RE salt preparing process and apparatus

A technology of rare earth salts and rare earths, applied in the fields of rare earth metal compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of storage, huge reaction equipment, fluctuations in the crystallization process of rare earth salts, increase product quality, etc., and reduce the process Steps and times of solid-liquid separation, eliminate the reaction time of dissolution, and ensure the effect of the wastewater treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

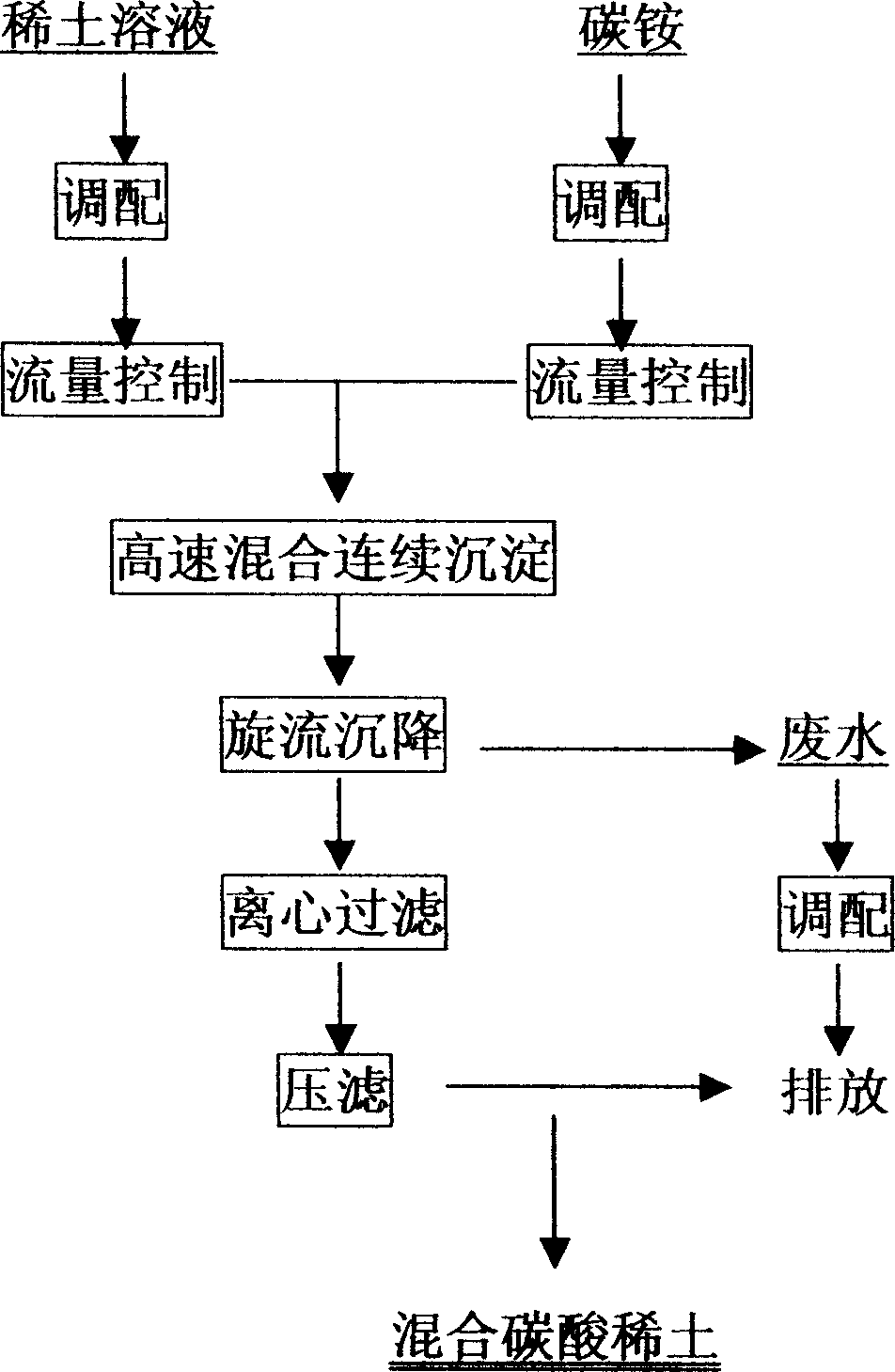

[0026] Example 1: Process steps of continuous precipitation method for producing mixed rare earth carbonate with rare earth sulfate solution:

[0027] (1) Prepare the mixed solution of rare earth sulfate with a concentration of 0.04-O.3 mol / l, and at the same time prepare the precipitation agent ammonium bicarbonate at a concentration of 1-1.5 mol / l;

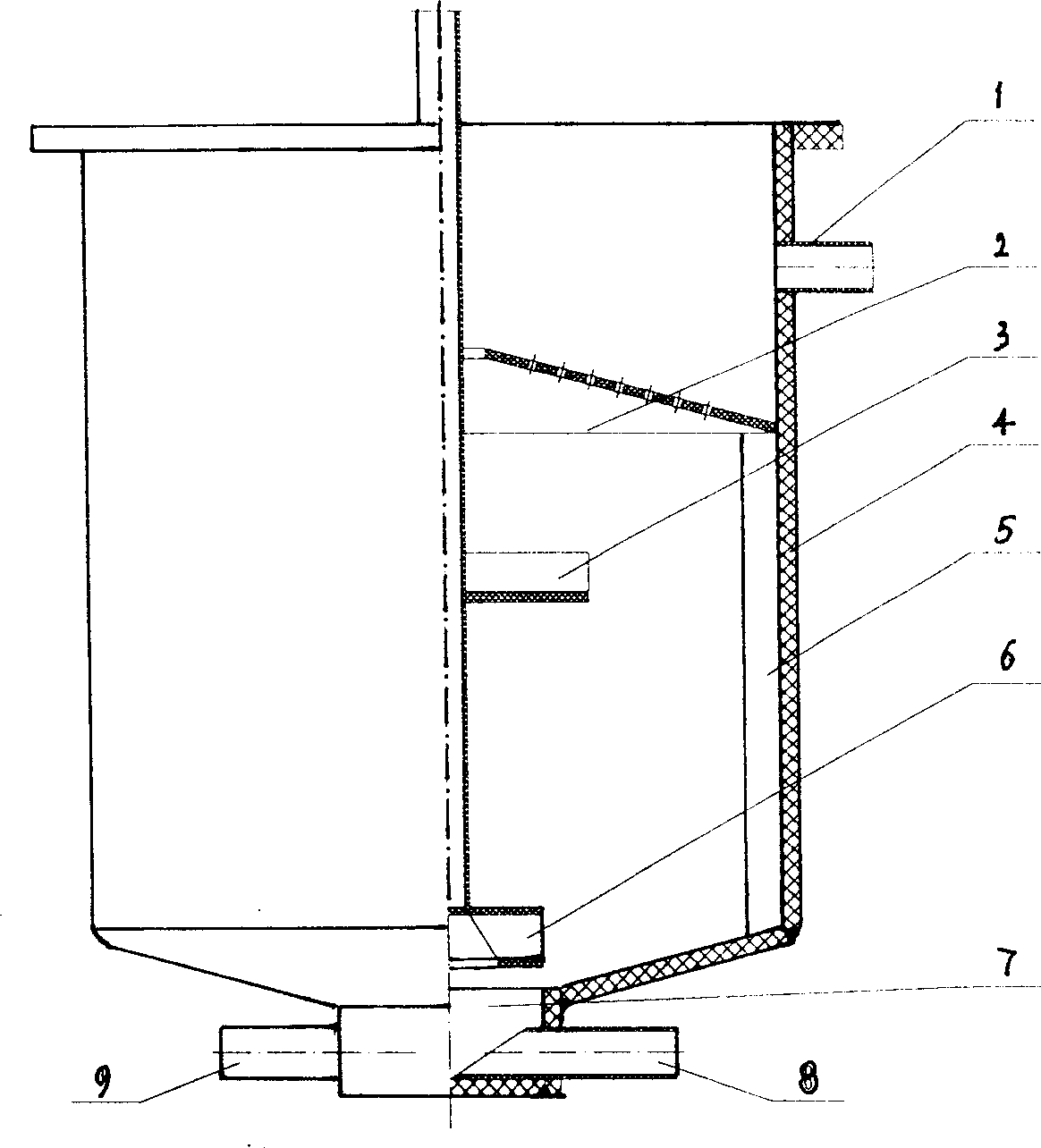

[0028] (2) Pass the prepared rare earth sulfate and rare earth mixed solution through the raw material inlet 9 and the ammonium bicarbonate solution through the reagent inlet 18 according to the mass flow ratio: RE0:NH 4 HCO 3 =1:1.3-1.7 into the mixing method submerged chamber 7, the temperature is 15-45℃, the rotation speed is 350-750 rpm, the vortex stirring paddle 6 is used to suck the above-mentioned raw materials and reagents into the cylinder 4 by the inclined stirring paddle 3 and The baffle 5 completes the mixing process, mixing for 3-12 minutes;

[0029] (3) The mixed rare earth carbonate produced by the reaction enters th...

Embodiment 2

[0031] Example 2: Process steps of continuous precipitation method for producing cerium carbonate with cerium nitrate solution:

[0032] (1) Prepare the cerium nitrate solution to a concentration of 0.1-1 mol / l, while preparing the precipitation agent ammonium bicarbonate to a concentration of 1-3.5 mol / l;

[0033] (2) Pass the cerium nitrate solution prepared above through the raw material feed port 9, and the ammonium bicarbonate solution through the reagent feed port 8 according to the mass flow ratio: REO:NH 4 HCO 3 =1:1.3-1.7 into the mixing method submerged chamber 7, the temperature is 25-50℃, the rotation speed is 255-600 rpm, the vortex stirring paddle 6 is used to suck the above-mentioned raw materials and reagents into the cylinder 4 by the inclined stirring paddle 3 and The baffle 5 completes the mixing process, mixing for 5-12 minutes;

[0034] (3) The mixed rare earth carbonate produced by the reaction enters the clarifier through the discharge port 1 of the mixer fo...

Embodiment 3

[0036] Example 3: Process steps of continuous precipitation method for producing rare earth oxalate using cerium chloride solution:

[0037] (1) Prepare the rare earth cerium chloride solution to a concentration of 0.04-O.6 mol / l, and at the same time prepare the precipitation agent oxalic acid to a concentration of 0.7-1.1 mol / l;

[0038] (2) Pass the prepared cerium chloride solution through the raw material feed port 9, and the oxalic acid solution through the reagent feed port 8 according to the mass flow ratio: REO:H 2 C 2 O 4 =1:1.1-1.6 into the mixing submerged chamber 7, the temperature is 15-75°C, the rotation speed is 180-325 rpm, the vortex stirring paddle 6 is used to suck the above-mentioned raw materials and reagents into the cylinder 4 by the inclined stirring paddle 3 and The baffle 5 completes the mixing process, mixing for 10-15 minutes;

[0039] (3) The cerium oxalate generated by the reaction enters the clarifier through the discharge port 1 of the mixer for se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com