Neutral silicone negative ion structure adhesive, plywood and preparation method

A technology of negative ions and structural adhesives, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve problems such as inability to generate negative ions, improve independent structure and anti-vibration performance, and increase stability , increase the effect of hardness and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

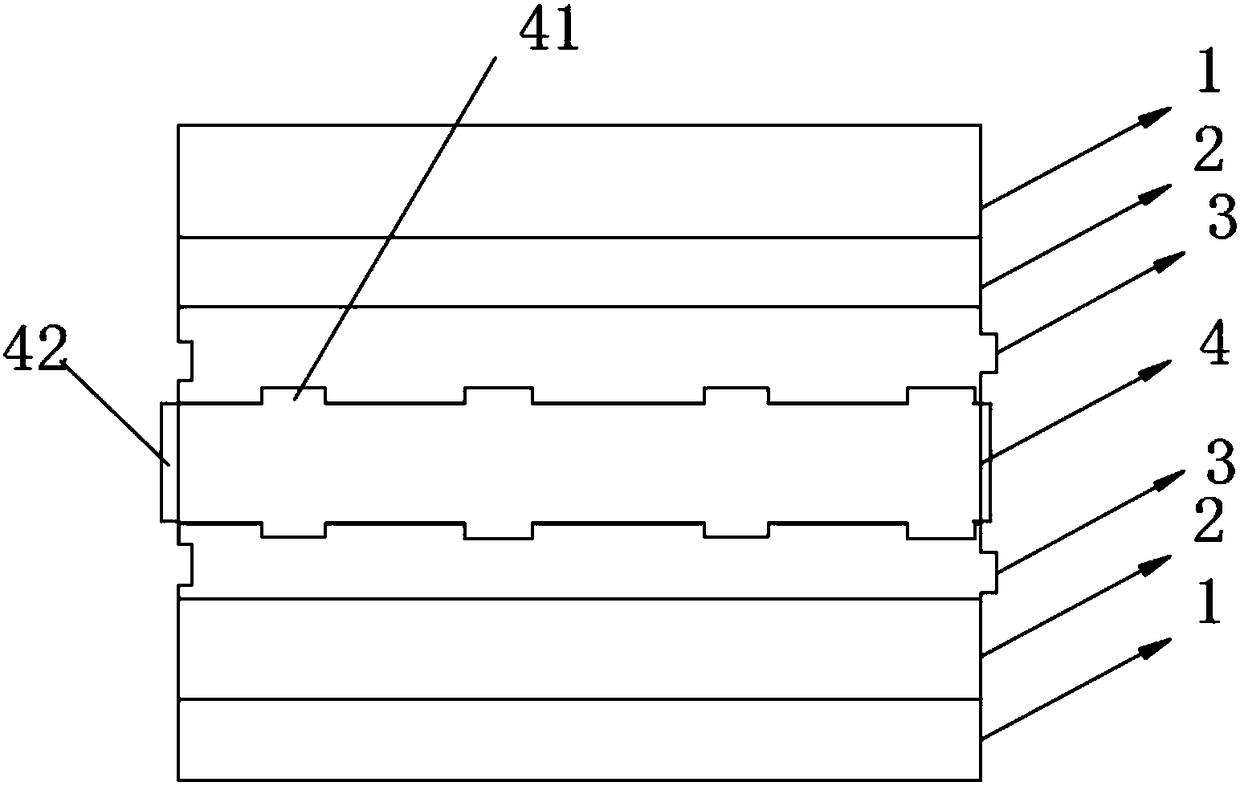

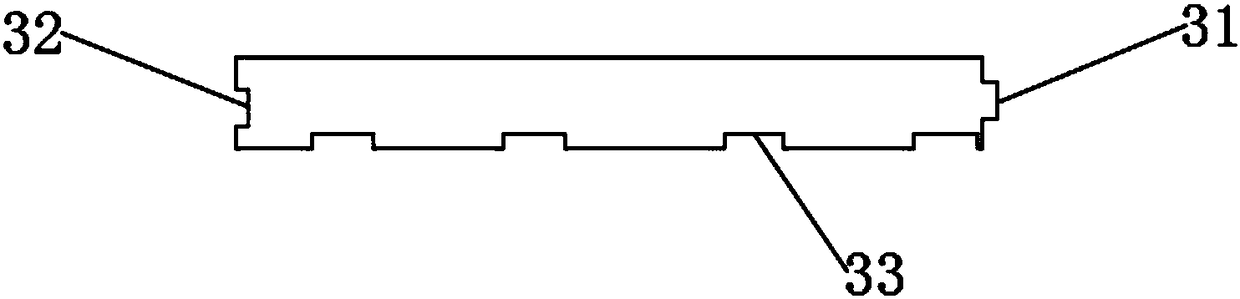

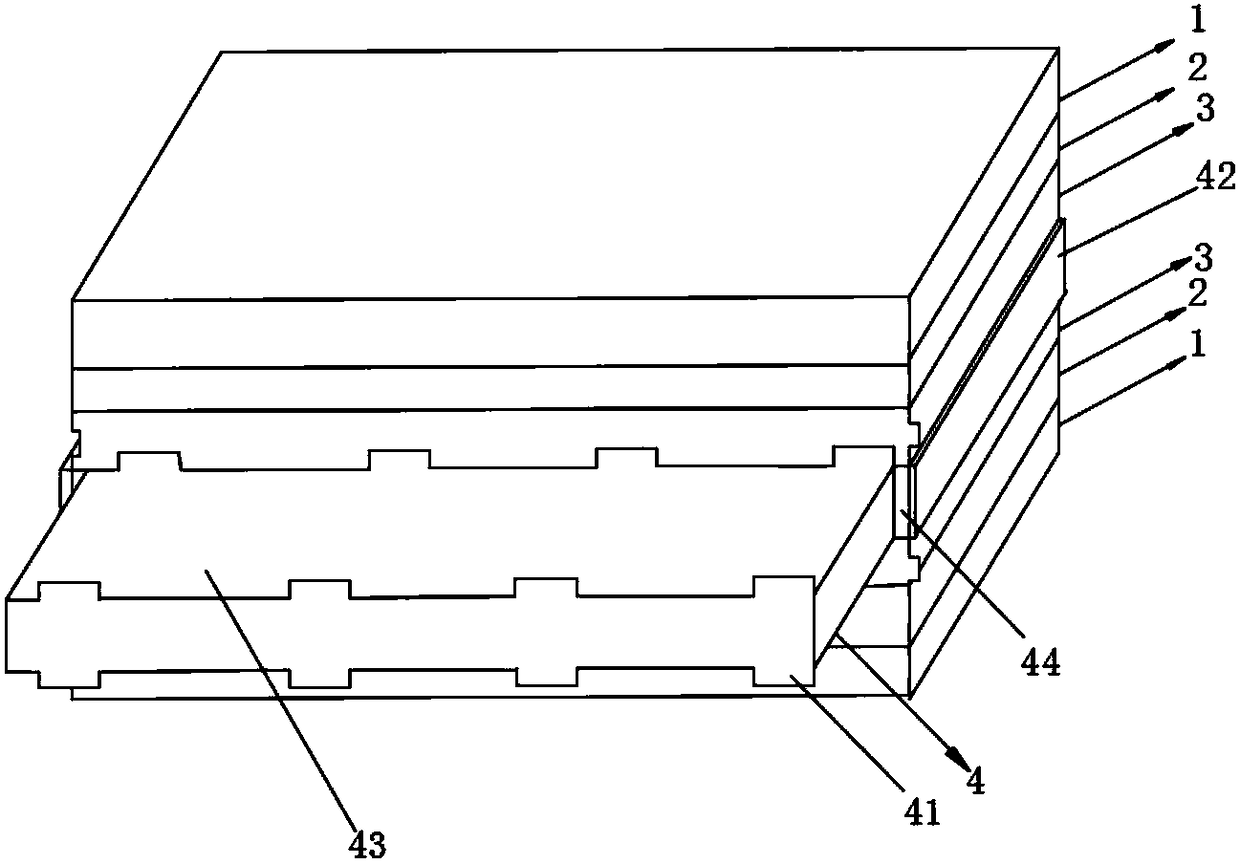

Image

Examples

Embodiment 1

[0084] A neutral silicone anion structural adhesive, made of the following components in parts by weight, 40 parts of organohydroxy silicone, 10 parts of methyl silicone, 20 parts of organic methyl ketone, 30 parts of calcium carbonate, aminosilane 0.7 parts, 10 parts of meteorological silica and 7 parts of negative ion wood powder; further, 5 parts of titanium dioxide or 5 parts of carbon powder.

[0085] Wherein, negative ion wood powder preparation method is as follows,

[0086] Step 1: Prepare banyan powder

[0087] (1) material selection, select the banyan tree more than 1 year old;

[0088] (2) wash the banyan tree three times with light salt water of 10% concentration, then take out and drain the water;

[0089] (3) drying, at a temperature of 80°C, drying for 3 hours;

[0090] (4) Disinfection, sterilize for 40 minutes with an ultraviolet disinfection device;

[0091] (5) crushing and grinding, using a powder grinder, grinding to 160 orders;

[0092] Step 2: Prepa...

Embodiment 2

[0103] A neutral silicone anion structural adhesive, made of the following components in parts by weight, 10 parts of organohydroxy silicone, 2 parts of methyl silicone, 5 parts of organic methyl ketone, 15 parts of calcium carbonate, aminosilane 0.1 part, 2 parts of meteorological silica and 2 parts of negative ion wood powder; further, 1 part of titanium dioxide and 1 part of carbon powder. Wherein, the preparation method of negative ion wood powder is as follows:

[0104] Step 1: Prepare banyan powder

[0105] (1) material selection, select the banyan tree more than 1 year old;

[0106] (2) wash the banyan tree three times with light salt water of 5% concentration, then take out and drain the water;

[0107] (3) drying, at a temperature of 60°C, drying for 2 hours;

[0108] (4) Disinfection, sterilize for 30 minutes with an ultraviolet disinfection device;

[0109] (5) crushing and grinding, using a powder grinder, grinding to 60 orders;

[0110] Step 2: Prepare Hokuto...

Embodiment 3

[0121] A neutral silicone anion structural adhesive, made of the following components in parts by weight, 25 parts of organohydroxy silicone, 6 parts of methyl silicone, 13 parts of organic methyl ketone, 23 parts of calcium carbonate, aminosilane 0.4 parts, 6 parts of meteorological silica and 5 parts of negative ion wood powder; further, 3 parts of titanium dioxide or 3 parts of carbon powder.

[0122] Wherein, the preparation method of negative ion wood powder is as follows:

[0123] Step 1: Prepare banyan powder

[0124] (1) material selection, select the banyan tree more than 1 year old;

[0125] (2) wash the banyan tree three times with light salt water of 10% concentration, then take out and drain the water;

[0126] (3) drying, at a temperature of 60°C, drying for 3 hours;

[0127] (4) Disinfection, sterilize for 30 minutes with an ultraviolet disinfection device;

[0128] (5) crushing and grinding, using a powder grinder, grinding to 160 orders;

[0129] Step 2: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com