Continuous posthydrolysis method for polyacrylamide

A technology of polyacrylamide and acrylamide, which is applied in the field of hydrolysis after continuous polyacrylamide, which can solve the problems of short mixing time of colloidal particles and hydrolyzing agent, uneven distribution of hydrolysis degree, unfavorable dispersion of hydrolyzing agent, etc., and increase the molecular weight of the product and solubility, which is beneficial to production control and improves the effect of temperature resistance and salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

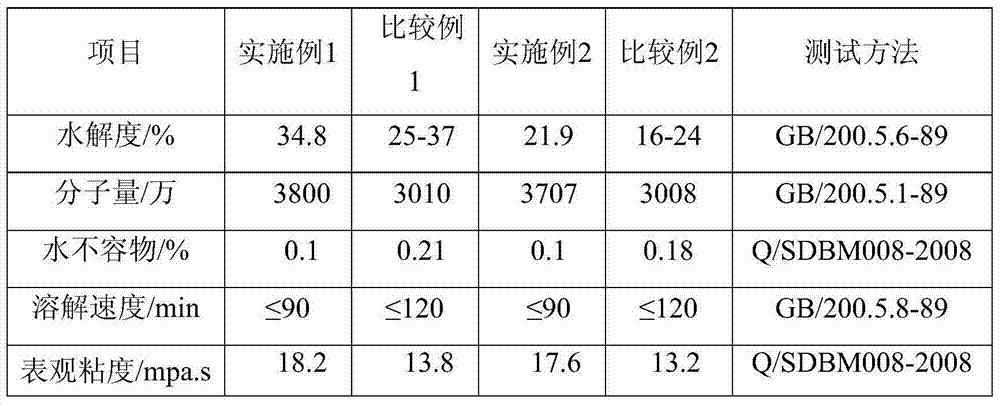

Embodiment 1

[0025] The weight of fresh rubber blocks with a water content of 80% is 900Kg. The rubber blocks are granulated through a granulation equipment, with a particle size of 5-9mm. The polyacrylamide rubber particles are 0.3- Add 9Kg dispersant polyglycerol ester at a uniform speed at 0.4m to disperse the colloidal particles without agglomeration. Add 35.1Kg NaOH (35% degree of hydrolysis) to the 0.7-0.8m of the thread for post-hydrolysis. The NaOH added per unit time The weight ratio of the outflow weight of polyacrylamide colloidal particles per unit time should be 1.5%-5%, and 9Kg dispersant Span 60 is added at 1.1-1.2m during the screw conveying process, so that the polyacrylamide colloidal particles and NaOH Mix well; after all the polyacrylamide colloidal particles are moved to the intermediate silo and sealed for 4 hours, the hydrolysis reaction of the polyacrylamide colloidal particles can be completed. The fully hydrolyzed colloidal particles are secondary granulated, drie...

Embodiment 2

[0029] The weight of fresh rubber blocks with a moisture content of 70% is 800Kg. The rubber blocks are granulated through a granulation equipment with a particle size of 5-9mm. The polyacrylamide rubber particles are 300- Add 8Kg of dispersant fatty alcohol ethylene oxide condensate at a constant speed at 400cm to disperse the colloidal particles without sticking and agglomerating. Add 62.5KgNaHCO at 700-800cm of the thread 3 (22% degree of hydrolysis) after carrying out hydrolysis, the NaHCO added per unit time 3 The weight ratio of the outflow weight of polyacrylamide colloidal particles per unit time should be 1.5%-5%. Add 9Kg dispersant sorbitan fatty acid ester at 1100-1200cm during the screw conveying process to make the polyacrylamide gel Granules can be mixed with NaHCO 3 Mix well; after all the polyacrylamide colloidal particles are moved to the intermediate silo and sealed for 4 hours, the hydrolysis reaction of the polyacrylamide colloidal particles can be complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com