Normal-temperature drinking type yoghourt and preparation method thereof

A drinkable yogurt technology, applied in the field of fermentation, can solve problems such as poor drinking experience and thick texture of yogurt at room temperature, and achieve the effects of easy operation, good product condition, and simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

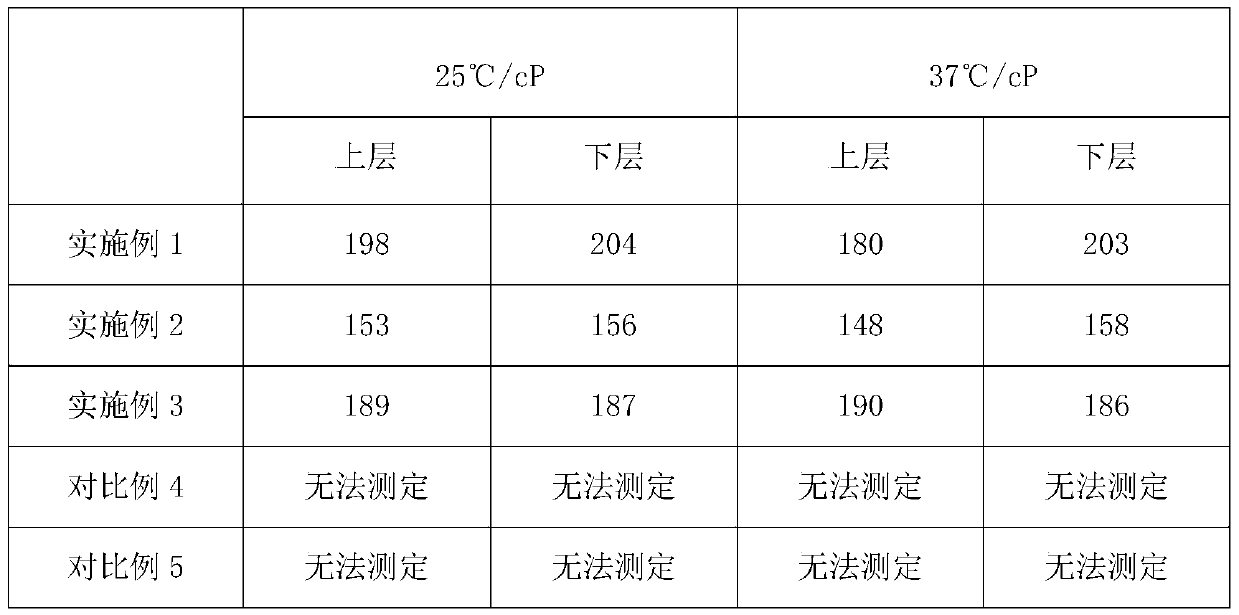

Examples

Embodiment 1

[0024] A preparation method of drinking yoghurt at normal temperature, the raw materials are as follows:

[0025] raw material Amount added (%) anti milk 91.157 White sugar 7 Diacetyl tartrate mono-diglycerides 0.04 low ester pectin 0.5 low acyl gellan gum 0.02 agar 0.2 essence 0.08 starch 1 starter 0.003 total 100

[0026] The protein content of antibiotic-free milk in the above ingredients is 3.1wt%, fat is 2.8wt%, lactose content is 3.0wt%, non-fat milk solids (SNF) content≥8.1wt%, titrated acidity≤18°T.

[0027] The preparation method comprises the following steps:

[0028] S1. Mix the antibiotic-free milk sterilized at 137°C for 3s with the raw materials in the above table except the starter at 65°C for 30 minutes at high speed to obtain a mixed solution;

[0029] S2, homogenize the mixed solution obtained in step S1 at 65°C, the primary and secondary homogenization pressures are 200bar and 30bar...

Embodiment 2

[0035] A preparation method of drinking yoghurt at normal temperature, the raw materials are as follows:

[0036] raw material Amount added (%) anti milk 93.869 White sugar 5 Diacetyl tartrate mono-diglycerides 0.02 low ester pectin 0.3 low acyl gellan gum 0.01 agar 0.1 essence 0 starch 0.7 Streptococcus thermophilus and Lactobacillus bulgaricus 0.001 total 100

[0037] The antibiotic-free milk in the above ingredients has a protein content of 2.8wt%, a fat content of 2.8wt%, a lactose content of 3.0wt%, a non-fat solid (SNF) content of ≥8.1wt%, and a titrated acidity of ≤18°T.

[0038] The preparation method comprises the following steps:

[0039] S1. Mix the antibiotic-free milk sterilized at 135°C for 5s with the raw materials in the above table except the starter at 70°C for 20 minutes at high speed to obtain a mixed solution;

[0040] S2, homogenize the mixed solution obtained in step S1 at 70°C,...

Embodiment 3

[0046] A preparation method of drinking yoghurt at normal temperature, the raw materials are as follows:

[0047] raw material Amount added (%) anti milk 89.735 White sugar 8 Diacetyl tartrate mono-diglycerides 0.03 low ester pectin 0.6 low acyl gellan gum 0.03 agar 0.3 essence 0.1 starch 1.2 Streptococcus thermophilus and Lactobacillus bulgaricus 0.005 total 100

[0048] The protein content of antibiotic-free milk in the above ingredients is 3.1wt%, fat is 2.8wt%, lactose content is 3.1wt%, non-fat milk solids (SNF) content≥8.1wt%, titrated acidity≤18°T.

[0049] The preparation method comprises the following steps:

[0050] S1. Mix the antibiotic-free milk sterilized at 136°C for 4s with the raw materials in the above table except the starter at 68°C for 25 minutes at high speed to obtain a mixed solution;

[0051] S2, homogenize the mixed solution obtained in step S1 at 68°C, the primary and second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com