Gas-solid method production technology of cellulose mixed ether

A production process and technology of mixed ethers, applied in the field of gas-solid production process of cellulose mixed ethers, can solve the problems of low production efficiency, low yield, long reaction time, etc., to improve utilization rate, reduce production cost, utilize rate-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

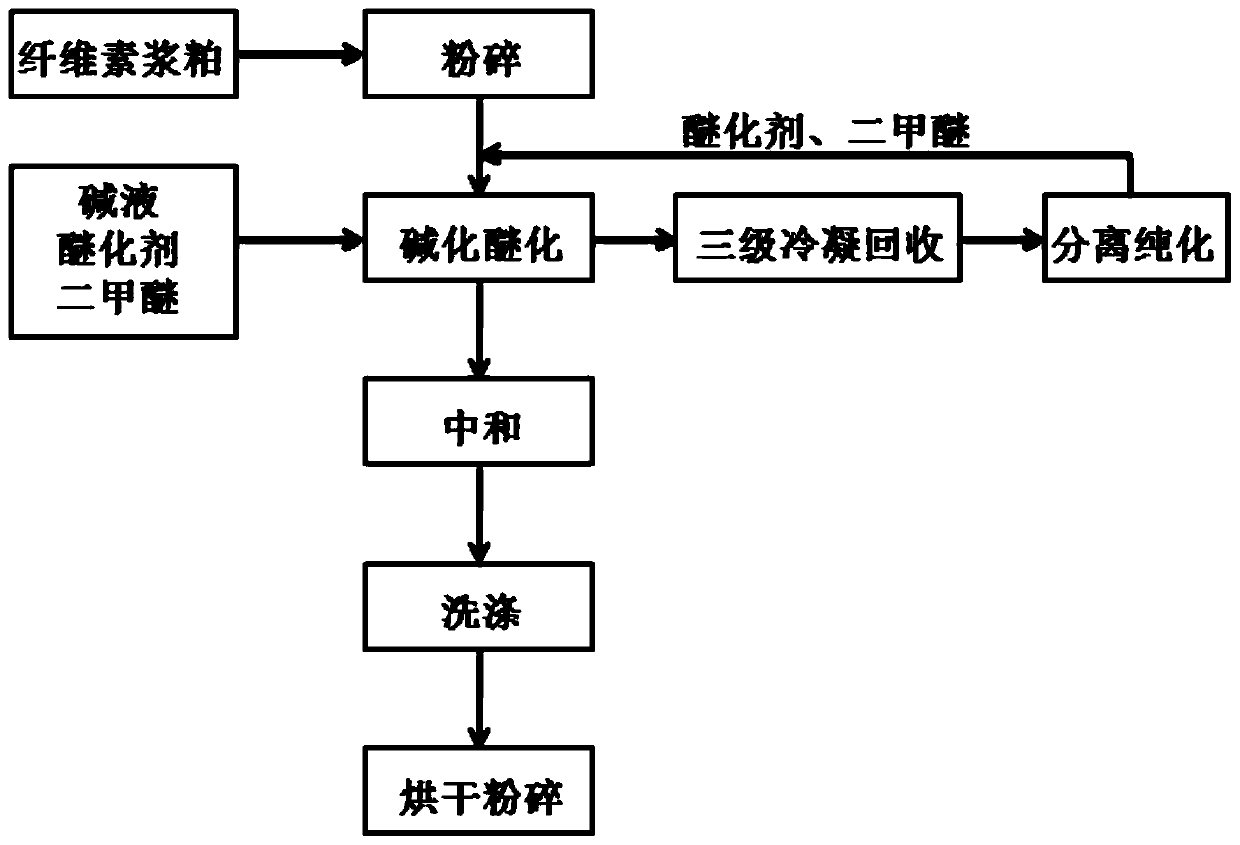

Method used

Image

Examples

Embodiment 1

[0047] Adopt the gas-solid method production technique of the present invention to prepare hydroxyethyl methyl cellulose ether, the steps are as follows:

[0048] (1) Grinding: Grinding the cellulose pulp to a particle size of 200±20 μm and a bulk density of 180±20 g / L to obtain powdery cellulose;

[0049] (2) Alkalinization and etherification: 2650kg powdery cellulose is added in the horizontal reaction kettle, then add 4000kg concentration of 50wt% sodium hydroxide solution, 400kg ethylene oxide, 1860kg methyl chloride and 1600kg dimethyl ether, control horizontal The pressure of the reaction kettle is 2.3MPa, the temperature is raised to 70°C at a uniform speed, the heating time is 1.5h, and the temperature is kept for 1.5h to carry out the alkalization etherification reaction;

[0050] (3) Neutralization: after the reaction finishes, unreacted etherifying agent and dimethyl ether are recovered, then hydrochloric acid is added for neutralization, so that the pH value of the...

Embodiment 2

[0066] Adopt the gas-solid method production technique of the present invention to prepare hydroxypropyl methylcellulose ether, the steps are as follows:

[0067] (1) Grinding: Grinding the cellulose pulp to a particle size of 200±20 μm and a bulk density of 180±20 g / L to obtain powdery cellulose;

[0068] (2) Alkalinization and etherification: 2650kg powdery cellulose is added in the horizontal reaction kettle, then add 4200kg concentration of 50wt% sodium hydroxide solution, 650kg propylene oxide, 2600kg methyl chloride and 1600kg dimethyl ether, control the horizontal reactor The pressure of the reaction kettle is 2.3MPa, the temperature is raised to 70°C at a uniform speed, the heating time is 1.5h, and the temperature is kept for 1.5h to carry out the alkalization etherification reaction;

[0069] (3) Neutralization: after the reaction finishes, unreacted etherifying agent and dimethyl ether are recovered, then hydrochloric acid is added for neutralization, so that the pH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com