Water-base polyurethane coating for fan blades and preparation method thereof

A technology of water-based polyurethane and fan blades, which is applied in coatings and other directions, can solve problems such as environmental pollution, application restrictions, and poor low-temperature performance of coatings, and achieve low VOC emissions, eliminate safety hazards, and excellent overall performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] (1) Preparation of component A: first add deionized water according to the formula amount, slowly add anti-sedimentation agent under stirring, disperse at high speed for about 10 minutes until it becomes a uniform viscous slurry liquid, add wetting dispersant and defoamer and stir After 15 minutes, add pigments and fillers such as rutile titanium dioxide, carbon black, and precipitated barium sulfate. After dispersing evenly, use a sand mill to grind to a fineness of less than 30 μm. Filter to remove the grinding sand, and add acrylic acid dispersion, film-forming agent, and matting agent. , dispersed evenly and with a fineness of less than 30 μm, finally add a thickener, adjust the solid content with deionized water, filter and pack to become A component.

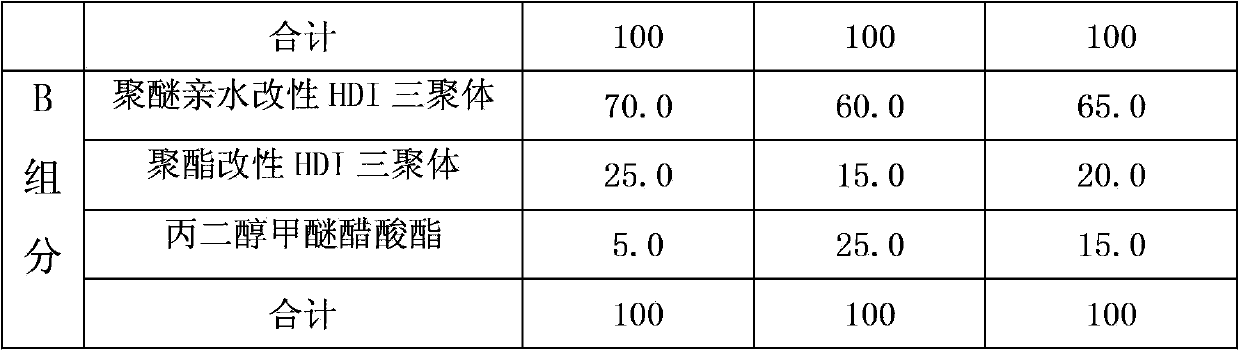

[0033] (2) Preparation of component B: mix and disperse polyether hydrophilic modified HDI trimer, polyester modified HDI trimer, and propylene glycol methyl ether acetate according to the formula amount, adjust the ...

example 1

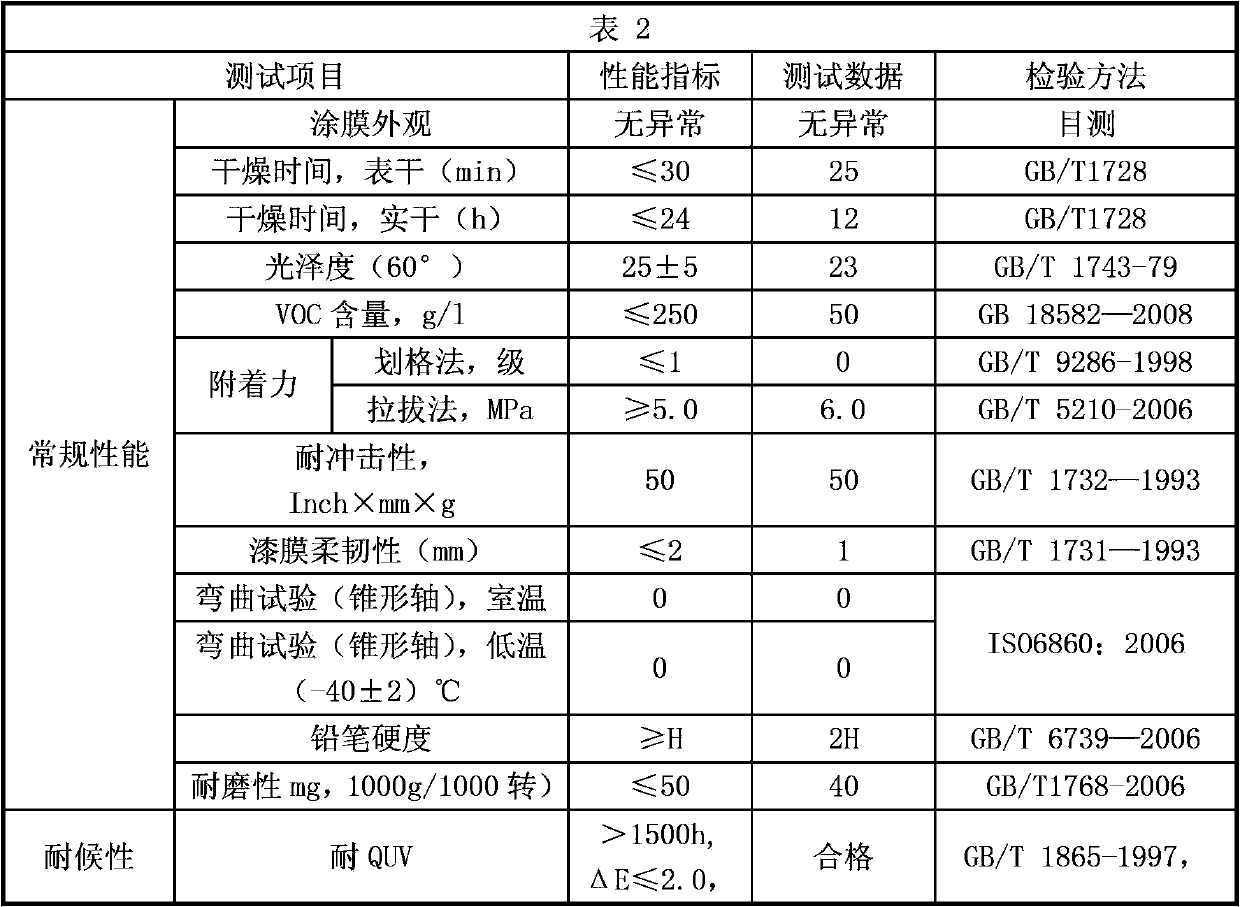

[0036] The test results of the fan blade water-based polyurethane coating in Example 1 are shown in Table 2:

[0037]

[0038]

example 2

[0039] The test results of the fan blade water-based polyurethane coating in Example 2 are shown in Table 3:

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com