Patents

Literature

43results about How to "Product properties are stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

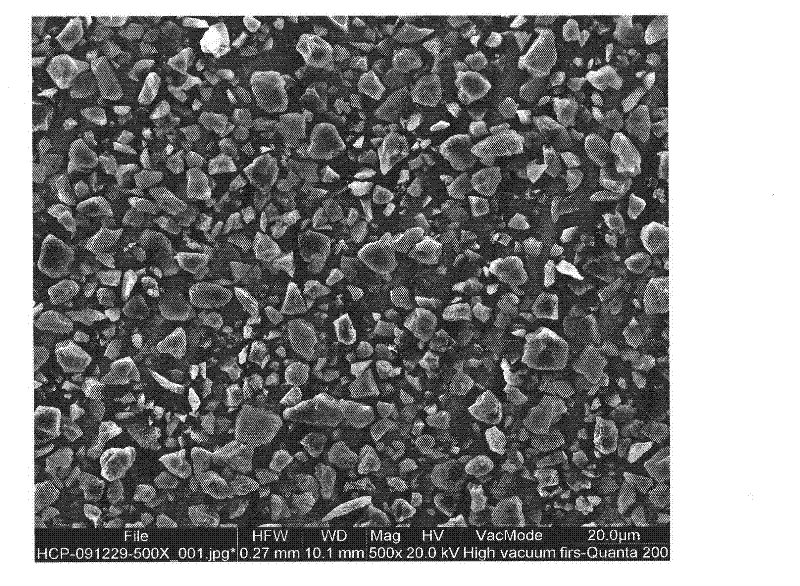

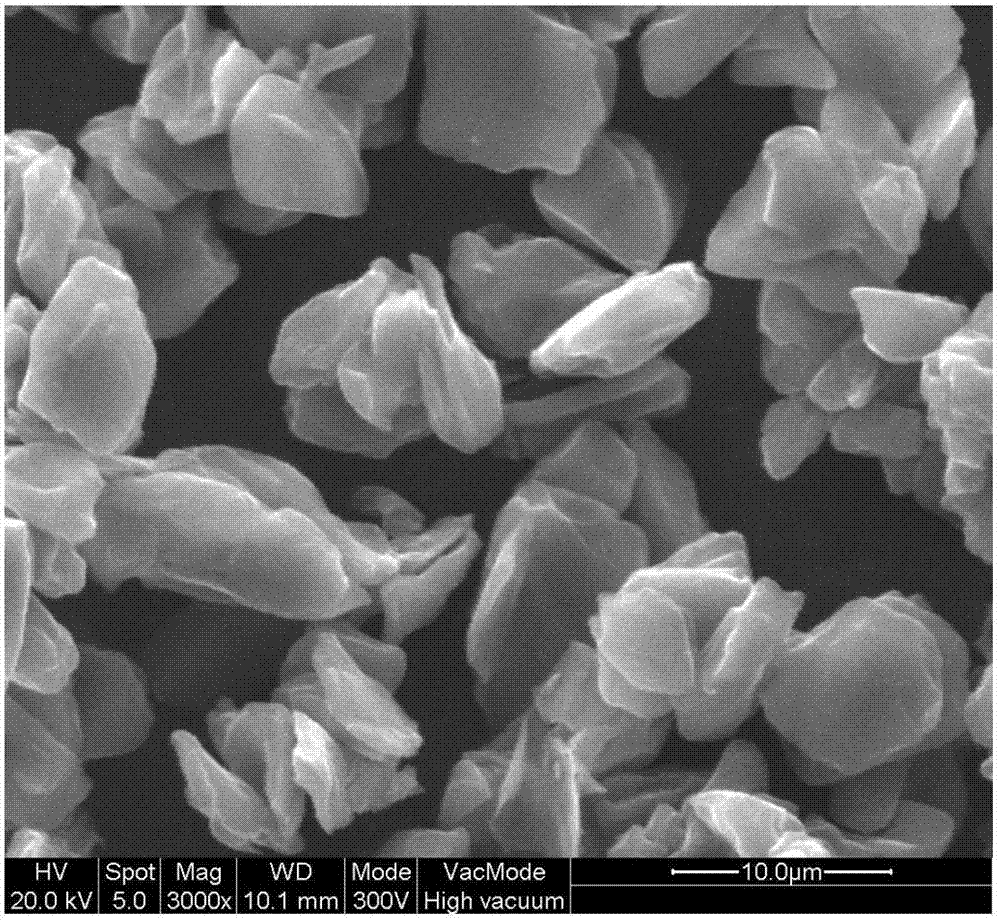

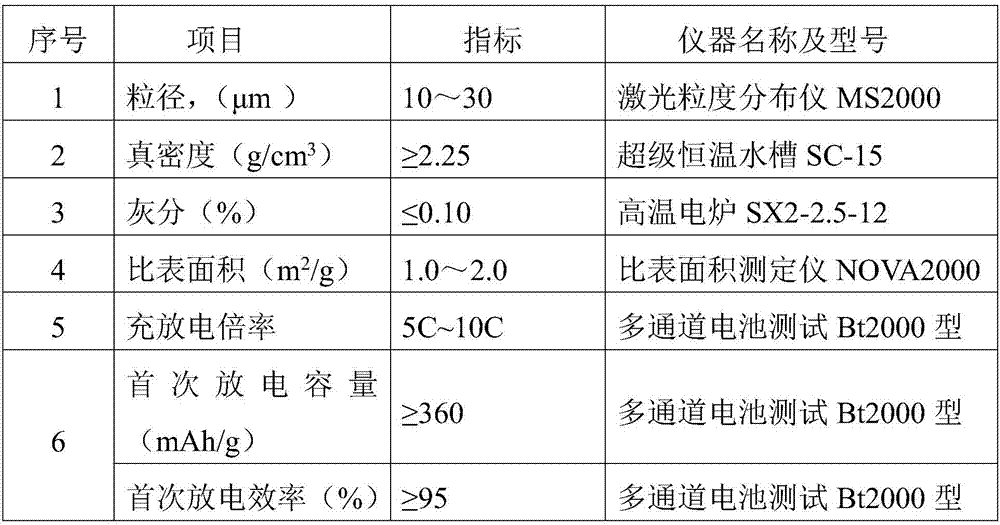

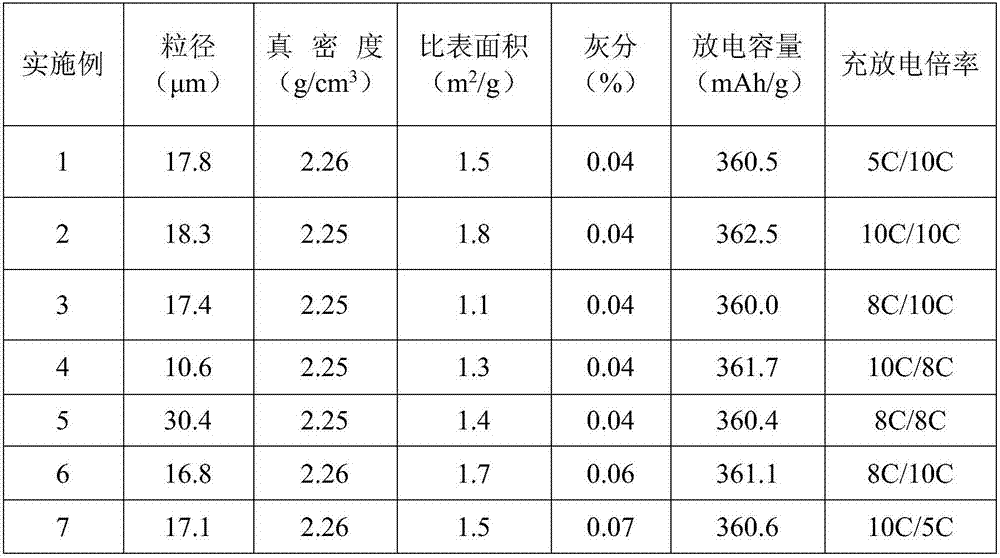

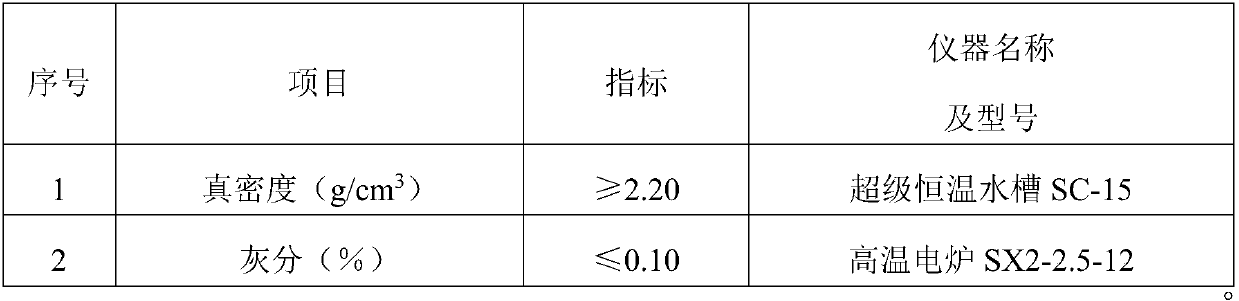

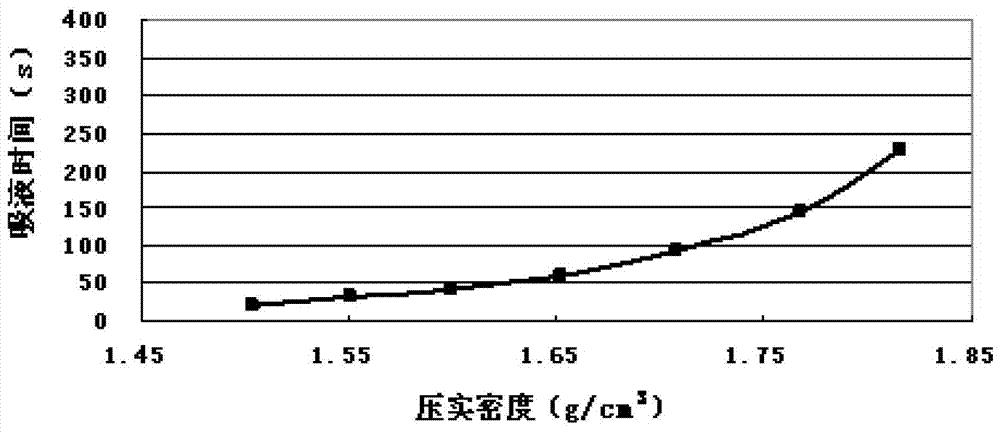

Synthetic graphite negative electrode material and preparation method thereof

ActiveCN104143635AIncrease compaction densityImprove discharge capacityCell electrodesSecondary cellsAdhesiveRoom temperature

The invention discloses a synthetic graphite negative electrode material and a preparation method thereof. The preparation method comprises the following steps: (1) uniformly mixing spherical natural graphite, needle coke-produced coke powder and a graphitization catalyst so as to obtain a mixture; 2) subjecting the mixture and an adhesive which can be graphitized to heating and kneading for 1 to 2 h; 3) pressing the kneaded object into a block shape so as to obtain a formed body of the kneaded object; 4) charring the formed body at 800 to 1500 DEG C under the protection of inert gas and cooling the charred formed body to room temperature; and 5) carrying out catalytic graphitization high temperature treatment at 2800 to 3200 DEG C. The method provided by the invention overcomes the defects of insufficient compacted density and low discharge capacity of a synthetic graphite negative electrode material prepared by using a conventional negative electrode preparation method, can improve cycle performance of the negative electrode material and enables the synthetic graphite negative electrode material with high charge and discharge capacity and high charge and discharge efficiency to be obtained.

Owner:NINGBO SHANSHAN NEW MATERIAL TECH

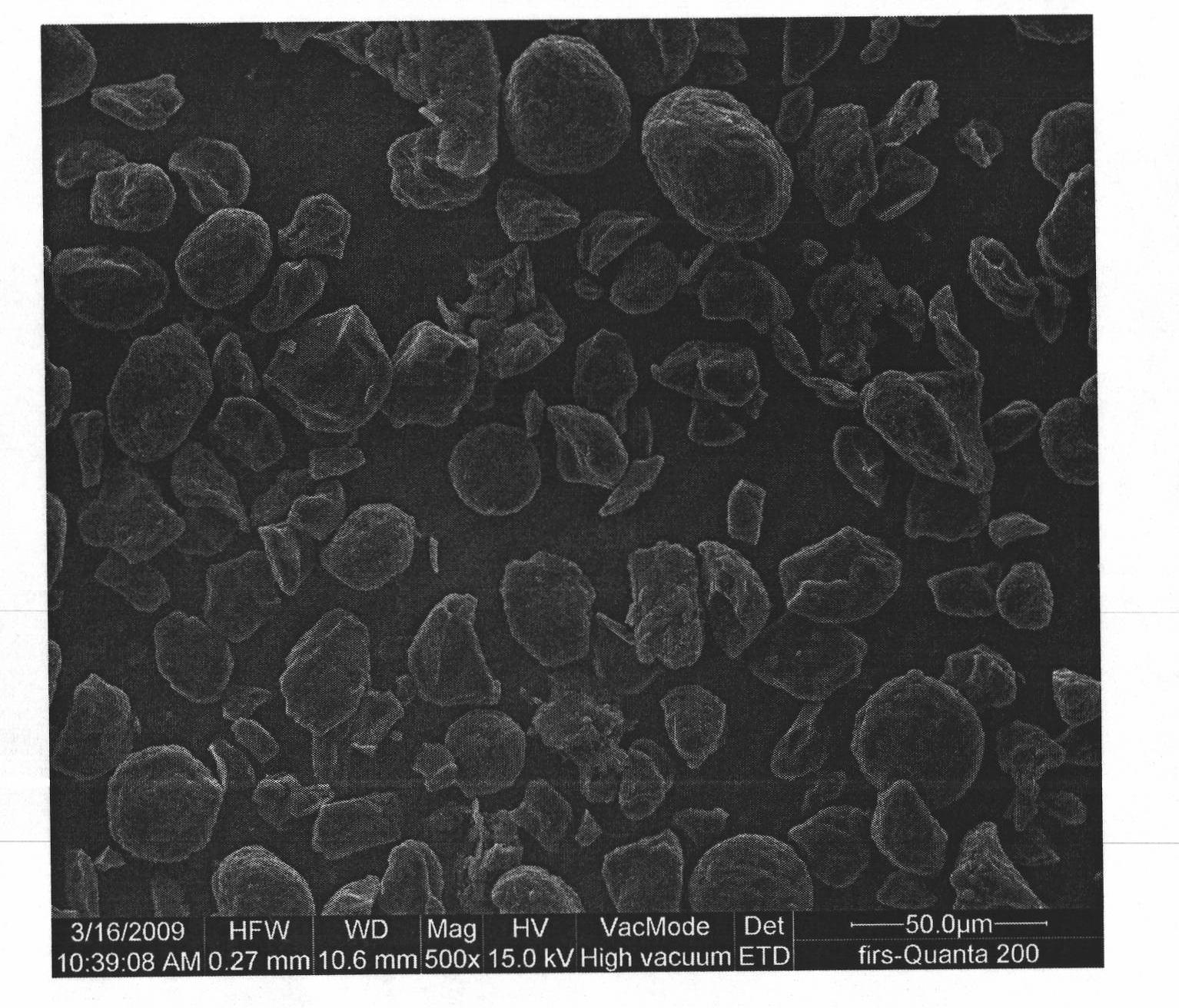

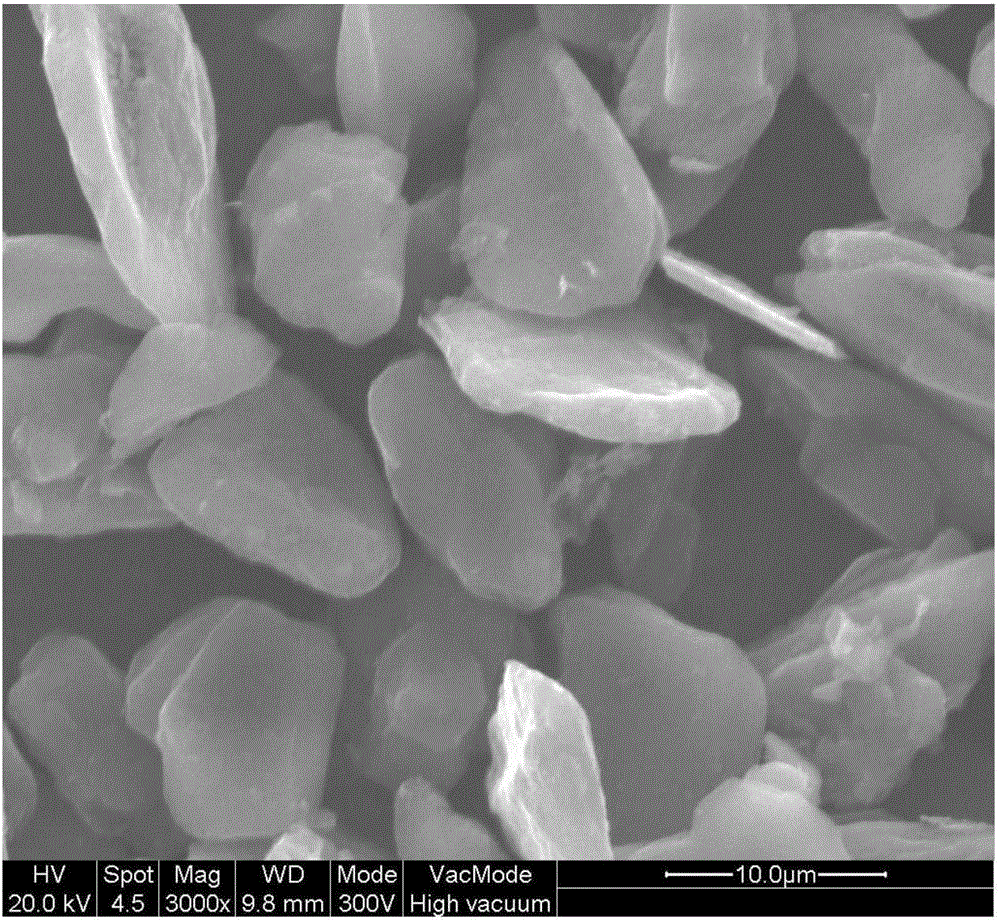

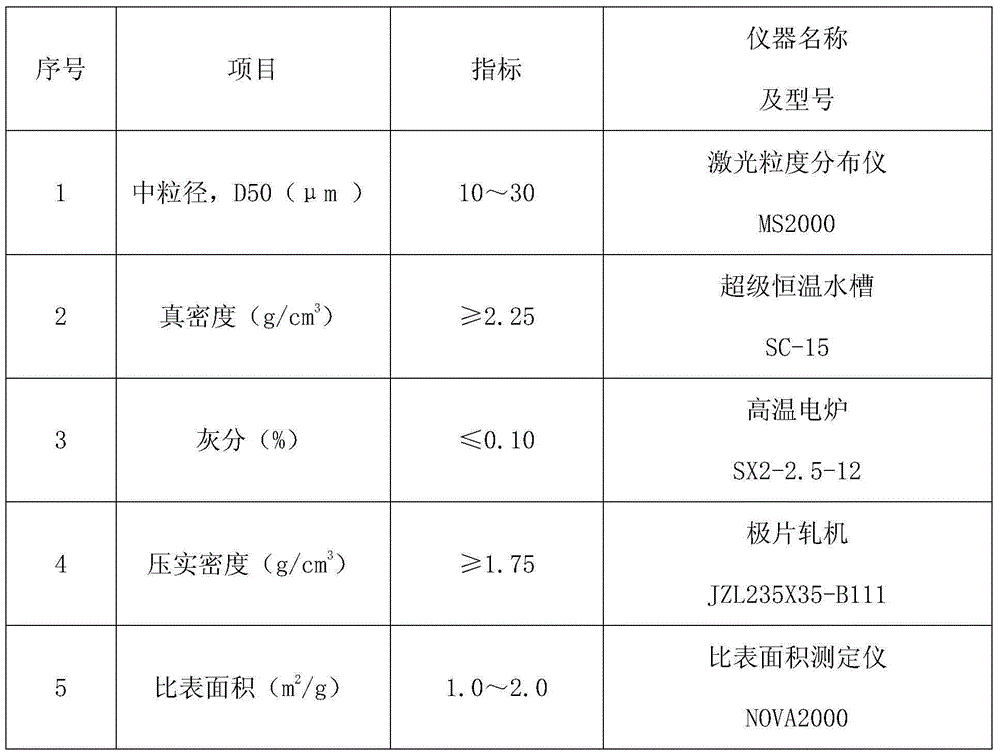

Composite graphite particles for lithium secondary battery and preparation method thereof

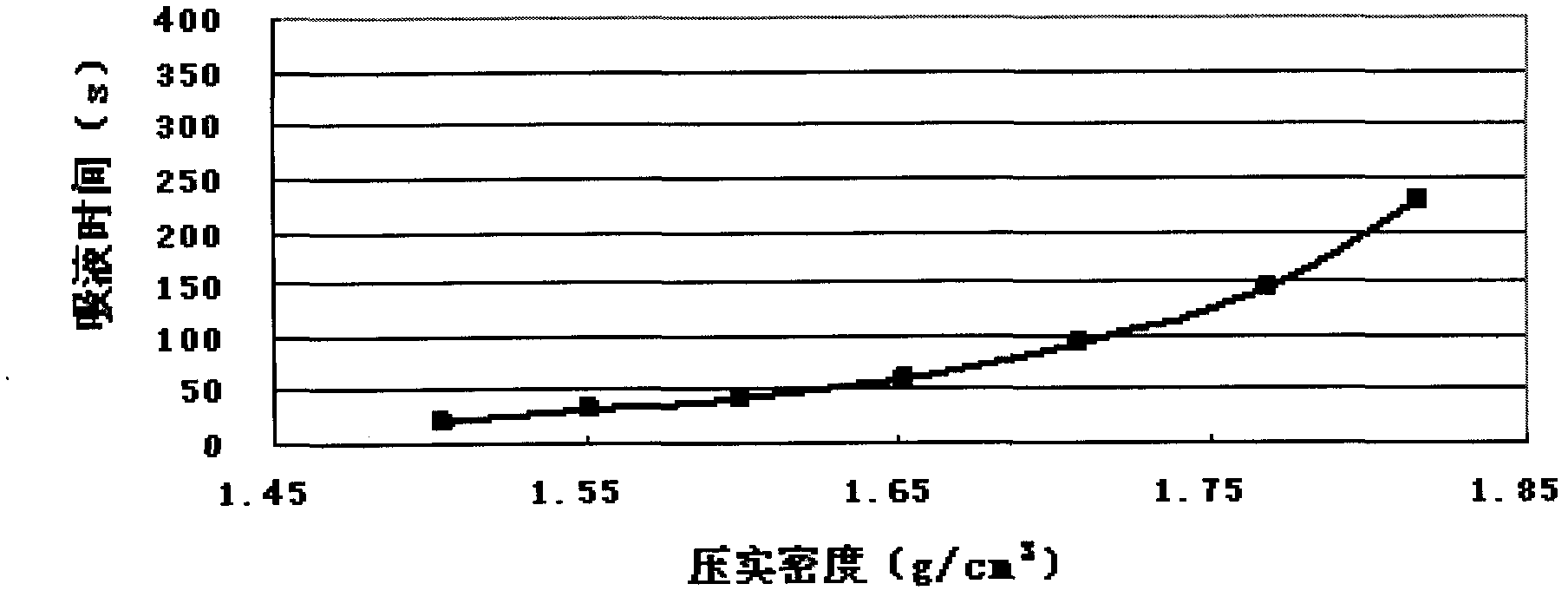

ActiveCN102593434AIncrease compaction densityImprove discharge capacityCell electrodesLithiumRoom temperature

The invention relates to a preparation method for composite graphite particles for a lithium secondary battery. The method comprises the following steps: 1, heating and kneading spherical natural graphite particles, adhesive capable of being graphitization, and graphitized catalyst to form a kneaded thing; 2, pressing the kneaded thing into block to form a formed kneaded thing; 3, under the protection of an inert gas, carbonizing the formed kneaded thing at the temperature of 800-1,500 DEG C, and cooling the kneaded thing to room temperature; 4, under the protection of the inert gas, allowing the formed kneaded thing to be subjected to catalysis and graphitization high-temperature processing at the temperature of 2,800-3,200 DEG C; and 5, performing classifying or screening after the kneaded thing is smashed. The invention further relates to composite graphite particles for the lithium secondary battery prepared by the method. The composite graphite particles have higher compacted density, large discharge capacity, good circulation performance, good electrochemistry performance, better high-current charge-discharge performance, and better safety, discharge platform availability and higher platform retention rate.

Owner:SHANGHAI SHANSHAN TECH CO LTD +1

Graphite material at negative pole of lithium ion battery and preparation method thereof

ActiveCN102110813AImprove adaptabilityImprove performanceCell electrodesMicroballoon preparationMass ratioGraphite

The invention discloses a graphite material at the negative pole of a lithium ion battery, which comprises interphase graphite and artificial graphite in mass ratio of 90:10 to 20:80. The graphite material has the advantages of highly compacted density, small specific surface area, high discharge capacity, long circulating life, high charge-discharge efficiency and high product performance-price ratio. The invention also provides a method for preparing the graphite material, which has the advantages of simple, convenient and feasible technology, wide raw material sources and lower cost.

Owner:福建杉杉科技有限公司

Lithium secondary battery composite graphite and preparation method thereof

InactiveCN106532044AIncrease compaction densityImprove discharge capacityGraphiteNegative electrodesPtru catalystElectrical battery

The invention discloses lithium secondary battery composite graphite and a preparation method thereof. The method comprises the following steps: (1) pitch coke raw materials are crushed, shaped and treated, median particle size D 50 is controlled between 5-10[mu]m; (2) pitch coke raw materials, an easily graphitized adhesive and a graphitized catalyst are mixed; (3) in the protection of inert gas, low temperature heat treatment is carried out at 300-800 DEG C, combination and granulation are carried out, and the temperature is cooled to room temperature; (4) in the protection of inert gas, catalytic graphitization is carried out at 2800-3200 DEG C, and high temperature treatment is carried out; (5) batch mixing and sieving are carried out in order to obtain the graphite. The invention also relates to lithium secondary battery composite graphite prepared by the method. The lithium secondary battery composite graphite has the advantages of large discharge capacity, good cycle performance, high compacted density, good electrochemical performance, high discharging platform conservation rate, good heavy current charging and discharging performance, and good safety.

Owner:SHANGHAI SHANSHAN TECH CO LTD

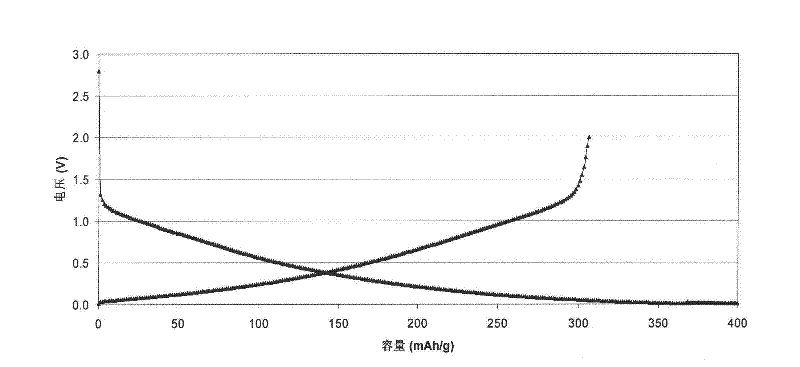

Hard carbon negative electrode material, its preparation method and application

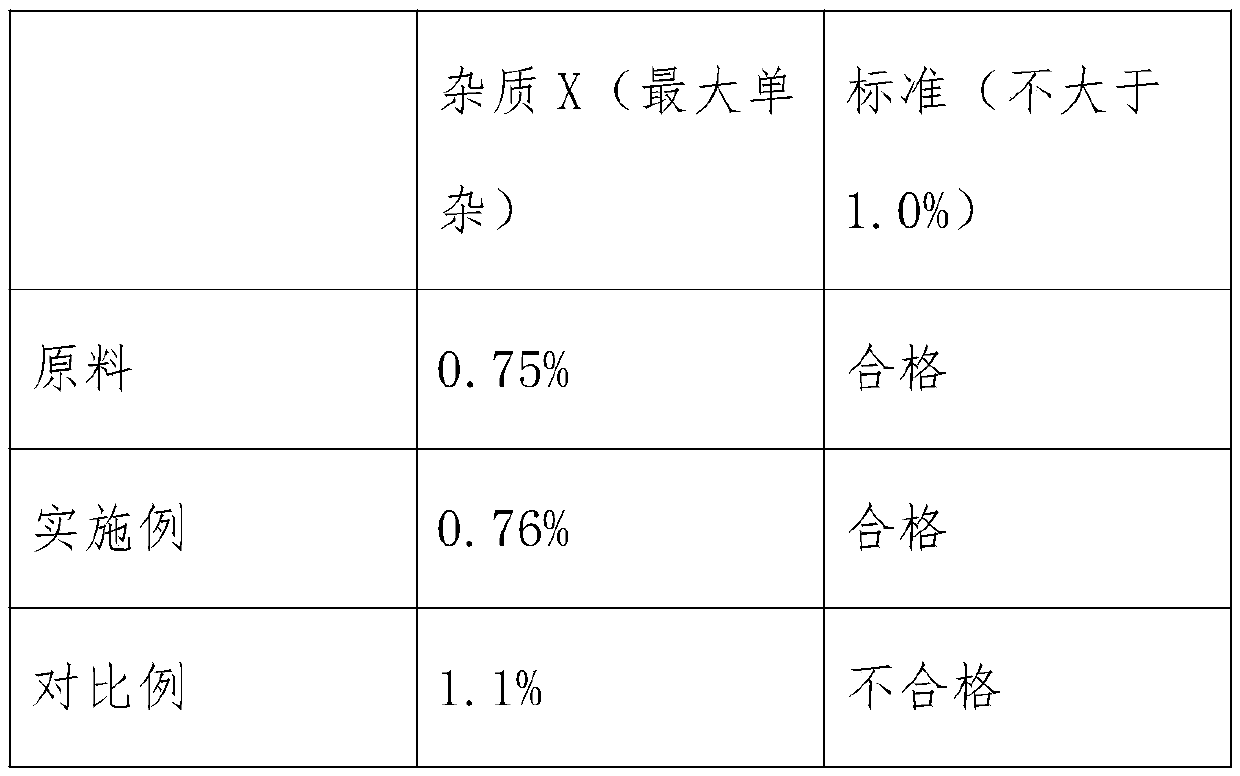

ActiveCN102479942AImprove performanceImprove electrochemical performanceCell electrodesEpoxyElectrolytic agent

The invention provides a preparation method of a hard carbon negative electrode material. The method comprises the steps of: (1) subjecting a high molecular polymer and a cross-linking agent to crosslinking and polymerization reactions so as to obtain a cross-linked polymer; (2) conducting crushing and screening; (3) under the protection of an inert gas, carrying out pre-carbonization treatment at a temperature of 400-600DEG C, performing cooling to room temperature, and carrying out crushing and screening; (4) under the protection of an inert gas, carrying out carbonization treatment at a temperature of 1000-1600DEG C, thus obtaining a hard carbon negative electrode material. The high molecular polymer is asphalt, epoxy resin or phenolic resin. The invention also provides a hard carbon negative electrode material prepared by the method as well as its application as a lithium ion battery negative electrode material. The preparation method of the invention is simple and practicable, and has easily available and cheap raw materials. The hard carbon negative electrode material provided in the invention has the advantages of: good comprehensive performance; good electrochemical performance; good cycle performance; good high current charge-discharge performance; good security; good adaptability to electrolyte and other additives; and stable product property, with almost no difference among batches.

Owner:SHANGHAI SHANSHAN TECH CO LTD

Processing method for black tea fungus solid beverage

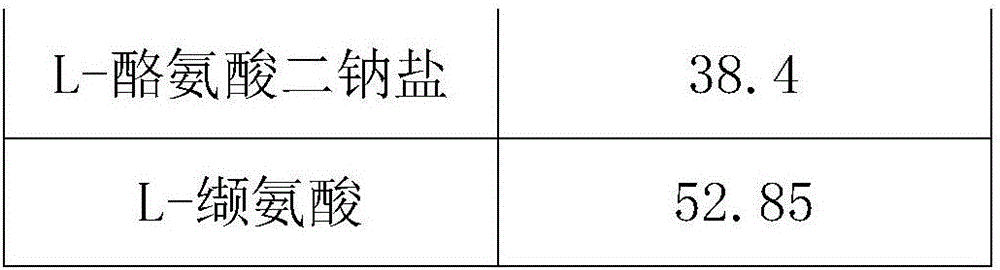

ActiveCN103859089AProduct properties are stableEasy to store and transportPre-extraction tea treatmentCitrate sodiumMaltodextrin

The invention discloses a processing method for a black tea fungus solid beverage. The processing method sequentially comprises the following steps: (1) preparing tea soup; (2) inoculating; (3) fermenting; (4) centrifuging; (5) sterilizing; (6) spraying and drying, namely adding a maltodextrin drying aid into concentrated liquid and uniformly mixing; and then drying by using a spraying dryer under the condition that an air inlet temperature is controlled at 150-180 DEG C, an air outlet temperature is controlled at 70-90 DEG C, and the water content is 5-7% after spraying and drying, thus preparing black tea fungus dried powder; and (7) blending and putting into bags, namely mixing and blending following materials into mixed powder I in percentage by weight: 1%-3% of instant black tea powder, 2%-3% of citric acid, 0.15%-0.45% of sodium citrate, 90%-96% of white granulated sugar powder; uniformly mixing the mixed powder I and the black tea fungus dried powder according to the ratio of (15%-50%) to (85%-50%) to obtain mixed powder II; and putting the powder into the bags. The sterilization treatment guarantees the stability of product properties and the product obtained by concentration and drying procedures is convenient to store and transport.

Owner:LISHUI VOCATIONAL & TECHN COLLEGE

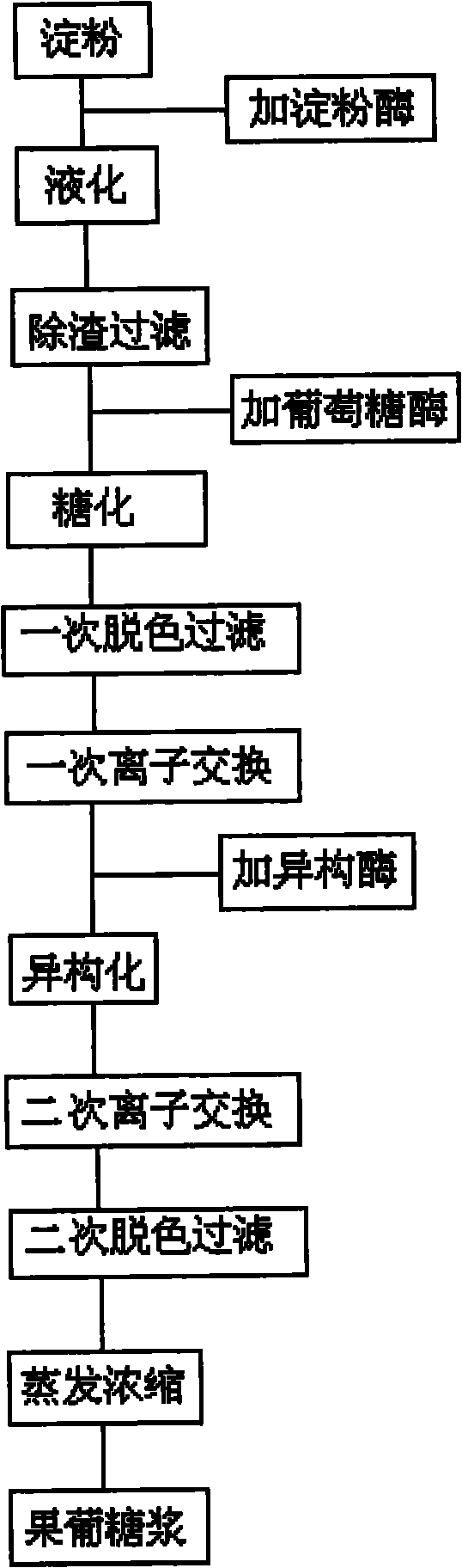

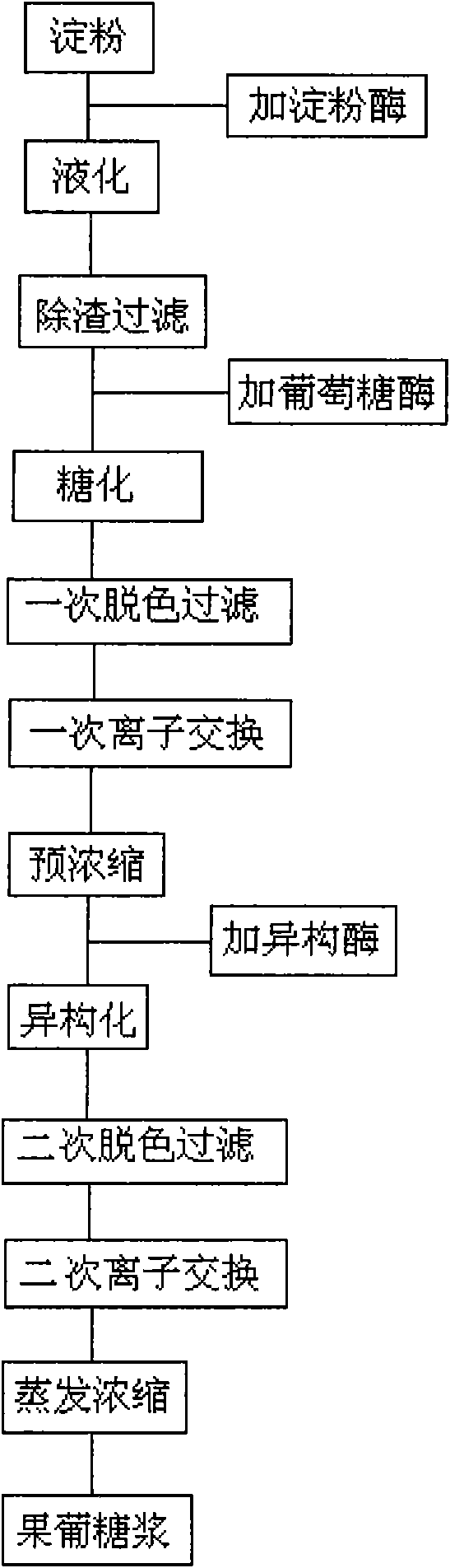

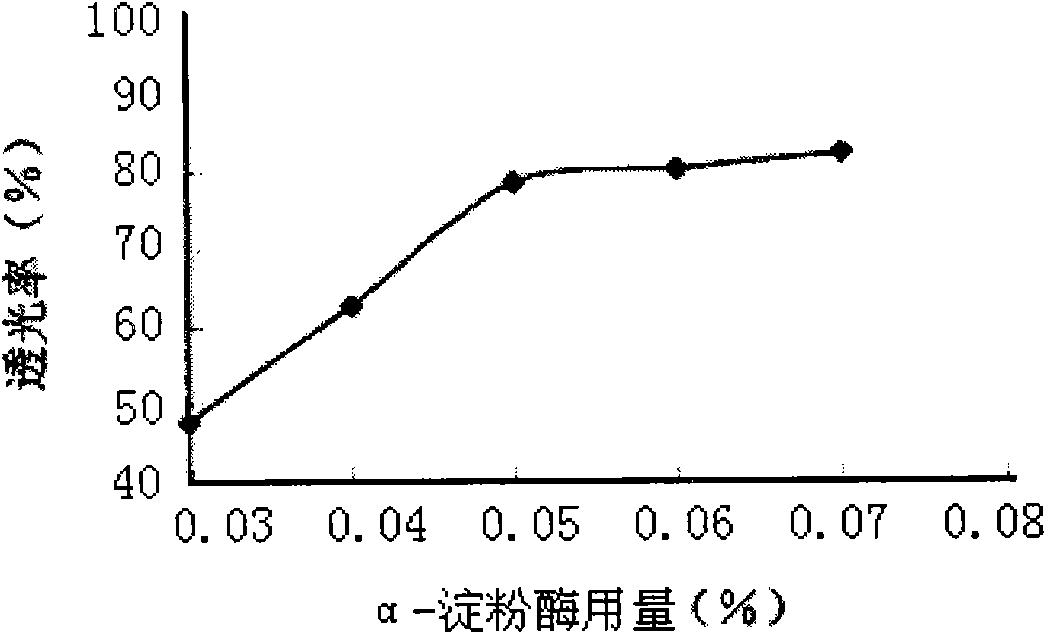

Production process of high fructose corn syrup

InactiveCN101864469AProduct properties are stableLow costFermentationHigh-fructose corn syrupFiltration

The invention provides a production process of high fructose corn syrup, which comprises the following steps that: adding amylase into starch to obtain hydrolysised starch, and then liquefying at high temperature; filtering and deslagging a liquefied product and adding glucolase to be glycated; carrying out the first time of decoloring, filtration, ion exchange and impurity removal to the glycated product; adding isomerase into discharge liquid so that part of the glucose is converted into fructose through isomerism; and evaporating and concentrating feed liquid after the second time of ion exchange, impurity removal, decoloring and filtration to obtain the high fructose corn syrup. Simultaneously, the production process neutralizes the initially discharged material with higher pH value by decoloring and filtration, thereby reducing the used amount of auxiliary materials, and controlling the production of color substances during production. In addition, after the process is changed, an ion-exchange column does not need to be regenerated in advance. The high fructose corn syrup product obtained from the production process has stable quality, saves cost and has very strong practicality.

Owner:武汉市金德戈糖业有限公司

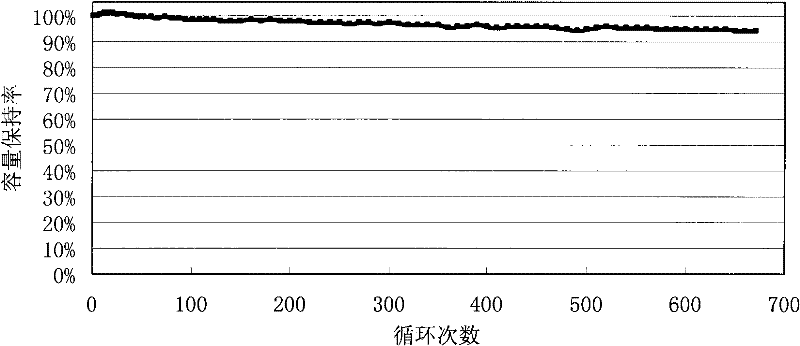

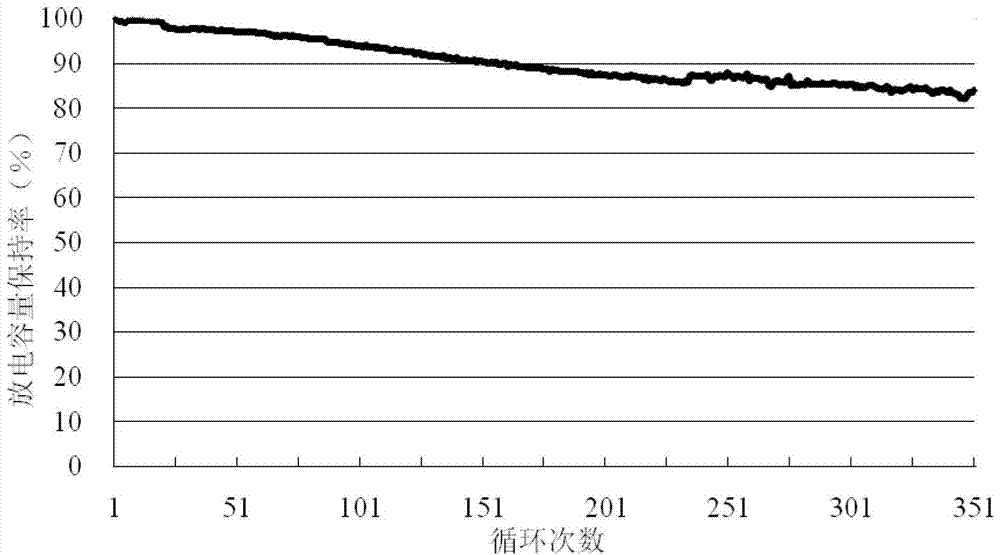

Preparation method of high-rate and rapid-charge graphite

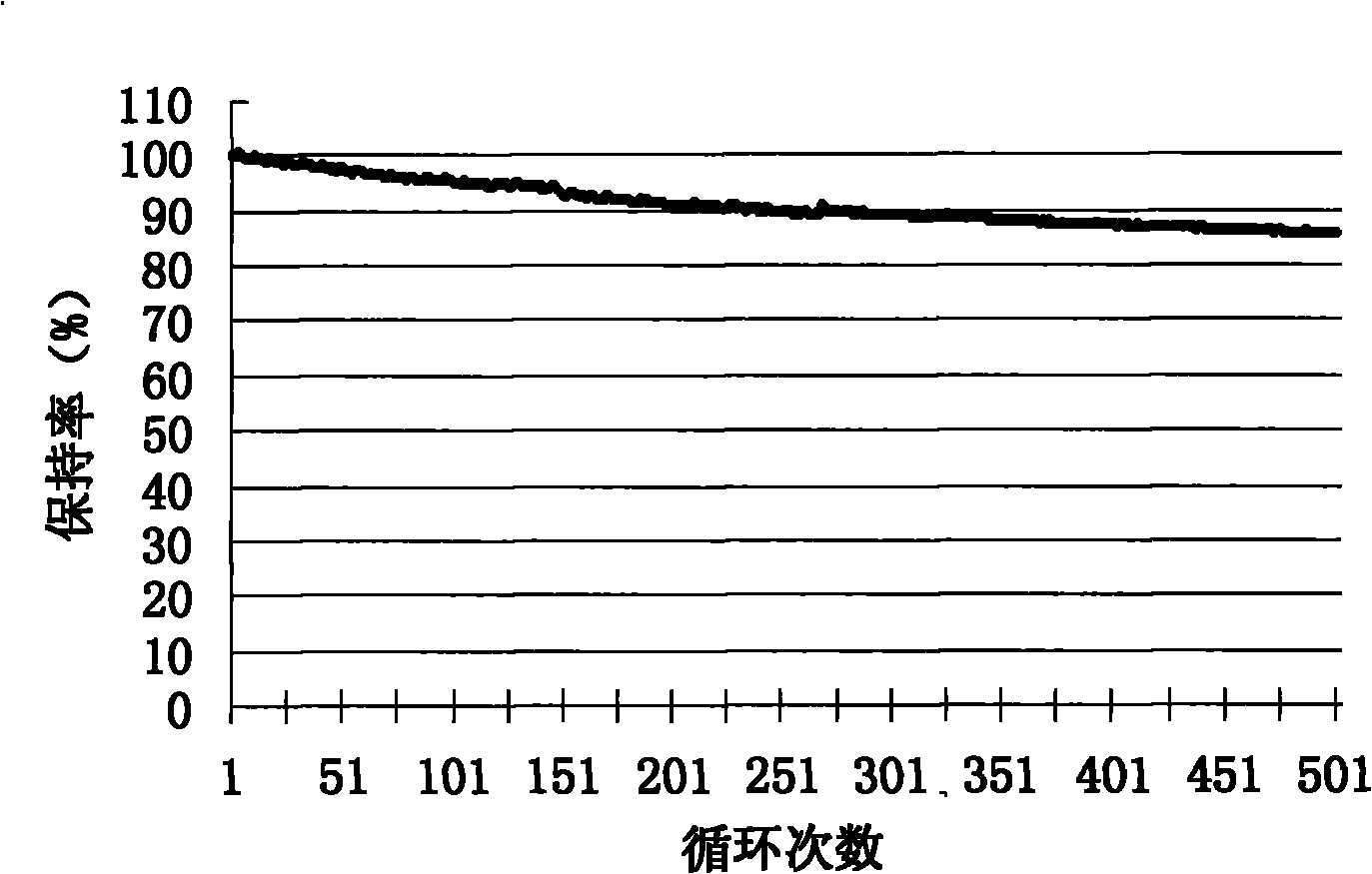

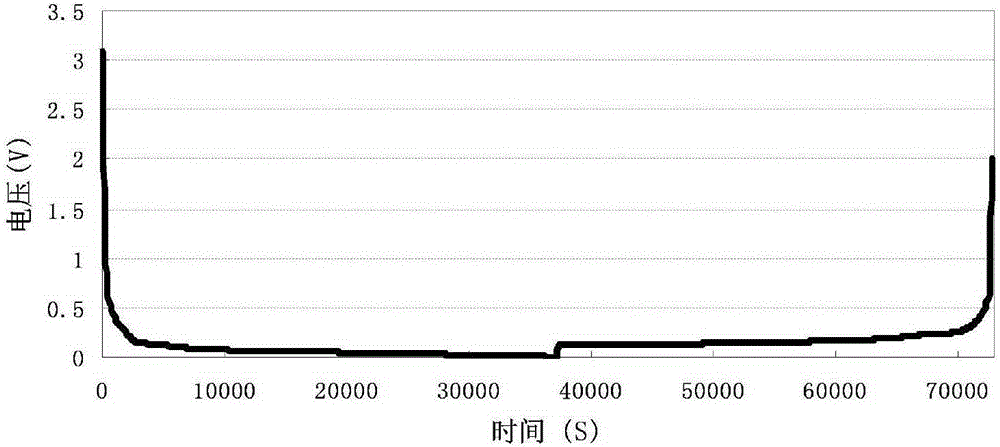

PendingCN107146880AHigh retention rateImprove adaptabilityCell electrodesSecondary cellsLithiumHigh rate

The invention relates to the technical field of a lithium ion secondary battery, in particular to a preparation method of high-rate and rapid-charge graphite. The preparation method is characterized by comprising the following steps of (1) smashing and shaping; (2) mixing a modifying agent; (3) performing graphitization high-temperature processing; (4) mixing an adhesive; (5) performing low-temperature thermal treatment; (6) performing carbonization thermal treatment; and (7) screening a mixture. Compared with the prior art, the graphite has the advantages of high charge-discharge rate, large discharge capacity and good cycle performance; and the prepared button cell is excellent in integral performance and mainly has the following advantages that 1, the large-current charge-discharge performance is relatively good; 2, the electrochemical performance is good; 4, the cycle property is good; 5, the safety is relatively good; 6, the adaptability to an electrolyte and other additives is relatively good; and 7, the product property is stable, and the button cell is suitable for industrial production.

Owner:NINGBO SHANSHAN NEW MATERIAL TECH

Feed additive for improving output and quality of silkworm cocoons and preparation method thereof

InactiveCN102626183AProduct properties are stableSimple and efficient operationBacteriaMicroorganism based processesWater contentElectric field

The invention discloses a preparation method for a feed additive for improving output and quality of silkworm cocoons, which comprises the following steps: inoculating strains of D. radiopugnance with the preservation number of ATCC 19172 on a solid medium to be cultivated, and then picking single bacterial colony to be inoculated on a liquid medium to obtain activated seed bacterium liquid; inoculating the activated seed bacterium liquid on a fermentation medium according to the inoculation amount of 4.5% to 6.0%, and cultivating for 60-72 hours at the temperature of 28 DEG C to 32 DEG C to obtain fermentation liquid; and centrifuging the fermentation liquid, laying obtained thallus of the D. radiopugnance to enable the thickness to be from 0.1cm to 1.0cm, then processing the obtained thallus of the D. radiopugnance for 40-60s with the frequency of 600-700MHz and the electric-field strength of 8,000-9,000 V / cm, drying with cold air until the water content is smaller than 8% and obtaining the feed additive for improving output and quality of silkworm cocoons.

Owner:ZHEJIANG UNIV

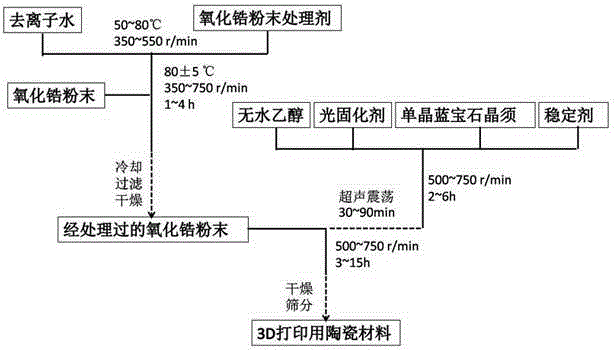

Ceramic material for 3D printing and preparation method thereof

The invention provides a ceramic material for 3D printing and a preparation method thereof. The ceramic material is prepared from, by weight, 50-150 parts of zirconia powder, 10-30 parts of zirconia powder treating agents, 100-500 parts of dispersion media, 1-10 parts of single-crystal sapphire whisker, 1-10 parts of stabilizing agents and 5-50 parts of light curing agents. The single-crystal sapphire whisker is added into the zirconia ceramics, so that the modulus of elasticity in static bending and the tensile strength of the product are significantly improved, and the preparation method is used for preparing high-strength and high-toughness fine engineering ceramics.

Owner:TSINGHUA INNOVATION CENT IN DONGGUAN +1

Needle milling production process of powdery cell culture medium

InactiveCN106222127ARealize continuous productionSmall footprintCulture processCell culture mediaCell culture mediaSmall footprint

The invention discloses a needle milling production process of a powdery cell culture medium. The process includes the steps of: 1) weighing raw materials according to types for later use; 2) pre-mixing the weighed raw materials in the step 1); 3) grinding and pulverizing the pre-mixed raw materials by means of a needle-type grinding miller; 4) final-mixing the pulverized materials in the step 3); and 5) packaging the final-mixed product. The process can achieve continuous production of the cell culture medium, wherein the productivity of the process is equal to that of a process with a large-size ball miller. The process is less in occupied area of equipment, saves production cost and production time, is high in productivity, is less in batch difference and has stable product quality.

Owner:TIANXINHE SUZHOU BIOTECH CO LTD

Ferment liquid

InactiveCN107581598ABalanced nutritional content of finished productsProduct properties are stableFood scienceMushroomBiotechnology

The invention provides a ferment composition. The ferment composition is prepared by performing mixing and then performing chelating on the following components in parts by weight: 26-34 parts of vegetable fermentation liquid, 55-60 parts of fruit fermentation liquid, 3-5 parts of herbaceous fermentation liquid, 6-8 parts of mushroom fermentation liquid, and 1-3 parts of lotus seed fermentation liquid. The ferment composition is partially neutral, and is suitable for women to use for a long term; besides, each fermentation raw material is singly fermented, so that the condition that various raw materials are fermented at the same time and are in interaction to influence the quality of finished products is avoided; and besides, the condition that because of different fermentation periods for different raw materials, part fermentation is incomplete, and the finished products are unstable, is avoided.

Owner:SHENZHEN CHUNRUI TRADE CO LTD

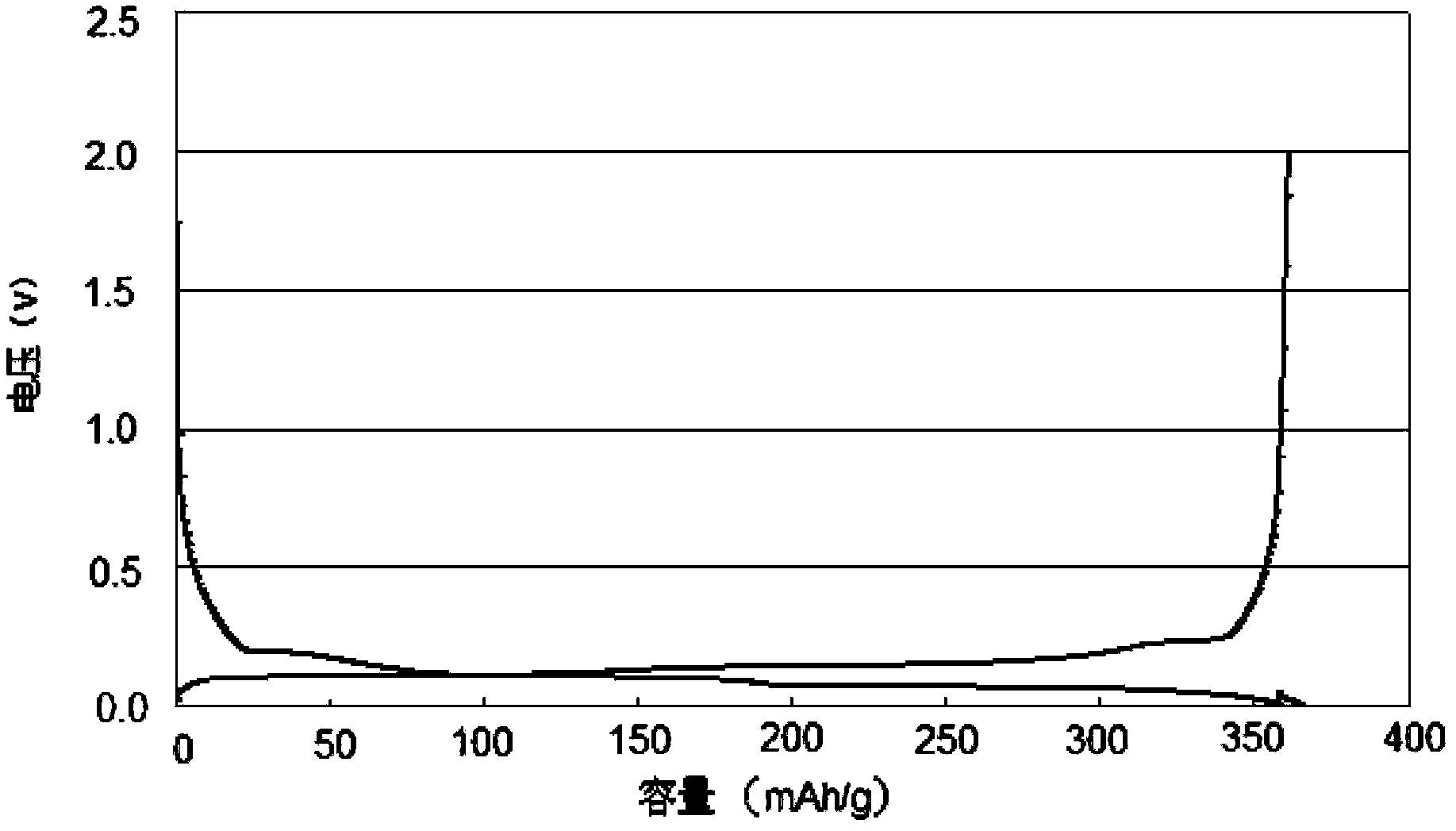

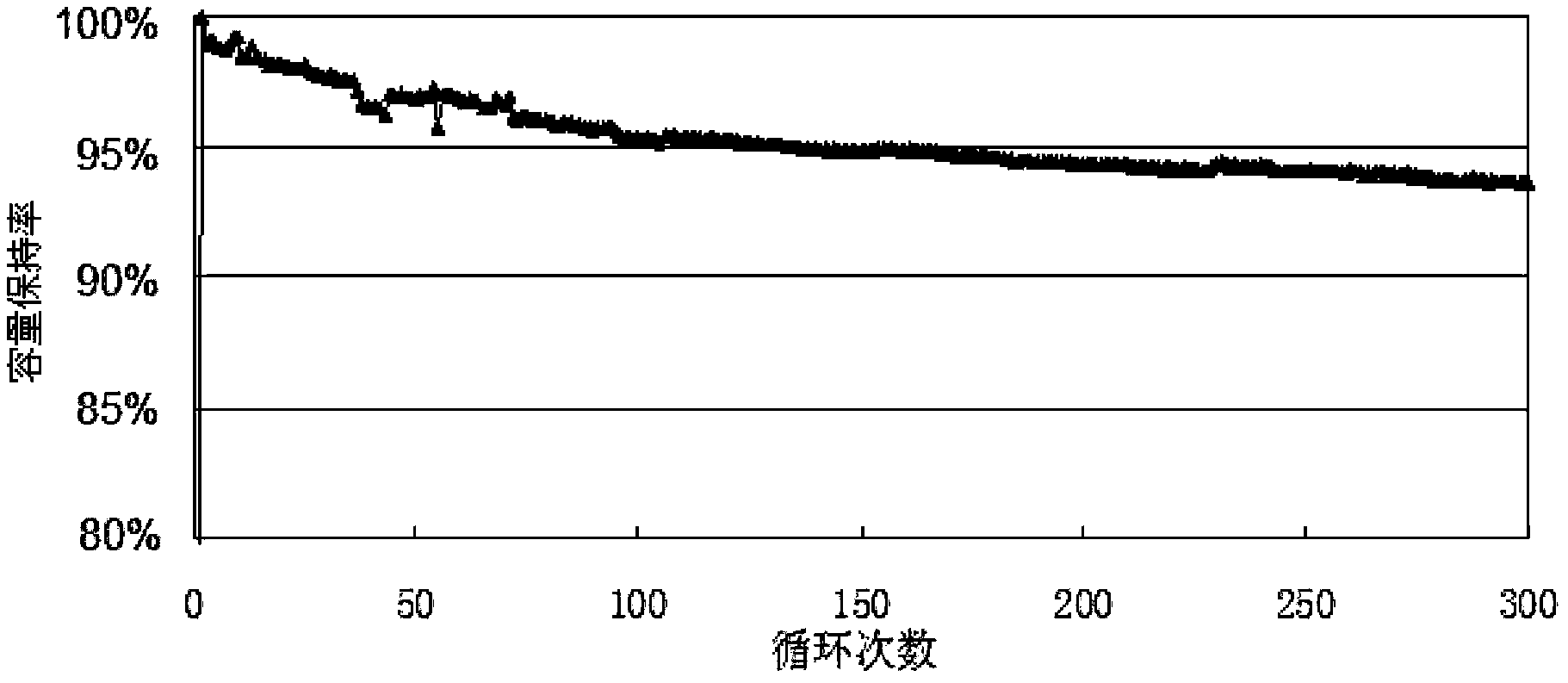

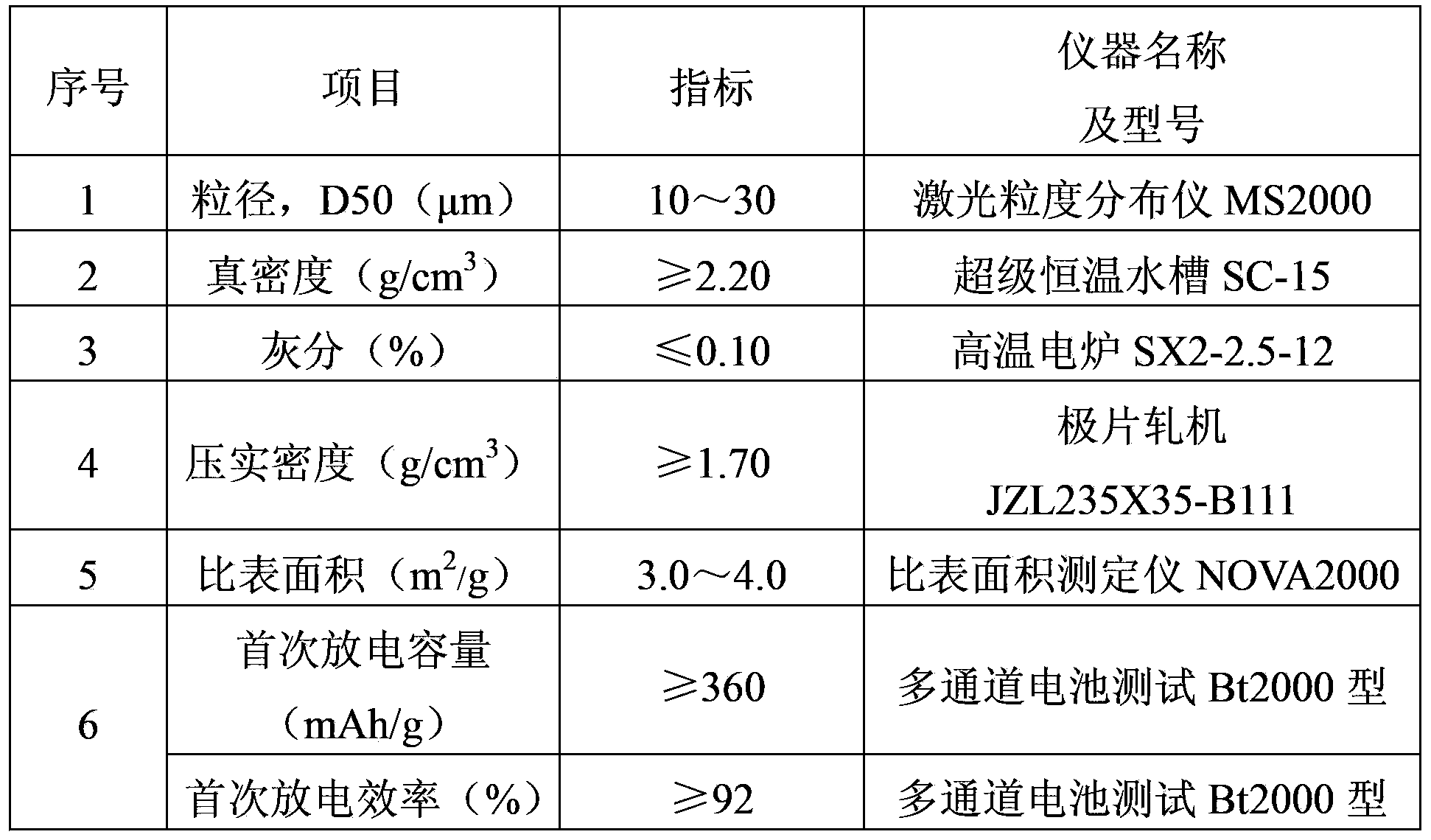

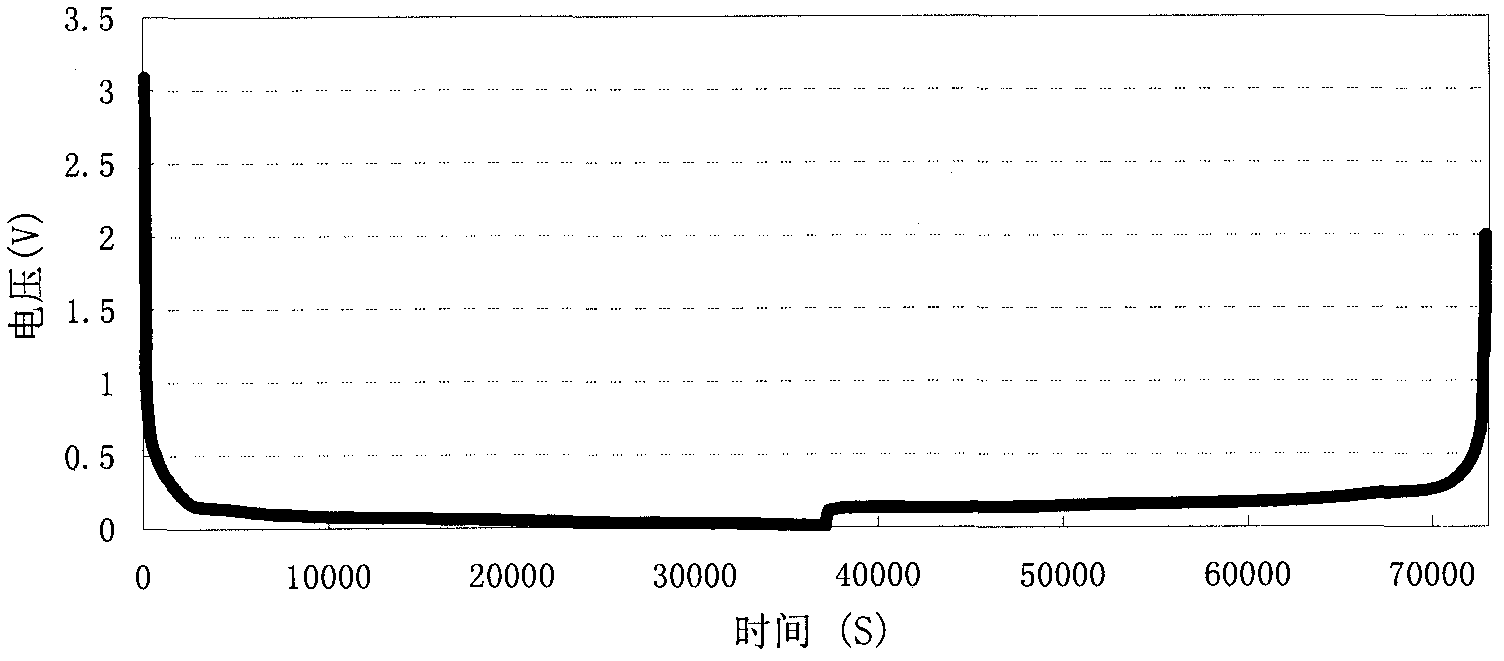

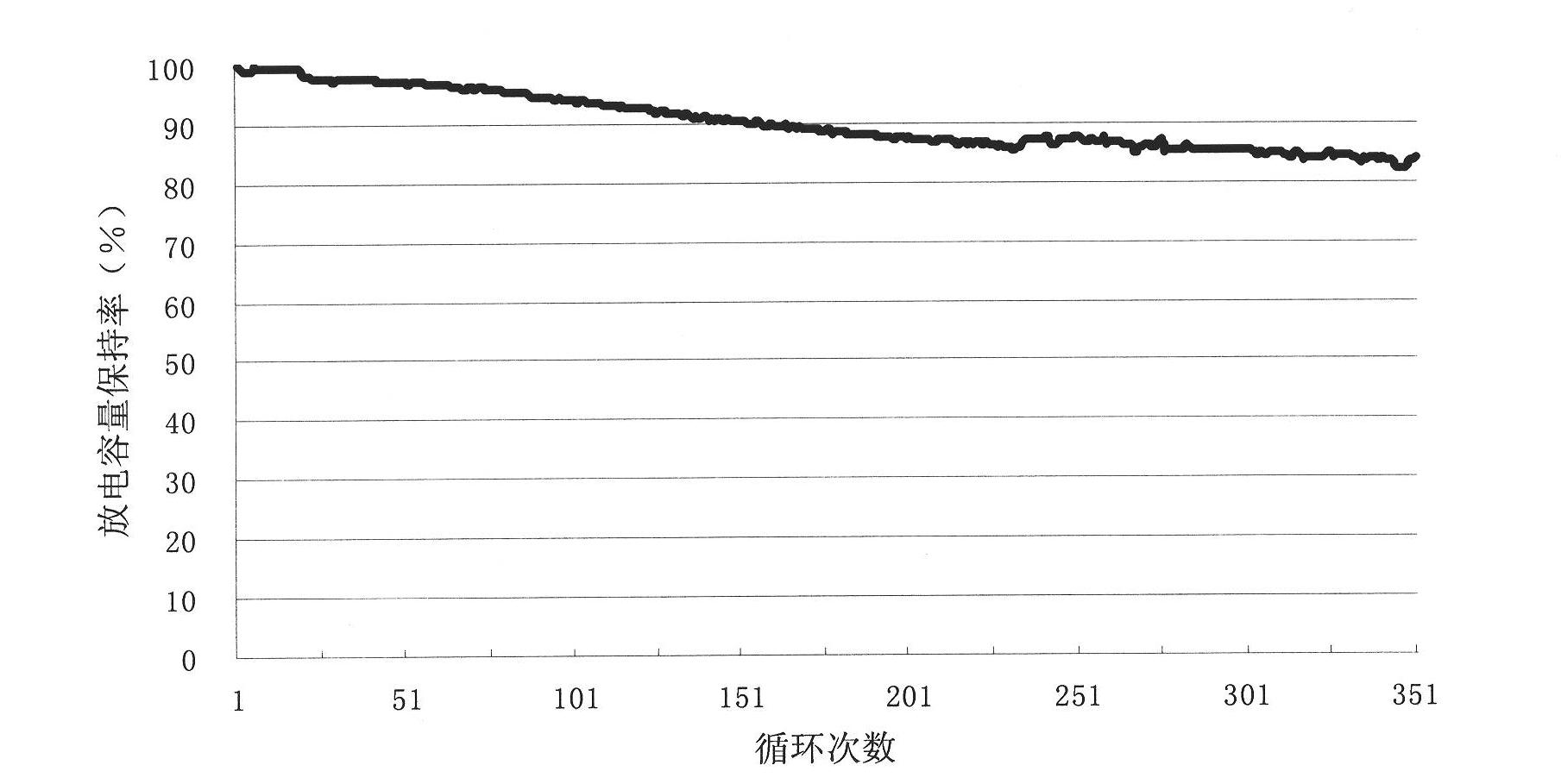

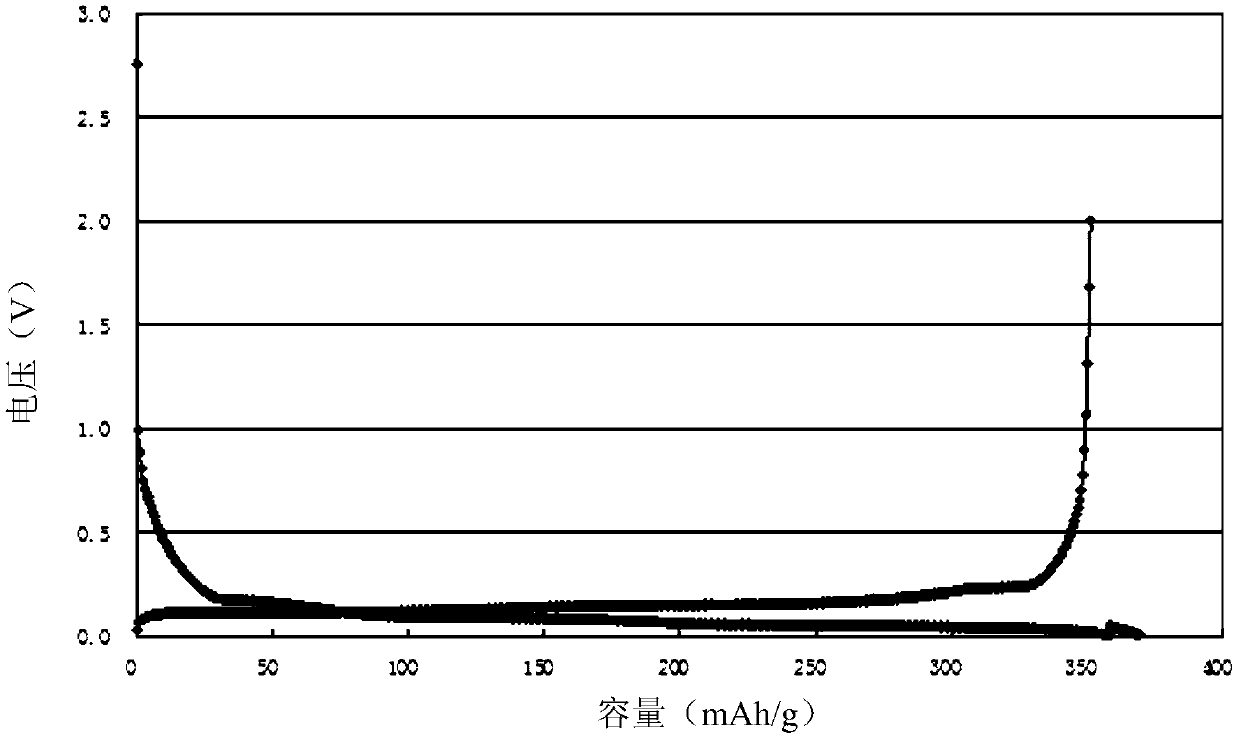

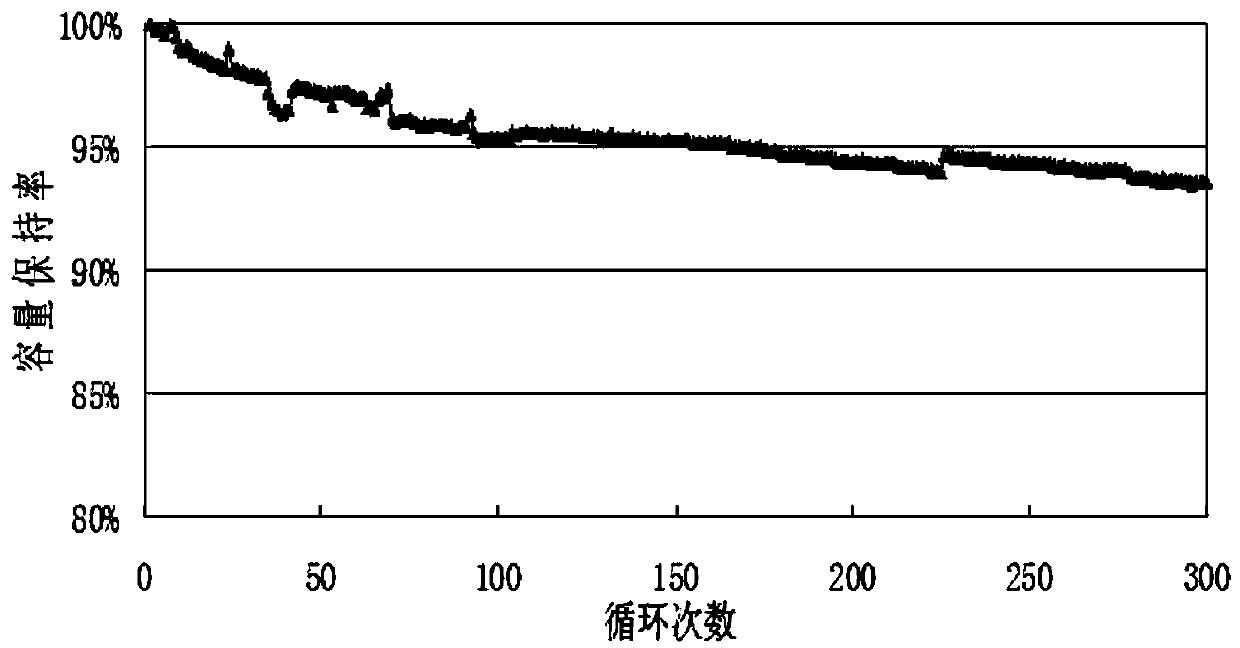

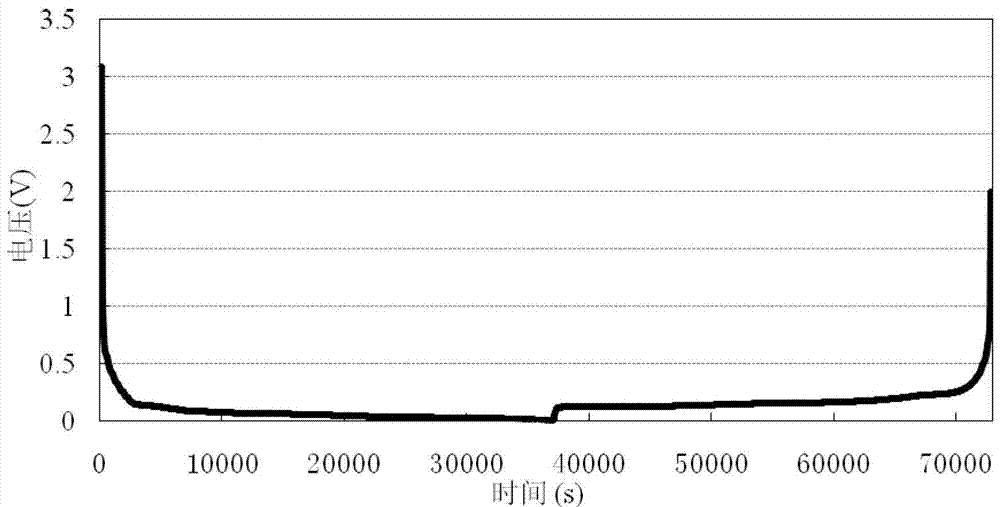

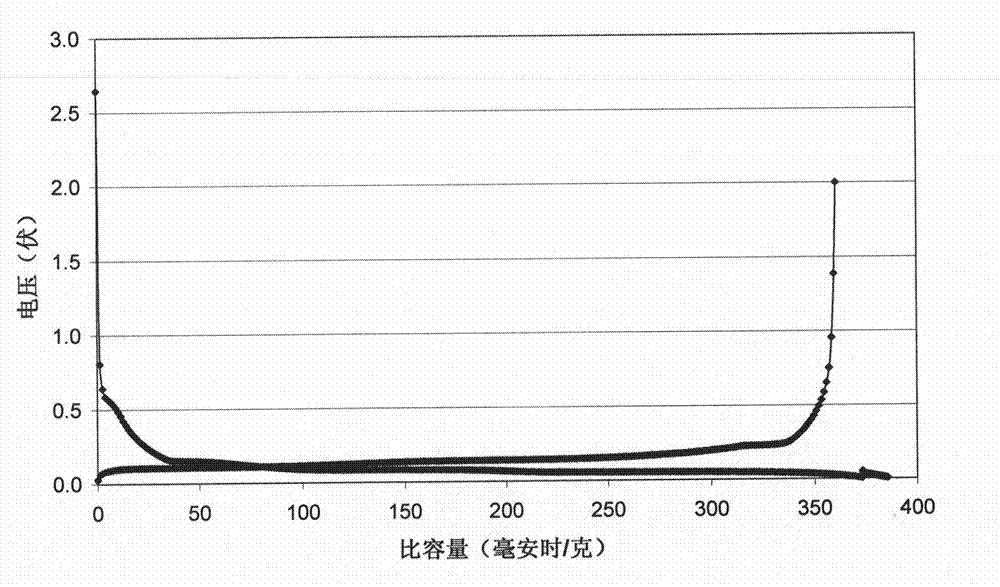

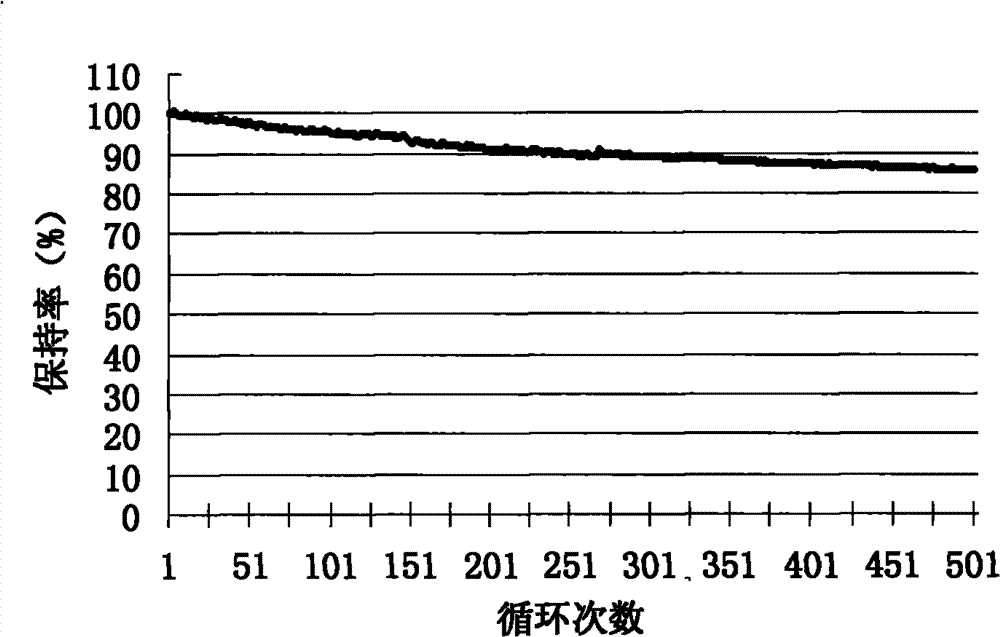

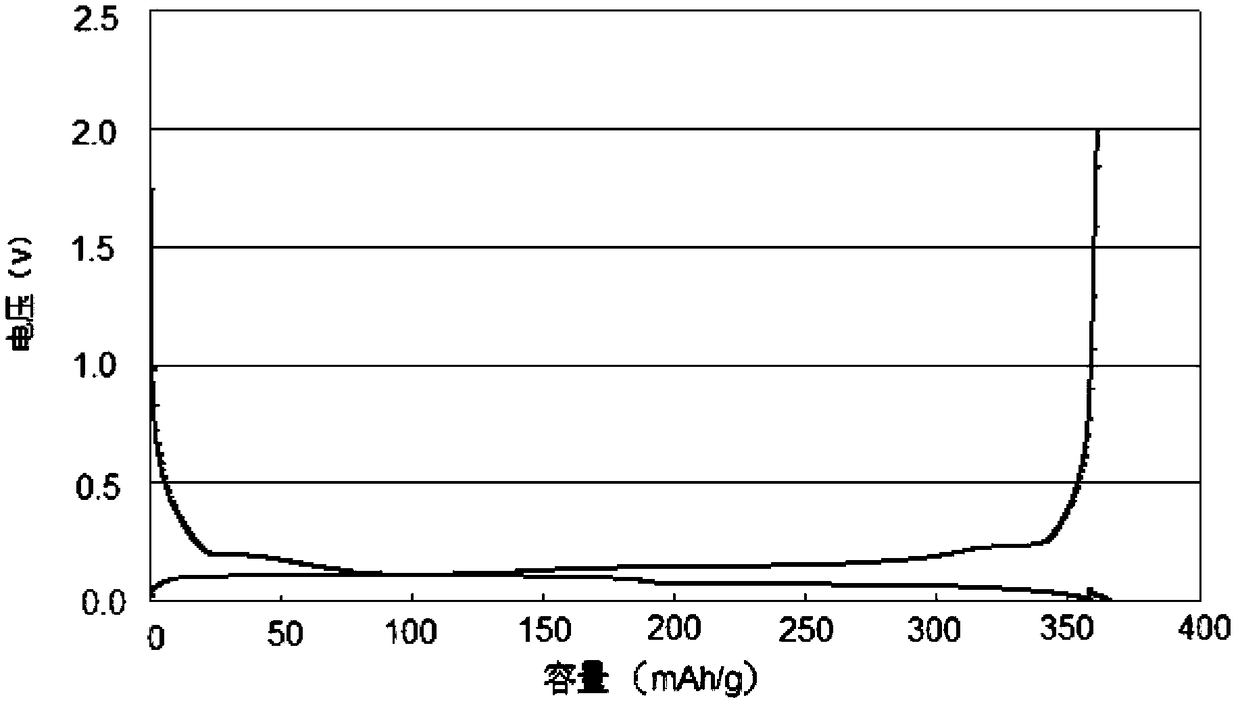

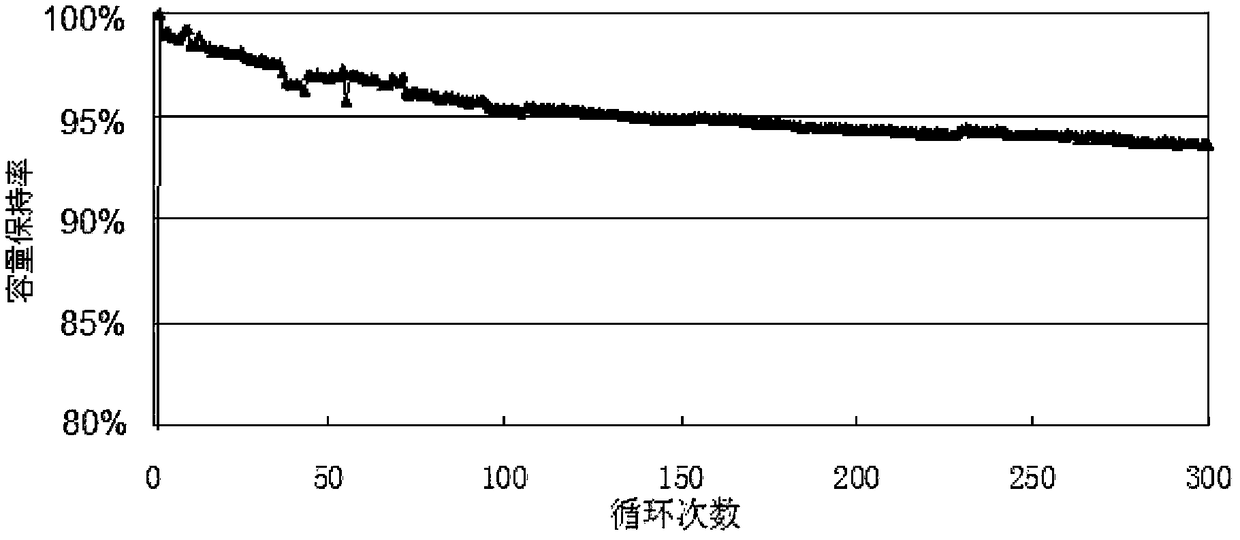

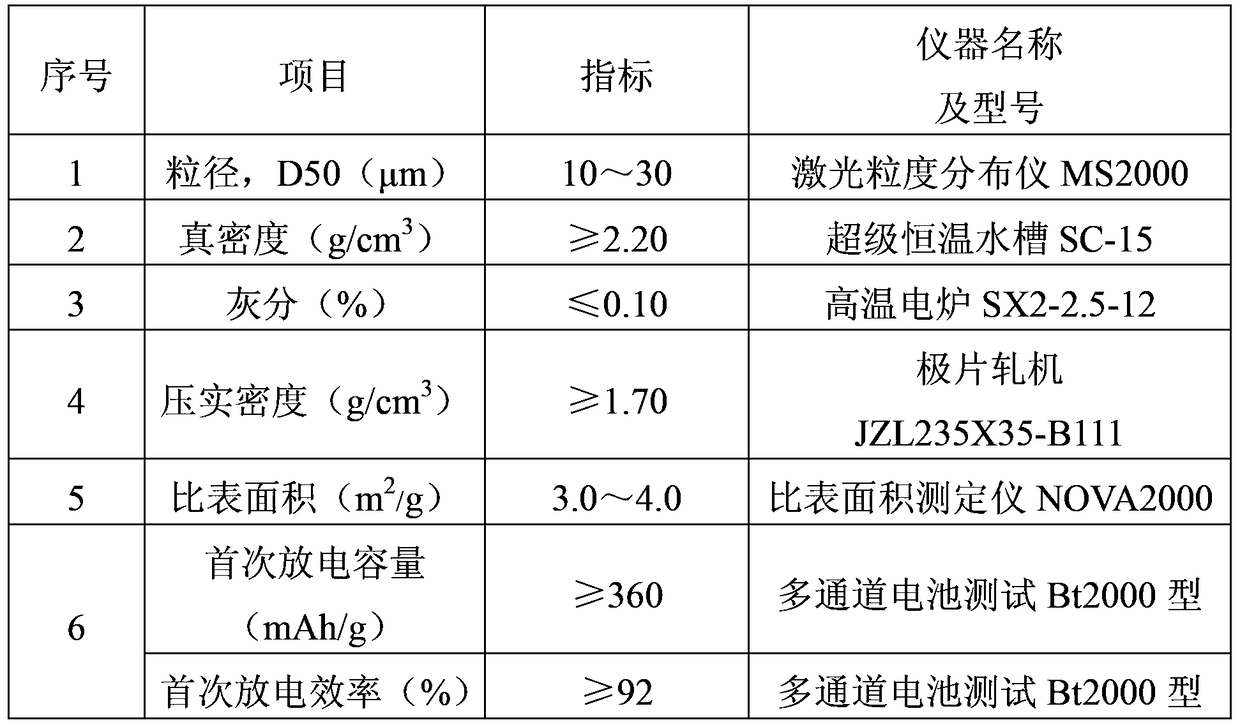

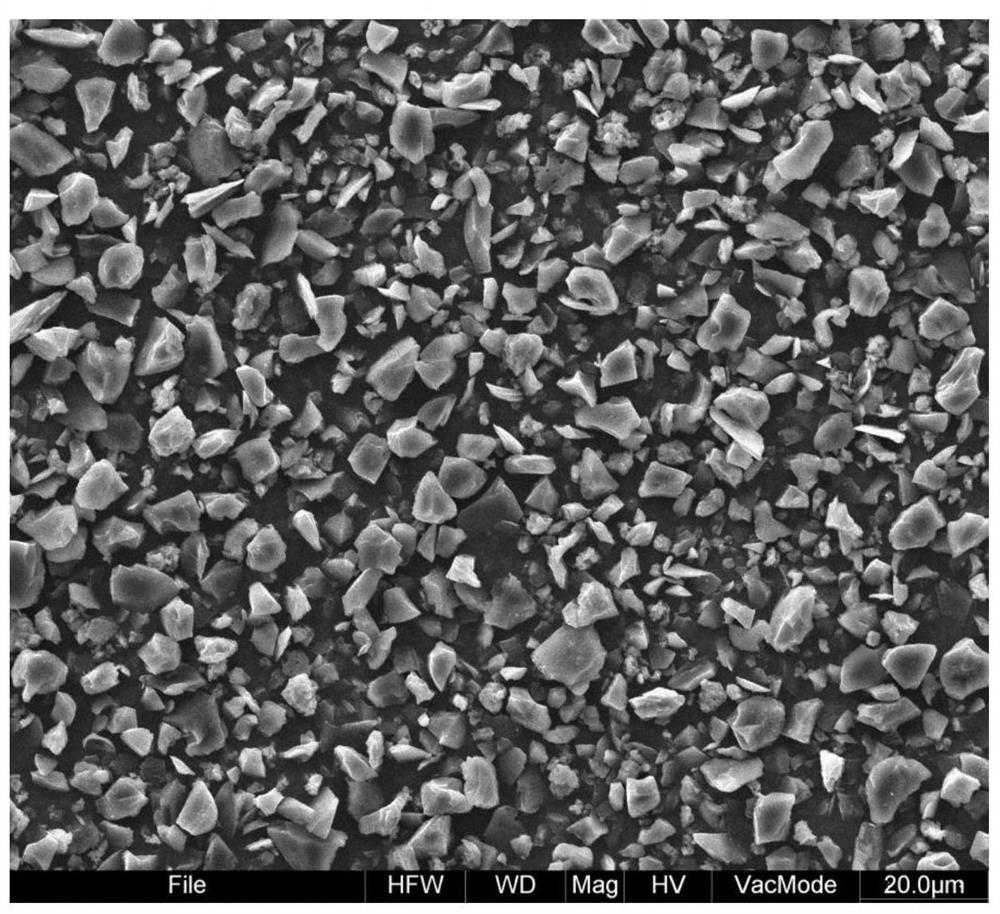

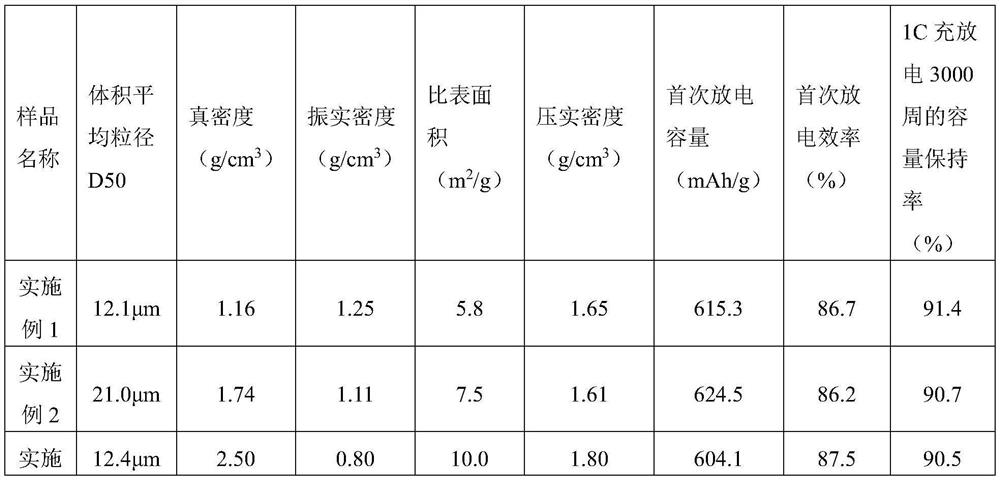

Composite mesophase negative electrode material, lithium ion secondary battery, preparation method and application

ActiveCN111232969AImprove adaptabilityImprove performanceCarbon compoundsSecondary cellsElectrolytic agentPtru catalyst

The invention discloses a composite intermediate phase negative electrode material, a lithium ion secondary battery, a preparation method and application. The preparation method comprises the following step: carrying out catalytic graphitization treatment on a blocky mixture containing uncalcined green coke powder, mesocarbon microbead green pellets, a graphitization catalyst and an adhesive capable of being graphitized, wherein the particle size D50 of the uncalcined green coke powder is 1-50 [mu] m, and the mass ratio of the uncalcined green coke powder to the mesocarbon microbead green pellets is (0.25-1): 1. The composite intermediate-phase negative electrode material prepared by the method is large in discharge capacity and good in cycle performance; a prepared button cell has excellent comprehensive performance, the discharge capacity is 365 mAh / g or above, the cycle performance is good (300 cycles, the capacity is maintained to be greater than or equal to 90%), the safety is better (130 DEG C / 60 minutes, explosion and expansion are avoided), the adaptability to electrolytes and other additives is better, the preparation method is simple and feasible, and the preparation method is suitable for industrial production.

Owner:SHANGHAI SHANSHAN TECH CO LTD

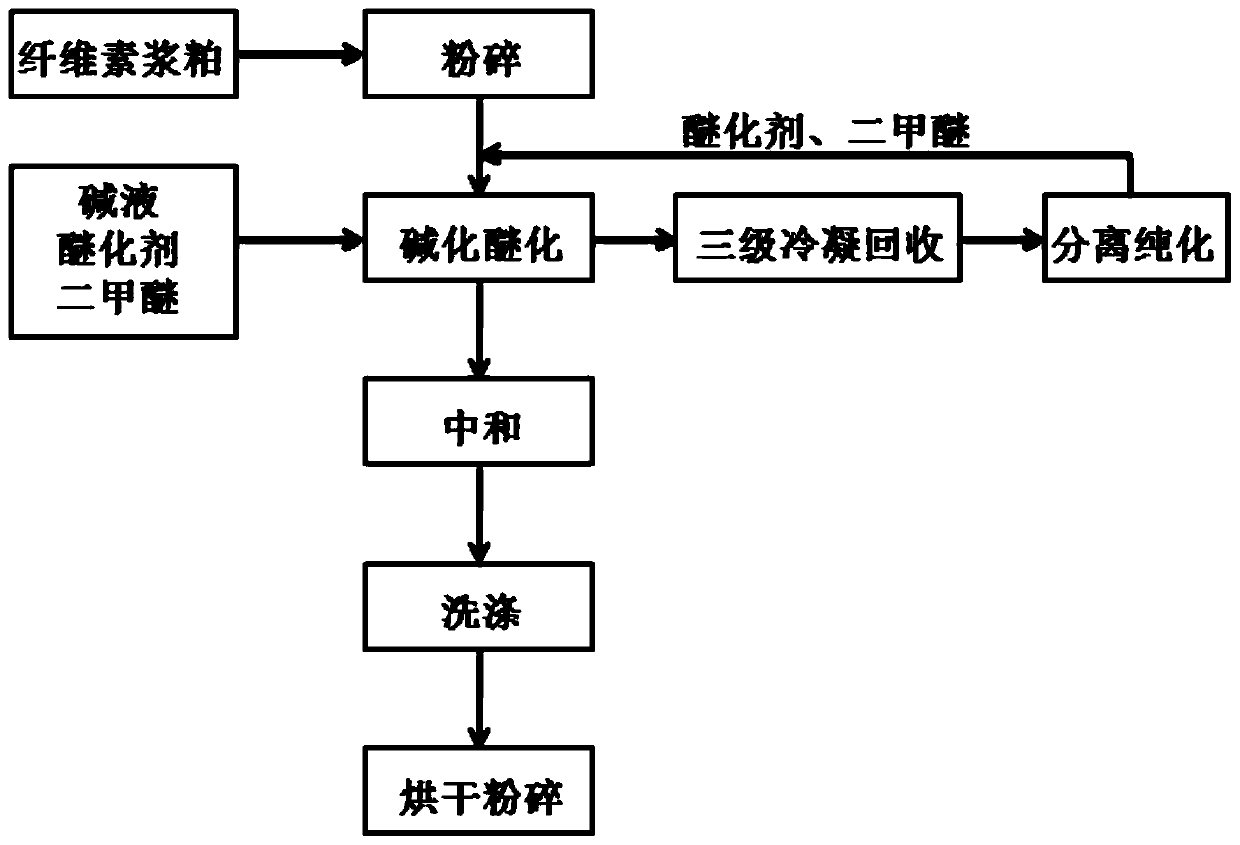

Gas-solid method production technology of cellulose mixed ether

InactiveCN110804103AEtherification substitution uniformity is goodProduct properties are stableEtherCellulose pulp

The invention relates to the technical field of cellulose mixed ethers, and concretely relates to a gas-solid method production technology of cellulose mixed ether. The gas-solid method production technology of the cellulose mixed ether comprises the following steps: crushing cellulose pulp to obtain powdery cellulose; adding the powdery cellulose into a reactor, adding an alkali liquor, an etherifying agent and dimethyl ether, and raising the temperature at a constant speed for a reaction; recovering the unreacted etherifying agent and dimethyl ether after the reaction is finished, and then adding hydrochloric acid to neutralize; and adding water into the neutralized material to wash, and carrying filtering, leaching and steam filter pressing, and crushing and drying the obtained materialto obtain the finished product cellulose mixed ether. The gas-solid method production technology of the cellulose mixed ether is simple and efficient, solves the problems of long reaction time, low yield and low production efficiency of conventional technologies, and has he advantages of good etherification substitution uniformity, uniform and stable product properties, reduction of side reactions, increase of the utilization rate of the etherifying agent, and saving of the production cost.

Owner:山东赫达集团股份有限公司

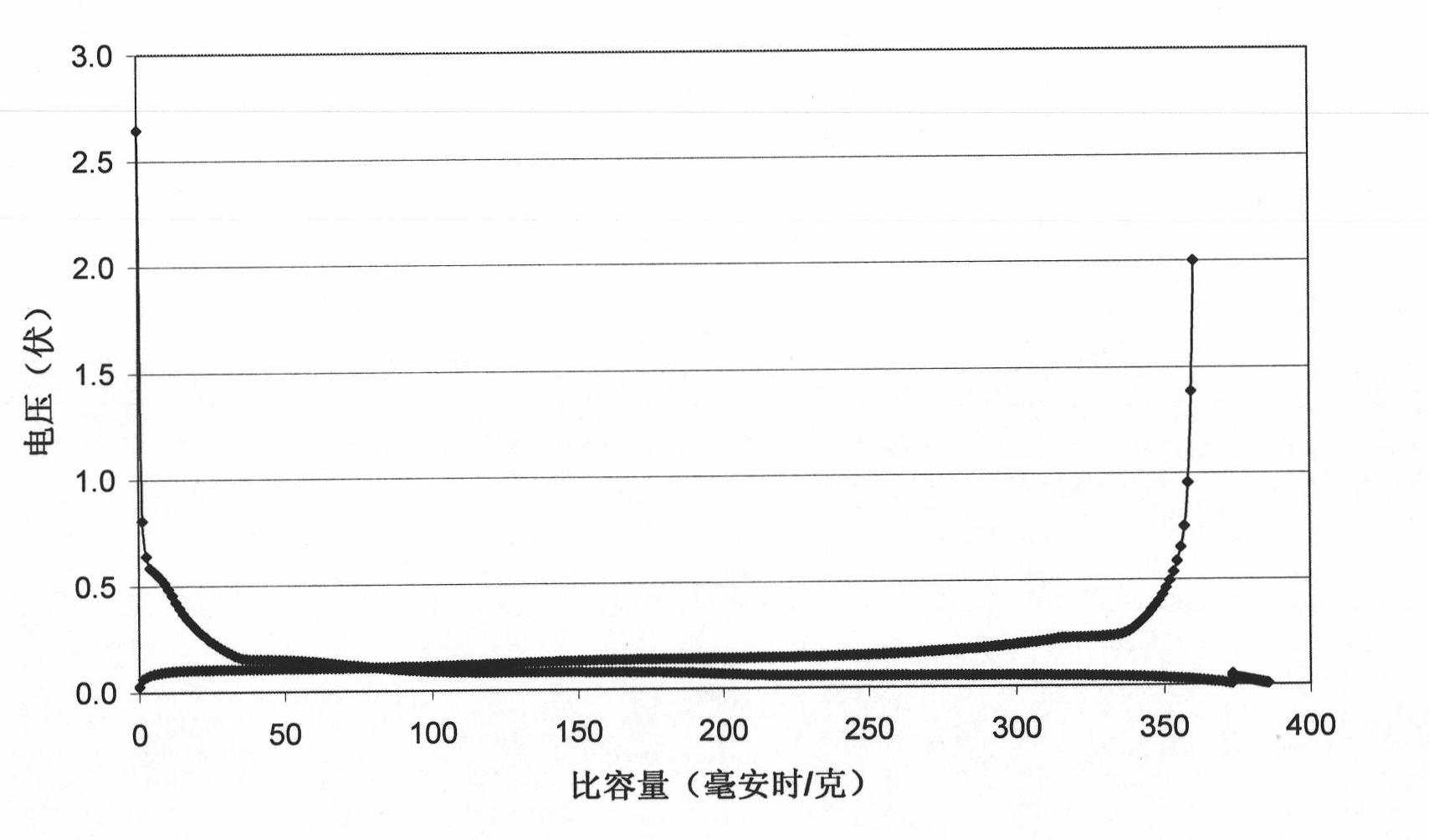

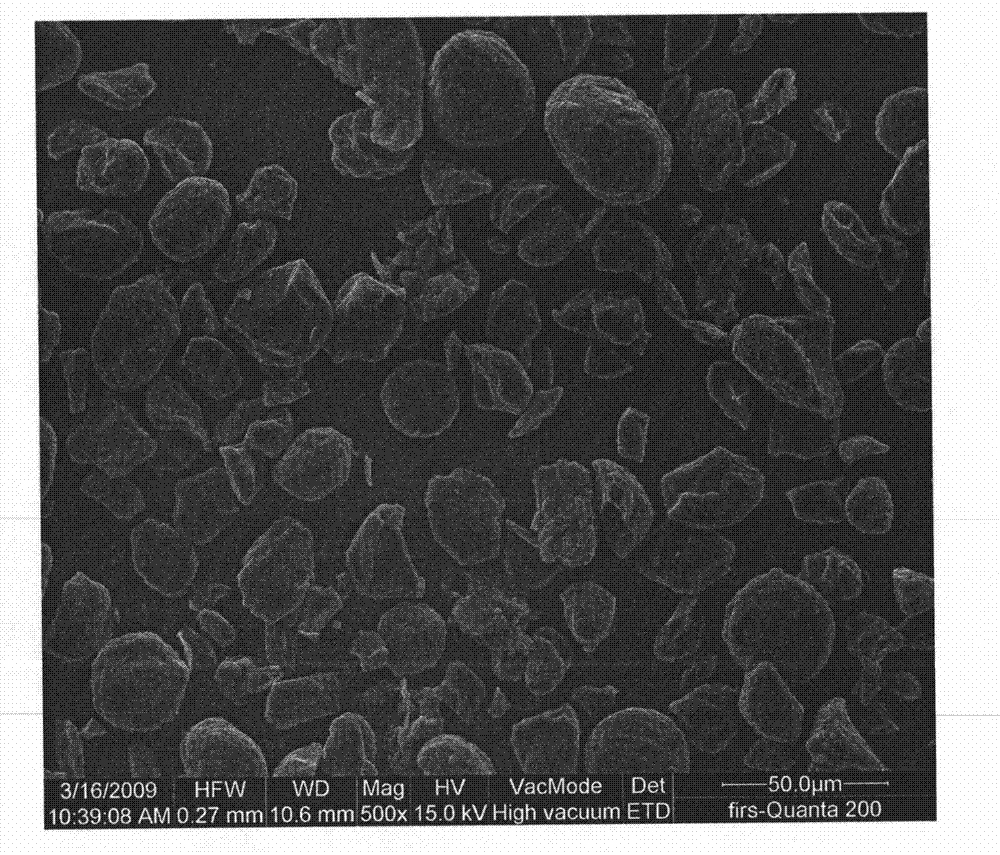

A kind of lithium ion battery natural graphite negative electrode material and preparation method thereof

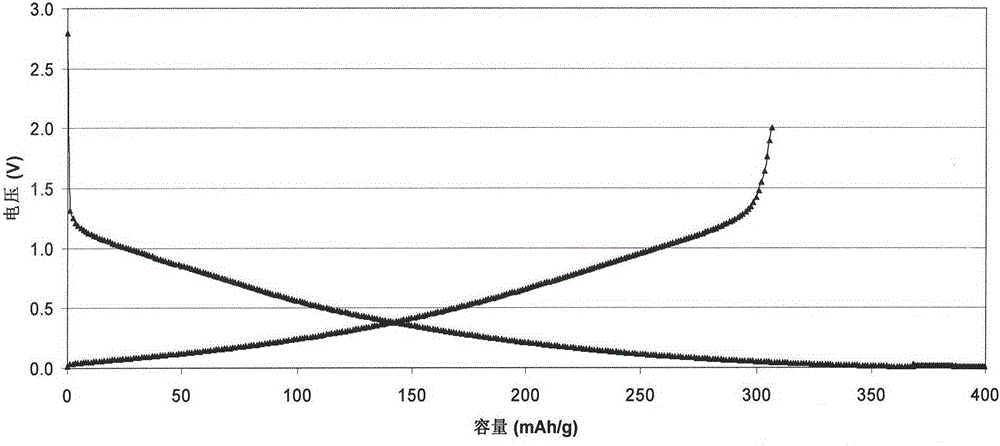

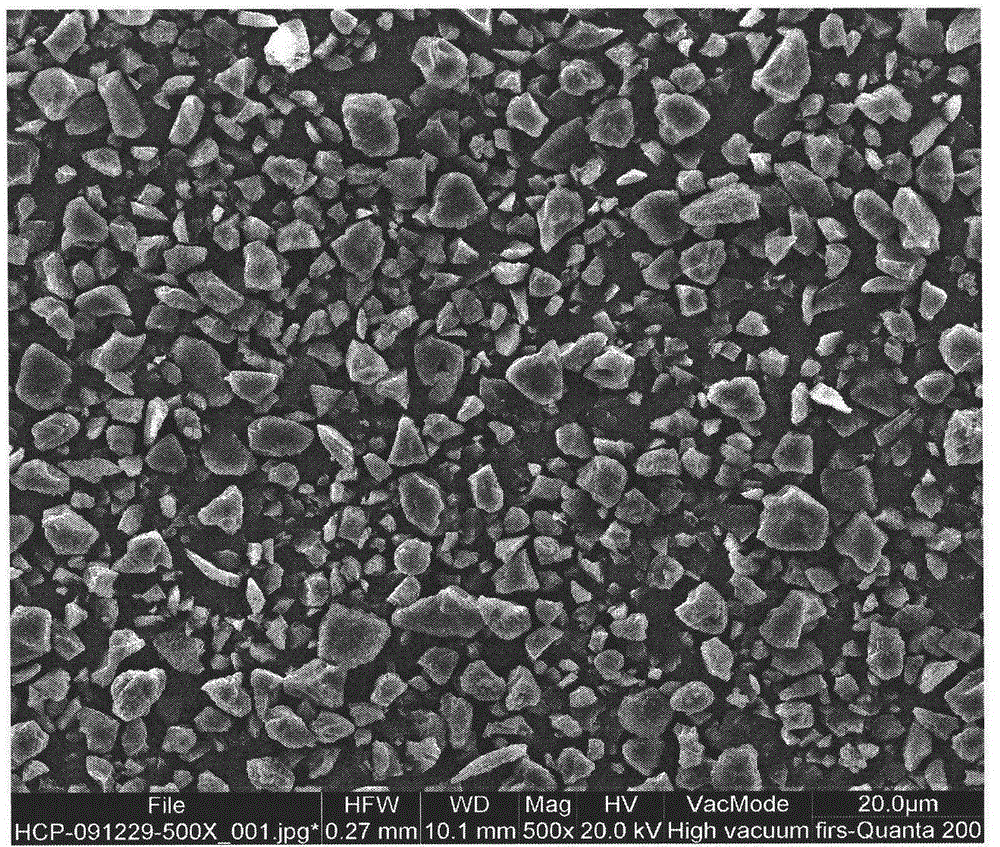

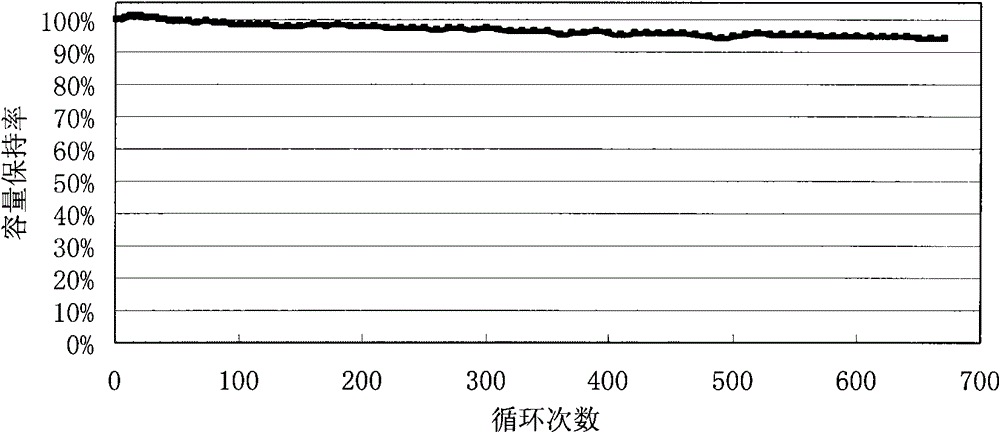

ActiveCN103855395BImprove discharge capacityImprove cycle performanceSecondary cellsNegative electrodesButton batteryElectrical battery

The invention discloses a preparation method and a natural graphite negative electrode material of a lithium ion battery prepared by the method. The method comprises the following steps: (1) preprocessing spherical natural graphite at high temperature of 500-600 DEG C for 4-6 hours; (2) uniformly mixing the spherical natural graphite in the step (1), a graphitized catalyst and petroleum asphalt to obtain a mixture; (3) carbonizing the mixture in the step (2), cooling, and performing high-temperature catalytic graphitization treatment; and (4) grading. The preparation method of the graphite negative electrode material is simple and feasible and is suitable for industrialization production. The graphite negative electrode material is large in discharge capacity and good in circulating performance; a button battery manufactured by the graphite negative electrode material is excellent in comprehensive performance.

Owner:SHANGHAI SHANSHAN TECH CO LTD

Doxycycline hydrochloride tablets for pets and preparation method thereof

PendingCN110859813AReduce hydrolysisPalatability is not compromisedAntibacterial agentsTetracycline active ingredientsDoxycycline hydrochlorideChicken Liver

The invention discloses doxycycline hydrochloride tablets for pets and a preparation method of the doxycycline hydrochloride tablets. The doxycycline hydrochloride tablets are characterized by being prepared from the following raw materials in parts by weight: 10-50 parts of doxycycline hydrochloride, 100-150 parts of microcrystalline cellulose, 20-30 parts of sodium carboxymethyl starch, 1-3 parts of magnesium stearate and 10-15 parts of a phagostimulant. Wherein the phagostimulant is one of a chicken liver extract and a beef-flavored milk cake. The preparation method comprises the followingsteps: uniformly mixing doxycycline hydrochloride, microcrystalline cellulose, sodium carboxymethyl starch and the phagostimulant, granulating by a dry method, mixing the prepared granules with magnesium stearate for 3 minutes, and tabletting to obtain the doxycycline hydrochloride tablets.

Owner:河北远征药业有限公司 +1

Graphite material at negative pole of lithium ion battery and preparation method thereof

ActiveCN102110813BImprove adaptabilityImprove performanceCell electrodesMicroballoon preparationMass ratioGraphite

The invention discloses a graphite material at the negative pole of a lithium ion battery, which comprises interphase graphite and artificial graphite in mass ratio of 90:10 to 20:80. The graphite material has the advantages of highly compacted density, small specific surface area, high discharge capacity, long circulating life, high charge-discharge efficiency and high product performance-price ratio. The invention also provides a method for preparing the graphite material, which has the advantages of simple, convenient and feasible technology, wide raw material sources and lower cost.

Owner:福建杉杉科技有限公司

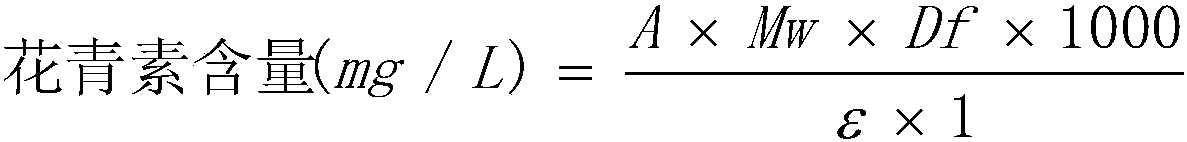

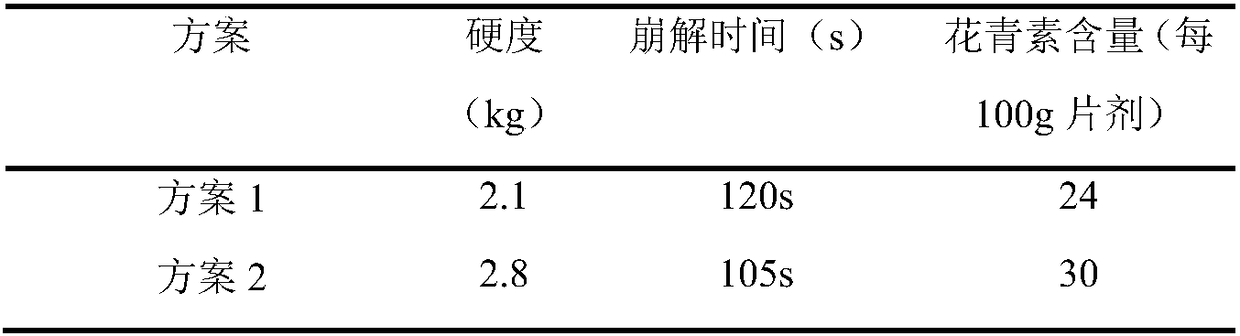

Instant tablet rich in aronia anthocyanins and preparation method thereof

InactiveCN108403800AThe method flow is simpleEasy to operateOrganic active ingredientsDispersion deliveryAlcoholPropylene glycol

The invention discloses an instant tablet rich in aronia anthocyanins and a preparation method thereof, and belongs to the field of biomedicine. An aronia anthocyanin extract is used as raw materials,and corresponding medicinal auxiliary materials are adopted for pulverizing, sieving, blending, granulating, drying, granulating and tableting to prepare the instant tablet. An edible alcohol solution containing PEG6000 and propylene glycol is used as a wetting agent, the product dissolves rapidly, and the content of the aronia anthocyanins is high.

Owner:JIANGNAN UNIV

A kind of artificial graphite anode material and preparation method thereof

ActiveCN104143635BIncrease compaction densityImprove discharge capacityCell electrodesSecondary cellsAdhesiveRoom temperature

The invention discloses a synthetic graphite negative electrode material and a preparation method thereof. The preparation method comprises the following steps: (1) uniformly mixing spherical natural graphite, needle coke-produced coke powder and a graphitization catalyst so as to obtain a mixture; 2) subjecting the mixture and an adhesive which can be graphitized to heating and kneading for 1 to 2 h; 3) pressing the kneaded object into a block shape so as to obtain a formed body of the kneaded object; 4) charring the formed body at 800 to 1500 DEG C under the protection of inert gas and cooling the charred formed body to room temperature; and 5) carrying out catalytic graphitization high temperature treatment at 2800 to 3200 DEG C. The method provided by the invention overcomes the defects of insufficient compacted density and low discharge capacity of a synthetic graphite negative electrode material prepared by using a conventional negative electrode preparation method, can improve cycle performance of the negative electrode material and enables the synthetic graphite negative electrode material with high charge and discharge capacity and high charge and discharge efficiency to be obtained.

Owner:NINGBO SHANSHAN NEW MATERIAL TECH

Soft carbon negative electrode material and preparation method and application thereof

ActiveCN112563475AGood dispersionGood sieving effectNegative electrodesSecondary cellsCarbonizationLithium-ion battery

The invention discloses a soft carbon negative electrode material as well as a preparation method and application thereof. The soft carbon negative electrode material comprises carbonized particles and monocrystalline silicon; and the preparation method comprises the following steps: (1) carrying out polymerization reaction on coal tar to obtain mesocarbon microbeads; (2) carrying out fusion on the mesocarbon microbeads, then carrying out crushing treatment, and then carrying out low-temperature carbonization treatment to obtain a carbon precursor; (3) crushing the carbon precursor, and carrying out high-temperature carbonization treatment to obtain carbonized particles; and (4) mixing the carbonized particles with monocrystalline silicon to prepare the soft carbon negative electrode material. The soft carbon negative electrode material disclosed by the invention is high in compaction density, high in electrochemical performance and high in cycle performance; the preparation method issimple, convenient and feasible, and the raw material cost is relatively low; and the lithium ion battery prepared from the soft carbon negative electrode material is high in safety performance.

Owner:NINGBO SHANSHAN NEW MATERIAL TECH

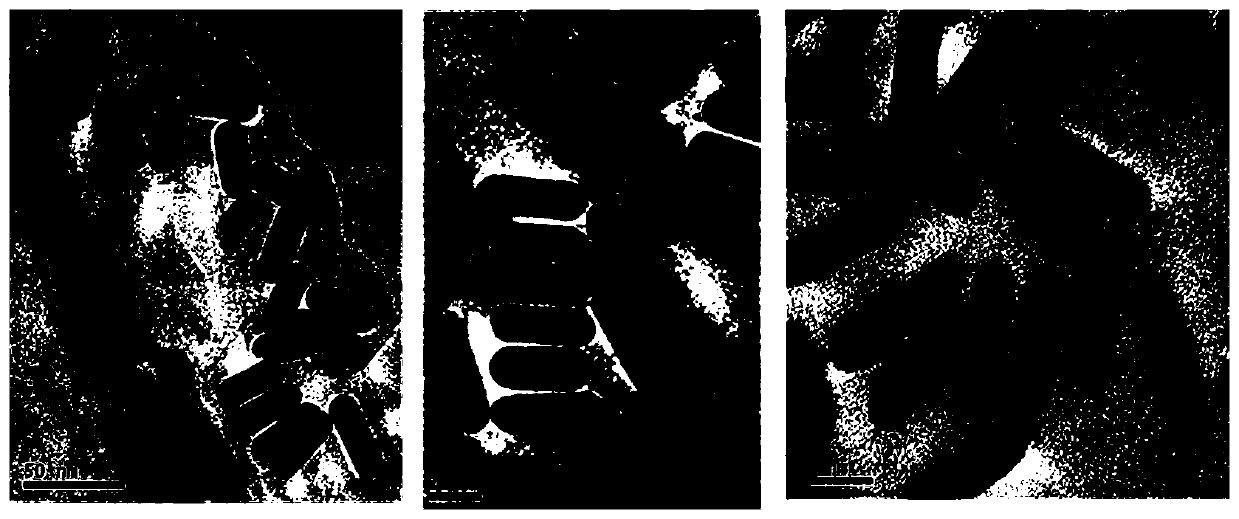

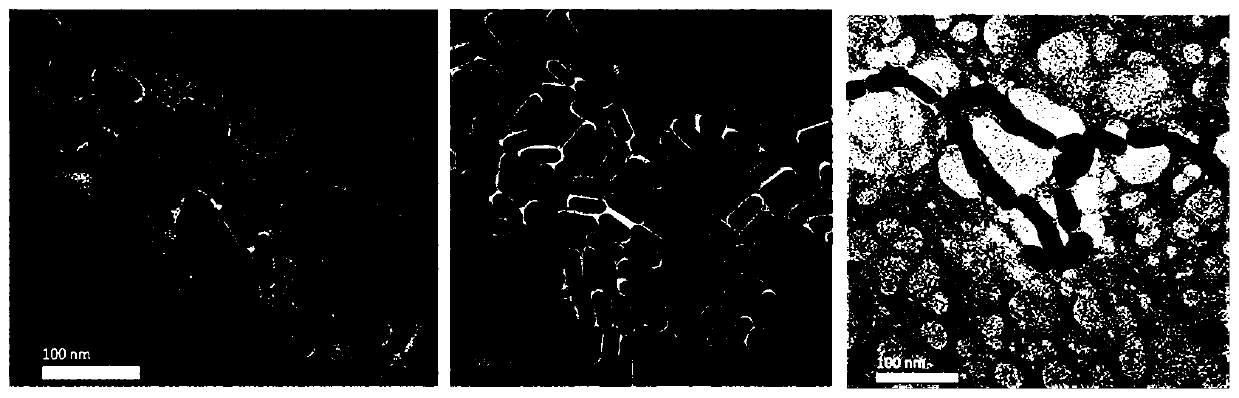

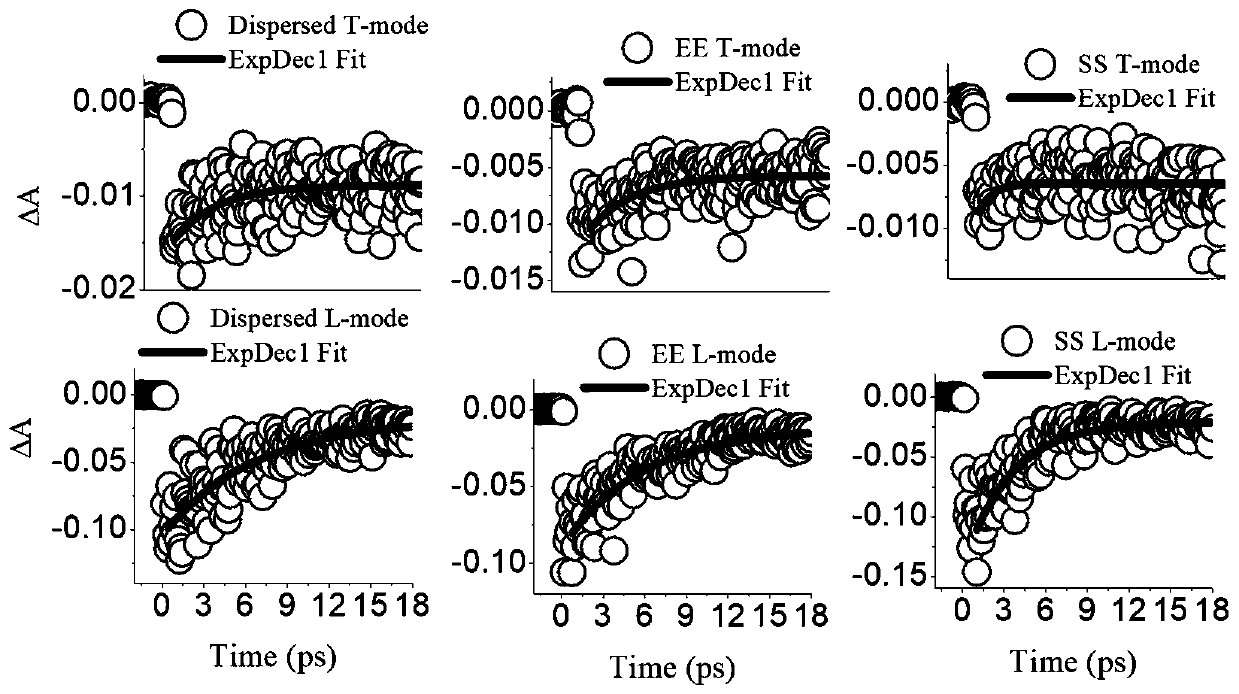

Gold nanorod self-assembly body as well as preparation method and application thereof

ActiveCN110181038AQuick switch effectProduct properties are stableMaterial nanotechnologyTransportation and packagingSelf-assemblyOptical switch

The invention provides a gold nanorod self-assembly body as well as a preparation method and application thereof. The preparation method of the gold nanorod self-assembly body comprises the followingsteps of adding an ethylene diamine tetraacetic acid solution and a sodium hydroxide solution into a gold nanorod solution, and stirring the mixed solution for 20-40 seconds. According to the preparation method, the gold nanorod self-assembly body is prepared by adding the ethylene diamine tetraacetic acid solution and the sodium hydroxide solution into the gold nanorod solution and stirring the mixed solution, the modification and assembly are completed in one step, only 20-40 seconds are needed, so that the method is simple and rapid; the addition amount of the ethylene diamine tetraacetic acid solution and the addition amount of the sodium hydroxide solution can be adjusted, so that the gold nanorod self-assembly bodies with two modes of shoulder-by-shoulder and tail-to-tail are obtained, the product property is stable, and the application prospect is wide; and especially the various gold nanorod assembly bodies with different thermion service life can be prepared, the service lifeof thermions is modulated by changing the assembly structure, so that the property of the ultrafast optical switch is optimized.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Normal-temperature drinking type yoghourt and preparation method thereof

ActiveCN111011503AViscosity does not fluctuate muchNo stratificationMilk preparationFood additiveProcess engineering

The invention discloses normal-temperature drinking type yoghourt and a preparation method thereof. The preparation method comprises the following steps: pre-sterilized raw milk is mixed with sugar, starch and a food additive, and a mixed solution is obtained; wherein the pre-sterilization is ultra-high temperature instantaneous sterilization; homogenizing, sterilizing and cooling the mixed solution, adding an edible essence, and inoculating a leavening agent for fermentation to obtain a yoghourt base material; and demulsifying the yoghourt base material, carrying out smooth pump treatment, cooling, sterilizing, cooling and filling to obtain the normal-temperature drinking type yoghourt. The formula, the process and other aspects are optimized, the preparation method is simple in process,easy to operate and convenient for industrial processing and production, and compared with common normal-temperature yoghourt, the product prepared by the preparation method is fresh and cool in taste, smooth and good in flowability.

Owner:BRIGHT DAIRY & FOOD CO LTD

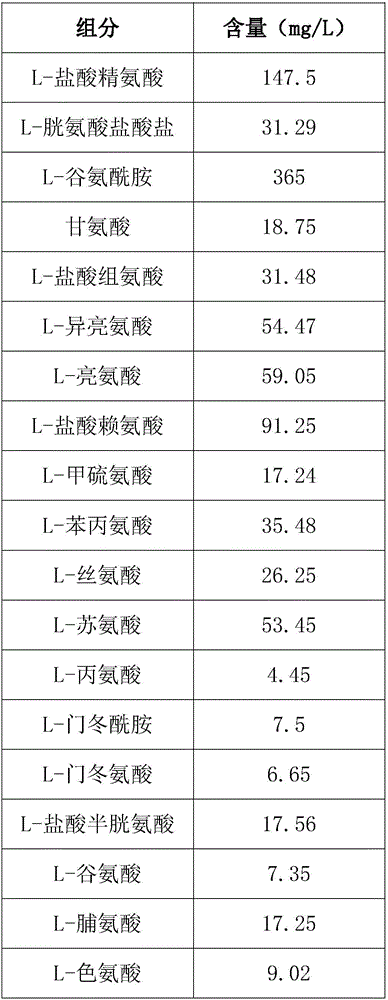

Millet fermented powder and preparation method thereof

InactiveCN106901162AReasonable proportionEasy to eatFood ingredient as taste affecting agentFood ingredient as mouthfeel improving agentNutritive valuesTotal amino acids

The invention belongs to the field of cereal fermented food preparation and specifically provides a millet fermented powder and a preparation method thereof. The preparation method of the millet fermented powder comprises the following steps: using Lambic acetobacter aceti as the bacterial strain and using millet as a medium, fermenting, drying, and crushing to obtain the millet fermented powder product. The prepared millet fermented powder contains the following main nutrients: 81.7-83.5% of total sugar, 1.8-1.9% of fat, 11.0-11.7% of protein, 10.2-10.7% of total amino acids, 201.8-205.8 mg / 100g of total phenols and 40.2-42.1 mg / 100 g of calcium. The millet fermented powder provided by the invention has high nutritive value, is sweet and fragrant, is easy to store and convenient to eat, and is a good democratized nutritious food.

Owner:SHANXI UNIV

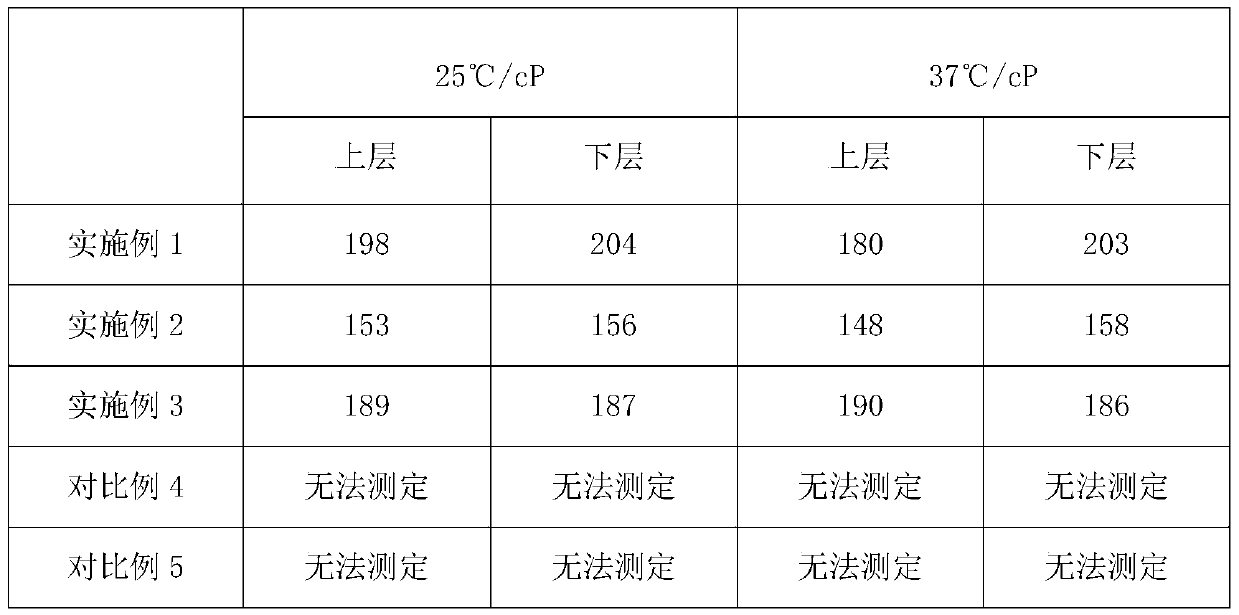

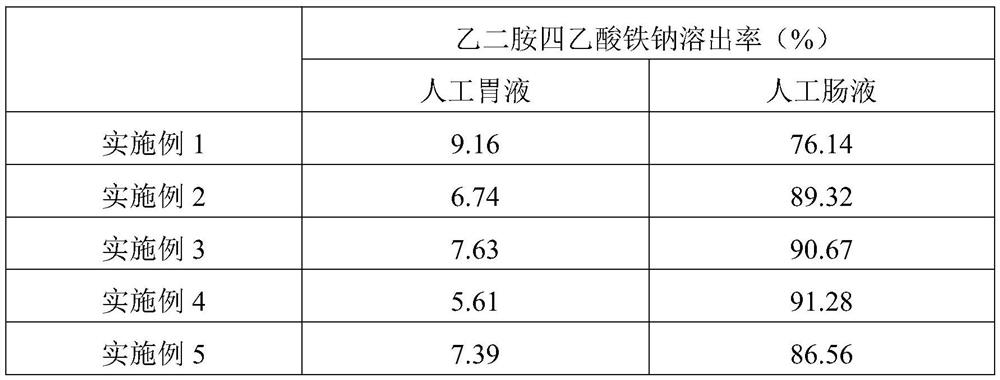

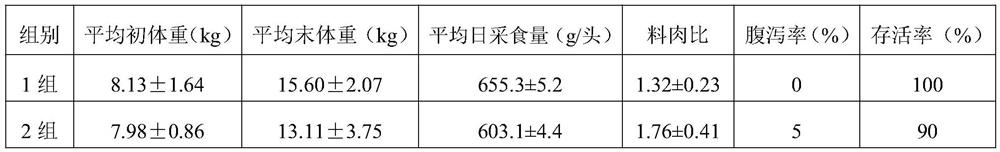

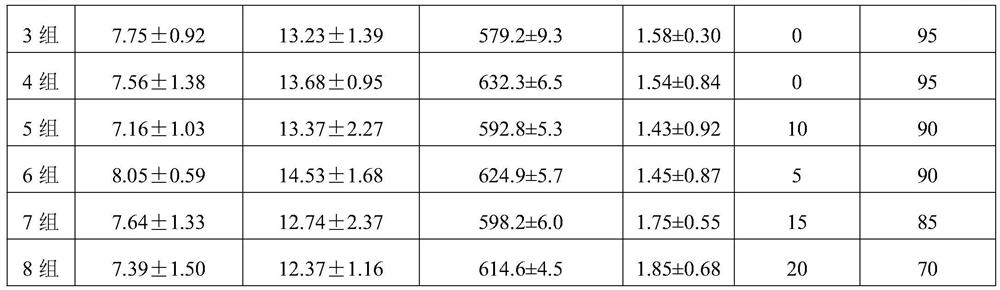

Veterinary slow-release ferric sodium ethylenediamine tetraacetate premix and preparation method thereof

ActiveCN111714470AProduct properties are stableGood liquidityHeavy metal active ingredientsPharmaceutical non-active ingredientsEthylenediaminetetraacetic acidSustained release pellets

The invention relates to a veterinary slow-release ferric sodium ethylenediamine tetraacetate premix and a preparation method thereof, and belongs to the technical field of veterinary drugs. The ferric sodium ethylenediamine tetracetate premix comprises the following components in percentage by weight: 2-8% of ferric sodium ethylenediamine tetracetate, 1-15% of a coating agent, 0.5-1% of a flavouring agent, 2-5% of a synergist and the balance of a diluent, totalling 100%. The ferric sodium ethylenediamine tetraacetate premix disclosed by the invention is an enteric sustained-release pellet prepared by coating with an enteric sustained-release coating agent, can effectively reduce the stress of a common iron supplement agent on an animal body, has a remarkable sustained-release effect, andhas a good effect of improving the hemoglobin content in the weaned pig body.

Owner:瑞普高科(天津)生物技术有限公司

Formula and preparation of chicken/duck heart-liver seasoning sauce

InactiveCN109123599AReduce fishy smellProduct properties are stableFood ingredient as taste affecting agentFood ingredient as flavour affecting agentUltrasonic assistedProduction cycle

The invention relates to a formula and a preparation method of chicken / duck heart-liver seasoning sauce. In the invention, high-quality and inexpensive chicken and duck hearts and chicken / duck liversare used as main raw materials for processing the seasoning sauce, various auxiliary materials of resistant dextrin, beta-cyclodextrine and the like are used for removing fishy smell and seasoning, and the production cycle is shortened through an ultrasonic assisted pickling process, the product is rich in flavor, and the meat sauce is fine, smooth and soft through the secondary chopping process and colloid grinding, finally the chicken / duck heart-liver seasoning sauce rich in liver flavor, unique in flavor and fine, and smooth and soft in taste is obtained.

Owner:ZAOZHUANG UNIV

Expression of recombinant human papilloma virus subtype 6 and 11 protein in pichia pastoris

ActiveCN110699366AIncrease productionMeet the requirements of industrial productionFungiViral antigen ingredientsImmunogenicityCapsid

The invention discloses a codon-optimized human papilloma virus main capsid protein L1 coding gene, which can efficiently express human papilloma virus main capsid protein L1 after being transferred into yeast cells. The invention further discloses a macromolecule with immunogenicity, which is mainly generated by the expression of the codon-optimized human papilloma virus main capsid protein L1 coding gene in yeast cells. The invention further discloses an application and a composition of the macromolecule with immunogenicity.

Owner:SHANGHAI ZERUN BIOTECHNOLOGY CO LTD

A kind of hard carbon negative electrode material and its preparation method and application

ActiveCN102479942BImprove performanceImprove electrochemical performanceCell electrodesCross-linkEpoxy

The invention provides a preparation method of a hard carbon negative electrode material. The method comprises the steps of: (1) subjecting a high molecular polymer and a cross-linking agent to crosslinking and polymerization reactions so as to obtain a cross-linked polymer; (2) conducting crushing and screening; (3) under the protection of an inert gas, carrying out pre-carbonization treatment at a temperature of 400-600DEG C, performing cooling to room temperature, and carrying out crushing and screening; (4) under the protection of an inert gas, carrying out carbonization treatment at a temperature of 1000-1600DEG C, thus obtaining a hard carbon negative electrode material. The high molecular polymer is asphalt, epoxy resin or phenolic resin. The invention also provides a hard carbon negative electrode material prepared by the method as well as its application as a lithium ion battery negative electrode material. The preparation method of the invention is simple and practicable, and has easily available and cheap raw materials. The hard carbon negative electrode material provided in the invention has the advantages of: good comprehensive performance; good electrochemical performance; good cycle performance; good high current charge-discharge performance; good security; good adaptability to electrolyte and other additives; and stable product property, with almost no difference among batches.

Owner:SHANGHAI SHANSHAN TECH CO LTD

Mushroom and white pear combined fermented beverage and preparation method thereof

PendingCN114395459AGood for lowering blood pressureGood for lowering blood fatAlcoholic beverage preparationBiotechnologyNutritive values

The invention discloses a mushroom and white pear combined fermented beverage and a preparation method thereof. The preparation method mainly comprises the following steps: carrying out combined fermentation on lactic acid and alcohol; the lactic acid bacteria are mixed strains and are subjected to high-temperature fermentation; the saccharomycetes are mixed strains and are subjected to low-temperature fermentation; besides mushroom, white pears and beet are added to the raw materials, so that the flavor and nutritional value of the mushroom beverage are improved; the process comprises the treatment measures of sterilization, blanching, color protection, enzyme deactivation, homogenization, addition of an antioxidant, a preservative, essence and the like. The lentinus edodes and white pear combined fermentation process provided by the invention further enriches lentinus edodes deep processing products, and promotes sustainable development of the lentinus edodes industry.

Owner:SHENYANG AGRI UNIV

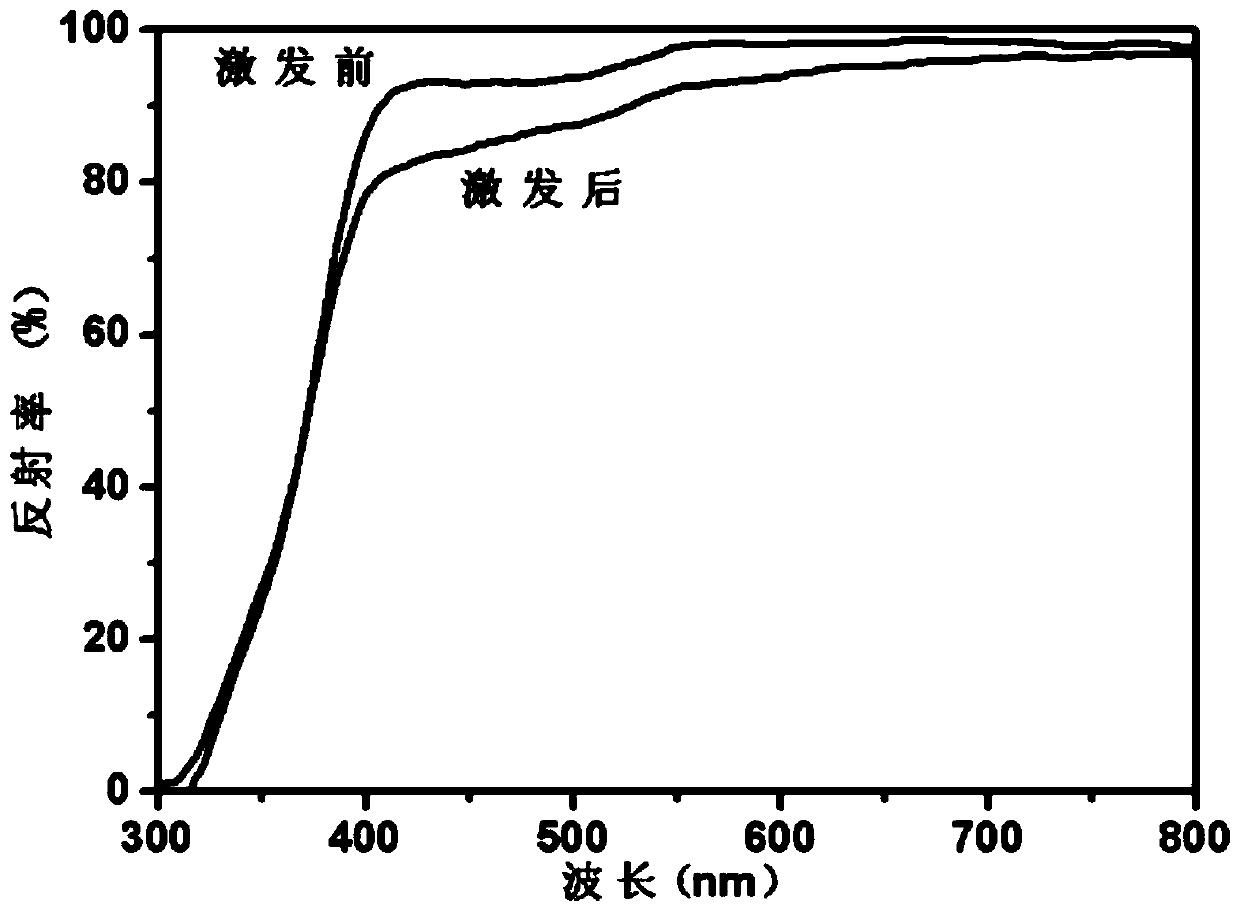

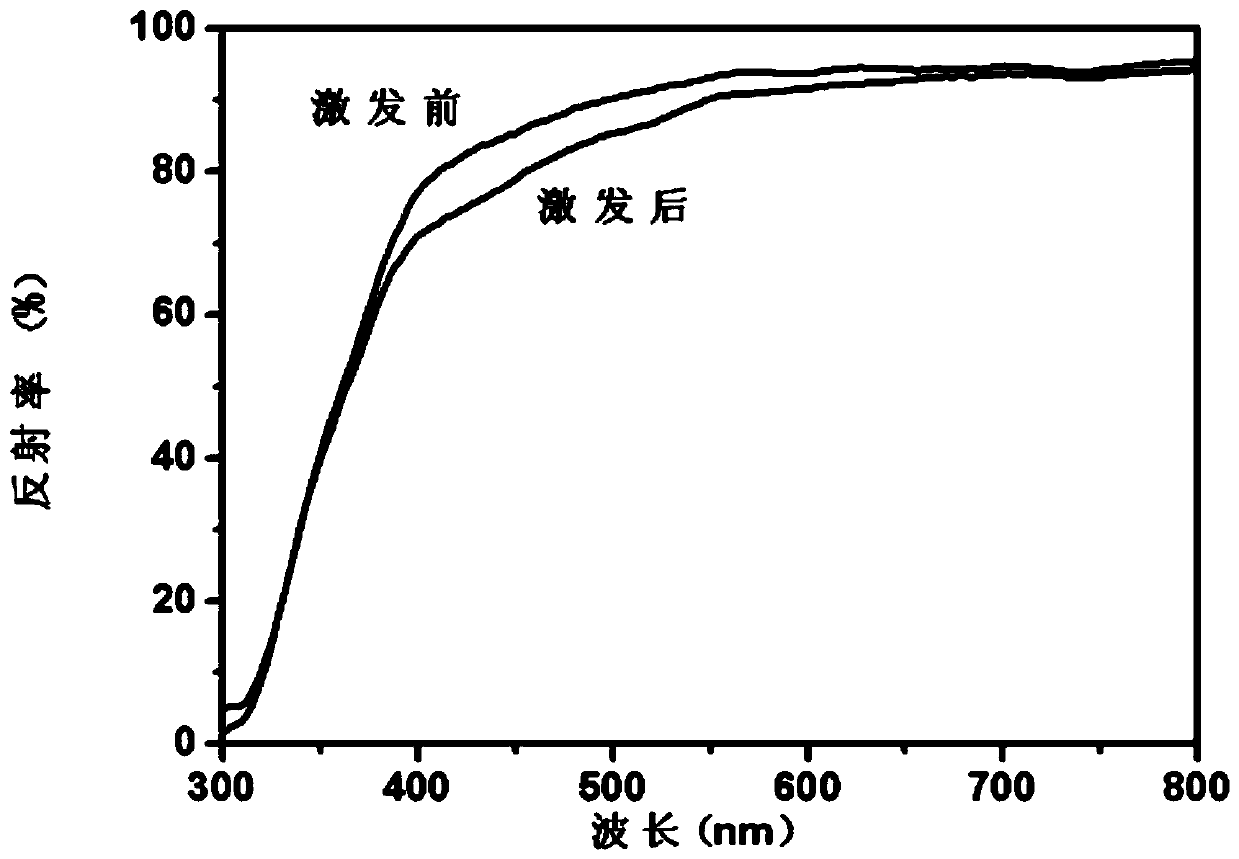

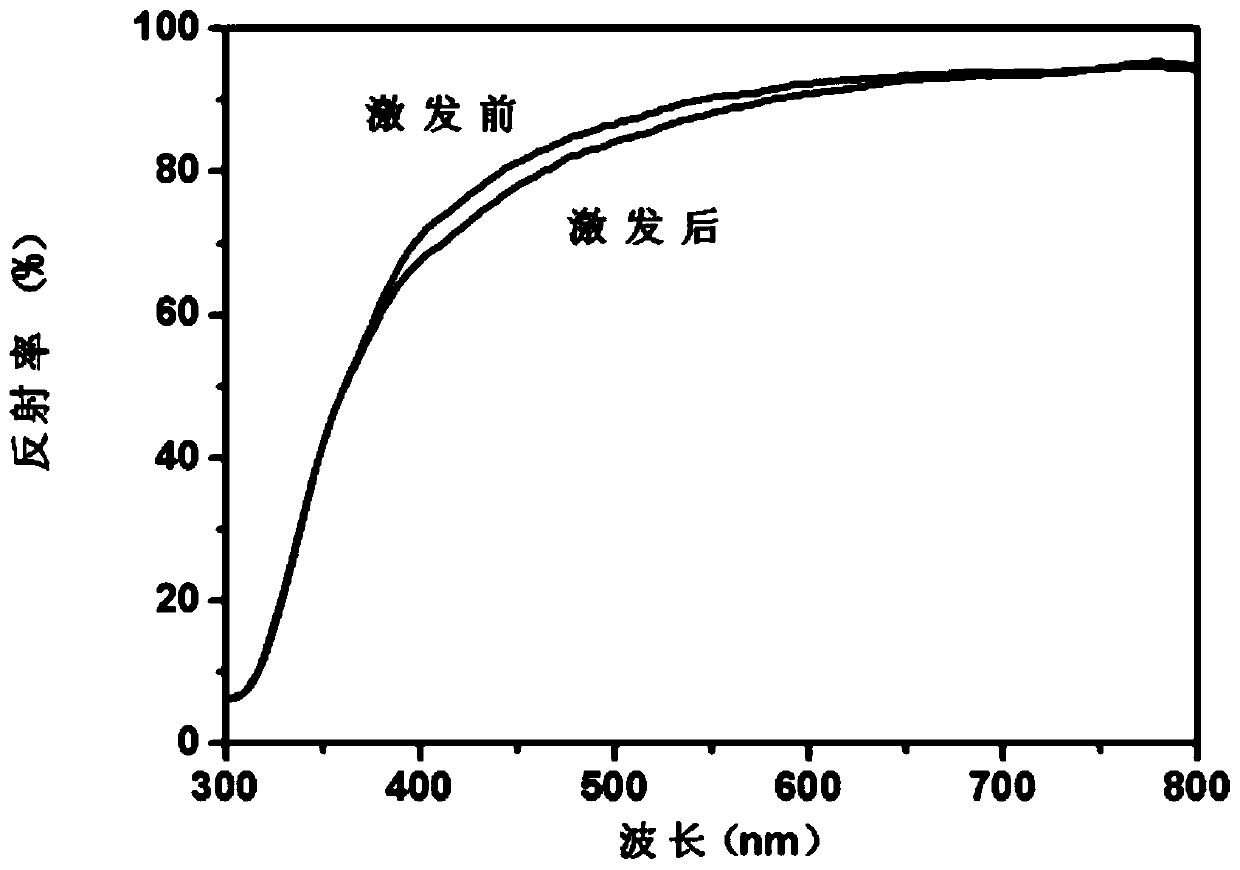

A niobate reversible photochromic material and its preparation method and application

ActiveCN107236535BColor Variation AdjustmentSimple manufacturing processTenebresent compositionsLuminescent compositionsRare-earth elementDevice material

The invention provides a niobate reversible photochromic material. The expression formula is Ba1+x-yNb2O6+x:yPr<3+>; x is 0 or 1; y is the molar weight of doped Pr; and y is more than or equal to 0 but less than or equal to 0.03. The color change degree of the inorganic photochromic material provided by the invention is adjusted in the manner of doping rare earth elements. The preparation raw materials of the reversible photochromic material are low in cost; the reducing atmosphere is not required by the preparation; the equipment requirement is low; the preparation process is simple and feasible; the repeatability is high; and the product nature is stable. The color of the niobate reversible photochromic material provided by the invention gradually becomes gray under the irradiation of ultraviolet light, and can recover the original color under the irradiation of sunlight; and the material has the advantage of excellent fatigue resistance and can be widely applied to the fields of optical information storage, light control, optical device materials, inductors, anti-fake products, self-developing holographic recording cameras, decoration, radiation meters, packaging material protection, and the like.

Owner:GUANGDONG UNIV OF TECH

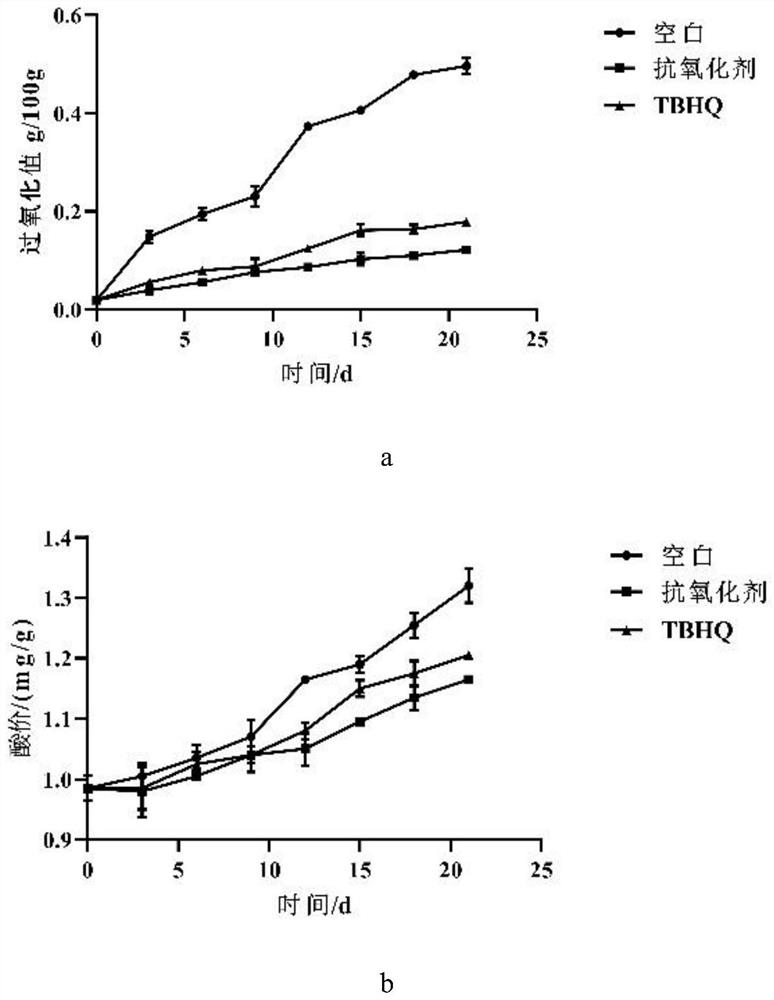

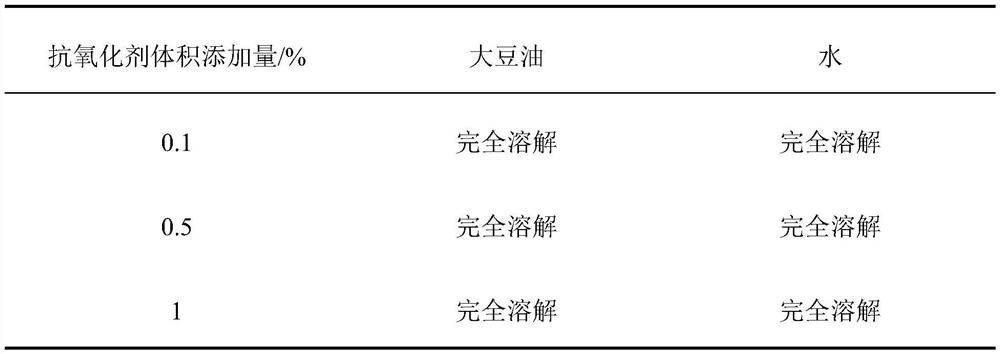

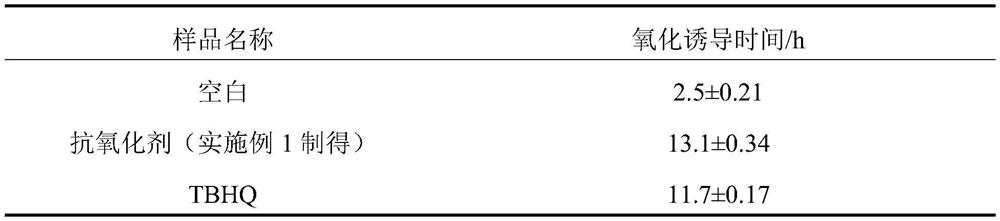

Preparation method and application of water-oil amphiphilic antioxidant

PendingCN113229434AProduct properties are stableGood solubilityClimate change adaptationFood preservationProcess engineeringAqueous solubility

The invention discloses a preparation method and application of a water-oil amphiphilic antioxidant. The method comprises the following steps: (1) uniformly mixing Tween 80 and an oil-soluble antioxidant; (2) uniformly mixing a water-soluble antioxidant with water; and (3) slowly adding the solution obtained in the step (2) into the solution obtained in the step (1), and slowly stirring until the mixed solution is clear and transparent. According to the invention, the water-soluble and oil-soluble antioxidants can be compounded together to prepare a clear and transparent antioxidant solution, the product property is stable, and the phenomena of layering or solute precipitation and the like are avoided after long-term placement.

Owner:南京泛成生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com