A device and method for pelletizing steelmaking sludge

A steelmaking sludge and pelletizing technology, which is applied in the field of pelletizing equipment for steelmaking sludge, equipment for pelletizing directly using steelmaking water-containing sludge, and equipment for pelletizing metallurgical dust sludge, can solve steelmaking sludge Mud cannot be directly used for pelletizing and other problems, so as to save the dehydration process, achieve uniform size, and reduce the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

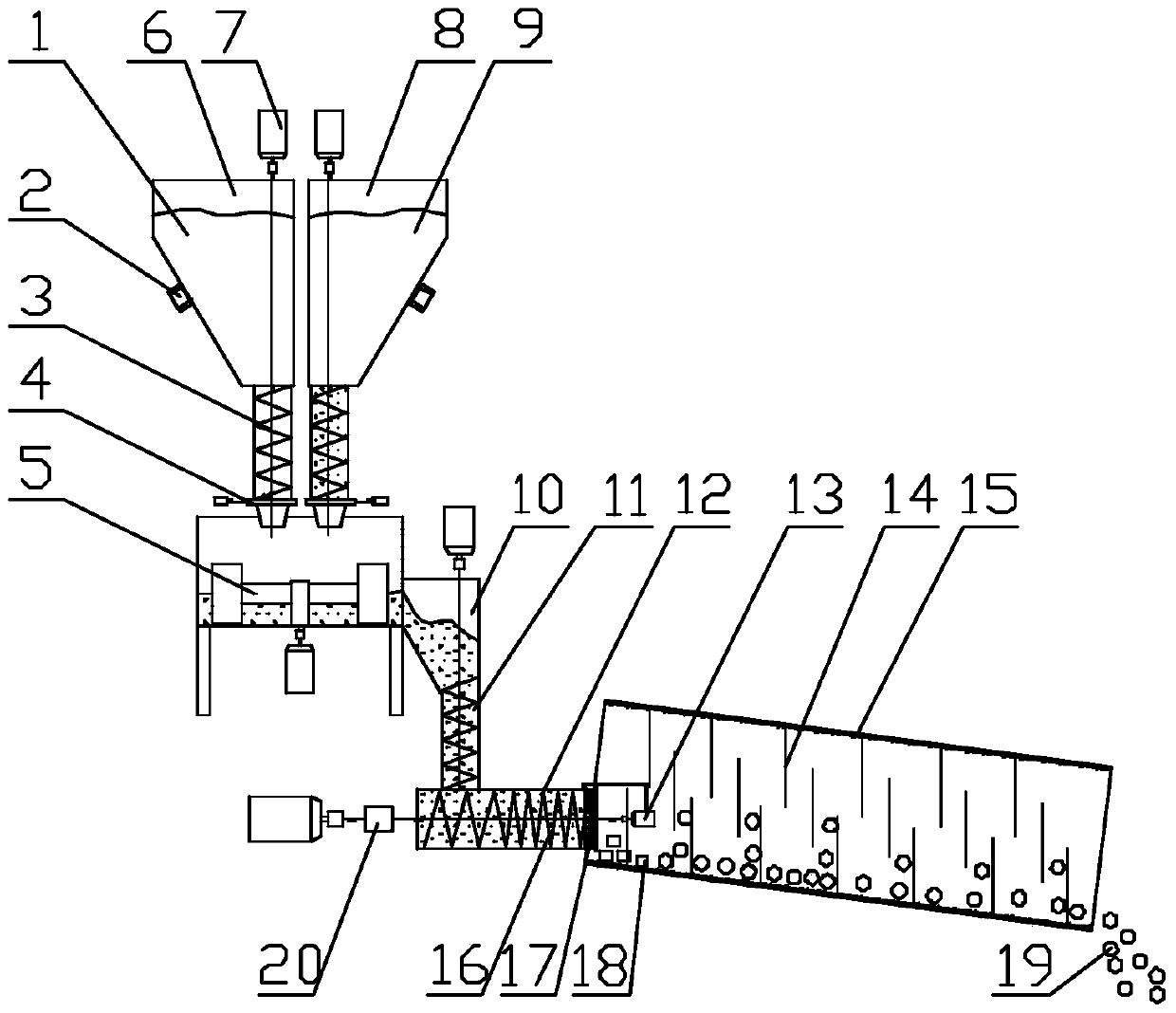

[0018] refer to figure 1, a device for pelletizing steelmaking sludge, comprising a vibrator 2, a screw feeder 3, a gate valve 4, a powerful mixer 5, a dry silo 6, a motor 7, a wet silo 8, a hopper 10, Mixed material screw feeder 11, screw pressure granulator 12, cutting machine 13, screw blade 14, barrel 15, pressure enhancing blade 16, cylinder forming orifice 17 and reducer 20; the side of the dry material bin 6 A vibrator 2 is fixedly installed, and the discharge port of the dry material bin 6 is connected with the feed port of the conveying pipe of the screw feeder 3, and one end of the conveying shaft of the screw feeder 3 is connected to the motor 7, and the discharge of the screw feeder 3 The port is connected with the feed port of the strong mixer 5 through the gate valve 4; a vibrator is fixedly installed on the side of the wet feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com