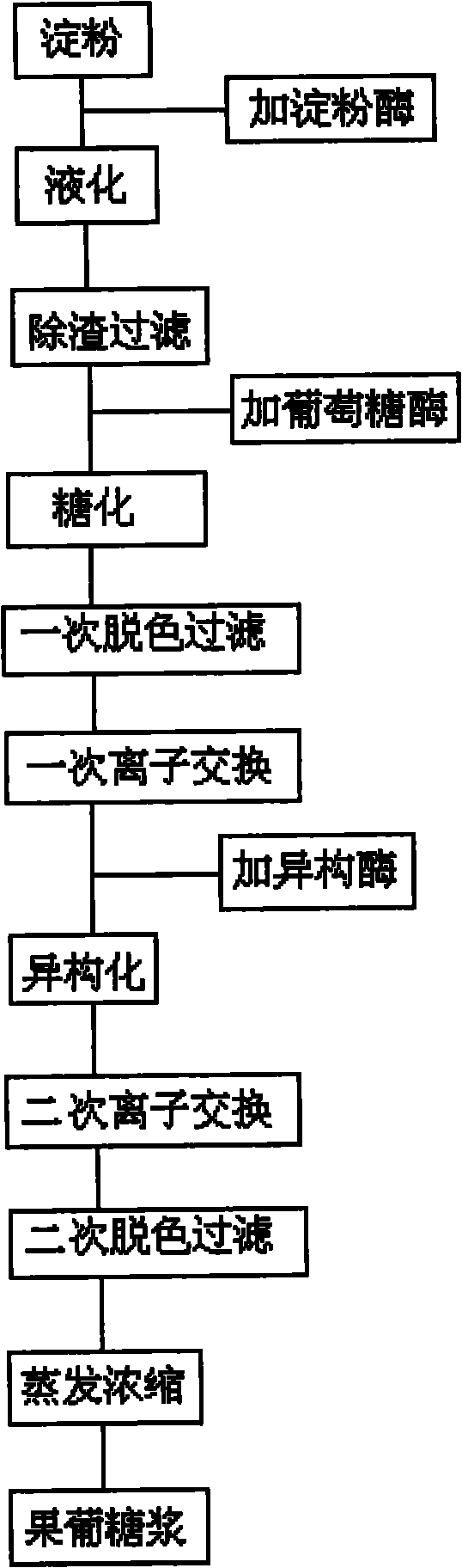

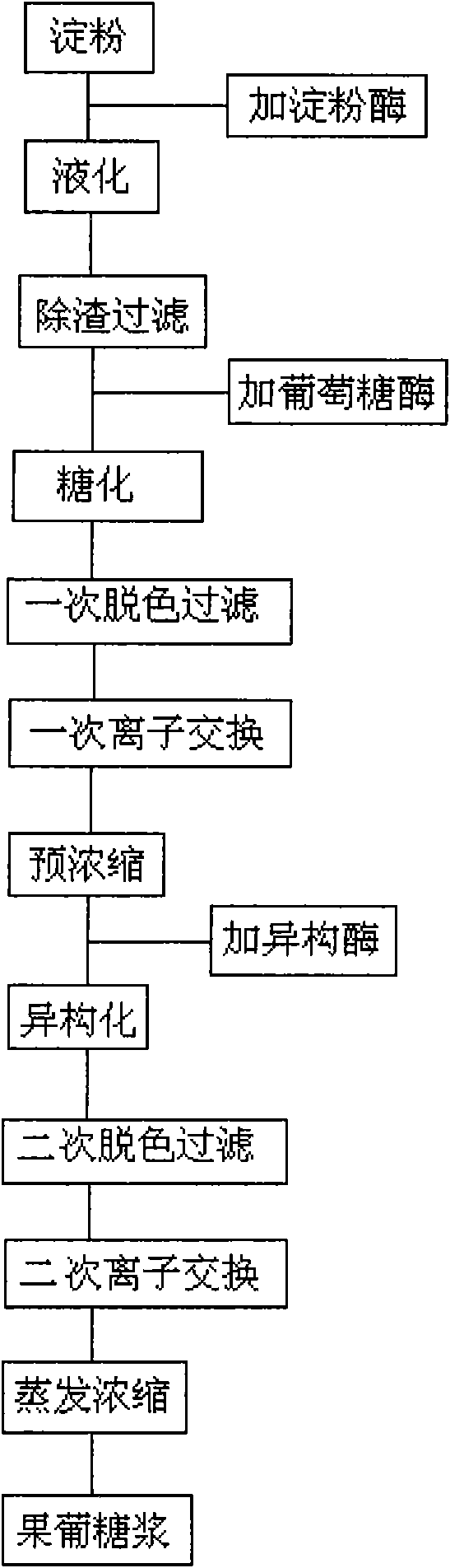

Production process of high fructose corn syrup

A high-fructose syrup and production process technology, applied in the field of high-fructose syrup production process, can solve the problems of colorless and transparent products, complicated process, deepening of color, etc., to reduce the amount of auxiliary materials, stabilize product properties, and improve product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further illustrated below by specific examples:

[0027] Add water to the rice to soak the rice, the soaking time is 2-4 hours in summer and 4-6 hours in winter. While soaking the rice, use an air compressor to turn it for 5-10 minutes to wash the rice. Then the soaked rice is ground to the fineness with a hand feeling without particles with a stone mill, and then passed through a 60 mesh sieve, and Be' (starch milk concentration) is in the range of 18-22.

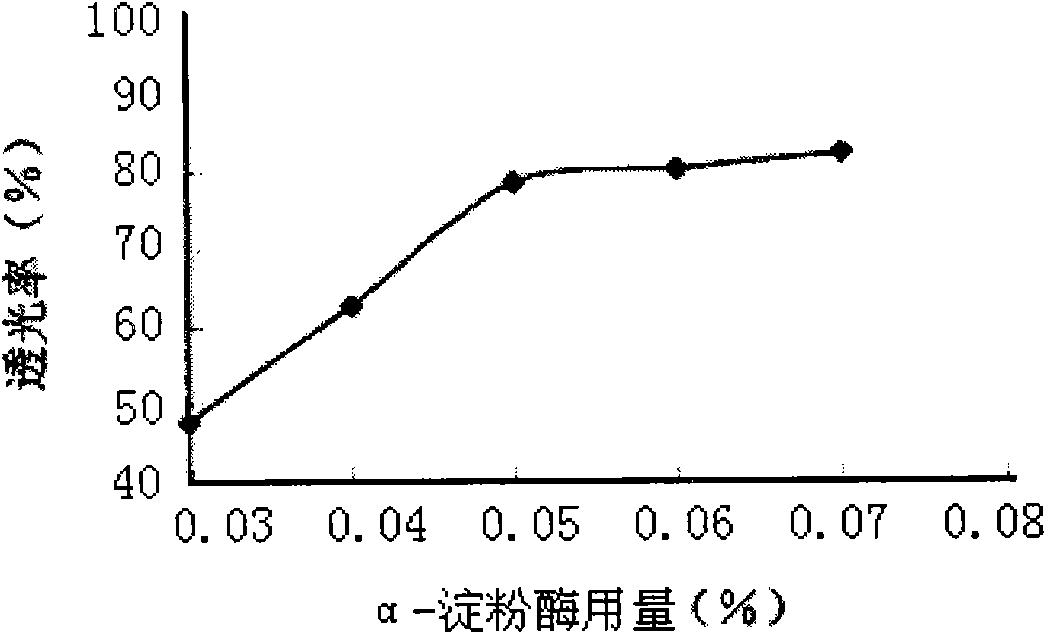

[0028] Control the starch milk concentration Be 'in the range of 17.5-18, the solid content after liquefaction is in the range of 30-33%, the DE value (the percentage of glucose in dry matter) is in the range of 18-22%, and the pH value is in the range of 18-22%. In the range of 6.0-6.5, add α-amylase after stirring evenly, and the dosage of α-amylase is about 5 / 10,000 of the raw rice. like image 3 As shown, when the amount of α-amylase is about 5 / 10,000 of the raw material, the light tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com