Method for hydrothermal synthesis of SnS2 nano-materials

A technology of hydrothermal synthesis and nanomaterials, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of high cost, high equipment requirements, inconvenient operation, etc., and achieve improved appearance, simple operation and low cost cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

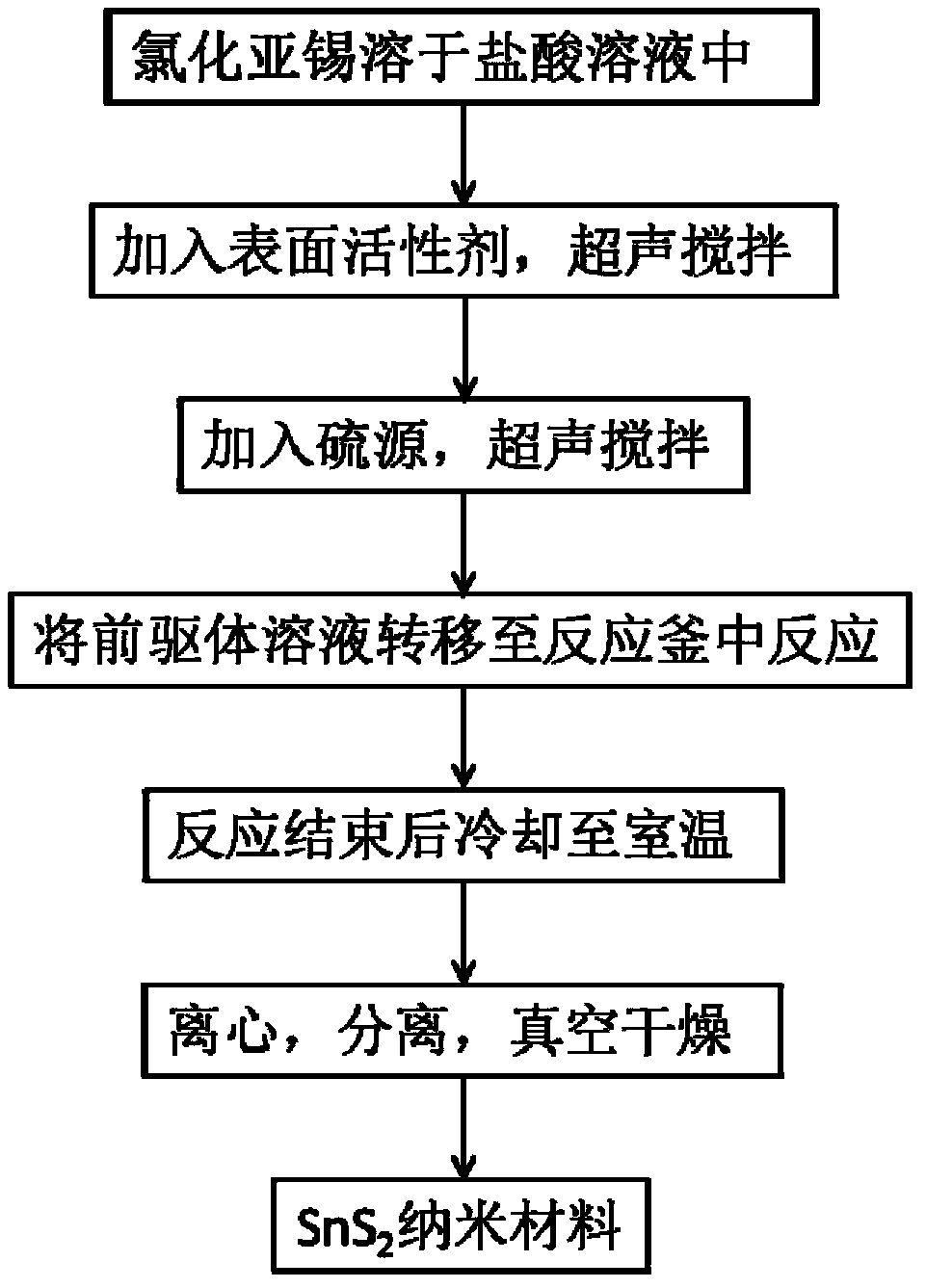

[0027] SnS of this embodiment 2 The synthesis process of nanomaterials is as follows figure 1 As shown, the specific steps are as follows:

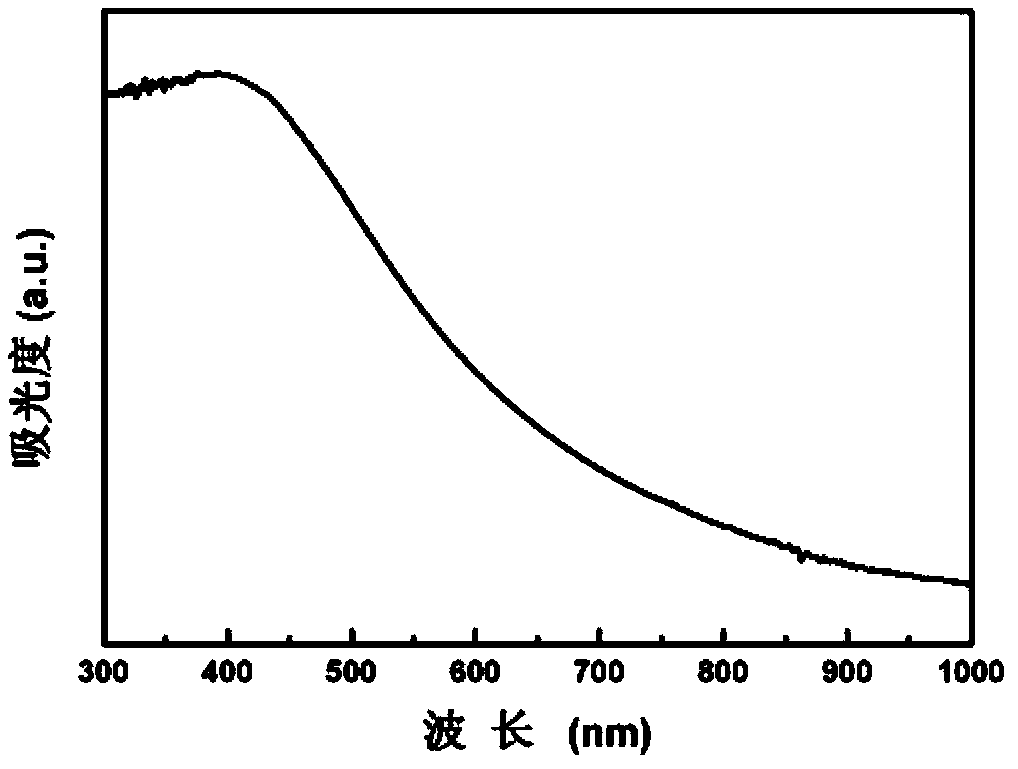

[0028] At room temperature, add 0.225g SnCl 2 ·2H 2 O dissolved in dilute hydrochloric acid (2mL concentrated hydrochloric acid, 25mL deionized water), continue to add 0.2mL Triton X-100 (Triton X-100 and SnCl 2 ·2H 2 The molar ratio of O is 0.33:1), the mixture is uniformly mixed by ultrasonic stirring; then 0.075g of TAA is added, and ultrasonic stirring is continued for 30 minutes. The obtained precursor was transferred to a stainless steel reactor lined with polytetrafluoroethylene. React at 180°C for 10h. After the reaction, cool to room temperature naturally, then centrifuge at 8000 rpm, and wash several times with deionized water and absolute ethanol, and dry to obtain SnS 2 . SnS 2 The ultraviolet absorption spectrum of nanomaterials dispersed in ethanol is shown as figure 2 Shown. SnS prepared 2 The projection electron microscope...

Embodiment 2

[0033] SnS of this embodiment 2 The synthesis process of nanomaterials is as follows figure 1 As shown, the specific steps are as follows:

[0034] 0.225g SnCl 2 ·2H 2 O dissolved in dilute hydrochloric acid (2mL concentrated hydrochloric acid, 25mL deionized water), continue to add 0.61mL Triton X-100 (Triton X-100 and SnCl 2 ·2H 2 The molar ratio of O is 1:1), the mixture is uniformly mixed by ultrasonic stirring; then 0.078 g of sodium sulfide is added, and the ultrasonic stirring is continued for 30 minutes. The obtained precursor was transferred to a stainless steel reactor lined with polytetrafluoroethylene. Reaction at 140°C for 12h. After the reaction, it was cooled to room temperature naturally, then centrifuged at 20000rpm, washed several times with deionized water and absolute ethanol, and dried to obtain SnS 2 nanomaterials.

Embodiment 3

[0036] SnS of this embodiment 2 The synthesis process of nanomaterials is as follows figure 1 As shown, the specific steps are as follows:

[0037] 0.225g SnCl 2 ·2H 2 O dissolved in dilute hydrochloric acid (2mL concentrated hydrochloric acid, 25mL deionized water), continue to add 0.06mL Triton X-100 (Triton X-100 and SnCl 2 ·2H 2 The molar ratio of O is 0.1:1), the mixture is uniformly mixed by ultrasonic stirring; then 0.075g of TAA is added, and ultrasonic stirring is continued for 30 minutes. The obtained precursor was transferred to a stainless steel reactor lined with polytetrafluoroethylene. React at 200°C for 10h. After the reaction, cool to room temperature naturally, then centrifuge at 10000rpm, wash several times with deionized water and absolute ethanol, and dry to obtain SnS 2 nanomaterials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com