Patents

Literature

366results about How to "Generation of control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intelligent lithium ion battery management system for electric vehicle and balance control method thereof

ActiveCN104052087AReduce volumeStable performanceBatteries circuit arrangementsElectric powerElectric vehicleLithium electrode

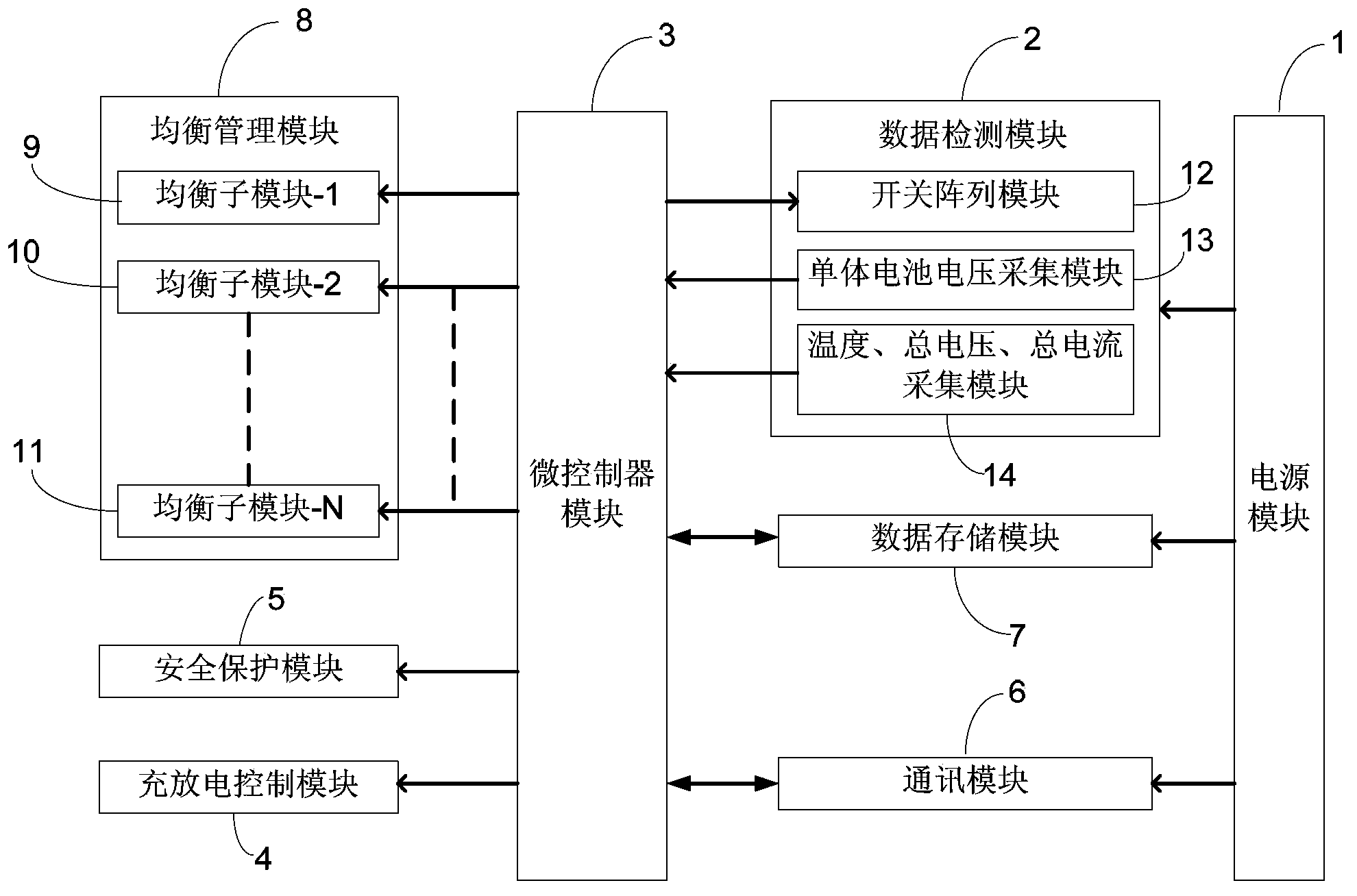

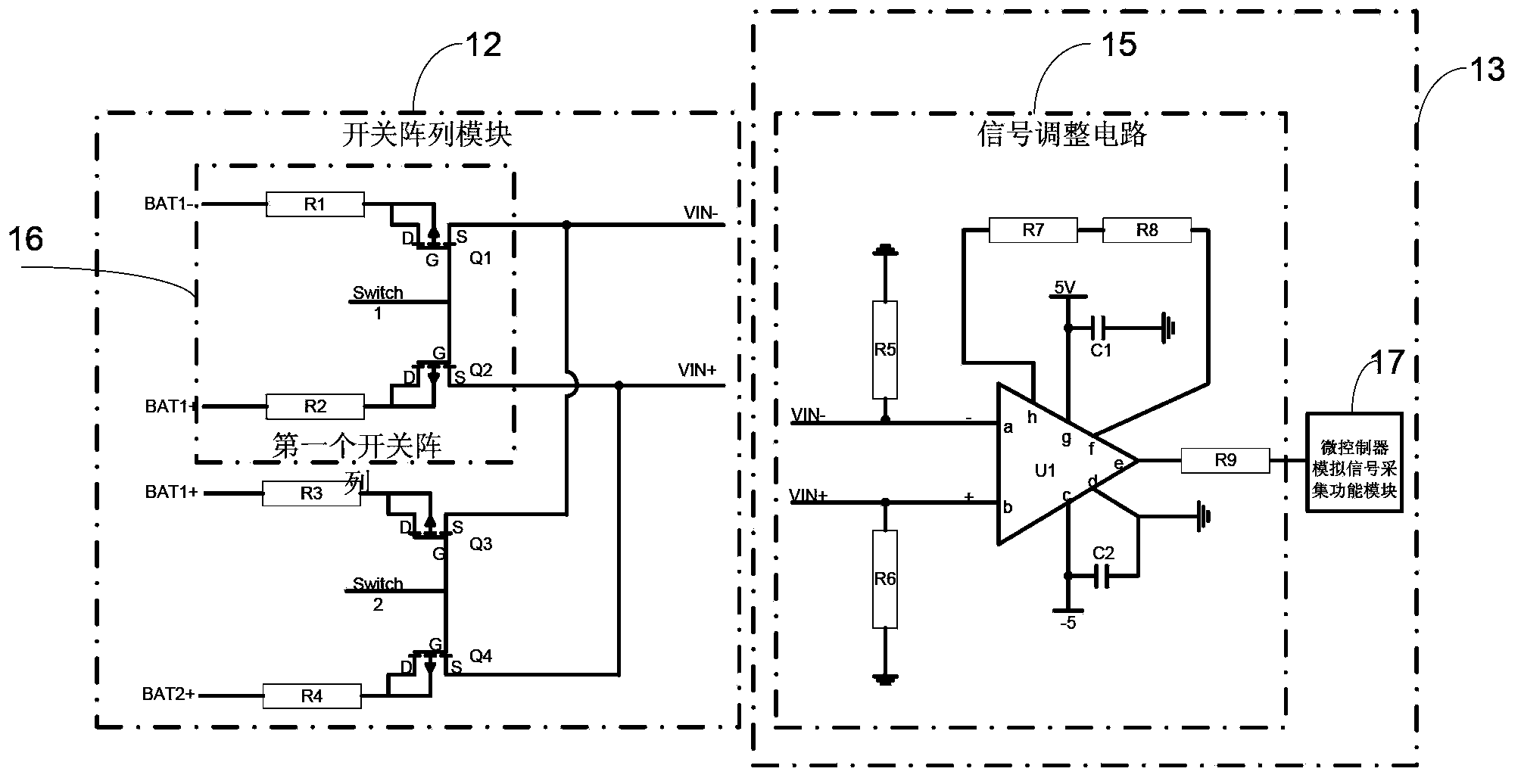

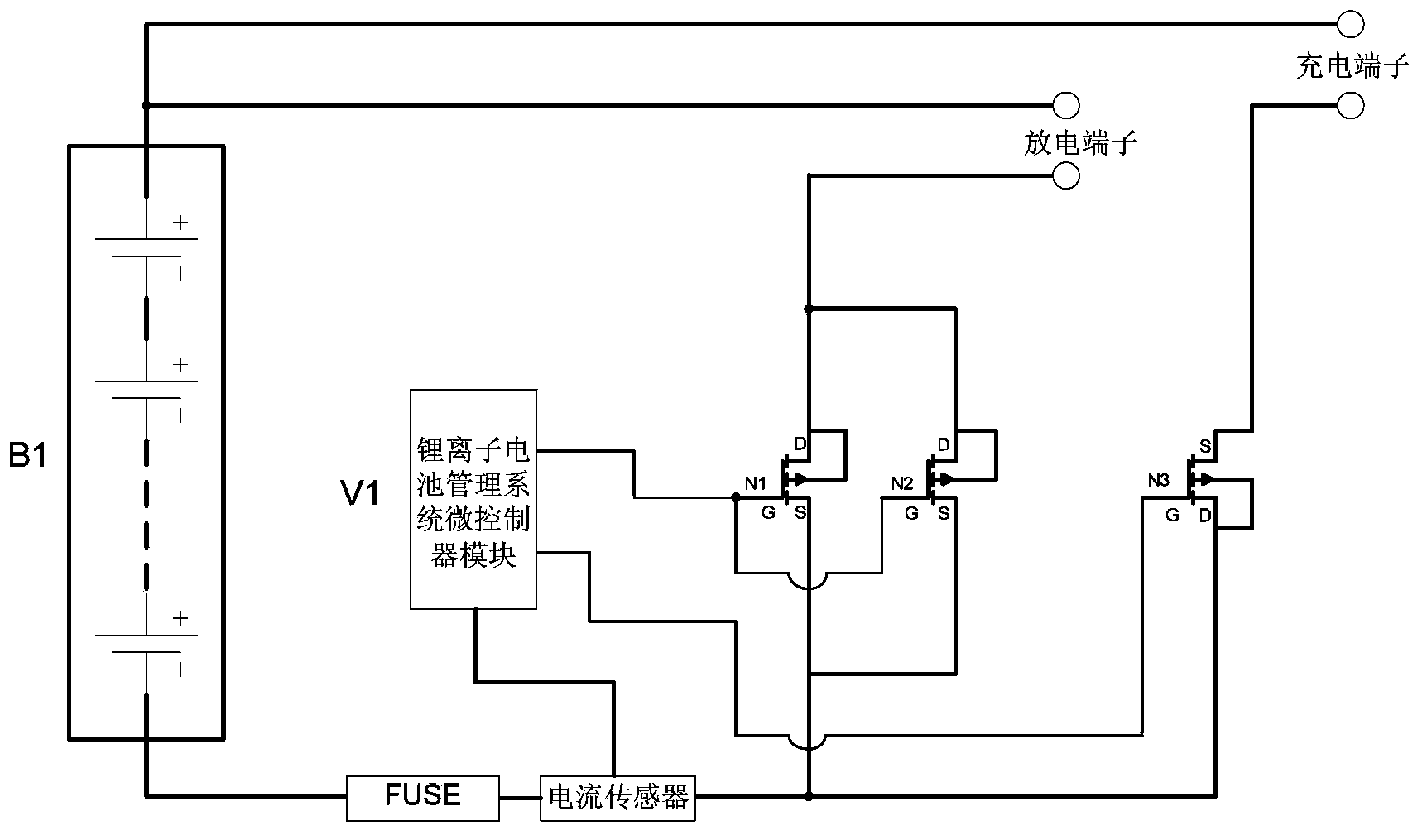

The invention relates to an intelligent lithium ion battery management system for an electric vehicle. The management system is characterized in that a microcontroller module is connected with a power supply module, a data detection module, a charge-discharge control module, a safety protection module, a communication module, a data storage module and a balance management module. The balance control method comprises the following steps: carrying out balance self-inspection according to each collected single cell voltage data in a cell unit; if the balance self-inspection is successful, judging whether to start balance control; if the difference between the single cell voltage and the average value voltage is larger than a preset threshold voltage and the voltage of a certain single cell is larger than a preset threshold, carrying out balance control with PWM duty ratio obtained based on the single cell voltage being as balance time; or otherwise, giving up carrying out the balance control. The management system in the invention is a centralized battery management system, and has the advantages of small size, stable performance, high detection precision, low cost and high reliability and the like.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Lactobacillus plantarum strain and application thereof

ActiveCN101724591AStrong growth abilitySimple preparation processBacteriaMicroorganism based processesTryptamineGram

The invention relates to a lactobacillus plantarum strain of which the preservation number is CGMCC No.3166, which can be enriched in a modified MRS liquid culture medium. The lactobacillus plantarum strain is a white colony on an MRS solid culture medium, is straight, short-chained, Gram-positive and atrichous, has homofermentation, does not generate gas when fermenting glucose, generates acetic acid and lactic acid when fermenting ribose, and does not reduce nitrite. In application, the strain is activated and propagated and thalli are collected to form a fermenting agent which can inhibit the growth of amine producing bacteria in the fermenting production of meat products and generate biogenic amine oxidase which oxidizes and degrades tyramine, phenylethylamine, tryptamine and histamine. The invention has the advantages that the lactobacillus plantarum has strong growing ability, the fermenting agent has simple preparation technology and can effectively inhibit the growth and propagation of enterobacteria in the fermenting production of meat products and control the generation of biogenic amine, the generated biogenic amine oxidase can oxidize and degrade the contents of tyramine, phenylethylamine, tryptamine and histamine, and the lactobacillus plantarum strain as the fermenting agent for producing the fermented meat products can effectively reduce the accumulation of the biogenic amine.

Owner:NANJING AGRICULTURAL UNIVERSITY

Chemical-copper plating liquid and copper plating production process

ActiveCN101654797AImprove bindingApplicable functionLiquid/solution decomposition chemical coatingPorosityCopper plating

The invention relates to chemical-copper plating liquid and a copper plating production process, which are used for copper plating of tubular steel and iron pieces and non-metal pieces, and are characterized in that: the chemical-copper plating liquid consisting of copper sulphate, a retarder, a complexant, a reductant and deionized water is used to pretreat a workpiece and then the workpiece is subjected to chemical-copper plating; an anode is 0.3 percent phosphor-containing copper plate; the area ratio of the anode and the cathode is 2:1; the current intensity in the cathode is 0.5 to 4A / dm<2>; the pH value of the copper plating liquid is 1.0 to 3.0; the temperature of the copper plating liquid is normal temperature; and the carrying capacity is 1 to 4dm<2> / kg; the copper plating time is8 to 10 minutes. The liquid and the process have the advantages of firm bonding between cladding and a substrate, stable process, high impurity resistance, long service life, crystalline simple copper cladding, fine cladding crystallization, low porosity, high anticorrosion performance, simple operation, convenient maintenance, no formaldehyde, no damages to human bodies and environment and environmentally-friendly product.

Owner:河北聚贤环保科技股份有限公司

Fiber concrete

InactiveCN104030642AImprove impermeabilityLow bleeding rateSolid waste managementSuperplasticizerCarboxylic acid

The invention discloses fiber concrete comprising the following components in parts by weight: 170-180 parts of water, 335-345 parts of cement, 60-70 parts of coal ash, 13-19 parts of silicon ash, 1755-1775 parts of aggregates, 2.8-3.5 parts of basalt fiber, 3-5 parts of polycarboxylate superplasticizer and 30-34 parts of light silica fiber anti-crack reinforcer. Basalt fiber is not only good in stability, but also has various excellent performances such as electric insulation property, corrosion resistance, combustion resistance, high temperature resistance and the like. Due to the doping of the light silica fiber anti-crack reinforcer, the separation tendency of the concrete can be effectively avoided and inhibited, and cracks generated after the concrete is poured can be remarkably reduced and even completely eliminated, so that the concrete has the advantages of high compactness, high strength, good durability, low bleeding rate, high anti-crack coefficient and the like. Due to the doping of the coal ash, the silicon ash and the polycarboxylate superplasticizer, the performance of the concrete is improved, the generation of cracks is controlled effectively, and the positive significance for the durability of the concrete is taken.

Owner:HUNAN CONSTR ENG GRP COR +1

A hollow microsphere masonry dedicated thermal insulation mortar and a dedicated surface mortar

InactiveCN102690091AEliminate hot and cold bridgesEliminate hot and cold bridge phenomenonThermal insulationMicrosphere

A hollow microsphere masonry dedicated thermal insulation mortar and a dedicated surface mortar, especially a wall self-insulation system-matching hollow microsphere masonry dedicated thermal insulation mortar and a dedicated surface mortar, relate to a constuction energy-saving technology. The hollow microsphere masonry dedicated thermal insulation mortar comprises, by weight, 20-30% of special cement, 2-6% of coal ash, 20-35% of quartz sand, 5-8% of master batch, 35-45% of hollow microphere, and 3-6% of coarse whiting; and the hollow microsphere masonry dedicated surface mortar comprises, by weight, 28-40% of ordinary Portland cement, 3-6% of coal ash, 7-10% polymer, 40-55% of quartz sand, 10-16% of hollow microsphere, and 1-3% of coarse whiting. With a low heat conductivity coefficient, excellent thermal insulation effect, high compression strength, high bonding strength, low contractibility, environment-friendly and fire-proof properties and notable composite economic results, the wall self-insulation system-matching dedicated thermal insulation mortar and a dedicated surface mortar provided in the invention can be widely popularized and used in wall self-insulation system buildings.

Owner:HUBEI TIANQUAN NEW BUILDING MATERIALS

High-strength plasticity aluminum-base composite material employing TiB2 particles and preparation method thereof

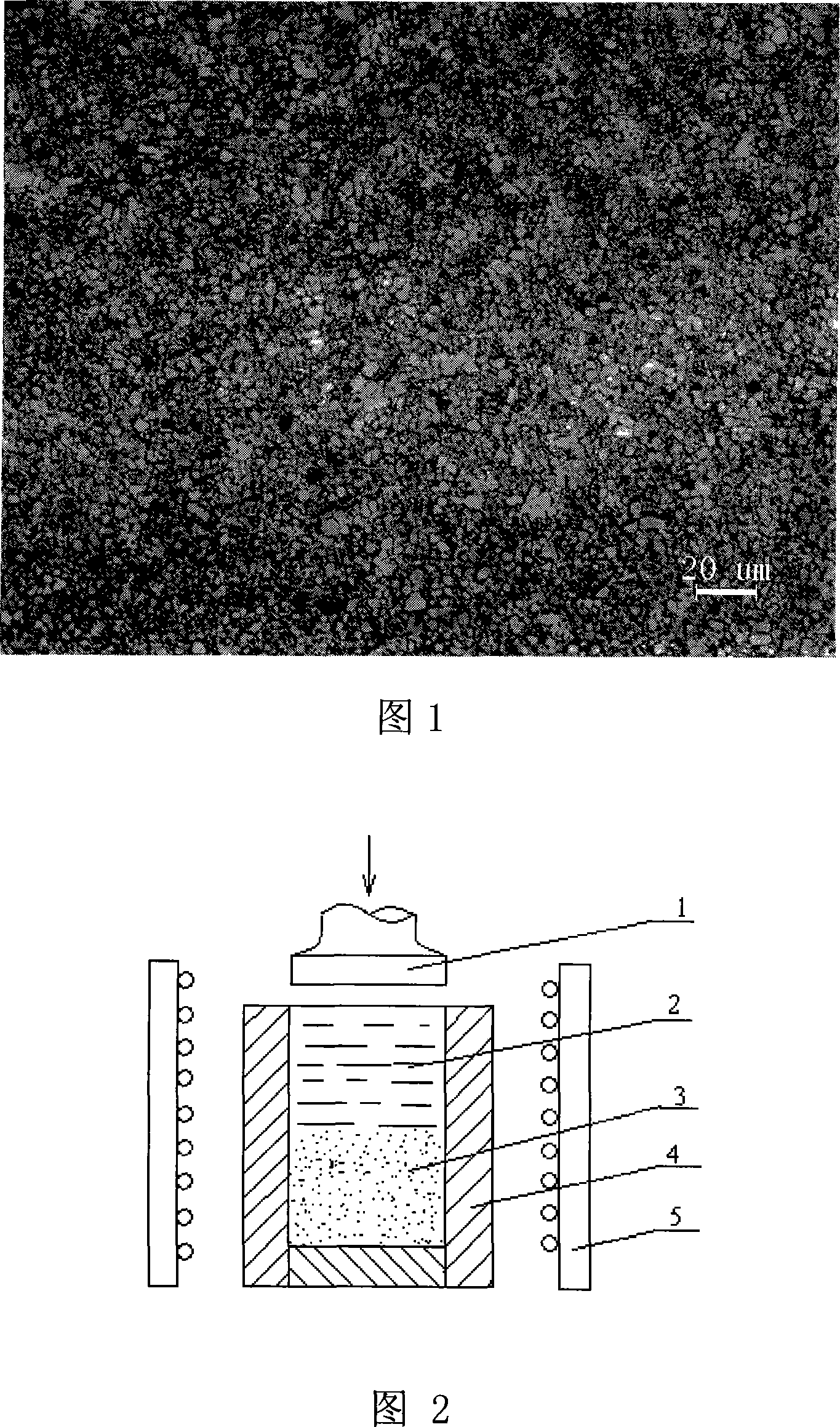

The invention provides a high-plasticity aluminum-based composite material containing TiB2 particles and a preparation method thereof, and relates to an aluminum-based composite material and a preparation method thereof. The invention solves the problems of the prior art, such as poor plasticity and toughness and difficulty in secondary processing. The composite material contains (by volume) titanium diboride reinforcement particles 10-25 percent, aluminum particles 25-35 percent, and aluminum alloy matrix in balance. The preparation method comprises: (1) weighing titanium diboride reinforcement particles, aluminum particles and aluminum alloy matrix; (2) mixing by mechanical dry method to obtain a reinforcement powder; (3) placing the reinforcement powder in a die and compression-molding; (4) heating the die; (5) melting aluminum alloy and casting in the die; (6) applying a pressure on the die with molten aluminum and maintaining the pressure for a period of time and cooling; (7) demoulding and taking the cast ingot, that is reinforced aluminum-based composite material. The inventive aluminum-based composite material has high plasticity and good wear resistance and is adapted to secondary processing and machining.

Owner:HARBIN INST OF TECH

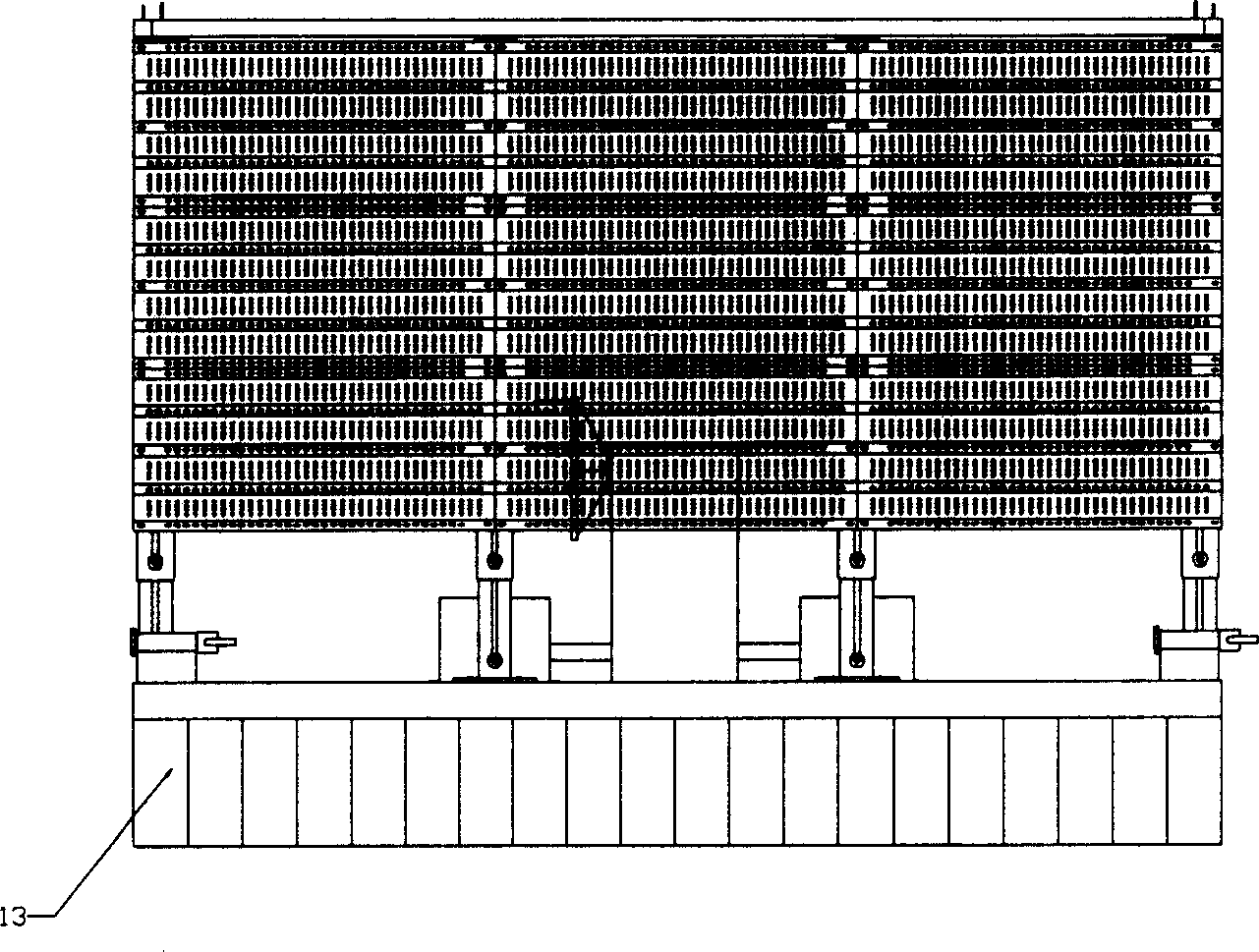

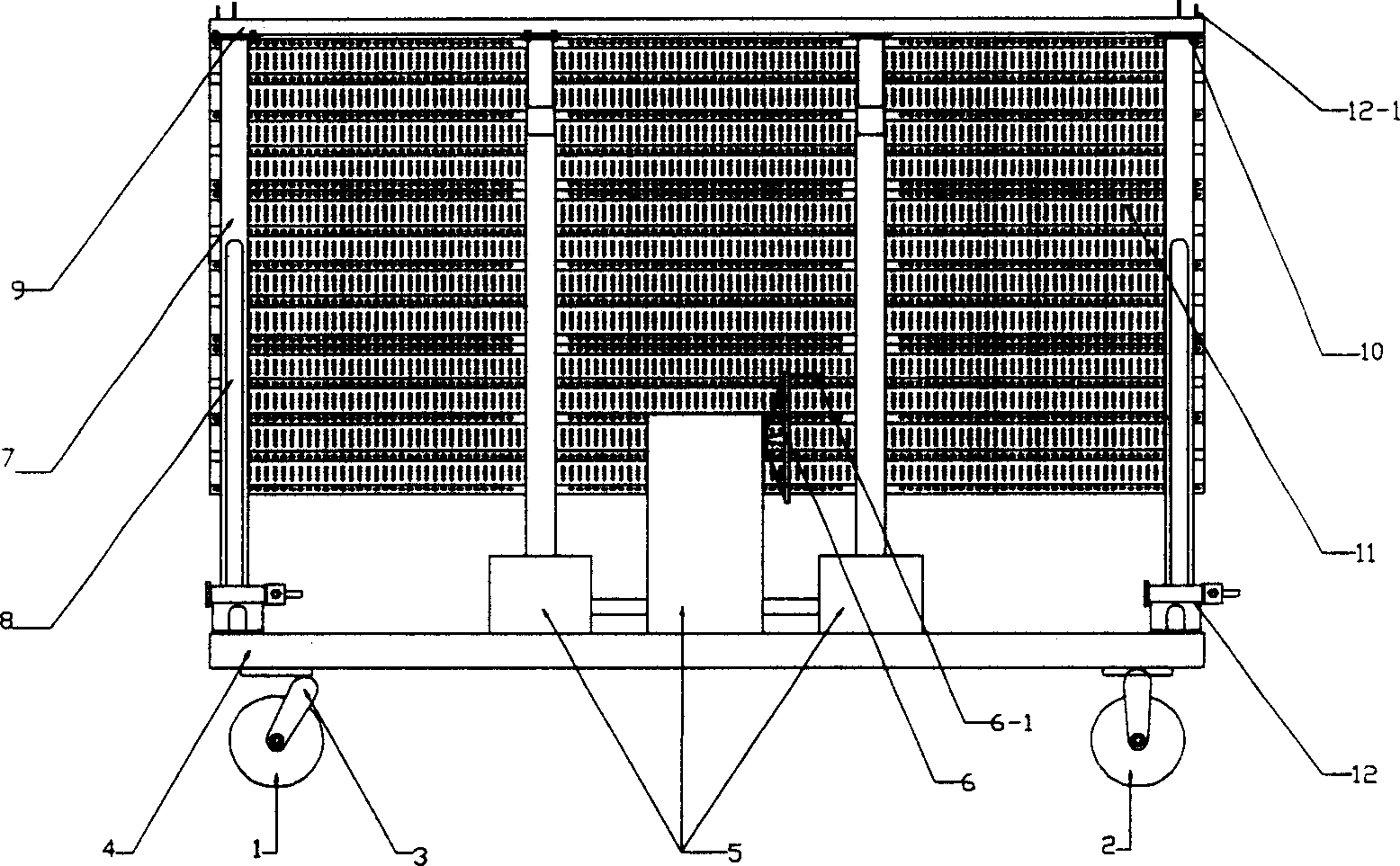

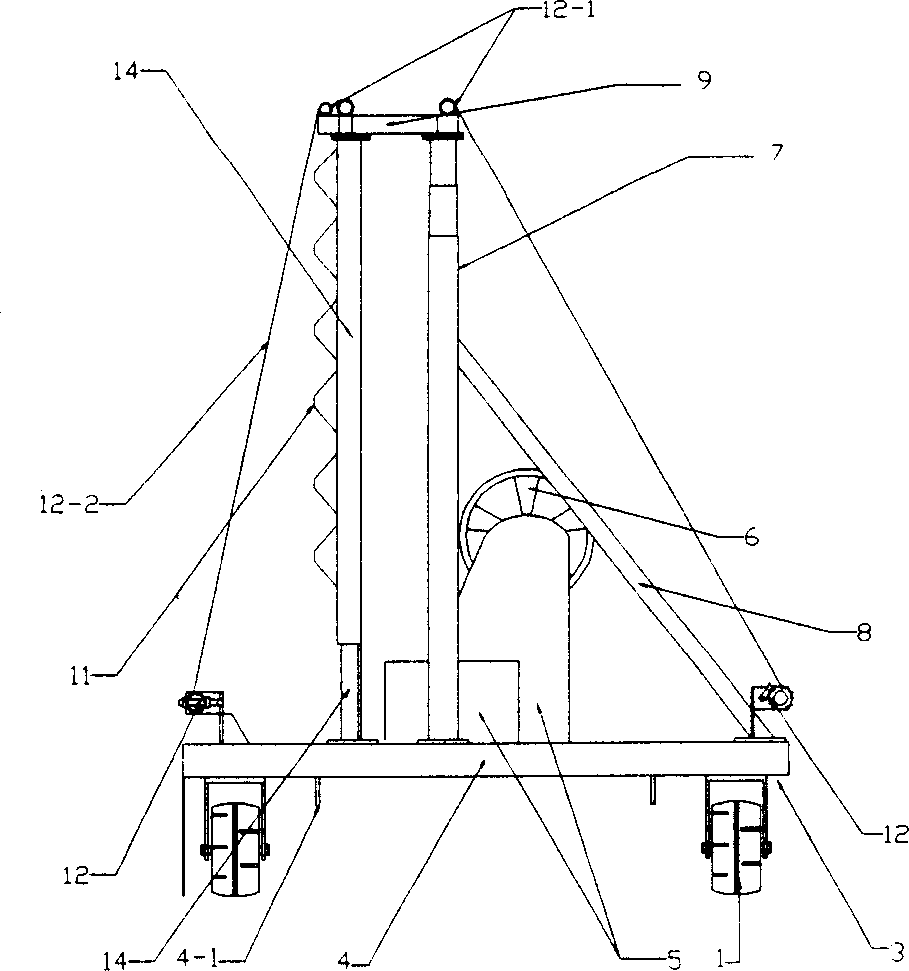

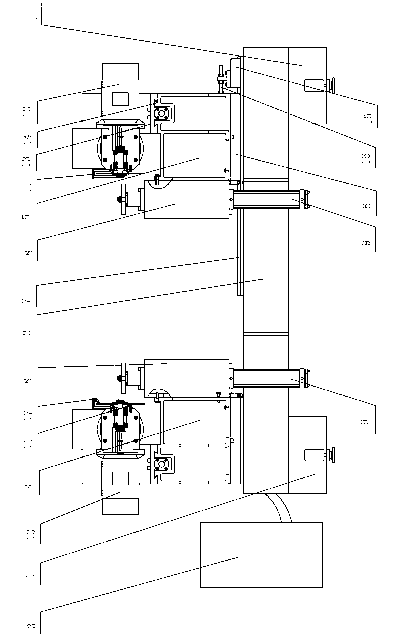

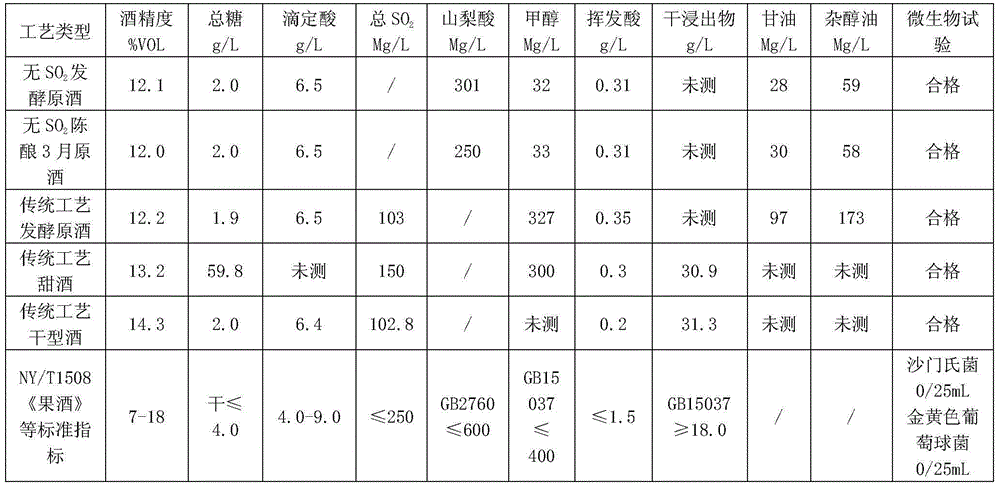

Lifting moving windproof net device

The invention relates to a lift movable wind-proof net device, which comprises a wind-proof net, a movable device and a transmission lifter. Wherein, the wind-proof net and the transmission lifter are arranged on one platform; said platform is mounted with front and back rows of several support posts, while the top ends of each two front and back relative support posts are mounted with connecting support; said wind-proof net is fixed at the front row of support posts; two support posts of back row of support posts that near the platform are fixed with one end of incline support post; another end of incline support post is fixed at one end of platform; the middle of platform is arranged with transmission lifter, to control the wind-proof net. The invention has lower cost to control the powder pollution and save water, while it can be used for more than 20 years. The invention can effectively reduce the wind speed and reduce the wind impulse speed, to protect the environment.

Owner:交通部天津水运工程科学研究所 +1

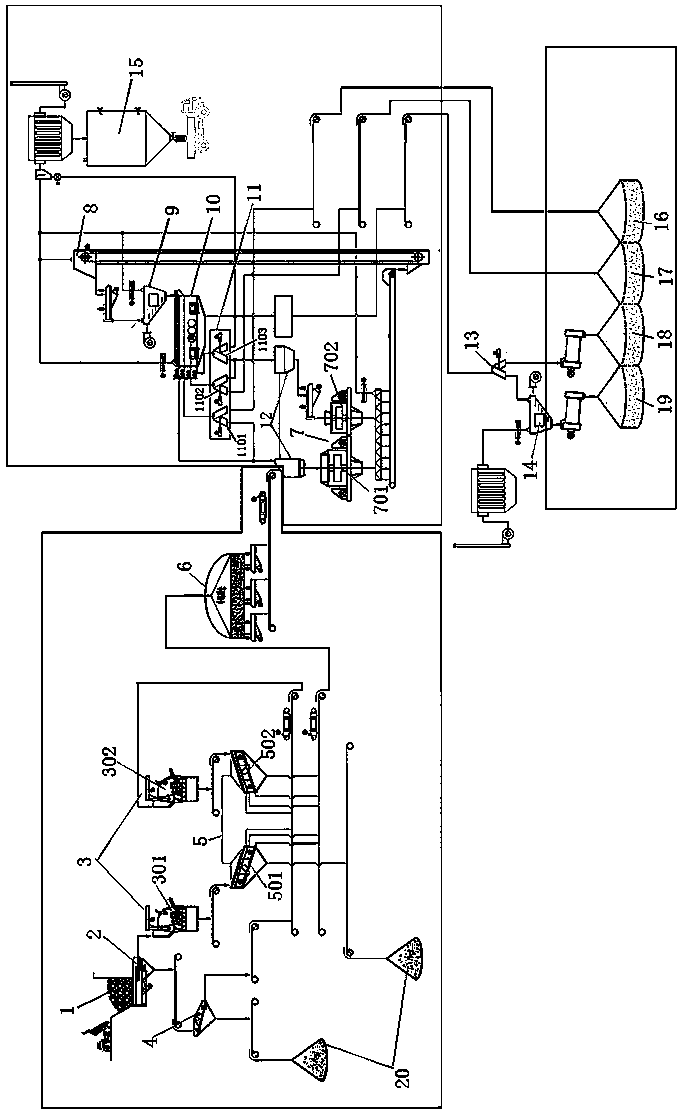

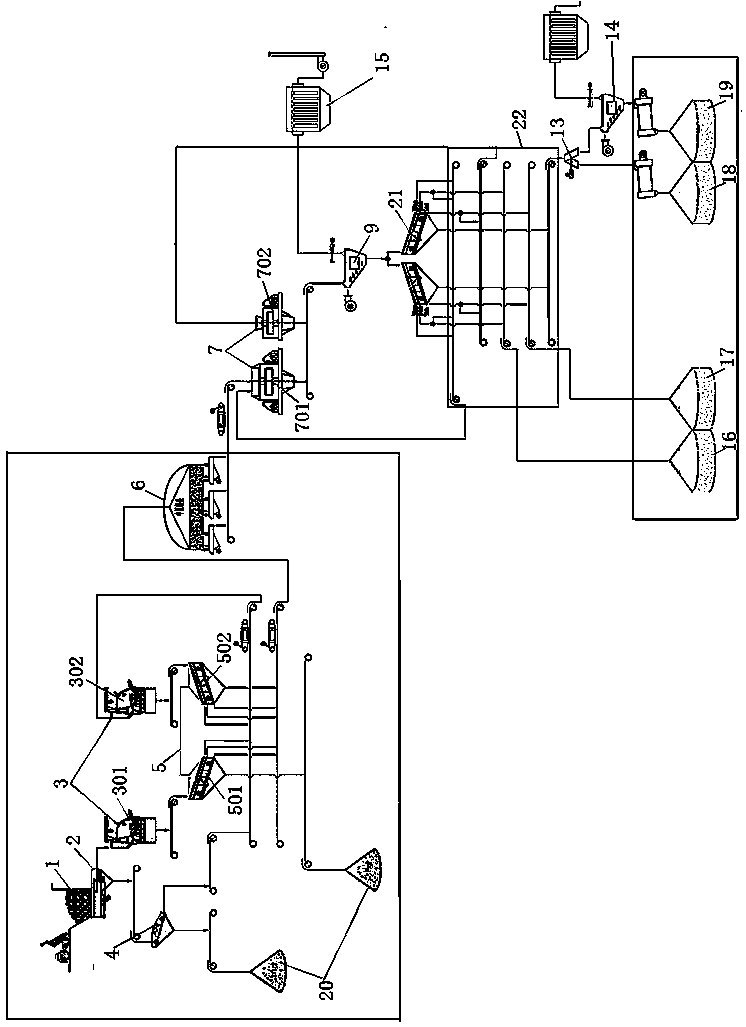

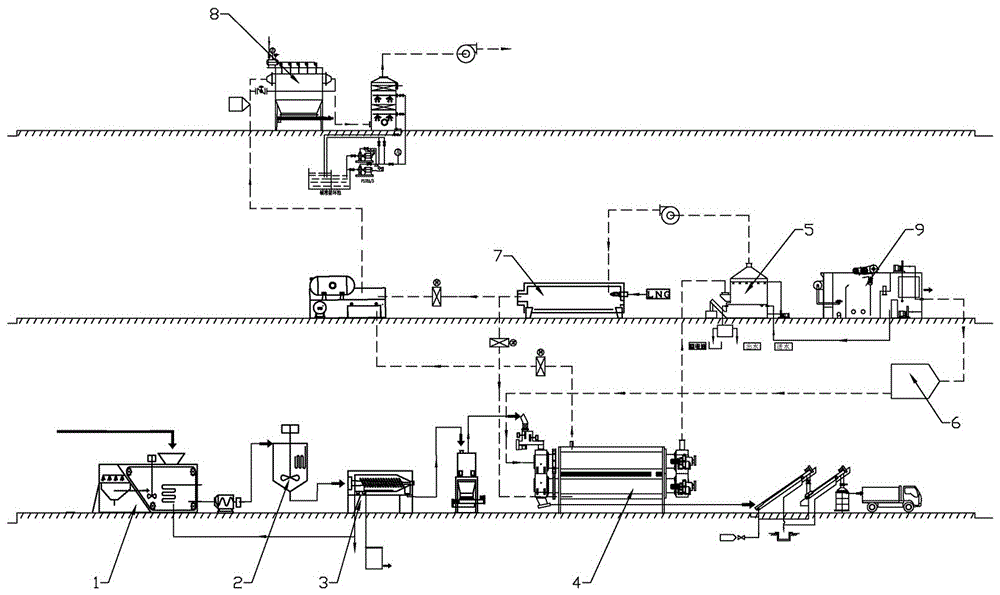

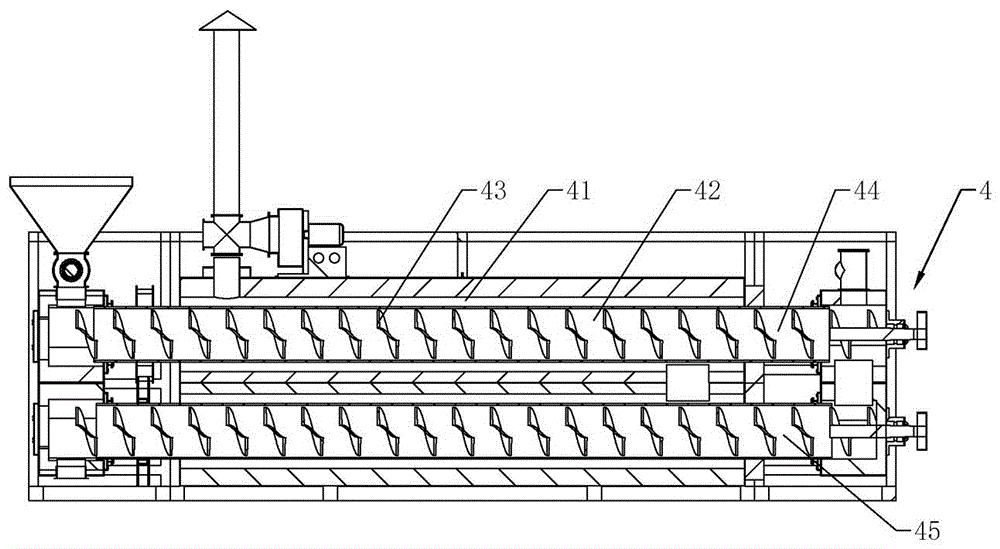

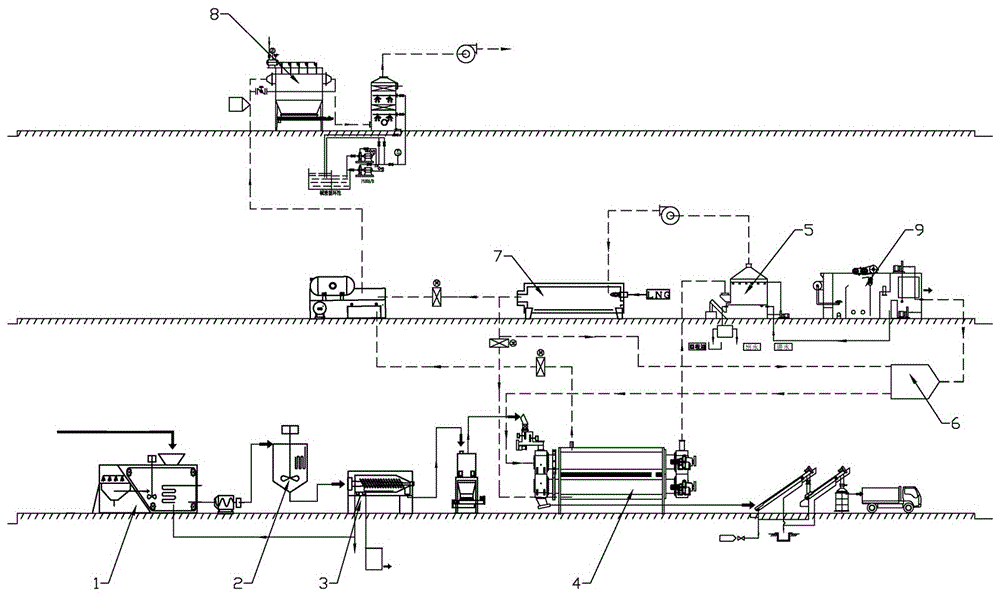

Five-double full-dry method crushing production line and processing method for high-quality sandstone aggregates

PendingCN109731661AGuaranteed cleanlinessGuaranteed growthGrain treatmentsSolid waste managementProduction linePre treatment

The invention discloses a five-double full-dry method crushing production line and processing method for high-quality sand aggregates. The production line comprises a material pretreatment system. A discharge port of the material pretreatment system is connected with a feed port of double-impact crushing equipment of a fine coarse aggregate processing system, a discharge port of the material pretreatment system is connected with a primary classifier, and a discharge port of the primary classifier is connected with a finished product screening and proportion adjusting circulation system. A super-particle-size material outlet of the finished product screening and proportion adjusting circulation system is circularly connected to a feed inlet of double-speed double-frequency crushing sand making equipment. The fine sand aggregates are connected to corresponding finished product bins or are circularly connected to the feed inlet of the double-speed double-frequency crushing sand making equipment, and multi-stage powder selecting equipment is arranged below a fine sand outlet. According to the production line, the production line with multi-stage desliming, double-countering-impact crushing, double-vertical-shaft impact crushing shaping sand making, multi-stage powder selecting and multi-stage circulation is adopted, so that the system productivity and the quality of the finished sand aggregates are improved effectively, the efficient and energy-saving effects are realized, and the practicability is high.

Owner:GUIZHOU CHENGZHI HEAVY IND SCI TECH

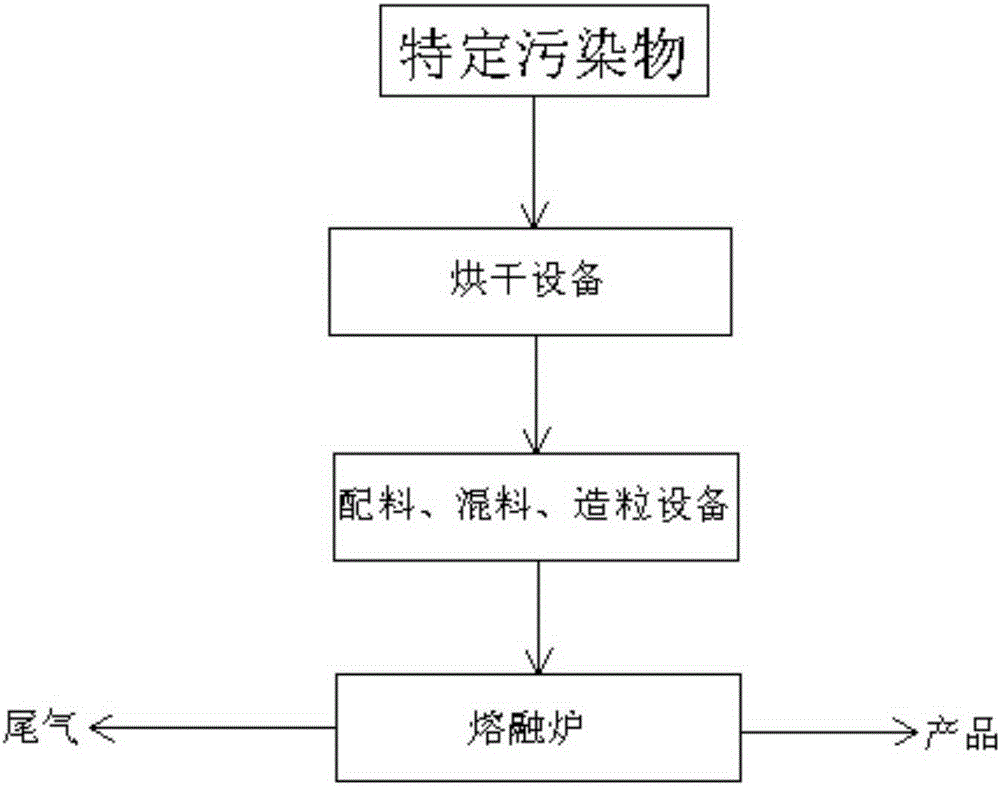

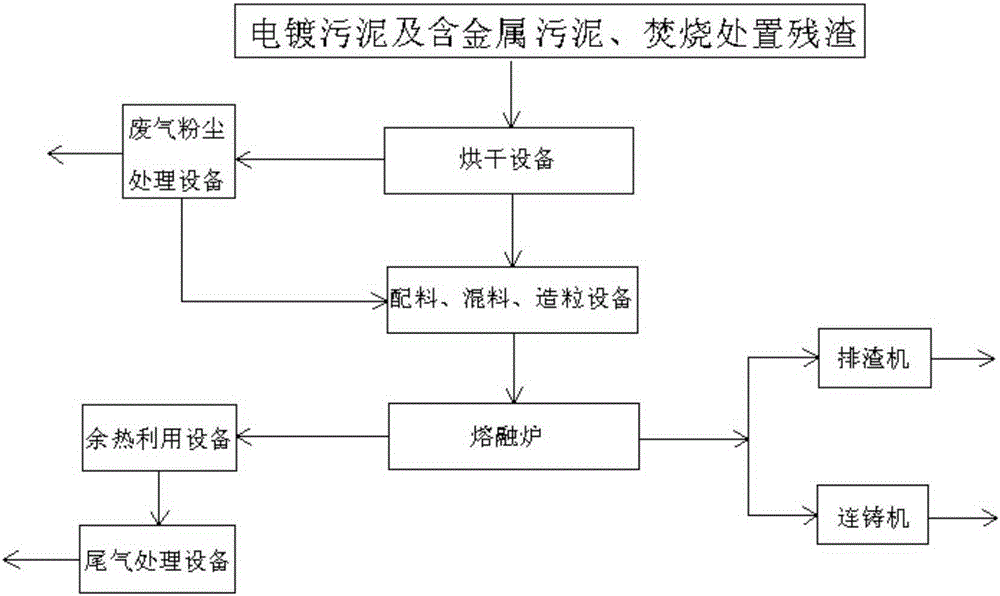

Method for treating specific pollutants through high-temperature melting technology

InactiveCN105344698AReduce operating costsResourcefulSolid waste disposalTransportation and packagingSludgeSlag

The invention provides a method for treating specific pollutants through a high-temperature melting technology. The specific pollutants comprise electroplating sludge, sludge containing metal and / or incineration disposal residues. The method comprises the steps that pretreatment is carried out, wherein the specific pollutants are pretreated, the water content of the specific pollutants is reduced to be 10 wt% or lower, and dry specific pollutant materials are obtained; burdening, blending and granulating are carried out, wherein regulating components are added as needed, mixed and granulated, and a granulated mixture is obtained; melting is carried out, wherein the granulated mixture is melted at the melting temperature ranging from 1,200 DEG C to 1,800 DEG C; and products are obtained, wherein the melted metal is settled on the lower layer and is discharged to obtain a metal alloy, and slag and a small part of metal float above the melted metal and are discharged to obtain glassy-state slag. After the specific pollutants are treated through the method, harmless and pollution-free resource materials can be obtained, and the method can be used for resource recycling, and is good in economic benefit and beneficial to commercial popularization.

Owner:SHANGHAI LVCHENG ENVIRONMENTAL PROTECTION TECH

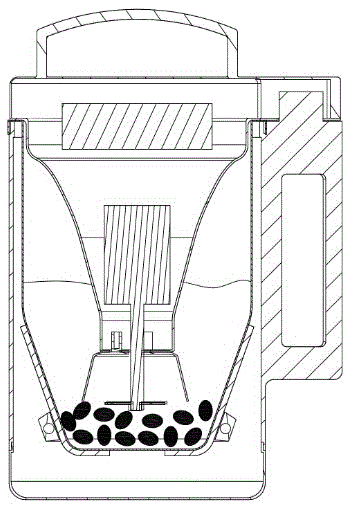

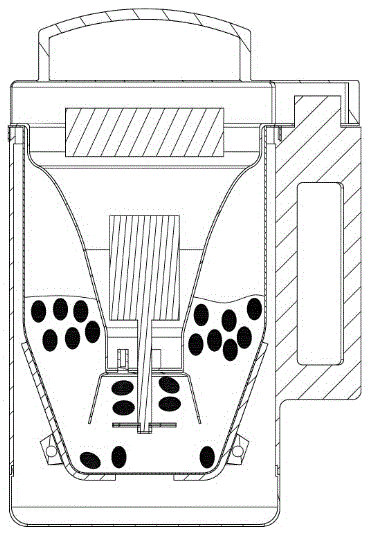

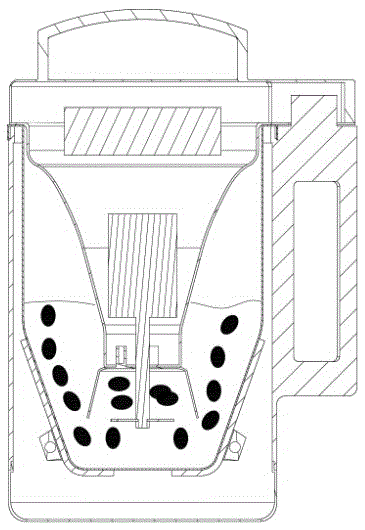

Soybean milk making method of soybean milk machine

ActiveCN105411430AShorten pulping cycleGuaranteed service lifeKitchen equipmentMilk substitutesSoybean oilEngineering

The invention provides a soybean milk making method of a soybean milk machine so as to solve the problems existing in the making process of an existing soybean milk machine, particularly, the problems that noise is too large and the making cycle is too long. A smashing cover is arranged on a machine head of the soybean milk machine. The soybean milk making method is characterized by comprising the steps that firstly, a mixture of materials and water is heated to boil, the materials are softened and float to the liquid surface, and part of the materials are blocked and limited in the smashing cover; then, the boiling state is kept for a preset time, the materials are smashed with a smashing cutter in the kept boiling state, and at the moment, the materials are gradually taken into the smashing cover to be smashed under flowing of slurry; then, the materials are continuously smashed with the smashing cutter; finally, the mixture of the materials and the water continues to be heated so that the materials can be thoroughly cooked. According to the method, the slurry is heated to boil firstly, the boiling state is kept for a certain time, and the materials are smashed in the state, so that soybean milk making noise is greatly reduced, the soybean milk making cycle is shortened, and energy is saved.

Owner:HONGYANG HOME APPLIANCES

Coal producers from consumer waste regeneration

The invention relates to a living garbage renewable coal product and a preparation method thereof. The product comprises: 65 percent to 70 percent of living garbage, 15 percent to 20 percent of comburent, 3 percent to 6 percent of deodorant, 3 percent to 7 percent of ignition agent, 2 percent to 5 percent of sulfur fixing and hydrogen chloride fixing substances, 1 percent to 2 percent of preservative and 2 percent to 3 percent of adhesive. The preparation method comprises the following steps: the garbage is collected to all the additive components are prepared to the scratch, the vibration selection and the magnetic selection pre-treatment are carried out, thereby removing coarse visible inert materials and iron and steel metals and then carrying out the coarse breaking of the garbage by using a coarse breaker to the coarsely broken garbage is extruded to carry out the dehydration by using a high-speed rotary extruder, the deodorant and the sulfur fixing and chloride fixing substances are added for even mixing to the high-temperature drying by a tunnel kiln is carried out to the fine breaking is carried out after the drying, the ignition agent, the comburent, the preservative and the adhesive are added to the even mixing with the garbage particles after the fine breaking is carried out to the extrusion forming is carried out. The product and the preparation method can ensure the urban living garbage to achieve the purposes of resourceful treatment, harmless treatment and industrialization.

Owner:周泽宇

Cast-in-place box girder low-temperature steam maintenance operating method

InactiveCN1830644ASolve insulation problemsGuaranteed uniformityCeramic shaping apparatusEngineeringUltimate tensile strength

A low-temp steam curing method for in-situ cast box beam includes such steps as spraying insulating layer on external mould, laying down steam tubes, building steam curing shed, burying a temp strain gauge at each measuring point, parallelly connecting them via a switch to a reader, laying aside, heating, making temp constant, cooling and post curing. Its advantages are high speed, high strength and no crack.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

Oil-base mud treatment process

InactiveCN106810038AImprove thermal efficiencyThe treatment effect is thoroughCombination devicesSludge treatment by de-watering/drying/thickeningSimple Organic CompoundsDesorption

The invention relates to the field of sludge treatment, in particular to an oil-base mud treatment process which includes the steps: a, pretreatment: sorting, tempering and initial separation; b, pyrolysis and desorption; c, condensation and oil-water separation; d, utilization of combustible gas; e, flue-gas treatment. The treatment process adopts an internal and external heating pyrolysis and desorption method and is high in heat effectiveness and complete in treatment effect, a pyrolysis gas heat value is sufficiently utilized in the process, oil and conditioners in oil mud without mechanically separating are thoroughly removed, decomposed macromolecular organic compounds are reserved in an inorganic carbon manner, and final products have wide reuse pathways.

Owner:ZHE JIANG ECO ENVIRONMENTAL TECH CO LTD

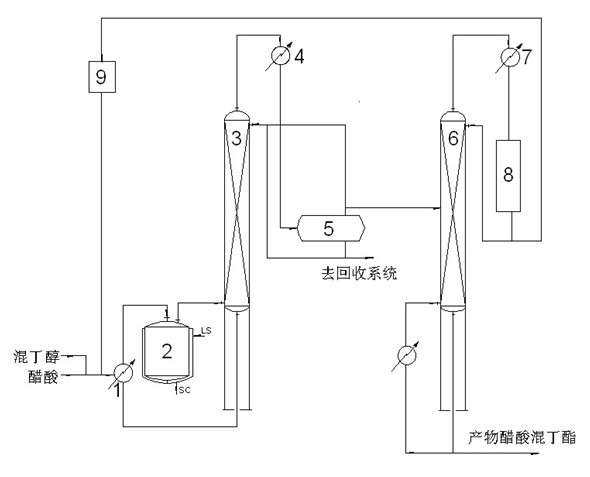

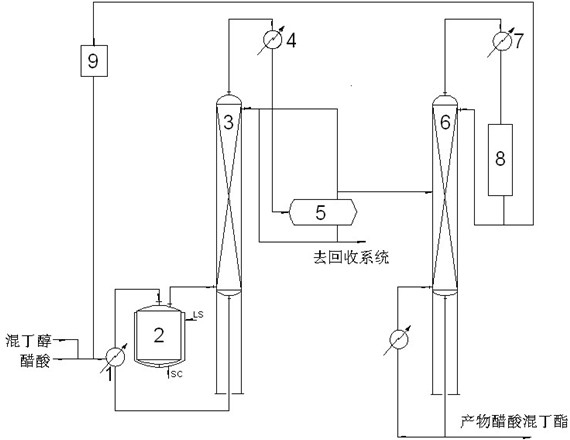

Method for preparing acetic acid mixed butyl ester by continuous reaction and rectification

InactiveCN102690197AEliminate dehydration processLow investment costOrganic compound preparationCarboxylic acid esters preparationAcetic acidPtru catalyst

The invention relates to a method for preparing acetic acid mixed butyl ester by continuous reaction and rectification. The method includes: acetic acid and mixed butanol are mixed and preheated according to molar ratio of 1:1, and temperatures of the mixed and preheated acetic acid and mixed butanol are increased after entering an esterification reactor and are reacted under catalysis of acid catalyst, a reaction product is performed initial gross separation in an esterification column in azeotrope form after being heated, a part of aqueous phase is performed reflux to the esterification column after a distillate at the top of the esterification column is performed condensation and phase separation, another part of the aqueous phase is discharged to a recovery column, a part of oil phase is performed reflux, and another part of the oil phase enters a rectification column as rough product to be further refined; and the rough product enters the rectification column from the middle of the same after being heated, a part of water and light components are removed by a membrane separator after a distillate at the top of the rectification column is condensed, a large part of the material reflows to the rectification column, a small part of the material is extracted to be reacted in the esterification reactor, and high-purity acetic acid mixed butyl ester is obtained at the bottom of the rectification column. Continuous production is achieved, and processes of neutralization, sedimentation and dehydration are omitted.

Owner:谦信化工集团有限公司

Method for controlling generation quantity of bromic acid radicle in treating procedure for oxidizing drinking water by ozone

InactiveCN101050036AGeneration of controlInhibitionMultistage water/sewage treatmentWater/sewage treatment using germicide/oligodynamic-processCatalytic oxidationWater quality

This invention relates to a method for controlling the quantity of bromate ions produced during treatment of ozone-oxidized drinking water. The method solves the problems of consuming residual chlorine, eroding pipes and meshes, and generating toxic substances by present techniques. The method controls the quantity of bromate ions by introducing cerium oxide, transition metal oxide-doped cerium oxide or supported cerium oxide catalyst for catalytic oxidation. The quantity of produced bromate ions is decreased by 80% when the bromic ions concentration is 100-200 mu.g / L and the consumption of cerium oxide is 100 mg / L. The method has a high efficiency in inhibiting the generation of bromate ions, and the yield of byproducts is 20-30% lower than that produced by pure ozone oxidation.

Owner:HARBIN INST OF TECH

Dual-station cutting machine tool

InactiveCN102794784AGeneration of controlIncrease productivityMetal working apparatusElectrical controlElectric machinery

The invention discloses a dual-station cutting machine tool, relates to equipment for the end surface of a water blocking seal strip, and solves the problem that the water blocking seal strip of automotive glass needs to be clamped twice to finish one rubber strip at present. The dual-station cutting machine tool comprises a base, a machine body and an electric control cabinet, wherein a left box body is fixed on the left side of the machine body; a right box body is arranged on the right side of the machine body and fixed to a first sliding plate; the first sliding plate is movably fixed to a first guide rail of the machine body parallel to the machine body through a sliding groove; common clamping devices are fixed to the left box body and the right box body; cylinders are arranged below the common clamping devices; power heads are fixed to the upper parts of the left box body and the right box body respectively; a cutting tool bit is fixed at one end of each power head through a shaft; a motor is mounted at the other end of each power head; the cutting tool bit is driven by the motor and can rotate up and down around the shaft; and the common clamping devices on the left side and the right side and the cutting tool bits are opposite to each other respectively. According to the dual-station cutting machine tool, the two ends of the rubber strip can be processed at the same time, multiple rubber strips can be clamped, the production efficiency is high, the conformity of production is guaranteed and the unqualified products are avoided.

Owner:山东水星博惠汽车部件股份有限公司

Method for preparing ampicillin sodium

InactiveCN101486717AEasy to recycleEasy to produceAntibacterial agentsOrganic chemistryManufacturing cost reductionOrganic solvent

The invention discloses a preparation method of ampicillin sodium, which comprises the steps: (a) a 15%-50% sodium iso-octoate solution is prepared; (b) ampicillin amine slat is prepared: firstly, ampicillin is dissolved in an organic solvent to prepare an organic ampicillin solution which is then dehydrated till the moisture thereof is lower than 1% and then reacts with diisopropylamine; (c) the amine salt obtained from step (b) is pressed into a crystallizing tank and added with the sodium iso-octoate solution for two times, and after crystallization the growing of crystal is carried out; and (d) after the crystallization reaction is finished, separation, washing and menstruum recovering processes are carried out. The preparation method has simple processes and easy operation, is capable of further improving the quality of the finished ampicillin sodium products and being beneficial to the recovery of the menstruum in the technical system, and can effectively reduce the production costs simultaneously.

Owner:NORTH CHINA PHARMA COMPANY

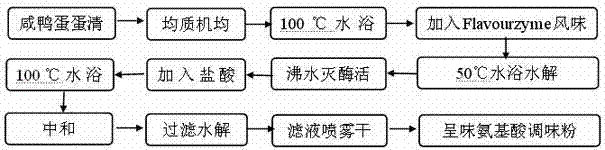

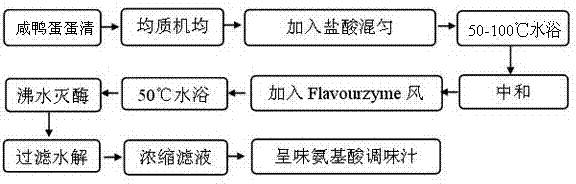

Method for preparing odor-free delicious amino acid through combination of acid hydrolysis and enzymatic hydrolysis of salted egg white

A method for preparing an odor-free delicious amino acid through combination of acid hydrolysis and enzymatic hydrolysis of salted egg white belongs to the field of deep processing of bird egg by-products. According to the invention, the salted egg white is taken as a raw material and is then subjected to homogenization, combined action of acid hydrolysis and enzymatic hydrolysis, neutralization and filtering to obtain the odor-free delicious amino acid. The method combining acid hydrolysis and enzymatic hydrolysis replaces a method of direct acid hydrolysis and enzymatic hydrolysis on protein of animals and plants in the traditional process, not only are harmful byproducts and extraneous odor well controlled in the acid hydrolysis process due to the subsequent enzymatic hydrolysis, but also the hydrolysis time is effectively shortened, the pollution to the neighboring environment is reduced, and the state environmental protection requirement is met; the salted egg white whose fat content is about 0.25% is used as the raw material, so that the production of trichloropropanol is inhibited in the process of acid hydrolysis, and then an odor-free amino acid hydrolysate product containing no trichloropropanol is obtained, wherein the degree of hydrolysis of the product is 52%-54%, delicate amino acids (glutamic acid and aspartic acid) and sweet amino acids (alanine, glycine, proline, serine and threonine) account for about 60% of the total amino acids.

Owner:JIANGNAN UNIV +1

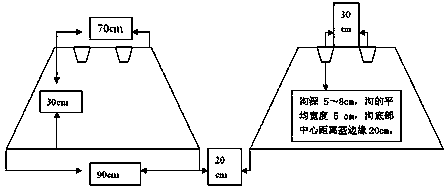

Sowing method for traditional Chinese medicines in saline and alkaline land

InactiveCN104160810ASolve the problem of fear of waterloggingEnsure normal drainageClimate change adaptationSowingSoil scienceAlkali soil

The invention relates to the technical field of traditional Chinese medicine planting methods, and in particular relates to a sowing method for traditional Chinese medicines in a saline and alkaline land. The sowing method comprises the steps of (1) applying a base fertilizer, performing deep ploughing and raking, carrying out ridge planting, controlling the ridging space to be 110cm, the bottom width of the ridging surface to be 90cm, the top width to be 70cm and the ridging height to be 25-30cm; (2) digging two rows of sowing ditches in a ridge, wherein the ditch depth is 5-8cm, the average width of the ditches is 5cm, the distance between the center of the bottom of each ditch and the edge of the ridge is 20cm, and the distance between the centers of the bottoms of two ditches is 30cm; (4) performing broadcast sowing or hole sowing in the two ditches on the ridge, and covering the ridge by soil by 1-2cm; and (5) covering the ridge by a black mulching film. By virtue of the technologies such as ridging, ditching in the ridge, coverage by the black film and deep ditch shallow seeding, the difficulties of planting of the traditional Chinese medicines, in particular small traditional Chinese medicine seeds, in the saline and alkaline land are solved; an advanced technical support is supplied to planting of the traditional Chinese medicines in the saline and alkaline land.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

Method for preparing low/zero trans-fatty acid plastic grease from camphor tree seed oil

InactiveCN102326630ANot easy to accumulateReduce manufacturing costEdible oils/fats production/working-upCinnamomum camphoraHYDROGENATED SOYBEAN OIL

The invention relates to a method for preparing low / zero trans-fatty acid plastic grease from camphor tree seed oil. The method comprises the following steps of: putting refined camphor tree seed oil and palm oil stearin or fully-hydrogenated soybean oil serving as raw materials into a temperature-controlled reaction kettle, and uniformly mixing the palm oil stearin or the fully-hydrogenated soybean oil with the camphor tree seed oil in the mass ratio (3-6):(4-1) for 1-3 hours; after mixing, adding 5-15 percent of preferred Lipozyme RM IM lipase or TL IM lipase, and reacting at the temperature 55-75 DEG C for 6-12 hours, wherein the optimal temperature is 55-75 DEG C; after reacting, standing for 1-5 hours and filtering the lipase; and deacidifying with 0.05-0.5 N of sodium hydroxide solution and drying in vacuum for 12-24 hours to obtain a finished product. According to the method, low / zero trans-fatty acid plastic grease (including base oil such as margarine, shortening and the like) of different melting points and solid fat contents can be prepared.

Owner:NANCHANG UNIV

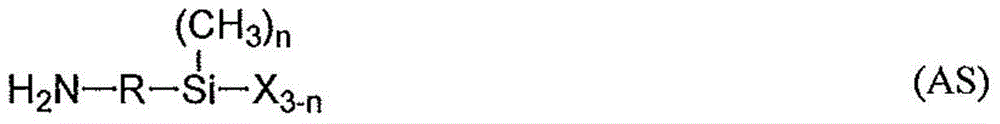

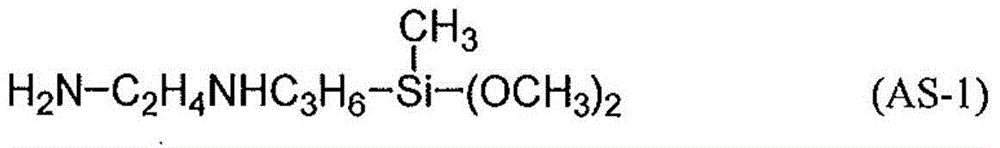

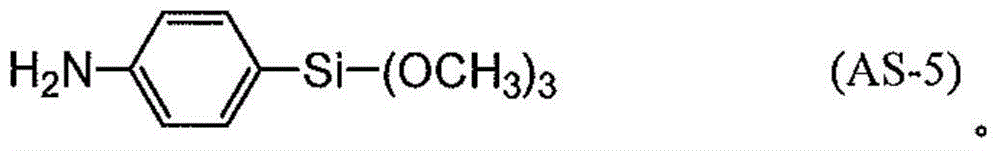

Liquid crystal aligning agent, liquid crystal aligning film and liquid crystal display element

InactiveCN104974768AMaintain liquid crystal orientationMaintain orientation stabilityLiquid crystal compositionsNon-linear opticsSilane compoundsForeign matter

The invention relates to a liquid crystal aligning agent, a liquid crystal aligning film and a liquid crystal display element. The subject of the invention is end capped polyamide acid or liquid crystal aligning agent for optical aligning film of the derivative of the end capped polyamide acid which is obtained by reaction of Tetracarboxylic acid dianhydride, diamine compounds and amino silane compounds. The liquid crystal display element for a liquid crystal aligning film formed through the liquid crystal aligning agent for the optical aligning film can control generation of the foreign matter in the liquid crystal layer in the element to maintain orientation, aligning stableness, contrast, AC after image and other characteristics.

Owner:JNC CORP +1

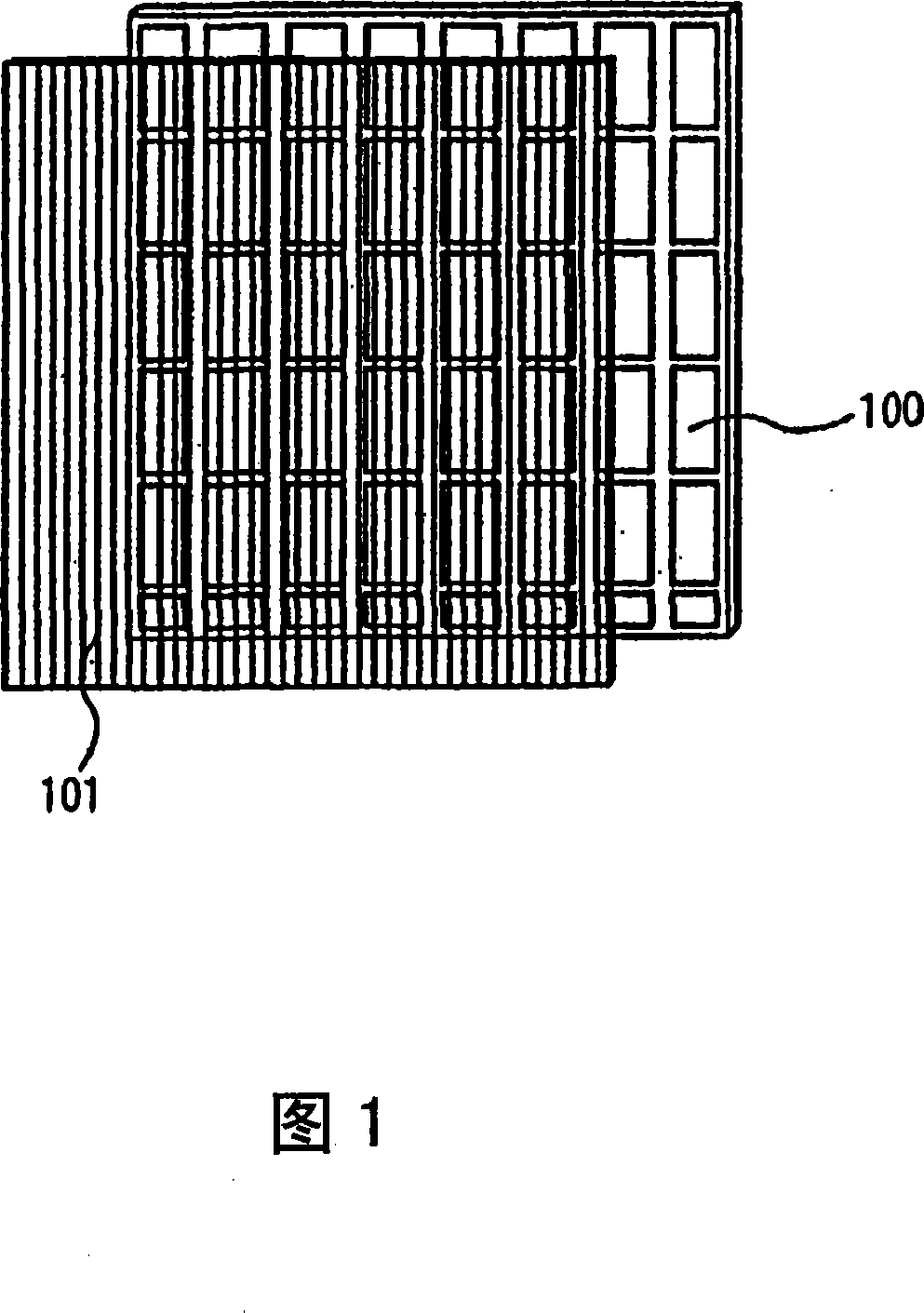

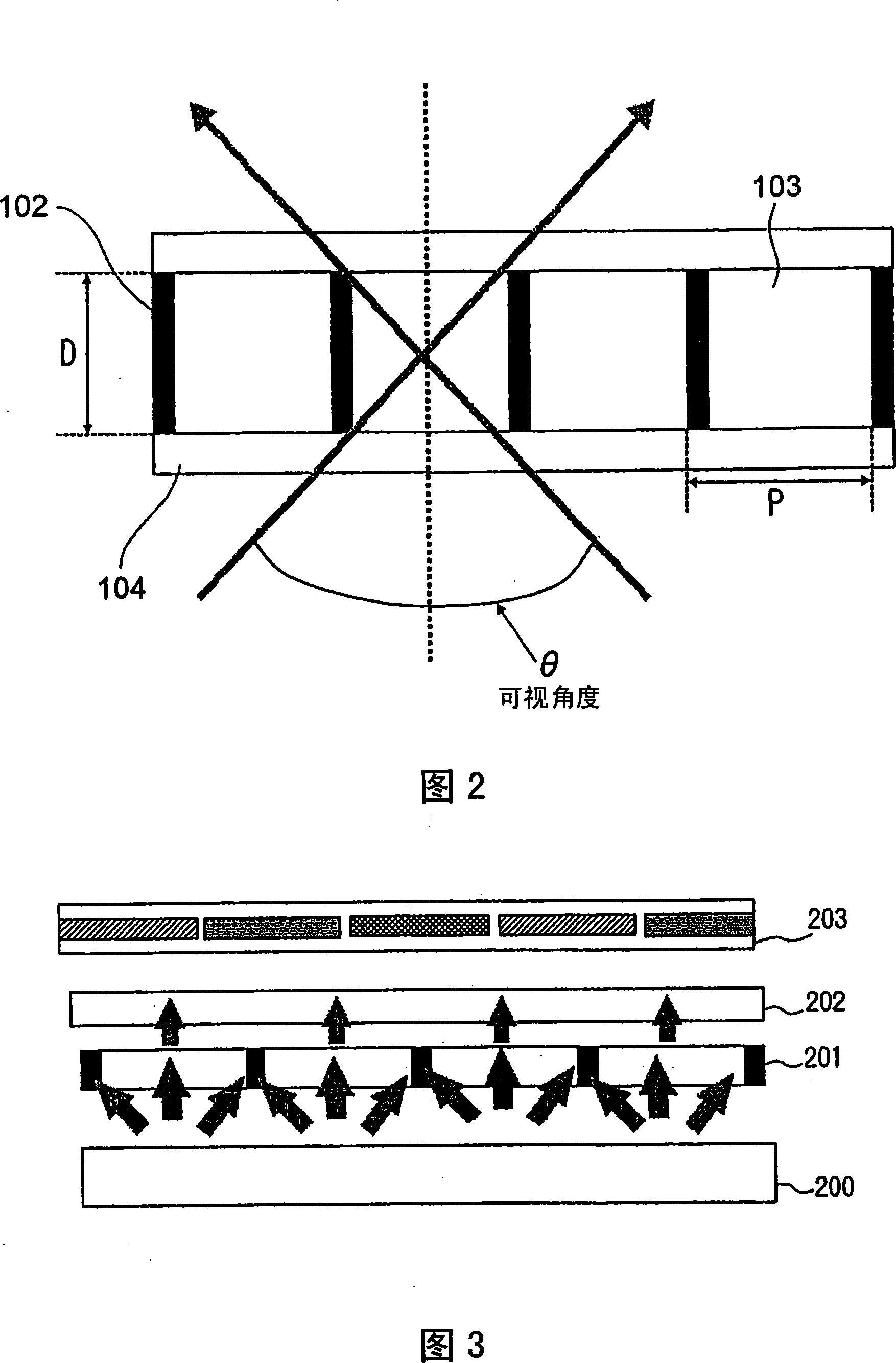

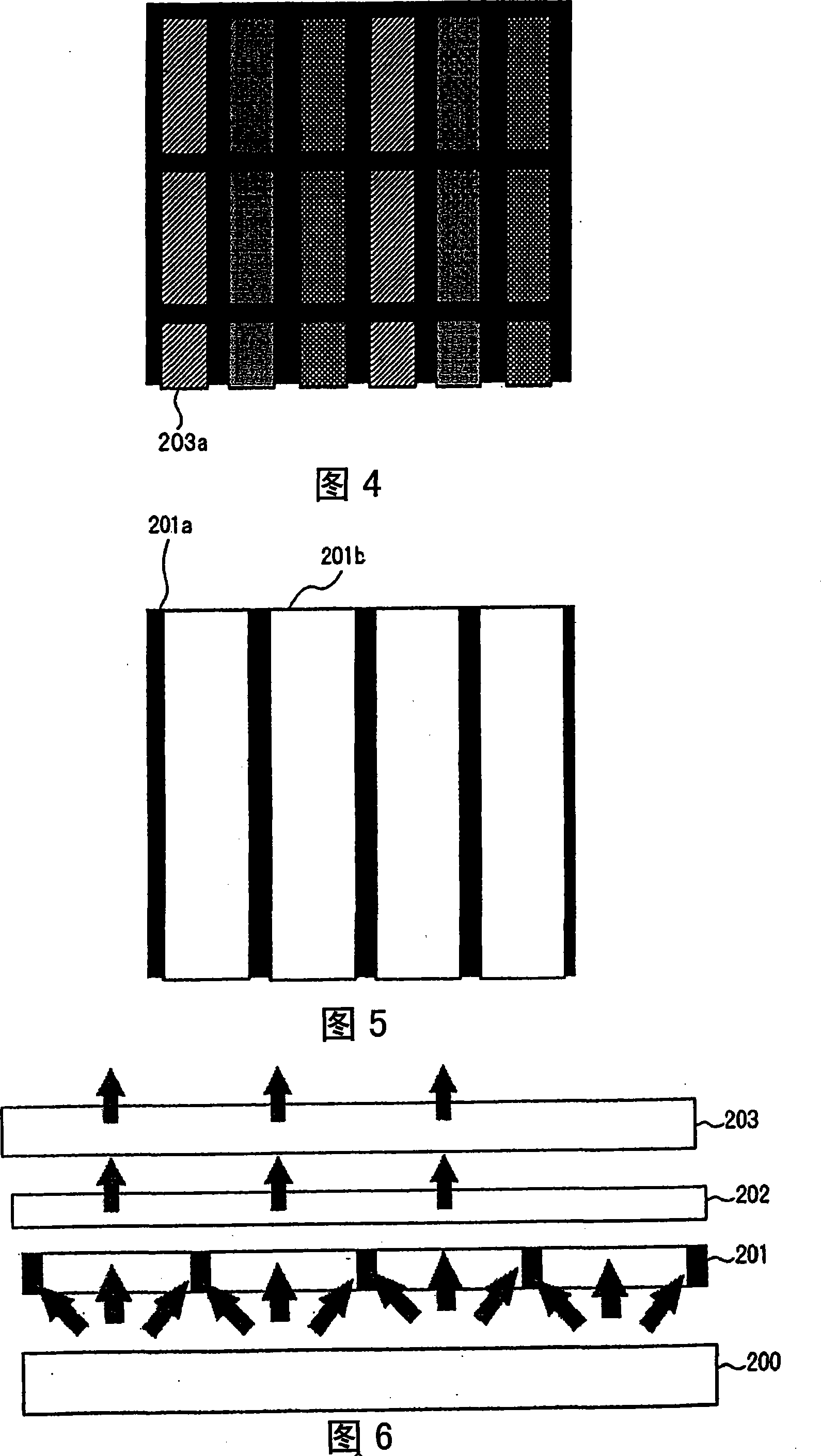

Optical element, and illuminating optical device, display device and electronic device using the same

A microlouver includes a periodic structure in which a transparent layer and a light absorption layer are alternately disposed with a constant, repetitive period. The range of the exit direction of a light beam passing through the transparent layer is restricted by the light absorption layer. The periodic structure includes a periodic structure portion divided in the direction that intersects the direction in which the transparent layer and the light absorption layer are repeatedly disposed. In the periodic structure portion, between the periodic structures adjacent to each other, there is a difference of 180 degree in the phase of spatial frequency of each periodic structure.

Owner:NEC LCD TECH CORP

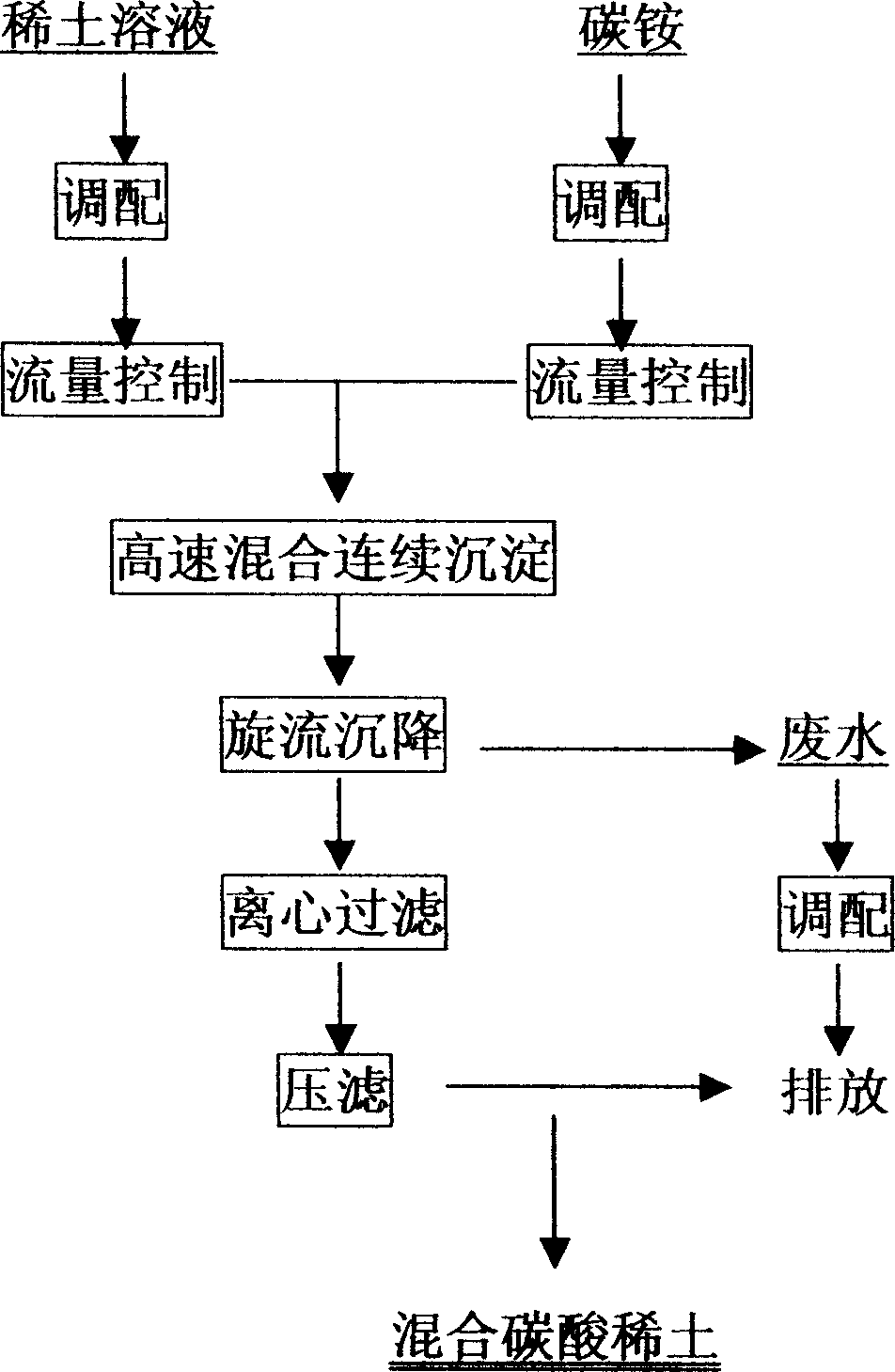

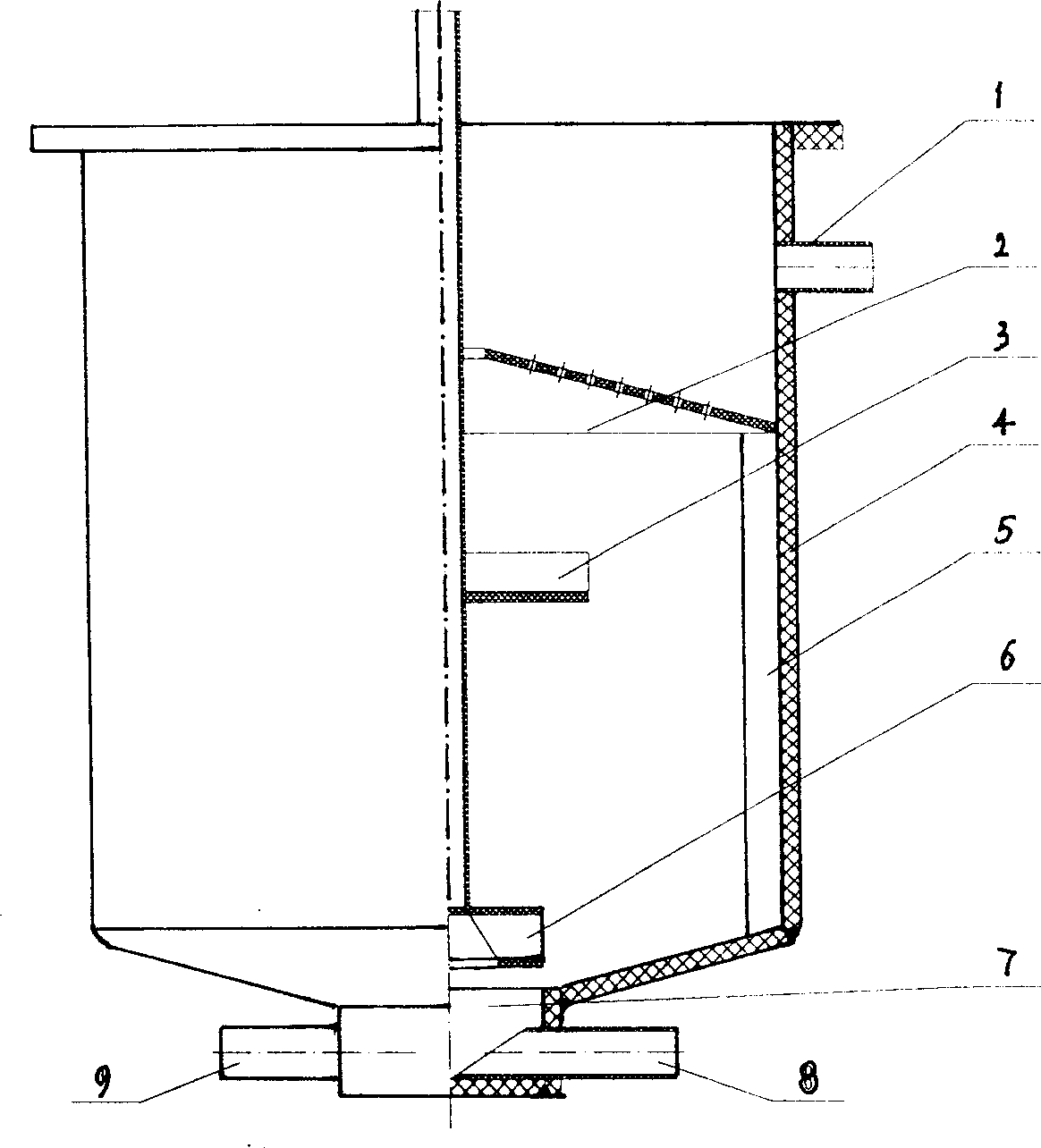

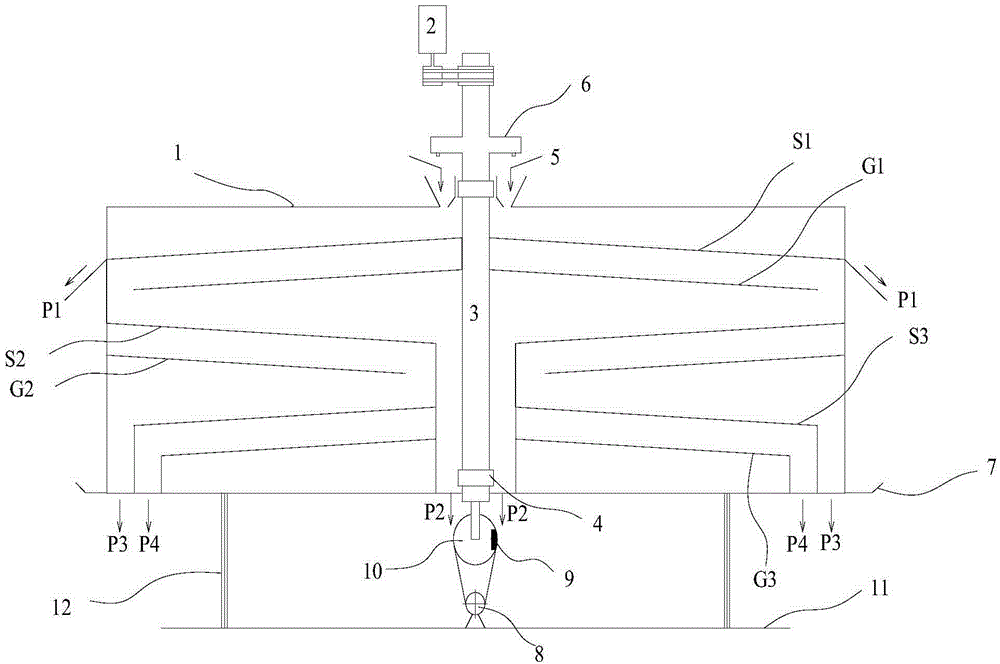

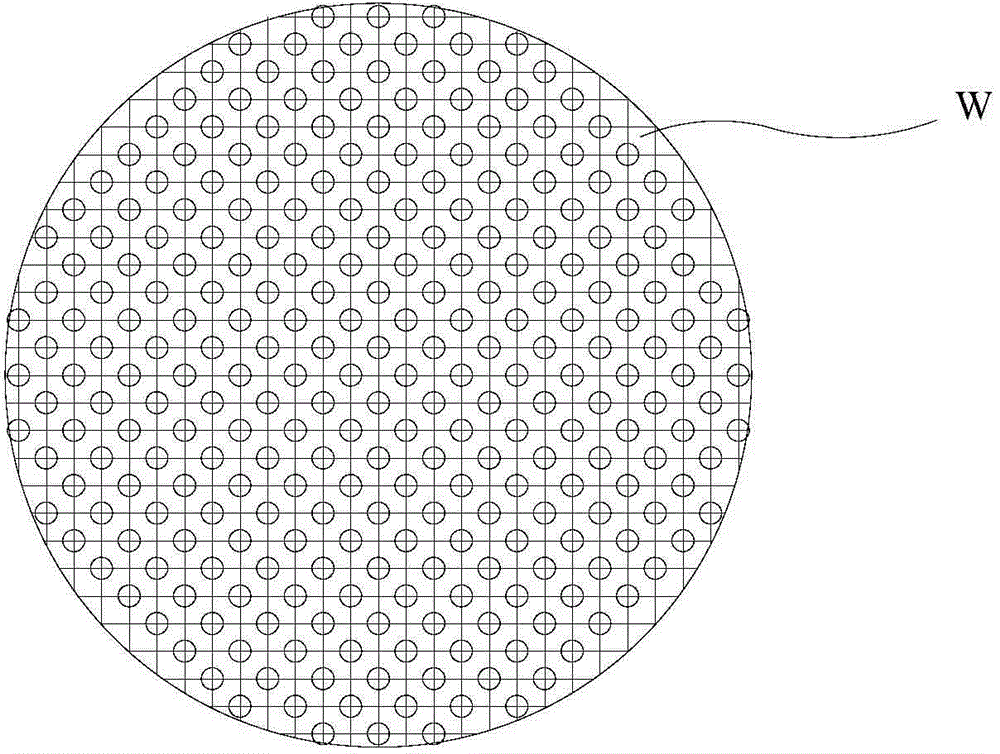

RE salt preparing process and apparatus

The present invention belongs to the field of non-ferrous metallurgy technology, and is especially RE salt preparing process and apparatus. The RE salt preparing process includes the following steps: compounding RE salt solution of 0.04-1.2 mol / l concentration and precipitant solution of 0.1-3.5 mol / l concentration; mixing the RE salt solution and precipitant solution in the mass flow rate between REO and precipitant of 1 to 1.1-1.7 at 15-60 deg.c temperature and 150-890 rpm rotation speed for 3-30 min; precipitating in a clarificator; injecting with one mud pump into a plate-frame press to obtain RE salt precipitate. The apparatus includes one barrel with material feeding port and precipitant feeding port in the bottom, eddy flow stirring rake, mixing sub chamber in the center and porous mist discharging plate in the upper part. The present invention realizes continuous production by means of the fast precipitation and solid-liquid separation.

Owner:CHINA NORTHERN RARE EARTH (GROUP) HIGH TECH CO LTD

Composite emulsifying agent for peanut milk and method for preparing peanut milk by adopting emulsifying agent

InactiveCN101695347AExtended shelf lifeFully emulsified and dispersedFood preparationMilk substitutesFood additiveMonoglyceride

The invention belongs to the technical field of peanut food additive and peanut beverage processing, and provides a composite emulsifying agent for peanut milk, which is formed by mixing isolated soybean protein, fatty acid monoglyceride, sucrose fatty acid ester, sorbitan fatty acid ester and sodium alga acid in a mass ratio of 1: 1: 1: 1: 1, wherein the mass percentage concentration of the composite emulsifying agent in the peanut milk is 0.05 to 0.15 percent. The invention also provides a method for preparing the peanut milk by adopting the emulsifying agent. The method comprises the following steps: low-temperature cold pressing, soaking, filtering and mixing, grinding, centrifugal separation, emulsifying agent addition, homogenizing, super-high temperature instant sterilization, canning and sealing, and high-temperature sterilization. The fat in the peanut milk prepared by adopting the composite emulsifying agent can be fully emulsified and dispersed, so the generation of a fat ring can be effectively controlled; and meanwhile the shelf life of the peanut milk can be prolonged, and adverse phenomena such as settling, elutriation, demixing and the like of the peanut milk during storage and transportation are prevented.

Owner:QINGDAO HUINENGDUO AGRI DEV

Manufacturing technology for copper-clad aluminum composite busbar

ActiveCN104733133AGeneration of controlReduce the number of brittle phasesCable/conductor manufactureMolten stateCopper plating

The invention discloses a manufacturing technology for a copper-clad aluminum composite busbar, and belongs to the technical field of metal processing. The manufacturing technology solves the problem that by means of an existing manufacturing technology for a copper-clad aluminum composite busbar, the copper and aluminum bonding strength is low, the uniformity of a copper plating layer is poor, and a copper layer is too thick. According to the manufacturing technology for the copper-clad aluminum composite busbar, a continuous passing type induction heating furnace is used for conducting high-temperature induction heating on a copper-clad aluminum pipe blank, the heating temperature ranges from 600 DEG C to 900 DEG C, and the heating time ranges from 30s to 300s. A molten aluminum film in a semi-molten state or semi-solid state is formed on the outer surface of an aluminum bar, the inside of the aluminum bar and a copper pipe keep solid, hot forging and pressing with the single-stroke reduction ratio being equal to or smaller than 40% is conducted on the heated copper-clad aluminum pipe blank, the molten aluminum film is diffused and permeated into the copper pipe, and a copper and aluminum atom composite layer is formed. Accordingly, the bonding strength of copper and aluminum is improved.

Owner:ZHEJIANG HAILIANG

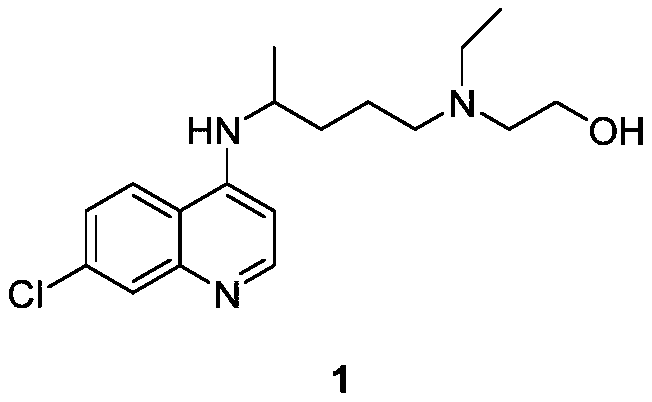

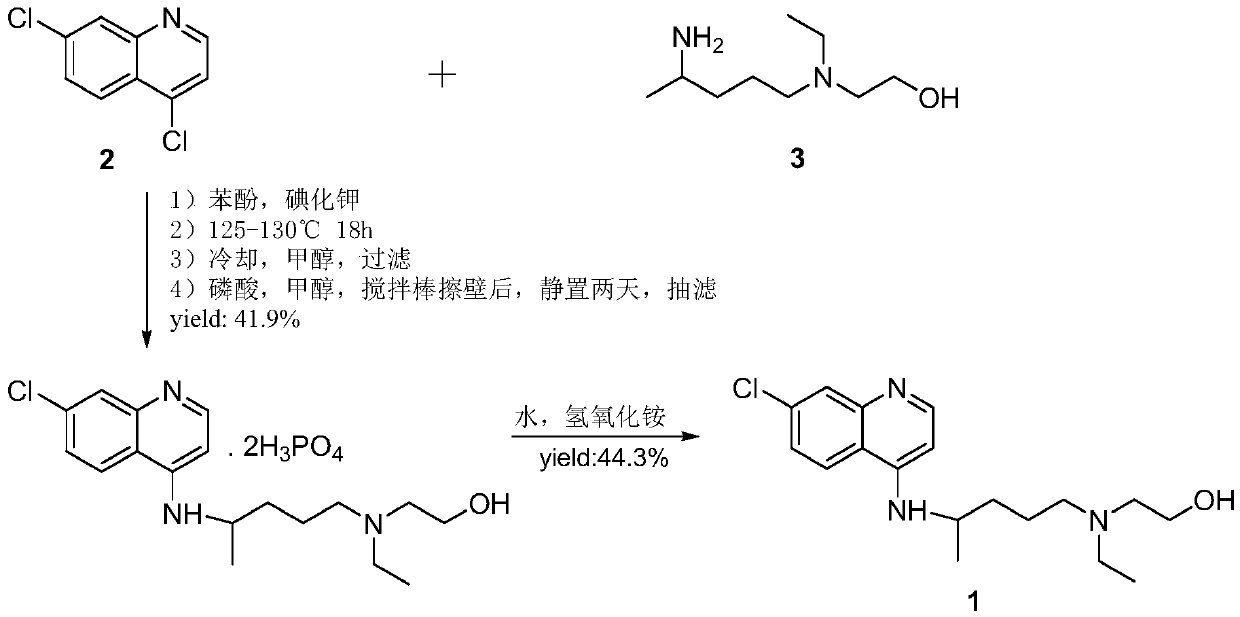

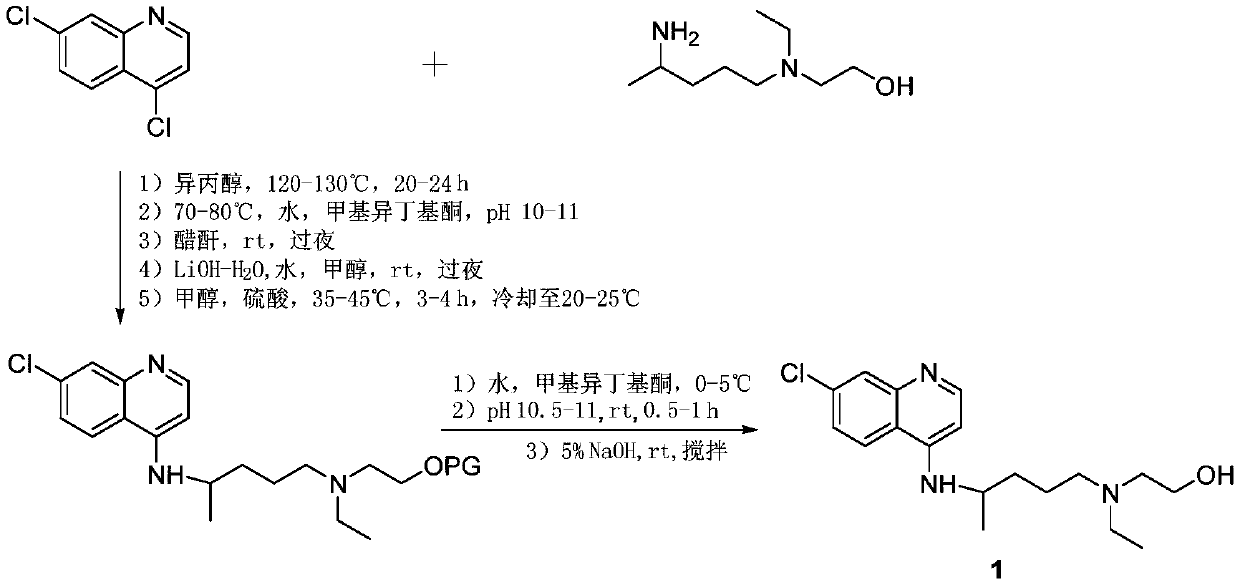

Hydroxychloroquine synthetic method

InactiveCN110283121AEasy to recycleReduce manufacturing costOrganic chemistryHydroxychloroquineAfter treatment

The invention provides a hydroxychloroquine synthetic method, including the steps of mixing 4,7-dichloroquinoline, 2-[(4-aminopentyl)(ethyl)amino]ethanol and N,N-diisopropylethylamine, reacting under protective gas, and after the reaction, performing extraction, concentration and purification to obtain the hydroxychloroquine. By using the synthetic method provided by the invention, N,N-diisopropylethylamine is used as both an acid-binding and a solvent to promote smooth reaction, the amount is small (only theoretical amount), and the consumption is low; the reaction time is short, alkalization is not needed after treatment, the hydroxychloroquine can be obtained by just the operations of extraction and recrystallization, and the operation is simple; the extraction solvent and the recrystallization solvent may be the same solvent, which is beneficial to the recovery and utilization of the solvent, and the production cost is reduced; the total recovery is increased from 45.9% to 74.7%, the product quality is increased from 99.0% to 99.8% or above (HPLC purity), and single impurity being less than or equal to 0.1%.

Owner:EAST CHINA UNIV OF SCI & TECH +1

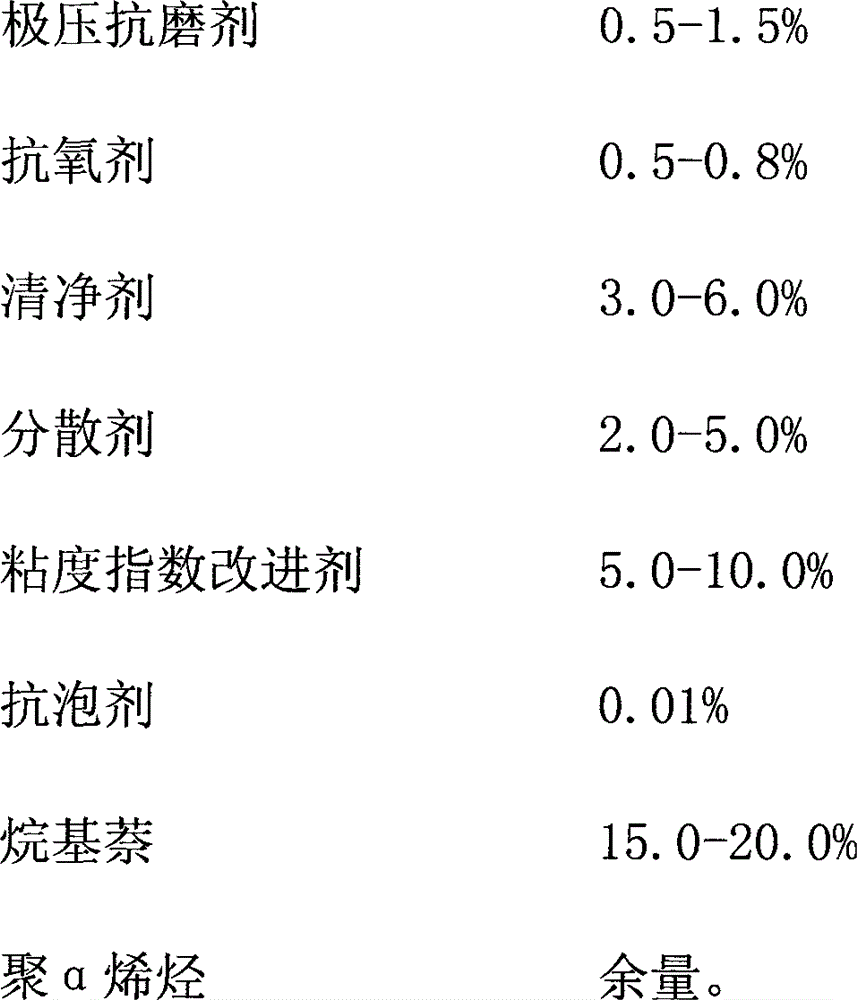

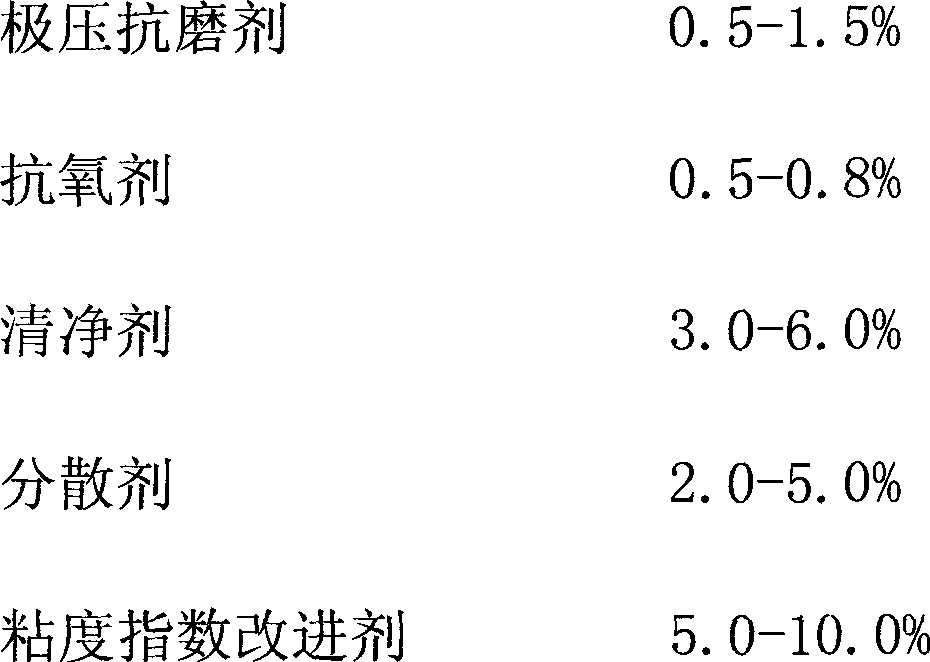

Ultra-low temperature total synthesis engine oil

InactiveCN103146463AGood cold startGood high temperature oxidation resistanceLubricant compositionAntioxidantOil sludge

The invention discloses ultra-low temperature total synthesis engine oil which comprises an anti-wear reagent at extreme pressure, an antioxidant, a clearing agent, a dispersing agent, a viscosity index improver, an anti-foaming agent, alkyl naphthalene and poly alpha olefin. By mass, the anti-wear reagent at the extreme pressure is of 0.5-1.5%, the antioxidant is of 0.5-0.8%, the clearing agent is of 3.0-6.0%, the dispersing agent is of 2.0-5.0%, the viscosity index improver is of 5.0-10.0%, the anti-foaming agent is of 0.01%, the alkyl naphthalene is of 15.0-20.0% and the balance is the poly alpha olefin. The ultra-low temperature total synthesis engine oil can be applied to a number of extremely cold regions, the low-temperature starting performance and the high-temperature oxidation resistance performance are excellent, generation of oil sludge can be well controlled, and an engine is protected.

Owner:杨敏

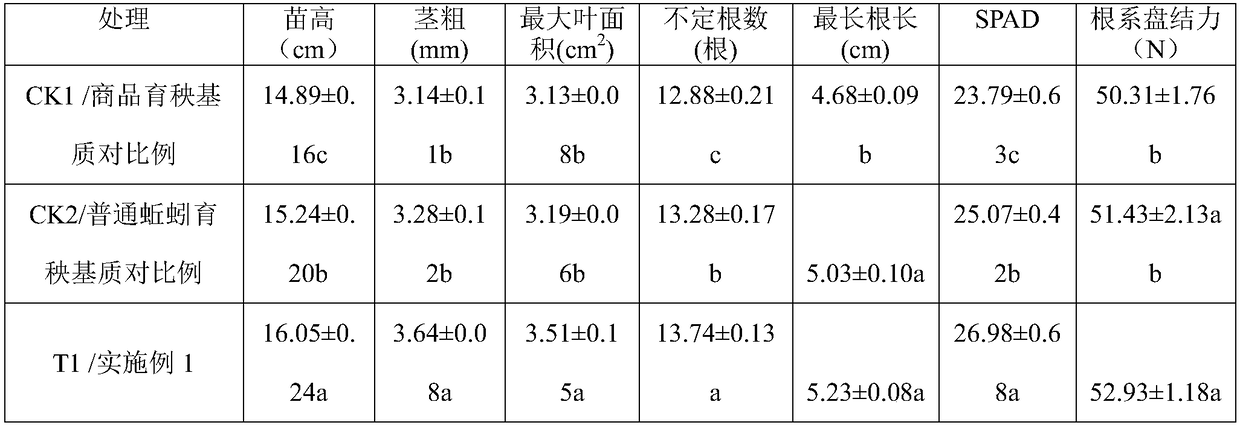

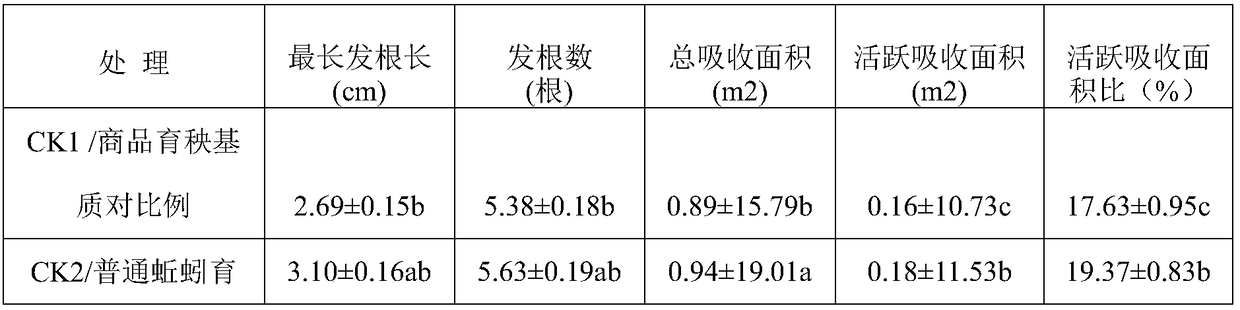

Method for producing biological organic fertilizer by using earthworms to treat livestock manure waste

ActiveCN109160859ARealize resource utilizationPromote growthBio-organic fraction processingMagnesium fertilisersFecesLivestock manure

The invention belongs to the field of plant nutrition and fertilizer, and discloses a method for producing biological organic fertilizer by using earthworms to treat livestock manure waste. The main raw material used in the method is pretreated livestock manure, and the livestock manure waste is used as bio-organic fertilizer of earthworms and manure, which realizes resource utilization of the waste and develops the recycling agriculture and the recycling economy. A rice seedling breeding matrix prepared by using the bio-organic fertilizer of the invention can improve the quality of seedlings,prevent the occurrence of rice blight, is more suitable for rice transplanting, and promotes the growth of the seedlings in the field. The use of the bio-organic fertilizer of the invention in tea leaves improves the fertility of the soil and promotes the growth and development of a tea tree. The density of tea buds per area is 1.29 times higher than that of chemical fertilizer treatment, and theyield per area is increased by 56.25 percent; and the content of polyphenols and amino acids is high, the phenol to ammonia ratio is low, and the tenderness is good.

Owner:长沙飞宇生物肥业有限公司

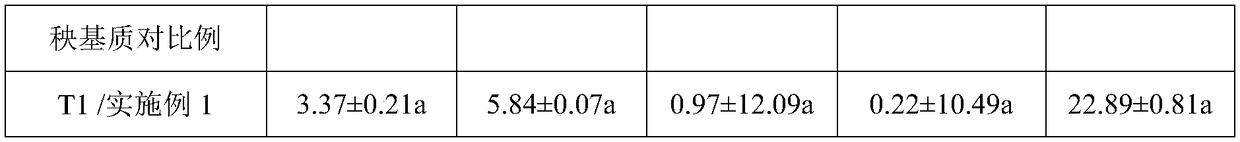

Sulfur-dioxide-free full juice fermented orange wine and production process thereof

ActiveCN104130905AGuaranteed normal fermentationInhibit bacteriaAlcoholic beverage preparationMicroorganism based processesFruit juiceAdditive ingredient

The invention provides a sulfur-dioxide-free full juice fermented orange wine and a production process thereof, belonging to fermented fruit wines and production technologies thereof. The production process comprises the steps of making the juice turbid and making the pulp resist oxidation, adjusting the acidity of the juice and neutralizing bitter precursor substances, making the juice resist bacteria and adjusting the sugar content, preparing mother liquor of the wine, blending and fermenting the juice, ageing the wine base, fining and blending the aged wine base and adjusting the taste of the aged wine base, wherein the juice comprises essential oil, calcium oil and bitter substances. The orange wine has the beneficial effects that an innovative process of replacing SO2 with a composite of non-toxic materials such as antibacterial and oxidation-resistant D-erythorbic acid, nisin, sorbic acid, chitosan and the like is adopted; compared with traditional processes, in the production process, the operation of adding toxic gaseous and liquid SO2 step by step is safer and more convenient; the production process is an innovation of popularizing the traditional processes of wines for more than a hundred years to make wine with other fruit raw materials; the navel orange wine produced by the technology does not contain SO2 and has the advantages that the content of methanol is reduced by about 90%, the content of fusel oil is reduced by about 65% and the harmful ingredients such as bioamine, sulfate, methanol, fusel oil and the like are controlled compared with the fruit wines produced by the traditional processes.

Owner:达州市好汉子酒业有限公司

Rotary vibrating screening machine

ActiveCN104353608AIncrease productivityImprove efficiencySievingScreeningBarrel ShapeMultiple stages

The invention discloses a rotary vibrating screening machine, which comprises a barrel-shaped screening box, a rotating mechanism, a vibrating mechanism and a multistage screening mechanism, wherein the rotating mechanism comprises a rotating shaft and a driving mechanism for driving the rotating shaft to rotate; the rotating shaft is arranged on an elastic bracket in a rotating way; the screening box is fixedly arranged on the rotating shaft in a sleeving way; the elastic bracket is driven by the vibrating mechanism to rotate; the multistage screening mechanism comprises a plurality of stages of screening groups which are obliquely arranged from top to bottom; the screening groups are fixedly arranged between the screening box and the rotating shaft; the diameters of screen pores in the screening groups are gradually reduced from top to bottom; discharge ports corresponding to oversize materials and undersize materials are formed in the downwards-inclined tail end of the screening group of each stage; a feed port for uniformly spreading the materials on the upper end face of the screening group at the highest position is formed in the upper end of the screening box. The rotary vibrating screening machine is simple in structure; the materials can be screened in multiple stages according to production needs, so that the production efficiency and the uniformity of screened particles are effectively improved, and the production cost is lowered.

Owner:ANHUI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com