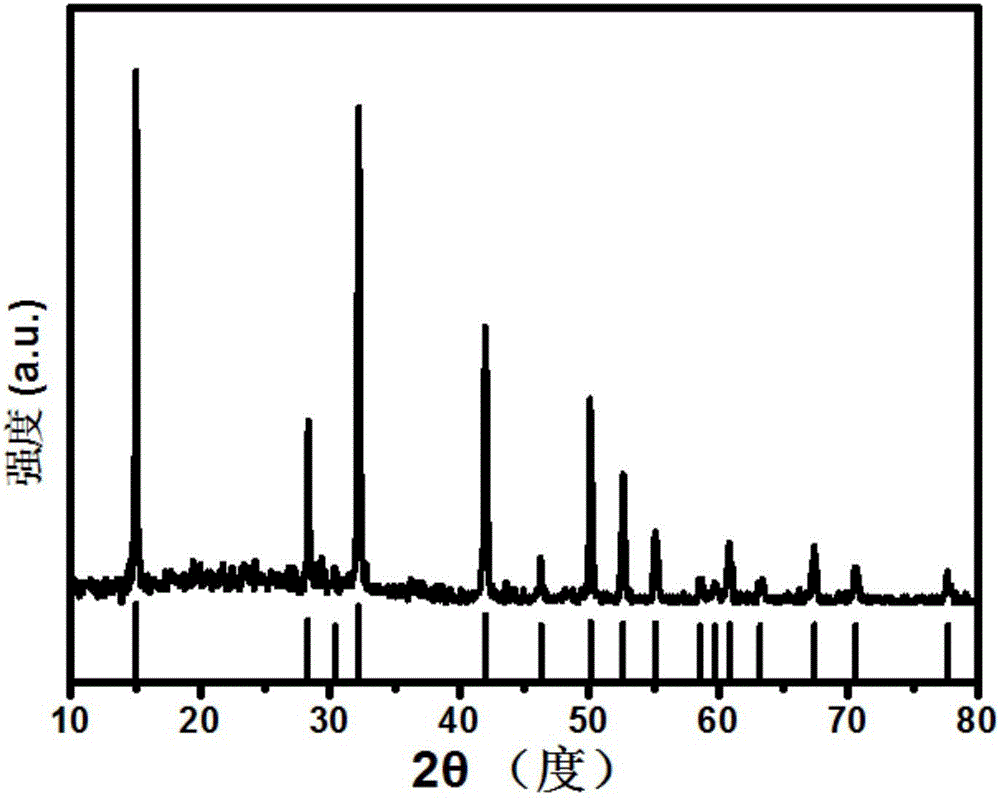

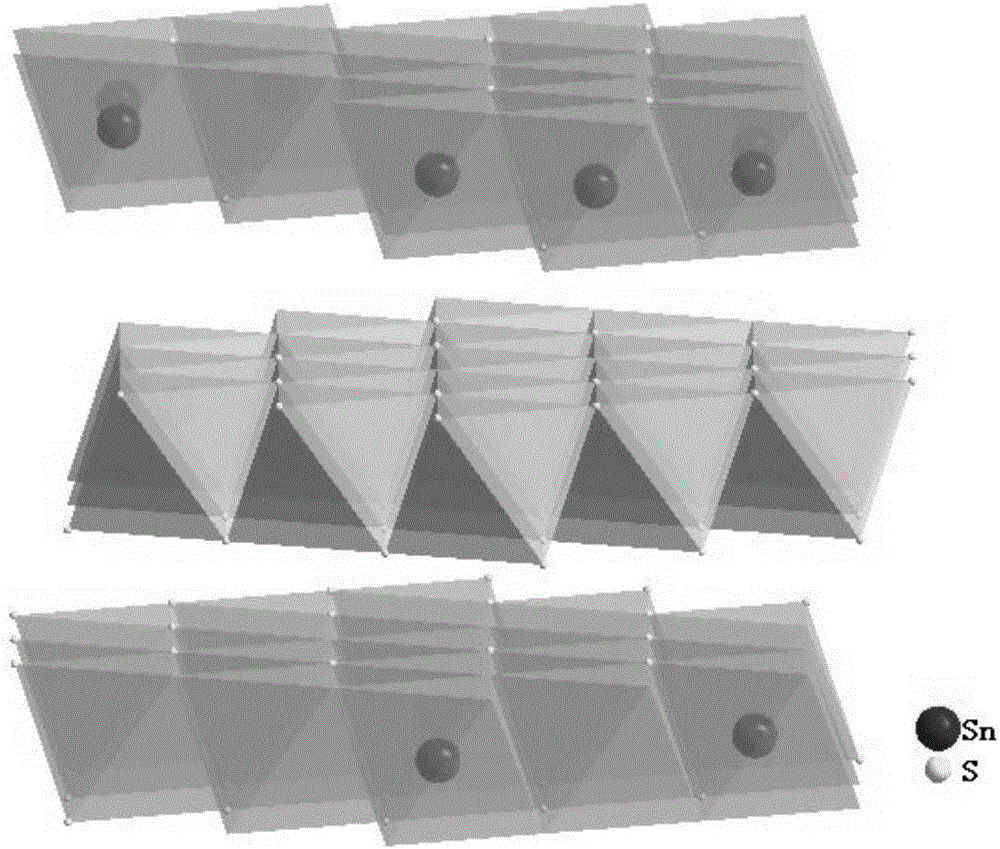

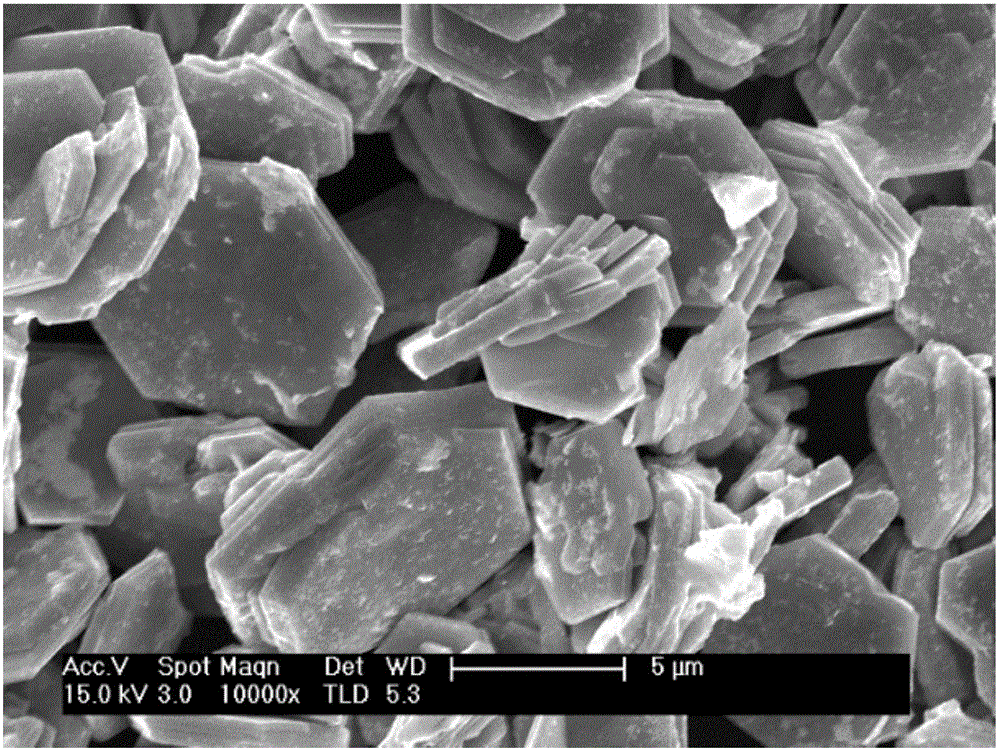

Method for preparing SnS2 hexagonal nanosheets by hydrothermal process

A technology of nanosheets and hydrothermal method, which is applied in the field of materials science, can solve problems such as easy agglomeration and poor dispersion of hexagonal nanosheets, and achieve the effects of low cost, significant technological progress, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] First, add the reactant precursor 0.64 g sulfur powder, 5.22 g tin tetrachloride pentahydrate, 10 g potassium hydroxide, and 20 mL deionized water into the reactor in sequence, and stir at room temperature for 5 min to the reactant precursor. Then the reaction kettle was sealed and placed in a vacuum oven at 200°C for 3 days, cooled to room temperature naturally, and finally washed and separated to obtain SnS. 2 Hexagonal nanosheets.

Embodiment 2

[0027] First, the reactant precursor 2.24 g sulfur powder, 10.52 g tin tetrachloride pentahydrate, 8 g potassium hydroxide, and 30 mL deionized water were sequentially added to the reaction kettle, and stirred at room temperature for 15 min to the reactant precursor Dissolve, then seal the reactor and put it in a vacuum oven at 230°C for 5 days, cool to room temperature naturally, and finally wash and separate the precipitate to obtain SnS 2 Hexagonal nanosheets.

Embodiment 3

[0029] First, add 1.25 g sulfur powder, 3.50 g tin tetrachloride pentahydrate, 15 g potassium hydroxide, and 40 mL deionized water into the reaction kettle in sequence, and stir at room temperature for 30 min to reach the reactant precursor Dissolve, then seal the reactor and put it in a vacuum oven at 190°C for 6 days, cool to room temperature naturally, and finally wash and separate the precipitate to obtain SnS 2 Hexagonal nanosheets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com