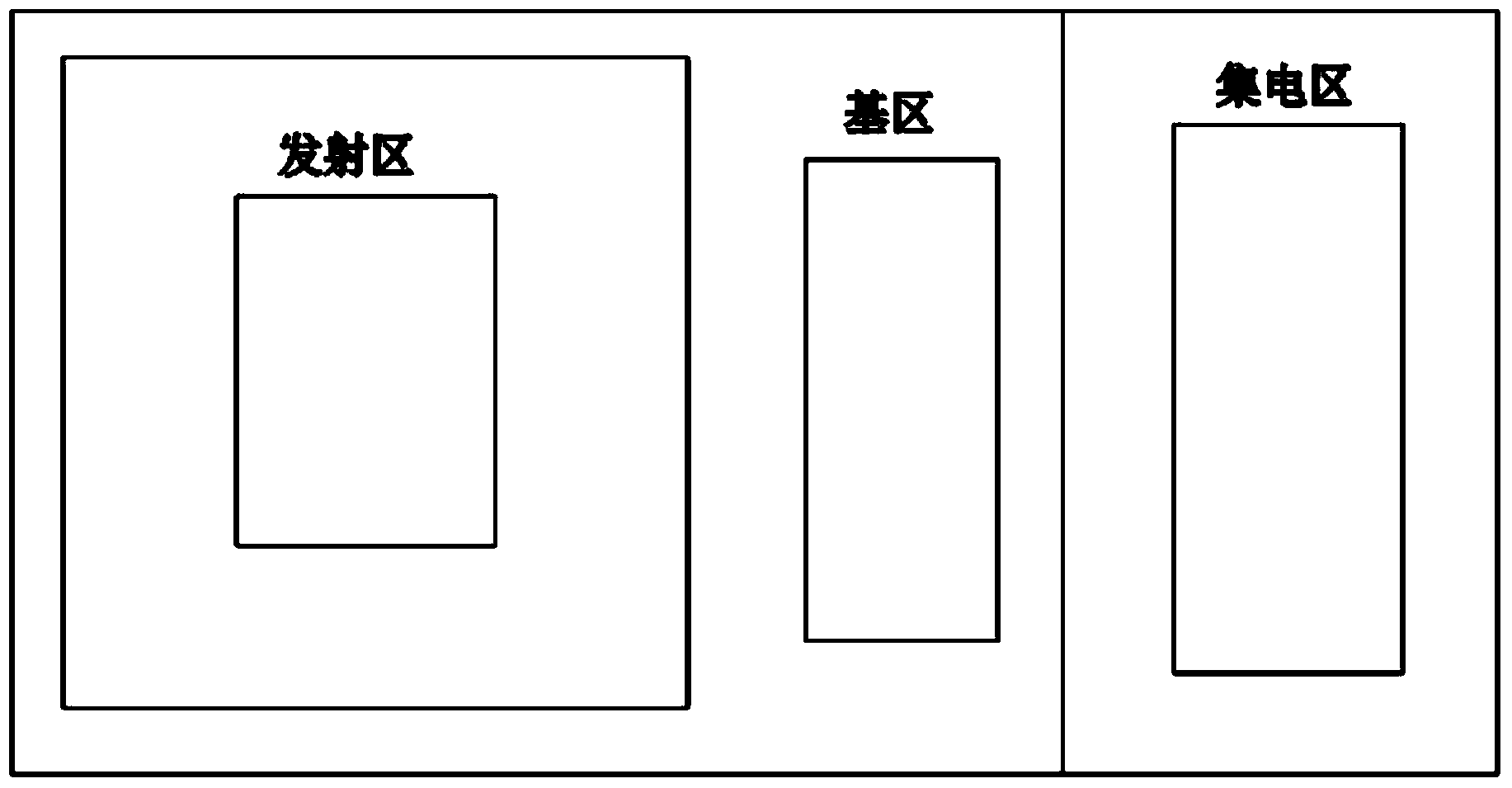

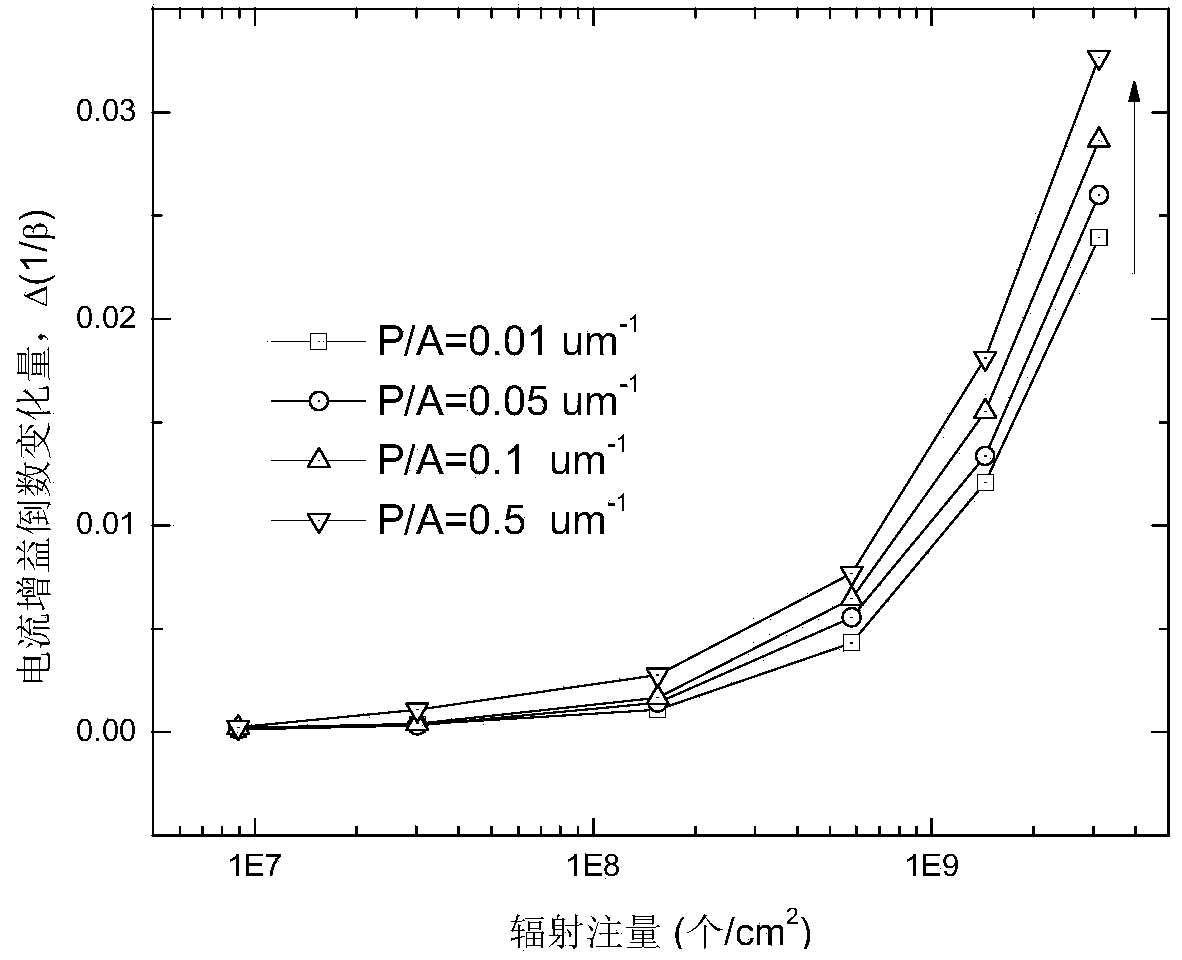

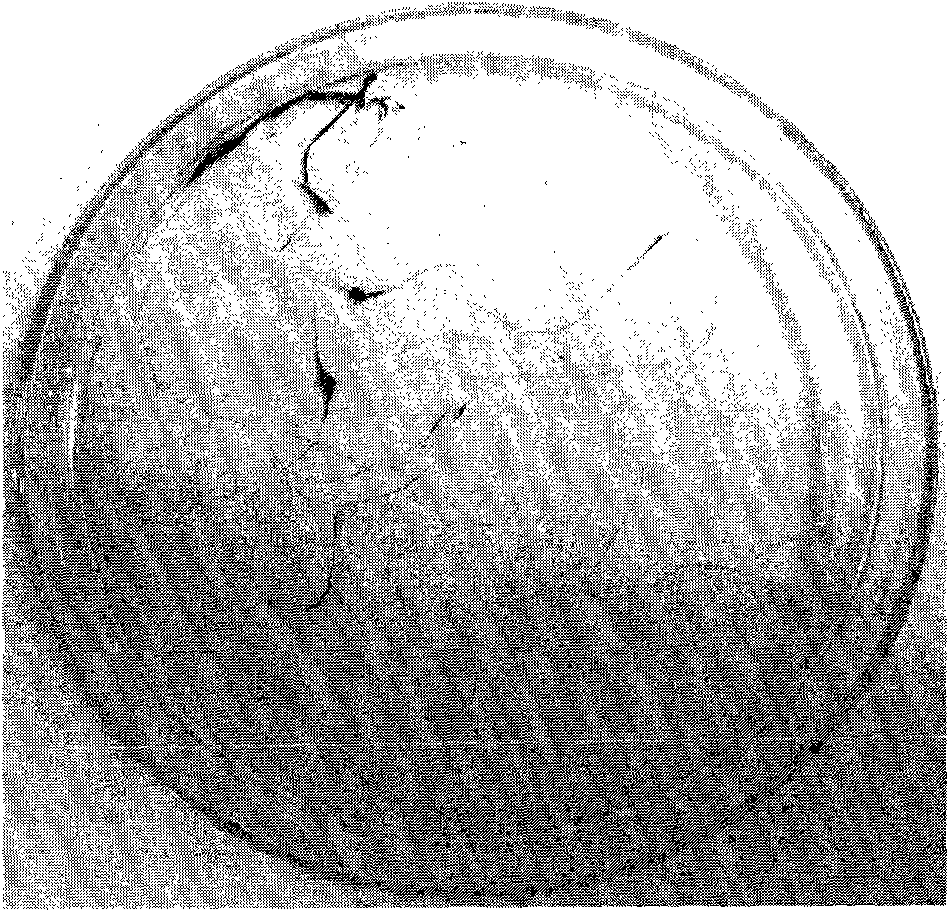

Radiation-proof strengthening method for bipolar device based on geometric structure of emitter region

ActiveCN103871873AImprove radiation resistanceThe preparation process steps are simpleSemiconductor/solid-state device manufacturingSemiconductor devicesPower flowIonizing irradiation

The invention relates to and is applicable to the technical field of electronics, in particular to a radiation-proof strengthening method for a bipolar device based on the geometric structure of an emitter region. The radiation-proof strengthening method aims to solve the problems that an existing bipolar junction transistor and a circuit are high in damage degree of current gain in a space radiation environment, and an existing bipolar device is low in radiation resistance ability. According to the radiation-proof strengthening method for the bipolar device, the traditional bipolar device process is reserved, and manufacturing process steps are very simple. By means of the radiation-proof strengthening method for the bipolar device, the influence of positive charges captured by oxide induced through ionizing irradiation and the interface state on performance parameters of the device can be lowered substantially by improving the geometric structure of the emitter region, and the radiation resistance ability of the bipolar device is enhanced remarkably by 2-5 times compared with that of the existing bipolar device.

Owner:HARBIN INST OF TECH +2

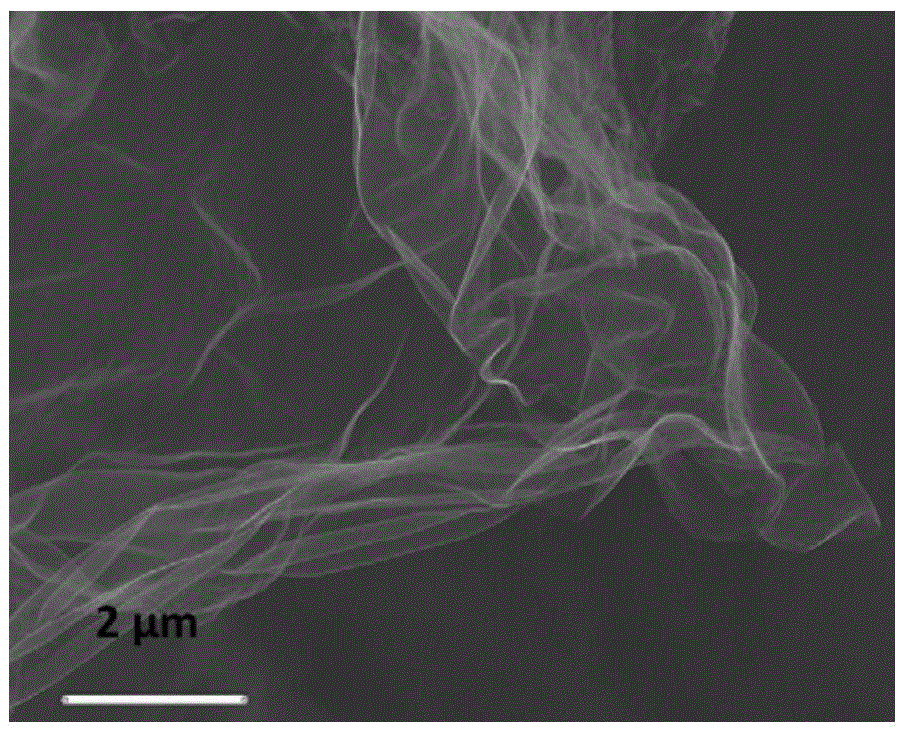

Method for continuously synthesizing single-wall carbon nano tube by high temperature chemical vapor deposition method

InactiveCN101891184AUniform supplyEasy and quick passNanostructure manufactureChemical synthesisCarbon nanotube

The invention relates to a method for continuously synthesizing a single-wall carbon nano tube by a high temperature chemical vapor deposition method, belonging to the technical field of chemosynthesis. The method comprises the following specific steps: introducing inert gas in an alundum tube reactor and heating to 1300-1500 DEG C; introducing a mixing solution containing a catalyst, a carbon source and an additive, thiophene and inert gas in the alundum tube reactor; collecting a product at the opening of the alundum tube reactor; paving the product in an alundum boat, placing the alundum boat in the alundum tube reactor for heat treatment, heating to 400-500 DEG C at a speed of 10 DEG C / min and keeping the temperature for 1h; sealing the two ends of the alundum tube, introducing inert gas, heating to 800-900 DEG C at a speed of 10 DEG C / min and keeping the temperature for 1h; introducing argon, cooling to room temperature, and enabling the product to react with diluted hydrochloric acid; and filtering, washing and drying. The raw materials are simple and easily obtained and have no obvious inflammable danger; the product is easy to collect and has high yield; the device is simple and can realize continuous operation; and the invention has low cost and no environmental pollution and can be applied to large-scale production.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com