Porous-compact double-layer electrolyte ceramic sintered body, lithium ion battery and lithium-air battery

A lithium ion and electrolyte technology, which is applied in the field of all-solid lithium ion battery and lithium-air battery manufacturing, can solve safety problems and other problems, and achieve the effect of solving liquid leakage and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A method for preparing a porous-dense double-layer electrolyte ceramic sintered body based on an inorganic solid-state lithium-ion electrolyte material according to an embodiment of the present invention includes the following steps:

[0033] a) Provide powder of inorganic solid lithium ion electrolyte material

[0034] Among them, the inorganic solid-state lithium ion electrolyte material can be preferably, but not limited to, lithium lanthanum zirconium oxide with a cubic garnet structure (the chemical formula can be written as Li 7 La 3 Zr 2 o 12 )-based electrolyte material, NASICON type lithium-ion electrolyte Li 1+x A x m 2-x (Si y P 1-y o 4 ) 3 (A=Al 3+ , Ga 3+ ,Sc 3+ ,Y 3+ , or Cr 3+ ; M = Ti 4+ , Ge 4+ ,Hf 4+ or Zr 4+ ), perovskite electrolyte Li 3x La 2 / 3-x□1 / 3-2x TiO 3 (Wherein, □ represents A-site atomic vacancy, 0.06<x<0.15) and so on.

[0035]Preferably, lithium-lanthanum-zirconium-based electrolytes, such as Li 6.75 La 3 Zr 1.75 T...

Embodiment 1

[0083] Example 1 Preparation of porous-dense double-layer electrolyte ceramic sintered body based on inorganic solid lithium ion electrolyte material

[0084] The powder of the electrolyte material is Li 6.75 La 3 Zr 1.75 Ta 0.25 o 12 , the powder preparation process refers to the method recorded in the above literature [1]. In the preparation of the powder, LiOH·H 2 O.

[0085] Mix a part of the above-mentioned powder with the graphite pore-forming agent uniformly at a mass ratio of 1:1 to obtain a mixed powder.

[0086]Thereafter, the mixed powder is combined with the powder not containing the pore-forming agent by lamination to form a green body.

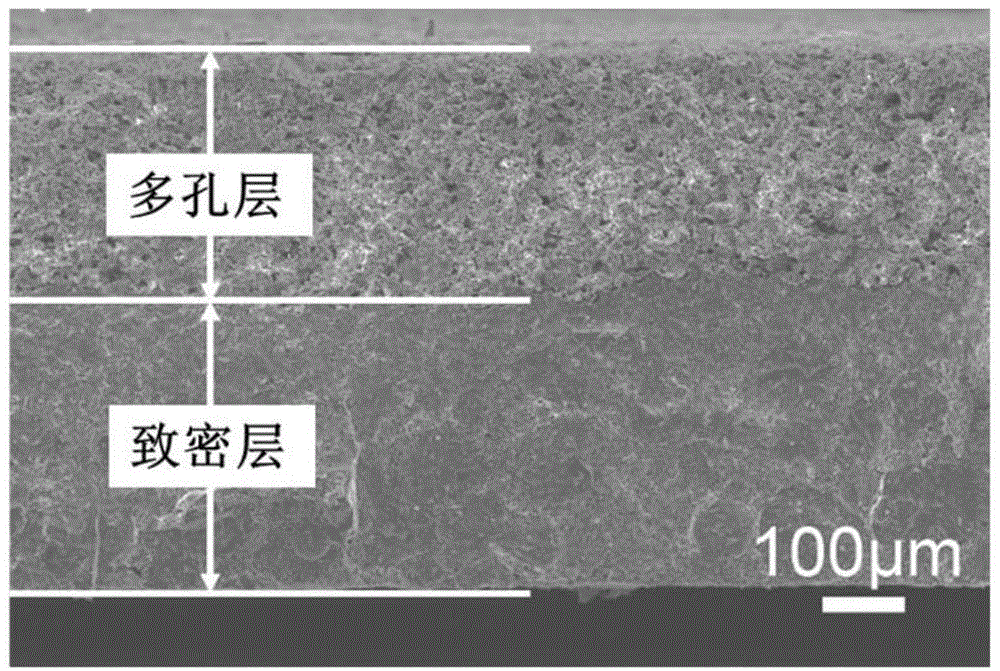

[0087] Next, the green body is embedded in the sacrificial powder composed of mother powder, sintered at 1100°C for 4 hours, taken out, and the excess sacrificial powder on the surface is removed to obtain a porous-dense double-layer ceramic sintered body.

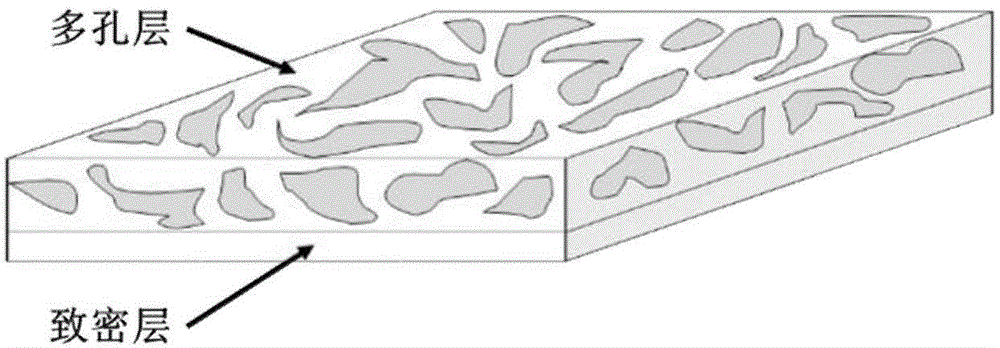

[0088] Figure 1 shows the schematic structure of the porous-doubl...

Embodiment 2

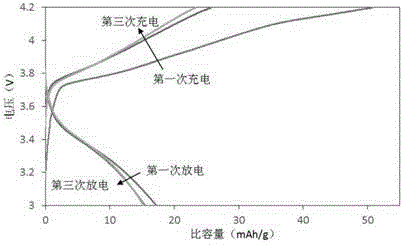

[0090] Example 2 Preparation of all-solid-state secondary lithium-ion battery

[0091] As an all-solid-state secondary lithium-ion battery, the positive electrode active material is LiCoO 2 .

[0092] As the introduction method of the positive electrode active material, the nitrates of Li and Co were dissolved in deionized water, and citric acid was added to make LiCoO 2 sol precursors. The precursor is injected into the porous layer of the double-layer structure prepared in Example 1, and heat-treated at 600 ° C for 1 hour to convert it into LiCoO 2 , and after heat treatment, the positive electrode active material is tightly bonded to the inner wall of the porous layer, which is conducive to the conduction of electrons during the charging and discharging process.

[0093] Thereafter, as the negative electrode, the metal lithium sheet is heated and melted, and combined with one side of the dense layer of the double-layer structure, that is, an all-solid-state secondary lit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com