Method for preparing acetic acid mixed butyl ester by continuous reaction and rectification

A technology for the production of mixed butyl acetate, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of large amount of waste water and low yield, achieve clean production, and increase product yield. Efficiency and reduction of equipment maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

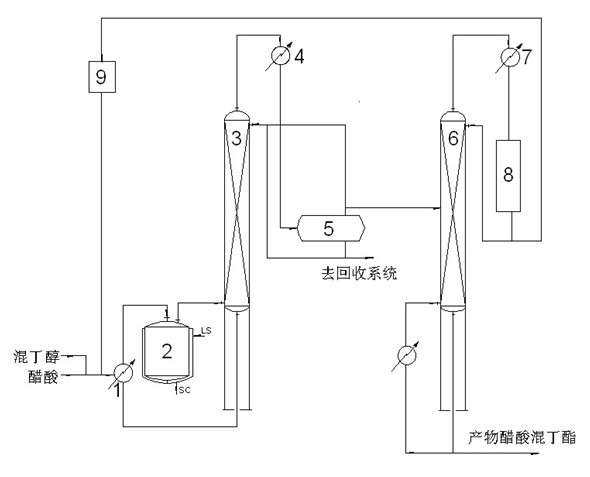

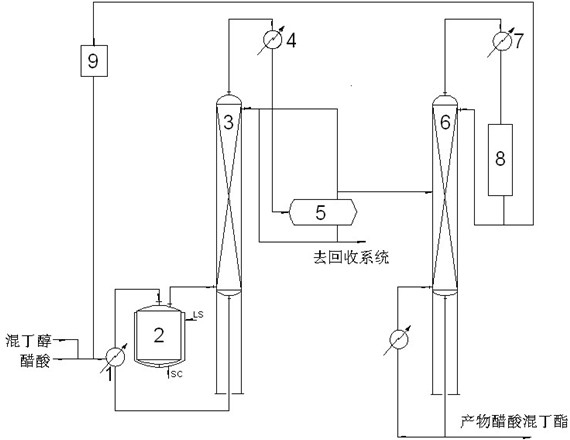

[0025] The raw material mixed butanol and acetic acid enter the reboiler 1 with a molar ratio of 1:1, and the feed rate is 1500L / h. After mixing and preheating, it enters the esterification reaction kettle 2, and is further heated up under the catalysis of p-toluenesulfonic acid catalyst. The kettle temperature is controlled at 110-115°C, and the reaction product enters the esterification tower 3 in the form of an azeotrope. The tower tank of the esterification tower is 113°C, the middle of the tower is 93°C, and the top of the tower is 90°C. After being condensed and cooled by the condenser 4, the overhead distillate enters the phase separator 5, and the lower water phase is refluxed to the esterification tower at a reflux ratio of 1.1. The rest is sent to the recovery system; the upper oil phase material is refluxed to the top of the esterification tower at a reflux ratio of 2.5, and the rest is sent to the rectification tower 6 as crude mixed butyl acetate for further refine...

Embodiment 2

[0027] The raw material mixed butanol and acetic acid enter the reboiler 1 at a molar ratio of 1:1, and the feed rate is 1000L / h. After mixing and preheating, they enter the esterification reactor 2 and are catalyzed by the mixed catalyst of p-toluenesulfonic acid and methanesulfonic acid. Further temperature-raising reaction is carried out, and the temperature of the kettle is controlled at 105-115°C. After the reaction, the product enters the esterification tower 3 in the form of an azeotrope. The tower tank of the esterification tower is 114°C, the middle of the tower is 95°C, and the top of the tower is 91°C. After being condensed and cooled by the condenser 4, the overhead distillate enters the phase separator 5, and the lower water phase is refluxed to the esterification tower at a reflux ratio of 1.2. The rest is sent to the recovery system; the upper oil phase material is refluxed to the top of the esterification tower at a reflux ratio of 2.0, and the rest is sent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com