Negative ion far infrared nanometer multifunctional material

A negative ion far-infrared, multi-functional technology, applied in phototherapy, radiotherapy, cosmetic preparations, etc., can solve the problems of failing to meet hygienic standards, restricting the development of natural materials, and a small amount of negative ions, and achieves good economic effects and is suitable for The effect of mass production and large atomic radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] Preparation of phosphate buffer solution: Take 250ml of 0.2mol / L potassium dihydrogen phosphate solution, add 118ml of 0.2mol / L sodium hydroxide solution, dilute with water to 1000ml, and obtain.

[0056] First, use elutriation and separation to remove impurities such as clay minerals, mica, and dust in the powder sample, and dry it at 90°C with an electric constant temperature blast dryer; then use a WCF-2 multi-purpose magnetic analyzer Sorting is carried out to remove some impurities such as magnetite, quartz and feldspar in the sample and iron pollution introduced during the crushing process, so as to obtain a relatively pure tourmaline powder sample.

[0057] Crushing of tourmaline crystal particles: the washed ore is crushed for the first time with SP-100×100 jaw crusher to obtain samples with a particle size of 0-15mm; The roller crusher crushed for the second time to obtain a sample with a particle size of 1-5 mm; the vibration mill was used for the third cru...

Embodiment 1

[0094] 1. Modified silica gel

[0095] The grade of silica gel is ZY-820 food grade silica gel raw material.

[0096] (1) Activated silica gel

[0097] Weigh 100g of food silica gel, first treat it with 1:1.2 nitric acid aqueous solution at 95°C for 2 hours, wash it with distilled water until neutral, then soak it with 1:1.2 hydrochloric acid for 5 hours, and then wash it with distilled water several times until there is no chloride ion , and finally dried in a muffle furnace at 150° C. for 5 h, cooled for later use.

[0098] (2) SiO2 -NH 2 Synthesis

[0099] Put the activated silica gel in a four-neck round bottom flask, add 80ml of silylating reagent γ-aminopropyltrimethoxysilane (APTS) and 400ml of redistilled toluene respectively, stir and reflux at 75°C for 8.5h, and filter out the solid , followed by extraction with toluene for 5h, ethanol for 5h, and drying to obtain the product SiO 2 -NH 2 .

[0100] (3) SiO 2 -NH 2 Reaction with Tetramethylene Pentamine

[0...

Embodiment 2

[0112] 1. Modified silica gel

[0113] The grade of silica gel is ZY-820 food grade silica gel raw material.

[0114] (1) Activated silica gel

[0115] Weigh 160g of food silica gel, first treat it with 1:1.5 nitric acid aqueous solution at 95°C for 2 hours, wash it with distilled water until neutral, then soak it with 1:1.5 hydrochloric acid for 5 hours, and then wash it with distilled water several times until there is no chloride ion , and finally dried in a muffle furnace at 120° C. for 5 hours, and cooled for later use.

[0116] (2) SiO 2 -NH 2 Synthesis

[0117] Put the activated silica gel in a four-necked round-bottomed flask, add 100ml of silylating agent γ-aminopropyltrimethoxysilane (APTS) and 420ml of redistilled toluene respectively, stir and reflux at 72°C for 8.5h, filter out Solid, sequentially extracted with toluene for 5h, ethanol for 5h, and dried to obtain the product SiO 2 -NH 2 .

[0118] (3) SiO 2 -NH 2 Reaction with Tetramethylene Pentamine

...

PUM

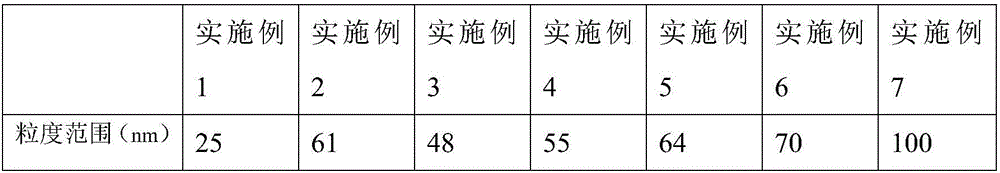

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com