Method for preparing odor-free delicious amino acid through combination of acid hydrolysis and enzymatic hydrolysis of salted egg white

A combined preparation and amino acid technology, applied in food preparation, application, food science, etc., to achieve the effect of reducing hydrolysis time, low fat content, and avoiding harmful by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

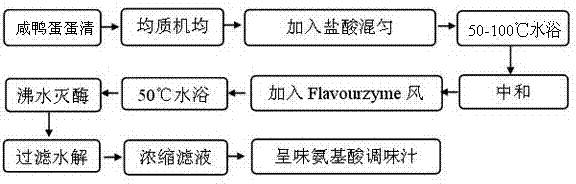

[0042] Example 1 Salted protein was first hydrolyzed with strong acid and then enzymatically hydrolyzed to prepare a flavorless amino acid sauce without peculiar smell

[0043] Put the salted egg white into the container, according to the ratio of salted egg white: hydrochloric acid = 1:2.5 (v / v), slowly add the hydrochloric acid solution with a concentration of 6mol / L into the salted egg white, stir while adding the hydrochloric acid solution, and wait until it is completely added After the hydrochloric acid solution was fully stirred and mixed, the reaction vessel was sealed and placed in a water bath. Adjust the temperature of the water bath to 100°C, and bathe in water at this temperature for 4 hours. During the hydrolysis process, stir the salted egg white hydrochloride mixture in the container every half an hour to ensure that the reaction can be fully carried out. After the hydrolysis reaction is finished, the container is removed from the water bath, and the reactant ...

Embodiment 2

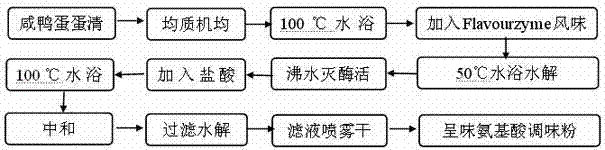

[0046] Example 2 Combined preparation of salty protein with enzymatic hydrolysis and then mild acid hydrolysis to produce odorless amino acid seasoning powder

[0047] Put the salted egg white into a container for pretreatment, adjust its pH with an appropriate amount of weak acid to the optimum pH of Flavourzyme protease = 7.0, then place the container in an electric heating constant temperature water bath, adjust the temperature to 100°C, and heat for 15 minutes. Stir with a glass rod to prevent gel formation. Take it out and cool it down to 50°C, then pour it into a stirring enzymatic reactor and keep the temperature of the egg white at a constant temperature of 50°C, and start the electric stirrer (6-12 rpm) to stir. Weigh 0.05% enzyme by weight of added salted egg white and dissolve it in 5mL distilled water, add it to the reactor, and start timing when 2 / 3 of the enzyme amount is added; as the reaction progresses, the pH value will drop and the water will evaporate, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com